Friedrich RC-RH 20, RC-RH 45, RC 21, RC 12, RC 11 User Manual

...

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

DUAL MOTOR PACKAGED TERMINAL

AIR CONDITIONERS

RC 11, 12 & 21

RC/RH 10, 20, 35, 45, 80, 90

RC/RH10

RC11

RC12

RC/RH20

RC21

RC/RH35

RC/RH80

Enviromaster International LLC |

|

|

5780 Success Dr. |

An ISO 9001-2000 Certified Company |

|

Rome, NY 13440 |

||

|

||

www.retroaire.com |

P/N# 240004146, Rev. 1.7 [02/07] |

|

|

DUAL MOTOR PACKAGED TERMINAL AIR CONDITIONERS

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

P/N# 240004146, Rev. 1.7 [02/07]

Shipping Damage MUST be Reported to the Carrier IMMEDIATELY!!!

Examine the exterior. Remove cover and examine compressor and piping for signs of damage.

This manual is intended as an aid to qualified service personnel for proper installation, operation, and mainte-

nance of the RetroAire Dual Motor Packaged TerminalAir Conditioner (PTAC). Read these instructions thoroughly and carefully before attempting installation or operation. Failure to follow these instructions may result in improper installation, operation, service or maintenance, possibly resulting in fire, electrical shock, property damage, personal injury, or death.

TO THE INSTALLER

(1)Retain this manual and warranty for future reference.

(2)Before leaving the premises, review this manual to be sure the unit has been installed correctly and run the unit for one complete cycle to make sure it functions properly.

To obtain technical service or warranty assistance during or after the installation of this unit, contact your local representative. Visit our website www.retroaire.com for a local representative listing. For further assistance call 1-800-228-9364.

When calling for assistance, please have the following information ready:

•Model Number___________________________

•Serial Number____________________________

•Date of Installation________________________

SAFETY INSTRUCTIONS

Read all instructions before using the RetroAire PTAC. Install or locate this unit only in accordance with these instructions. Use this unit only for its intended use as described in this manual.

Read all instructions before using the RetroAire PTAC. Install or locate this unit only in accordance with these instructions. Use this unit only for its intended use as described in this manual.

Check the rating plate on the RetroAire PTAC before installation to make certain the voltage shown is the same as the electric supply to the unit.

Check the rating plate on the RetroAire PTAC before installation to make certain the voltage shown is the same as the electric supply to the unit.

The RetroAire PTAC must be connected only to a properly grounded electrical supply. Do not fail to properly ground this unit.

The RetroAire PTAC must be connected only to a properly grounded electrical supply. Do not fail to properly ground this unit.

Turn off the electrical supply before servicing the RetroAire PTAC.

Turn off the electrical supply before servicing the RetroAire PTAC.

Do not use the RetroAire PTAC if it has damaged wiring, is not working properly, or has been damaged or dropped.

Do not use the RetroAire PTAC if it has damaged wiring, is not working properly, or has been damaged or dropped.

[Save These Instructions]

! |

Recognize this symbol as an indication |

! |

of important safety information |

The Right Fit For Comfort |

2 |

www.retroaire.com |

TABLE OF CONTENTS |

|

Warnings and Precautions..................................... |

2-3 |

The Dual Motor PTAC Family ................................... |

4 |

Controls and Components........................................ |

4 |

Preparation for Installation ....................................... |

5 |

Electrical Wiring ....................................................... |

5 |

Installation Instruction for: |

|

RC/RH10 Replacement PTAC ............................. |

6 |

RC11 Replacement PTAC.................................... |

7 |

RC12 Replacement PTAC ................................... |

8 |

RC/RH20 Replacement PTAC ........................ |

9-10 |

RC21 Replacement PTAC ............................. |

11-12 |

RC/RH35 Replacement PTAC ............................ |

13 |

RC/RH45 Replacement PTAC ....................... |

14-15 |

RC/RH80 Replacement PTAC ....................... |

16-17 |

RC/RH90 Replacement PTAC ....................... |

18-19 |

Final Inspection and Start-Up.............................. |

20 |

Sequence of Operation....................................... |

20-23 |

Cleaning and Maintenance ..................................... |

24 |

Troubleshooting ....................................................... |

24 |

Specifications........................................................... |

25 |

Warranty .................................................................. |

26 |

INSTALLER RESPONSIBILITIES

This manual has been prepared to acquaint you with the installation, operation and maintenance of RetroAire Dual Motor PTACs and to provide important safety information in these areas.

We urge you to read all of these instructions thoroughly before attempting the installation or operation of your unit. This manual should be kept for future reference.

The manufacturer of this unit will not be liable for any damages caused by failure to comply with the installation and operating instructions outlined in this manual.

A rating plate identifying your RetroAire Dual Motor PTAC can be found on the unit. When referring to your unit, always have the information listed on the rating plate readily available.

MODIFICATION AND TAMPERING

!DANGER !

Tampering with the RetroAire Dual Motor PTAC is dangerous and may result in serious injury or death. Tampering voids all warranties. Do not attempt to

modify or change this unit in any way.

IMPORTANT SAFETY FEATURE

Power Cord With Integral Safety Protection

All PTACs rated 250V or less that are cord connected to the power supply are equipped with a power cord with integral safety protection as standard. Providing personal shock protection as well as arcing and fire prevention, the device is designed to sense any damage in the line cord and disconnect power before a fire can occur. Tested in accordance with Underwriters Laboratories, the cord set also offers a unique “passive” operation, meaning the unit does not require resetting if main power is interrupted.

WARNING -ADAMAGED POWER SUPPLY CORD MUST BE REPLACED WITH A NEW CORD FROM THE MANUFACTURER, AND NOT REPAIRED.

Each power cord should be checked before every use. Follow the instructions in the order listed on the device.

WARNING - DO NOT USE THE PRODUCT IF THE UNIT FAILS THE TEST.

!DANGER !

Do not use the RetroAire Dual Motor PTAC with any electrical supply voltage other than the one listed on the rating plate.

!WARNING !

Completely read all instructions prior to assembling, installing, operating, or repairing this product. Inspect all parts for damage prior to installation and start-up.

!CAUTION !

PTAC Chasses are heavy. To avoid injury, use assistance when lifting.

Note: Unit uses R22 refrigerant.

The Right Fit For Comfort |

3 |

www.retroaire.com |

THE DUAL MOTOR PTAC FAMILY

The RetroAire Dual Motor PTAC is available as a coolingonly model or, for those who wish to up-grade to a heat pump, the RH10, 20, 35, 45, 80, and 90 heat pump chassis will fit the existing wall sleeve. The heat pump version will reduce energy costs during periods of outdoor temperature ranging down to as low as 40° F.

The Dual Motor PTAC uses a high-efficiency rotary com- pressorprotectedundera5-yearwarrantyandanenhanced high-efficiency heat exchanger to make the replacement of worn out and inefficient units a very attractive option.

The RetroAire Dual Motor PTAC offers two fan speeds

– three in the RC12 – and has an optional motorized fresh airfeaturewithapositivepressureseal,overrideswitch,and positive condensate re-evaporation to improve efficiency.

Whisper quiet operation improves the room ambience and the 20 gauge galvanized steel construction of the chassis ensures long service life.

The RetroAire Dual Motor Packaged Terminal Air Conditioner family consists of:

RC/RH10: Astraight cool/heat pump replacement for

RC/RH10: Astraight cool/heat pump replacement for

theAmericanAirFilter 16Series,AmericanStandard

45, Carteret 45, Remington Type 45, McQuay 45,

Singer 45, and Nelson Aire 16.

RC11: A straight cool only replacement for the Westinghouse RB Series.

RC11: A straight cool only replacement for the Westinghouse RB Series.

RC12: A straight cool only replacement for the Lennox PTEIA Series.

RC12: A straight cool only replacement for the Lennox PTEIA Series.

RC/RH20: A straight cool/heat pump replacement for the Climate Master (Friedrich) 702 & 703, Cool Heat RM Series, TPI Ra-Matic, Weather Twin, and ZoneAire S, SC & RM.

RC/RH20: A straight cool/heat pump replacement for the Climate Master (Friedrich) 702 & 703, Cool Heat RM Series, TPI Ra-Matic, Weather Twin, and ZoneAire S, SC & RM.

RC21: A straight cool only replacement for the Climate Master 701.

RC21: A straight cool only replacement for the Climate Master 701.

RC/RH35:Astraight cool/heat pump replacement for

RC/RH35:Astraight cool/heat pump replacement for

the Singer/Remington/McQuay EA, ES & RS.

RC/RH45: A straight cool/heat pump replacement for the American Standard Type 40.

RC/RH45: A straight cool/heat pump replacement for the American Standard Type 40.

RC/RH80:Astraight cool/heat pump replacement for FeddersCMEO“Unizone,” andMueller/Worthington “Climatrol.”

RC/RH80:Astraight cool/heat pump replacement for FeddersCMEO“Unizone,” andMueller/Worthington “Climatrol.”

RC/RH90:Astraight cool/heat pump replacement for

RC/RH90:Astraight cool/heat pump replacement for

Cool Heat AD & 700 and Friedrich Climate Master

AD & 700.

The RetroAire Dual Motor PTAC is available in nominal sizes of 9,000 Btuh, 12,000 Btuh, 15,000 Btuh, and 18,000 Btuh.* With energy efficiency ratings as high as 10, the replacement of worn out and inefficient units is a very attractive option.

* The RC12 PTAC, however, is only available in nominal sizes of 12,000 Btuh and 15,000 Btuh.

All Retroaire products are backed by Enviromaster International LLC and are rated in accordance withARI Standards 310 and 380 and UL Standard 484.

PRE-INSTALLATION

Test run the Dual Motor PTAC prior to installation. Connect the line cord to a proper power supply (such as the one the old unit is plugged into) and check all controls for proper operation. Disconnect the chassis before installing.

Review baffle and foam tape installation to ensure proper air seal and unit operation.

CONTROLS AND COMPONENTS

Standard Unit Features

1.Unit mounted operating controls

•Thermostat

•Fan speed control

•Heat/cool switch

•Fan cycle switch

2.Low ambient protection

3.Foam strip seal for supply air duct

4.Weather strip insulation

5.Baffle kit bag

6.Condenser baffles to accommodate extended wall sleeve applications (consult factory)

7.Sea coast coated drainpan

8.Normally/open normally/closed motor valve-switch, (hydronic heat only)

Optional Controls and Accessories

1.Remote thermostat

2.Motorized fresh air damper

3.Electric/hydronic heat

4.Disconnect switch

5.Sea coast coated coils

6.Wall sleeves, louvers, and cabinets (consult factory)

The Right Fit For Comfort |

4 |

www.retroaire.com |

!WARNING !

Moving parts can cause personal injury. Exercise all due caution when test running the chassis.

!WARNING !

The correct condenser air baffles must be properly installed or performance will be impaired and/or the warranty will be voided!!

PREPARATION FOR INSTALLATION

IMPORTANT: RetroAire Dual Motor PTACs are to be used with metal wallsleeves. The sleeves must employ front panels secured by screws that prevent contact with all parts with minor dimensions of openings not exceeding 1/2”.The final assembly must employ an indoor air discharge grill having dimensions not less than 26” x 4”, separating the top surface of the chassis from the top surface of the discharge grill by a minimum of 1”. For all models, the outdoor openingsmustpreventcontactofallmovingpartsbymeans of louvers or grills with minor dimension not exceeding 1”. All cord connected 265 Volt units must be plugged into receptacles within the unit subbase or chassis.

1.Remove the front of the existing room enclosure. This will expose the old chassis.

2.Disconnect the power supply. If a line cord and plug were used, remove it from the receptacle. If the chassis is hard wired, locate the circuit breaker, place it in the “OFF” position, and tag it, announcing work is being done. DO NOT TURN ON.

3.Loosen any tie down bolts or screws and remove the old chassis.

IMPORTANT: Dispose of old chassis per present state and federal regulations.

4.Inspect the wall sleeve/cabinet for rust, holes, and damage.Cleanthewallsleeveofanydirt,repairanydamage, and ensure proper drainage of condensate or rainwater to exterior of building.

5.Remove or repair old weather seals and note location for installation of any new seals.

6.Check the wall sleeve/cabinet to assure all drain holes are open and that (A) the unit is level left to right and (B) the back is pitched to the outside by 1/2” maximum.

7.Check the present voltage to verify the new chassis is a matching voltage and that the line cord and receptacle match.

8.Before installing the new chassis, inspect the outdoor louver for a minimum free area of 70% and remove any obstructions. Any variation will restrict air flow over the condenser coil and cause serious damage to the chassis. It will also void the warranty.

The Right Fit For Comfort

See individual unit installation instructions for more information.

ELECTRICAL WIRING

All wiring should be in accordance with the National Electric Code (NEC) and the local building codes.

! WARNING !

To avoid possible injury or death due to electrical shock, open the power supply disconnect switch and secure it in an open position during installation. On a plug and receptacle connection, keep the unit unplugged until installation is complete.

1.Inspect the existing wiring for any deficiencies such as cut or frayed wires. Replace such wiring if found.

2.Check the unit rating plate for circuit ampacity and breaker or fuse size. Use only HACR type breakers. Select the proper wire for the ampacity rating.

3.If plug and receptacle are used, check the compatibility. The chassis can be hard wired or direct connected as well.

4.Each unit must have a separate branch ciruit protected by a fuse or breaker. Refer to the unit rating plate for the proper wire and breaker or fuse size. Use of extension cords is prohibited.

!DANGER !

The RetroAire Dual Motor PTAC must:

Be connected to a properly grounded electrical supply with the proper voltage as stated on the rating plate.

Be connected to a properly grounded electrical supply with the proper voltage as stated on the rating plate.

Use the proper maximum over current protection device stated on the rating plate.

Use the proper maximum over current protection device stated on the rating plate.

The use of extension cords is prohibited.

Failure to follow these instructions can result in a fire, explosion or electrical shock causing property damage, personal injury or death.

5 |

www.retroaire.com |

INSTALLATION INSTRUCTIONS

RC/RH10 REPLACEMENT PTAC

Install 1/2” x 1/2” Foam Tape

OFF

BLOCK

EVAP

RC/RH10 BAFFLE INSTALLATION KIT

• 1 |

Installation Manual |

• 1/2” x 1/2” Open Cell Foam Tape |

|

• 1 Top Baffl e |

|

• 1” x 1” Open Cell Foam Tape |

|

• 2 |

Sets of Lt.&Rt. Baffl es |

• 2” x 1 1/2” Open Cell Foam Tape |

|

• Screws |

HYDRONIC |

• 1ea. 2-Position Connector & Pin Mate |

|

|

|

ONLY |

• 14AWG Yellow Wire |

1.Take unit out of packaging.

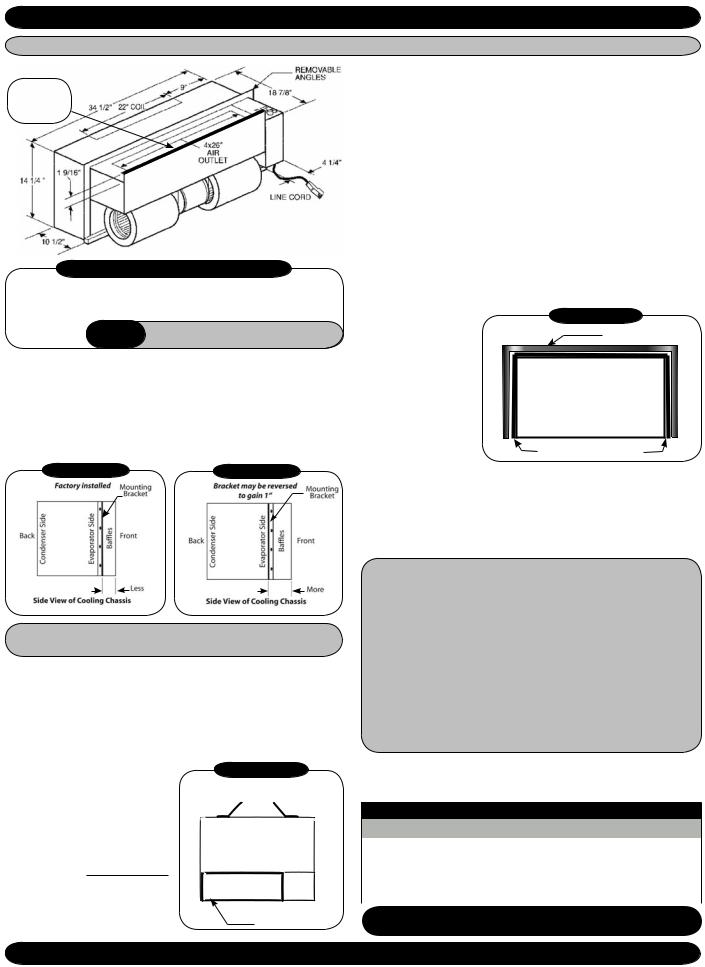

2.Slideunitintowallsleeve.Ifsupplyductoncoolingchassisdoes not line up with supply vent on room cabinet it is possible that factory installed angle brackets on the top and sides will have to be reversed. This will allow approximately 1” in or out of the wall sleeve (see figures A & B) below.

Figure A1 |

Figure B1 |

Two sets of baffl es are provided in your kit to accommodate mounting brackets in either position A or B.

3.Slide unit out of wallsleeve.

4.Baffl e Installation - Remove baffl es from kit bag supplied with unit. Install left and right side baffl es on the condenser coil in existing holes:

•Choose the proper fi tting baffl es for your application.

•Baffl es must come in contact with the outdoor louver.

•Make sure baffles are directed inward toward the center of coil.

•Secure baffl es tightly to the condenser coil using the screws provided.

(Figures A1,B1 & C1).

IMPORTANT: The correct condenser air baffl es must be installed or performances may be impaired and/or the warranty will be voided.

The Right Fit For Comfort

Figure C1

Baffl es Directed Inward

Toward Coil

Toward Coil

|

|

|

|

||

|

2” X 1 1/2” Supply Air

Duct Foam Tape

5.Apply one piece of 1/2” x 1/2” open cell polyfoam to top fl ange of evaporator block off (See illustration at left).

6.Apply 2” x 1 1/2” open cell foam strips around supply air duct to ensure that all the conditioned air is delivered into the room. Failure to do so results in recirculation of the conditioned air around the wall sleeve and through the unit causing the unit to short cycle and coils to freez, thus raising operating costs through improper heating and cooling

(Figure C1).

7.1” x 1” Open cell foam strips are provided to prevent outside air from entering around the chassis to the room from the sides and top of the cabinet. Install between wall sleeve and cooling chassis. It is imperative to have a solid air seal between wall

sleeve and chassis. Failure to do so will result in air leakage from outdoor to

indoor causing system problems i.e.coilsfreezing, shortcycling,and constant running of unit. If installer is in need of more foam than

supplied in kit, consult factory

(Figure D1).

8.Once confi dent that all seals are the correct size and in the proper location, and the correct baffl es are attached to the condenser coil in the proper orientation, slide unit into fi nal position and tighten any tie down bolts or screws as necessary.

Hydronic Only: Remove the 2-position connector assembly from kit bag supplied with unit (this will have 2 yellow wires attached). Connect this 2-position connector to the 2-position connection located on the bottom of the control box panel.

To Connect Aquastat:

A.Remove the black jumper wire located on the bottom panel of the control box (this is also terminated with a 2-position connector).

B.Cut the jumper wire in the middle and splice the aquastat to the jumper.

C.Place the connecter back into original location. Refer to wire diagram on the unit for details.

9.Connect line cord.

10. See Final Inspection and Startup on page 20.

RC/RH 10 PERFORMANCE DATA*

Unit Size |

Cooling Btuh |

EERs |

Heat Pump Btuh |

COP |

Fresh Air CFM |

9 |

9,500 |

10.0 |

8,500 |

2.8 |

40/35 |

12 |

11,900 |

10.0 |

11,400 |

2.9 |

40/35 |

15 |

14,700 |

9.2 |

13,800 |

2.8 |

40/35 |

18 |

16,900 |

9.1 |

N/A |

N/A |

40/35 |

|

*Refer to the charts on page 23 for electrical and |

|

optional electric heat specifi cations. |

6 |

www.retroaire.com |

INSTALLATION INSTRUCTIONS

RC11 REPLACEMENT PTAC

Removable

Weather Seals

|

|

|

|

|

34 |

1/2 |

” |

|

|

|

|

|

|

|

|

|

|

|

39 |

3/4 |

” |

|

|

|

|

|

|

|

|

|

|

14 |

” |

|

|

|

|

|

|

|

1/8 |

|

|

|

|

|

|

Air Filter |

|

|

|

|

|

|

|

|

30 |

1/4 |

” |

|

|

|

|

|

|

|

|

|

|

|

Install 1/2” x 1/2” Foam Tape

11 |

1/4 |

” |

|

|

|

|

|

|

|

|

18 |

7/8 |

” |

|

RC11 BAFFLE INSTALLATION KIT

• 1 |

Installation Manual |

• 1/2” x 1/2” Open Cell Foam Tape |

|

• 1 Top Baffl e |

|

• 1” x 1” Open Cell Foam Tape |

|

• 2 |

Sets of Lt.&Rt. Baffl es |

• 2” x 1 1/2” Open Cell Foam Tape |

|

• Screws |

HYDRONIC |

• 1 ea. 2-Position Connector & Pin Mate |

|

|

|

ONLY |

• 14AWG Yellow Wire |

Two sets of baffl es are provided in your kit to accommodate varying wall sleeve depth.

1.Take unit out of packaging.

2.Slide unit into wall sleeve. The supply duct on the cooling chassis should line up with the supply vent on the room cabinet. The weather angles should require no adjustment.

3.Slide unit out of wallsleeve.

IMPORTANT: The correct condenser air baffl es must be installed or performances may be impaired and/or the warranty will be voided.

4.Baffl e Installation - Remove baffl es from kit bag supplied with unit. Install left and right side baffl es on the condenser coil in existing holes:

•Choose the proper fi tting baffl es for your applica-

tion.

•Baffles must come in contact with the outdoor louver.

•Make sure baffles are directed inward toward the center of coil.

•Secure baffl es tightly to the condenser coil using the screws provided.

Figure A2 |

|

|

Baffl es-Directed Inward |

||

|

Toward Coil |

|

|

|

|

|

|

|

|

|

|

|

||

|

||

2” X 1 1/2” Supply Air |

||

Duct Foam Tape |

||

5.Apply one piece of 1/2” x 1/2” open cell polyfoam to top

flange of evaporator block off (See illustration: top of

this page).

6.Apply 2” x 1 1/2” open cell foam strips around supply air duct to ensure that all the conditioned air is delivered into the room. Failure to do so results in recirculation of the conditioned air around the wall sleeve and through the unit causing the unit to short cycle, thus raising operating costs through improper heating and cooling

(Figure A2).

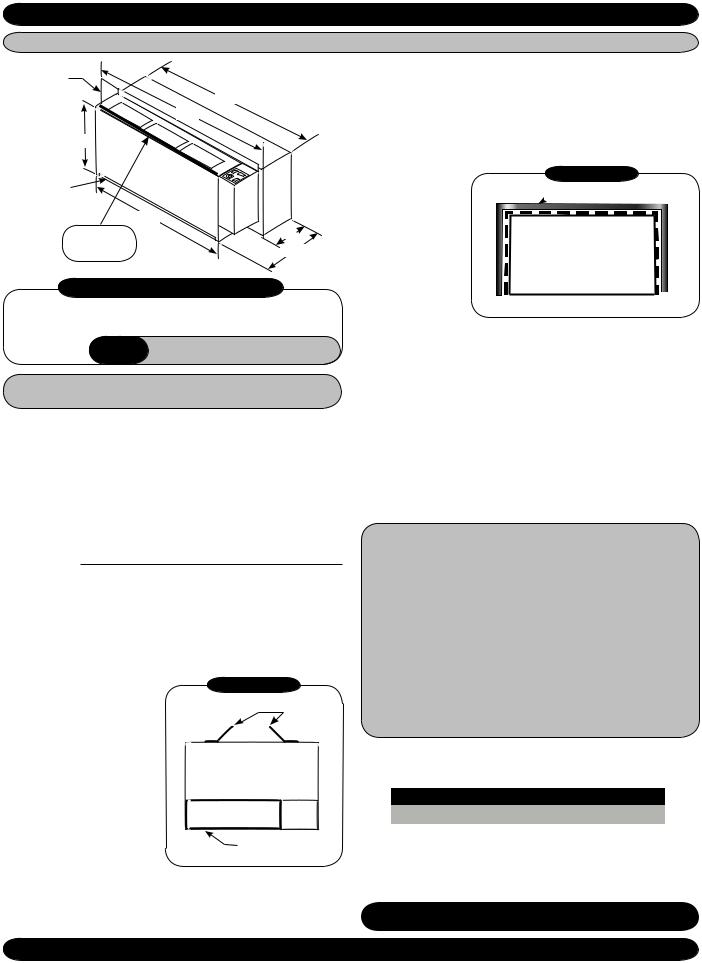

7. 1” x 1” Open cell foam strips are provided to preventoutside air from entering around the chassis to the room from the sides and top

Wall Sleeve

Wall Sleeve

Front View

Cooling Chassis

1 x1 Foam Tape

1 x1 Foam Tape

of the cabinet. Install between wall sleeve and cooling chassis. It is imperative to have a solid air seal between wall sleeve and chassis. Failure to do so will result in air leakage from outdoor to indoor causing system problems i.e. Coils freezing, short cycling, and constant running of unit. If installer is in need of more foam than supplied in kit, consult factory (Figure B2).

8.Once confi dent that all seals are the correct size and in the proper location, and the correct baffl es are attached to the condenser coil in the proper orientation, slide unit into final position and tighten any tie down bolts or screws as necessary.

Hydronic Only: Remove the 2-position connector assembly from kit bag supplied with unit (this will have 2 yellow wires attached). Connect this 2-position connector to the 2-position connection located on the bottom of the control box panel.

To Connect Aquastat:

A.Remove the black jumper wire located on the bottom panel of the control box (this is also terminated with a 2-position connector).

B.Cut the jumper wire in the middle and splice the aquastat to the jumper.

C.Place the connecter back into original location. Refer to wire diagram on the unit for details.

9.Connect line cord.

10. See Final Inspection and Startup on page 20. |

|||||

|

|

|

|

|

|

|

|

RC11 PERFORMANCE DATA* |

|||

|

UNIT SIZE |

|

COOLING BTUH |

EER |

FRESH AIR CFM |

|

|

|

|

|

|

|

9 |

|

9500 |

10 |

40/35 |

|

|

|

|

|

|

|

12 |

|

11,900 |

10 |

40/35 |

|

|

|

|

|

|

|

15 |

|

14,700 |

9.2 |

40/35 |

|

18 |

|

16,900 |

9.1 |

40/35 |

*Refer to the charts on page 23 for electrical and optional electric heat specifi cations.

The Right Fit For Comfort |

7 |

www.retroaire.com |

INSTALLATION INSTRUCTIONS

RC12 REPLACEMENT PTAC

|

RC12 INSTALLATION KIT |

• 1 Installation Manual |

|

HYDRONIC |

• 1ea. 2-Position Connector & Pin Mate |

ONLY |

• 14AWG Black Wire |

1.Take unit out of packaging.

2.Slide unit into wall sleeve. The supply duct on the cooling chassis should line up with the supply vent on the room cabinet. The weather angles should require no adjustment.

3.Make sure baffles come in contact with the outdoor louver.

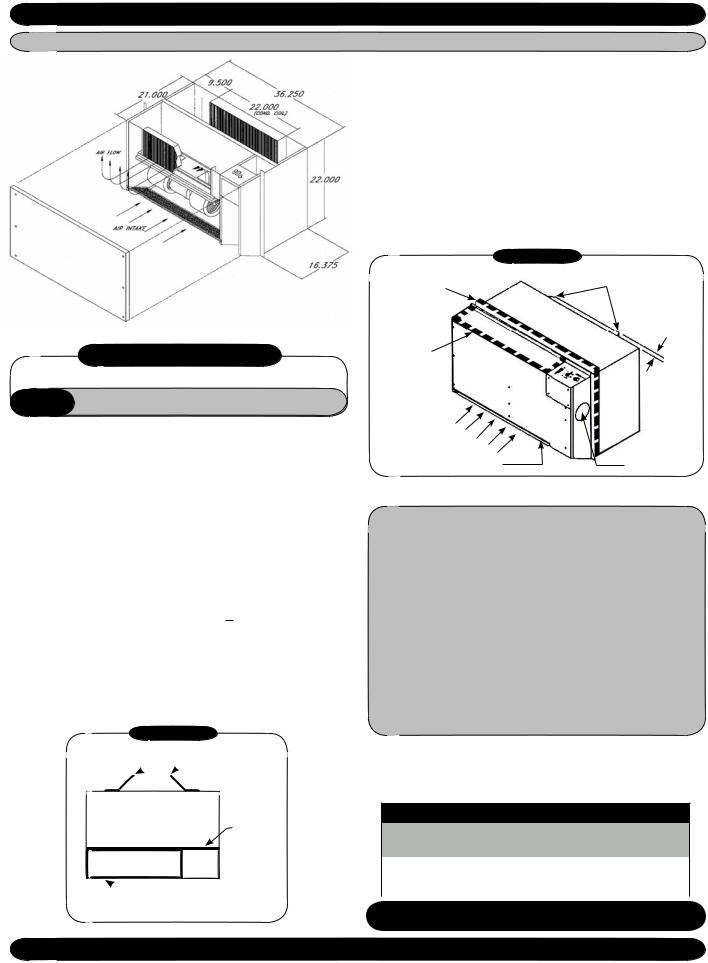

IMPORTANT: Baffles and open cellfoam tape seals are factory installed on the RC12 . Baffles fill the gap between the rear of the chassis and the outdoor louver and prevent the air from recirculating. Consult the factory if baffles supplied are not deep enough to accommodate wall sleeve application as system efficiency and reliability are dependent on proper air flow. (Figure A3)

Figure A3

Baffles-Directed Inward

Toward Coil

Toward Coil

1” X 1 ”

Open Cell

Foam Tape

1” X 1/2” Supply Air

1” X 1/2” Supply Air

Duct Foam Tape

IMPORTANT: If adjoining room conditioning is required, the RC12 is able to discharge to the right and left by utilizing the four-inch knockouts (Figure B3) on either side of the evaporator compartment using 4” flex duct.

3.Once confident that all seals are the correct size and in the proper location and the correct baffles are attached to the condenser coil and in the proper orientation, slide unit into final position and tighten any tie down bolts or screws as necessary.

|

Figure B3 |

1” x 1” Open Cell |

Left and Right |

Foam Tape |

Condenser Baffles |

1” X 1/2” |

5/8” Ref. |

Open Cell |

|

Foam Tape |

|

Air Intake |

|

Removeable Filter |

4” Knockout |

Hydronic Only: Remove the 2-position connector assembly from kit bag supplied with unit (this will have 2 yellow wires attached). Connect this 2-position connector to the 2-position connection located on the bottom of the control box panel.

To Connect Aquastat:

A.Remove the black jumper wire located on the bottom panel of the control box (this is also terminated with a 2-position connector).

B.Cut the jumper wire in the middle and splice the aquastat to the jumper.

C.Place the connecter back into original location. Refer to wire diagram on the unit for details.

4.Connect line cord.

5.See Final Inspection and Startup on page 20.

RC12 PERFORMANCE DATA*

UNIT |

COOLING |

EER |

EVAP CFM |

FRESH |

SIZE |

BTUH |

|

HIGH/LOW |

AIR CFM |

12 |

12,200 |

10 |

390/340 |

40/35 |

15 |

15,500 |

9 |

440/390 |

40/35 |

*Refer to the charts on page 23 for electrical and optional electric heat specifications.

The Right Fit For Comfort |

8 |

www.retroaire.com |

Loading...

Loading...