Page 1

YASKAWA

1/129

MOTOWELD-EH500

INSTRUCTIONS

TYPE: YWE-EH500-6N0(INPUT VOLTAGE: 480V)

Upon receipt of the product and prior to initial operation, read these instructions thoroughly, and retain

for future reference.

YASKAWA

180369-1CD

0

MANUAL NO.

HW0480311

2

Page 2

HW0480311

2/129

MANDATORY

• This instruction manual is intended to explain operating instructions

and maintenance procedures primarily for the MOTOWELD-EH500. Read

this manual carefully and understand the contents before handling the

MOTOWELD-EH500. For the wire feeder, the welding torch, and the gas

regulator, read each instruction manual carefully.

• General items related to safety are listed in the Safety Manual Section

1: Safety. To ensure correct and safe operation, carefully read the Setup

Manual before reading this manual.

CAUTION

• Some drawings in this manual are shown with the protective covers or

shields removed for clarity. Be sure all covers and shields are replaced

before operating this product.

• The drawings and photos in this manual are representative examples

and differences may exist between them and the delivered product.

• Y ASKAWA may modify this model without notice when necessary due to

product improvements, modifications, or changes in specifications. If

such modification is made, the manual number will also be revised.

• If your copy of the manual is damaged or lost, contact a YASKAWA representative to order a new copy. The representatives are listed on the

back cover. Be sure to tell the representative the manual number listed

on the front cover.

• YASKAWA is not responsible for incidents arising from unauthorized

modification of its products. Unauthorized modification voids your product’s warranty.

ii

HW0480311

Page 3

HW0480311

3/129

Notes for Safe Operation

Read this manual carefully before installation, operation, maintenance, or inspection of the

MOTOWELD-EH500.

In this manual, the Notes for Safe Operation are classified as “WARNING,” “CAUTION,”

“MANDATORY,” or “PROHIBITED.”

Indicates a potentially hazardous situation wh ich, if not

WARNING

CAUTION

avoided, could result in death or serious injury to personnel.

Indicates a potentially hazardous situation wh ich, if not

avoided, could result in minor or moderate injury to personnel

and damage to equipment. It may also be used to alert against

unsafe practices.

MANDATORY

PROHIBITED

“Serious injury” described above indicates loss of eyesight, injuries, burns (both due to high/

low temperature), electric shock, fractures, poisoning, etc. which may cause personnel to suffer aftereffects, hospitalization, or prolonged out-patient medical treatment.

“Moderate injury” indicates injuries, burns, or electric shock which does not require hospitalization or prolonged out-patient medical treatment.

“Damage to equipment” indicates expanded damages relating to property or equipment.

Even items described as “CAUTION” may result in a serious accident in some situations. At

any rate, be sure to follow these important items.

NOTE

To ensure safe and efficient operation at all times, be sure to follow all instructions, even if

not designated as “CAUTION” and “WARNING.”

Always be sure to follow explicitly the items listed under this

heading.

Must never be performed.

For safe training concerning welding, utilize technical institutes held by the welding society or

association, or related societies or associations, technical courses held by the headquarters

or their branches, or qualifications examinations for welding technicians or engineers.

iii

HW0480311

Page 4

HW0480311

4/129

WARNING

Be sure to observe the following warnings to avoid serious injury to personnel.

• Be sure to observe the precautions in this instruction manual although

this welder is designed and manufactured with sufficient consideration

given to safety.

Failure to observe this warning may result in death or serious injury to personnel.

• Observe the regulations and your own references for the construction of

the input power sources, selection of the installation site, handling of

high-pressure gases, storage and piping, storage of manufactured products after welding, disposal of wastes, etc.

• Do not let personnel to approach the welder or welding sites unnecessarily.

• Any person using a pacemaker must not approach the welder or welding

site under operation unless permitted by doctor.

The welder generates a magnetic field around it during current conduction, resulting in

bad influence on the pacemaker.

• Clean the cooling-water path once a month when using a water-cooled

torch and the cooling water circulator.

Failure to observe this warning may result in explosion or burns due to the choked path.

• In order to secure safe operations, only a trained or qualified person

who has understood the welder must perform installation, maintenance

and inspection, or repair of the welder.

• In order to secure safe operations, only a person that has understood

this instruction manual and has knowledge and techniques to handle

the welder safely must operate the welder.

• Do not use the welder for any applications other than welding.

iv

HW0480311

Page 5

HW0480311

5/129

WARNING

Be sure to observe the following warnings to avoid an electric shock.

• Never touch the charged parts.

Touching the charged parts may result in critical electric shock or burns.

• Only a qualified person in electric construction should perform grounding construction for the welder case and base metals (to be welded) or

jigs that are electrically connected to the base metals as specified in

the electric facility technical reference.

• Be sure to perform installation or maintenance and inspection five minutes after all the input power supplies are turned OFF by using switches

in the switch box.

Even if the input power supply is turned OFF, the capacitor may still be charged. Be sure

to confirm that charged voltage is gone before starting operations.

• Do not use any cable of insufficient capacity or damaged or with its conductor exposed.

• Tighten the cable connecting sections firmly and insulate them.

• Do not use the welder with its case or cover removed.

• Do not use worn, damaged or wet gloves. Always use dry insulated

gloves.

• Use lifelines when working at hights.

• Perform maintenance and inspection periodically. Repair damaged

parts immediately.

• Turn OFF all equipment input power supplies when not being used.

• When performing AC arc welding in a small space or at hights, be sure

to use equipment to prevent critical electric shock as specified by labor

safety and sanitary regulations.

v

HW0480311

Page 6

HW0480311

6/129

WARNING

Be sure to observe the following warnings and use protectors to protect

yourself or other people from the fumes or gases generated at welding and

short of the oxygen.

• In order to prevent gas poisoning or suffocation, be

sure to ventilate sufficiently or use an inhaler, etc.

when welding at a place specified by regulations such

as labor safety and sanitary regulations or hypoxia

preventive regulations.

• In order to prevent dust trouble or gas poisoning due to the fumes or

gases, use a local air exhaust facility specified by regulations such as

labor safety and sanitary regulations or dust trouble preventive regulations or use effective protectors for breathing.

Fumes or gases generated at welding may harm your health.

• When welding within such areas as a tank, a boiler, or a ship’s hold, be

sure to ventilate sufficiently or use an inhaler, etc. in order to prevent or

offset any actual or potential oxygen shortage.

Gas heavier than air such as carbon dioxide gas or argon gas stays at the bottom.

• When welding in a small space, be sure to ventilate the site sufficiently

or use an inhaler. At the same time, operations must be done under

trained supervisor.

Welding operations at a small sp ace may result in short of the air, cau sin g a p erson to be

suffocated.

• Do not perform welding near degreasing, cleaning, or spraying operations.

Failure to observe this warning may generate extremely noxious gases.

• Before welding coated steel plates, be sure to ventilate sufficiently or

use protectors for breathing.

Welding such coated steel plates generates noxious fumes or gases.

vi

HW0480311

Page 7

HW0480311

7/129

WARNING

Observe the following cautions to prevent fire, explosion, or rupture.

• Remov e inflammables so that they will not get spattered.

If they cannot be removed, use the inflammables with

nonflammable covers.

Spatters or hot base metal immediately after welding may result in fire.

• Do not weld near flammable gases.

If arc is generated in a container (for inflammables) in which gasoline or the like is put, the

container may explode.

• Do not make hot base metals immediately after welding close to inflammables.

• Remove inflammables at the hidden side when welding ceiling, floor, or

wall.

Failure to observe this caution may result in fire.

• Tighten and insulate the cable connections.

Imperfect cable connections or imperfect contacting section of the current path at the

base metal such as iron framework may result in fire due to heat generation by current

conduction.

• Connect the cable at the base metal as close to the welding part as possible.

• Do not weld a gas tube having gas inside or an enclosed tank or pipe.

Welding an enclosed tank or pipe may result in rupture.

• Locate fire extinguishers near the welding site.

vii

HW0480311

Page 8

HW0480311

8/129

CAUTION

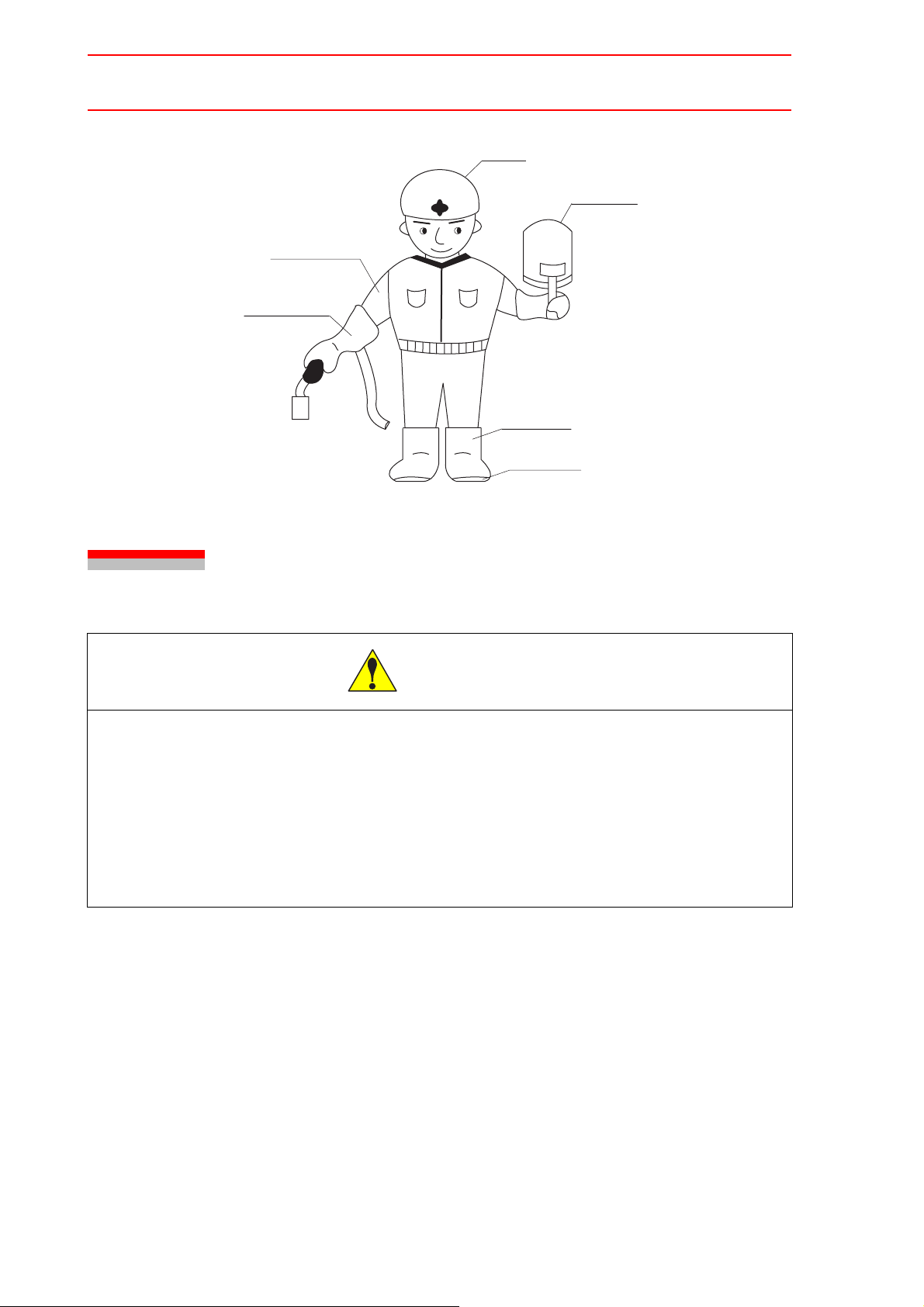

Be sure to observe the following cautions and use protectors to protect yourself

or other people from arc beams, spatters, slugs or noise generated from welding.

• Wear welding mask or shaded glasses appropriate for

welding.

• Wear protective glasses to protect your eyes from spatters or slags.

Scattered spatters or slags may damage eyes or burn the skin.

• Use such protectors as leather gloves, clothes with long sleeves, leg

covers, or leather aprons for welding.

• Install protective curtains around the welding site to protect your eyes

from arc beams.

Arc beams may irritate eyes or burn skins.

• Use noise protector when there is excessive noise.

Noise may damage hearing.

viii

HW0480311

Page 9

HW0480311

9/129

CAUTION

Be sure to observe the following cautions to prevent a gas cylinder from falling or a gas regulator from rupturing.

• Observe the regulations and your own references for

the handling of gas cylinders.

Since a gas

pressure gas to blow up, resulting in personal injury.

• Use the attached gas regulator or our recommended one.

• Read carefully the instruction manual of the gas regulator and observe

the precautions before using it.

• Hold the gas cylinder in the exclusive-use gas cylinder stand.

A gas

• Do not expose the gas cylinder to high temperature.

• Do not bring your face close to the discharging opening when opening

the valve of the gas cylinder.

• Be sure to attach the protective cap when the gas cylinder is not used.

• Do not hang the welding torch over the gas cylinder or keep the electrode away from the gas cylinder.

cylinder is filled with high pressure gas, improper handling may cause high

cylinder falling may result in personal injury.

Observe the following cautions to prevent personal injury due to improper handling.

• Do not use the welder with the case or cover removed.

• Only a qualified person or a person who has understood the

welder must remove the welder case for maintenance and

inspection or repair. Take preventive measures not to let

other personnel approach the welder or welding sites unnecessarily by

putting up a guard fence or the like.

• Do not contact the rotating cooling fan or feeding roll of the wire feeder

with hands, fingers, hair, or clothes.

Failure to observe this caution may cause someone to be caught in the machine resulting

in personal injury.

ix

HW0480311

Page 10

HW0480311

10/129

CAUTION

Observe the following cautions to prevent personal injury by the end tip of the welding wire.

• Do not peep through the chip hole to confirm that the wire

is being fed.

If the wire is projected from the end tip of the welding torch, it may poke

you in the eyes or face.

• Do not bring the welding torch end close to eyes, face, or body to perform inching or pulling the torch switch.

If the wire is projected from the end tip of the welding torch, it may poke you in the eyes,

face, or body.

• When hanging the wire feeder, remove the anti-fall fastening

from the spool shaft and tighten.

Failure to observe this caution may cause the wire to

be removed from the spool shaft, resulting in personal injury.

Observe the following cautions to prevent burns due to the plasma arc.

If body parts such as hands and fingers directly touch the plasma arc,

burns will result.

• Do not put your hands and fingers near the chip and

the electrodes of the torch end during cutting operation.

• Do not grasp near the base metal during cutting operation.

• Turn OFF the power supply before replacing the chip or the electrodes

of the torch.

x

HW0480311

Page 11

HW0480311

11/129

CAUTION

Observe the following cautions to prevent a fire accident caused by deterioration of

welder insulation.

• Perform all welding and grinding away from welder to protect welder from spattering and metal powder.

Spatter and metal powder inside the welder may cause a deterioration of

insulation resulting in accidental fire.

• Be sure to perform maintenance and inspection periodically to prevent

deterioration of insulation caused by accumulation of dust and dirt.

• If spatter or metal powder enters the inside of the welder, remove it by

forced air spray after turning OFF the welder and switch in the switch

box.

Sp atter a nd met al powder in side th e welder may cause a deterio ration of insulation resulting in accidental fire.

xi

HW0480311

Page 12

12/129

1 Basic Specifications

2 Installation and Connection

2.1 Installation Site and Welding Source Environment .2-1

2.2 Precautions on Grounding. . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.3 Power Supply Installed Capacity and Connection

Cables

2.4 Combination with Earth Leakage Breaker . . . . . . . . . .2-3

2.5 Connection of Electrical System. . . . . . . . . . . . . . . . . . . .2-3

2.6 Connection of Welding Voltage Detecting Line . . . . .2-7

2.7 Connection of Shielding Gas System. . . . . . . . . . . . . .2-10

2.7.1 For Mixed Gas or Carbon Dioxide Gas Welding. . . . . . . . . . . 2-10

2.7.2 Installation Site and Gas Cylinder Environment . . . . . . . . . . . 2-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

HW0480311

2.8 Ambient Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2.9 Precautions on Transporting . . . . . . . . . . . . . . . . . . . . . .2-13

3 Welding Preparation

4 Operations on Panel

4.1 Explanation of Welding Source Panel . . . . . . . . . . . . .4-1

4.2 Settings on Welding Source Panel . . . . . . . . . . . . . . . . .4-4

4.2.1 Changing Welding Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.2.2 User Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.2.3 Changing P Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.2.4 Changing Common (C) Parameters. . . . . . . . . . . . . . . . . . . . . 4-7

4.2.5 Changing D Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.2.6 Saving Welding Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

4.2.7 Checking the Flow Amount of Shielding Gas . . . . . . . . . . . . .4-11

4.2.8 Selecting Feeding Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.2.9 Monitoring of Motor Current . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.2.10 System Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4.2.11 Lock Of Panel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

4.3 List of Process Parameters. . . . . . . . . . . . . . . . . . . . . . . .4-16

4.4 List of Common Parameters. . . . . . . . . . . . . . . . . . . . . . .4-19

4.5 List of D Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

xii

HW0480311

Page 13

HW0480311

13/129

5 Welding Operation

5.1 Checking the Welding Conditions. . . . . . . . . . . . . . . . . . 5-1

5.2 Wire Stickout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 Direction of Welding and Torch Angle. . . . . . . . . . . . . . 5-1

5.4 Precautions on Using Extension Cable . . . . . . . . . . . . 5-2

6 Precautions on Welding

6.1 Error Detection Function. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Tripped Power Supply Switch. . . . . . . . . . . . . . . . . . . . . . 6-4

6.3 Precautions on Welding Operation. . . . . . . . . . . . . . . . . 6-4

7 Built-in Functions

7.1 Internal Selecting Switches . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Location of Printed Boards. . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.2.1 DIP Switch Settings for Pr(MB)-021 Board . . . . . . . . . . . . . . . .7-4

7.2.2 Jumper-pin Settings of the Pr(MB)-021 Board . . . . . . . . . . . . .7-4

8 Maintenance and Inspection

8.1 Daily Inspection Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Bimonthly to Semiannual Inspection Items. . . . . . . . . 8-2

8.3 Annual Overhaul and Repair. . . . . . . . . . . . . . . . . . . . . . . 8-2

8.4 Guideline for Service Lifetime and Replacement of

Components Used

8.5 Replace Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

9 Failure Analyses

9.1 Confirming Setting conditions. . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 Cause and Remedy of Welding Section Failure. . . . 9-3

9.3 Cause and Remedy of Failure at Electrical Circuit

Section

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

xiii

HW0480311

Page 14

14/129

10 Robot Interface Signals

10.1 Specifications of Robot Interface Signals. . . . . . . . .10-1

10.2 Meaning and Function of Pr(RC2)-001 Terminal .10-4

10.2.1 TB2 Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

10.2.2 TB3 Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-5

10.3 Meaning and Function of Signal for Starting Point

Detecting Function (Optional board Pr(OP)-003

HW0480311

[EH500])

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

11 Connection System Diagram

12 Diagnosis Function

12.1 Starting up Welding Source in Diagnosis Mode . .12-1

12.2 Confirmation of DIP Switch Set Status . . . . . . . . . . .12-3

12.3 Confirmation of Software Version . . . . . . . . . . . . . . . .12-4

12.4 Confirmation of the Number of Welding Source Errors

12-5

12.5 Clear of Error Record. . . . . . . . . . . . . . . . . . . . . . . . . . . .12-6

12.6 End of Diagnosis Mode . . . . . . . . . . . . . . . . . . . . . . . . . .12-6

13 Process Parameters

(Adjustment of Welding Characteristics)

13.1 Adjustable Welding Characteristics . . . . . . . . . . . . . .13-1

13.2 Adjustment of Arc Start Characteristics . . . . . . . . . .13-2

13.2.1 Adjustment of Start Pulse. . . . . . . . . . . . . . . . . . . . . . . . . . . 13 -2

13.2.2 Adjustment of Hot Characteristics . . . . . . . . . . . . . . . . . . . .13-3

13.3 Adjustment of Arc End Characteristics . . . . . . . . . . .13-4

13.4 Adjustment of Short-circuit Welding Characteristics. .

13-6

13.5 Adjustment of Pulse Welding Characteristics. . . . .13-7

13.5.1 Adjustment of MAG/MIG Pulse Welding Characteristics . . . 13-7

13.5.2 Adjustment of MIG Pulse Welding Characteristics. . . . . . . . 13-8

13.6 Adjustment of Other Pulse Welding Characteristics .

13-9

13.7 Adjustment of Current Output Characteristics . . .13-10

xiv

HW0480311

Page 15

HW0480311

15/129

14 Calibration for External Resistance

14.1 Outline of External Resistance Calibration. . . . . . . 14-1

14.2 Procedure of External Resistance Calibration . . . 14-2

14.2.1 Connecting the Cable for Resistance Measurement. . . . . . .14-2

14.2.2 Measuring the External Resistance Value . . . . . . . . . . . . . .14-4

14.2.3 Display of External Resistance Setting Parameter . . . . . . . .14-6

14.2.4 Setting the D Parameter for Calibration of External Resistance to

"Enabled". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-6

15 Calibration Function of Welding Current

15.1 Overview of the Welding Current Calibration Function

15-1

15.2 Procedure of Welding Current Calibration. . . . . . . 15-2

15.3 Parameters for Welding Current Calibration Function

15-6

16 Welding Source Condition File of the Robot

Controller

17 Setting of Arc Monitoring Function

18 Operation by External Remote Mode

18.1 Gas Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1

18.2 Switch of User Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-2

19 List of Service Parts

xv

HW0480311

Page 16

16/129

1 Basic Specifications

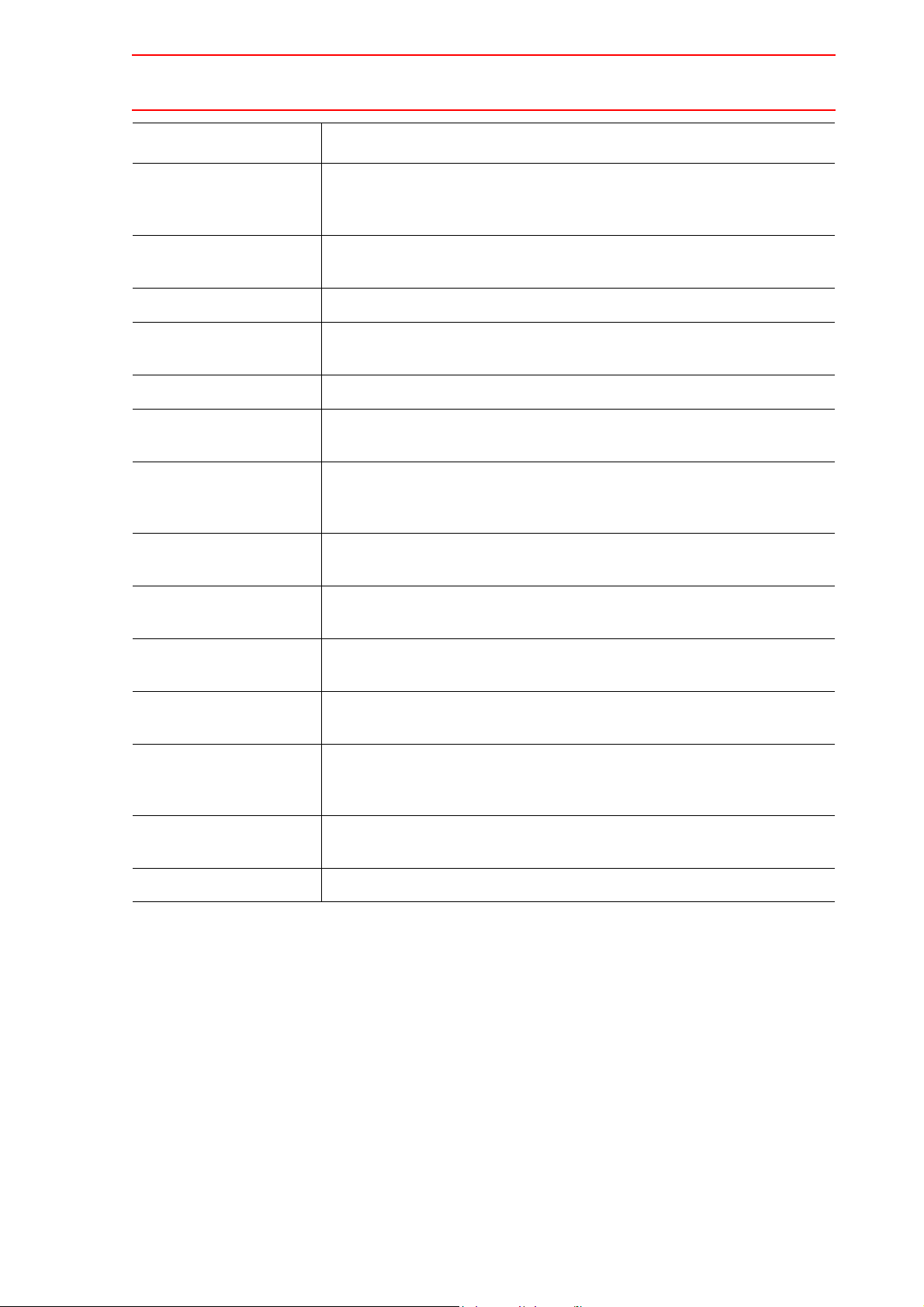

Item Specifications

Model MOTOWELD-EH500

Type YWE-EH500-6N0

HW0480311

Number of Phases,

Rated Input Voltage

Rated Frequency 50/60 Hz common

Rated Input 27.5kVA

Welding Current Adjustment Range

Welding Voltage Adjustment Range

Rated Operational Ratio 100 % (for 10 minutes)

Welding Type CO

Welding Object Material Iron, stainless steel, aluminium (Refer to the “Type” on the panel for

Feeding Motor Types of feeding motors can be selected among;

Three-phase, 480 V

24.3 kW

30 to 500 A (depends on the wire diameter)

12 to 45 V (depends on the wire diameter)

short-circuit welding, MAG/MIG short-circuit welding, pulse welding

2

details.)

0: Print servomotor (default setting)

1: Minertia servomotor for servo torch

2: 4-roller servomotor (YWE-WF-340MELC)

±10 %

Wire Feeding speed 1.5 to 18 m/min

Wire Feeding

Slow-down Speed

Encoder cable 5 m (standard), 7m max.

Gas Running-in Time Approx. 20 seconds (Can be adjusted by panel operation: 60000 sec-

Gas Pre-flow Time Approx. 0.06 seconds (Can be adjusted by panel operation)

Gas After-flow Time Approx. 0.5 seconds (Can be adjusted by panel operation)

Wire-stick Prevention

Time

CO2 short-circuit welding: Approx. 3 m/min

MAG/MIG short-circuit welding and pulse welding: Approx. 2 m/min

(adjustable range by panel operation: 1 to 4m/min)

(Optional: 25 m max with a cable extender)

onds max.)

Approx. 0.2 seconds (Can be adjusted by panel operation: 0.02 to 0.4

seconds)

(adjustable range by panel operation: 1.5 to 6 m/min)

1-1

HW0480311

Page 17

HW0480311

17/129

Item Specifications

Volt age for St arting Point

Detecting Function

(Optional)

External Dimensions

[mm]

Mass Approx. 70kg

Welding V oltage Setting

Method

Arc Touch Start Function This function can be used by the parameters D2-2, D2-3, and D2-4.

User File Number of files: 3

Adjustment of Voltage

and Current Waveform

Control

Interface for Robot Controller

Output Setting Analog

Input

Peak value: 220 V

371 x 810 x 641 (width x depth x height)

(excluding the projections such as screws or eyebolts)

Can be switched by "Auto Adjustment/Individual" (Synergic/Independent) button on the welding source panel.

"Panel" or "robot" can be switched by the parameter D1-11.

Can be changed by P parameters in the user file.

Refer to " 10 Robot Interface Signals ".

0 to 14 V (The set voltage, current, and wire feeding speed are displayed

on the welding source panel.)

±20 % (full-wave rectification)

Error Output Outputs the arc failure signal to the robot side. (Error contents are indi-

cated on the welding source panel.)

Output for Arc

Monitoring

Power Supply of the

Heater for the Gas

Regulator

Standard Accessory Fuse contained in glass tube of 5A (2 fuse)

Remarks Front panel: Written in English

Outputs the signal corresponding to current or voltage to the robot side.

The output terminal stand for analog indicator is also available.

None

Fuse contained in glass tube of 10 A (1 fuse) for Pr(SD)-006 board

1-2

HW0480311

Page 18

HW0480311

18/129

2.1 Installation Site and Welding Source Environment

2 Installation and Connection

2.1 Installation Site and Welding Source Environment

CAUTION

• The welding source can be moved easily by using the caster. After

installation, use the stopper to fix the welding source before starting

operations.

For precautions on transporting, see

" 2.9 Precautions on Transporting ".

The welding source can be used under the following environmental conditions:

• Dry, indoor and at least 30 cm from the wall or peripheral devices

• Free from direct sunlight, wind, and rain

• Ambient temperature of 0 to 40

• Altitude less than 1000 m

• Free from direct splash of welding spatter or metallic fine powder at grinding

°C

2.2 Precautions on Grounding

CAUTION

• Be sure to turn OFF the main switch of the switchboard before performing the grounding work.

• If the welding source is used with rated input voltage: 480 V(6N0), the

ground resistance must be 100

by authorized or certified personnel.

Ω or less. Grounding must be performed

1. Be sure to perform secure grounding work (ground resistance must be 100 Ω or less)

on the welding source so as not to charge its case or lead to unstable operation.

2. Connect a grounding cable of 14 mm2 or thicker to the terminal marked "GROUND" or

"EARTH".

3. Be sure to ground the base metal (ground resistance must be 100

when or any other non-conductive material is placed under the base metal.

2-1

Ω or less) as well

HW0480311

Page 19

HW0480311

19/129

2.3 Power Supply Installed Capacity and Connection Cables

4. If there is a pool or pond between the grounding of the power supply switchboard and

the welding source, the leak current is concentrated in the pool or pond. In such a

case, connect the grounding with a cable to escape the leak current through the cable.

2.3 Power Supply Installed Capacity and Connection

Cables

The following table " Table. 1 Power Supply Installed Capacity and Cables " shows the power

supply installed capacity and connection cables which are required for using the welding

source.

The rated input voltage for the welding source is three-phase, 480V(6N0). The welding

source supports a voltage compensation circuit so that the equipment can operate at a power

voltage within

power supply as stable as possible. If fluctuations in power supply voltage exceed

welding source conditions cannot be guaranteed and problems may occur.

±10 % fluctuations of the rated value. All the same, it is recommended to use a

±10 %,

Diameter of the input cable and the fuse capacity must be in compliance with the t able " Table.

1 Power Supply Installed Capacity and Cables ". Insta ll a non-fuse breaker (NF B) or a switch

with fuse for each welding source.

The non fuse breaker used should be the same capacity of the fuse indicated in " Table. 1

Power Supply Installed Capacity and Cables ", and the tripp ing time at 600 % o f the rated current should be one second or longer (General motor breakers satisfy these requirements). If

breaker capacity is insufficient or primary voltage is too high, the breaker will be tripped when

the welding source is turned ON.

Table. 1 Power Supply Installed Capacity and Cables

Installed Capacity 30 kVA

Fuse Rated Current 75 A

(rated voltage: 480 V(6N0))

Input Cable

Outside diameter of acceptable

Input Cable

Exclusive-use base metal cable

2

14mm

φ27.0~φ30.0mm *1

60mm

80mm

~22mm

2

or more (cable length:5m or less)

2

or more (cable length:5m or more ) *2

2

Grounding Cable

14 mm

2-2

2

or more

HW0480311

Page 20

HW0480311

20/129

2.4 Combination with Earth Leakage Breaker

*1

The input cable is passed from the hole for wiring in the back of the po we r su pp ly.

NOTE

When the outside diameter of the cable exceeds φ30.0mm, match the plate to the

size of the input cable, process the hole, and use it.

*2 Be sure to use cables for welding. Also, use cables with sufficient thickness for pulse

welding or current of 250 A or more. Excessively small gauge cables may result in

poor welding and cause abnormal heating resuoting in burn or fire.

2.4 Combination with Earth Leakage Breaker

When the welding source is used in a construction site, in a place with high humidity, or on an

iron plate, iron framework, or surface plate with high conductivity , a leakage breaker should be

installed according to the proper regulations or laws. In such a case, connect a leakage

breaker of current sensitivity 30 mA for each welding source. The welding source may malfunction because of the inverter operations depending on the model or current sensitivity of

the leakage breaker. Therefore, select a proper one for inverter drives.

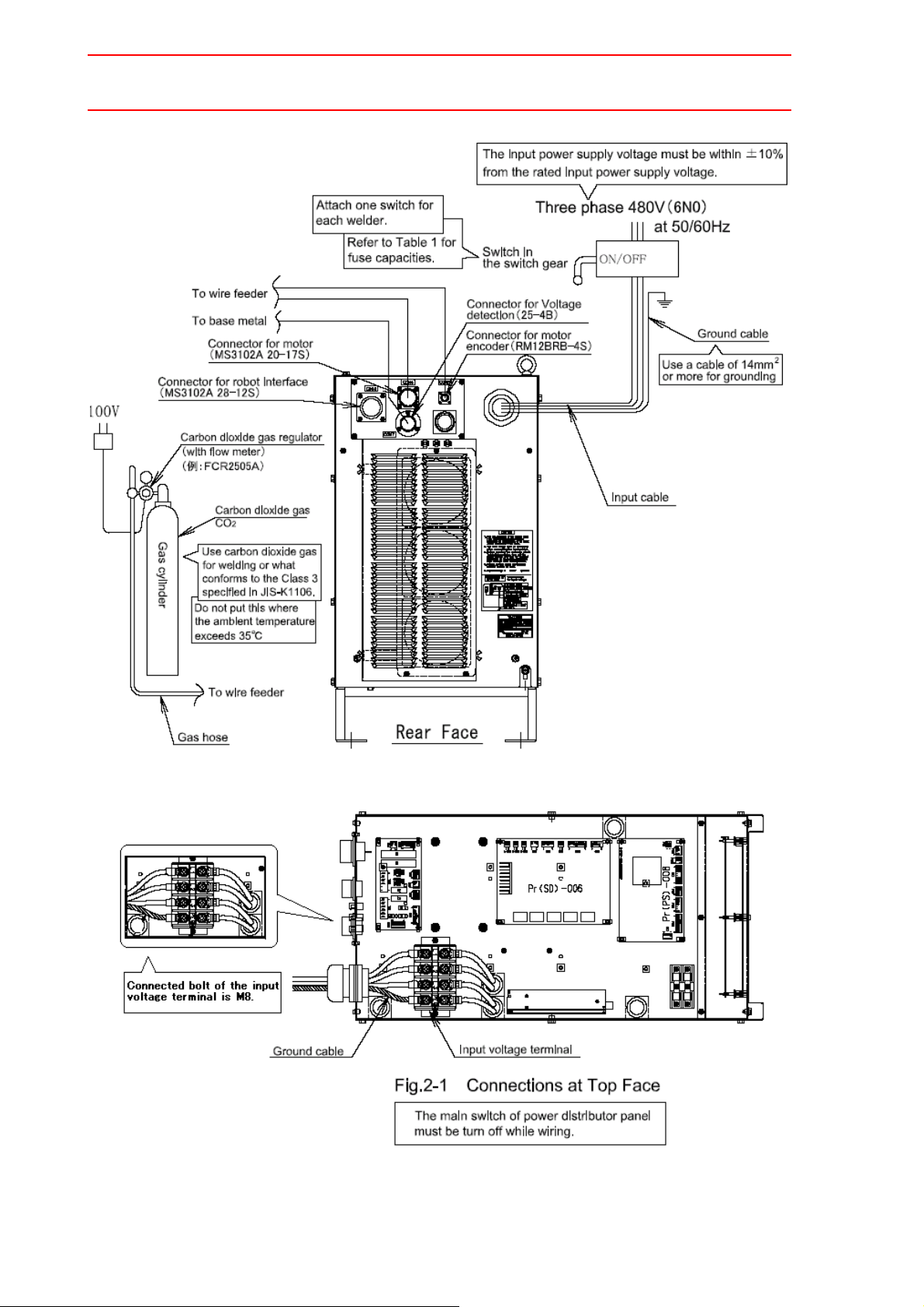

2.5 Connection of Electrical System

CAUTION

• Open the disconnect switch of the swtichgear before connecting wires

between welding machine and primary power supply.

Even one imperfect contact in the connections precludes proper welding. Be sure to

make perfect connection to the base metal by using jigs.

1. Connection on the Welding Source Side

See " Fig. 1 Connection Diagram of Welding Source at Re ar Face " for proper connections.

1) Input cable

Please remove the top cover and connect the cable with the input terminal of

the partition board.

Connected bolt of the input voltage terminal is M8.

2) Ground cable

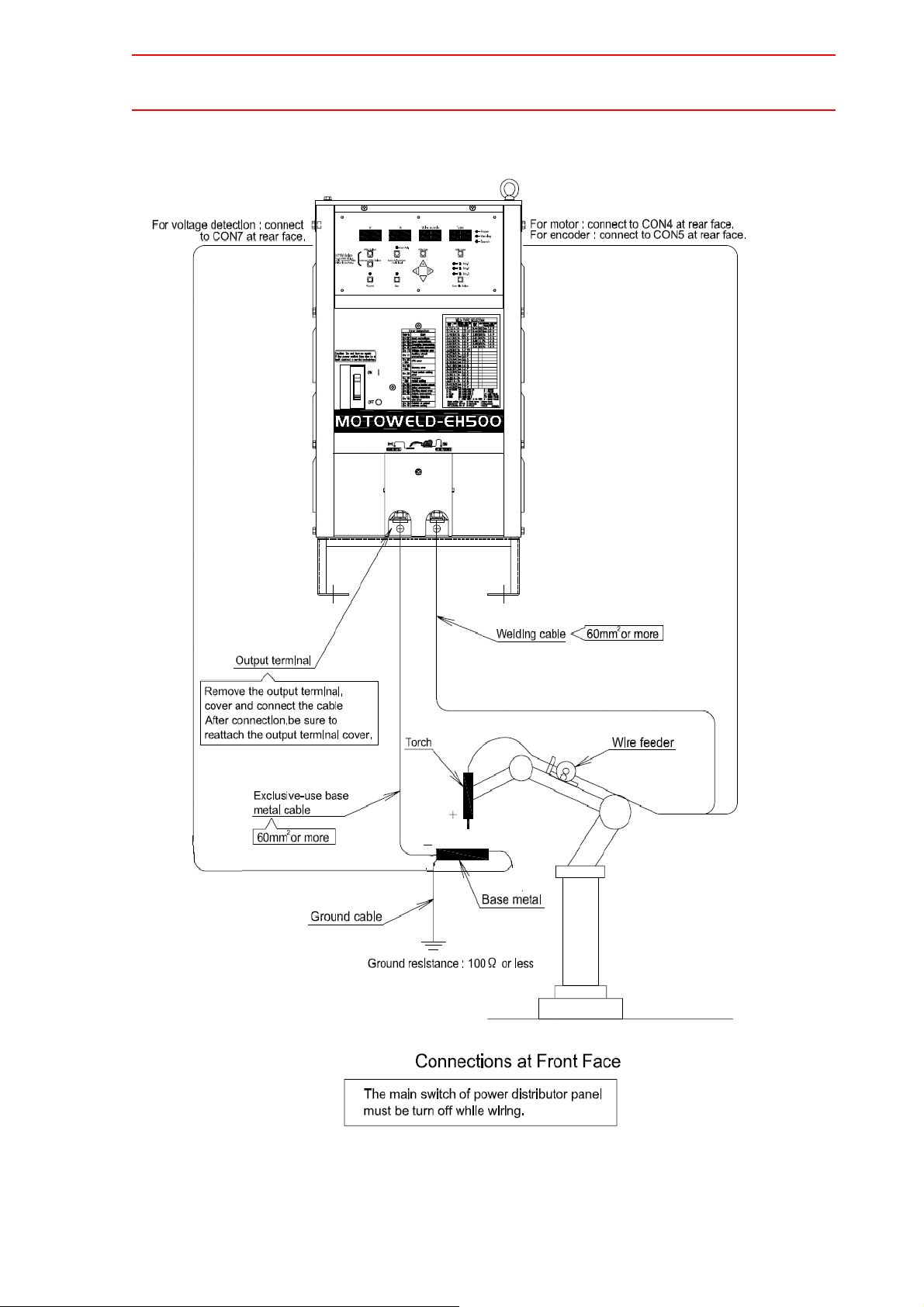

2. Connection on the Welding Side

See " Fig. 2 Connection Diagram of Welding Source at Front Face " for proper connections.

1) Welding cable

The welding cable connects between the welding torch and power output termi-

2-3

HW0480311

Page 21

HW0480311

21/129

2.5 Connection of Electrical System

nal (+).

2) Exclusive-use base metal cable

The exclusive-use base metal cable connects between the base metal and

power output terminal (-).

3) Welding Voltage Detecting Line

The welding voltage detecting line connects between the base metal and connector "CON 7" at rear face of the welding source.

CAUTION

• Be sure to connect the welding voltage detecting line.

If the welding voltage detecting line is not connected, the error "Err70 2: Voltage Detection

Wire Error" may occur, and welding cannot be performed.

• Only if the length of the welding cable and exclusive-use base metal

cable is 5 m or less respectively, the welding source can be used with

connecting a short-circuiting cap for detecting voltage of output terminal (-) to the connector "CON 7" at rear face of the welding source. For

improving the welding performance, connect the base metal and connector "CON 7" with the welding voltage detecting line whenever possible.

3. Connection of Control Cable

Connect cables of every kind to connectors at rear face of the welding source. When

connecting the cables, securely tighten the plug until it stops rotating.

1) Connect the control cable of the robot controller to the connector "CON 3".

2) Connect the motor cable of the wire feeder to the connector "CON 4".

3) Connect the encoder cable of the wire feeder to the connector "CON 5".

2-4

HW0480311

Page 22

2.5 Connection of Electrical System

22/129

HW0480311

Acrobat 文書

Fig. 1 Connection Diagram of Welding Source at Rear Face

2-5

HW0480311

Page 23

HW0480311

23/129

2.5 Connection of Electrical System

Fig 2 Connection Diagram of Welding source at Front Face

2-6

HW0480311

Page 24

HW0480311

24/129

2.6 Connection of Welding Voltage Detecting Line

4. Grounding

Ground terminal is provided at the input voltage terminal in the partition board of the

welding source for safe operation. Connect the grounding cable of 14 mm

the crimp contact. Ground resistance must be 100

Be sure to ground the base metal at resistance of 100

in " Fig. 2 Connection Diagram of Welding Source at Front Face ". If it is not

grounded, voltage may be generated in the base metal resulting in electric shock.

Make sure that the grounding is always done individually , sep arated from grounding for

the manipulator. Also, connect the welding source and the base metal with exclusiveuse base metal cable.

Ω or less.

Ω or less individually as shown

2

or more to

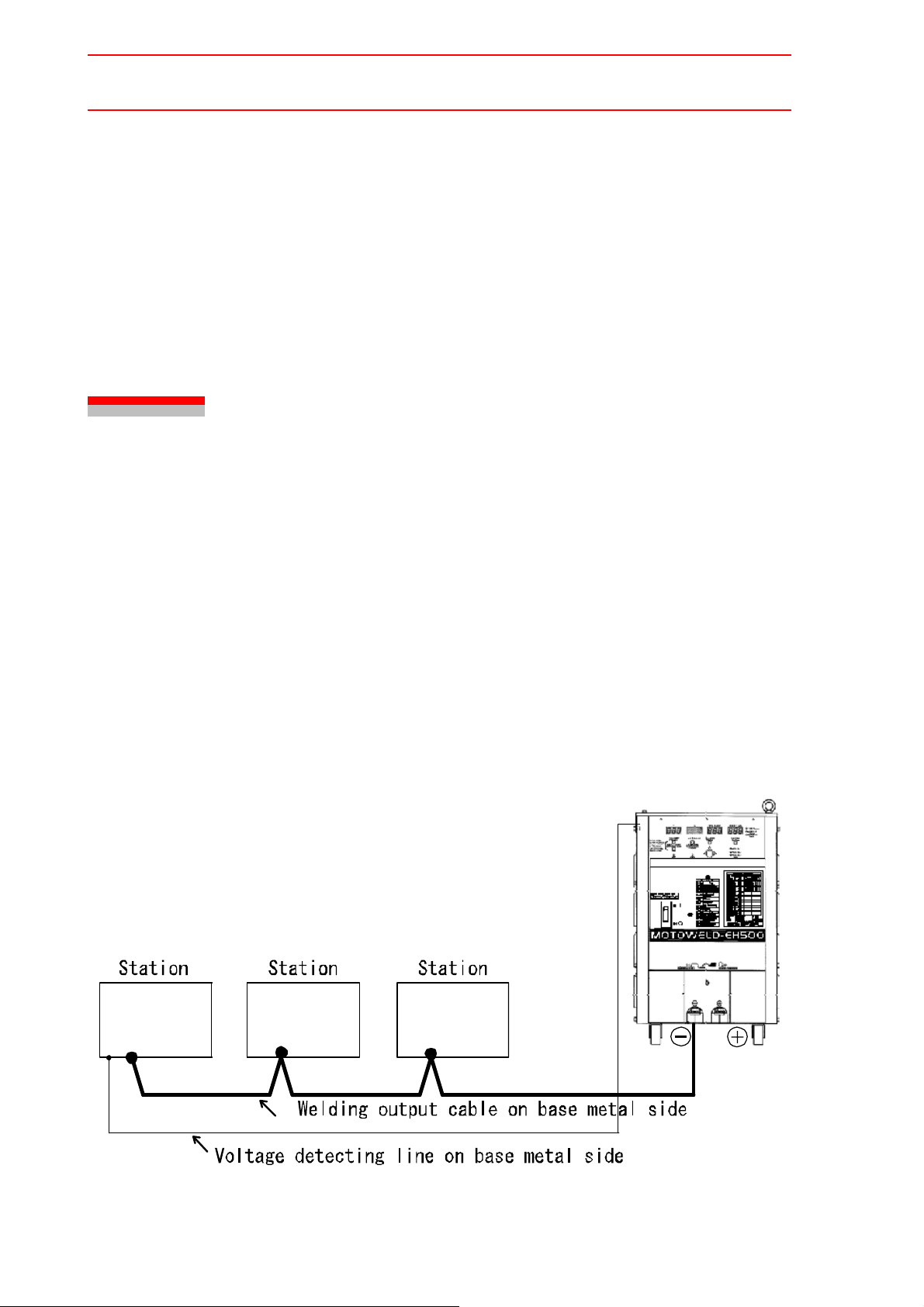

2.6 Connection of Welding Voltage Detecting Line

In the connection of the welding voltage detecting line, Be sure to observe the following items

.If the following items are not observed, the amount of the spatter generation might increase.

1. Connect the welding voltage detecting line as close to the position where welding is

performed as possible.

2. The welding voltage detecting line and the welding output cable must separate as far

as possible.(The distance is required 100mm or more.)

3. When you use MOTOPOS(external welding positioner), Connect the welding voltage

detecting line with with the screw of the cover that exists in the base of MOTOPOS.

When two or more stations are used, connect the weldin g voltage detecting line with a station

as far away from the welding source as possible as indicated in " Fig. 2 Connection of Welding Voltage Detecting Line when Multiple Stations are Used ".

Fig. 2 Connection of Welding Voltage Detecting Line when Multiple Stations are Used

2-7

HW0480311

Page 25

HW0480311

25/129

2.6 Connection of Welding Voltage Detecting Line

When a rotation axis is used, connect the welding voltage detecting line with the screw of the

cover that exists in the base of MOTOPOS. Don’t connect output cable and the welding voltage detection line with the same part as indicated in " Fig. 3 Connection of Welding Voltage

Detecting Line when Rotation Axis and two welders is Used ".(Don't connect the welding voltage detection line with the route where the welding current flows).

Please confirm it has run electrically between the welding workpiece and the screw of the

cover by the tester before it wires.

-

Two voltage detect

Two voltage de

-

tecting lines

ing lines

Two welding out

-

put cables

(a) Connection of voltage detecting line (b) Connection of welding output cable

Fig. 3 Connection of Welding Voltage Detecting Line when Rotation Axis and two welders is Used

2-8

HW0480311

Page 26

HW0480311

26/129

2.6 Connection of Welding Voltage Detecting Line

When you use two or more welders, Connect the each welding output cable of the welder as

close to the position where welding is performed as possible.

Separate the welding output cable A from the welding voltage detecting line B,and separate

the welding output cable B from the welding voltage detecting line A as far as possible.(Distance between Cable A and cable B is required 100mm or more.)

Don't connect the welding voltage detection line with the route where the welding current flows

Fig. 4 Connection of Welding Voltage Detecting Line and Welding outputcable

when two or more welders are used.

CAUTION

• Be sure to connect the welding voltage detecting line.

If the welding voltage detecting line is not connected, the error "Err702: Voltage Detection

Wire Error" may occur, and welding cannot be performed.

• Only if the length of the welding cable and exclusive-use base metal

cable is 5 m at a maximum respectively, the welding source can be used

with a short-circuiting cap for detecting voltage of output terminal (-) on

the connector "CON 7" at rear face of the welding source. For improving

the welding performance, connect the base metal and connector "CON

7" with the welding voltage detecting line whenever possible.

2-9

HW0480311

Page 27

HW0480311

27/129

2.7 Connection of Shielding Gas System

2.7 Connection of Shielding Gas System

2.7.1 For Mixed Gas or Carbon Dioxide Gas Welding

The 100 VAC power supply is required for a heater of carbon dioxide gas regulator. Connect

the gas cylinder as follows:

1. Remove dust from the gas cylinder connecting port. Install the MAG/carbon dioxide

common gas regulator. Check the quality of the gas and the type of the cylinder.

2. Insert one end to the supplied rubber gas hose into the output of the gas regulator, and

the other end into the gas terminal inlet of the wire feeder. Clamp both ends securely

with hose bands.

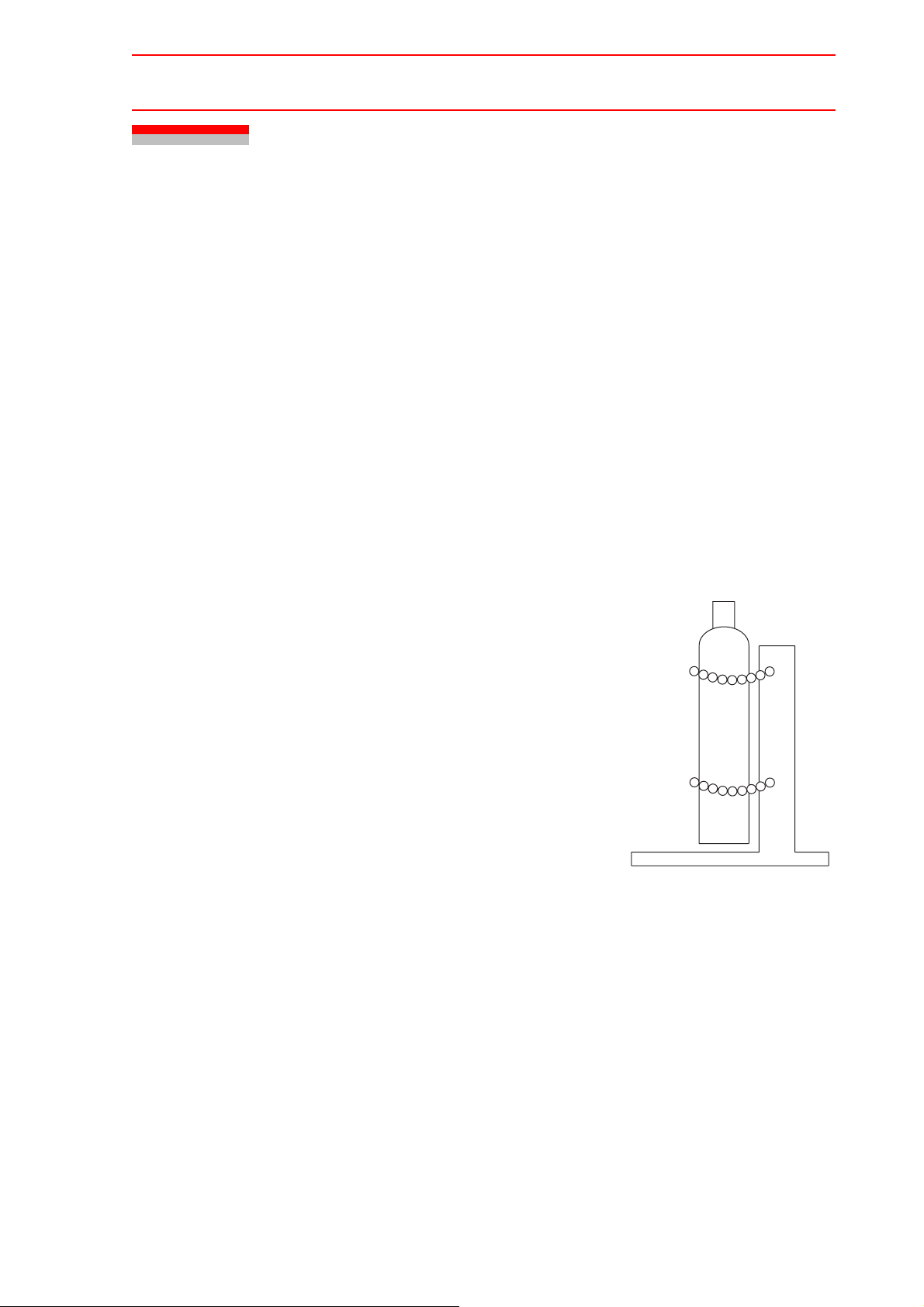

2.7.2 Installation Site and Gas Cylinder Environment

Handle the gas cylinder with special care because it contains high pressure gas. Refer to the

instruction manual attached to the gas cylinder.

1. Installation SIte of Gas Cylinder

Place the gas cylinder in a specified gas container position that is not exposed to direct sunlight. If the gas cylinder is unavoidable placed at the welding site, it must

be fixed to post or cylinder stand in an upright position to

prevent it from falling. Also, the gas cylinder must not be

heated by a welding arc or the like.

2. Type of Gas Cylinder

Carbon dioxide gas-filled cylinders can be classified into

two types: one is the general type that is not the siphon

type, and the other is the siphon type.

Never use siphon type gas cylinders. The provided carbon dioxide gas regulator is not applicable to siphon

type cylinder. If the regulator is connected to a siphon

type gas cylinder, the contents of the cylinder are not

gaseous and enter the regulator as remaining liquefied.

In such a case, the pressure reduction mechanism of

the regulator cannot be operated. The type of gas cylinder can be distinguished by cylinder color according to

the cylinder’s manufacturer. Contact the gas distributor

for details.

The safety valve operates when the pressure goes

extremely high. When the valve operates, stop operation immediately, confirm the reason, and take appropriate corrective actions to prevent that the same error

occurs again.

Gas cylinder

Fix the gas cylinder to prevent

it from falling.

Fig. 5 Installation Site of Gas

Cylinder

Gas cylinder stand

2-10

HW0480311

Page 28

2.7 Connection of Shielding Gas System

28/129

3. Quality of Gas for Welding

Moisture or impurity in the carbon dioxide gas or argon gas used to shield welding arcs

adversely influenced welding. High purity and low moisture gas must be used.

Use MAG gas

containing 80 % argon and 20 % carbon dioxide gas for mixed gas.

The gas mixing ratio of MAG gas is content, which contributes to constant welding

quality. Especially for pulse welding, improper pulse welding will be resulted if the

argon gas ration is less than 80 %.

Use carbon dioxide gas

designated as "for welding" or what conforms to Class 3

specified in JIS-K1106 (moisture content 0.005 % or less) or the equivalent. Avoid

using carbon dioxide gas containing moisture more than 0.005 %, not only for the

adverse effect on welding, but also because it may cause clogging in the gas reg ulator

if the water content freezes.

4. Gas Regulator with Flow Meter

Use gas regulator with flow meter suitable for the gas to be used. The following table

show the examples of the gas regulator.

HW0480311

Table. 2 Gas Regulator with Flow Meter

No. Type Applicable Gas Remarks

1 FCR-2505A CO

2 FCR-225 CO

*1

The power supply for the heater is not provided with the welding source. Prepare a 10 0

VAC power supply for the heater of the gas regulator.

, MAG Meter: Indicates secondary pressure

2

, MAG, Ar Meter: Indicates primary pressure and

2

and flow amount

1

Heater: 100 VAC*

float-type flow amount

Heater: 100 VAC*

, 190 W

1

, 190 W

2-11

HW0480311

Page 29

HW0480311

29/129

2.8 Ambient Environment

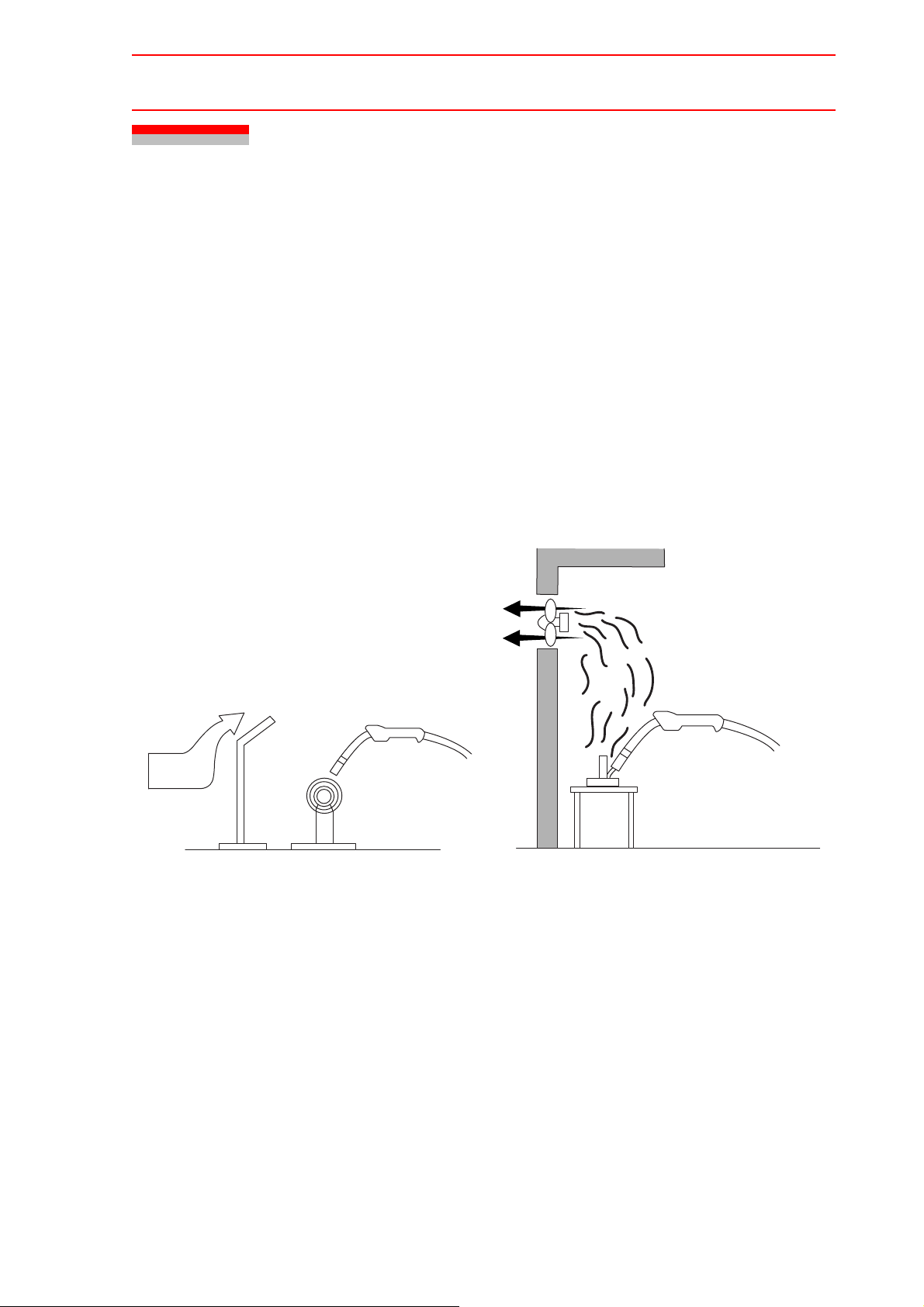

1. Wind Prevention

Normally, the allowable wind limit for welding using shielding gas is approx. 1.5 m/s or

less. If the wind speed is higher than this limit, stop operation or take some countermeasures such as putting up a screen.

Even for indoor operations, sufficient attention to the shield effect must be paid when

using air tools or fans around the welding.

2. Ventilation

The carbon dioxide gas used as the shielding gas is decomposed by arc heating, and a

small amount of carbon monoxide is generated.

For operations indoor or in a container or a t ank, ventilation is needed. In this case, do

not use a fan to blow the air, but ventilate the accumulated gas by providing a ventilation fan or exhaust duct.

2.8 Ambient Environment

Ventilating fan

Torch

Torch

Wind

Fig. 6 Shielding Wind for Welding

Screen

Object to be welded

Fig. 7 Ventilation Example

3. Shading Measures

For shaded glasses of helmets or hand shields, use filter numbers 8 to 10 of JIS T8141

for welding of thin plates since it has a weak arc beam and the arc must be seen easily.

Use numbers 10 to 13 for welding of medium-hick plates since the arc is bright. For

MAG welding, for which stronger arc light is required compared to CO

welding, use

2

greater filter numbers.

The welder brings in ultraviolet rays stronger than that caused by manual welding.

Periodically check protectors for eyes and the skin. Also, be sure to always wear these

protectors.

When the welding source is controlled by external control input signal or while operating the manipulator, provided proper shade around the welding torch.

Accidental arc generation may damage eyes or burn the skin of those without proper

protection.

2-12

HW0480311

Page 30

2.9 Precautions on Transporting

30/129

Jacket must be

long-sleeved.

Welding gloves

HW0480311

Helmet

Handshield

Foot covers

Safety boots

Fig. 8 Protection Example

2.9 Precautions on Transporting

CAUTION

• Sling applications and crane or forklift operations must be performed by

authorized personnel only.

Failure to observe this caution may result in injury or damage.

• Avoid excessive vibration or shock while transporting.

The welding source consists of precision components. Failure to observe this caution

may affect its performance.

1. Transporting with Using Casters

When using the casters, move the welding source slowly so that it can be stopped

quickly at any time. Moving the welding source with casters quickly may result in an

accident due to inertia, and you cannot control the direction of movement.

Moreover, be sure to stop the welding source with casters at a ste p and move it slowly

to prevent any shock sudden. Do not move the welding source with casters up a slope,

stairs, etc.

2-13

HW0480311

Page 31

HW0480311

31/129

2. Transporting with Using a Crane

When using the crane, be sure to confirm the following points before transporting.

1) Confirme the mass of the welding source by referring to " 1 Basic Specifications

". Select the wire rope suitable for the mass and angle.

2) Use eyebolts for transporting and confirm that the eyebolts are tightened firmly

before transporting.

3) Lift the welding source using the crane after the above confirmation.

2.9 Precautions on Transporting

3. Transporting with Using a Forklift

Observe the following points to use the forklift for transporting.

1) Con firm availability of safe operations site, and transfer the weldin g source to the

installing site.

2) After determining the operation site, warnings must be placed on transport path

to prevent accidents.

3) Put the welding source on the transporting pallet and fix firmly to prevent falling

or shifting. Employ a stopper on the casters to fix the welding source.

Over-tightening the cover may cause it to deform.

4) Do not raise the lift excessively.

5) Avoid excessive shock or vibration while transporting since the system consists

of precision component.

6) Transport the welding source at yield speed when using the forklift.

2-14

HW0480311

Page 32

2.9 Precautions on Transporting

32/129

4. Others

1) Do not climb up on the welding source or place anything on it.

2) Do not p a ss a rope directly arou nd the welding source case durin g transporting .

Failure to observe this caution may deform the shape of the case or cause malfunction.

HW0480311

2-15

HW0480311

Page 33

HW0480311

33/129

3 Welding Preparation

The following table describes the preparation procedure to start actual welding.

Table. 3 Welding Preparation Procedure

Step Item Details

Setting welding wire Set a wire suitable to the welding method. Make sure

1

Checking torch Confirm that a contact tip suitable to the diameter of

2

that the diameter of the roller of wire feeder matches

the wire diameter.

the wire is installed on the torch.

Turning ON the switch in the

3

switch gear

Turning ON switches for the weld-

ing source

4

Setting feeding motor The feeding motor type can be set by the parameter

5

Confirm that connections are correct, then turn ON the

switch of the switch gear of the welding source.

Turn ON the power switch. The power indicator lamp

lights and the built-in cooling fan starts. The fan stops

after fifteen minutes unless the arc starts. The fan

automatically restarts when the arc starts.

C09.

0: Print servomotor (default setting)

1: Minertia servomotor for servo torch

2: 4-roller servomotor (YWE-WF340MELC)

Incorrect setting of the feeding motor precludes proper

welding because the wire cannot be fed at wire feeding speed as directed by the set value.

When the parameter was changed, follow the instructions as follows:

1. Keep on pressing the "Record" button for

more than three seconds to save changes.

Do not turn OFF the welding source while

saving.

2. Confirm that the 7-segment LED indicators

light again, then turn OFF the welding source

once and ON again.

For details, refer to " 4.2.8 Selecting Feeding Motor ".

Setting welding source voltage

control

6

Setting at the robot side Set the welding source condition files (including “Syn-

7

Set the welding source voltage control: either "Synergic (auto adjustment)" or "Independent (individual)".

When "Synergic" is set, the LED indicator lamp above

"Auto Adjustment/Individual" button will light up.

"Synergic (auto adjustment)" is set before shipping.

ergic (auto adjustment)” or “Independent (individual)”).

For details, refer to " 16 Welding Source Condition

File of the Robot Controller ".

3-1

HW0480311

Page 34

34/129

Table. 3 Welding Preparation Procedure

Step Item Details

HW0480311

Selecting welding type Before Setting;

the type of shielding gas and wire, or short-circuit/

8

Checking the indicated value on

the welding source panel

9

Wire inching Adjust the welding wire by wire inching so that it can

10

pulse.

Selectable types are written on the nameplate on the

front face of the panel. Set the welding type number to

the Type on the welding source panel.

Check the settings for the voltage, current, wire feeding speed, and welding type of the digital meter on the

welding source panel. Check the indicated value on

the panel by changing command value from the robot

controller.

be used for welding as follows:

1. Output the inching command from the robot

controller.

Select the welding type according to

2. Inch the wire until it comes out from the end of

the torch.

Adjusting gas flow Adjust the gas flow as follows:

1. Press the "Gas" button on the panel of welding source. The LED indicator lights and the

gas flows for 20 seconds. The gas automatically stops after the 20 seconds. (The gas

flow time can be set by the parameter C00.

Refer to " 4.2.7 Checking the Flow Amount of

11

Shielding Gas ".)

2. Turn the valve of the gas cylinder counterclockwise to open.

3. Turn the knob of the gas regulator to adjust

the flow according to welding conditions.

Proper gas flow rate is 10 to 25 liters per

minute. The flow rate must be increased in

proportion to the welding current (the higher

the current, the larger the flow rate).

Saving welding conditions Save the conditions before turning OFF the welding

source as follows:

1. Keep on pressing the "Record" button for

more than three seconds to save changes.

12

Do not turn OFF the welding source while

saving.

2. The 7-segment LED indicators light up again

at the completion of the saving. Confirm that

the 7-segment LED indicators light again.

End

13

3-2

HW0480311

Page 35

HW0480311

35/129

4.1 Explanation of Welding Source Panel

4 Operations on Panel

4.1 Explanation of Welding Source Panel

NOTE

Pressing the panel buttons during welding does not change any oper ation othe r than user

file selection.

Be sure to stop welding before starting the panel operations.

1

V

PRM Select

8

Common PRM Select

9

14

Record

2

A

Auto Adj.

Auto Adjustment

10

/Individual

15

Gas

3

Wire m/min

PRM Set

11

+

L

-

13

R

4

Type

Weld.Type

12

File No.1

File No.2

File No.3

16

User File Select

5

Power

Warning

Search

6

7

Fig. 9 Welding Source Panel

4-1

HW0480311

Page 36

4.1 Explanation of Welding Source Panel

36/129

The following table explains the display of the meters c, d, e, and f.

The content of the display differs according to the status as follows:

HW0480311

Status

During

standb

y

During welding

During wire inching

When

Parameter

C32=0,

Displays

Setting

Conditions.

When

Parameter

C32=1,

Displays

Stanby

V

c Welding Volt-

age Indicator

Displays the set

welding voltage

value (V).

Displays 0.0V Displays 0A Displays 0.0m/min Displays the weld-

Displays the welding voltage value

(V) that is fedback.

d Welding Cur-

rent Indicator

Displays the set

welding current

value (A).

Displays the welding current value

(A) that is fedback.

A

Wire m/min

e Wire Feeding

Speed Indi cator

Displays the feed-

ing amount (m/

min) of the set

welding current

value.

Displays the feeding amount (m/

min) of the motor

that is fed-back, or

the motor current.

(Can be switched

by the parameter

D1-5.)

Type

f Welding Type

Indicator

Displays the weld-

ing type (Type).

ing type (Type).

Displays the welding type (Type).

During setting parameter

Displays the

parameter number.

Normally displays

"---". When the arc

touch start is

selected, displays

"-" in the parameter P01.

Display Lamps

Item Content Explanation

g

h

i

Power Lamp Lights when the power supply is turned ON.

Warning Lamp Lights or blinks when an error occurs. The error number is dis-

played on the digital meter.

Search Lamp Lights while the starting point detecting function is used. High

voltage is being generated while the lamp is turned ON. ( E ffective only when the starting point detecting unit is installed.)

Displays

-P parameter:

ratio (%)

-C parameter:

value

(in decimal)

-D parameter

ON/OFF

Displays the welding type (Type).

4-2

HW0480311

Page 37

HW0480311

37/129

4.1 Explanation of Welding Source Panel

Setting Buttons

Item Content Explanation

j

k

l

11

12

Parameter Select

(P parameter)

Common Parameter

Select (C parameter)

Auto Adjustment/Individual (synergic/independent) Switch

Parameters Setting When setting parameters or common pa rameters, the numbers and

Selecting of Welding

Type

When the "PRM Select" button is pressed during standby status,

the display changes to the P parameter setting display. The 7-seg-

ment LED indicator

e displays the parameter set value. (Effective only when the

cator

user file is selected.)

Press this button again to return to the standby display.

When the "Common PRM Select" button is pressed during standby

status, the display changes to the common para meter setting dis-

play. The indicator

the common parameter set value.

Press this button again to return to the standby display.

Switches the control type of welding voltage.

-Auto adjustment: LED indicator lamp lights.

(Output voltage is set at % from the robot controller.)

-Individual: LED indicator lamp turns OFF.

(Output voltage is set by welding voltage command from the

robot controller.)

the parameter set values can be switched. The blinking 7-segment

LED indicator is the selected item.

Press the button "Weld Type" button during standby status to

change the welding type (Type), and the 7-segment LED indicator

c displays "P.00", and the 7-segment LED indi-

c displays "C.00", and the indicator e displays

12

f blinks. The welding type setting is confirmed with pressing of this

button again, and the 7-segment LED indicator

f stops blinking.

13

14

15

16

Right to Left or Up and

Down Move Button

Saving Conditions Used to save the setting. The LED indicator lamp blinks when the

Checking Gas Checks the gas. The LED indicator lamp lights when pressing the

Selecting of the User

File

Used to change the settings. Press "L" or "R" to move the digit.

Press "+" or "-" to increase or decrease the value.

setting is changed.

To save the changed setting, keep pressing the "Record" button for

three seconds or more. If the welding source is turned OFF when

the 7-segment LED indicators go out, the changed setting cannot

be saved successfully. Wait until the 7-segment LED indicators are

lit again. If the welding source is turned OFF and back ON af ter the

7-segment LED indicators are lit again (the conditions are saved),

the settings return to the status where the conditions were saved.

Turn the welding source OFF and back ON without pressing this

button so as not to save the changed settings.

"Gas" button, and the gas flows for 20 seconds. (The default setting

for the gas flow time is 20 seconds. This time can be changed by

C00 parameter.) When this button is pressed again during the gas

check, the gas stops flowing.

Selects the file to save the contents of the changed settings. Each

time the "User File Select" button is pressed, the LED indic ator

lamp for the file number is changed.

(No File→ File No.1→ File No.2→File No.3)

P parameters cannot be changed or saved without a file: "No File".

4-3

HW0480311

Page 38

4.2 Settings on Welding Source Panel

38/129

4.2 Settings on Welding Source Panel

4.2.1 Changing Welding Type

The following describes how to change the welding type.

(1) Press the button "Weld. Type", and the 7-segment LED indicator

blinks.

12

HW0480311

f "Type"

V

(2) Use the button "+" or "-" to increase or decrease the value. Use t he button "L"

or "R" to move the digit.

(3) After changing the value, press the button "Weld. Type" or leave it without doing

anything for 10 seconds, and the 7-segment LED indicator

V

Press the button "Record" for 3 seconds or more to save the changed value. Do

not turn OFF the welding source while pressing this button. The saving of conditions is completed when the 7-segment LED indicators are lit again.

13

14

A

A

Wire m/min

12

Wire m/min

Type

13

f "Type" lights.

Type

The welding types available for software version 3.20-000-6 (CPU) are listed on the

nameplate attached to the front panel of the welding source.

Welding types other than listed on the nameplate are not available. Using improper

welding type will result in unstable welding, which causes excessive spatters or

imperfect bead appearance. Before starting welding, confirm that the welding type

has been correctly selected.

4-4

HW0480311

Page 39

HW0480311

39/129

4.2 Settings on Welding Source Panel

Table. 4 List of Weld Types

Shielding Gas Wire

MAG

(Ar 80%, CO

20%)

MAG

(Ar 80%, CO

20%)

CO

2

MIG

(Ar 98%, O

2%)

2

2

2

Soft steel

Fe

Soft steel

Fe

Soft steel

Fe

Stainlesssteel

SUS

Pulse or

Short-circuit

Short-circuit

Pulse

Short-circuit

Short-circuit

Wire

Diameter

Weld

Type No.

φ 0.9 3.21

φ 1.0 3.24

φ 1.2 3.27

φ 1.4 3.61

φ 0.9 3.19

φ 1.0 3.22

φ 1.2 3.25

φ 1.4 3.60

φ 0.9 3.35

φ 1.0 3.36

φ 1.2 3.37

φ 1.4

3.62

φ 0.9 5.29

φ1.0 5.31

φ1.2 5.33

Remarks

MIG

(Ar 98%, O

2%)

MAG

(Ar 80%, CO

20%)

MIG

(Ar 98%, O

2%)

Ar

MIG

(Ar 92%, O

8%)

Welding types other than listed on the nameplate are not ava ila ble .

SUPPLE

-MENT

Using improper welding type will result in unstable welding,which causes excessive spatters or imperfect bead appearance.Before starting welding,confirm that the welding type

has been correctly selected.

Stainlesssteel

2

Pulse

SUS

Stainlesssteel

2

Pulse

SUS

SUS Pulse φ 1.2 4.43

2

Aluminum

Pulse φ 1.2 2.12

φ 0.9 5.46

φ 1.0 5.42

φ 1.2 5.44

φ 0.9 5.28

φ 1.0 5.30

φ 1.2 5.32

5000

Low pulse φ 1.2 2.14 Servo torch: Necessary

Mild steel

2

Fe

Zinc Pulse φ 1.2 3.59

Servo torch:

Recommended

For galvanized

sheet iron

4-5

HW0480311

Page 40

HW0480311

40/129

4.2 Settings on Welding Source Panel

4.2.2 User Files

The conditions changed by the P parameter concerning any welding type are saved in the

user files: File No. 1, File No. 2, and File No. 3.

Also, the user file can be called up from the manipulator controller to perform welding.

The P parameters cannot be changed or saved unless the user file is selected (No File status).

1. When the content of P parameter is to be changed, confirm that the user file can be

changed by the panel operation (D1 parameter D1-11=OFF), then select the user file:

file No. 1, 2, or 3. The file No. is changed each pressing of “User File Select” button,

16

and the LED indicator lamp of selected file lights. The file No. is changed as: No

File

ÆFile No.1ÆFile No.2ÆFile No.3.

2. Press the button “Weld.Type” to change the welding type (Type).

12

Refer to " 4.2.1 Changing Welding Type " for details on changing of the welding type.

When conditions are changed, the LED indicator lamp for "Record" blinks.

SUPPLE

-MENT

Keep pressing the button "Record" for three seconds or more to save the changed content. Do not turn OFF the welding source while pressing this button. The saving of conditions is completed when the 7-segment LED indicators are lit again.

14

CAUTION

• When the welding type which is set in the user file is changed, the P

parameters are initialized and everything becomes the value at 100 %.

4.2.3 Changing P Parameters

The P parameters are used for welding adjustment. The P parameters are changed by multiplying the internal set data of the selected welding type by the modification ratio. The change

of the P parameters is allowed only when the user file: file No.1, No.2, or No.3 is selected.

For details on the P parameter, refer to " 4.3 List of Process Parameters ".

Follow the instructions to change P parameter value as follows:

(1) Press the button

c voltmeter (V) displays "P.00" blinking, and the 7-segment LED indicator e

cator

j "PRM Select" during standby status. The 7-segment LED indi-

"Wire m/min" (WF) displays the parameter value lighting.

(2) Press the button "L" or "R" button to change the number of blinking digits to one.

Press the button "L" button to move the blinking to the left, and press the button

13

"R" to move the blinking to the right.

(3) Using the button “L” or “R”, move the blinking digits to the number to be

13

13

13

changed.

(4) Use the button “+” or “-“ to increase or decrease the value.

13

4-6

HW0480311

Page 41

HW0480311

41/129

4.2 Settings on Welding Source Panel

(5) Press the button “PRM Set”, and the parameter value on the 7-segment LED indi-

e “Wire m/min” blinks. The set value of parameter is ready to be changed.

cator

11

Change the set value in the range between 10 and 200 %.

For changing the parameter number, press the button “PRM Set” again.

The blinking digits move as shown below with each pressing of the button “PRM

11

11

Set”.

V

V

A

A

(6) After changing the value, press the button

Wire m/min

Wire m/min

j “PRM Set” or leave it without doing

Type

Type

anything for 10 seconds to return to the standby display.

Press the button "Record" for three seconds or more to save the changed values

14

(conditions). Do not turn OFF the welding source during saving conditions. When

the 7-segment LED indicators are lit again, the saving of conditions is completed.

4.2.4 Changing Common (C) Parameters

For the details on the common parameter, refer to " 4.4 List of Common Parameters ".

The C parameter is the common parameters for the welding source.

Follow the instructions to change C parameter value as follows:

(1) Press the button

LED indicator

cator

e "Wire m/min" (WF) displays the parameter value lighting.

(2) Press the button "L" or "R" to change the numb er of blinking digit s to one. Press

the button "L" to move the blinking to the left, and press the button "R" to

move the blinking to the right.

(3) Using the button "L" or "R", move the blinking digits to the number to be changed.

(4) Use the button "+" or "-" to increase or decrease the value.

k "Common PRM Select" during standby status. The 7-segment

c voltmeter (V) displays "C.00" blinking, and the 7-segment LED indi-

13

13

13

13

13

(5) Press the button "PRM Set", and the parameter value on the 7-segment LED

11

4-7

HW0480311

Page 42

4.2 Settings on Welding Source Panel

42/129

indicator e "Wire m/min" blinks. The set value of parameter is ready to be

HW0480311

changed. If the set value is four digits or more, use the button "L" to move the

cursor to the indicator

d ammeter (A). The indicator d ammeter (A) displays the

13

number(s) above the forth digit.

For changing the parameter number, press the button "PRM Set" again.

The blinking digits move as shown below with each pressing of the button "PRM

11

11

Set".

V

V

A

A

Wire m/min

Wire m/min

Type

Type

(6) After changing the value, press the button

k "Common PRM Select" or leave it

without doing anything for 10 seconds to return to the standby display.

Press the button "Record" for three seconds or more to save the changed values

14

(conditions). Do not turn OFF the welding source during saving conditions. When

the 7-segment LED indicators are lit again, the saving of conditions is completed.

4-8

HW0480311

Page 43

HW0480311

43/129

4.2 Settings on Welding Source Panel

4.2.5 Changing D Parameters

For details on the D parameter, refer to " 4.5 List of D Parameters ".

D parameters specify the setting or operation conditions for the welding source by ON/OFF.

The D parameters consist of D-1 parameter and D-2 parameter. The setting items for each

parameter are: No.1 to No.16, altogether 32 setting items are available.

Follow the instructions to change D parameter as follows:

(1) Keep pressing the button

Select" during standby status. The 7-segment LED indicator

plays "d-1" blinking, the 7-segment LED indicator

ware switch number blinking, and the 7-segment LED indicator

(WF) displays ON or OFF lighting.

k "Common PRM Select" and press the button j "PRM

c voltmeter (V) dis-

d ammeter (A) displays the soft-

e "Wire m/min"

(2) Use the button "+" or "-" to switch "d-1" and "d-2"

(3) The blinking digits move as shown below with each pressing of the button "PRM

13

11

Set".

V

V

V

A

A

A

Wire m/min

Wire m/min

Wire m/min

Type

Type

Type

Use the button "L","R", "+", or "-" to change the parameter number and the set

13

contents.

When the 7-segment LED indicator

d ammeter (A) is blinking, the software switch

numbers (1 to 16) can be selected.

When the 7-segment LED indicator

e "Wire m/min" is blinking, the setting of soft-

ware switch (ON/OFF) can be changed. ON and OFF are switched with each press-

ing of the button "+" or "-".

(4) After changing the setting, press the button

13

k "Common PRM Select" or leave it

without doing anything for 10 seconds to return to the standby display.

4-9

HW0480311

Page 44

4.2 Settings on Welding Source Panel

44/129

<Example>

When the parameter D1-11 is ON (enabled):

HW0480311

V

Press the button "Record" for three seconds or more to save the changed values

14

A

Wire m/min

Type

(conditions). Do not turn OFF the welding source during saving conditions. When

the 7-segment LED indicators are lit again, the saving of conditions is completed.

4.2.6 Saving Welding Conditions

When the parameter set value is changed by the operations on the welding source panel, the

LED indicator lamp above the button "Record" blinks.

The following describe how to save the settings.

(1) Referring to " 4.2.2 User Files ", specify the file number where the data are to be

saved.

(2) Press the button "Record" for 3 seconds or more, and the 7-segment LED indica-

14

tors display dashes "- - -".

(3) When the saving is completed, the 7-segment LED indicators returns to the status

where the conditions were saved.

If the power supply is turned OFF while saving the welding conditions, the data cannot be successfully saved. Confirm that the 7 segment LED indicators are lit again

before turning OFF the power supply.

14

CAUTION

• For P parameters, the changed data are validated at the same time the

change is made. However, when the welding type is changed or the

power supply switch of the welding source is turned OFF, the changed

data will be lost.

The changed data are overwritten on the da ta of the file where the data

are to be stored.

4-10

HW0480311

Page 45

HW0480311

45/129

4.2 Settings on Welding Source Panel

4.2.7 Checking the Flow Amount of Shielding Gas

The shielding gas flow amount can be checked.

Press the button "Gas" button. The LED indicator lamp above the "GAS" button lights and

the gas flows for 20 seconds.

Press the button again during gas checking to stop the gas flow.

The checking time of the gas flow amount can be adjusted by change in the numerical value

of C parameter C00, while, the default setting is 20 seconds (unit: second).

Press the button "Record" for 3 seconds or more to save the changed value.

15

14

NOTE

Do not turn OFF the breaker until the 7-segment LED indicators are lit again when the

“Record” button was pressed.

4.2.8 Selecting Feeding Motor

The feeding motor can be selected by change in the numerical value of C parameter C09.

C09: 0 Print servo (Default setting)

C09: 1 Servo torch

C09: 2 4-roller servo

Press the button "Record" button for 3 seconds or more to save the changed value.

To validate the change in setting, turn OFF the welding source and ON again after saving the

conditions.

NOTE

Do not turn OFF the breaker until the 7-segment LED indicators are lit again when the

“Record” button was pressed.

14

(YWE-WF340MELC)

CAUTION

• Welding performance will be unsatisfactory, since the wire cannot be

fed at the wire feeding speed as instructed by the command value

unless the feeding motor is set correctly.

• The change in the motor setting will be first reflected when the welding

source is restarted (turned OFF

Æ ON) after saving the conditions.

4-11

HW0480311

Page 46

HW0480311

46/129

4.2 Settings on Welding Source Panel

4.2.9 Monitoring of Motor Current

The motor current of rotating feeding motor can be displayed in the 7-segment LED indicator

"Wire m/min" by setting D parameter D1-5 to "OFF". During the standby status, the 7-segment LED indicator displays the command of wire feeding amount (m/min).

V

When the 7-segment LED indicator displays the motor current, "A" is indicated at the third digit

of the indicator.

In the figure above, the motor current is 0.5 A.

When the 7-segment LED indicator does not display "A" at the third digit, D paramete r D1-5 is

set to "ON" status, and the indicator shows the feedback speed of wire feeding.

There are two levels for monitoring the motor current: the warning level and the error level.

• Motor current warning

Outputs a warning signal when the motor current exceeds the warning level which has

been set by C parameter C25. Wire feeding and welding will be continued although the

motor current exceeds the warning level. The warning signal will be output through the

terminals 524 and 525 on the Pr(RC2)-001 board.

• Motor current error

Outputs Err502 "motor overcurrent" and ends wire feeding and welding when the motor

current is passed more than the rated current.

A

Wire m/min

Type

4.2.10 System Reset

System Reset initializes all the setting data in the welding source. Reset the system only when

the software is updated or initialization or when Memory Error (Error 205 to 299) occurs.

CAUTION

• Be sure that executing System Reset initializes all the internal data.

If some parameters must be retained, write them down on a sheet of

paper before System Reset. The data cannot be restored after the system reset operation.

4-12

HW0480311

Page 47

HW0480311

47/129

The following describes how to reset the system.

(1) Press the button

LED indicator

cator

e "Wire m/min" (WF) displays the parameter value lighting.

k "Common PRM Select" during standby status. The 7-segment

c voltmeter (V) displays "C.00" blinking, and the 7-segment LED indi-

4.2 Settings on Welding Source Panel

V

(2) Use the button "+", "-", "L" or "R" to display the parameter "C23".

V

(3) Press the button "PRM Set", and the parameter value on the 7-segment LED

indicator

e "Wire m/min" blinks. Change the setting value of parameter "C23" to

13

11

A

A

Wire m/min

Wire m/min

"2004". When the setting value is four digits or more , use the button "L" to move

the cursor to the 7-segment LED indicator

d ammeter (A). The indicator d amme-

Type

Type

13

ter (A) displays the number(s) above the forth digit. The system reset will be executed at C23=2004.

Wait until "sys rst" starts blinking.

V

A

Wire m/min

Type

(4) Turn OFF the welding source when "sys rst" is displayed. This is end of the initial-

ization.

V

A

Wire m/min

Type

(5) Turn ON the power supply and the parameters retu rn to the de fault setting. Set the

recorded parameters again if necessary.

4-13

HW0480311

Page 48

HW0480311

48/129

4.2 Settings on Welding Source Panel

4.2.11 Lock Of Panel Operation

"Lock of panel operation" is a function to invalidate the button operation so as not to operate

the button of a front panel of the welding power supply by mistake. The button that can be

operated with the panel operation locked is only a gas check button.

Method of setting "lock of panel operation"

R button is pushed continuousness three times while pushing L button.

V

PRM Select

Common PRM Select

Record

A

Auto Adj.

Auto Adjustment

/Individual

Gas

Wire m/min

LR

After the condition is stored, HOLd is displayed.

V