—

ABB GENERAL PURPOSE DRIVES

ACS580-01 drives

(0.75 to 250 kW, 1.0 to 350 hp)

Hardware manual

Related documents are listed on page 27.

Hardware manual

ACS580-01 drives

(0.75 to 250 kW, 1.0 to 350 hp)

Table of contents

1. Safety instructions

4. Mechanical installation

2019 ABB Oy. All Rights Reserved.

6. Electrical installation –

IEC

7. Electrical installation –

North America

3AXD50000044794 Rev B

EFFECTIVE: 2019-03-13

IEC

UL

NEC

EN

Table of contents 5

Table of contents

1. Safety instructions

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Use of warnings and notes in this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

General safety in installation, start-up and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Electrical safety in installation, start-up and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Precautions before electrical work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Additional instructions and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Additional instructions for permanent magnet motor drives . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Safety in installation, start-up and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

General safety in operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2. Introduction to the manual

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Target audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Purpose of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Contents of this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Categorization by frame (size) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Related documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

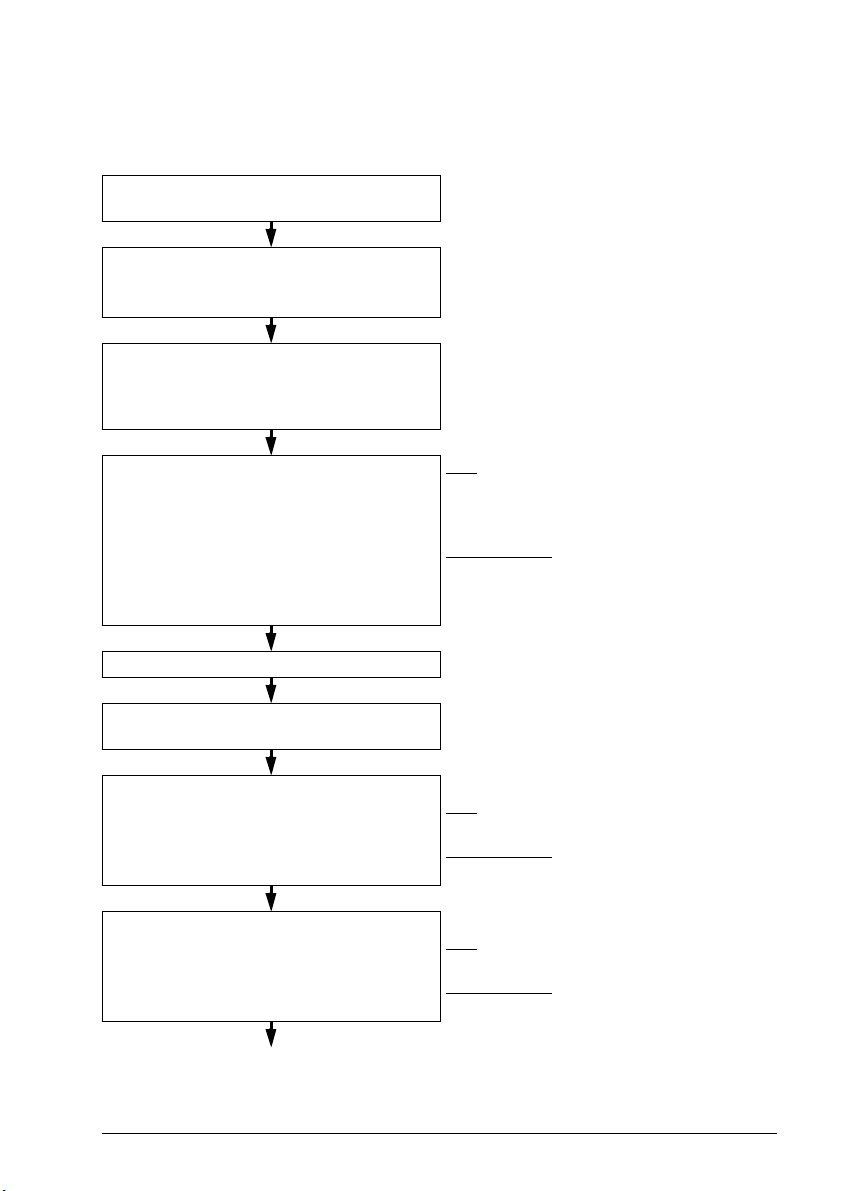

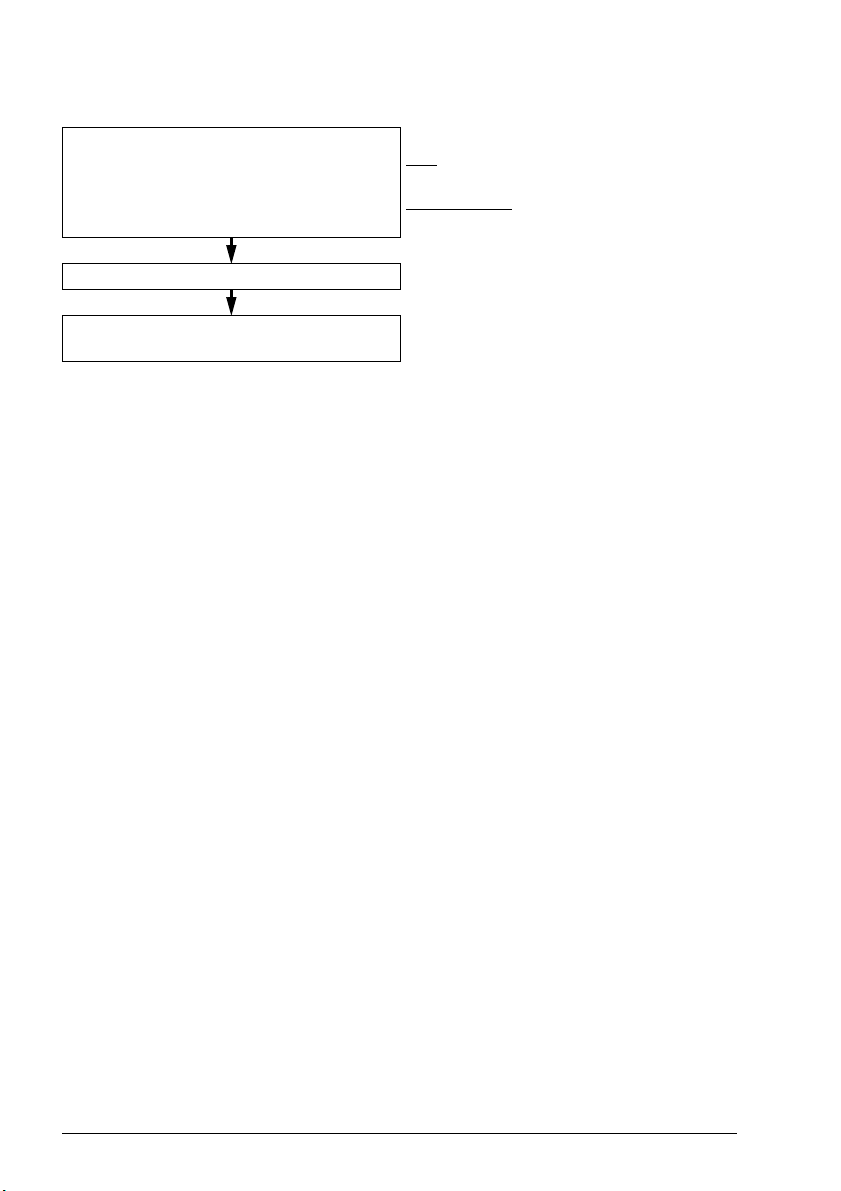

Quick installation and commissioning flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Safety

3. Operation principle and hardware description

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Operation principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Overview of power and control connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

External control connection terminals, frames R1…R5 . . . . . . . . . . . . . . . . . . . . . . . . . . 44

External control connection terminals, frames R6…R9 . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Control panel door mounting kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Type designation label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Type designation key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4. Mechanical installation

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Checking the installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Moving the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Unpacking and examining delivery, frames R1 and R2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6 Table of contents

Frames R1 and R2 cable box (IP21, UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Unpacking and examining delivery, frame R3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Unpacking and examining delivery, frame R4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Unpacking and examining delivery, frame R5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Frame R5 cable box (IP21, UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Unpacking and examining delivery, frames R6…R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Frame R6 cable box (IP21, UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Frame R7 cable box (IP21, UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Frame R8 cable box (IP21, UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Frame R9 cable box (IP21, UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Installing the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Installing the drive vertically, frames R1…R4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Install the cable box, frames R1…R2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Installing the drive vertically, frame R5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Installing the drive vertically, frames R6…R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Installing the drive vertically side by side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Installing the drive horizontally, frames R1…R5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Flange mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5. Guidelines for planning the electrical installation

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Limitation of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Selecting the supply disconnecting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

European Union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

North America . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Other regions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Checking the compatibility of the motor and drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Protecting the motor insulation and bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Requirements table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Selecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

General guidelines, IEC and North America . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Power cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Additional guidelines, North America . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Conductor type, IEC and North America . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Power cable shield, IEC and North America . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Typical power cable sizes, IEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Typical power cable sizes, UL/NEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Armored cable / shielded power cable, IEC and North America . . . . . . . . . . . . . . . . . . 101

Selecting the control cables, IEC and North America . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Signals in separate cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Signals allowed to be run in the same cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Relay cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Control panel cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Drive composer PC tool cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

FPBA-01 PROFIBUS DP adapter module connectors . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Routing the cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

General guidelines, IEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

General guidelines, North America . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Continuous motor cable shield or enclosure for equipment on the motor cable . . . . . . 106

Table of contents 7

Separate control cable ducts, IEC and North America . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Implementing short-circuit and thermal overload protection . . . . . . . . . . . . . . . . . . . . . . . . . 107

Protecting the drive and input power cable in short-circuits . . . . . . . . . . . . . . . . . . . . . . 107

Protecting the motor and motor cable in short-circuits . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Protecting the drive and the input power and motor cables against thermal overload . . 108

Protecting the motor against thermal overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Protecting the motor against overload without thermal model or temperature sensors . 108

Implementing a ground fault detection function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Residual current device compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Implementing the Emergency stop function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Implementing the Safe torque off function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Implementing the ATEX-certified Safe motor disconnection function (option +Q971) . . . . . 109

Using a safety switch between the drive and the motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Using a contactor between the drive and the motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Implementing a bypass connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Example bypass connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Implementing the undervoltage control (power-loss ride-through) . . . . . . . . . . . . . . . . . . . . 112

Protecting the contacts of relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Limiting relay output maximum voltages at high installation altitudes . . . . . . . . . . . . . . . . . . 113

Implementing a motor temperature sensor connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

6. Electrical installation – IEC

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Checking the insulation of the assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Input power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Motor and motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Brake resistor assembly for R1…R3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Checking the compatibility with IT (ungrounded), corner-grounded delta, midpoint-grounded

delta and TT systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

EMC filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Ground-to-phase varistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

When to disconnect EMC filter or ground-to-phase varistor: TN-S, IT, corner-grounded

delta and midpoint-grounded delta systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Guidelines for installing the drive to a TT system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Identifying different types of electrical power systems . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Frames R1…R3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Frames R4…R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Connecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Connection procedure, frames R1…R4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Connection procedure, frame R5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Connection procedure, frames R6…R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

DC connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Connecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Default I/O connection diagram (ABB standard macro) . . . . . . . . . . . . . . . . . . . . . . . . . 147

Control cable connection procedure R1…R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Installing option modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

8 Table of contents

Mechanical installation of option modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Wiring the modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Reinstalling grommets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Reinstalling covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Reinstalling cover, frames R1…R4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Reinstalling covers, frame R5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Reinstalling side plates and covers, frames R6…R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Connecting a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

7. Electrical installation – North America

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Checking the insulation of the assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Input power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Motor and motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Brake resistor assembly for R1…R3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Checking the compatibility with IT (ungrounded), corner-grounded delta, midpoint-grounded

delta and TT systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

EMC filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Ground-to-phase varistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

When to connect EMC filter or disconnect ground-to-phase varistor: TN-S, IT, corner-

grounded delta and midpoint-grounded delta systems . . . . . . . . . . . . . . . . . . . . . . . . . 175

Guidelines for installing the drive to a TT system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Identifying different types of electrical power systems . . . . . . . . . . . . . . . . . . . . . . . . . 177

Frames R1…R3, disconnecting EMC or varistor screws . . . . . . . . . . . . . . . . . . . . . . . . 178

Frames R4…R9, disconnecting EMC or varistor screws . . . . . . . . . . . . . . . . . . . . . . . . 180

Connecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Connection procedure, frames R1…R4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Connection procedure, frame R5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Connection procedure, frames R6…R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

DC connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Connecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Default I/O connection diagram (ABB standard macro) . . . . . . . . . . . . . . . . . . . . . . . . . 201

Control cable connection procedure R1…R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Installing option modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Mechanical installation of option modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Wiring the modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Reinstalling grommets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Reinstalling covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Reinstalling cover, frames R1…R4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Reinstalling covers, frame R5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Reinstalling side plates and covers, frames R6…R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Installing UL Type 12 hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Connecting a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Table of contents 9

8. Installation checklist

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

9. Maintenance and hardware diagnostics

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Description of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Functional safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Recommended annual actions by the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Recommended maintenance actions by the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Heatsink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Replacing the main cooling fan, IP21 and IP55 (UL Type 1 and UL Type 12)

frames R1…R4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Replacing the main cooling fan, IP21 and IP55 (UL Type 1 and UL Type 12)

frames R5…R8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Replacing the main cooling fans, IP21 and IP55 (UL Type 1 and UL Type 12)

frame R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Replacing the auxiliary cooling fan, IP21 and IP55 (UL Type 1 and UL Type 12)

frames R5…R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Replacing the auxiliary cooling fan, IP55 (UL Type 12) frames R1…R2 . . . . . . . . . . . . 238

Replacing the auxiliary cooling fan, IP55 (UL Type 12) frame R3 . . . . . . . . . . . . . . . . . 239

Replacing the auxiliary cooling fan, IP55 (UL Type 12) frame R4 . . . . . . . . . . . . . . . . . 240

Replacing the second auxiliary cooling fan, IP55 (UL Type 12) frames R8…R9 . . . . . . 241

Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Reforming the capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Cleaning the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Replacing the battery in the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Drive LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Control panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

10. Technical data

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Electrical ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

IEC ratings at UN = 230 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

IEC ratings at UN = 400 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

IEC ratings at UN = 480 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

UL (NEC) ratings at UN = 208/230 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

UL (NEC) ratings at UN = 460 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

UL (NEC) ratings at UN = 575 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Conversion tables for IEC and North American type codes . . . . . . . . . . . . . . . . . . . . . . 257

Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Ambient temperature derating, IP21 (UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

10 Table of contents

Ambient temperature derating, IP55 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Altitude derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Switching frequency derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Output frequency derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Fuses (IEC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

gG fuses (IEC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

uR and aR fuses (IEC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Circuit breakers (IEC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Fuses (UL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Dimensions, weights and free space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Losses, cooling data and noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Cooling air flow, heat dissipation and noise for stand-alone drives . . . . . . . . . . . . . . . . 283

Cooling air flow and heat dissipation for flange mounting (option +C135) . . . . . . . . . . . 287

Terminal and lead-through data for the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

IEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

UL (NEC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Terminal and lead-through data for the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

IEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

UL (NEC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Electrical power network specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Voltage (U1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Motor connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Brake resistor connection data for frames R1…R3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Control connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Applicable standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Compliance with the European Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . 309

Compliance with the European EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Compliance with the European ROHS II Directive 2011/65/EU . . . . . . . . . . . . . . . . . . . 309

Compliance with the European WEEE Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Compliance with the European Machinery Directive 2006/42/EC 2nd Edition –

June 2010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Compliance with the IEC 61800-3:2017 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Category C1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Category C2 . . . . . . . . . . . . . . . . . . . . . . . . . .

Category C3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Category C4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

UL marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

UL checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

China RoHS marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

RCM marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

WEEE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

EAC marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Cyber security disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Table of contents 11

11. Dimension drawings

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Frame R1, IP21 (UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Frame R1, IP55 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

Frame R1, IP55+F278 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

Frame R2, IP21 (UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Frame R2, IP55 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Frame R2, IP55+F278 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

Frame R3, IP21 (UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Frame R3, IP55 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Frame R3, IP55+E223 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

Frame R3, IP55+F278/F316 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Frame R4, IP21 (UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Frame R4, IP55 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Frame R4, IP55+E223 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Frame R4, IP55+F278/F316 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Frame R5, IP21 (UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

Frame R5, IP55 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

Frame R5, IP55+E223 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

Frame R5, IP55+F278/F316 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Frame R6, IP21 (UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Frame R6, IP55 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Frame R7, IP21 (UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

Frame R7, IP55 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Frame R8, IP21 (UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Frame R8, IP55 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Frame R9, IP21 (UL Type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

Frame R9, IP55 (UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

12. Resistor braking

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

Operation principle and hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

Resistor braking, frames R1…R3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

Planning the braking system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Resistor braking, frames R4…R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Planning the braking system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Parameter settings for external braking chopper and resistor . . . . . . . . . . . . . . . . . . . . 352

13. Safe torque off function

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Compliance with the European Machinery Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

Connection principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

Single drive, internal +24 V DC power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

Single drive, external +24 V DC power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

12 Table of contents

Multiple ACS580-01 drives, internal +24 V DC power supply . . . . . . . . . . . . . . . . . . . . 359

Multiple ACS580-01 drives, external +24 V DC power supply . . . . . . . . . . . . . . . . . . . . 360

Activation switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Cable types and lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Grounding of protective shields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Operation principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Start-up including acceptance test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

Competence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

Acceptance test reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

Acceptance test procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

Competence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

Fault tracing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

Safety data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

14. Optional I/O extension modules

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

CHDI-01 115/230 V digital input extension module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 378

CMOD-01 multifunction extension module (external 24 V AC/DC and digital I/O) . . . . . . . . 380

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380

Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380

Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 382

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 385

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 386

CMOD-02 multifunction extension module (external 24 V AC/DC and isolated PTC

interface) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 390

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

CBAI-01 bipolar analog IO extension module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 397

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 397

Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 397

Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 398

Table of contents 13

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 399

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

15. Common mode, du/dt and sine filters

Content of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

Common mode filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

When is a common mode filter needed? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

du/dt filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

When is a du/dt filter needed? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

Common mode filter types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 406

du/dt filter types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

Description, installation and technical data of the FOCH filters . . . . . . . . . . . . . . . . . . . 407

Description, installation and technical data of the NOCH filters . . . . . . . . . . . . . . . . . . . 407

Sine filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

Selecting a sine filter for the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

Description, installation and technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 409

Further information

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

14 Table of contents

Safety instructions 15

1

Safety instructions

Contents of this chapter

This chapter contains the safety instructions which you must obey when you install

and operate the drive and do maintenance on the drive. If you ignore the safety

instructions, injury, death or damage can occur.

Use of warnings and notes in this manual

Warnings tell you about conditions which can cause injury or death, or damage to the

equipment. They also tell you how to prevent the danger. Notes draw attention to a

particular condition or fact, or give information on a subject.

The manual uses these warning symbols:

Electricity warning tells about hazards from electricity which can cause

injury or death, or damage to the equipment.

General warning tells about conditions, other than those caused by

electricity, which can cause injury or death, or damage to the equipment.

Electrostatic sensitive devices warning tells you about the risk of

electrostatic discharge which can cause damage to the equipment.

16 Safety instructions

General safety in installation, start-up and maintenance

These instructions are for all personnel that install the drive and do maintenance work

on it.

WAR NING! Obey these instructions. If you ignore them, injury or death, or

damage to the equipment can occur.

• Use safety shoes with a metal toe cap to avoid foot injury. Wear protective gloves

and long sleeves. Some parts have sharp edges.

• Handle the drive carefully.

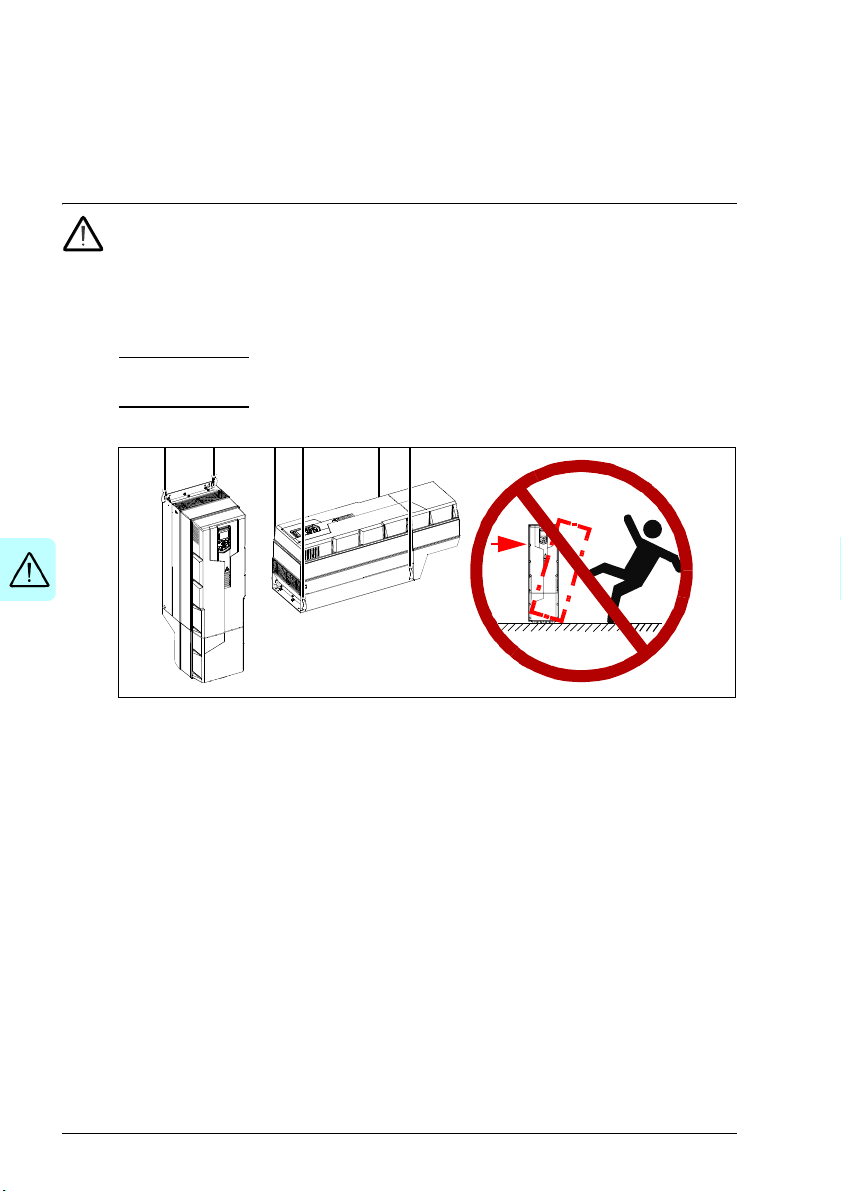

•Frames R

drive.

•Frames R5…R9: Do not tilt the drive. The drive is heavy and its center of

gravity is high. An overturning drive can cause physical injury.

5…R9: Lift the drive with a lifting device. Use the lifting eyes of the

• Beware of hot surfaces. Some parts, such as heatsinks of power semiconductors,

remain hot for a while after disconnection of the electrical supply.

• Keep the drive in its package or protect it otherwise from dust and burr from

drilling and grinding until you install it.

• Protect also the installed drive against dust and burr. Electrically conductive

debris inside the drive may cause damage or malfunction.

• Vacuum clean the area below the drive before the start-up to prevent the drive

cooling fan from drawing the dust inside the drive.

• Do not cover the air inlet and outlet when the drive runs.

• Make sure that there is sufficient cooling. See sections Checking the installation

site on page 54 and Losses, cooling data and noise on page 283 for more

information.

• Before you connect voltage to the drive, make sure that the drive covers are on.

Keep the covers on during the operation.

• Before you adjust the drive operation limits, make sure that the motor and all

driven equipment can operate throughout the set operation limits.

Safety instructions 17

• Before you activate the automatic fault reset or automatic restart functions of the

drive control program, make sure that no dangerous situations can occur. These

functions reset the drive automatically and continue operation after a fault or

supply break. If these functions are activated, the installation must be clearly

marked as defined in IEC/EN 61800-5-1, subclause 6.5.3, for example, “THIS

MACHINE STARTS AUTOMATICALLY”.

• If you have connected safety circuits to the drive (for example, emergency stop

and Safe torque off), validate them at the start up. For the validation of the Safe

torque off, see ACS580 standard control program firmware manual

(3AXD50000016097 [English]). For the validation of other safety circuits, see the

instructions provided with them.

Note:

• If you select an external source for start command and it is on, and the start

command is level-triggered, the drive will start immediately after fault reset. See

parameters 20.02 Ext1 start trigger type and 20.07 Ext2 start trigger type in

ACS580 standard control program firmware manual (3AXD50000016097

[English]).

• When the control location is not set to Local (text Local is not shown on the top

row of the panel and parameter 19.17 Local control disable has value Disabled),

the stop key on the control panel will not stop the drive.

• Frames R1…R5

: Do not attempt to repair a malfunctioning drive; contact your

local representative for replacement or repair by authorized persons.

Frames R6…R9: Can be repaired by authorized persons.

18 Safety instructions

Electrical safety in installation, start-up and maintenance

Precautions before electrical work

These warnings are for all personnel who do work on the drive, motor cable or motor.

WAR NING! Obey these instructions. If you ignore them, injury or death, or

damage to the equipment can occur. If you are not a qualified electrical

professional, do not do electrical installation or maintenance work. Go through these

steps before you begin any installation or maintenance work.

1. Clearly identify the work location.

2. Disconnect all possible voltage sources. Lock and tag.

• Open the main disconnector at the power supply of the drive.

• Make sure that reconnection is not possible.

• Disconnect any external power sources from the control circuits.

• After you disconnect the drive, always wait for 5 minutes to let the

intermediate circuit capacitors discharge before you continue.

3. Protect any other energized parts in the work location against contact.

4. Take special precautions when close to bare conductors.

5. Measure that the installation is de-energized.

• Use a multimeter with an impedance of at least 1 Mohm.

• Make sure that the voltage between the drive input power terminals (L1, L2,

L3) and the grounding terminal (PE) is close to 0 V.

• Make sure that the drive DC voltage is close to 0 V.

Frames R1…R3

grounding terminal (PE) with one multimeter. As there is no UDC- terminal,

measure the voltage between the drive T1/U terminal and grounding terminal

(PE) with another multimeter. Make sure that the voltage difference between

the multimeters is close to 0 V.

Frames R4…R9

and UDC-) and the grounding terminal (PE) and make sure that it is close to

0V.

: Measure the voltage between the drive UDC+ terminal and

: Measure the voltage between the drive DC terminals (UDC+

6. Install temporary grounding as required by the local regulations.

7. Ask for a permit to work from the person in control of the electrical installation

work

Safety instructions 19

Additional instructions and notes

WARNING! Obey these instructions. If you ignore them, injury or death, or

damage to the equipment can occur.

• A drive with the internal EMC filter connected can be installed to a symmetrically

grounded TN-S system. If you install the drive to another system, check if you

must disconnect the EMC filter. See sections

•IEC:

•North America:

drive.

Note: When the internal EMC filter is disconnected, the EMC compatibility of the

drive is considerably reduced. See section EMC compatibility and motor cable

length on page 297.

• A drive with the ground-to-phase varistor connected can be installed to a

symmetrically grounded TN-S system. If you install the drive to another system,

check if you must disconnect the varistor. See sections

•IEC:

•North America:

varistor circuit can be damaged.

• Use all ELV (extra low voltage) circuits connected to the drive only within a zone

of equipotential bonding, that is, within a zone where all simultaneously

accessible conductive parts are electrically connected to prevent hazardous

voltages appearing between them. You can accomplish this by a proper factory

grounding, that is, make sure that all simultaneously accessible conductive parts

are grounded to the protective earth (PE) bus of the building.

• Do not do insulation or voltage withstand tests on the drive or drive modules.

When to disconnect EMC filter or ground-to-phase varistor: TN-S, IT,

corner-grounded delta and midpoint-grounded delta systems on page 121,

and Guidelines for installing the drive to a TT system on page 122.

When to connect EMC filter or disconnect ground-to-phase

varistor: TN-S, IT, corner-grounded delta and midpoint-grounded delta

systems on page 175, and Guidelines for installing the drive to a TT system on

page 176.

WARNING! Do not install a drive with the EMC filter connected to a system

that the filter is not suitable for. This can cause danger, or damage the

When to disconnect EMC filter or ground-to-phase varistor: TN-S, IT,

corner-grounded delta and midpoint-grounded delta systems on page 121,

and Guidelines for installing the drive to a TT system on page 122.

When to connect EMC filter or disconnect ground-to-phase

varistor: TN-S, IT, corner-grounded delta and midpoint-grounded delta

systems on page 175, and Guidelines for installing the drive to a TT system on

page 176.

WARNING! Do not install a drive with the ground-to-phase varistor

connected to a system that the varistor is not suitable for. If you do, the

20 Safety instructions

Note:

• The motor cable terminals of the drive are at a dangerous voltage when the input

power is on, regardless of whether the motor is running or not.

• The DC and brake resistor terminals (UDC+, UDC-, R+ and R-) are at a

dangerous voltage.

• External wiring can supply dangerous voltages to the terminals of relay outputs

(RO1, RO2 and RO3).

• The Safe torque off function does not remove the voltage from the main and

auxiliary circuits. The function is not effective against deliberate sabotage or

misuse.

WARNING! Use a grounding wrist band when you handle the printed circuit

boards. Do not touch the boards unnecessarily. The boards contain

components sensitive to electrostatic discharge.

Grounding

These instructions are for all personnel who are responsible for the electrical

installation, including the grounding of the drive.

WAR NING! Obey these instructions. If you ignore them, injury or death, or

equipment malfunction can occur, and electromagnetic interference can

increase.

• If you are not a qualified electrical professional, do not do grounding work.

• Always ground the drive, the motor and adjoining equipment to the protective

earth (PE) bus of the power supply. This is necessary for the personnel safety.

Proper grounding also reduces electromagnetic emission and interference.

• In a multiple-drive installation, connect each drive separately to the protective

earth (PE) bus of the power supply.

• Make sure that the conductivity of the protective earth (PE) conductors is

sufficient. See section Selecting the power cables on page 91. Obey the local

regulations.

• Connect the power cable shields to the protective earth (PE) terminals of the

drive.

• Make a 360° grounding of the power and control cable shields at the cable entries

to suppress electromagnetic disturbances.

Safety instructions 21

Note:

• You can use power cable shields as grounding conductors only when their

conductivity is sufficient.

• Standards IEC/EN 61800-5-1 (section 4.3.5.5.2.) and UL 68100-5-1 require that

as the normal touch current of the drive is higher than 3.5 mA AC or 10 mA DC,

you must use a fixed protective earth (PE) connection. In addition,

• install a second protective earth conductor of the same cross-sectional area

as the original protective earthing conductor,

or

• install a protective earth conductor with a cross-section of at least 10 mm

or 16 mm

2

Al (when aluminum cables are allowed),

2

or

• install a device which automatically disconnects the supply if the protective

earth conductor breaks.

Cu

22 Safety instructions

Additional instructions for permanent magnet motor drives

Safety in installation, start-up and maintenance

These are additional warnings concerning permanent magnet motor drives. The other

safety instructions in this chapter are also valid.

WAR NING! Obey these instructions. If you ignore them, injury or death and

damage to the equipment can occur.

• Do not work on a drive when a rotating permanent magnet motor is connected to

it. A rotating permanent magnet motor energizes the drive including its input

power terminals.

Before installation, start-up and maintenance work on the drive:

• Stop the motor.

• Disconnect the motor from the drive with a safety switch or by other means.

• If you cannot disconnect the motor, make sure that the motor cannot rotate during

work. Make sure that no other system, like hydraulic crawling drives, can rotate

the motor directly or through any mechanical connection like felt, nip, rope, etc.

• Measure that the installation is de-energized.

• Use a multimeter with an impedance of at least 1 Mohm.

• Make sure that the voltage between the drive output terminals (T1/U, T2/V,

T3/W) and the grounding (PE) busbar is close to 0 V.

• Make sure that the voltage between the drive input power terminals (L1, L2,

L3) and the grounding (PE) busbar is close to 0 V.

• Make sure that the voltage between the drive DC terminals (UDC+, UDC-) and

the grounding (PE) terminal is close to 0 V.

• Install temporary grounding to the drive output terminals (T1/U, T2/V, T3/W).

Connect the output terminals together as well as to the PE.

Start-up and operation:

• Make sure that the motor cannot be run into overspeed, e.g. driven by the load.

Motor overspeed causes overvoltage that can damage or destroy the capacitors

in the intermediate circuit of the drive.

Safety instructions 23

General safety in operation

These instructions are for all personnel that operate the drive.

WARNING! Obey these instructions. If you ignore them, injury or death, or

damage to the equipment can occur.

• Do not power up the drive more than five times in ten minutes. Too frequent

power-ups can damage the charging circuit of the DC capacitors. If you need to

start or stop the drive, use the control panel start and stop keys or commands

through the I/O terminals of the drive.

• Give a stop command to the drive before you reset a fault. If you have an external

source for the start command and the start is on, the drive will start immediately

after the fault reset, unless you configure the drive for pulse start. See the

firmware manual.

• Before you activate automatic fault reset functions of the drive control program,

make sure that no dangerous situations can occur. These functions reset the

drive automatically and continue operation after a fault.

Note: When the control location is not set to Local, the stop key on the control panel

will not stop the drive.

24 Safety instructions

Introduction to the manual 25

2

Introduction to the manual

Contents of this chapter

The chapter describes applicability, target audience and purpose of this manual. It

describes the contents of this manual and refers to a list of related manuals for more

information. The chapter also contains a flowchart of steps for checking the delivery,

installing and commissioning the drive. The flowchart refers to chapters/sections in

this manual.

Applicability

The manual applies to the ACS580-01 drives, including the new (2017) R1…R3

frames (see all applicable types in section Electrical ratings on page 248).

Note: The manual does not apply to R0…R3 frames with type codes ACS580-01:

02A6-4, 03A3-4, 04A0-4, 05A6-4, 07A2-4, 09A-4, 12A6-4, 017A-4, 025A-4, 032A-4,

038A-4, 045A-4. For these types, see ACS580-01 (0.75 to 250 kW, 1.0 to 350 hp)

hardware manual (3AXD50000018826 [English]).

Target audience

The reader is expected to know the fundamentals of electricity, wiring, electrical

components and electrical schematic symbols.

The manual is written for readers worldwide. Both SI and imperial units are shown.

Special instructions for installations in North America are given.

Purpose of the manual

This manual provides information needed for planning the installation, installing, and

servicing the drive.

26 Introduction to the manual

Contents of this manual

The manual consists of the following chapters:

• Safety instructions (page 15) gives safety instructions you must obey when

installing, commissioning, operating and servicing the drive.

• Introduction to the manual (this chapter, page 25) describes applicability, target

audience, purpose and contents of this manual. It also contains a quick

installation and commissioning flowchart. At the end, it lists terms and

abbreviations.

• Operation principle and hardware description (page 35) describes the operation

principle, layout, power connections and control interfaces, type designation label

and type designation information in short.

• Mechanical installation (page 53) describes how to check the installation site,

unpack, check the delivery and install the drive mechanically.

• Guidelines for planning the electrical installation (page 83) describes how to plan

the electrical installation of the drive, for example, how to check the compatibility

of the motor and the drive and select cables, protections and cable routing.

• Electrical installation – IEC (page 117) describes how to check the insulation of

the assembly and the compatibility with other than symmetrically grounded TN-S

systems. It then shows how to connect the power and control cables, install

optional modules and connect a PC.

• Electrical installation – North America (page 171) describes how to check the

insulation of the assembly and the compatibility with other than symmetrically

grounded TN-S systems. It then shows how to connect the power and control

cables, install optional modules and connect a PC.

• Installation checklist (page 227) contains a checklist for checking the mechanical

and electrical installation of the drive before start-up.

• Maintenance and hardware diagnostics (page 229) contains preventive

maintenance instructions and LED indicator descriptions.

• Technical data (page 247) contains technical specifications of the drive, eg,

ratings, sizes and technical requirements as well as provisions for fulfilling the

requirements for CE, UL and other marks.

• Dimension drawings (page 317) shows dimension drawings of the drive.

• Resistor braking (page 345) tells how to select the brake resistor.

• Safe torque off function (page 353) describes STO features, installation and

technical data.

• Optional I/O extension modules (page 373) describes CMOD-01, CMOD-02, and

CHDI-01 and CBAI-01 extension modules, their installation, start-up, diagnostics

and technical data.

• Common mode, du/dt and sine filters (page 405) describes selection of external

filters for the drive.

Introduction to the manual 27

• Further information (inside of the back cover, page 411) tells how to make product

and service inquiries, get information on product training, provide feedback on

manuals and find documents on the Internet.

Categorization by frame (size)

The ACS580-01 is manufactured in frames (frame sizes) R1…R9. Some instructions

and other information that only concern certain frames are marked with the symbol of

the frame (R1…R9). The frame is marked on the type designation label attached to

the drive, see section Type designation label on page 47.

Related documents

You can find manuals and other product documents in PDF format on the Internet.

See section Document library on the Internet on the inside of the back cover. For

manuals not available in the Document library, contact your local ABB representative.

Drive manuals and guides Code (English)

ACS580 standard control program firmware manual

ACS580-01 (0.75 to 250 kW, 1.0 to 350 hp) hardware

manual

ACS580-01 frames R1 to R5 quick installation and start-

up guide

ACS580-01 frames R6 to R9 quick installation and start-

up guide

ACx-AP-X assistant control panels user’s manual

3AXD50000016097

3AXD50000044794

3AXD50000044838

3AXD50000009286

3AUA0000085685

Option manuals and guides

ACS580, ACH580 and ACQ580 drive module frames

R3 and R5 to R9 for cabinet installation (options +P940

and +P944) supplement

ACS580-01, ACH580-01 and ACQ580-01 installation

guide for UK gland plate (option +H358)

CPTC-02 ATEX-certified thermistor protection module,

Ex II (2) GD (+L537+Q971) user's manual

CDPI-01 communication adapter module user's manual

DPMP-01 mounting platform for control panels

DPMP-02/03 mounting platform

DPMP-06/07 mounting platform

FCAN-01 CANopen adapter module user's manual

FCNA-01 ControlNet adapter module user's manual

FDNA-01 DeviceNet™ adapter module user's manual

FECA-01 EtherCAT adapter module user's manual

FEIP-21 Ethernet/IP adapter module user’s manual

FENA-01/-11/-21 Ethernet adapter module user's

manual

FEPL-02 Ethernet POWERLINK adapter module user's

manual

FMBT-21 Modbus/TCP adapter module user’s manual

for control panels

for control panels

3AXD50000210305

3AXD50000034735

3AXD50000030058

3AXD50000009929

3AUA0000100140

3AUA0000136205

3AXD50000289561

3AFE68615500

3AUA0000141650

3AFE68573360

3AUA0000068940

3AXD50000158621

3AUA0000093568

3AUA0000123527

3AXD50000158607

28 Introduction to the manual

ACS580-01 manuals

FPBA-01 PROFIBUS DP adapter module user's manual

FPNO-21 PROFINET adapter module user’s manual

FSCA-01 RS-485 adapter module user's manual 3AUA0000109533

ACS580-01…, ACH580-01… and ACQ580-01…+C135

drives with flange mounting kit supplement

ACS580-01…, ACH580-01… and ACQ580-01…+C135

frames R1 to R3 flange mounting kit quick installation

guide

ACS580-01…, ACH580-01… and ACQ580-01…+C135

frames R4 to R5 flange mounting kit quick installation

guide

ACS880-01…, ACS580-01…, ACH580-01… and

ACQ580-01…+C135 frames R4 to R5 flange mounting

kit quick installation guide

Main switch and EMC C1 filter options (+F278, +F316,

+E223) installation supplement for ACS580-01,

ACH580-01 and ACH580-01 frames R1 to R5

UL Type 12 hood quick installation guide for ACS58001, ACH580-01 and ACQ580-01 frames R1 to R9

Tool and maintenance manuals and guides

Drive composer PC tool user's manual 3AUA0000094606

Converter module capacitor reforming instructions

NETA-21 remote monitoring tool user's manual

NETA-21 remote monitoring tool installation and start-up

guide

3AFE68573271

3AXD50000158614

3AXD50000019100

3AXD50000119172

3AXD50000287093

3AXD50000019099

3AXD50000155132

3AXD50000196067

3BFE64059629

3AUA0000096939

3AUA0000096881

Introduction to the manual 29

Quick installation and commissioning flowchart

Tas k Se e

Identify the frame of your drive: R1…R9. Operation principle and hardware description:

Type designation key on page 49

Plan the installation: select the cables, etc.

Check the ambient conditions, ratings and

required cooling air flow.

Unpack and check the drive.

Check that all necessary optional modules

and equipment are present and correct.

If the drive will be connected to another

system than symmetrically grounded TN-S

system: Check if you must disconnect the

EMC filter or ground-to-phase varistor.

Install the drive on a wall. Mechanical installation on page 53

Route the cables. Guidelines for planning the electrical

Check the insulation of the input cable and the

motor and the motor cable.

Guidelines for planning the electrical

installation on page 83

Technical data on page 247

Mechanical installation: Unpacking and

examining delivery, frames R1 and R2 on

page 59; R3 on page 62; R4 on page 64; R5

on page 66; R6…R9 on page 68

IEC:

Checking the compatibility with IT

(ungrounded), corner-grounded delta,

midpoint-grounded delta and TT systems on

page 120

North America:

with IT (ungrounded), corner-grounded delta,

midpoint-grounded delta and TT systems on

page 174

installation: Routing the cables on page 104

Electrical installation:

IEC:

Checking the insulation of the assembly

on page 118

North America:

assembly on page 172

Checking the compatibility

Checking the insulation of the

Connect the power cables. Electrical installation:

IEC:

Connecting the power cables on page

127

North America:

on page 182

Connecting the power cables

30 Introduction to the manual

Tas k Se e

Connect the control cables. Electrical installation:

IEC:

Connecting the control cables on page

146

North America:

on page 182

Check the installation. Installation checklist on page 227

Commission the drive. ACS580 standard control program firmware

manual (3AXD50000016097 [English])

Connecting the control cables

Introduction to the manual 31

Terms and abbreviations

Term/abbreviation Explanation

ACS-BP-S Basic control panel, basic operator keypad for communication with the

Assistant control

panel

Brake chopper Conducts the surplus energy from the intermediate circuit of the drive to

Brake resistor Dissipates the drive surplus braking energy conducted by the brake

Control board Circuit board in which the control program runs.

Capacitor bank See DC link capacitors.

CBAI-01 CBAI-01 bipolar analog IO extension module

CCA-01 Configuration adapter

CDPI-01 Communication adapter module

CHDI-01 Optional 115/230 V digital input extension module

CMOD-01 Optional multifunction extension module (external 24 V AC/DC and

CMOD-02 Optional multifunction extension module (external 24 V AC/DC and

CPTC-02 Optional multifunction extension module (external 24 V and ATEX

DC link DC circuit between rectifier and inverter

DC link capacitors Energy storage which stabilizes the intermediate circuit DC voltage

DPMP-01 Mounting platform for ACS-AP control panel (flange mounting). CDP-01

DPMP-02 Mounting platform for ACS-AP control panel (surface mounting).

DPMP-EXT Door mounting kit for the panel. For one drive; contains both DPMP-02

Drive Frequency converter for controlling AC motors

EMC Electromagnetic compatibility

EFB Embedded fieldbus

FBA Fieldbus adapter

FCAN-01 Optional CANopen adapter module

drive. The ACS580 supports ACS-BP-S basic control panel.

Assistant control panel (ACS-AP-x) is an advanced operator keypad for

communication with the drive. The ACS580 supports types ACS-AP-I

and ACS-AP-S, as well as ACS-AP-W, which has a Bluetooth interface.

the brake resistor when necessary. The chopper operates when the DC

link voltage exceeds a certain maximum limit. The voltage rise is

typically caused by deceleration (braking) of a high inertia motor.

chopper to heat. Essential part of the brake circuit. See Brake chopper.

digital I/O extension)

isolated PTC interface)

certified PTC interface)

communication adapter module is needed to connect the DMP0-01 to

the drive. For up to 32 drives on a panel bus with a single panel on

cabinet door, one DMP-02 with one CDPI-01 per each drive are used.