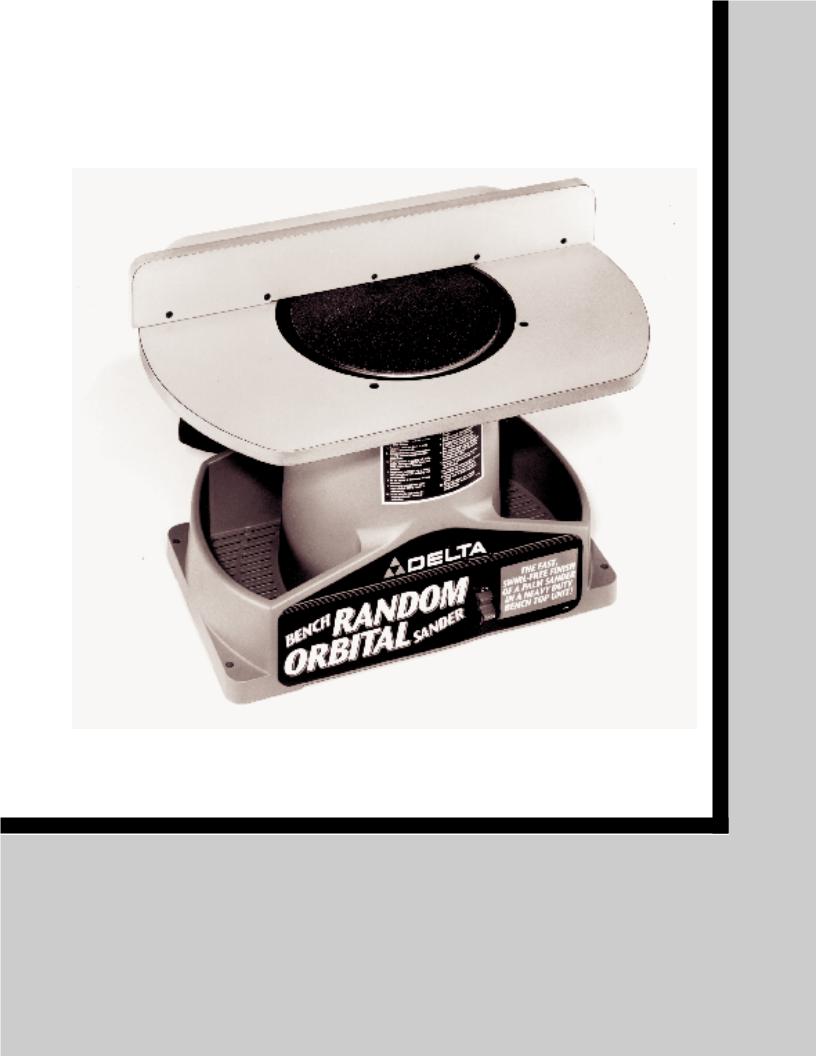

Delta 31-750 User Manual

Bench Random Orbital Sander

(Model 31-750)

REVISED 3-29-99 |

PA RT NO. 1348132 |

|

'Delta International Machinery Corp. 1999 |

LAUNAM INSTRUCTION

TABLE O F CONTENTS

SAFETY RULES F O R ALL TO O L S ........................................................ 3

ADDITIONAL SAFETY RULES FOR ALL TOOLS ............................................ 4

U N PACKING A N D CLEANING ........................................................... 4

ASSEMBLY INSTRUCTIONS

Assembling Abrasive Discs To Disc Plate ............................................. 6

Adjusting Table ................................................................... 6

Assembling Fence To Table ......................................................... 7

Assembling Dust Bag .............................................................. 8

Assembling Accessory 50-780 Stand ................................................. 8

Assembling Sander To Accessory Stand .............................................. 8

ACCESSORY 31-752 DISC HOLDER ...................................................... 9

FASTENING SANDER TO SUPPORTING SURFA C E.......................................... 9

CONNECTING SANDER TO P O W E R SOURCE |

|

Power Connections ................................................................ |

9 |

Motor Specifications ............................................................... |

9 |

Grounding Instructions............................................................ |

10 |

Extension Cords ................................................................. |

10 |

OPERATING CONTROLS A N D ADJUSTMENTS

Starting And Stopping Sander ...................................................... 11

Locking Switch In The OFF Position ............................................... 11

Changing Abrasive Discs .......................................................... 11

OPERATIONS ........................................................................ 12

Delta Building Trades and Home Shop Machinery

Two Year Limited Warranty

Delta will repair or replace, at its expense and at its option, any Delta machine, machine part, or machine accessory which in normal use has proven to be defective in workmanship or material, provided that the customer returns the product prepaid to a Delta factory service center or authorized service station with proof of purchase of the product within two years and provides Delta with reasonable opportunity to verify the alleged defect by inspection. Delta may require that electric motors be returned prepaid to a motor manufacturer s authorized station for inspection and repair or replacement. Delta will not be responsible for any asserted defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically authorized by anyone other than an authorized Delta Service facility or representative. Under no circumstances will Delta be liable for incidental or consequential damages resulting from defective products. This warranty is Delta s sole warranty and sets forth the customer s exclusive remedy, with respect to defective products; all other warranties, express or implied, whether of merchantability, fitness for purpose, or otherwise, are expressly disclaimed by Delta.

2

SAFETY RULES

W oodworking can be dangerous if safe and proper operating procedures are not followed. As with all machinery, there are certain hazards involved with the operation of the product. Using the machine with respect and caution will considerably lessen the possibility of personal injury. However, if normal safety precautions are overlooked or ignored, personal injury to the operator may result. Safety equipment such as guards, push sticks, hold-downs, featherboards, goggles, dust masks and hearing protection can reduce your potential for injury.But even the best guard won t make up for poor judgment, carelessness or inattention. Always use common sense and exercise caution in the workshop. If a procedure feels dangerous, don t try it. Figure out an alternative procedure that feels safer. REMEMBER: Your personal safety is your responsibility.

This machine was designed for certain applications only. Delta Machinery strongly recommends that this machine not be modified and/or used for any application other than that for which it was designed. If you have any questions relative to a particular application, DO N O T use the machine until you have first contacted Delta to determine if it can or should be performed on the product.

DELTA INTERNATIONAL MACHINERY C O R P. M A N A G E R O F TECHNICAL SERVICES

246 ALPHA DRIVE

PITTSBURGH, PENNSYLVANIA 15238

(IN CANADA: 644 IMPERIAL ROAD, GUELPH, ONTARIO N1H 6M7)

W ARNING: FAILURE TO F O L L O W THESE RULES M AY RESULT IN SERIOUS PERSONAL INJURY

1. F O R Y O U R O W N SAFETY, READ INSTRUCTION M A N U A L BEFORE O P E R ATING THE TO O L. Learn the tool s application and limitations as well as the specific hazards peculiar to it.

2.KEEP GUARDS IN PLACE and in working order.

3.ALW AYS W E A R EYE PROTECTION.

4.G R O U N D ALL TOOLS. If tool is equipped with threeprong plug, it should be plugged into a three-hole electrical receptacle. If an adapter is used to accommodate a twoprong receptacle, the adapter lug must be attached to a known ground. Never remove the third prong.

5.REMOVE ADJUSTING KEYS A N D WRENCHES. Form habit of checking to see that keys and adjusting wrenches are removed from tool before turning it on.

6. KEEP W O R K A R E A CLEAN. Cluttered areas and benches invite accidents.

7.DON T USE IN DANGEROUS ENVIRONMENT. Don t use power tools in damp or wet locations, or expose them to rain. Keep work area well-lighted.

8.KEEP CHILDREN A N D VISITO R S AW AY.All children and visitors should be kept a safe distance from work area.

9. M A K E W O R K S H O P CHILDPROOF with padlocks, master switches, or by removing starter keys.

10. DON T FORCE TO O L. It will do the job better and be safer at the rate for which it was designed.

11.USE RIGHT TO O L. Don t force tool or attachment to do a job for which it was not designed.

12.W E A R PROPER APPAREL. No loose clothing, gloves, neckties, rings, bracelets, or other jewelry to get caught in moving parts. Nonslip footwear is recommended. Wear protective hair covering to contain long hair.

13.ALW AYS USE SAFETY GLASSES.W ear safety glasses. Everyday eyeglasses only have impact resistant lenses; they are not safety glasses. Also use face or dust mask if cutting operation is dusty.

14.SECURE W O R K. Use clamps or a vise to hold work when practical. It s safer than using your hand and frees both hands to operate tool.

15. DON T OVERREACH. Keep proper footing and balance at all times.

16. MAINTAIN TO O L S IN TO P CONDITION. Keep tools sharp and clean for best and safest performance. Follow instructions for lubricating and changing accessories.

17.DISCONNECT TO O L S before servicing and when changing accessories such as blades, bits, cutters, etc.

18.USE RECOMMENDED ACCESSORIES. The use of accessories and attachments not recommended by Delta may cause hazards or risk of injury to persons.

19.R E D U C E THE RISK O F UNINTENTIONAL STA R T- ING. Make sure switch is in OFF position before plugging in power cord.

20.NEVER STA N D O N TO O L. Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted.

21.CHECK D A M A G E D PARTS. Before further use of the tool, a guard or other part that is damaged should be carefully checked to ensure that it will operate properly and

perform its intended function check for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced.

22. DIRECTION O F FEED.Feed work into a blade or cutter against the direction of rotation of the blade or cutter only.

23. NEVER LEAVE TO O L RUNNING UNATTENDED. TURN P O W E R OFF. Don t leave tool until it comes to a complete stop.

24. DRUGS, ALCOHOL, MEDICATION. Do not operate tool while under the influence of drugs, alcohol or any medication.

25. M A K E SURE TO O L IS DISCONNECTED FROM POWER SUPPLY while motor is being mounted, connected or reconnected.

26. W ARNING: The dust generated by certain woods and wood products can be injurious to your health. Always operate machinery in well ventilated areas and provide for proper dust removal. Use wood dust collection systems whenever possible.

3

ADDITIONAL SAFETY RULES FOR RANDOM ORBITAL SANDERS

1. W ARNING: D O N O T operate your random orbital sander until it is completely assembled and installed according to the instructions.

2.IF Y O U A R E N O T thoroughly familiar with the operation of the random orbital sander, obtain advice from your supervisor, instructor or other qualified person.

3.USE FA C E O R DUST MASK. WARNING: The dust generated by certain woods and wood products can be injurious to your health. ALW AYS operate machinery in well-ventilated areas and provide for proper dust removal. USE wood dust collection systems whenever possible. Sanding of Lead-based paintis N O T RECOMMENDED.

4.KEEP fingers away from rotating abrasive disc.

5.M A K E SURE abrasive disc is not damaged and is properly secured on the disc plate before operating.

6.NEVER perform layout, assembly or set-up work on thetable while the sander is operating.

7.M A K E SURE workpiece is clear of abrasive disc before turning unit on.

8.KEEP W O R K AREA CLEAN. Cluttered areas can create slipping or tripping hazards.

9.DON T FORCE TO O L. It will do the job better and be safer at the rate for which it was designed.

10.NEVER use machine for wet sanding which can create hazard of electrical shock.

11.USE correctly sized abrasive disc. Maintain minimum table opening to keep fingers from being pinched or workpiece being pulled down.

12.D O N O T sand near flammable liquids, vapors, or gases.

13.ALW AYS support workpiece on work table. USE sander on a solid supporting surface where there is plenty of room for handling and supporting workpiece.

14. CLEAR all debris from table before sanding the workpiece.

15. D O N O T use this sander to sand pieces too small to be held safely and securely by hand.

16.ALW AYS W E A R PROPER EYE PROTECTION.

17.THE USE ofattachments and accessories not recommended by Delta may result in the risk of injuries.

18.PROTECT Y O U R EARS. W ear proper hearing protection.

19.AFTER turning off power switch, disconnect tool from power source and wait for sander to stop before servicing.

20.D O N O T wear gloves, neckties, jewelry or loose clothing.

21.MAINTAIN minimum clearance between abrasive disc and fence.

22.AVOID KICKBACKS by sanding left of disc center, holding workpiece firmly, and using support fence when possible.

23.KEEP hands and fingers out of dust chute.

24.D O N O T expose to rain or use in damp locations.

25.DISCONNECT MACHINE F R O M P O W E R SOURCE BEFORE MAKING REPAIRS O R ADJUSTMENTS.

26.ADDITIONAL INFORMATION regarding the safe and proper operation of this product is available from the National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201, in the Accident Prevention Manual for Industrial Operations and also in the Safety Data Sheets provided by the NSC. Please also refer to the American National Standards Institute ANSI 01.1 Safety Requirements for Woodworking Machinery and the U.S. Department of Labor OSHA 1910.213 Regulations.

27.S AVE THESE INSTRUCTIONS.Refer to them often and use them to instruct others.

U N PACKING A N D CLEANING

Your new random orbital sander is shipped complete in one container.Carefully unpack the sander and all loose items from the shipping container. Clean all loose parts. Fig. 2, illustrates the sander and all loose parts supplied with the machine. If you purchased the accessory Model 50-780 Stand, Fig. 3 illustrates the components of the stand.

ASSEMBLY INSTRUCTIONS

W ARNING: F O R Y O U R O W N SAFETY, DO N O T CONNECT THE SANDER TO A P O W E R S O U R C E UNTIL THE MACHINE IS COMPLETELY ASSEMBLED A N D Y O U H AV E R E A D A N D UNDERSTO O D THE ENTIRE O W N E R S MANUAL. NOTE: Place the machine on a firm supporting surface and proceed with the assembly instructions. If you purchased the accessory 50-780 Steel Stand, this manual also contains instructions for its assembly.

4

Loading...

Loading...