ABB ACS580-01 Quick Start Guide

ABB general purpose drives

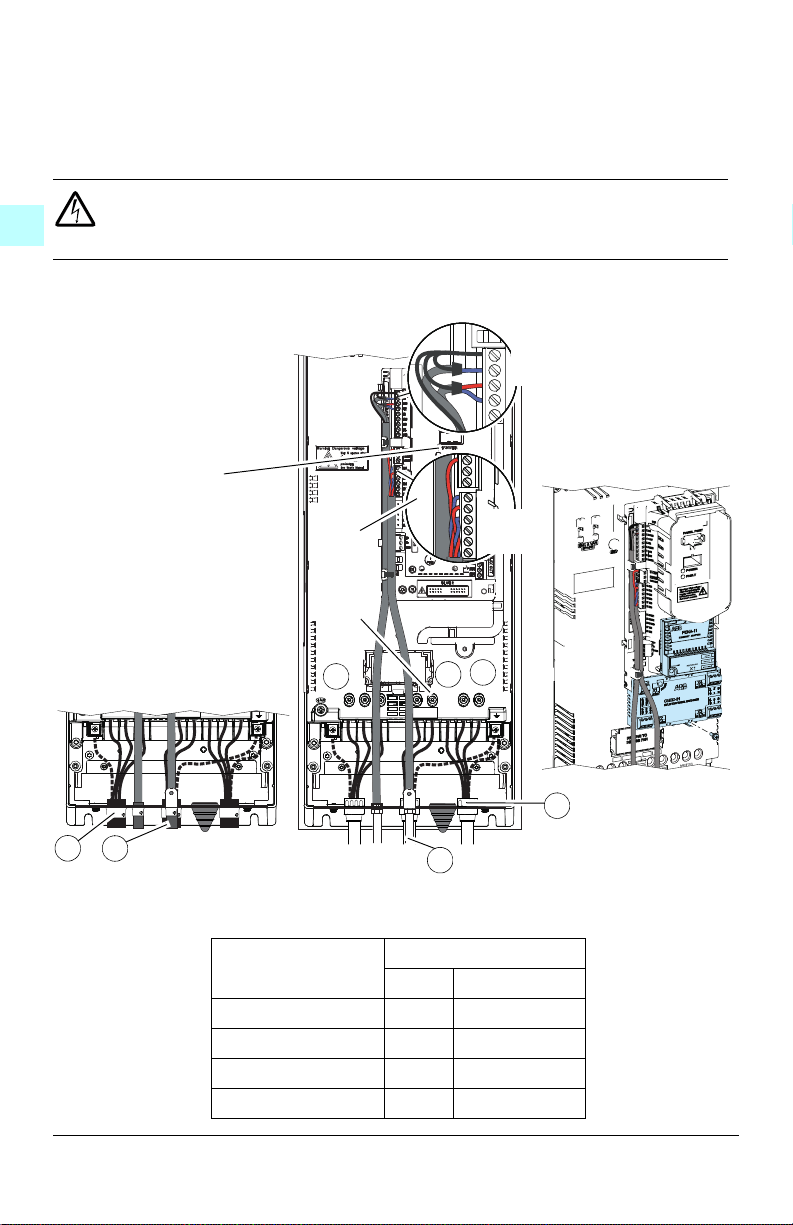

R1R4

R5

R6R9

Quick installation and start-up guide

ACS580-01 drives

Frames R1 to R9

List of related manuals in English

Drive manuals and guides Code (English)

ACS580 standard control program firmware manual

ACS580-01 (0.75 to 250 kW, 1.0 to 350 hp) hardware

manual

ACS-AP-X assistant control panels user’s manual 3AUA0000085685

Option manuals and guides

CDPI-01 communication adapter module user's manual 3AXD50000009929

DPMP-01 mounting platform for control panels 3AUA0000100140

DPMP-02/03 mounting platform for control panels 3AUA0000136205

FCAN-01 CANopen adapter module user's manual 3AFE68615500

FCNA-01 ControlNet adapter module user's manual

FDNA-01 DeviceNet™ adapter module user's manual 3AFE68573360

FECA-01 EtherCAT adapter module user's manual

FENA-01/-11/-21 Ethernet adapter module user's manual 3AUA0000093568

FEPL-02 Ethernet POWERLINK adapter module user's

manual

FPBA-01 PROFIBUS DP adapter module user's manual 3AFE68573271

FSCA-01 RS-485 adapter module user's manual 3AUA0000109533

Flange mounting kit quick installation guide for

ACX580-01 frames R0 to R5

Flange mounting kit quick installation guide for

ACX580-01 frames R6-R9

Flange mounting kit installation supplement 3AXD50000019100

Tool and maintenance manuals and guides

Drive composer PC tool user's manual 3AUA0000094606

Converter module capacitor reforming instructions 3BFE64059629

NETA-21 remote monitoring tool user's manual

NETA-21 remote monitoring tool installation and start-up

guide

3AXD50000016097

3AXD50000018826

3AUA0000141650

3AUA0000068940

3AUA0000123527

3AXD50000036610

3AXD50000019099

3AUA00000969391

3AUA0000096881

You can find manuals and other product documents in PDF format on the Internet. S ee section Document library

on the Internet on the inside of the back cover. For manuals not available in the Document library, contact your

local ABB representative.

The QR code below opens an online listing of the manuals applicable to this product.

ACS580-01 manuals

2017 ABB Oy. All Rights Reserved.

Table of contents 3

Table of contents

List of related manuals in English

R1…R4 Ratings and fuses

I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

R5 Ratings and fuses

I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

R6…R9 Ratings and fuses

I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety

Frames R1 to R4

R1…R4 Quick installation guid e

Obey the safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Check if capacitors need to be reformed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Select the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Ensure the cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Protect the drive and input power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Install the drive on the wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Check the insulation of the power cables and the motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Switch off the power and open the cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Install the cable box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Attach the warning sticker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Check the compatibility with IT (ungrounded) and corner-grounded TN systems . . . . . . . . . 17

EMC filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ground-to-phase varistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Disconnect EMC filter or ground-to-phase varistor, if needed . . . . . . . . . . . . . . . . . . . . . 19

Wiring R1...R2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Wiring R3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Wiring R4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Default I/O connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Install optional modules, if any . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Reinstall cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4 Table of contents

Frame R5

R5 Quick installation guide

Obey the safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Check if capacitors need to be reformed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Select the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Ensure the cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Protect the drive and input power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Install the drive on the wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Check the insulation of the power cables and the motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Switch off the power and open the cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Check the compatibility with IT (ungrounded) and corner-grounded TN systems . . . . . . . . . 33

EMC filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Ground-to-phase varistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Disconnect EMC filter or ground-to-phase varistor, if needed . . . . . . . . . . . . . . . . . . . . . 35

Wiring R5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Default I/O connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Install optional modules, if any . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Reinstall cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Frames R6 to R9

R6…R9 Quick installation guide

Obey the safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Check if capacitors need to be reformed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Select the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Ensure the cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Protect the drive and input power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Install the drive on the wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Check the insulation of the power cables and the motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Check the compatibility with IT (ungrounded) and corner-grounded TN systems . . . . . . . . . 45

EMC filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Ground-to-phase varistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Disconnect EMC filter or ground-to-phase varistor, if needed . . . . . . . . . . . . . . . . . . . . . 47

Wiring R6…R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Default I/O connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Install optional modules, if any . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Install side plates and covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Quick start-up guide

Quick start-up guide

Before you start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Start-up with the First start assistant on an assistant control panel . . . . . . . . . . . . . . . . . . . . 55

Compliance with the European Machinery Directive 2006/42/EC

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table of contents 5

Installation figures

R1…R4 Figures A

B1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

B2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

B3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

C1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

C2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

E1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

E2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

G1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

G2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

R1…R4 Figures H

I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

I2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

J . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

R5 Figures A

B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

R5 Figures F

G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

R6…R9 Figures A

B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

R6…R9 Figures E

Further information

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6 Table of contents

[Page intentionally left blank]

R1R4

R5

R6R9

ENDADEESFI

FRITNLPLPTRUSVTRZH

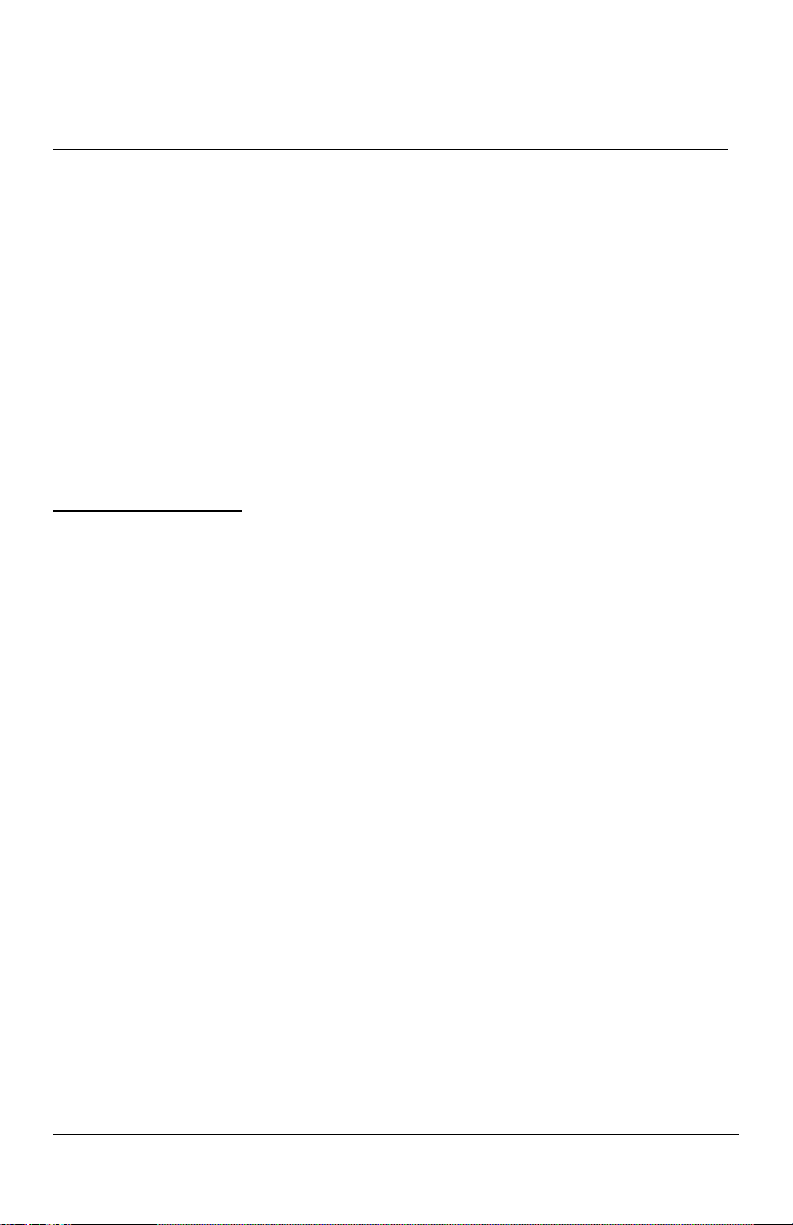

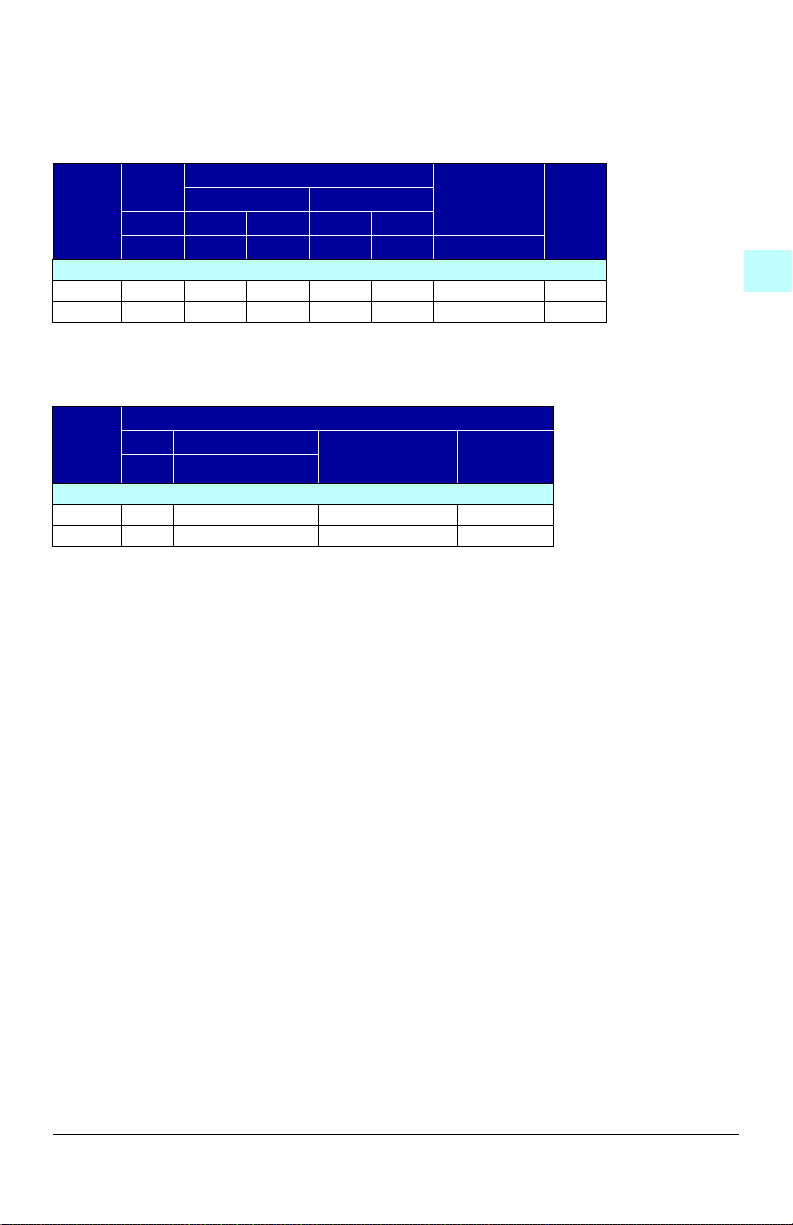

R1…R4 Ratings and fuses

I

Type

ACS580-

01

Input

rating

Output ratings Maximum

Nominal use Heavy duty use

heat

dissipation

Frame

size

7

I1N I

P

Ld

I

Ld

P

Hd

Hd

A A hp A hp W

3-phase UN = 480 V (440…480 V)

02A1-4 2.1 2.1 1 1.6 0.75 45 R1

03A0-4 3 3 1.5 2.1 1 55 R1

03A5-4 3.5 3.5 2 3 1.5 66 R1

04A8-4 4.8 4.8 3 3.4 2 84 R1

06A0-4 6 6 3 4 3 106 R1

07A6-4 7.6 7.6 5 4.8 3 133 R1

012A-4 12 12 7.5 7.6 5 174 R1

014A-4 14 14 10 11 7.5 228 R2

023A-4 23 23 15 14 10 322 R2

027A-4 27 27 20 21 15 430 R3

034A-4 34 34 25 27 20 525 R3

044A-4 44 44 30 34 25 619 R3

052A-4 52 52 40 40 30 835 R4

065A-4 65 65 50 52 40 1024 R4

8

R1R4

R5

R6R9

ENDADEESFI

FRITNLPLPTRUSVTRZH

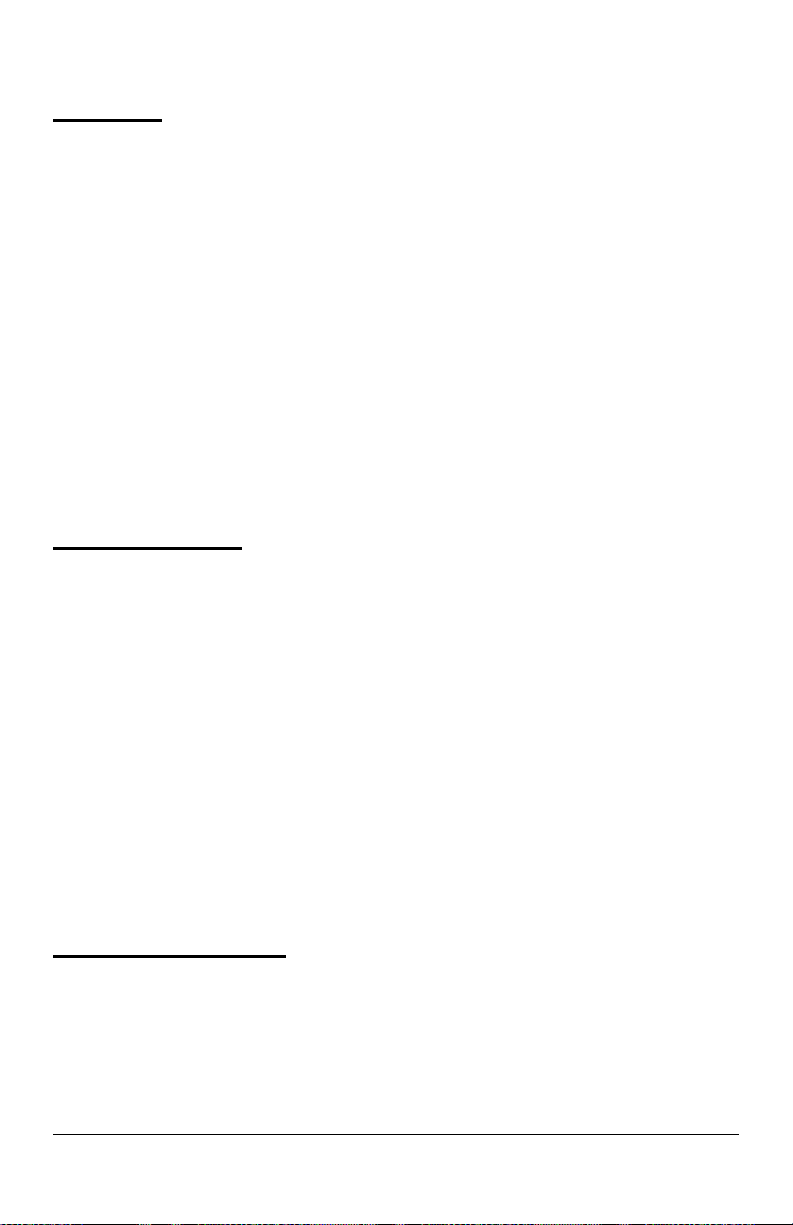

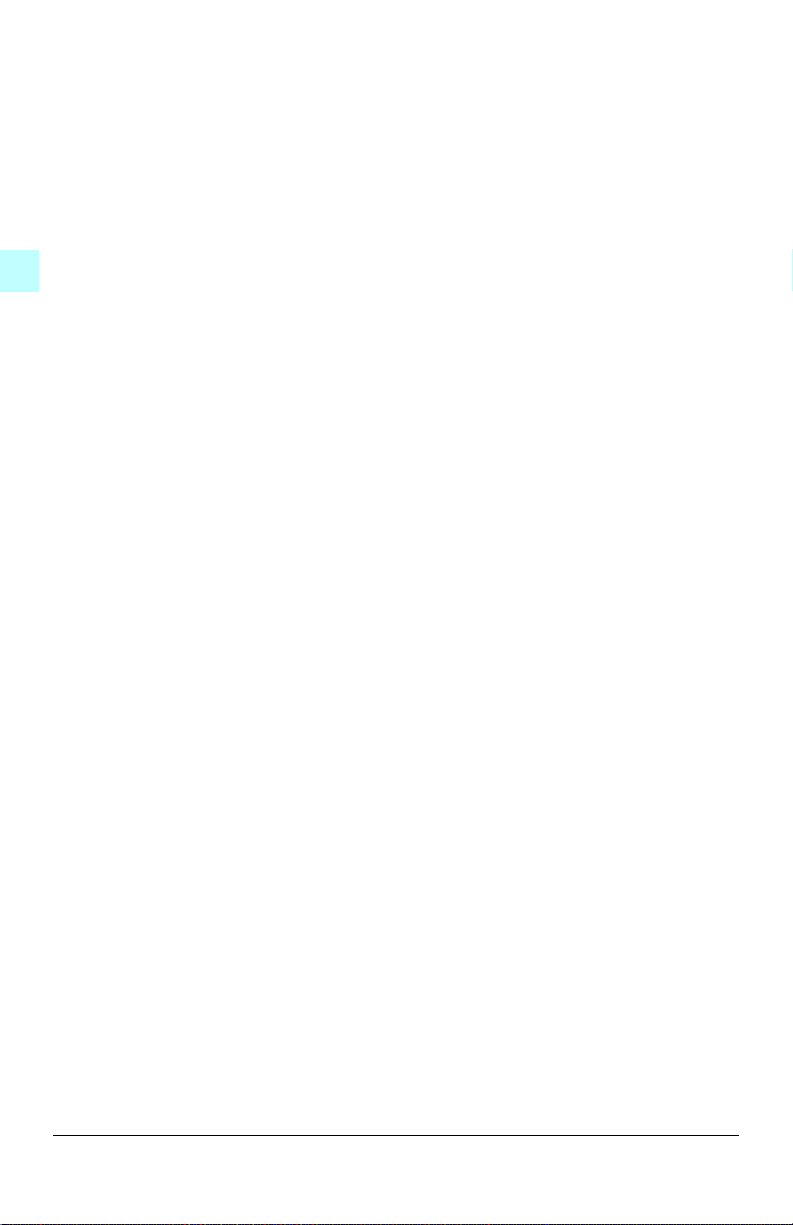

II

NEC

type

ACS580

3-phase UN = 480 V (440…480 V)

02A1-4

03A0-4

03A5-4

04A8-4

06A0-4

07A6-4

012A-4

014A-4

023A-4

027A-4

034A-4

044A-4

052A-4

065A-4

ABB does not require Bussmann brand fuses. Fuses which meet the

1)

appropriate UL class type, current rating, and are rated at 600V, 200 kA

may be used.

I

Voltage rating Bussmann type

N

A V

15

15

15

15

15

15

15

30

30

40

50

60

80

90

600

600

600

600

600

600

600

600

600

600

600

600

600

600

UL

JJS-15

JJS-15

JJS-15

JJS-15

JJS-15

JJS-15

JJS-15

JJS-30

JJS-30

JJS-40

JJS-50

JJS-60

JJS-80

JJS-90

1)

UL class

T

T

T

T

T

T

T

T

T

T

T

T

T

T

R0R4

R5

R6R9

ENDADEESFI

FRITNLPLPTRUSVTRZH

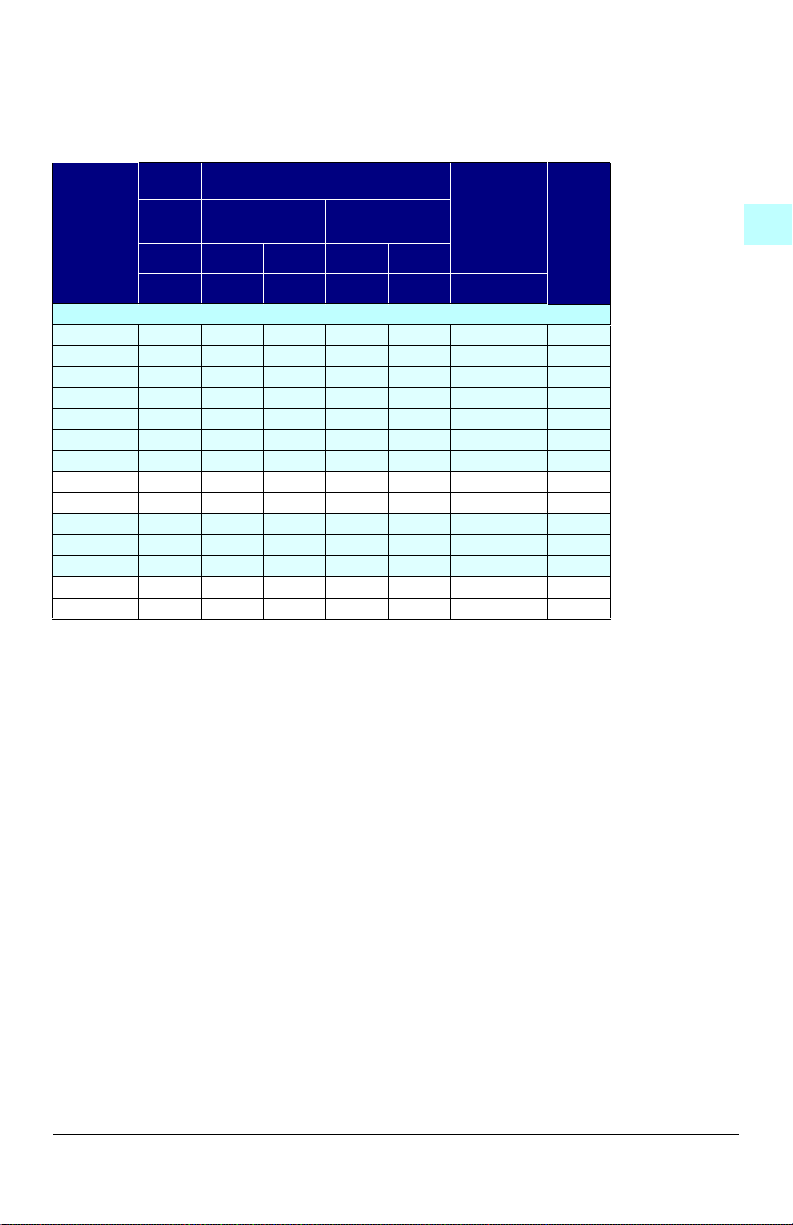

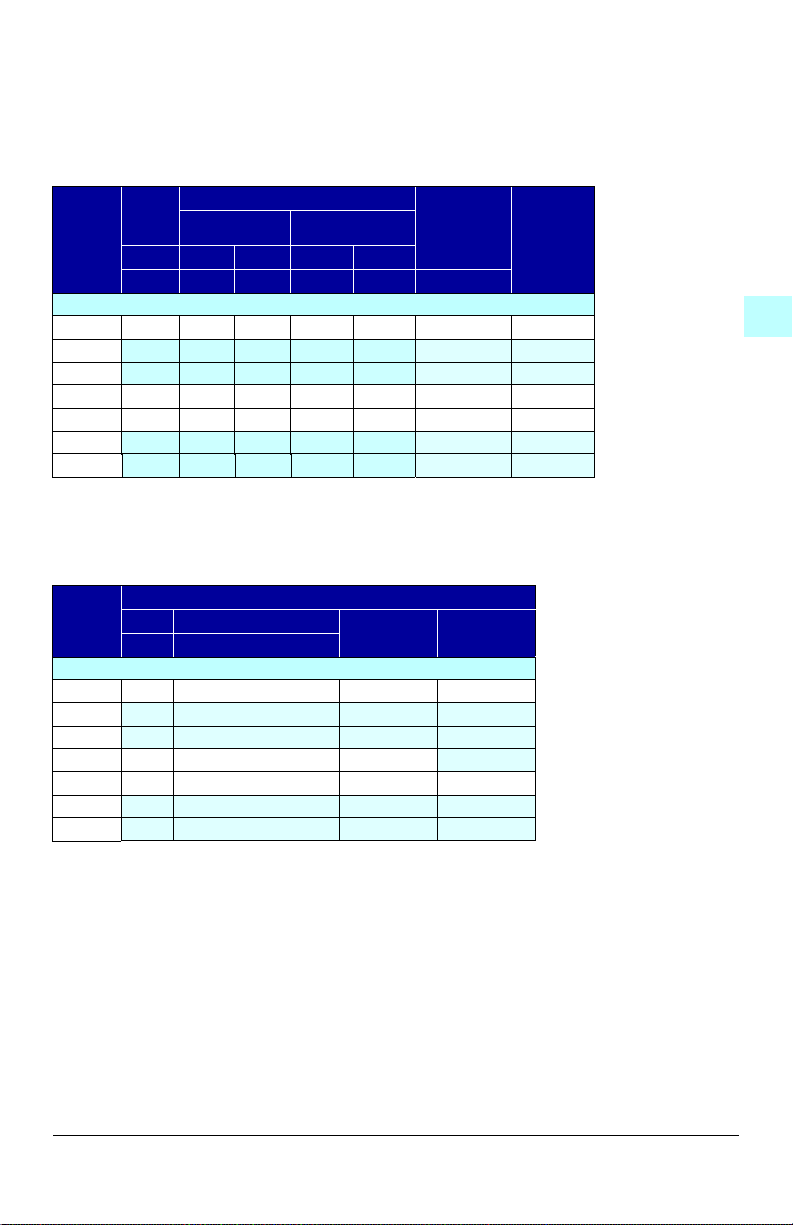

R5 Ratings and fuses

I

NEC

type

ACS580

3-phase UN = 480 V (440…480 V)

077A-4 77 77 60 65 50 1240 R5

096A-4 96 96 75 77 60 1510 R5

-01-

Input

rating

I

1N

A A hp A hp

Output ratings Maximum

Nominal use Heavy duty use

I

Ld

P

I

Ld

Hd

P

heat

dissipation

Hd

W

II

IEC

type

ACS580

3-phase UN = 480 V (440…480 V)

077A-4 100 600 JJS-100 T

096A-4 150 600 JJS-150 T

1) ABB does not require Bussmann brand fuses. Fuses which meet

the appropriate UL class type, current rating, and are rated at 600V,

200 kA may be used.

I

Voltage rating Bussmann type

N

A V

UL

1)

UL class

9

Frame

size

R0R4

R5

R6R9

ENDADEESFI

FRITNLPLPTRUSVTRZH

10

[Page intentionally left blank]

R6…R9 Quick installation guide 11

R6R9

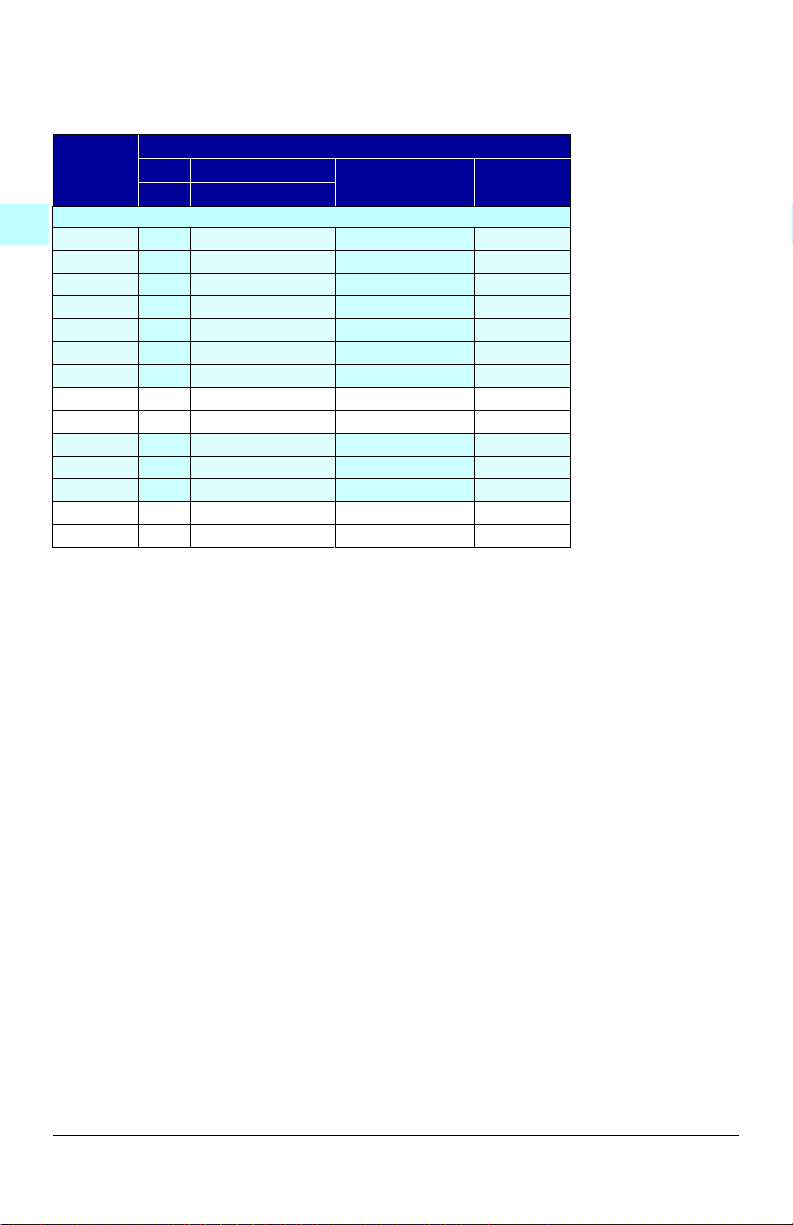

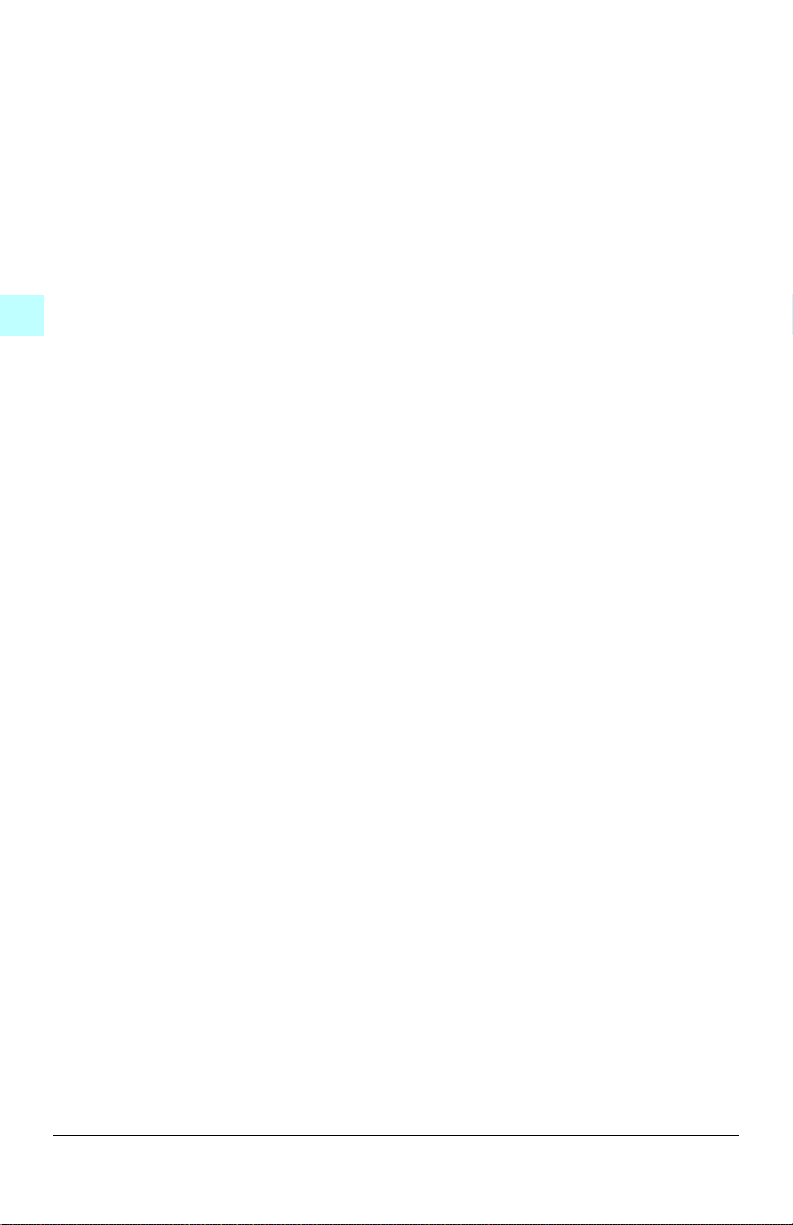

R6…R9 Ratings and fuses

I

Input

-o1

rating

I

1NI 2LdPLdI 2Hd

A A kW A kW W

ACS580

3-phase UN = 480 V (440…480 V)

124A-4 124 124 100 96 75 1476 R6

156A-4 156 156 125 124 100 1976 R7

180A-4 180 180 150 156 125 2346 R7

240A-4 240 240 200 180 150 3336 R8

260A-4 260 260 200 240* 150 3936 R8

361A-4 361 361 300 302 250 4836 R9

414A-4 414 414 350 361** 300 6036 R9

* 130% overload only

** 125% overload only

Output ratings Maximum

Nominal use Heavy duty use

P

Hd

losses

II

UL

ACS580

-01-

3-phase UN = 480 V (440…480 V)

124A-4 200 600 JJS-200 T

156A-4 225 600 JJS-225 T

180A-4 300 600 JJS-300 T

240A-4 350 600 JJS-350 T

260A-4 400 600 JJS-400 T

361A-4 500 600 JJS-500 T

414A-4 600 600 JJS-600 T

1) ABB does not require Bussmann brand fuses. Fuses which meet

the appropriate UL class type, current rating, and are rated at 600V ,

200 kA may be used.

I

A V

Voltage rating Bussmann

N

type

UL class

1)

Frame

size

3AXD50000009286 Rev D

12 R6…R9 Quick installation guide

R6R9

[Page intentionally left blank]

R1R4

R5

Quick installation guide

ACS580-01 drives

Frames R1 to R4

[Page intentionally left blank]

R1…R4 Quick installation guide 15

R1R4

R5

R6R9

DADEESFIFR

ITNLPLPTRUSVTR

ZH

ZH

R1…R4 Quick installation guide

This guide briefly describes how to install the drive. For complete information on

installation, see ACS580-01 (0.75 to 250 kW, 1.0 to 350 hp) hardware manual

(3AXD50000018826 [English]). For start-up instructions, see chapter Quick start-up

guide on page 55.

To read a manual, go to www.abb.com/drives/documents and search for the document

number.

Obey the safety instructions

WARNING! Obey these instructions. If you ignore them, injury or death, or

damage to the equipment can occur:

• If you are not a qualified electrician, do not do electrical installation work.

• Do not work on the drive, motor cable or motor when main power is applied. If

the drive is already connected to the input power, wait for 5 minutes after

disconnecting the input power.

• Do not work on the control cables when power is applied to the drive or to the

external control circuits.

• Make sure that debris from borings and grindings does not enter the drive when

installing.

• Make sure that the floor below the drive and the wall where the drive is installed

are non-flammable.

Check if capacitors need to be reformed

If the drive has not been powered (either in storage or unused) for over one year, you

must reform the capacitors.

You can determine the manufacturing time from the serial number, which you find on

the type designation label attached to the drive. The serial number is of format

MYYWWRXXXX. YY and WW tell the manufacturing year and week as follows:

YY: 16, 17, 18, … for 2016, 2017, 2018,

WW: 01, 02, 03, … for week 1, week 2, week 3, …

For information on reforming the capacitors, see Converter module capacitor reforming

instructions (3BFE64059629 [English]), available on the Internet at

www.abb.com/drives/documents.

…

16 R1…R4 Quick installation guide

R1R4

R5

R6R9

DADEESFIFR

ITNLPLPTRUSVTR

ZH

Select the power cables

Size the power cables according to local regulations to carry the nominal current

given on the type designation label of your drive.

Ensure the cooling

See table I on page 7 for the losses.The allowed operating temperature range of the

drive is -15 to +50 °C (+5 to +122 °F). No condensation or frost is allowed. For more

information on the ambient temperature and derating, see chapter Technical data in

ACS580-01 (0.75 to 250 kW, 1.0 to 350 hp) hardware manual (3AXD50000018826

[English]).

Protect the drive and input power cable

See table II on page 8 for the fuses.

If you use gG fuses, make sure that the operating time of the fuse is below 0.5

seconds. Follow the local regulations.

Install the drive on the wall

See figure R1…R4 Figures A on page 67.

Check the insulation of the power cables and the motor

Check the insulation of the input cable according to local regulations before

connecting it to the drive.

See figure B1 on page 67.

1. Check the insulation of the motor cable and motor when the cable is disconnected

from the drive. Measure the insulation resistance between each phase conductor

and then between each phase conductor and the Protective Earth conductor

using a measuring voltage of 1000 V DC. The insulation resistance of an ABB

motor must exceed 100 Mohm (reference value at 25 °C or 77 °F). For the

insulation resistance of other motors, see the manufacturer’s instructions.

Note: Moisture inside the motor casing will reduce the insulation resistance. If

moisture is suspected, dry the motor and repeat the measurement.

R1…R4 Quick installation guide 17

R1R4

R5

R6R9

DADEESFIFR

ITNLPLPTRUSVTR

ZH

ZH

Switch off the power and open the cover

See figure B1 on page 67.

2. Switch off the power from the drive.

3. Remove the front cover: Loosen the retaining screw, if any, with a screwdriver (3a)

and lift the cover from the bottom outwards (3b) and then up (3c).

Install the cable box

Only for frames IP21, R1….R2 and IP55, R1….R2.

See figures B1 and B2 on page 67.

4. IP21, R1….R2: Remove the screw (4a) and lift the cover off (4b) from the separate

cable box.

5. IP21, R1….R2:

Attach the cable box cover to the front cover.

6. IP21, R1….R2:

tighten the screws (6b).

Install the cable box to the frame. Position the cable box (6a) and

Attach the warning sticker

See figure B2 on page 67.

7. Attach the residual voltage warning sticker in the local language.

Check the compatibility with IT (ungrounded) and cornergrounded TN systems

EMC filter

The internal EMC filter is not suitable for use on an IT (ungrounded) system or on a

corner-grounded TN system. Disconnect the EMC filter before connecting the drive to

the supply network. Check the table on page 18.

WARNING! Do not install the drive with the internal EMC filter connected on an

IT system (an ungrounded power system or a high-resistance-grounded [over

30 ohms] power system), otherwise the system will be connected to ground potential

through the EMC filter capacitors of the drive. This can cause danger, or damage the

drive.

Do not install the drive with the internal EMC filter connected on a corner-grounded TN

system, otherwise the drive will be damaged.

Note: When the internal EMC filter is disconnected, the drive EMC compatibility is

considerably reduced.

18 R1…R4 Quick installation guide

R1R4

R5

R6R9

DADEESFIFR

ITNLPLPTRUSVTR

ZH

Drive

PE

N

L3

L2

L1

Drive Drive

PE

L3

L2

L1

L3

L2

L1

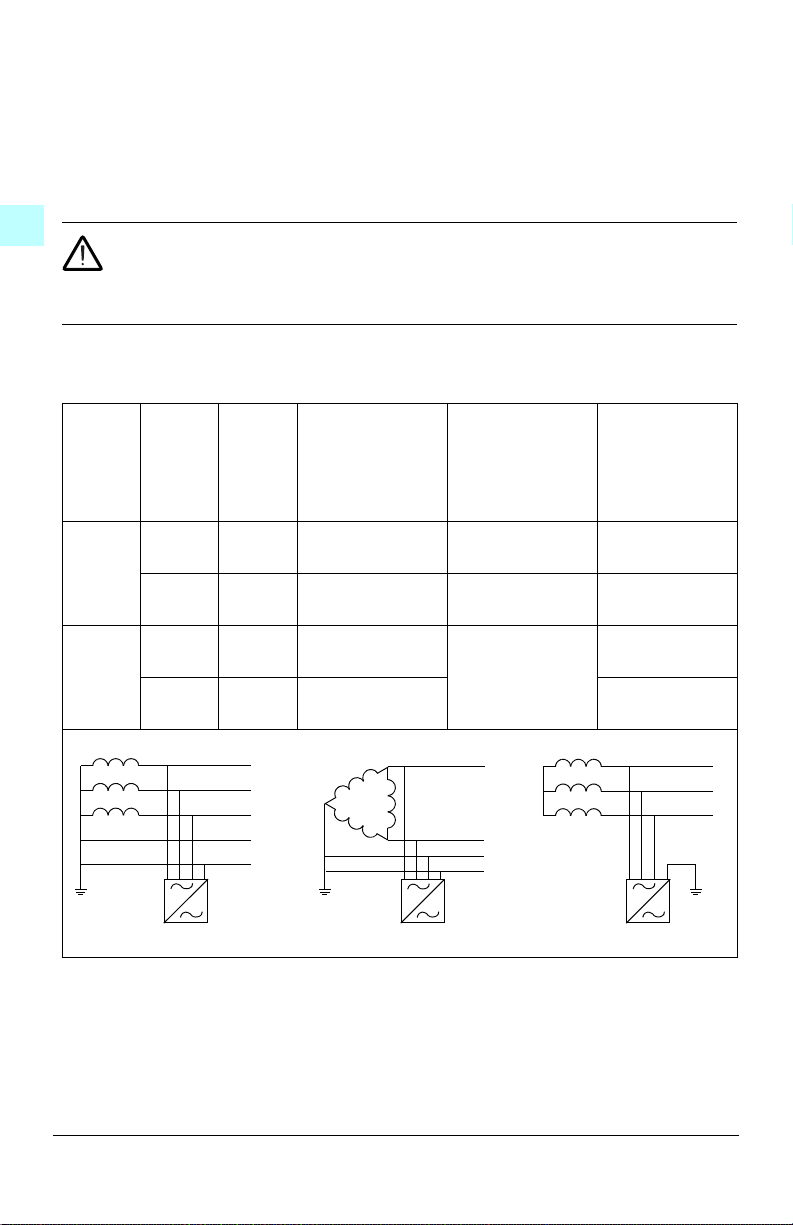

Ground-to-phase varistor

The ground-to-phase varistor is not suitable for use on an IT (ungrounded) system.

Disconnect the ground-to-phase varistor before connecting the drive to the supply

network. Check the table on page 18.

WARNING! Do not install the drive with the ground-to-phase varistor

connected on an IT system (an ungrounded power system or a highresistance-grounded [over 30 ohms] power system), otherwise the varistor circuit can

be damaged.

Check from the table below if you have to disconnect the EMC filter (EMC) or groundto-phase varistor (VAR). For instructions on how to do this, see page 19.

Frame

sizes

R1…R3 EMC

R4 EMC

1 2 3

EMC

filter

(EMC)

Ground-

to-phase

varistor

(VAR)

(1 screw)

-VAR

(1 screw)

(2 screws)

-VAR

(1 screw)

Symmetrically

grounded TN

systems (TN-S

systems)

- Do not disconnect Disconnect Disconnect

Do not disconnect Disconnect Disconnect

- Do not disconnect Frame R4 cannot

Do not disconnect Disconnect

Corner grounded

TN systems

1

be used in corner

grounded TN

systems.

IT systems

2

(ungrounded or

high-resistance

grounded [>30

ohms])

Disconnect

3

R1…R4 Quick installation guide 19

R1R4

R5

R6R9

DADEESFIFR

ITNLPLPTRUSVTR

ZH

ZH

4a

4b

R1…R2 R3

3a

3b

4a

3a

3b4b

4

3

3

R4

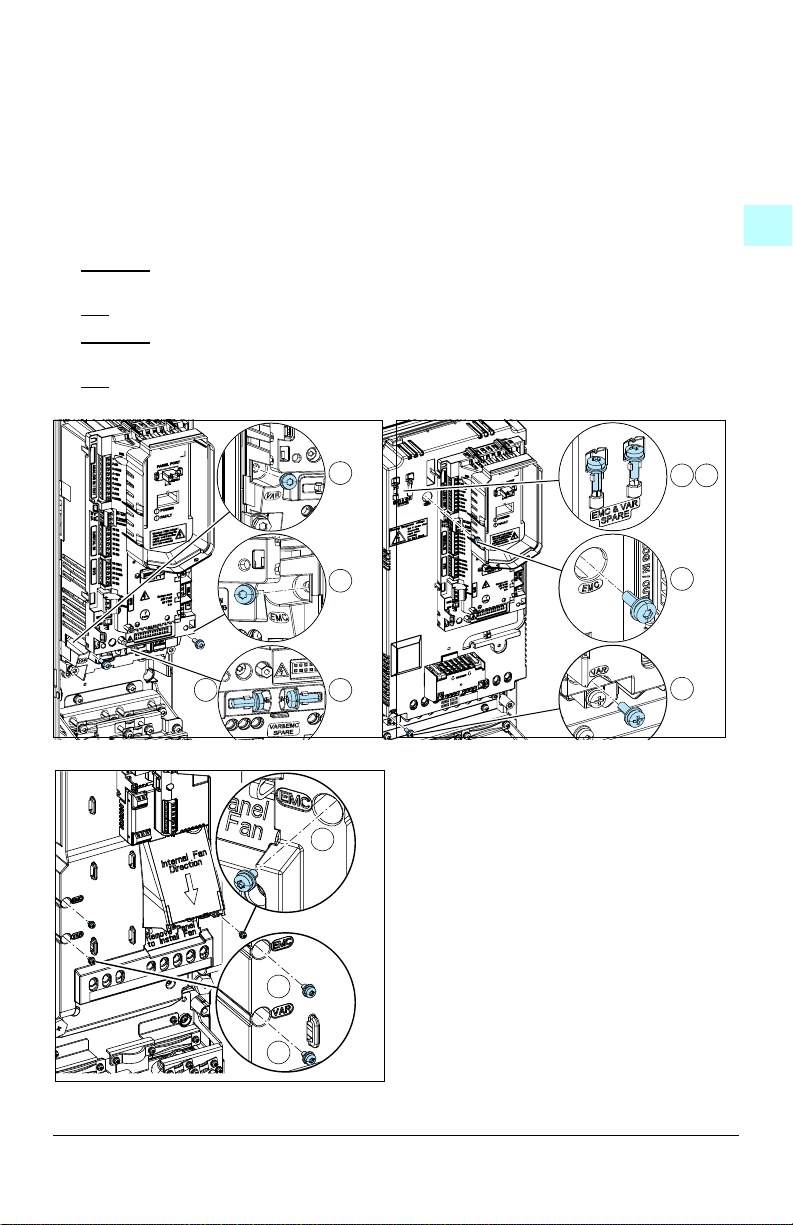

Disconnect EMC filter or ground-to-phase varistor, if needed

To disconnect the internal EMC filter or ground-to-phase varistor, if needed, do as

follows:

1. Switch off the power from the drive.

2. Open the front cover, if not already opened, see figure B1 on page 67.

3. R

1…R3: To disconnect the internal EMC filter, remove the EMC screw (3a) and

place it in the storage place (3b).

To disconnect the internal EMC filter, remove the two EMC screws.

R4:

4. R

1…R3: To disconnect the ground-to-phase varistor, remove the varistor screw

(4a) and place it in the storage place (4b).

To disconnect the ground-to-phase varistor, remove the varistor screw.

R4:

20 R1…R4 Quick installation guide

R1R4

R5

R6R9

DADEESFIFR

ITNLPLPTRUSVTR

ZH

Wiring R1...R2

Note: These are instructions for conduit wiring. For cable wiring, see the ACS580

Hardware manual, publication number 3AXD50000018826.

Note: In US deliveries, options are already installed at the factory. If installing on site,

option slot 1 modules (fieldbus adapter) may be installed by mounting the module on

the control board and tightening the mounting screw, which is also the grounding

screw. Option slot 2 modules (I/O extension) should not be installed until after the

power cables. Refer to Warning and step 8 below.

WARNING! If installing modules, obey the instructions in Safety instructions in

the ACS580 Hardware manual, publication number 3AXD50000018826. If you

ignore them, injury or death, or damage to the equipment can occur. Option slot 2 in

frames R1…R5 is at U

installing or removing an I/O extension module.

See figure on page 22.

1. Install thin-wall conduit clamps for IP21/UL Type 1 or liquid-tight conduit

connectors for IP55/UL Type 12 (not supplied). Type 12 has a Pressfit gasket.

2. Connect conduit runs for input power, motor and control cables to the conduit box.

Ensure grommets (pointing down) are inserted into all unused holes.

3. Route the input power and motor wiring through separate conduits.

potential. You must disconnect power supplies before

DC

4. Strip wires.

5. Connect the motor and ground wires to the drive terminal. Tighten the screws to

torques shown in the Power wiring torque table.

6. Connect the input power and ground wires to the drive terminal. Tighten the

screws to torques shown in the Power wiring torque table.

7. If brake resistor is used — Connect the resistor and ground wires. Tighten the

screws to torques shown in the Power wiring torque table.

8. Install option slot 2 modules (I/O extension), if necessary, at this point.

A Frame R1 only: Install the option mounting.

B Put the module carefully into its position on the control board and tighten the

mounting screw.

C Tighten the grounding screw, which is necessary for proper operation and for

fulfilling EMC requirements.

Note: Frame R1 — The module in option slot 2 covers the power terminals. Do not

install a module in option slot 2 before you have installed the power cables.

9. Route the control cables through the conduit (not the same conduit as either input

power or motor wiring).

R1…R4 Quick installation guide 21

R1R4

R5

R6R9

DADEESFIFR

ITNLPLPTRUSVTR

ZH

ZH

10.Strip the control cable sheathing and twist the copper screen into a pig-tail.

11. Refer to page 27. Connect the ground screen pig-tail for digital and analog I/O

cables. (Ground only at drive end.)

12.Connect the ground screen pig-tail for Embedded fieldbus, EFB (EIA-485) cables at

X5. (Ground only at drive end.)

13.Strip and connect the individual control wires to the drive terminals. Tighten the

screws to 0.4 lb-ft (0.5…0.6 N-m).

WARNING! To avoid danger or damage to the drive on IT systems and corner

grounded TN systems, see section Check the compatibility with IT (ungrounded)

and corner-grounded TN systems on page 17.

22 R1…R4 Quick installation guide

R1R4

R5

R6R9

DADEESFIFR

ITNLPLPTRUSVTR

ZH

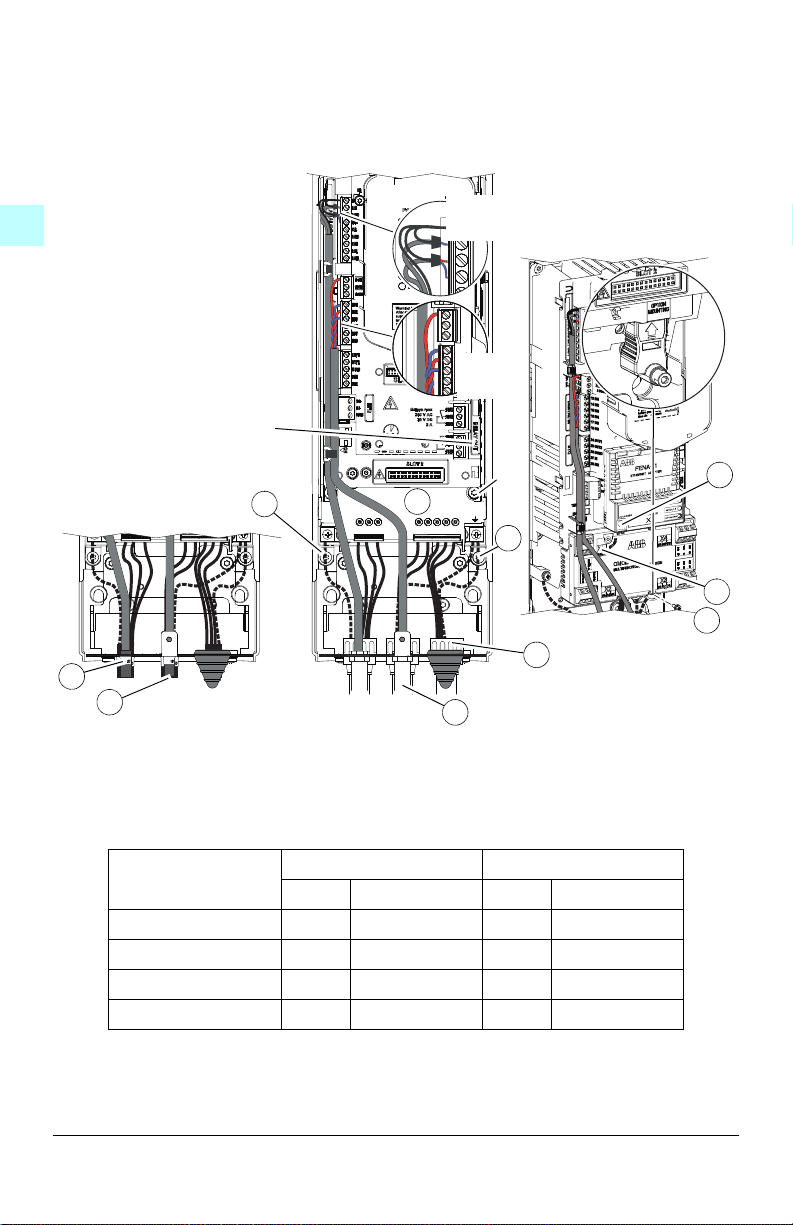

T y pical Type 1

1

9

6

Relay Outputs

9

1

Digital

Inputs

Analog Inputs

and Outputs

EMC

7

5

Option Mounting

8A

8C

8B

R1...R2 Type 12

Power wiring torque table

Frame size

T1/U, T2/V, T3/W 0.4 1.2...1.5 1.1 1.2...1.5

L1, L2, L3 0.4 1.2...1.5 1.1 1.2...1.5

R+, R- 0.4 1.2...1.5 1.1 1.2...1.5

PE Ground 1.1 1.5 1.1 1.5

lb-ft N-m lb-ft N-m

R1 R2

R1…R4 Quick installation guide 23

R1R4

R5

R6R9

DADEESFIFR

ITNLPLPTRUSVTR

ZH

ZH

Wiring R3

Note: These are instructions for conduit wiring. For cable wiring, see the ACS580

Hardware manual, publication number 3AXD50000018826.

Note: In US deliveries, options are already installed at the factory. If installing on site,

option slot 1 modules (fieldbus adapter) may be installed by mounting the module on

the control board and tightening the mounting screw, which is also the grounding

screw. Option slot 2 modules (I/O extension) may be installed by mounting the module

on the control board and tightening both the mounting screw and the grounding screw.

Refer to Warning.

WARNING! If installing modules, obey the instructions in Safety instructions in

the ACS580 Hardware manual, publication number 3AXD50000018826. If you

ignore them, injury or death, or damage to the equipment can occur. Option slot 2 in

frames R1…R5 is at U

installing or removing an I/O extension module.

See figure on page 24.

1. Install thin-wall conduit clamps for IP21/UL Type 1 or liquid-tight conduit connectors

for IP55/UL Type 12 (not supplied). Type 12 has a Pressfit gasket.

2. Connect conduit runs for input power, motor and control cables to the conduit box.

Ensure grommets (pointing down) are inserted into all unused holes.

3. Route the input power and motor wiring through separate conduits.

potential. You must disconnect power supplies before

DC

4. Strip wires.

5. Connect the motor and ground wires to the drive terminal. Tighten the screws to

torques shown in the Power wiring torque table.

6. Connect the input power and ground wires to the drive terminal. Tighten the screws

to torques shown in the Power wiring torque table.

7. If brake resistor is used — Connect the resistor and ground wires. Tighten the

screws to torques shown in the Power wiring torque table.

8. Route the control cables through the conduit (not the same conduit as eithe r input

power or motor wiring).

9. Strip the control cable sheathing and twist the copper screen into a pig-tail.

10.Refer to page 27. Connect the ground screen pig-tail for digital and analog I/O

cables. (Ground only at drive end.)

1 1. Connect the ground screen pig-tail for Embedded fieldbus, EFB (EIA-485) cables at

X5. (Ground only at drive end.)

24 R1…R4 Quick installation guide

R1R4

R5

R6R9

DADEESFIFR

ITNLPLPTRUSVTR

ZH

BREAKERSINPUT

PE

MOTOR

R-

R+

UDC+

W/3TV/2TU/1T3L2L1L

BREAKERSINPUT

PE

MOTOR

R-

R+

UDC+

W/3TV/2TU/1T3L2L1L

Typical Type 1

VAR

1

8

8

1

6

7

5

R3 Type 12

Power (Green) and

Fault (Red) LEDs

Digital

Inputs

Analog Inputs

and Outputs

Option Mounting

EMC

12.Strip and connect the individual control wires to the drive terminals. Tighten the

screws to 0.4 lb-ft (0.5…0.6 N-m).

WARNING! To avoid danger or damage to the drive on IT systems and corner

grounded TN systems, see section Check the compatibility with IT (ungrounded)

and corner-grounded TN systems on page 17.

Power wiring torque table

Frame size

T1/U, T2/V, T3/W 3.3 2.5...4.5

L1, L2, L3 3.3 2.5...4.5

lb-ft N-m

R+, R- 3.3 2.5...4.5

PE Ground 1.1 1.5

R3

Loading...

Loading...