Page 1

Machine Controller MP2000 Series

USER’S MANUAL

for Motion Programming

MANUAL NO. SIEP C880700 38C

Overview

Specifications

Program Development Flow

Motion Programs

Sequence Programs

Variables (Registers)

Programming

Command Reference

Engineering Tool MPE720

Troubleshooting

Appendices

1

2

3

4

5

6

7

8

9

10

App

Page 2

Copyright © 2008 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording,

or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed

with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this

manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this

publication.

Page 3

About This Manual

This manual provides information on motion commands for the MP2000 series Machine Control-

lers.

• Motion program overview

• Specifications

• Program development flow

• Motion programs and sequence programs

• Variables

• Programming

• Command reference

• Engineering tool MPE720

• Troubleshooting, etc.

Read this manual carefully to ensure the proper use of the MP2000 series Machine Controller.

Also, keep this manual in a safe place so that it can be referred to whenever necessary.

Using This Manual

Intended Audience

This manual is intended for the following users.

• Those responsible for designing the MP2000 series Machine Controller system

• Those responsible for writing MP2000 series Machine Controller motion programs and sequence programs

Engineering Tool MPE720 Version Number

In this manual, the operation of MPE720 is described using screenshots of MPE720 version 6.

For this reason, the screenshots and some descriptions may differ from those for MPE720 version 5.

Description of Abbreviation

In this manual, the following abbreviation is used.

• MP2000: Machine controller model including MP2100, MP2100M, MP2200, MP2300, MP2300S,

MP2310, MP2400, MP2500, MP2500M, MP2500D, and MP2500MD

Manuals for MP2000 Series

The user’s manuals are prepared by classifying MP2000 series Machine Controller models into

MP2100, MP2100M, MP2200, MP2300, MP2300S, MP2310, MP2400, MP2500, MP2500M,

MP2500D, and MP2500MD.

Refer to Related Manuals on the next page as required.

iii

Page 4

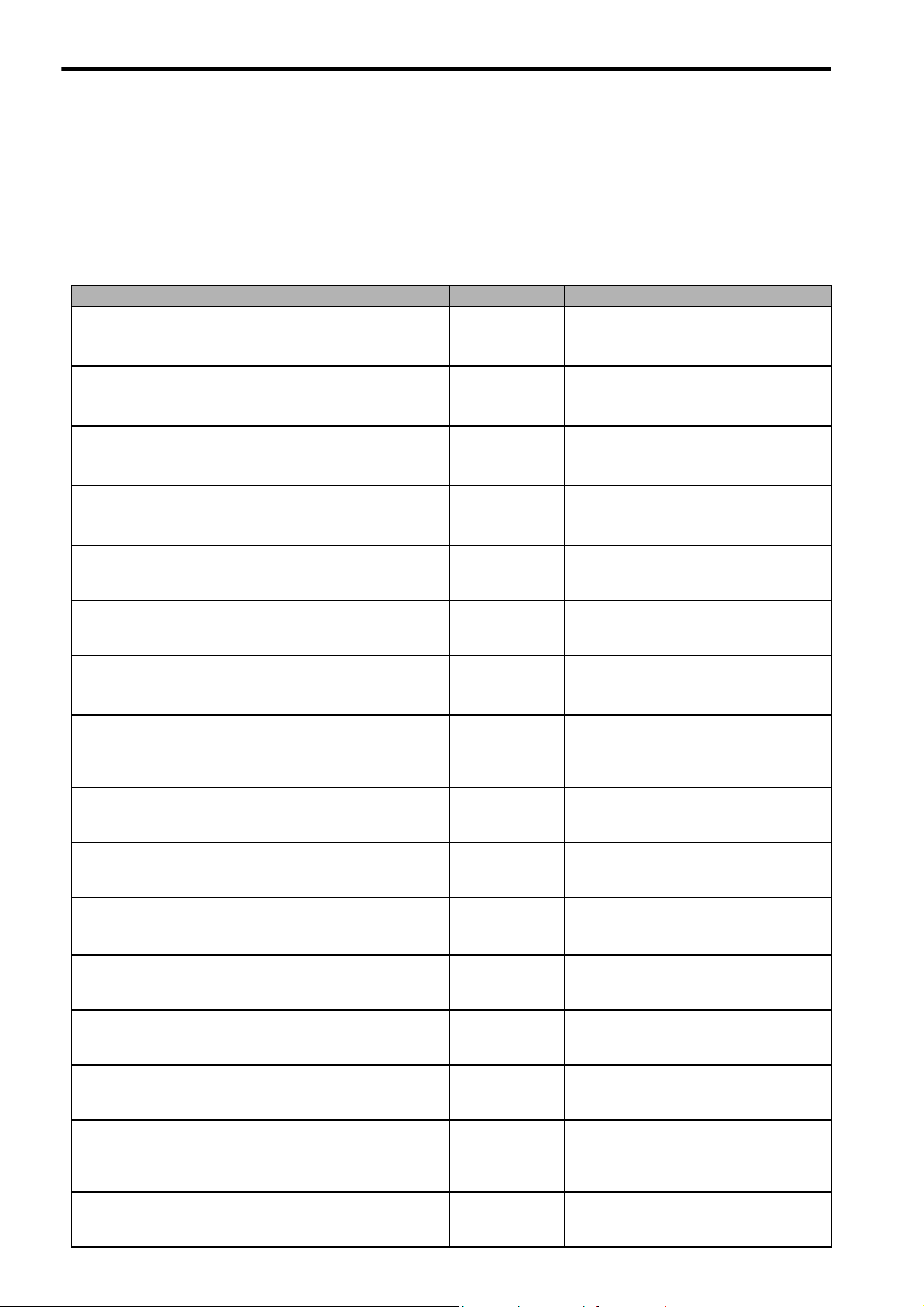

Related Manuals

The following table lists the related manuals. Refer to these manuals as required.

Before using, be sure you understand the product conditions, including specifications and usage

restrictions.

Manual Name Manual Number Contents

Machine Controller MP2100/MP2100M User’s Manual SIEPC88070001

Machine Controller MP2200 User’s Manual SIEPC88070014

Machine Controller MP2300 Basic Module User’s Manual SIEPC88070003

Machine Controller MP2300S Basic Module User’s Manual SIEPC88073200

Machine Controller MP2310 Basic Module

User’s Manual

Machine Controller MP2400 User’s Manual SIJPC88074200

Machine Controller MP2500/MP2500M/MP2500D/

MP2500MD User’s Manual

Machine Controller MP2000 series SVB/SVB-01

Motion Module User's Manual

Machine Controller MP2000 Series Motion Module SVA-01

User’s Manual

Machine Controller MP2000 Series Pulse Output Motion

Module PO-01 User’s Manual

Machine Controller MP2000 Series Communication Module

User’s Manual

Engineering Tool for Machine Controller MP2000 Series

MPE720 Version 6 User’s Manual

Machine Controller MP900/MP2000 Series MPE720

Software for Programming Device User’s Manual

Machine Controller MP900/MP2000 Series User’s Manual,

Ladder Programming

Machine Controller MP900/MP2000 Series

New Ladder Editor User’s Manual

Programming Manual

Machine Controller MP900/MP2000 Series

New Ladder Editor User’s Manual

Operation

SIEPC88073201

SIEPC88075200

SIEPC88070033

SIEPC88070032

SIEPC88070028

SIEPC88070004

SIEPC88070030

SIEPC88070005

SIEZ-C887-1.2

SIEZ-C887-13.1

SIEZ-C887-13.2

Describes the functions, specifications, setup

procedures, and operating methods of the

MP2100/MP2100M.

Describes the functions, specifications, setup

procedures, and operating methods of the

MP2200.

Describes the functions, specifications, setup

procedures, and operating methods of the

MP2300.

Describes the functions, specifications, setup

procedures, and operating methods of the

MP2300S.

Describes the functions, specifications, setup

procedures, and operating methods of the

MP2310.

Describes the functions, specifications, setup

procedures, and operating methods of the

MP2400.

Describes the functions, specifications, setup

procedures, and operating methods of the

MP2500/MP2500M/MP2500D/MP2500MD.

Describes the functions, specifications, and

application methods of the MP2000-series

Motion Module that is built into the SVB and

SVB-01 Module.

Describes the functions, specifications, and

operating methods of MP2000-series Motion

Module SVA-01.

Describes the functions, specifications, and

operating methods of MP2000-series Motion

Module PO-01.

Describes the functions, specifications, and

application methods of the MP2000 series

Communication Modules.

Describes the installation and operation of

the programming software MPE720 for

MP2000 series.

Describes the installation and operation of

the programming software MPE720 for

MP900/MP2000 series.

Describes the processing instructions used in

MP900/MP2000 series Machine Controller

ladder programs.

Describes

the New Ladder Editor, whic

MP900/MP2000-series design and maintenance.

Describes the operating methods of the New

Ladder Editor, which assists MP900/

MP2000-series design and maintenance.

the programming instructions of

h assists

iv

Page 5

Visual Aids

IMPORTANT

EXAMPLE

INFO

TERMS

CAUTION

PROHIBITED

MANDATORY

The following aids are used to indicate certain types of information for easier reference.

Indicates important information that should be memorized, including precautions such as alarm displays to

avoid damaging the devices.

Indicates supplemental information.

Indicates application examples.

Indicates definitions of difficult terms or terms that have not been previously explained in this manual.

Safety Information

The following conventions are used to indicate precautions in this manual. Information marked as shown

below is important for the safety of the user. Always read this information and heed the precautions that are

provided. The conventions are as follows:

WARNING

Indicates precautions that, if not heeded, could possibly result in loss of life or serious injury.

Indicates precautions that, if not heeded, could result in relatively serious or minor injury,

or property damage.

If not heeded, even precautions classified under can lead to serious

results depending on circumstances.

Indicates prohibited actions. Specific prohibitions are indicated inside .

For example, indicates no fire or open flame.

Indicates mandatory actions. Specific actions are indicated inside .

For example, indicates that grounding is required.

CAUTION

v

Page 6

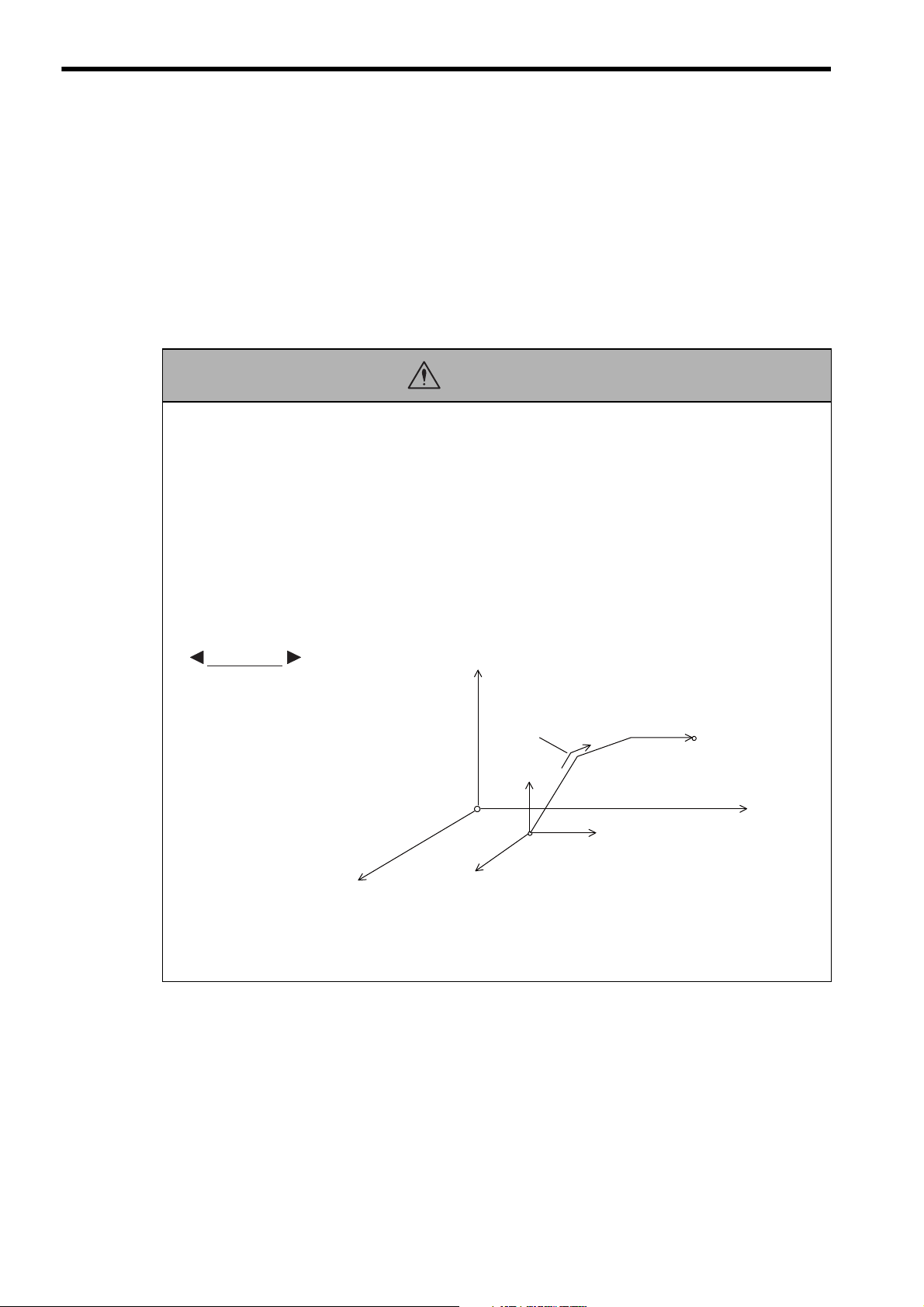

EXAMPLE

Safety Precautions

This section describes important precautions that apply to motion programming. Before programming,

always read this manual and all other attached documents to ensure correct programming.

Before using the equipment, familiarize yourself with equipment details, safety information, and all other

precautions.

Application Precautions

CAUTION

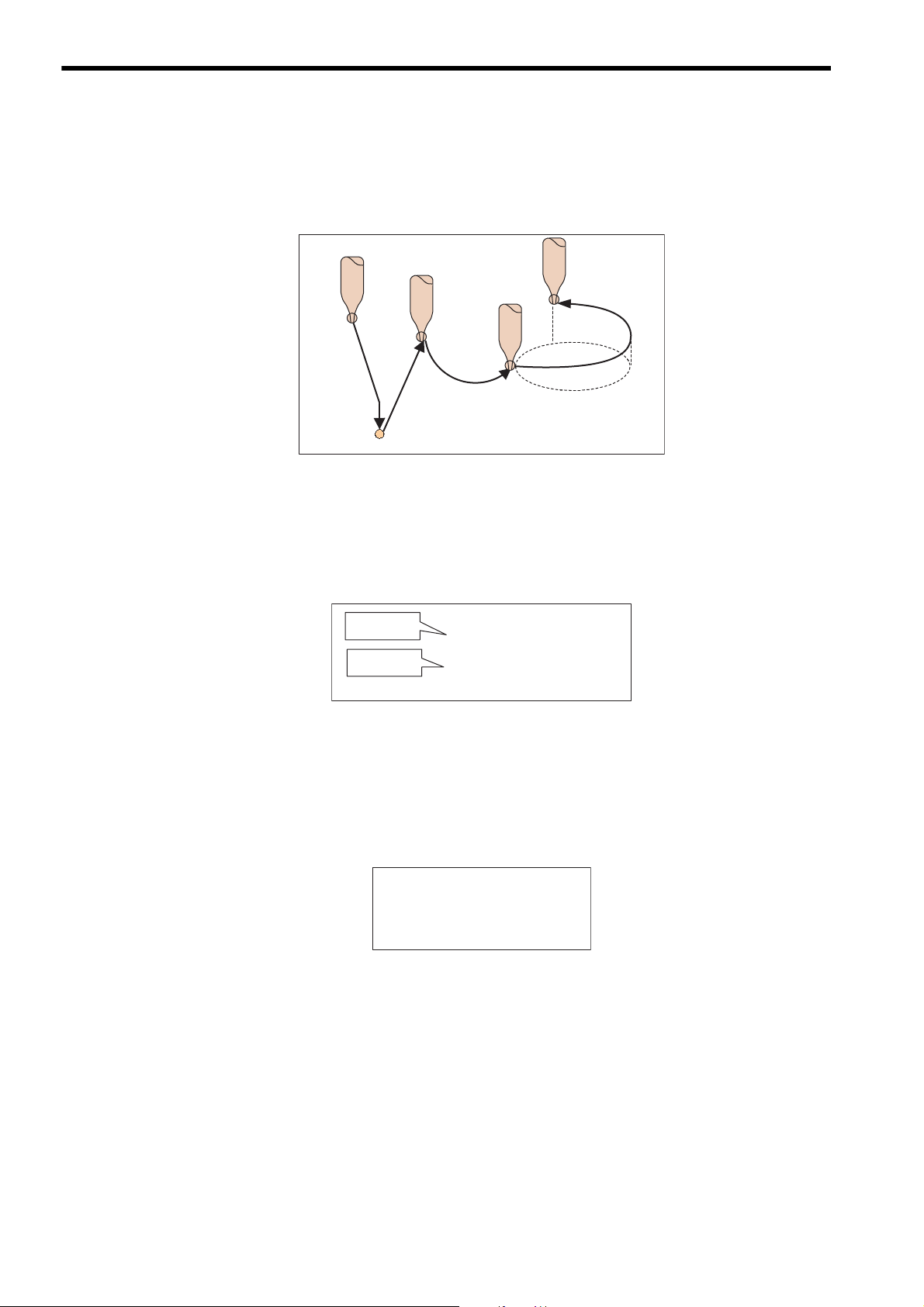

• When programming the following axis move commands, check the path to make sure that there are no

tools or other obstacles in the way of the workpiece.

The axis move commands that must be checked are as follows:

• Positioning (MOV)

• Linear Interpolation (MVS)

• Circular Interpolation (MCC, MCW)

• Helical Interpolation (MCC, MCW)

• Set Time Positioning (MVT)

• Linear Interpolation with Skip Function (SKP)

• Zero Point Return (ZRN)

• External Positioning (EXM)

axis 3

Each axis is moved

independently at rapid

traverse speed.

axis 3

Current position

axis 2

Failure to carry out the above checks may result in damage to equipment, serious personal injury,

or even death.

axis 2

Example of Basic Path for Positioning (MOV)

Positioning

axis 1

End position

axis 1

vi

Page 7

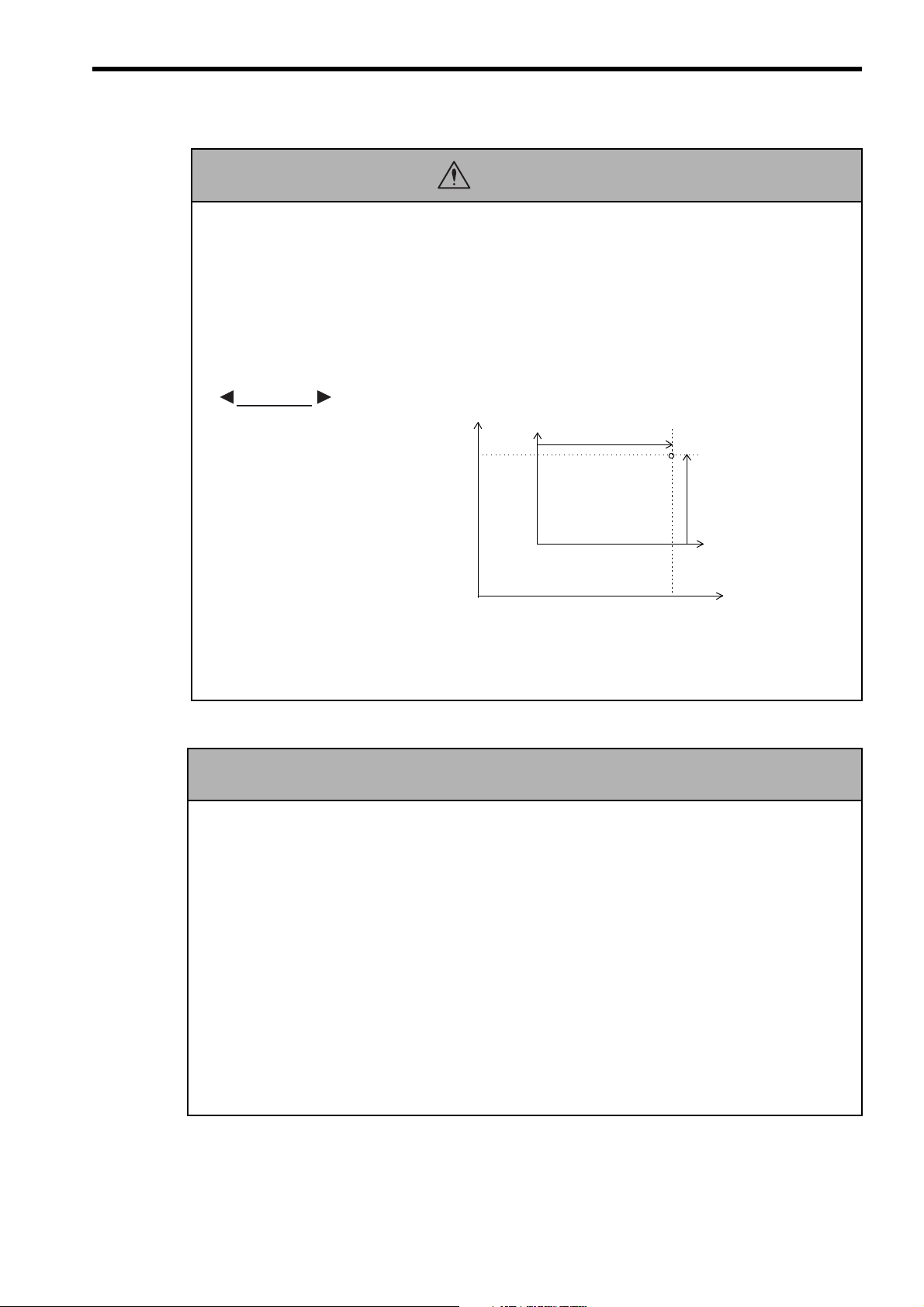

• If the following coordinate commands are designated incorrectly, the subsequent move operations will

CAUTION

be entirely different than those expected. Before starting operations, be sure to check that the settings

are designated correctly.

The coordinate commands that must be checked are as follows:

• Absolute Programming Mode (ABS)

• Incremental Programming Mode (INC)

• Current Position Set (POS)

• Move ON Machine Coordinates (MVM)

EXAMPLE

axis 2

axis 2

(axis 1)

Current position

(axis 2)

Failure to carry out the above checks may result in damage to equipment, serious personal injury, or even death.

General Precautions

• MP2000-series Machine Controller was not designed or manufactured for use in devices or systems directly

related to human life. Users who intend to use the product described in this manual for special purposes such as

devices or systems relating to transportation, medical, space aviation, atomic power control, or underwater use

must contact Yaskawa Electric Corporation beforehand.

• MP2000-series Machine Controller has been manufactured under strict quality control guidelines.

However, if this product is to be installed in any location in which a failure of MP2000-series Machine Controller involves a life and death situation or in a facility where failure may cause a serious accident, safety devices

MUST be installed to minimize the likelihood of any accident.

• Drawings and photos in this manual show typical product examples that may differ somewhat from the product

delivered.

• We will update the data sheet number for the manual and issue revisions when changes are made. The edition

number of the revised manual appears on the back of the manual.

• Contact your Yaskawa representative and quote the data sheet number on the front page of the manual if you

need to replace a manual that was lost or destroyed.

• Contact your Yaskawa representative to order new nameplates whenever a nameplate becomes worn or damaged.

(0, 0)

(0, 0)

Example of Work Coordinate System Created with

Machine coordinate system

Workpiece coordinate system

Current Position Set (POS)

Observe the following general precautions

to ensure safe application.

axis 1

axis 1

vii

Page 8

Warranty

(1) Details of Warranty

Warranty Period

The warranty period for a product that was purchased (hereinafter called “delivered product”) is one year

from the time of delivery to the location specified by the customer or 18 months from the time of shipment

from the Yaskawa factory, whichever is sooner.

Warranty Scope

Yaskawa shall replace or repair a defective product free of charge if a defect attributable to Yaskawa occurs

during the warranty period above. This warranty does not cover defects caused by the delivered product

reaching the end of its service life and replacement of parts that require replacement or that have a limited

service life.

This warranty does not cover failures that result from any of the following causes.

1. Improper handling, abuse, or use in unsuitable conditions or in environments not described in product catalogs or manuals, or in any separately agreed-upon specifications

2. Causes not attributable to the delivered product itself

3. Modifications or repairs not performed by Yaskawa

4. Abuse of the delivered product in a manner in which it was not originally intended

5. Causes that were not foreseeable with the scientific and technological understanding at the time of shipment from Yaskawa

6. Events for which Yaskawa is not responsible, such as natural or human-made disasters

(2) Limitations of Liability

1. Yaskawa shall in no event be responsible for any damage or loss of opportunity to the customer that arises

due to failure of the delivered product.

2. Yaskawa shall not be responsible for any programs (including parameter settings) or the results of program execution of the programs provided by the user or by a third party for use with programmable

Yaskawa products.

3. The information described in product catalogs or manuals is provided for the purpose of the customer purchasing the appropriate product for the intended application. The use thereof does not guarantee that there

are no infringements of intellectual property rights or other proprietary rights of Yaskawa or third parties,

nor does it construe a license.

4. Yaskawa shall not be responsible for any damage arising from infringements of intellectual property

rights or other proprietary rights of third parties as a result of using the information described in catalogs

or manuals.

viii

Page 9

(3) Suitability for Use

1. It is the customer’s responsibility to confirm conformity with any standards, codes, or regulations that

apply if the Yaskawa product is used in combination with any other products.

2. The customer must confirm that the Yaskawa product is suitable for the systems, machines, and equipment used by the customer.

3. Consult with Yaskawa to determine whether use in the following applications is acceptable. If use in the

application is acceptable, use the product with extra allowance in ratings and specifications, and provide

safety measures to minimize hazards in the event of failure.

• Outdoor use, use involving potential chemical contamination or electrical interference, or use in conditions or environments not described in product catalogs or manuals

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, vehicle systems, medical equipment, amusement machines, and installations subject to separate industry or government regulations

• Systems, machines, and equipment that may present a risk to life or property

• Systems that require a high degree of reliability, such as systems that supply gas, water, or electricity,

or systems that operate continuously 24 hours a day

• Other systems that require a similar high degree of safety

4. Never use the product for an application involving serious risk to life or property without first ensuring

that the system is designed to secure the required level of safety with risk warnings and redundancy, and

that the Yaskawa product is properly rated and installed.

5. The circuit examples and other application examples described in product catalogs and manuals are for

reference. Check the functionality and safety of the actual devices and equipment to be used before using

the product.

6. Read and understand all use prohibitions and precautions, and operate the Yaskawa product correctly to

prevent accidental harm to third parties.

(4) Specifications Change

The names, specifications, appearance, and accessories of products in product catalogs and manuals may be

changed at any time based on improvements and other reasons. The next editions of the revised catalogs or

manuals will be published with updated code numbers. Consult with your Yaskawa representative to confirm

the actual specifications before purchasing a product.

ix

Page 10

Contents

About This Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iii

Using This Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iii

Manuals for MP2000 Series - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iii

Related Manuals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iv

Visual Aids- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - v

Safety Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - v

Safety Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vi

Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

1 Overview

1.1 What is a Motion Program? - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2 Motion Program Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.2.1 Execution Method- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-3

1.2.2 Motion Control in Full Synchronization with Sequence Control - - - - - - - - - - - - - - - - - - - - - - -1-3

1.2.3 Easy to Realize High-level Motion Control- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-4

1.2.4 Easy-to-Understand Motion Language - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-4

1.2.5 Arithmetic Operations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-4

1.2.6 Data Transfer from/to Ladder Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-5

1.2.7 Memory Usage Reduced by Use of Subprograms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-5

1.2.8 Parallel Program Execution - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-6

1.2.9 Program Online Editing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-6

1.2.10 Enriched Easy Programming Functions (MPE720 Ver.6.04 or later) - - - - - - - - - - - - - - - - - - -1-7

1.3 Motion Program Execution Sequence- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

1.4 Motion Program Execution Registration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9

1.5 Motion Program Execution Timing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

1.6 Grouping - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1.7 Application Examples - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-12

1.7.1 Example 1: Handling System- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-12

1.7.2 Example 2: Mechanical Parts Inserting Machine - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-12

1.7.3 Example 3: Panel Processing Machine - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-13

1.7.4 Example 4: Metal Sheet Bending Equipment- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-13

1.8 What is a Sequence Program? - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-14

1.9 Sequence Program Features- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-15

1.9.1 Execution Method- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-15

1.9.2 Programming Language Commonly Used in Motion Programs - - - - - - - - - - - - - - - - - - - - - - 1-15

1.9.3 Data Transfer from/to Motion Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-15

1.9.4 Memory Usage Reduced by Use of Subprograms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-16

1.9.5 Easy Programming Functions (MPE720 Ver.6.04 or later) - - - - - - - - - - - - - - - - - - - - - - - - -1-16

x

Page 11

2 Specifications

2.1 MP2000 Series Machine Controller Specifications - - - - - - - - - - - - - - - - - - - - - - 2-2

2.1.1 Applicable Machine Controller Models- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.1.2 Applicable Motion Modules- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.1.3 List of Machine Controller Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

2.2 Engineering Tool MPE720 Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.2.1 Applicable Version Numbers of the Engineering Tool MPE720- - - - - - - - - - - - - - - - - - - - - - - 2-5

2.2.2 List of Engineering Tool MPE720 Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.3 List of Motion Language Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

3 Program Development Flow

3.1 Program Development Flow - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.2 Program Development Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

3.2.1 Hardware Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

3.2.2 Installing MPE720 Version 6- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

3.2.3 Communication Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

3.2.4 System Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

3.2.5 Creating Project Files - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

3.2.6 Group Definitions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-5

3.2.7 Creating a Motion Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

3.2.8 Registering the Program Execution - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7

3.2.9 Transferring the Motion Program- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-10

3.2.10 Debugging the Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-12

3.2.11 Saving the Programs in Flash Memory- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-13

3.2.12 Executing the Programs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-14

4 Motion Programs

4.1 Types of Motion Programs- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

4.2 Motion Programs For Each Axis Group- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

4.3 Running a Motion Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

4.3.1 How to Run a Motion Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

4.3.2 Registering the Program Execution - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-5

4.3.3 Work Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-6

4.4 Advanced Programming - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-11

4.4.1 Indirect Designation of a Program Number Using a Register - - - - - - - - - - - - - - - - - - - - - - - 4-11

4.4.2 Controlling the Motion Program Directly from an External Device- - - - - - - - - - - - - - - - - - - - 4-12

4.4.3 Monitor the Motion Program Execution Information Using S Register - - - - - - - - - - - - - - - - - 4-13

xi

Page 12

5 Sequence Programs

5.1 Sequence Program Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.2 How to Run a Sequence Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

5.2.1 How to Run a Sequence Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-3

5.2.2 Registering Program Execution - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-4

5.2.3 Work Register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-5

6 Variables (Registers)

6.1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

6.1.1 Variable Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-2

6.1.2 Global Variables and Local Variables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-4

6.2 Using Variables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-7

6.2.1 System Variables (S Registers) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-7

6.2.2 Data Variables (M Registers) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-8

6.2.3 Input Variables (I Registers)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-9

6.2.4 Output Variables (O Registers) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-11

6.2.5 C Variables (C Registers) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-13

6.2.6 D Variables (D Registers) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-14

6.3 How to Use Subscripts i, j - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-15

7 Programming

7.1 Motion Program Format - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

7.1.1 Motion Program Structure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-2

7.1.2 Block Format - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-2

7.1.3 Using Constants and Variables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-7

7.2 Motion Module Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-9

7.2.1 Axis Type Selection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-9

7.2.2 Reference Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-9

7.2.3 Electronic Gear - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-10

7.2.4 Speed Reference - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-12

7.2.5 Acceleration/Deceleration Setting- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-12

7.3 Group Definition - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-13

7.4 Priority Levels of Operations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-15

7.5 Commands and Execution Scans - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-17

7.5.1 Command Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-17

7.5.2 List of Command Types- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-18

xii

7.6 Sequence Program Format - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-19

Page 13

8 Command Reference

8.1 Axis Setting Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-3

8.1.1 Absolute Mode (ABS) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-3

8.1.2 Incremental Mode (INC)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-7

8.1.3 Acceleration Time Change (ACC) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-11

8.1.4 Deceleration Time Change (DCC)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-17

8.1.5 S-curve Time Constant Change (SCC) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-23

8.1.6 Set Velocity (VEL) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-29

8.1.7 Maximum Interpolation Feed Speed Setting (FMX)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-35

8.1.8 Interpolation Feed Speed Ratio Setting (IFP) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-37

8.1.9 Interpolation Acceleration Time Change (IAC) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-40

8.1.10 Interpolation Deceleration Time Change (IDC) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-43

8.2 Axis Move Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-46

8.2.1 Positioning (MOV) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-46

8.2.2 Linear Interpolation (MVS) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-50

8.2.3 Clockwise/Counterclockwise Circular Interpolation with Center Position Designation

(MCW, MCC) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-55

8.2.4 Clockwise/Counterclockwise Circular Interpolation with Radius Designation (MCW, MCC) - - 8-61

8.2.5 Clockwise/Counterclockwise Helical Interpolation with Center Position Designation

(MCW, MCC) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-65

8.2.6 Clockwise/Counterclockwise Helical Interpolation with Radius Designation (MCW, MCC) - - 8-68

8.2.7 Zero Point Return (ZRN) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-70

8.2.8 Linear Interpolation with Skip Function (SKP)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-72

8.2.9 Set Time Positioning (MVT) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-74

8.2.10 External Positioning (EXM)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-76

8.3 Axis Control Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-78

8.3.1 Current Position Set (POS) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-78

8.3.2 Move On Machine Coordinates (MVM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-80

8.3.3 Program Current Position Update (PLD) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-81

8.3.4 In-Position Check (PFN) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-82

8.3.5 Set In-Position Range (INP) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-84

8.3.6 Coordinate Plane Setting (PLN) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-86

8.4 Program Control Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-87

8.4.1 Branching Commands (IF ELSE IEND) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-87

8.4.2 Repeat (WHILE WEND) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-89

8.4.3 Parallel Execution (PFORK, JOINTO, PJOINT) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-92

8.4.4 Selective Execution (SFORK, JOINTO, SJOINT) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-95

8.4.5 Motion Subprogram Call (MSEE) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-99

8.4.6 Sequence Subprogram Call (SSEE) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-100

8.4.7 User Function Call From Motion Program (UFC) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-101

8.4.8 User Function Call from Sequence Program (FUNC) - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-109

8.4.9 Program End (END) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-110

8.4.10 Subprogram End (RET) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-111

8.4.11 Dwell Time (TIM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-112

8.4.12 I/O Variable Wait (IOW) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-113

8.4.13 One Scan Wait (EOX) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-115

xiii

Page 14

8.4.14 Single-block Signal Disabled (SNGD)/Single-block Signal Enabled (SNGE) - - - - - - - - - - - 8-116

8.5 Arithmetic Operations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-117

8.5.1 Substitute (=) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-117

8.5.2 Add (+) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-118

8.5.3 Subtract (-)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-119

8.5.4 Multiply (*) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-120

8.5.5 Divide (/) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-121

8.5.6 Remainder (MOD) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-122

8.6 Logic Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-123

8.6.1 OR (|) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-123

8.6.2 AND (&)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-125

8.6.3 XOR (^) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-126

8.6.4 NOT (!) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-127

8.7 Data Comparisons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-128

8.7.1 Data Comparison Commands (==, <>, >, <, >=, <=)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-128

8.8 Data Operations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-130

8.8.1 Bit Right Shift (SFR) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-130

8.8.2 Bit Left Shift (SFL) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-131

8.8.3 Block Move (BLK)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-132

8.8.4 Clear (CLR) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-133

8.8.5 ASCII Conversion 1 (ASCII)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-134

8.9 Basic Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-136

8.9.1 Sine (SIN) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-136

8.9.2 Cosine (COS)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-138

8.9.3 Tangent (TAN) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-139

8.9.4 Arc Sine (ASN)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-140

8.9.5 Arc Cosine (ACS) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-141

8.9.6 Arc Tangent (ATN) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-142

8.9.7 Square Root (SQT)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-143

8.9.8 BCD to Binary (BIN) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-145

8.9.9 Binary to BCD (BCD) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-146

8.9.10 Set Bit (S{ }) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-147

8.9.11 Reset Bit (R{ }) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-148

8.9.12 Rising Pulse (PON)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-149

8.9.13 Falling Pulse (NON) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-151

8.9.14 ON-Delay Timer (TON): Counting unit: 0.01 second - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-154

8.9.15 OFF-Delay Timer (TOF):Counting unit: 0.01 second- - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-156

xiv

8.10 C-Language Control Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-158

8.10.1 C-Language Task Control (CTSK) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-158

8.10.2 C-Language Function Call (CFUNC)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-160

Page 15

9 Engineering Tool MPE720

9.1 Motion Editor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

9.1.1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

9.1.2 Names and Descriptions of Motion Editor Window Components - - - - - - - - - - - - - - - - - - - - - 9-4

9.2 Command Input Assistant Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-6

9.2.1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-6

9.2.2 Motion Command Assist Dialog Box Details- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-8

9.3 Program Execution Registration Function - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-12

9.3.1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-12

9.3.2 Program Execution Registry Screen Dialog Box Details - - - - - - - - - - - - - - - - - - - - - - - - - - 9-13

9.4 Debug Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-15

9.4.1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-15

9.4.2 Motion Editor Window during Debugging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-16

9.5 Motion Task Manager - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-22

9.5.1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-22

9.5.2 Motion Task Manager Window Details - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-23

9.6 Drive Control Panel- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-24

9.6.1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-24

9.6.2 Drive Control Panel Details- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-26

9.7 Test Run Function- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-28

9.7.1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-28

9.7.2 Test Run Window Details - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-29

9.8 Axis Status and Alarm Monitor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-31

9.8.1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-31

9.8.2 Monitor Window Details - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-33

10 Troubleshooting

10.1 Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-2

10.1.1 Basic Flow of Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-2

10.2 Troubleshooting for Motion Programs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-3

10.2.1 Error Investigation Flow - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-3

10.2.2 Problem Starting a Motion Program- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-4

10.2.3 Confirming the Alarm Code - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-9

10.2.4 Motion Program Alarm Codes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-15

10.3 Troubleshooting for Sequence Programs - - - - - - - - - - - - - - - - - - - - - - - - - 10-17

10.3.1 Error Investigation Flow - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-17

10.3.2 Problem Starting a Sequence Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-18

xv

Page 16

Appendices

A Motion Language Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-2

A.1 Axis Setting Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-2

A.2 Axis Move Commands- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-3

A.3 Control Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-5

A.4 Program Control Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-6

A.5 Arithmetic Operations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-8

A.6 Logical Operations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-8

A.7 Data Comparison - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-9

A.8 Data Operations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-9

A.9 Basic Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-10

A.10 C-Language Control Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-11

B Sample Programs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-12

B.1 Programs for Controlling Motion Program Execution - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-13

B.2 Parallel Processing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-15

B.3 Motion Program for Speed Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-16

B.4 Simple Synchronized Operation Using a Virtual Axis - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-17

B.5 Sequence Programs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-19

C Differences between MP900 Series and MP2000 Series

Machine Controllers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-21

C.1 Motion Programs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-21

C.2 Sequence Programs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-21

C.3 Motion Programming Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-22

C.4 Group Definitions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-22

C.5 Debug Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-23

C.6 Motion Program Alarms- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-23

D Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-24

D.1 General Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-24

D.2 Precautions on Motion Parameter Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-24

Index

Revision History

xvi

Page 17

1

Overview

1

Overview

This chapter introduces motion programs and describes their features for those who are

unfamilier with them.

1.1 What is a Motion Program? - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2 Motion Program Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.2.1 Execution Method - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.2.2 Motion Control in Full Synchronization with Sequence Control - - - - - - - - - - - - - - - - - - 1-3

1.2.3 Easy to Realize High-level Motion Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.2.4 Easy-to-Understand Motion Language - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.2.5 Arithmetic Operations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.2.6 Data Transfer from/to Ladder Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

1.2.7 Memory Usage Reduced by Use of Subprograms - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

1.2.8 Parallel Program Execution - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

1.2.9 Program Online Editing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

1.2.10 Enriched Easy Programming Functions (MPE720 Ver.6.04 or later) - - - - - - - - - - - - - 1-7

1.3 Motion Program Execution Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

1.4 Motion Program Execution Registration - - - - - - - - - - - - - - - - - - - - - - - - - 1-9

1.5 Motion Program Execution Timing - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

1.6 Grouping - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1.7 Application Examples - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-12

1.7.1 Example 1: Handling System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-12

1.7.2 Example 2: Mechanical Parts Inserting Machine - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-12

1.7.3 Example 3: Panel Processing Machine - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-13

1.7.4 Example 4: Metal Sheet Bending Equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-13

1.8 What is a Sequence Program? - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-14

1.9 Sequence Program Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-15

1.9.1 Execution Method - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-15

1.9.2 Programming Language Commonly Used in Motion Programs - - - - - - - - - - - - - - - - 1-15

1.9.3 Data Transfer from/to Motion Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-15

1.9.4 Memory Usage Reduced by Use of Subprograms - - - - - - - - - - - - - - - - - - - - - - - - - 1-16

1.9.5 Easy Programming Functions (MPE720 Ver.6.04 or later) - - - - - - - - - - - - - - - - - - - - 1-16

1-1

Page 18

1 Overview

1.1 What is a Motion Program?

The motion program is a program written in motion language, Yaskawa’s unique textual language.

A motion program can be executed either by coding an MSEE command in a ladder program or by registering

the motion program in the program execution registry screen dialog box for the M-EXECUTOR Module.

Note: The M-EXECUTOR Module can not be used with the following modules and Machine Controllers:

MP2300, CPU-01, CPU-02

Apart from ladder programs, up to 256 motion programs can be created.

An example of a motion program is shown below.

The features of motion programs are described starting from the next page.

1-2

Page 19

1

Overview

1.2 Motion Program Features

Ladder program

(Scan execution)

Motion program

(Sequential execution)

One program

is executed

in a fixed

cycle.

IB00000 IB00001 OB00000

IB00002

IB00003

DB000005

IB00004 DB000006 OB00001

END

MOV [X]1000 [Y]2000;

MOV [X]-1000 [Y]-2000;

MVS [X]2000 [Y]1000 F30000;

END;

At the completion of

execution of one

move command,

the next command will

be executed.

Sequence Control Motion Control

(Motion Module)

Ladder program (High-speed scan)

MPM001

Motion program

Starts the motion

program

VEL [X]2000 [Y]2000;

ACC [X]100 [Y]100;

DCC [X]100 [Y]100;

MOV [X]0 [Y]0;

MVS [X]100.0 [Y]200.0;

Motion control in full

synchronization with

high-speed scans

Motion parameters

Set motion

parameters

Fully

synchronized

control

Position

control

Speed

control

Torque

control

1.2.1 Execution Method

A motion program employs an execution method that differs from the ladder program.

With a ladder program, processing from the program start to an END command is completed within one scan.

With a motion program, the processing requested by one command normally requires more than one scan.

Also, the commands are executed sequentially, in the order they are coded.

In this manual, the execution method of ladder program is referred to as Scan Execution, and that of a motion

program as Sequential Execution.

1.2 Motion Program Features

1.2.2 Motion Control in Full Synchronization with Sequence Control

The process written in a motion program is executed in full synchronization with high-speed scans of the

MP2000-series Machine Controller. The axis movement will start within one scan after the start request from the

ladder program, without any time lag to start the motion program.

1-3

Page 20

1 Overview

1.2.3 Easy to Realize High-level Motion Control

1.2.3 Easy to Realize High-level Motion Control

In addition to basic motion control, motion control that involves complicated movements can be easily realized

by using motion programs.

Positioning

Circular

interpolation

Linear

interpolation

Helical

interpolation

1.2.4 Easy-to-Understand Motion Language

A motion program employs intuitive motion language commands such as VEL to set a velocity and MOV for

positioning.

Set Velocity

Positioning

VEL [A1]1000 [B1]500;

MOV [A1]100 [B1]200;

1.2.5 Arithmetic Operations

The motion language includes commands for arithmetic operations and logical operations.

These commands allow you to include various calculations, such as calculation of target position in a motion program.

DL00000 = DL00002+DW00004;

DL00000 = DW00002

MW00000 = MW00000 & 00FFH;

MF00000 =

SIN(30.0);

DL00004;

*

1-4

Page 21

1

Overview

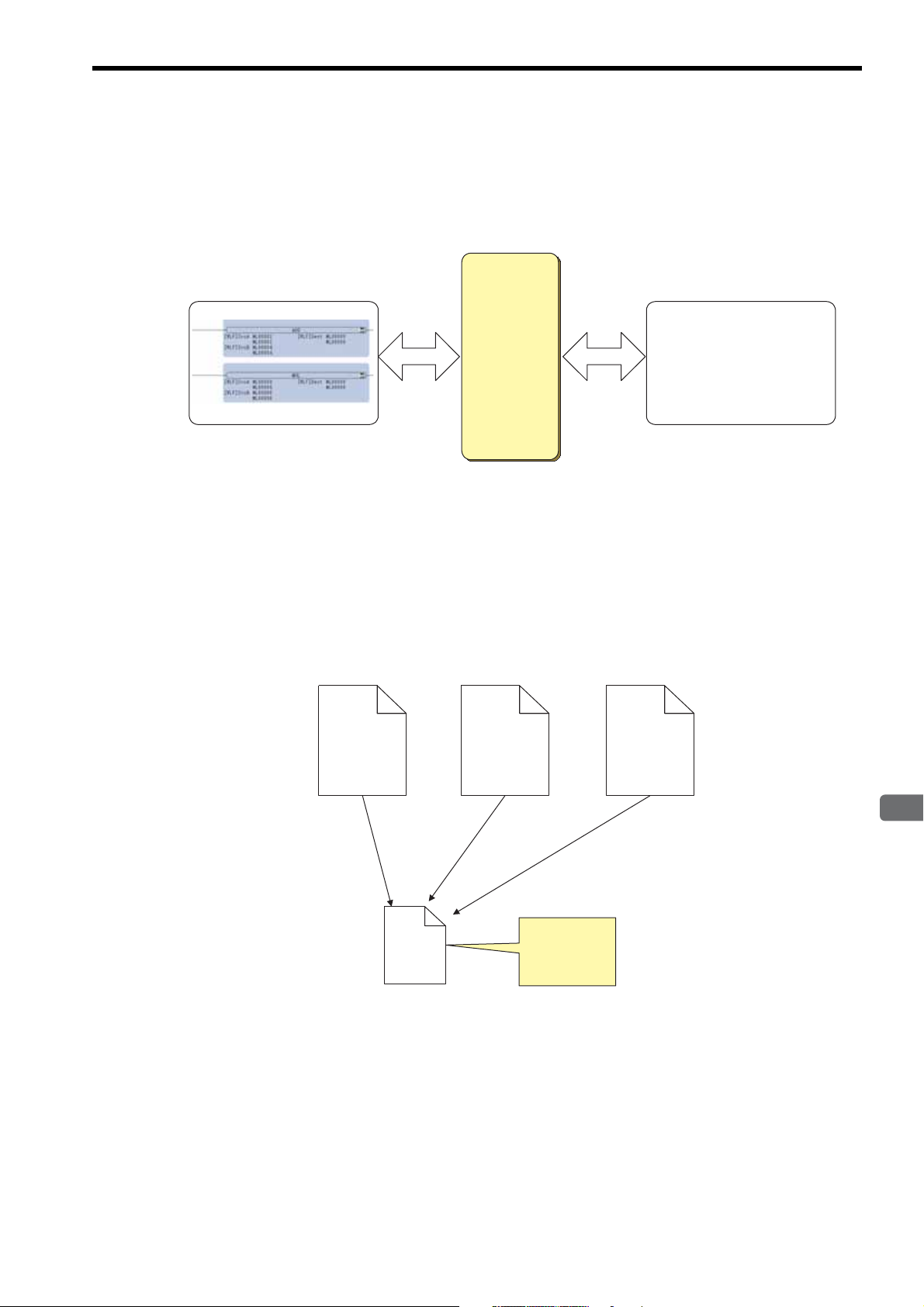

1.2.6 Data Transfer from/to Ladder Program

Data register

(M register)

MOV [A1] ML00000;

Ladder program

Motion program

Read Update

Read Update

Main program

MPM001

Main program

MPM002

Main program

MPM003

Subprogram

MPS010

Calling

(MSEE)

Write common

processing in a

subprogram.

Calling

(MSEE)

Calling

(MSEE)

Data can be transferred between a ladder program and motion program.

Data registers (M registers) are used to transfer the data.

In this way, a value updated in a ladder program can be used in a motion program, and vice versa

1.2 Motion Program Features

1.2.7 Memory Usage Reduced by Use of Subprograms

Subroutines (subprograms) can be created within a motion program.

The number of program steps can be minimized by creating a subprogram that includes a set of commands to

perform a repeated or regular task, thus reducing memory usage.

1-5

Page 22

1 Overview

MP2000series

Machine

Controller

Task 1

Task 2

Task 16

Processing 1

Subprogram

Processing

1-1

Processing

1-2

Processing 2

Processing 3

Processing 4

Task

Simultaneous

execution of

up to 16 tasks

Up to four main programs

can be executed

in parallel.

Up to two subprograms

can be executed in

parallel.

Offline editing

Online editing

Programming

Operation to transfer a program

to the Machine Controller

Debugging

INFO

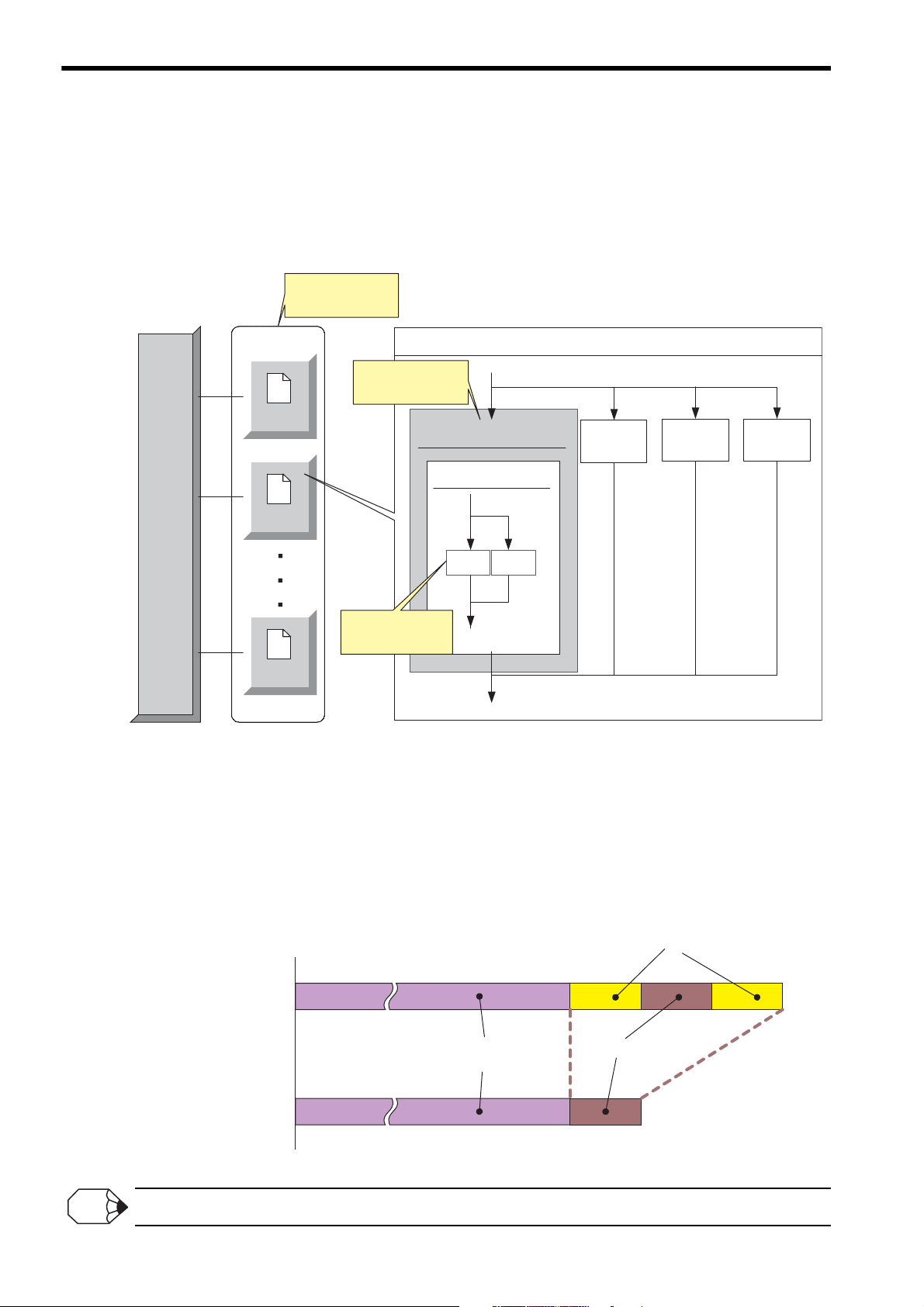

1.2.8 Parallel Program Execution

1.2.8 Parallel Program Execution

With a single MP2000-series Machine Controller, up to 16 tasks can be simultaneously executed using motion

programs. With one motion program, up to four main programs can be simultaneously executed. Additionally, up

to two subprograms can be simultaneously executed by calling subprograms from the main program. Multiple

different movements can be simultaneously controlled by using such the parallel program execution function.

1.2.9 Program Online Editing

Motion programs can be edited online in the same way as ladder programs.

Online editing refers to editing programs with the programming device logged on to the Machine Controller.

In online editing mode, the operation to save the edited program automatically transfers the saved program to the

Machine Controller. Thus, an operation to transfer to the Machine Controller is not required and program development efficiency is improved.

Online editing is disabled while a motion program is running.

1-6

Page 23

1.2 Motion Program Features

1

Overview

Test Run Function

Control the axes onscreen.

Program Execution Registration Function

Easily register programs to be executed in the system.

Operation Control Panel Function

Start motion programs from the Motion

Editor window.

Debug Function

Debug a motion program.

The debug commands, including step-by-step execution

and break point setting, are provided.

Axis Operation Monitor Function

View the motion status of each axis onscreen.

Command Input Assistant Function

Simply select a command and set data in the Motion

Command Assist dialog box to insert the command in

the editor.

Inserts the command

1.2.10 Enriched Easy Programming Functions (MPE720 Ver.6.04 or later)

The engineering tool MPE720 Ver.6 for MP2000-series Machine Controllers is provided with the following easy

programming functions.

1-7

Page 24

1 Overview

H

H01

H02

H01.01

H01.02

Ladder program

MP2000-series Machine Controller

M-EXECUTOR

Program Definition tab

Calling

Calling

Motion programs

SVR

Built-in

SVB

SVB-01

SVA-01

PO-01

Transfer the created programs

MSEE command

Motion Editor Window

Can call motion

programs without using

ladder program

Capable of storing

up to 256 programs

Motion parameters

MPE720

VEL [X]2000 [Y]2000;

ACC [X]100 [Y]100;

DCC [X]100 [Y]100;

MOV [X]0 [Y]0;

MVS [X]100.0 [Y]200.0;

ABS;

FMX T100000;

MVS [C1]300 [D1]400

F1000;

END;

MPM002

MPM001

Can call up to

16 programs at once

1.3 Motion Program Execution Sequence

The motion programs created on the MPE720 Motion Editor window are transferred to the MP2000-series

Machine Controller. The transferred motion programs can be called by MSEE commands coded in the ladder

program, or from the execution registry screen dialog box of the M-EXECUTOR Module. Motion commands are

sent to the motion module via the motion parameters to move axes.

The following diagram illustrates how motion programs created using the MPE720 are executed.

1-8

Page 25

1

Overview

1.4 Motion Program Execution Registration

INFO

M-EXECUTOR

Program definition

MPM001

INC;

VEL [A1]100 [B1]200;

MOV [A1]1000 [B1]2000;

END;

Motion program

Control registers

Calls

INFO

Execution of motion programs can be registered in two ways.

Calling a Motion Program from the Ladder Program

Code an MSEE command in an H drawing to call the motion program to run. An MSEE work register is used

to start/stop the called motion program. Motion programs can be called from any H drawing: parent drawing,

child drawing, or grandchild drawing.

DWG.H

Calls

INC;

VEL [A1]100 [B1]200;

1.4 Motion Program Execution Registration

Motion program

MPM001

Work register

Status

Control signal

Interpolation override

System work number

MOV [A1]1000 [B1]2000;

END;

In this manual, the high-speed processing drawing of a ladder program is referred to as H drawing.

Registering Motion Programs in M-EXECUTOR

Register motion programs in the M-EXECUTOR program execution definition. A control register (I/O register) is used to start or stop the registered motion program.

M-EXECUTOR is a software module to execute motion programs and sequence programs.

1-9

Page 26

1 Overview

Empty

I/O service

(Output)

H drawing

M-EXECUTOR

External device

Batch

output

Batch

input

MP2000-series CPU

Requests

to execute

Reports

Motion program

Status

Control signal

Subprogram

M-EXECUTOR

Requests

to execute

Reports

Status

Control signal

High-speed scan

High-speed scan

High-speed scan

I/O service

(Input)

Empty Empty

MSEE

END;

MPM001

RET;

MPS101

DWG.H

Motion program

Subprogram

MSEE

END;

MPM002

RET;

MPS102

System processing

Output (O)

register

Input (I)

register

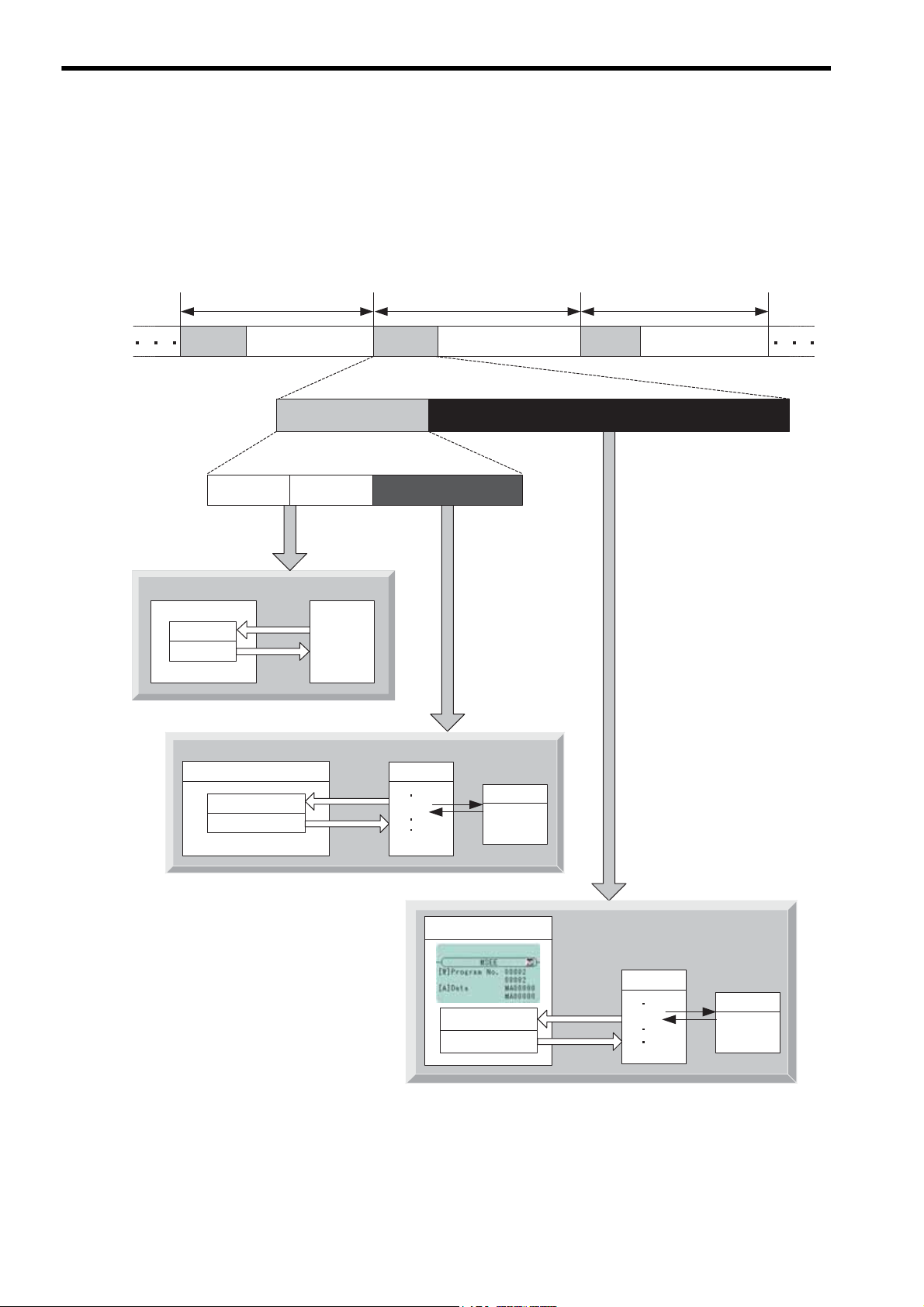

1.5 Motion Program Execution Timing

Motion programs are executed in full synchronization with MP2000 high-speed scans. In every high-speed scan

cycle, I/O services are performed first, and the motion program registered in M-EXECUTOR is executed.

Next, the motion program initiated in the MSEE command coded in the DWG.H is executed at the timing of the

MSEE command execution.

The following diagram illustrates motion program execution timing.

1-10

Page 27

1

Overview

1.6 Grouping

The axes involved in related operations are organized into individual groups. Motion programs can be created for

each group. This allows one MP2000-series Machine Controller to independently control multiple machines

using group operation. Group operation can be single group operation or multiple group operation.

Definitions for axes to be grouped together are made under Group Definitions.

Single Group Operation

1.6 Grouping

MP2000 series

Machine Controller

Multiple Group Operation

A1 B1 A2 D2 A3

SGDS

SGDS

A1 B1 C1 F1 G1

Group1

SGDS

SGDS

SGDS

MP2000 series

Machine Controller

SGDS

SGDS

G

roup1Group2Group3

SGDS

SGDS

SGDS

Groups are organized

in a tree structure.

1-11

Page 28

1 Overview

Pallet

Pallet

+

+

-

+

-

+

-

+

-

+

-

-

2

Printed

board

Stand

Parts tray

Robot 2

Robot 1

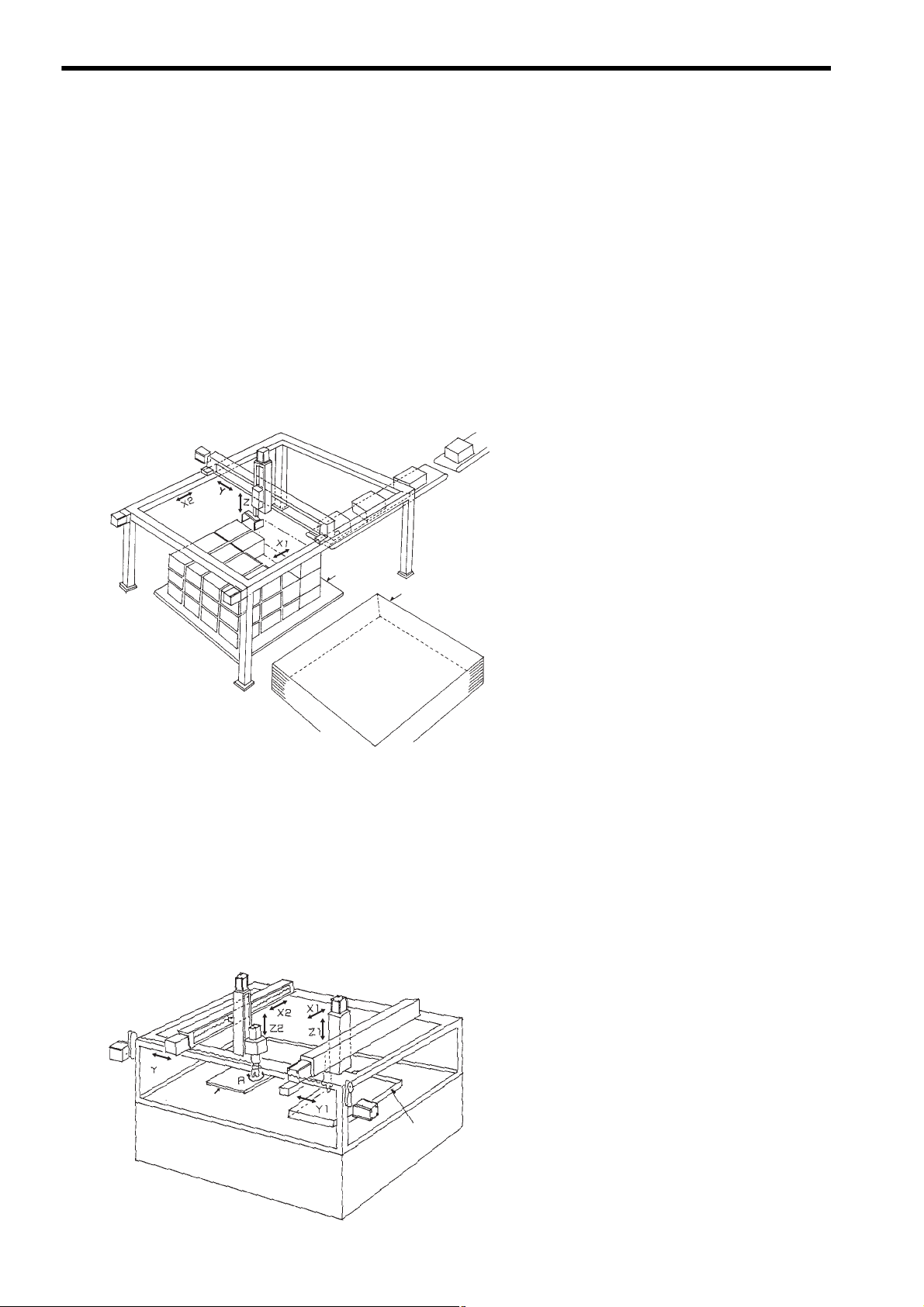

1.7.1 Example 1: Handling System

1.7 Application Examples

Motion programs can be used for operations of various systems.

Some application examples are shown below.

1.7.1 Example 1: Handling System

Outline

• To stack a specified number of cardboard boxes on a pallet

and transport them to the next process

• The system operation includes three axes motion control for

the palletizing process and an automatic pallet feeding

sequence.

Control points

• Moves X1 and X2 axes in synchronization using

• Realizes smooth movements by using interpola-

• Palletizes by calculating the position data with the

1.7.2 Example 2: Mechanical Parts Inserting Machine

Outline

• To insert parts, such as connectors, in a printed board.

• The handling robot takes out the parts and brings them to the

stand. The inserting robot inserts the parts in the specified position and angle on the board.

a virtual axis.

tion.

motion program according to predefined conditions (box dimensions, the number of boxes in a

horizontal row, the number of boxes in a vertical

row, and the number of boxes in a stack.

1-12

Control points

• Two groups of axes are organized, and programs

are created for each group, so that each robot is

independently controlled.

• The tact time can be shortened by using two-axes

or three-axes linear interpolation.

Page 29

1

Overview

1.7.3 Example 3: Panel Processing Machine

z

Y

Wave forms

Cutter

Flat panel

Outline

• To draw waveforms on a flat panel made of construction

material.

• More than ten cutters are mounted in series on the X axis, and

the width of the pattern can be easily changed.

1.7 Application Examples

Control points

• Moves X and Y axes in circular interpolation

to draw waveforms.

• Moves Y1 and Y2 axes in synchronization

using a vertical axis.

1.7.4 Example 4: Metal Sheet Bending Equipment

Outline

• To bend a metal sheet

• A metal sheet can be bent into various shapes by changing the

adjusting axis while feeding a sheet using the rolling axis.

Workpiece

Motor for

adjusting roller

platform

Gear

Motor for feeding roller

Feeding roller (urethane)

Adjusting roller

Workpiece

(metal sheet)

Motor for

inserting workpieces

Control points

• Controls two axes, a linear axis and rotational axis, in linear interpolation.

• Switches the motion program to be called

according to the process.

1-13

Page 30

1 Overview

1.8 What is a Sequence Program?

The sequence program is a scan execution type program written in the language commonly used for the motion

program.

An application to cyclically check a status, such as an interlock, can be created by using a sequence program.

A sequence program can be executed by calling from the program execution registry screen dialog box of MEXECUTOR Module.

Note: The M-EXECUTOR Module can not be used with the following modules and Machine Controllers:

MP2300, CPU-01, CPU-02

A total of up to 256 sequence and motion programs can be created.

An example of a sequence program is shown below.

The features of sequence programs are described, starting from the next page.

1-14

Page 31

1

Overview

1.9 Sequence Program Features

Sequence program

(Scan execution type)

Ladder program

(Scan execution type)

Executed in

a constant

cycle

IB00000 IB00001 OB00000

IB00002

IB00003

DB000005

IB00004 DB000006 OB00001

END

OB00000 = IB00000 & IB00001;

DB000005 = IB00002 | IB00003;

OB00001 = PON(IB00004 DB000006);

END;

Executed in

a constant

cycle

Data register

(M register)

MOV [A1] ML00000;

Sequence program

Motion program

Read

Update

Read Update

ML00000

= ML00002 + ML00004;

ML00000

= ML00000 * ML00006;

END;

1.9.1 Execution Method

A sequence program employs the same execution method as the ladder program.

A sequence program is a cyclically executed scan execution type program. Processing from the program start to

an END command is completed within one scan.

Sequence programs can be used by registering them in the program execution registry screen dialog box of MEXECUTOR Module.

1.9 Sequence Program Features

1.9.2 Programming Language Commonly Used in Motion Programs

A sequence program employs the same motion language as a motion program.

The motion language commands that can be used in sequence programs, however, are limited to sequence commands, such as math commands. Commands for motion control, such as axis move commands, cannot be used.

The use of sequence programs allows you to create an application for sequence control without using a ladder

program.

1.9.3 Data Transfer from/to Motion Program

Data can be transferred between a sequence program and a motion program.

Data registers (M registers) are used to transfer the data.

In this way, data updated in the sequence program can be used in the motion program, and vice versa.

1-15

Page 32

1 Overview

Debug Function

Debug a sequence program.

The debug commands, including step-by-step execution

and break point setting, are provided.

Command Input Assistant Function

Simply select a command and set data in the Motion

Command Assist dialog box to insert the command

in the editor.

Inserts the command

1.9.4 Memory Usage Reduced by Use of Subprograms

1.9.4 Memory Usage Reduced by Use of Subprograms

Subroutines (subprograms) can be created within a sequence program.

The number of program steps can be minimized by creating a subprogram that includes a set of commands to

perform a repeated or regular task, thus reducing memory usage.

Main program

SPM001

Call

(SSEE)

SPS010

Subprogram

Main program

SPM002

Call

(SSEE)

Write a repeated

or regular task in

a subprogram

Main program

SPM003

Call

(SSEE)

1.9.5 Easy Programming Functions (MPE720 Ver.6.04 or later)

The following easy programming functions can also be used for sequence programs.

1-16

Page 33

2

Specifications

2

Specifications

This chapter describes the relevant specifications of motion program and engineering tool

MPE720.

2.1 MP2000 Series Machine Controller Specifications - - - - - - - - - - - - - - - - - -2-2

2.1.1 Applicable Machine Controller Models - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.1.2 Applicable Motion Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.1.3 List of Machine Controller Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

2.2 Engineering Tool MPE720 Specifications - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.2.1 Applicable Version Numbers of the Engineering Tool MPE720 - - - - - - - - - - - - - - - - - - 2-5

2.2.2 List of Engineering Tool MPE720 Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.3 List of Motion Language Commands - - - - - - - - - - - - - - - - - - - - - - - - - - -2-6

2-1

Page 34

2 Specifications

INFO

2.1.1 Applicable Machine Controller Models

2.1 MP2000 Series Machine Controller Specifications

2.1.1 Applicable Machine Controller Models

Motion programs can be used with the following MP2000-series Machine Controller models.

• MP2100

• MP2100M

• MP2200/CPU-01

• MP2200/CPU-02

• MP2200/CPU-03

• MP2200/CPU-04

• MP2300

• MP2300S

• MP2310

• MP2400

• MP2500

• MP2500D

• MP2500M

• MP2500MD

• MPU-01

With the exception of MP2300, CPU-01 and CPU-02, both motion programs and sequence programs can be used.

If using the M-EXECUTOR module or sequence programs with MP2100 or MP2100M, the programming tools with fol-

lowing versions are required.

MP2000 Series Controller Applicable Version MPE720 Applicable Version

MP2100

MP2100M

Ver 2.66 or later MPE720 Ver 5 MPE720 Ver 5.44 or later

2.1.2 Applicable Motion Modules

The following motion modules support motion programs.

The axes connected to the following motion modules can be controlled using motion programs.

• Built-in SVB (Built in MP2100, MP2100M, MP2300, MP2300S, MP2310, MP2400, and MP2500,

MP2500D, MP2500M, MP2500MD as a standard feature)

• SVR (Mounted on all models of MP2000-series Machine Controllers as standard)

• SVA-01

• SVB-01

• PO-01

MPE720 Ver 6 MPE720 Ver 6.10 or later

MPE720 Ver 6.10 Lite or later

2-2

Page 35

2

Specifications

2.1 MP2000 Series Machine Controller Specifications

2.1.3 List of Machine Controller Specifications

MP2200

MP2100,

MP2100M

Program Capacity 5.5 MB 7.5 MB 11.5 MB

Applicable N/A Applicable −

Start

Processing

Interrupt

Processing

High-speed

Processing

Ladder Program

Low-speed

Processing

User function 500 drawings max. −

Number of

Programs

Number of

Groups

Number of

Tasks

Number of

Parallel

Processes

(Per Task)

Execution

Method

Starting

Method

Override Can be set in the range from 0.01% to 327.67%. −

Operation

Motion Program

Mode

Reference Unit

Min.

Reference Unit

Reference

Range

Number of

Simultaneously

Controlled

Axes

(Per Task)

64 drawings max. −

64 drawings max. −

200 drawings max. −

500 drawings max. −

Applicable −

256 programs max.

Eight groups

16 tasks

Eight parallel processes

• By writing an MSEE instruction in the ladder program

• By using an M-EXECUTOR Module (Excluding MP2300, CPU-01 and CPU-02)

The program starts running at the rising edge of control signal bit 0

(Program start request).

ABS (absolute) and INC (incremental) mode

• Built-in SVB, SVB-01, and SVR Module:

pulse, mm, deg, inch, μm

• SVA-01 and PO-01 Module:

pulse, mm, deg, inch

• E pulse

1

• mm, deg, inch, μm

1, 0.1, 0.01, 0.001, 0.0001, 0.00001

-2147483648 to +2147483647 (32-bit with sign) −

16 axes max. −

MP2300 MP2300S MP2400

MP2200

/CPU-01

MP2310

MP2200

/CPU-02

/CPU-03,

MP2200

/CPU-04,

MPU-01

Remarks

Total user program

capacity including ladder programs, motion

programs, and

sequence programs.

Up to a total of 256

motion programs and

sequence program.

Up to 16 axes can be

set for one group.

Number of motion

programs that can be

executed simultaneously.

Parallel execution of

four main programs

parallel execution of

two subprograms.

−

−

Mode switching by

use of the exclusive

command (ABS/INC).

−

−

×

2-3

Page 36

2 Specifications

2.1.3 List of Machine Controller Specifications

MP2200

MP2100,

MP2100M

Applicable N/A Applicable N/A

Number of

Programs

Number of

Ta sk s

Number of

Parallel

Processings

(Per Task)

Sequence Program

Execution

Method

Start Method Started by the system.

M Register Accessible (65535 words)

S Register Accessible (8192 word)

I Register Accessible (32768 words and motion monitoring parameters) −

O Register Accessible (32768 words and motion setting parameters) −

C Register Accessible (16384 words) −

D Register Accessible (Can be specified in the range from 0 to 16384 words)

Accessible Registers

# Register

256 programs max.

(The execution timing can be selected from the start drawing, high-speed scan drawing,

or low-speed scan drawing.)

16 tasks max.

None −

By using the M-EXECUTOR Module −

Accessible only from ladder program (Can be specified in the range from 0 to 16384

words)

(# register cannot be accessed from motion program and sequence program.)

MP2300 MP2300S MP2400

MP2200

/CPU-01

MP2310

Applicable

MP2200

/CPU-02

N/A

/CPU-03,

MP2200

/CPU-04,

MPU-01

Applicable

Remarks

−

Up to a total of 256

motion programs and

sequence.

Number of sequence

programs that can be

executed simultaneously.