ABB ACS550 Technical Catalog

Technical Catalog

ABB low voltage drives

ACS550, 0.75 - 550 Hp

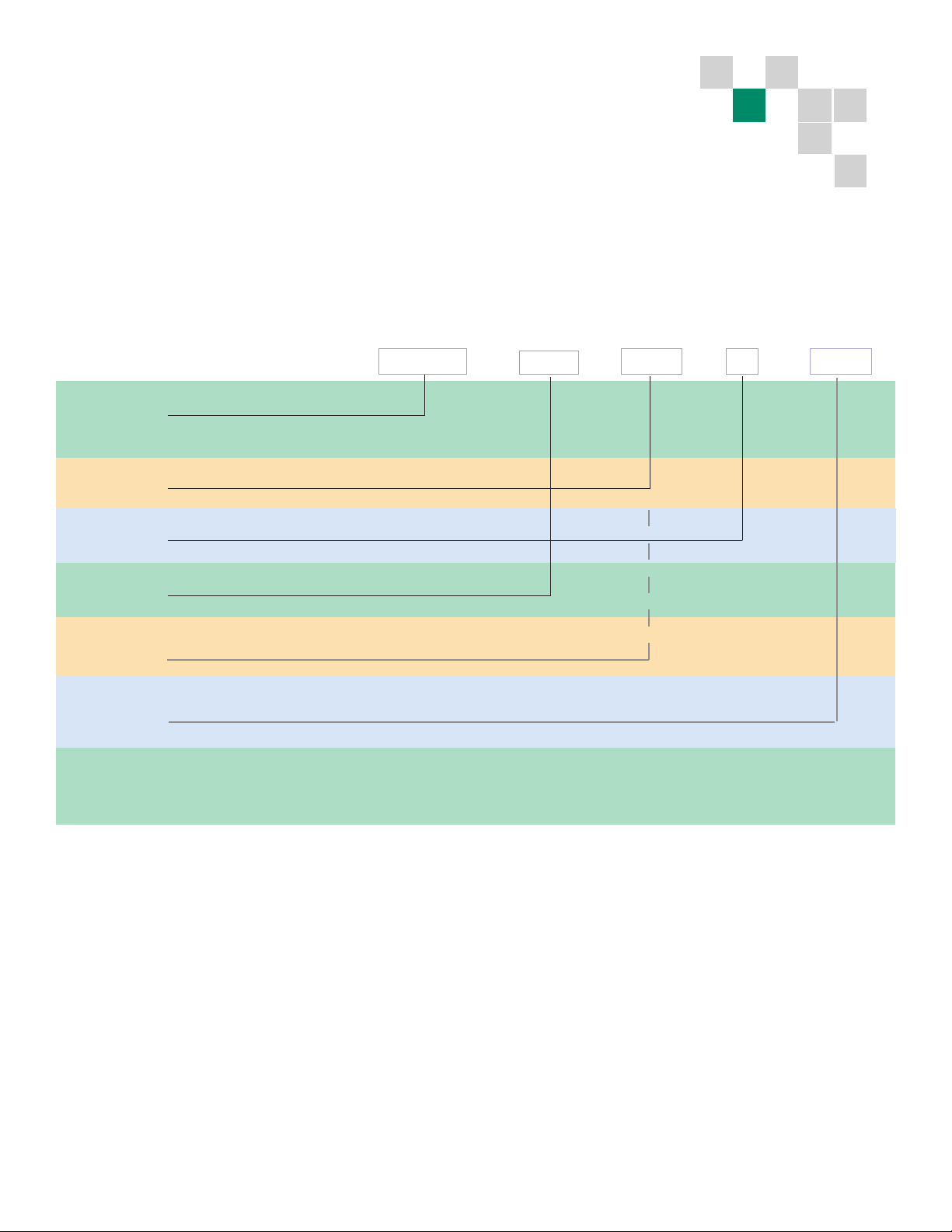

Two ways to select your drive

Choice 1: Simply contact your local ABB drives sales

ofce and let them know what you want. Use page 5 as

a reference section for more information.

Type code

Product series

ACS550 - U1 - 03A3 - 4 + B055

1

Ratings and Types

2

Voltages

3

Construction

4

Dimension

5

OR

Choice 2: Build up your own ordering code using the

simple 7-step approach below and then contact your

local ABB Drive Sales Ofce.

6

7

Options

External Options

2

Contents

ABB Standard Drive, ACS550

ABB Standard Base Drive........................................................................................................................4

Ratings, Types and Voltages ......................................................................................................6

Construction .................................................................................................................................7

Advanced Control Panel .............................................................................................................7

Options .........................................................................................................................................8

Control Interfaces

How to select options ......................................................................................................8

Panel Mounting Kit...........................................................................................................8

DriveWindow Light 2 ........................................................................................................8

Plug-in Options

Relay Output Extension Option Module ........................................................................9

Pulse Encoder Interface ..................................................................................................9

Plug-in Fieldbus Module..................................................................................................9

115/230V Digital Interface ................................................................................................ 9

External Options

Brake Units and Choppers ............................................................................................10

Technical Data ...........................................................................................................................11

Cooling .......................................................................................................................................12

Input Cable and Fuse Connections ......................................................................................... 13

Technical Specication .............................................................................................................14

Control Connections .................................................................................................................15

ABB Packaged Drives ............................................................................................................................16

Ratings, Types and Voltages .................................................................................................... 17

Dimensions ................................................................................................................................ 19

3

ABB ACS550 Standard Drive

What is the ACS550 Customer Value?

■ Reduced commissioning and installation costs

■ Many assistants including Start-up, Drive Optimizer,

Real-time Clock, Diagnostics, Maintenance, Serial

and PID.

■ Two soft-keys that change according to the operator

panel state

■ Field upgradeable rmware

■ Easy connection of cables

■ New conduit box is suitable for US and Europe

■ Built-in brake chopper (10Hp, 230V / 15Hp, 480V

and 600 V)

■ Optional plug-in eldbus modules

■ Reduced size and weight with Patented Swinging

Choke (R1-R6) - equivalent to a 5% Line Impedance

■ 3% Impedance AC Line Reactor (R8)

■ Removable operator panel

■ Only Class T fuses required for high speed short

circuit protection

■ NEMA 12 enclosure does not require derating

■ Smaller physical size of internal option slots

■ FlashDrop programming (unpowered drive)

■ Reduced energy costs without power factor

penalties and correction capacitors

■ Patented swinging choke provides substantially

reduced harmonics, more inductance to the correct

load and higher power factor

■ Up to 25% less THD v. traditional DC choke

■ Daily timer controls for time-of-day backoff e.g.

start/stop process changes

■ Reduced Drive-Motor system failures and costs

■ Preventative "Maintenance Assistant" annunciation

feature schedules Drive-Motor system maintenance

The ABB ACS550 AC drive combines a sophisticated microprocessor with an advanced IGBT power switching

technology to deliver V/Hz, Closed Loop Flux Vector and

Sensorless Vector control of AC motors. Its intuitive control

panel offers numerous benets making it the most userfriendly panel in the drives industry. The extensive library of

pre-programmed application macros maximizes convenience

and minimizes start-up time. This drive can handle the most

demanding industrial applications in an efcient, dependable

and economic manner

Where can it be used?

The ABB ACS550 standard drive can be used in a wide

range of industries. Typical applications include pump,

fan and constant torque use, such as conveyors. The ABB

ACS550 standard drive is ideal for those situations where

there is a need for simplicity to install, commission and use

and where customizing or special product engineering is not

required.

ABB ACS550 standard drive promises

■Quick delivery

■Easy installation

■Trouble-free start-up

■Intuitive operation

Highlights:

■Advanced control panel permitting intuitive operation

■Patented swinging choke for superior harmonic

reduction (R1-R4) and AC line reactor (R5-R8)

■Sensorless vector control

■Integral EMC lter as standard

■Built-in Modbus RTU and numerous internally

mountable eldbus adapters

■FlashDrop

■ Coated boards for harsh environments

■UL, cUL, C-Tick and Gost-R approved

■Built-in brake chopper (10Hp, 230V / 15Hp, 480V

and 600 V)

■Many assistants including Start-up, Drive Optimizer,

Real-time Clock, Diagnostics, Maintenance, Serial

and PID

■Seismic Certication to ICC AC-156 Criteria

4

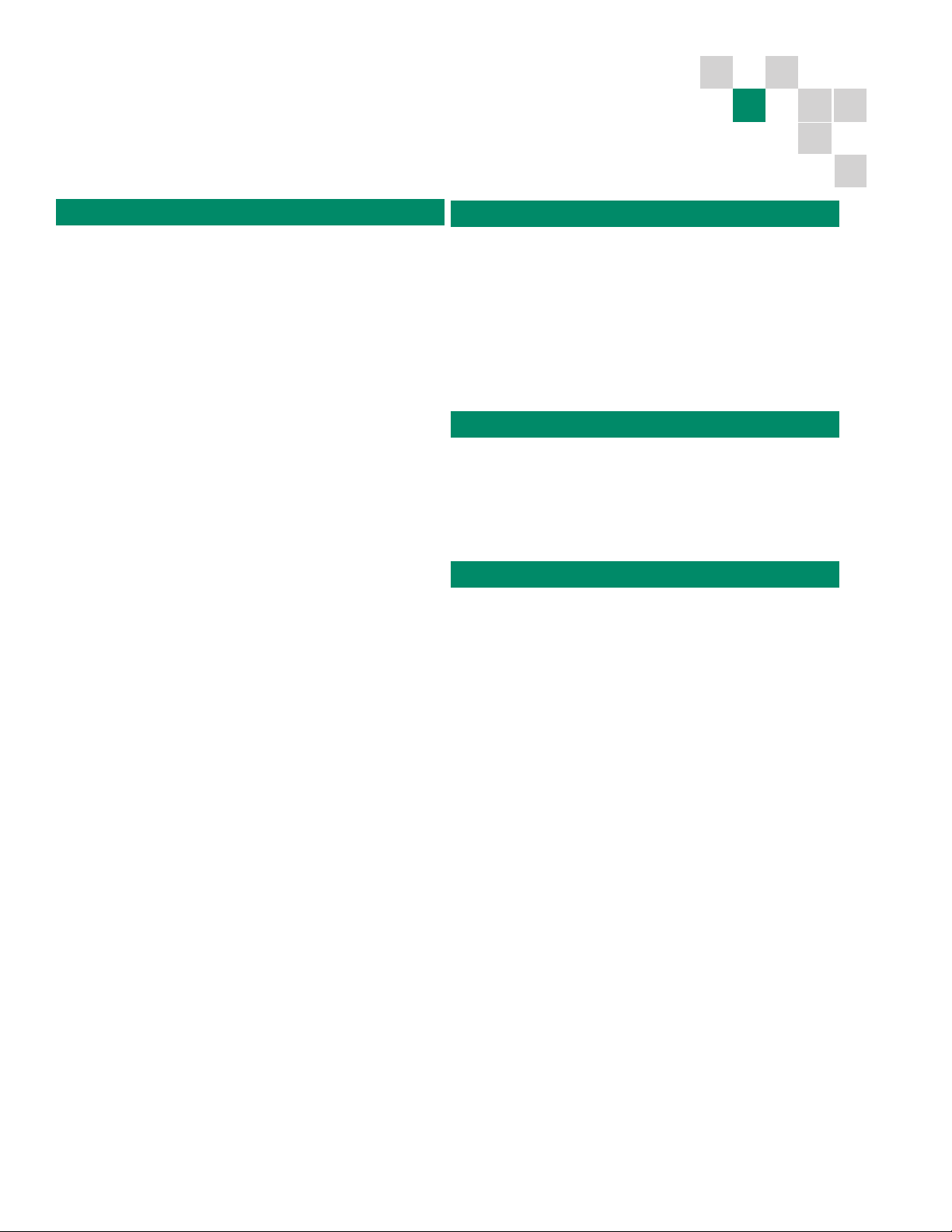

What are the ACS550's Main Features and Benets Supporting Customer Value?

Feature Note Benet

Advanced Control Panel Two soft-keys change according to the state of the panel

Built-in "Help" button

Real-time clock, allows timed tracing of faults and setting of parameters at various

times of day

Changed parameter menu

Brake Chopper Built-in up to 15 Hp (480 and 600V) and up to 10 Hp (240V) Reduced installation cost

Chokes 5% equivalent impedance swinging choke-matches the right inductance to the

right load, suppressing and reducing harmonics (R1-R4), 3% impedance AC line

reactor (R5-R8)

Connectivity Simple to install:

Easy connection of cables

Easy connection of external eldbus systems through multiple I/Os and plug-in

options

Assistants (v3.11a+) Diagnostic assistant activated when fault occurs

Maintenance assistant monitors running hours or motor rotation

Start-up assistant guides user through all essential settings without going to

parameter list and offers option for parameter backup automatically

PID Controller assistant guides user set-up without going to parameter list

Real-time clock assistant helps user adjust time and date functions

Serial communications assistant provides a convenient way to set-up eldbus

connections

Drive optimizer permits user to choose drive set-up for low noise, drive & motor

efciency or motor control accuracy

Built-in EMC Built-in category C2 (1st environment) lter No need for external ltering

Sensorless vector control Improve motor control performance Enables wider range of applications

Switching frequency control Permits the highest possible switching frequency based on operating and ambient

conditions

Flashdrop Faster and easier drive set-up and programming New fast, safe and trouble free method to download

Coated boards Longer lifetime in hostile environments. Reduced servicing requirements Protections against moisture and hostile particles

Flange Mounting Kits Allows mounting the drive with the heatsink external to a 3rd party enclosure

- frame size R1-R6.

Easy commissioning

Fast set-up

Easier conguration

Rapid fault diagnostics

Quick access to recent parameter changes

Reduces Total Harmonic Distortion (THD) emissions up to 25%

Reduced installation time

Secure cable connections

Quick fault diagnostics

Takes care of drive preventative maintenance

Easy set-up of parameters

Simplies closed loop process control adjustment

Allows quick adjustment of time and date

Provides easy set-up of eldbus connectivity

Quickly tailors drive to application

Considerable motor noise reduction and improved

efciency

parameters available without powering the drive

- patented

as standard

Reduces heat and enclosure size

5

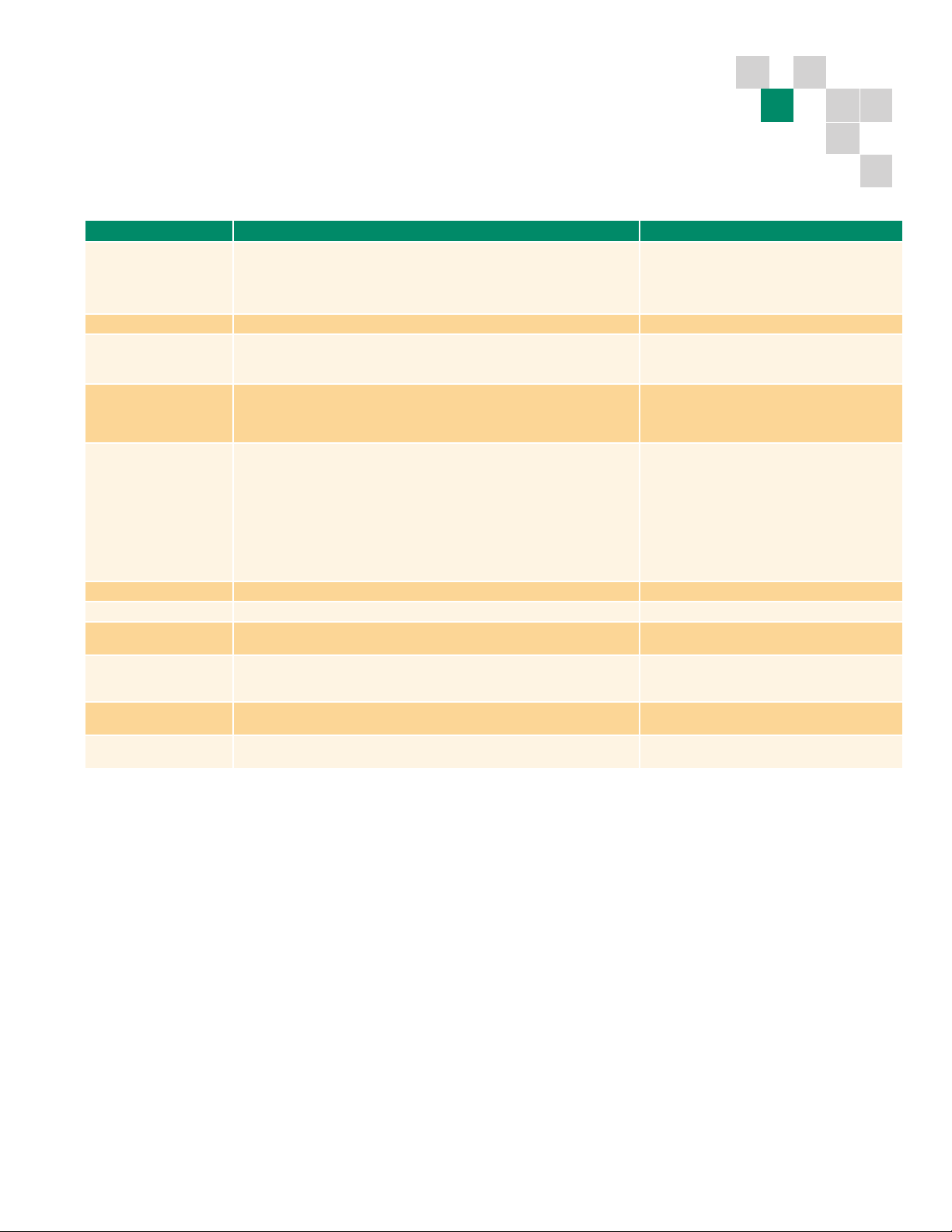

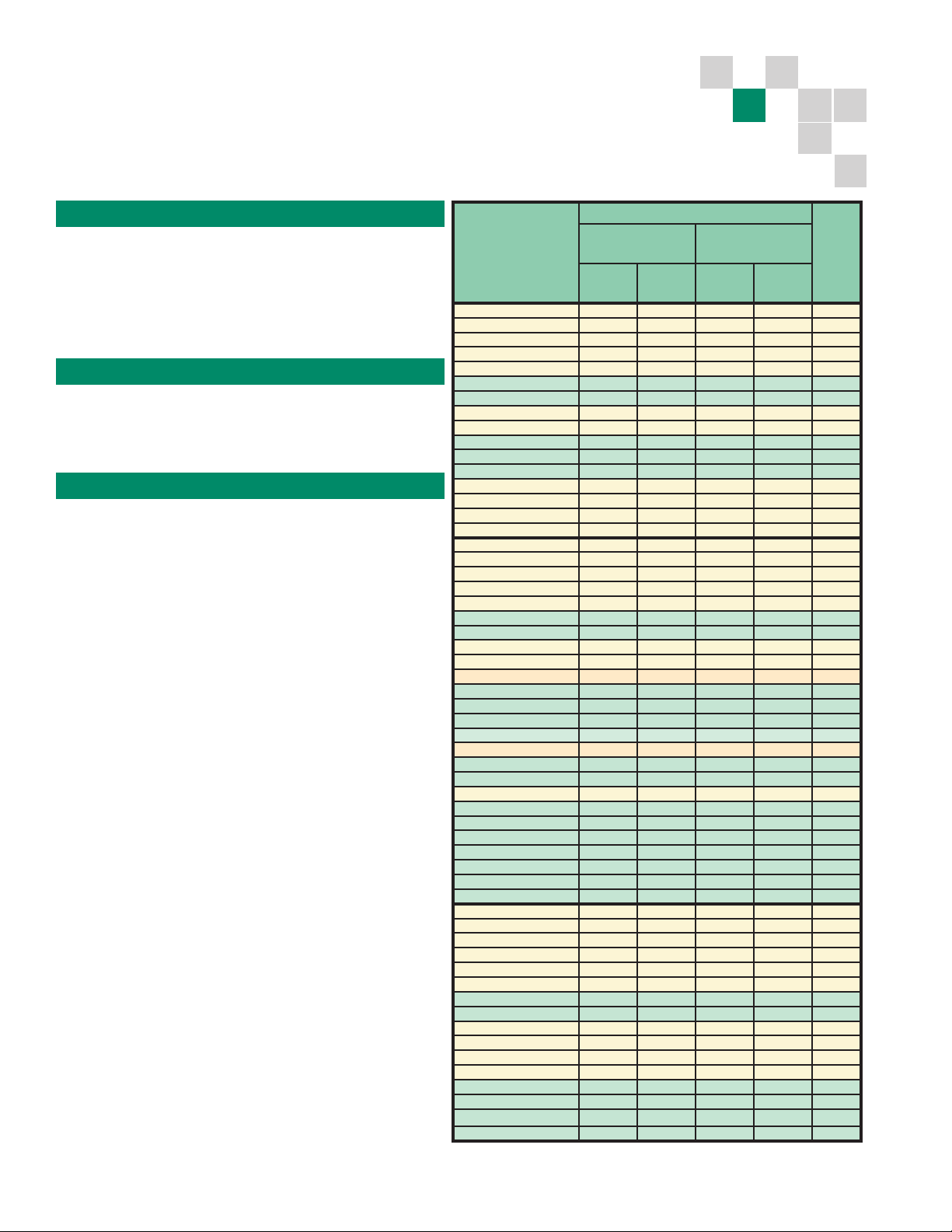

Ratings, Types and Voltages

Type code

This is the unique reference number that clearly indenties

the drive by mounting conguration, power rating and

voltage. Once you have selected the type code, the frame size

can be used to determine the drives dimensions, shown on

the next page.

Voltages

The ACS550 is available in three voltage ranges:

2 = 208 - 240V

4 = 380 - 480V

6 = 500 - 600V

Notes

1 I2N: continuous base current with 110% overload for

1 minute / 10 minutes.

2 I

3 180% Ihd continuous base current available for 2 seconds

4 The rated current of the ACS550 must be greater than

5 All -U1 models come with a conduit box and advanced

6 Horsepower is based on NEMA motor ratings for most

7 All 230V product can be operated on 230V single-phase

8 All -U2 models come standard with US conduit open-

: continuous base current with 150% overload for

2hd

1 minute / 10 minutes.

/ 1 minute.

or equal to the rated motor current to achieve the rated

motor power given in the table.

control panel as standard.

4-pole motors (1800 rpm). Check motor nameplate current for compatibility.

power, using a de-rate of the output current of 50%.

ings, top entry / top exit, common mode lter for drives

larger than 200 HP, fused disconnect and extended enclosure with advanced control panel.

Nominal Ratings

Normal Duty (CT)

Type Code

UL Type 1

NEMA 1

ACS550-U1-04A6-2 4.6 1.0 3.5 0.75 R1

ACS550-U1-06A6-2 6.6 1.5 4.6 1.0 R1

ACS550-U1-07A5-2 7.5 2.0 6.6 1.5 R1

ACS550-U1-012A-2 11.8 3.0 7.5 2 R1

ACS550-U1-017A-2 16.7 5.0 11.8 3 R1

ACS550-U1-024A-2 24.2 7.5 16.7 5 R2

ACS550-U1-031A-2 30.8 10 24.2 7.5 R2

ACS550-U1-046A-2 46.2 15 30.8 10 R3

ACS550-U1-059A-2 59.4 20 46.2 15 R3

ACS550-U1-075A-2 74.8 25 59.4 20 R4

ACS550-U1-088A-2 88 30 74.8 25 R4

ACS550-U1-114A-2 114 40 88 30 R4

ACS550-U1-143A-2 143 50 114 40 R6

ACS550-U1-178A-2 178 60 150 50 R6

ACS550-U1-221A-2 221 75 178 60 R6

ACS550-U1-248A-2 248 100 192 75 R6

ACS550-U1-03A3-4 3.3 1.5 2.4 1 R1

ACS550-U1-04A1-4 4.1 2 3.3 1.5 R1

ACS550-U1-06A9-4 6.9 3 5.4 2 R1

ACS550-U1-08A8-4 8.8 5 6.9 3 R1

ACS550-U1-012A-4 11.9 7.5 8.8 5 R1

ACS550-U1-015A-4 15.4 10 11.9 7.5 R2

ACS550-U1-023A-4 23 15 15.4 10 R2

ACS550-U1-031A-4 31 20 23 15 R3

ACS550-U1-038A-4 38 25 31 20 R3

ACS550-U1-045A-4 44 30 38 25 R3

ACS550-U1-059A-4 59 40 44 30 R4

ACS550-U1-072A-4 72 50 59 40 R4

ACS550-U1-078A-4 77 60 65 50 R4

ACS550-U1-097A-4 96 75 77 60 R4

ACS550-U1-125A-4 124 100 96 75 R5

ACS550-U1-157A-4 157 125 124 100 R6

ACS550-U1-180A-4 180 150 156 125 R6

ACS550-U1-246A-4 245 200 192 150 R6

ACS550-U2-316A-4 316 250 240 200 R8

ACS550-U2-368A-4 368 300 302 250 R8

ACS550-U2-414A-4 414 350 368 300 R8

ACS550-U2-486A-4 486 400 414 350 R8

ACS550-U2-526A-4 526 450 477 400 R8

ACS550-U2-602A-4 602 500 515 450 R8

ACS550-U2-645A-4 645 550 590 500 R8

ACS550-U1-02A7-6 2.7 2 2.4 1.5 R2

ACS550-U1-03A9-6 3.9 3 2.7 2.0 R2

ACS550-U1-06A1-6 6.1 5 3.9 3.0 R2

ACS550-U1-09A0-6 9 7.5 6.1 5.0 R2

ACS550-U1-011A-6 11 10 9 7.5 R2

ACS550-U1-017A-6 17 15 11 10 R2

ACS550-U1-022A-6 22 20 17 15 R3

ACS550-U1-027A-6 27 25 22 20 R3

ACS550-U1-032A-6 32 30 27 25 R4

ACS550-U1-041A-6 41 40 32 30 R4

ACS550-U1-052A-6 52 50 41 40 R4

ACS550-U1-062A-6 62 60 52 50 R4

ACS550-U1-077A-6 77 75 62 60 R6

ACS550-U1-099A-6 99 100 77 75 R6

ACS550-U1-125A-6 125 125 99 100 R6

ACS550-U1-144A-6 144 150 125 125 R6

(5,8)

(110% I2N)

I

2N

(1,7)

A

P

HP

Heavy Duty (CT)

N

(4,6)

A

(150% I

I

2hd

(2,3,7)

2hd

HP

)

Frame

P

hd

(4,6)

Size

6

Construction

“U1” within the type code indicates the drive mounting conguration. U1 models

are wall-mounted, while "U2" models are free-standing with an extended enclosure

and fused disconnect. Choose the correct one for your needs from the table below:

U1 U2

■Wall mounted, frame size R1-R6

■0.75 - 200 HP

■UL Type 1 (IP21) NEMA 1 or

UL Type 12 (IP54) NEMA 12

■Built-in EMC lter

■Standard software

■Built-in Modbus RTU interface

■Cable connection box

■Brake chopper in frame sizes R1-R2

■Advanced control panel

■Swinging choke (Frames R1-R6)

■AC Reactor (Frame R8)

■Free standing, frame size R8

■250 - 550Hp

■UL Type 1 (IP21) NEMA 1

■Standard software

■Built-in Modbus RTU interface

■Free-standing with extended

enclosure and fused disconnect

■Advanced control panel

■AC Reactor (Frame R8)

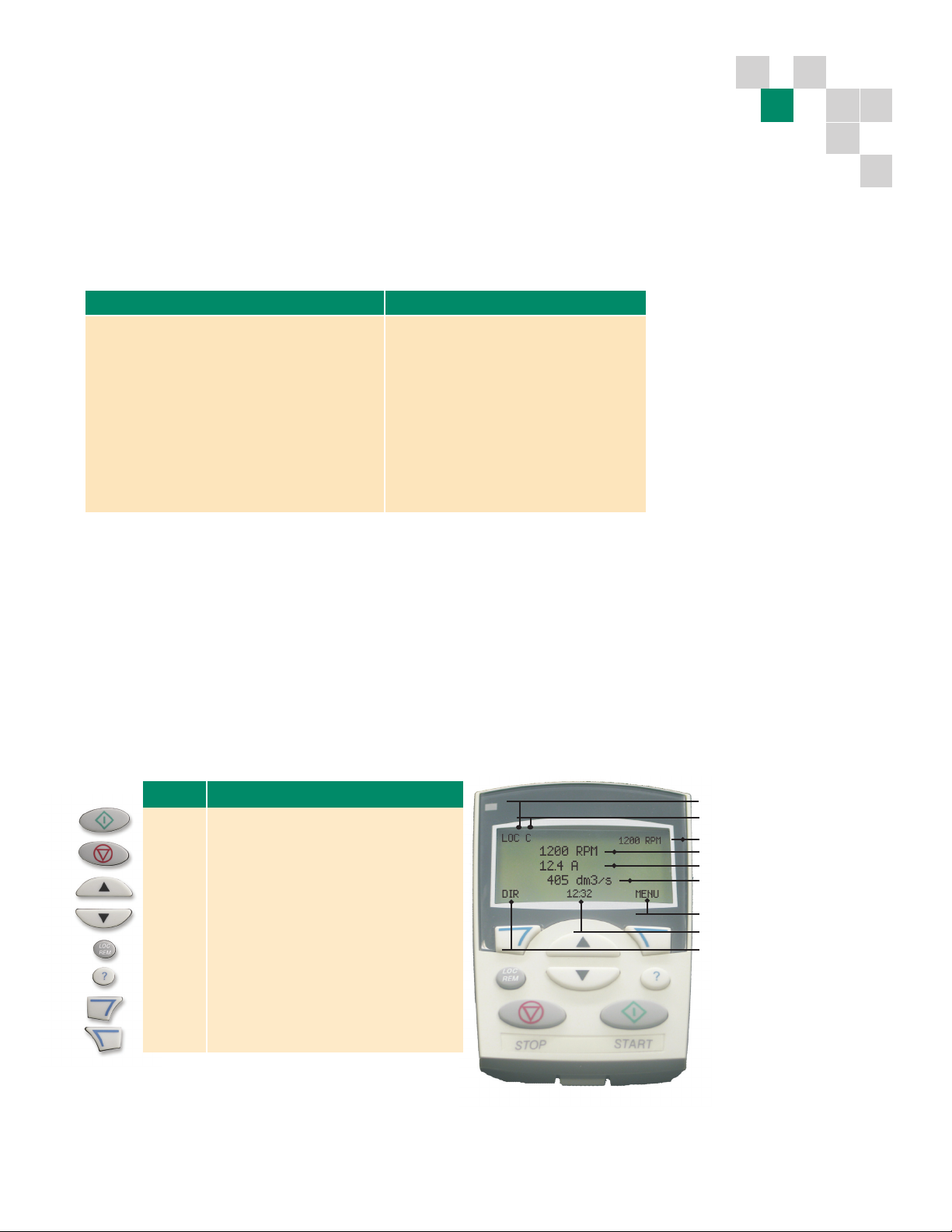

Advanced Control Panel

For easy drive programming, a detachable, multilingual

alphanumeric advanced control panel is delivered as standard. The control panel has various assistants and built-in

help functions to guide the user. It includes a real time

clock, which can be used during fault logging and in

Name Function

Start Initiates operation of drive

Stop Ceases operation of drive

Up Changes parameters and their value/ increases

reference

Down Changes parameters and their value/ decreases

reference

Loc/Rem Changes drive state from local control to

remote control (I/O or other external source)

HELP Built-in “Help” button

Soft key 1 Function changes according to state of panel

controlling the drive, such as start/stop and maintenance

reminders. The control panel can be used for copying parameters for back up or for downloading to another drive. A

large graphical display and soft keys make it extremely easy

to navigate.

Local/Remote indication

Motor rotation indicator

Speed reference

Actual value 1, Actual motor speed (selectable)

Actual value 2, Output current (selectable)

Actual value 3, Process value (selectable)

Soft key 2 function

Real time clock

Soft key 1 function

Soft key 2 Function changes according to state of panel

7

Options

Control Interfaces

How to select options

The options shown below are available for use with the

ACS550. Each item has a 4-digit option code, which is

shown in the table below. This code is added to the end of

the type code above using a '+'. Ordering options using the

plus option code provides a factory installed option, while

using the eld kit code provides a eld installable kit (-KIT).

Available options

Plus Option Description Field Kit Code

Code

Protection class

+B055 UL Type 12 (IP54) NEMA 12

Slot 1 Options

+L511 Relay Output Extension OREL-01-KIT

+L502 Pulse Encoder Interface OTAC-01-KIT

Slot 2 Options

+L512 115/230V Digital Input Interface OHDI-01-KIT

+K451 DeviceNet RDNA-01-KIT

+K454 Probus-DP RPBA-01-KIT

+K462 ControlNet RCNA-01-KIT

+K466 EtherNet/IP and Modbus/TCP RETA-01-KIT

+K457 CANopen RCAN-01-KIT

+K467 PROFINET and Modbus/TCP RETA-02-KIT

NOTE:

- Only one option can be installed in each option slot.

- Embedded Modbus RTU

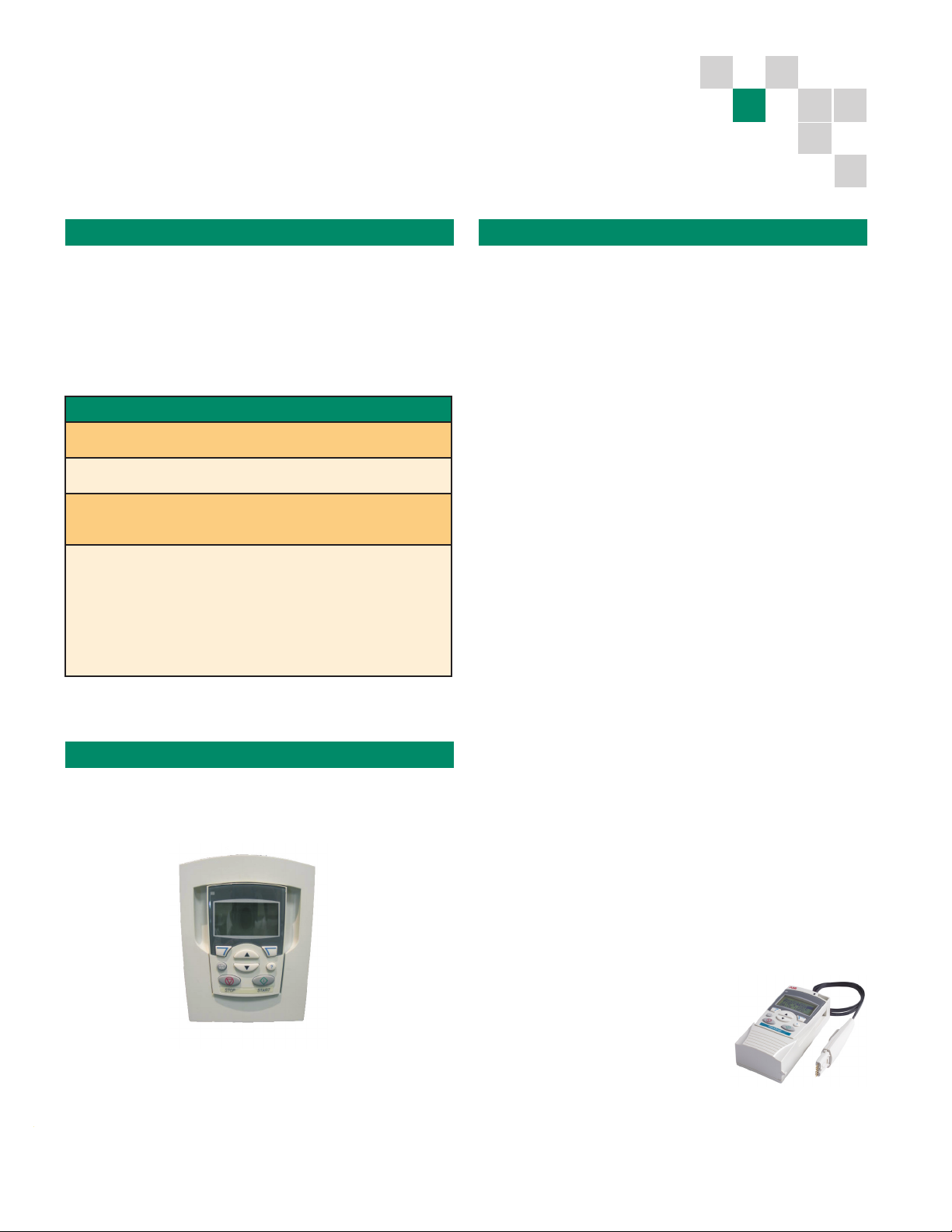

Panel Mounting Kit (OPMP-01)

The panel mounting kit, OPMP-01, enables mounting of control

panels on cabinet doors. This kit includes a 10 ft (3 m) extension

cable, a gasket, mounting screws and a mounting template.

DriveWindow Light 2 (3AFE64532871)

DriveWindow Light 2 is a PC software used for rapid

commissioning, operating and programming of drives. It has

features for programming, monitoring, troubleshooting and

maintenance.

It is also a set-up and control tool which is Win98, WinNT,

Win2000 and WinXP compatible.

DriveWindow Light 2 operates both off- and on-line. No

additional PC hardware is required. It uses the PC’s

RS-232 port. It is also compatible with drive types ACS350,

ACS800, DCS400 and DCS800.

DriveWindow Light 2 features

nGraphical start-up wizards

nOff- and on-line viewing and changing of drive

parameters

nBackup and restore parameters. In a fault situation, the

parameters can be reloaded resulting in time savings

nGraphical monitoring of actual signal values

nI/O mapping table

nControl of the drive

DrivePM

DrivePM (Parameter Manager) is a software tool designed to

create, edit and copy parameter sets included with a FlashDrop. For each parameter, and parameter group, the user

can change the default or hide the parameter or entire group.

FlashDrop does not require the drive to have power applied.

FlashDrop is also compatible with the ACS150 and ACS350.

ACS/H- CP-E X T: permits permanent mounting of panel to

external surface of NEM A 1 or NEMA 12 enclosures.

ACS/H-CP-EXT-IP66: permits permanent mounting of panel

to external surface of NEMA 4X enclosures.

8

FlashDrop MFDT-01

FlashDrop is a powerful palm-sized tool for fast and easy

parameter selecting and setting. This tool can be used to

download parameters to a drive in less than three seconds.

Using this tool, it is possible to hide

selected parameters to protect the

machine. Only parameters needed in

the application are shown. FlashDrop

does not require the drive to be powered. The MFDT-01 includes Drive PM

(Drive Parameter Manager) software

tool to create, edit and copy parameter sets.

FlashDrop

(MFDT-01)

Loading...

Loading...