Page 1

ABB general purpose drives

Firmware manual

ACS580 standard control program

Page 2

List of related manuals

ACS580-01 manuals

Drive manuals and guides Code (English)

ACS580 standard control program firmware manual

ACS580-04 quick installation and start-up guide for

frames R10 to R11

ACX-AP-x assistant control panels user’s manual

ACS-BP-S basic control panels user’s manual

Option manuals and guides

CPTC-02 ATEX-certified thermistor protection module,

Ex II (2) GD (+L537+Q971) user's manual

CDPI-01 communication adapter module user's manual

DPMP-01 mounting platform for

DPMP-02/03 mounting platform for control panels 3AUA0000136205

FCAN-01 CANopen adapter module user's manual

FCNA-01 ControlNet adapter module user's manual

FDNA-01 DeviceNet™ adapter module user's manual

FECA-01 EtherCAT adapter module user's manual

FENA-01/-11/-21 Ethernet adapter module user's

manual

FEPL-02 Ethernet POWERLINK adapter module user's

manual

FPBA-01 PROFIBUS DP adapter module user's manual

FSCA-01 RS-485 adapter module user's manual 3AUA0000109533

Flange mounting kit installation supplement

Flange mounting kit quick installation guide for

ACX580-01 frames R0 to R5

Flange mounting kit quick installation guide for

ACS880-01 and ACX580-01 frames R6 to R9

Main switch and EMC C1 filter options (+F278, +F316,

+E223) installation supplement for ACS580-01,

ACH580-01 and ACQ580-01 frames R1 to R5

UL Type 12 hood quick installation guide for ACS580-01,

ACH580-01 and ACQ580-01 frames R1 to R9

control panels 3AUA0000100140

3AXD50000016097

3AXD50000015469

3AUA0000085685

3AXD50000032527

3AXD50000030058

3AXD50000009929

3AFE68615500

3AUA0000141650

3AFE68573360

3AUA0000068940

3AUA0000093568

3AUA0000123527

3AFE68573271

3AXD50000019100

3AXD50000036610

3AXD50000019099

3AXD50000155132

3AXD50000196067

Tool and maintenance manuals and guides

Drive composer PC tool user's manual 3AUA0000094606

Converter module capacitor reforming instructions

NETA-21 remote monitoring tool user's manual

NETA-21 remote monitoring tool installation and start-up

guide

3BFE64059629

3AUA0000096939

3AUA0000096881

You can find manuals and other product

documents in PDF format on the Internet. See

section Document library on th e Internet on the

inside of the back cover. For manuals not available

in the Document library, contact your local ABB

representative.

Page 3

Firmware manual

ACS580 standard control program

Table of contents

1. Introduction to the manual

2. Start-up, control with I/O and

ID run

3. Control panel

4. Settings, I/O and diagnostics on the control panel

5. Control macros

6. Program features

7. Parameters

8. Additional parameter data

9. Fault tracing

10. Fieldbus control through the embedded fieldbus

interface (EFB)

11. Fieldbus control through a fieldbus adapter

12. Control chain diagrams

Further information

Page 4

3AXD50000016097 Rev E

EN

EFFECTIVE: 2018-02-15

2018 ABB Oy. All Rights Reserved.

Page 5

Table of contents 5

Table of contents

List of related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1. Introduction to the manual

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Target audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Purpose of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Contents of this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Categorization by frame (size) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Related documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cybersecurity disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2. Start-up, control with I/O and ID run

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

How to start up the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

How to start up the drive using the First start assistant on the assistant control panel . . . 20

How to control the drive through the I/O interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

How to perform the ID run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

ID run procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Safety

3. Control panel

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Removing and reinstalling the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Layout of the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Layout of the control panel display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Key shortcuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4. Settings, I/O and diagnostics on the control panel

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Primary settings menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Start, stop, reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Ramps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

PID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Pump and fan control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Advanced functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Clock, region, display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Reset to defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Page 6

6 Table of contents

I/O menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Diagnostics menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

System info menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Energy efficiency menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Backups menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5. Control macros

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

ABB standard macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Default control connections for the ABB standard macro . . . . . . . . . . . . . . . . . . . . . . . . 72

ABB standard (vector) macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Default control connections for the ABB standard (vector) macro . . . . . . . . . . . . . . . . . . 74

3-wire macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Default control connections for the 3-wire macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Alternate macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Default control connections for the Alternate macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Motor potentiometer macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Default control connections for the Motor potentiometer macro . . . . . . . . . . . . . . . . . . . 80

Hand/Auto macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Default control connections for the Hand/Auto macro . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Hand/PID macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Default control connections for the Hand/PID macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

PID macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Default control connections for the PID macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Panel PID macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Default control connections for the Panel PID macro . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

PFC macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Default control connections for the PFC macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Parameter default values for different macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

6. Program features

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Local control vs. external control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Local control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

External control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Operating modes of the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Speed control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Torque control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Frequency control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Special control modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Drive configuration and programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Configuring via parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Adaptive programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Control interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Programmable analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Programmable analog outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Programmable digital inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Programmable frequency input and output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Page 7

Table of contents 7

Programmable relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Programmable I/O extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Fieldbus control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Application control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Reference ramping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Constant speeds/frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Critical speeds/frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

User load curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Control macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Process PID control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Pump and fan control (PFC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Timed functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Motor potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Mechanical brake control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Motor types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Motor identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Scalar motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Vector control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Speed control performance figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Torque control performance figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Power loss ride-through . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

U/f ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Flux braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

DC magnetization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Energy optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Switching frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Rush control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Jogging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Speed compensated stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

DC voltage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Overvoltage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Undervoltage control (power loss ride-through) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Voltage control and trip limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Brake chopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Safety and protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Fixed/Standard protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Emergency stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Motor thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Programmable protection functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Automatic fault resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Signal supervision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Energy saving calculators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Load analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Diagnostics menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Backup and restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

User parameter sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Data storage parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

User lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Page 8

8 Table of contents

Sine filter support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

7. Parameters

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Summary of parameter groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Parameter listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

01 Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

03 Input references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

04 Warnings and faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

05 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

06 Control and status words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

07 System info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

10 Standard DI, RO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

11 Standard DIO, FI, FO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

12 Standard AI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

13 Standard AO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

15 I/O extension module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

19 Operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

20 Start/stop/direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

21 Start/stop mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

22 Speed reference selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

23 Speed ref erence ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

24 Speed reference conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

25 Speed cont rol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

26 Torque reference chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

28 Frequency reference chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

30 Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

31 Fault functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

32 Supervision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

34 Timed functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

35 Motor thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

36 Load analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

37 User load curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

40 Process PID set 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

41 Process PID set 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

43 Brake chopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

44 Mechanical brake control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

45 Energy efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

46 Monitoring/scaling settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

47 Data storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

49 Panel port communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

50 Fieldbus adapter (FBA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

51 FBA A settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

52 FBA A data in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

53 FBA A data out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

58 Embedded fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

71 External PID1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

76 PFC configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

77 PFC maintenance and monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

Page 9

Table of contents 9

95 HW configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

96 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

97 Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

98 User motor parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

99 Motor data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365

Differences in the default values between 50 Hz and 60 Hz supply frequency settings . . . . 371

8. Additional parameter data

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Fieldbus addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

Parameter groups 1…9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

Parameter groups 10…99 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 378

9. Fault tracing

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

Warnings and faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

Pure events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

Editable messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

Warning/fault history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

Event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

Viewing warning/fault information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 409

QR code generation for mobile service application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 409

Warning messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 410

Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 420

10. Fieldbus control through the embedded fieldbus interface (EFB)

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

Connecting the fieldbus to the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 432

Setting up the embedded fieldbus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

Setting the drive control parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 434

Basics of the embedded fieldbus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 436

Control word and Status word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

Data input/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

Register addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

About the control profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 439

Control Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 440

Control Word for the ABB Drives profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 440

Control Word for the DCU Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 441

Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 444

Status Word for the ABB Drives profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 444

Status Word for the DCU Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 445

State transition diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 447

Page 10

10 Table of contents

State transition diagram for the ABB Drives profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . 447

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

References for the ABB Drives profile and DCU Profile . . . . . . . . . . . . . . . . . . . . . . . . 449

Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 450

Actual values for the ABB Drives profile and DCU Profile . . . . . . . . . . . . . . . . . . . . . . . 450

Modbus holding register addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 451

Modbus holding register addresses for the ABB Drives profile and DCU Profile . . . . . . 451

Modbus function codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 452

Exception codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Coils (0xxxx reference set) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 454

Discrete inputs (1xxxx reference set) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 456

Error code registers (holding registers 400090…400100) . . . . . . . . . . . . . . . . . . . . . . . . . . 458

11. Fieldbus control through a fieldbus adapter

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 459

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 459

Basics of the fieldbus control interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 461

Control word and Status word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 462

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 464

Contents of the fieldbus Control word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

Contents of the fieldbus Status word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 467

The state diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 468

Setting up the drive for fieldbus control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 469

Parameter setting example: FPBA (PROFIBUS DP) . . . . . . . . . . . . . . . . . . . . . . . . . . . 470

12. Control chain diagrams

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 473

Frequency reference selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 474

Frequency reference modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 475

Speed reference source selection I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 476

Speed reference source selection II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 477

Speed reference ramping and shaping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 478

Speed error calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 479

Speed feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 480

Speed controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 481

Torque reference source selection and modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 482

Reference selection for torque controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 483

Torque limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 484

Process PID setpoint and feedback source selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 485

Process PID controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 486

External PID setpoint and feedback source selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 487

External PID controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 488

Direction lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 489

Further information

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 491

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 491

Page 11

Table of contents 11

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 491

Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 491

Page 12

12 Table of contents

Page 13

Introduction to the manual 13

1

Introduction to the manual

Contents of this chapter

The chapter describes applicability, target audience and purpose of this manual. It

also describes the contents of this manual and refers to a list of related manuals for

more information.

Applicability

The manual applies to the ACS580 standard control program ASCDX version 2.05,

which is compatible with CCU-23 and CCU-24 control units only. You can tell apart

these control units from the older control unit versions by the colored terminals.

Note: For ACS580 standard control program, there are different firmwares,

depending on the control unit construction and frame size.

For frame sizes R1…R5, firmware ASCD2 is used, and for frames sizes R6…R11,

firmware ASCD4 is used.

To check the firmware version of the control program in use, see system information

(select Menu - System info - Drive) or parameter 07.05 Firmware version (see page

173) on the control panel.

Safety instructions

Follow all safety instructions.

• Read the complete safety instructions in the Hardware manual of the drive

before you install, commission, or use the drive.

• Read the firmware function-specific warnings and notes before changing

parameter values. These warnings and notes are included in the parameter

descriptions presented in chapter Parameters on page 157.

Page 14

14 Introduction to the manual

Target audience

The reader is expected to know the fundamentals of electricity, wiring, electrical

components and electrical schematic symbols.

The manual is written for readers worldwide. Both SI and imperial units are shown.

Special US instructions for installations in the United States are given.

Purpose of the manual

This manual provides information needed for designing, commissioning, or operating

the drive system.

Contents of this manual

The manual consists of the following chapters:

• Introduction to the manual (this chapter, page 13) describes applicability, target

audience, purpose and contents of this manual. At the end, it lists terms and

abbreviations.

• Start-up, control with I/O and ID run (page 19) describes how to start up the drive

as well as how to start, stop, change the direction of the motor rotation and adjust

the motor speed through the I/O interface.

• Control panel (page 39) contains instructions for removing and reinstalling the

assistant control panel and briefly describes its display, keys and key shortcuts.

• Settings, I/O and diagnostics on the control panel (page 45) describes the

simplified settings and diagnostic functions provided on the assistant control

panel.

• Control macros (page 71) contains a short description of each macro together

with a connection diagram. Macros are pre-defined applications which will save

the user time when configuring the drive.

• Program features (page 97) describes program features with lists of related user

settings, actual signals, and fault and warning messages.

• Parameters (page 157) describes the parameters used to program the drive.

• Additional parameter data (page 373) contains further information on the

parameters.

• Fieldbus control through the embedded fieldbus interface (EFB) (page 431)

describes the communication to and from a fieldbus network using the drive

embedded fieldbus interface with the Modbus RTU protocol.

• Fieldbus control through a fieldbus adapter (page 459) describes the

communication to and from a fieldbus network using an optional fieldbus adapter

module.

Page 15

Introduction to the manual 15

• Fault tracing (page 407) lists the warning and fault messages with possible

causes and remedies.

• Control chain diagrams (page 473) describes the parameter structure within the

drive.

• Further information (inside of the back cover, page 491) describes how to make

product and service inquiries, get information on product training, provide

feedback on ABB Drives manuals and find documents on the Internet.

Categorization by frame (size)

The drive is manufactured in several frames (frame sizes), which are denoted as RN,

where N is an integer. Some information which only concern certain frames are

marked with the symbol of the frame (RN).

The frame is marked on the type designation label attached to the drive, see chapter

Operation principle and hardware description, section Type designation label in the

Hardware manual of the drive.

Related documents

See List of related manuals on page 2 (inside of the front cover).

Page 16

16 Introduction to the manual

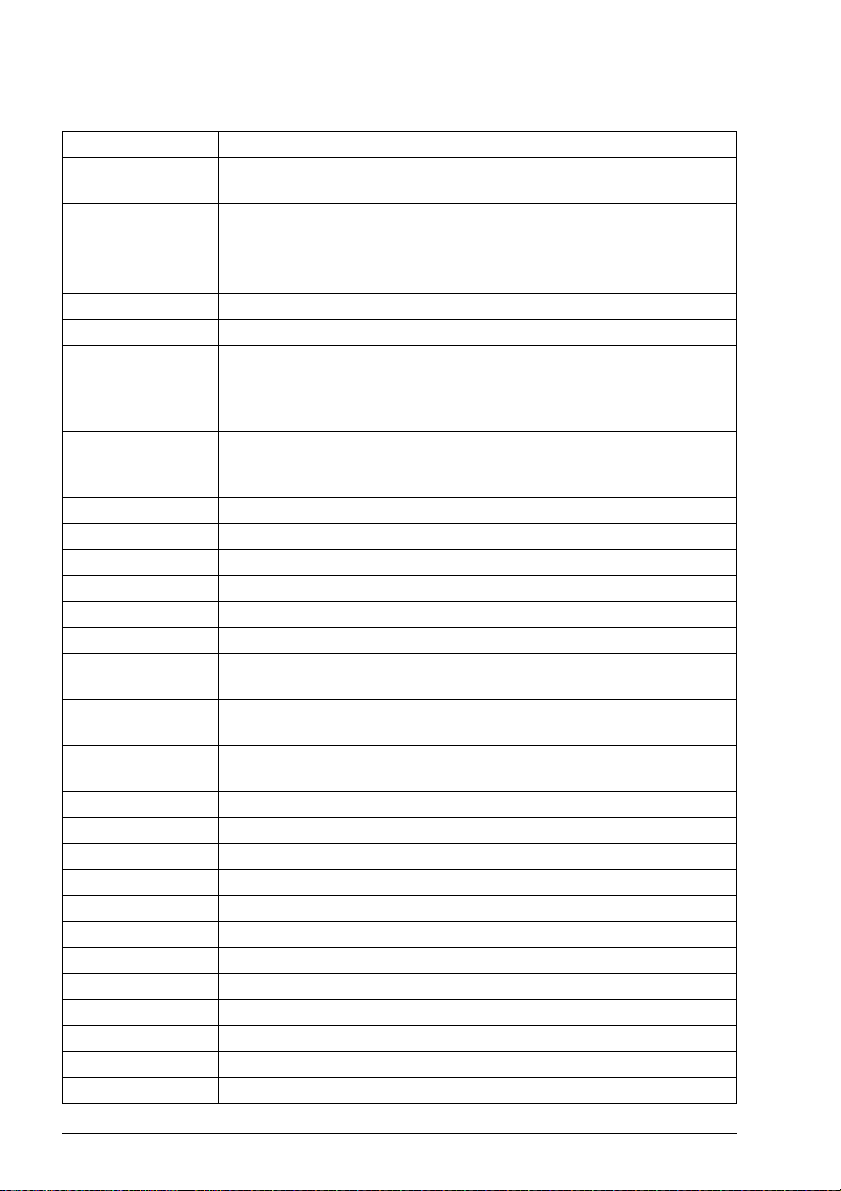

Terms and abbreviations

Term/abbreviation Explanation

ACS-BP-S Basic control panel, basic operator keypad for communication with the

ACX-AP-x Assistant control panel, advanced operator keypad for communication

AI Analog input; interface for analog input signals

AO Analog output; interface for analog output signals

Brake chopper Conducts the surplus energy from the intermediate circuit of the drive to

Brake resistor Dissipates the drive surplus braking energy conducted by the brake

Control board Circuit board in which the control program runs.

Control unit Control board built in a housing

CBAI-01 Bipolar to unipolar voltage converter option module

CDPI-01 Communication adapter module

CCA-01 Configuration adapter

CHDI-01 Optional 115/230 V digital input extension module

CMOD-01 Optional multifunction extension module (external 24 V AC/DC and

CMOD-02 Optional multifunction extension module (external 24 V AC/DC and

CPTC-02 Optional multifunction extension module (external 24 V and ATEX

DC link DC circuit between rectifier and inverter

DC link capacitors Energy storage which stabilizes the intermediate circuit DC voltage

DI Digital input; interface for digital input signals

DO Digital output; interface for digital output signals

DPMP-01 Mounting platform for ACX-AP control panel (flange mounting)

DPMP-02/03 Mounting platform for ACX-AP control panel (surface mounting)

Drive Frequency converter for controlling AC motors

EFB Embedded fieldbus

FBA Fieldbus adapter

FCAN-01 Optional CANopen adapter module

FCNA-01 ControlNet adapter module

FDNA-01 Optional DeviceNet adapter module

drive.

with the drive.

The ACS580 supports types ACS-AP-I, ACS-AP-S and ACS-AP-W

(with a Bluetooth interface).

the brake resistor when necessary. The chopper operates when the DC

link voltage exceeds a certain maximum limit. The voltage rise is

typically caused by deceleration (braking) of a high inertia motor.

chopper to heat. Essential part of the brake circuit. See chapter Brake

chopper in the Hardware manual of the drive.

digital I/O extension)

isolated PTC interface)

certified PTC interface)

Page 17

Introduction to the manual 17

Term/abbreviation Explanation

FECA-01 Optional EtherCAT adapter module

FENA-11/-21 Optional Ethernet adapter module for EtherNet/IP, Modbus/TCP and

PROFINET IO protocols

FEIP-21 Optional EtherNet/IP adapter module

FEPL-02 Ethernet POWERLINK adapter module

FMBT-21 Optional Modbus/TCP adapter module

FPBA-01 Optional PROFIBUS DP adapter module

FPNO-21 Optional PROFINET IO adapter module

Frame (size) Refers to drive physical size, for example R0 and R1. The type

designation label attached to the drive shows the frame of the drive, see

chapter Operation principle and hardware description, section Type

designation label in the Hardware manual of the drive.

FSCA-01 Optional RSA-485 adapter module

ID run Motor identification run. During the identification run, the drive will

identify the characteristics of the motor for optimum motor control.

IGBT Insulated gate bipolar transistor

Intermediate circuit See DC link.

Inverter Converts direct current and voltage to alternating current and voltage.

I/O Input/Output

LSW Least significant word

Macro Pre-defined default values of parameters in drive control program. Each

macro is intended for a specific application. See chapter Control macros

on page 71.

NETA-21 Remote monitoring tool

Network control With fieldbus protocols based on the Common Industrial Protocol

Parameter User-adjustable operation instruction to the drive, or signal measured or

PID controller Proportional–integral–derivative controller. Drive speed control is based

PLC Programmable logic controller

PROFIBUS,

PROFIBUS DP,

PROFINET IO

TM

), such as DeviceNet and Ethernet/IP, denotes the control of the

(CIP

drive using the Net Ctrl and Net Ref object s of the ODVA AC/DC Drive

Profile. For more information, see www.odva.org

, and the following

manuals:

• FDNA-01 DeviceNet adapter module user’s manual (3AFE68573360

[English]), and

• FENA-01/-11/-21 Ethernet adapter module user ’s manual

(3AUA0000093568 [English]) .

calculated by the dr ive

on PID algorithm.

Registered trademarks of PI - PROFIBUS & PROFINET International

Page 18

18 Introduction to the manual

Term/abbreviation Explanation

PTC Positive temperature coefficient, thermistor whose resistance is

dependent on temperature,

R0, R1, ... Frame (size)

RO Relay output; interface for a digital output signal. Implemented with a

relay.

Rectifier Converts alternating current and voltage to direct current and voltage.

STO Safe torque off. See chapter The Safe torque off function in the

Hardware manual of the drive.

Cybersecurity disclaimer

This product is designed to be connected to and to communicate information and

data via a network interface. It is Customer's sole responsibility to provide and

continuously ensure a secure connection between the product and Customer network

or any other network (as the case may be). Customer shall establish and maintain

any appropriate measures (such as but not limited to the installation of firewalls,

application of authentication measures, encryption of data, installation of anti-virus

programs, etc) to protect the product, the network, its system and the interface

against any kind of security breaches, unauthorized access, interference, intrusion,

leakage and/or theft of data or information. ABB and its affiliates are not liable for

damages and/or losses related to such security breaches, any unauthorized access,

interference, intrusion, leakage and/or theft of data or information.

See also section User lock on page 155.

Page 19

Start-up, control with I/O and ID run 19

2

Start-up, control with I/O and ID run

Contents of this chapter

The chapter describes how to:

• perform the start-up

• start, stop, change the direction of the motor rotation and adjust the speed of the

motor through the I/O interface

• perform an Identification run (ID run) for the drive.

Page 20

20 Start-up, control with I/O and ID run

?

How to start up the drive

How to start up the drive using the First start assistant on the

assistant control panel

Do not start-up the drive unless you are a qualified electrician.

Read and obey the instructions in chapter Safety instructions at the beginning of the

Hardware manual of the drive. Ignoring the instructions can cause physical injury or death, or

damage to the equipment

Check the installation. See chapter Installation checklist in the Hardware manual of the

drive.

Make sure there is no active start on (DI1 in factory settings, that is, ABB standard

macro). The drive will start up automatically at power-up if the external run

command is on and the drive is in the remote control mode.

Check that the starting of the motor does not cause any danger.

De-couple the driven machine if

• there is a risk of damage in case of an incorrect direction of rotation, or

•a Normal ID run is required during the drive start-up, when the load torque is higher

than 20% or the machinery is not able to withstand the nominal torque transient during

the ID run.

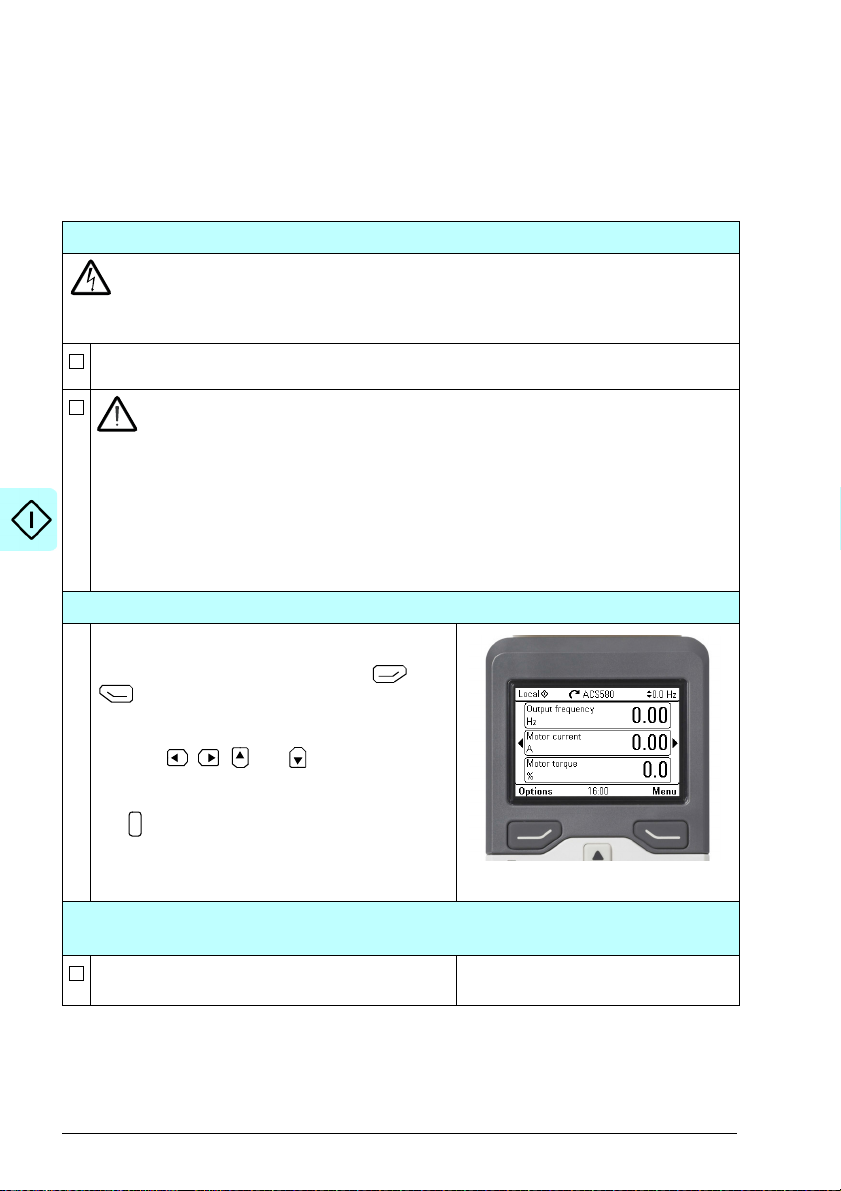

Hints on using the assistant control panel

The two commands at the bottom of the display

(Options and Menu in the figure on the right),

show the functions of the tw o softkeys and

located below the display. The commands

assigned to the softkeys vary depending on the

context.

Use keys , , and to move the cursor

and/or change values depending on the active

view.

Key shows a context-sensitive help page.

For more information, see ACS-AP-x assistant

control panels user’s manual (3AUA0000085685

[English]).

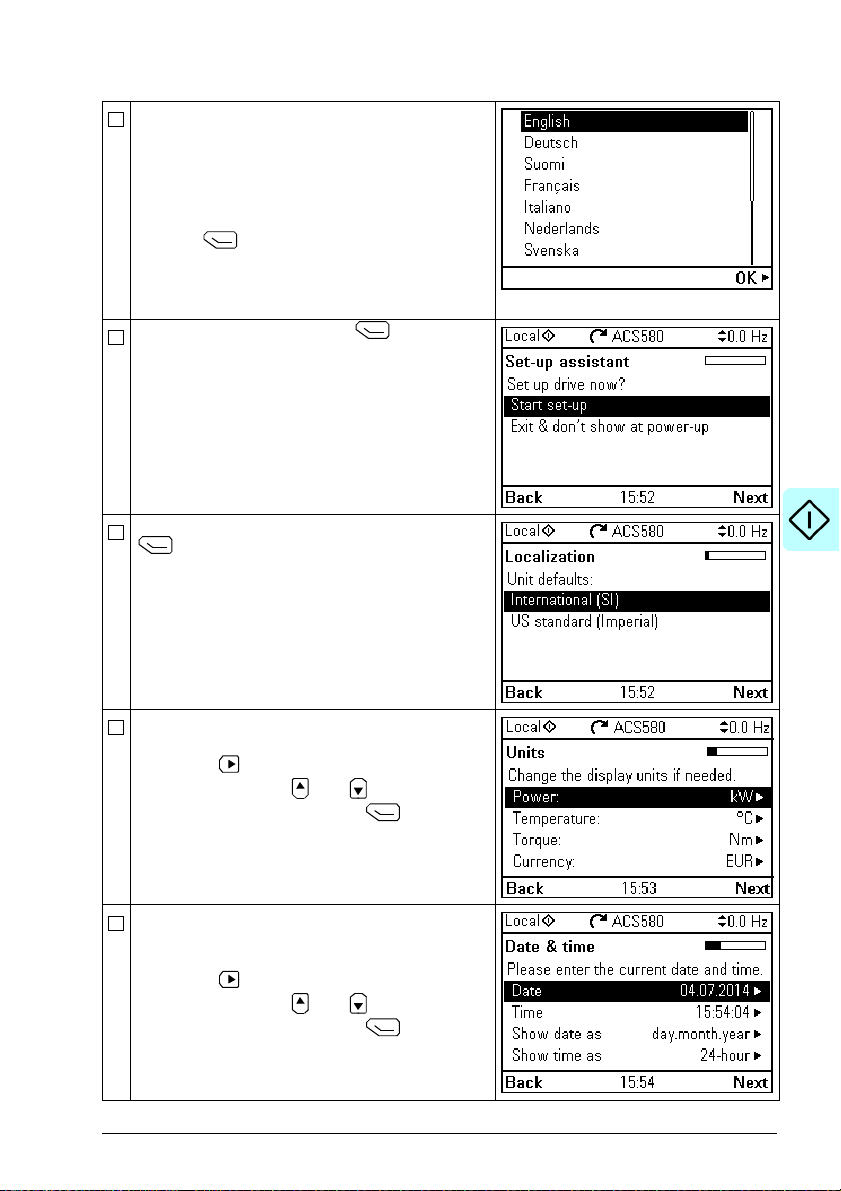

1 – First start assistant guided settings:

Language, date and time, and motor nominal values

Have the motor name plate data at hand.

Power up the drive.

Safety

Page 21

Start-up, control with I/O and ID run 21

The First start assistant guides you through the

first start-up.

The assistant begins automatically. Wait until the

control panel enters the view shown on the right.

Select the language you want to use by

highlighting it (if not already highlighted) and

pressing (OK).

Note: After you have selected the language, it

takes a few minutes to download the language file

to the control panel.

Select Start set-up and press (Next).

Select the localization you want to use and press

(Next).

Change the units shown on the panel if needed.

• Go to the edit view of a selected row by

pressing .

• Scroll the view with and .

Go to the next view by pressing (Next).

Set the date and time as well as date and time

display formats.

• Go to the edit view of a selected row by

pressing .

• Scroll the view with and .

Go to the next view by pressing (Next).

Page 22

22 Start-up, control with I/O and ID run

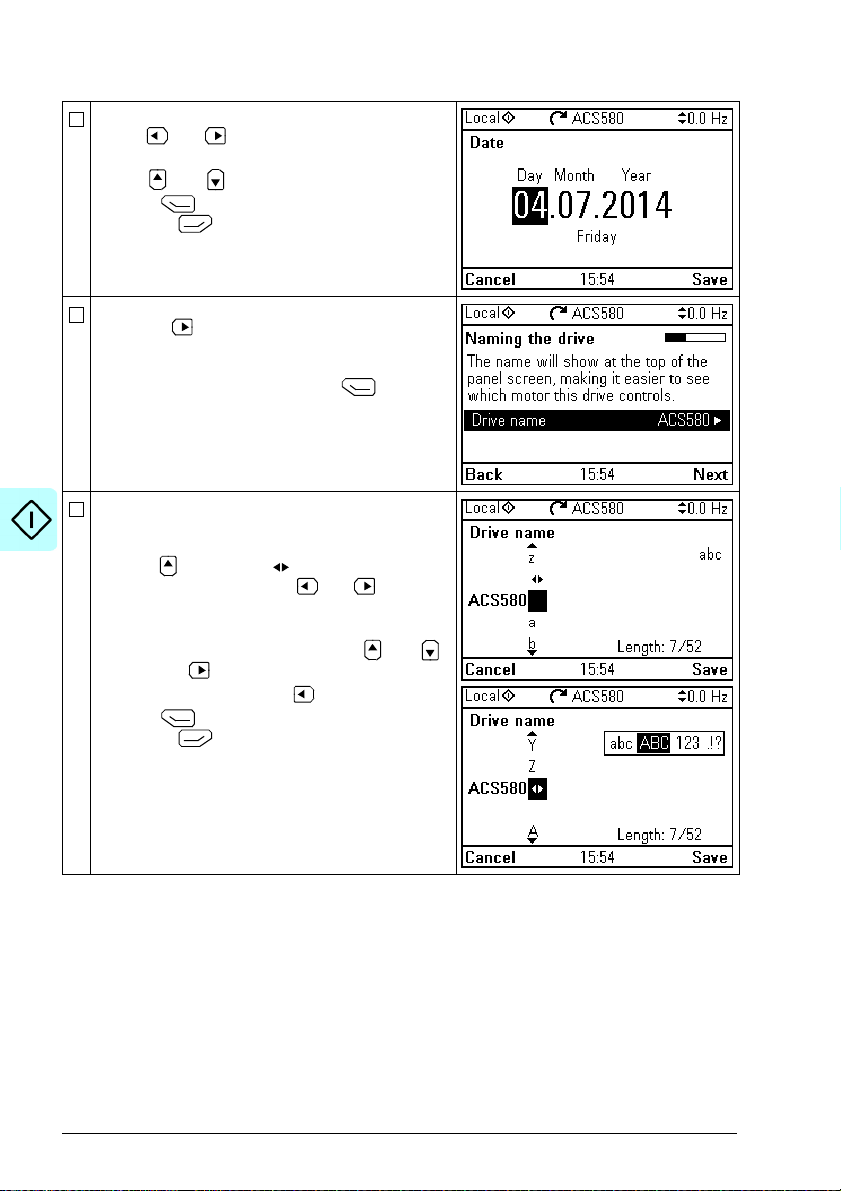

In an edit view:

• Use and to move the cursor left and

right.

• Use and to change the value.

•Press (Save) to accept the new setting,

or press (Cancel) to go back to the

previous view without making changes.

To give the drive a name that will be shown at the

top, press .

If you do not want to change the default name

(ACS580), continue straight to the set-up of the

motor nominal values by pressing (Next).

Enter the name:

• To select the character mode (lower case /

upper case / numbers / special characters),

press until symbol is highlighted and

then select the mode with and . Now you

can start adding characters. The mode remains

selected until you select another one.

• To add a character, highlight it with and ,

and press .

• To remove a letter, press .

•Press (Save) to accept the new setting,

or press (Cancel) to go back to the

previous view without making changes.

Page 23

Start-up, control with I/O and ID run 23

M2AA 200 MLA 4

1475

1475

1470

1470

1475

1770

32.5

56

34

59

54

59

0.83

0.83

0.83

0.83

0.83

0.83

3GAA 202 001 - ADA

180

IEC 34-1

6210/C36312/C3

Cat. no

35

30

30

30

30

30

50

50

50

50

50

60

690 Y

400 D

660 Y

380 D

415 D

440 D

V

Hz kW

r/min A

cos

IA/IN

t

E/s

Ins.cl. F

IP 55

No

IEC 200 M/L 55

3

motor

ABB Motors

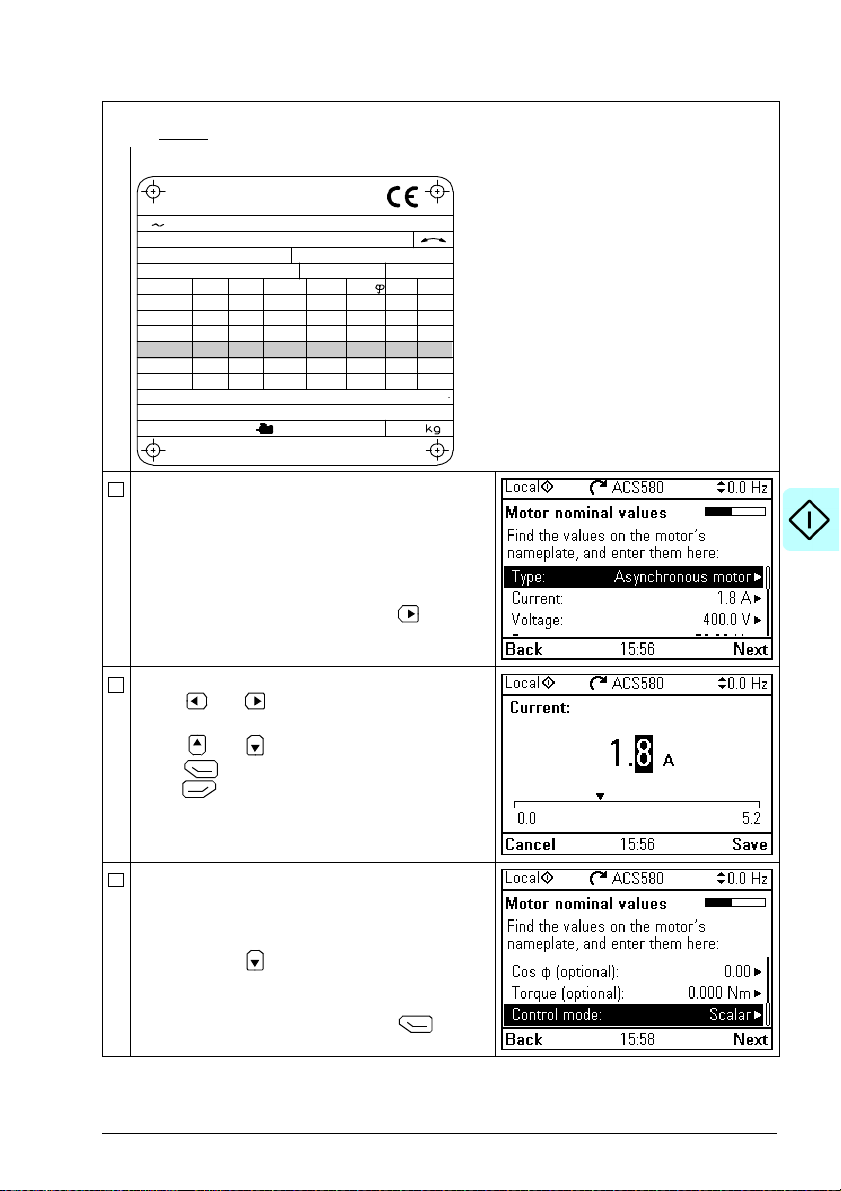

Refer to the motor nameplate for the following nominal value settings of the motor. Enter the

values exactly

Example of a nameplate of an induction (asynchronous) motor:

Select the motor type.

Check that the motor data is correct. Values are

predefined on the basis of the drive size but you

should verify that they correspond to the motor.

Start with the motor nominal current.

If you have to change the value, go to the edit

view of the selected row by pressing (when

this symbol is shown at the end of the row).

as shown on the motor nameplate.

Set the correct value:

• Use and to move the cursor left and

right.

• Use and to change the value.

Press (Save) to accept the new setting, or

press (Cancel) to go back to the previous

view without making changes.

Continue to check/edit the nominal values and

select scalar or vector control mode.

Motor nominal cos Φ and nominal torque are

optional.

Roll down with

After editing the last row, the panel goes to the

next view.

To go directly to the next view, press (Next).

to see the last row in the view.

Page 24

24 Start-up, control with I/O and ID run

Forward direction Reverse direction

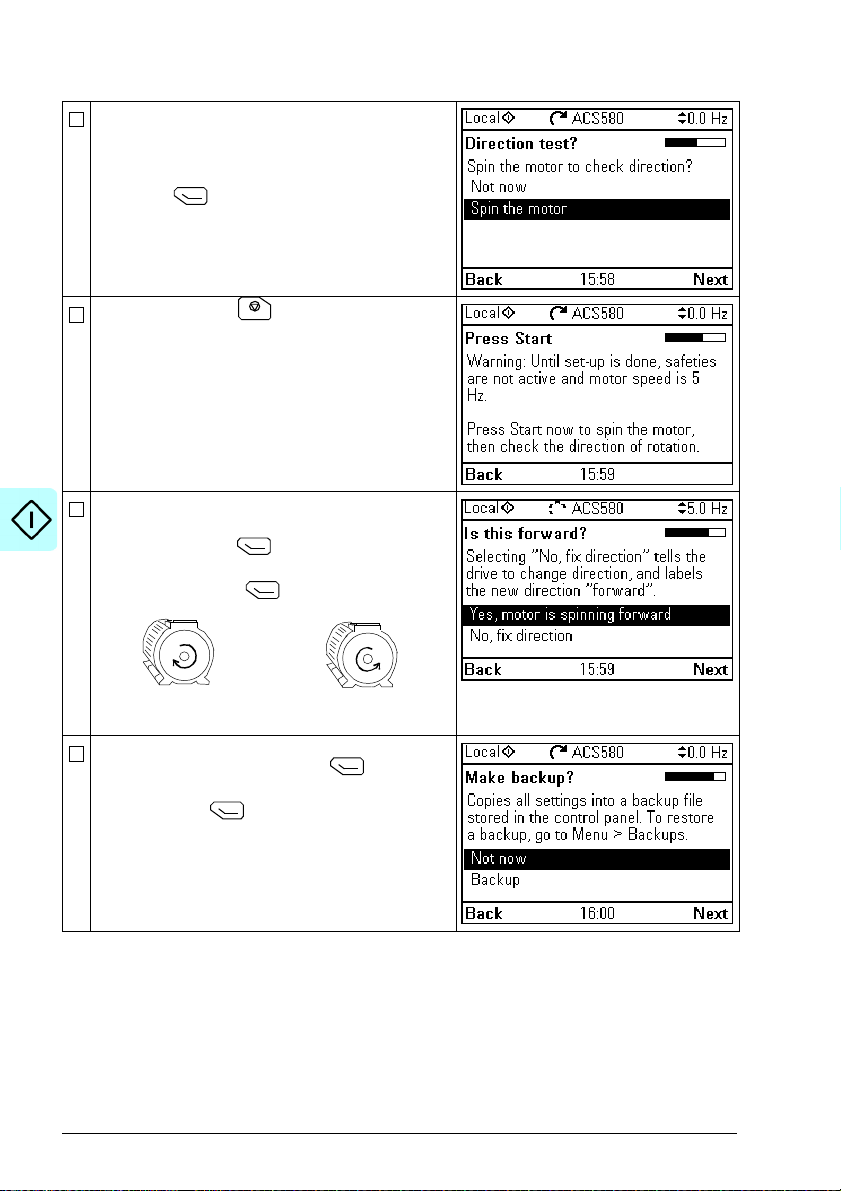

Direction test is optional, and requires rotating the

motor. Do not do this if it could cause any risk, or if

the mechanical set-up does not allow it.

To do the direction test, select Spin the motor

and press (Next).

Press the Start key on the panel to start the

drive.

Check the direction of the motor.

If it is forward, select Yes, motor is spinning

forward and press (Next) to continue.

If the direction is not forward, select No, fix

direction and press (Next) to continue.

If you want to make a backup of the settings made

so far, select Backup and press (Next).

If you do not want to make a backup, select Not

now and press (Next).

Page 25

Start-up, control with I/O and ID run 25

?

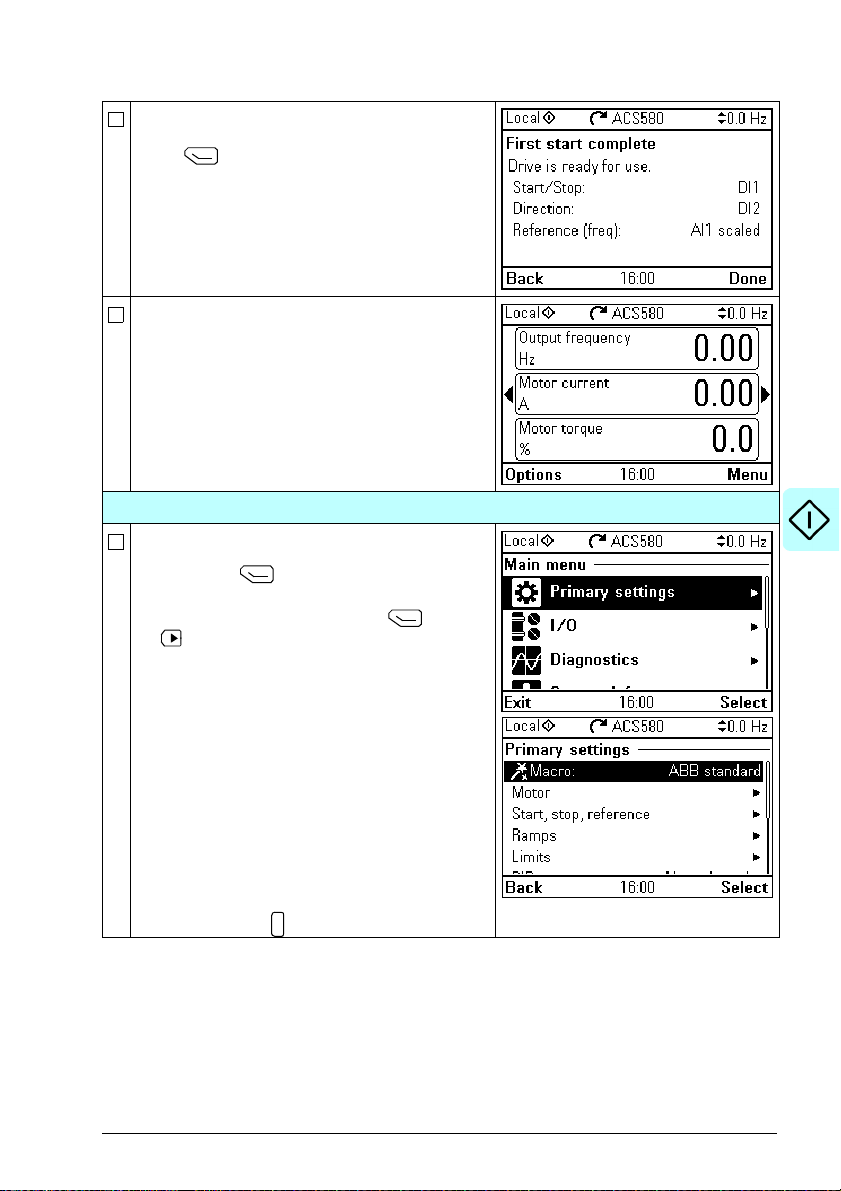

The first start is now complete and the drive is

ready for use.

Press (Done) to enter the Home view.

The Home view monitoring the values of the

selected signals is shown on the panel.

2 – Additional settings in the Primary settings menu

Make any additional adjustments, for example,

macro, ramps, and limits, starting from the Main

menu – press (Menu) to enter the Main

menu.

Select Primary settings and press

(or ).

ABB recommends that you make at least these

additional settings:

• Choose a macro or set start, stop and reference

values individually

• Ramps

•Limits

With the Primary settings menu, you can also

adjust settings related to the motor, PID, fieldbus,

advanced functions and clock, region and display.

In addition, the menu contains an item to reset the

panel Home view.

To get more information on Primary settings

menu items, press to open the help page.

(Select)

Page 26

26 Start-up, control with I/O and ID run

?

2 – Additional settings: Macro

Select Macro: and press (Select) (or ).

To change the macro in use, select the new macro

and press

changes, press (Back).

Notes:

• Changing macro resets all settings except

• When you change the macro, you also change

• All macros, except the ABB standard (vector)

(Select), or to go back without

motor data to the default values of the selected

macro.

the use of the I/O signals in the drive. Make

sure the actual I/O wiring and the use of I/O in

the control program match each other. You can

check the current I/O use in the I/O menu under

the Main menu (see page 28).

To get information on a selected macro, press

.The help page shows the use of signals and

I/O connections. For detailed I/O connection

diagrams, see chapter Control macros on page

71.

Scroll the page with and .

To return to the Control macro submenu, press

(Exit).

macro, use scalar motor control by default. At

the first start you can select to use scalar or

vector motor control. If you later want to change

the selection, Select Menu - Primary settings -

Motor - Control mode and follow the

instructions.

Page 27

Start-up, control with I/O and ID run 27

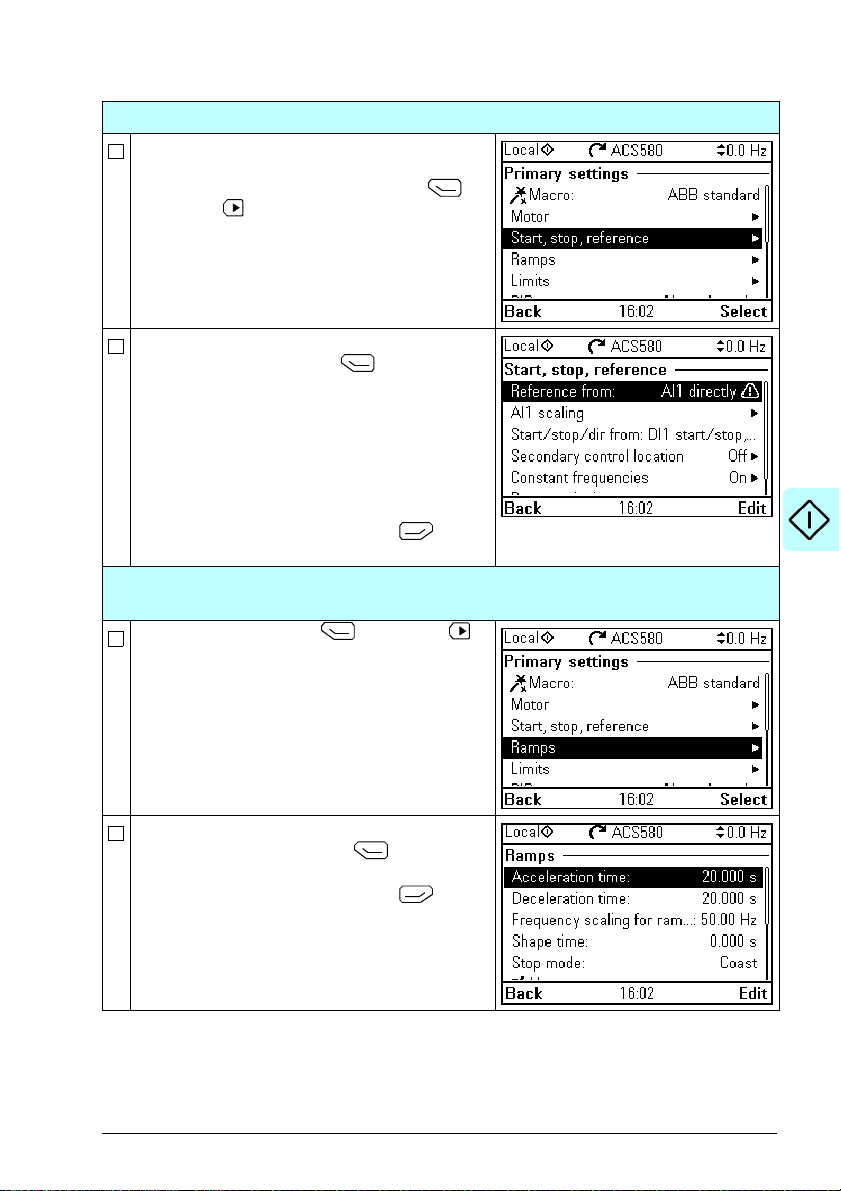

2 – Additional settings: Start, stop and reference values

If you do not wish to use a macro, define the

settings for start, stop and reference:

Select Start, stop, reference and press

(Select) (or ).

Adjust the parameters according to your needs.

Select parameter and press

When you change the settings, you also change

the use of the I/O signals in the drive. Make sure

the actual I/O wiring and the use of I/O in the

control program match each other. You can check

the current I/O use in the I/O menu under the

Main menu (see page 28).

After making the adjustments, go back to the

Primary settings menu by pressing

(Back).

(Select).

2 – Additional settings: Ramps

(acceleration and deceleration times for the motor)

Select Ramps and press (Select) (or ).

Adjust the parameters according to your needs.

Select a parameter and press

After making the adjustments, go back to the

Primary settings menu by pressing

(Back).

(Edit).

Page 28

28 Start-up, control with I/O and ID run

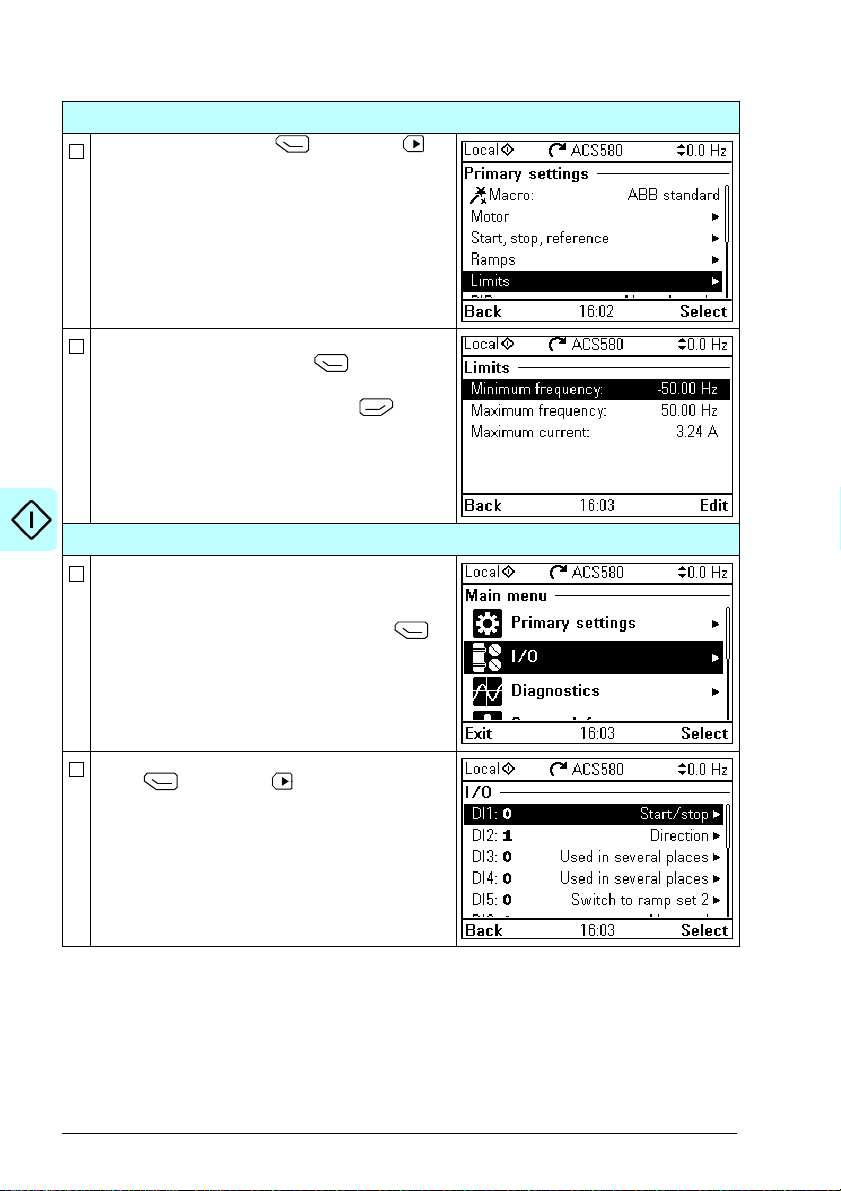

2 – Additional settings: Limits

Select Limits and press (Select) (or ).

Adjust the parameters according to your needs.

Select a parameter and press

After making the adjustments, go back to the

Primary settings menu by pressing

(Back).

(Select).

3 – I/O menu

After the additional adjustments, make sure that

the actual I/O wiring matches the I/O use in the

control program.

In the Main menu, select a I/O and press

(Select) to enter the I/O menu.

Select a the connection you want to check and

press

(Select) (or ).

Page 29

Start-up, control with I/O and ID run 29

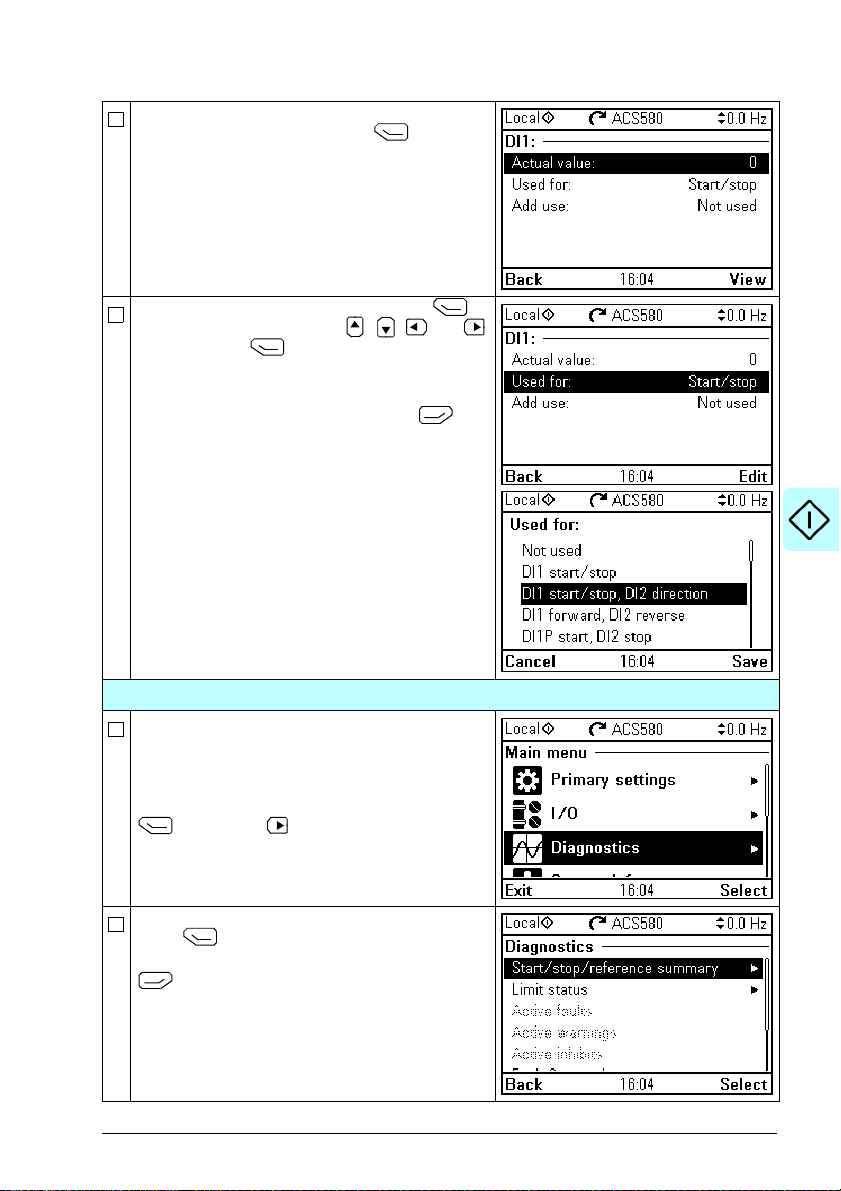

To view the details of a parameter that cannot be

adjusted via the I/O menu, press

(View).

To adjust the value of a parameter, press

(Edit), adjust the value using , , and

keys and press

wiring must match the new value.

Go back to the Main menu by pressing

(Back) repeatedly.

(Save). Note that the actual

4 – Diagnostics menu

After making the additional adjustments and

checking the I/O connections, use the

Diagnostics menu to make sure that the setup is

functioning correctly.

In the Main menu, select Diagnostics and press

(Select) (or ).

Select the diagnostics item you want to view and

press (Select).

Return to the Diagnostics menu by pressing

(Back).

Page 30

30 Start-up, control with I/O and ID run

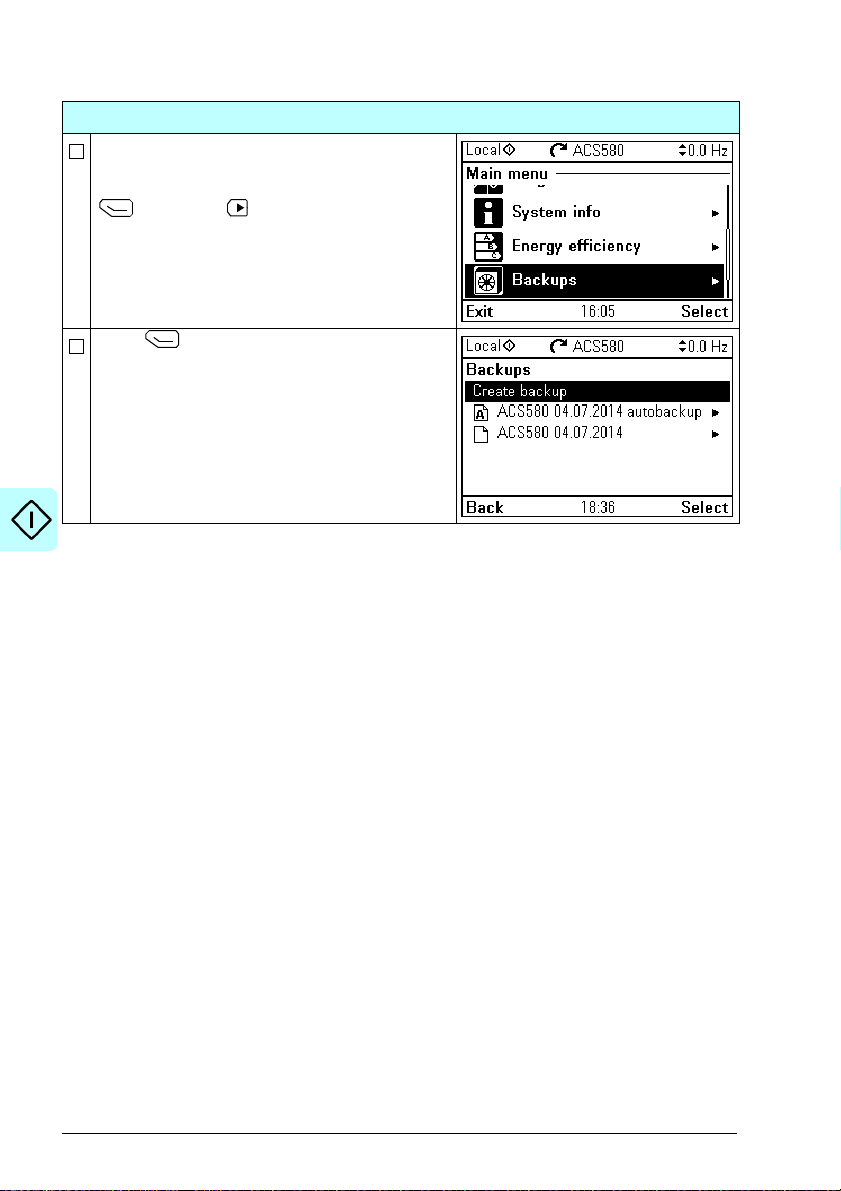

5 – Backup

After you have finished start-up ABB recommends

that you make a backup.

In the Main menu, select Backups and press

(Select) (or ).

Press

(Select) to start backup.

Page 31

Start-up, control with I/O and ID run 31

Loc/Rem

How to control the drive through the I/O interface

The table below describes how to operate the drive through the digital and analog

inputs when:

• the motor start-up is performed, and

• the default parameter settings of the ABB standard macro are in use.

Preliminary settings

If you need to change the direction of rotation, check

that limits allow reverse direction: Go to Menu -

Primary settings - Limits and make sure that the

minimum limit has a negative value and the maximum

limit has a positive value.

Make sure that the control connections are wired

according to the connection diagram given for the ABB

standard macro.

Make sure that the drive is in remote control. Press

key

to switch between remote and local

control.

Starting and controlling the speed of the motor

Start by switching digital input DI1 on.

The arrow starts rotating. It is dotted until the setpoint

is reached.

Regulate the drive output frequency (motor speed) by

adjusting voltage of analog input AI1.

See section ABB standard macro on

page 72.

In remote control, the panel display

shows text Remote at the top left.

Changing the direction of the motor rotation

Reverse direction: Switch digital input DI2 on.

Forward direction: Switch digital input DI2 off.

Page 32

32 Start-up, control with I/O and ID run

Stopping the motor

Switch digital input DI1 off. The arrow stops rotating.

Page 33

Start-up, control with I/O and ID run 33

How to perform the ID run

The drive automatically estimates motor characteristics using Standstill ID run when

the drive is started for the first time in vector control and after any motor parameter

(group 99 Motor data) is changed. This is valid when

• parameter 99.13 ID run requested selection is Standstill and

• parameter 99.04 Motor control mode selection is Vector.

In most applications there is no need to perform a separate ID run. The ID run should

be selected manually if:

• vector control mode is used (parameter 99.04 Motor control mode is set to

Vector), and

• permanent magnet motor (PM) is used (parameter 99.03 Motor type is set to

Permanent magnet motor), or

• synchronous reluctance motor (SynRM) is used (parameter 99.03 Motor type is

set to SynRM), or

• drive operates near zero speed references, or

• operation at torque range above the motor nominal torque, over a wide speed

range is needed.

Do the ID run with the ID run assistant by selecting Menu - Primary settings - Motor

- ID run (see page 34) or with parameter 99.13 ID run requested (see page 36).

Note: If motor parameters (group 99 Motor data) are changed after the ID run, it must

be repeated.

Note: If you have already parameterized your application using the scalar motor

control mode (99.04 Motor control mode is set to Scalar) and you need to change

motor control mode to Vector,

• change the control mode to vector with the Control mode assistant (go to Menu -

Primary settings - Motor - Control mode) and follow the instructions. The ID run

assistant then guides you through the ID run.

or

• set parameter 99.04 Motor control mode to Ve cto r , and

• for I/O controlled drive, check parameters in groups 22 Speed reference

selection, 23 Speed reference ramp, 12 Standard AI, 30 Limits

Monitoring/scaling settings.

• for torque controlled drive, check also parameters in group 26 Torque

reference chain.

and 46

Page 34

34 Start-up, control with I/O and ID run

Loc/Rem

ID run procedure

With the ID run assistant

Pre-check

WARNING!

speed during the ID run. The motor will rotate in the forward direction. Make

sure that it is safe to run the motor before performing the ID run.

Do not do ID run on a rotating motor. Make sure that the motor is stopped

before starting the ID run.

De-couple the motor from the driven equipment

Check that the values of the motor data parameters are equivalent to those on the motor

nameplate.

Check that the STO circuit is closed.

The assistant will ask if you want to use temporary motor limits. They must meet the

following conditions:

Minimum speed <

Maximum speed = motor rated speed (Normal ID run procedure needs the motor to be

run at 100% speed.)

Maximum current > I

Maximum torque > 50%

Make sure that the panel is in local control (text Local shown at the top left). Press key

to switch between local and remote control.

Go to the Main menu by pressing (Menu)

in the Home view.

Select Primary settings and press

(Select) (or ).

The motor will run at up to approximately 50…80% of the nominal

0rpm

HD

ID run

Select Motor and press

(Select) (or ).

Page 35

Start-up, control with I/O and ID run 35

Select ID run (shown only when the drive is in

vector control mode) and press

).

Select the type of ID run you want to do and

press

(Select) (or ).

Warning message Identification run is shown at

the top for a few seconds.

Panel LED starts blinking green to indicate an

active warning.

Check the motor limits shown on the panel. If you

need other limits during the ID run you can enter

them here. The originals limits will be restored

after the ID run.

Press

(Next).

Press the start key

In general, ABB recommends not to press any

control panel keys during the ID run. However,

you can stop the ID run at any time by pressing

the stop key

During the ID run a progress view is shown.

After the ID run is completed, text ID run done is

shown. The LED stops blinking.

If the ID run fails, fault FF61 ID run is shown. See

chapter Fault tracing on page 407 for more

information.

() to start the ID run.

().

( Select) (or

Page 36

36 Start-up, control with I/O and ID run

Loc/Rem

With parameter 99.13 ID run requested

Pre-check

WARNING!

speed during the ID run. The motor will rotate in the forward direction. Make

sure that it is safe to run the motor before performing the ID run.

Do not do ID run on a rotating motor. Make sure that the motor is stopped

before starting the ID run.

De-couple the motor from the driven equipment

Check that the values of the motor data parameters are equivalent to those on the motor

nameplate.

Check that the STO circuit is closed.

If parameter values (from group 10 Standard DI, RO to group 99 Motor data) are changed

before the ID run, check that the new settings meet the following conditions:

30.11 Minimum speed <

30.12 Maximum speed = motor rated speed (Normal ID run procedure needs the motor to

be run at 100% speed.)

30.17 Maximum current > I

30.20 Maximum torque 1 > 50% or 30.24 Maximum torque 2 > 50%, depending on which

torque limit set is in use according to parameter 30.18 Torq lim sel.

Check that signals

run enable (parameter 20.12 Run enable 1 source) is active

start enable (parameter 20.19 Enable start command) is active

enable to rotate (parameter 20.22 Enable to rotate) is active.

Make sure that the panel is in local control (text Local shown at the top left). Press key

to switch between local and remote control.

The motor will run at up to approximately 50…80% of the nominal

0rpm

HD

ID run

Go to the Main menu by pressing (Menu)

in the Home view.

Press .

Page 37

Start-up, control with I/O and ID run 37

Select Parameters and press (Select) (or

).

Select Complete list and press

(or ).

Scroll the page with and , and select

parameter group 99 Motor data and press

(Select) (or ).

Scroll the page with and , and select

parameter 99.13 ID run requested (99.13 ID run

requested) and press

(Select) (or ).

(Select)

Select the ID run type and press

).

(Save) (or

Page 38

38 Start-up, control with I/O and ID run

The panel returns to the previous view and

warning message Identification run is shown at

the top for a few seconds.

Panel LED starts blinking green to indicate an

active warning (AFF6).

The AFF6 warning view is shown when no key

has been pressed for one minute. Pressing

(How to fix) shows text informing that the ID run

will be done at the next start. You can hide the

warning view by pressing (Hide).

Press the start key

In general, ABB recommends not to press any

control panel keys during the ID run. However,

you can stop the ID run at any time by pressing

the stop key

During the ID run the arrow is rotating at the top.

After the ID run is completed, text ID run done is

shown. The LED stops blinking.

If the ID run fails, fault FF61 ID run is shown. See

chapter Fault tracing on page 407 for more

information.

() to start the ID run.

().

Page 39

Control panel 39

3

1a

1b

Control panel

Contents of this chapter

This chapter contains instructions for removing and reinstalling the assistant control

panel and briefly describes its display, keys and key shortcuts. For more information,

see ACX-AP-x assistant control panels user’s manual (3AUA0000085685 [English]).

Removing and reinstalling the control panel

To remove the control panel, press the retaining clip at the top (1a) and pull it forward

from the top edge (1b).

Page 40

40 Control panel

1a

1b

1c

4

3

6

7 8

5

10

2

9

1

To reinstall the control panel, put the bottom of the container in position (1a), press

the retaining clip at the top (1b) and push the control panel in at the top edge (1c).

Layout of the control panel

1 Layout of the control panel display 6 The arrow keys

2 Left softkey 7Stop (see Start and Stop)

3 Right softkey 8 Start (see Start and Stop)

4 Status LED, see chapter Maintenance

and hardware diagnostics, section

LEDs in the Hardware manual of the

drive.

5 Help 10 USB connector

9 Local/Remote (see Loc/Rem)

Page 41

Layout of the control panel display

1

51

2

4

6

7 78

13

In most views, the following elements are shown on the display:

Control panel 41

1. Control location and related icons: Indicates how the drive is controlled:

• No text: The drive is in local control, but controlled from another device. The

icons in the top pane indicate which actions are allowed:

Text/Icons Starting from this

• Local: The drive is in local control, and controlled from this control panel. The

icons in the top pane indicate which actions are allowed:

Text/Icons Starting from this

Local

control panel

Not allowed Not allowed Not allowed

control panel

Allowed Allowed Allowed

Stopping from this

control panel

Stopping from this

control panel

Giving reference

from this panel

Giving reference

from this panel

Page 42

42 Control panel

• Remote: The drive is in remote control, ie, controlled through I/O or fieldbus.

The icons in the top pane indicate which actions are allowed with the control

panel:

Text/Icons Starting from this

Remote

Remote

Remote

Remote

control panel

Not allow ed Not allowed Not allowed

Allowed Allowed Not allowed

Not allowed Allowed Allowed

Allowed Allowed Allowed

Stopping from this

control panel

Giving reference

from this panel

2. Panel bus: Indicates that there are more than one drive connected to this panel.

To switch to another drive, go to Options - Select drive.

3. Status icon: Indicates the status of the drive and the motor. The direction of the

arrow indicates forward (clockwise) or reverse (counter-clockwise) rotation.

Status icon Animation Drive status

-

- Stopped, start inhibited

Blinking Stopped, start command given but start inhibited. See

Blinking Faulted

Blinking Running, at reference, but the reference value is 0

Rotating Running, not at reference

Rotating Running, at reference

- Pre-heating (motor heating) active

- PID sleep mode active

Stopped

Menu - Diagnostics on the control panel

4. Drive name: If a name has been given, it is displayed in the top pane. By default,

it is “ACS580”. You can change the name on the control panel by selecting Menu

- Primary settings - Clock, region, display (see page 61).

5. Reference value: Speed, frequency, etc. is shown with its unit. For information on

changing the reference value in the Primary settings menu (see page 46).

6. Content area: The actual content of the view is displayed in this area. The

content varies from view to view. The example view on page 41 is the main view

of the control panel which is called the Home view.

7. Softkey selections: Displays the functions of the softkeys (

and ) in a

given context.

8. Clock: The clock displays the current time. You can change the time and time

format on the control panel by selecting Menu - Primary settings - Clock,

region, display (see page 61).

Page 43

Control panel 43

?

Loc/Rem

You can adjust the display contrast and back light functionality on the control panel by

selecting Menu - Primary settings - Clock, region, display (see page 61).

Keys

The keys of the control panel are described below.

Left softkey

The left softkey ( ) is usually used for exiting and canceling. Its function in a given

situation is shown by the softkey selection in the bottom left corner of the display.

Holding down exits each view in turn until you are back in the Home view. This

function does not work in special screens.

Right softkey

The right softkey ( ) is usually used for selecting, accepting and confirming. The

function of the right softkey in a given situation is shown by the softkey selection in

the bottom right corner of the display.

The arrow keys

The up and down arrow keys ( and ) are used to highlight selections in menus

and selection lists, to scroll up and down on text pages, and to adjust values when,

for example, setting the time, entering a passcode or changing a parameter value.

The left and right arrow keys ( and ) are used to move the cursor left and right in

parameter editing and to move forward and backward in assistants. In menus, and

function the same way as

Help

The help key (

words, the content of the page is relevant to the menu or view in question.

Start and Stop

In local control, the start key ( ) and the stop key ( ) start and stop the drive,

respectively.

Loc/Rem

The location key ( ) is used for switching the control between the control panel