Page 1

MOTOMAN-MPL80 II

1 of 81

INSTRUCTIONS

TYPE:

YR-MPL0080-J00 (DX200 STANDARD SPECIFICATION)

Upon receipt of the product and prior to initial operation, read these instructions thoroughly, and

retain for future reference.

MOTOMAN INSTRUCTIONS

MOTOMAN-MPL80 II INSTRUCTIONS

DX200 INSTRUCTIONS

DX200 OPERATOR’S MANUAL (for each purpose)

DX200 MAINTENANCE MANUAL

Part Number: 170904-1CD

Revision: 5

MANUAL NO.

HW1482870

6

Page 2

MPL80 II

2 of 81

170904-1CD

Copyright © 2018, 2015, 2014 Yaskawa America, Inc.

Terms of Use and Copyright Notice

All rights reserved. This manual is freely available as a service to Yaskawa

customers to assist in the operation of Motoman robots, related equipment

and software This manual is copyrighted property of Yaskawa and may

not be sold or redistributed in any way. You are welcome to copy this

document to your computer or mobile device for easy access but you may

not copy the PDF files to another website, blog, cloud storage site or any

other means of storing or distributing online content.

Printed in the United States of America

First Printing, 2014

Yaskawa America, Inc.

Motoman Robotics Division

100 Automation Way

Miamisburg, OH 45342

Phone: 937-847-6200

www.motoman.com

ii

HW1482870

Page 3

170904-1CD

MANDATORY

CAUTION

3 of 81

MPL80 II

• This instruction manual is intended to explain mainly on the

mechanical part of the MOTOMAN-MPL80 II for the application to

the actual operation and for proper maintenance and inspection. It

describes on safety and handling, details on specifications,

necessary items on maintenance and inspection, to explain

operating instructions and maintenance procedures. Be sure to

read and understand this instruction manual thoroughly before

installing and operating the manipulator.

• General items related to safety are listed in the Chapter 1: Safety of

the DX200 instructions. To ensure correct and safe operation,

carefully read the DX200 instructions before reading this manual.

• Some drawings in this manual are shown with the protective covers

or shields removed for clarity. Be sure all covers and shields are

replaced before operating this product.

• The drawings and photos in this manual are representative

examples and differences may exist between them and the

delivered product.

• YASKAWA may modify this model without notice when necessary

due to product improvements, modifications, or changes in

specifications.

If such modification is made, the manual number will also be

revised.

• If your copy of the manual is damaged or lost, contact a YASKAWA

representative to order a new copy. The representatives are listed

on the back cover. Be sure to tell the representative the manual

number listed on the front cover.

• YASKAWA is not responsible for incidents arising from unauthorized

modification of its products. Unauthorized modification voids your

product’s warranty.

iii

HW1482870

Page 4

MPL80 II

4 of 81

170904-1CD

We suggest that you obtain and review a copy of the ANSI/RIA National

Safety Standard for Industrial Robots and Robot Systems (ANSI/RIA

R15.06-2012). You can obtain this document from the Robotic Industries

Association (RIA) at the following address:

Robotic Industries Association

900 Victors Way

P.O. Box 3724

Ann Arbor, Michigan 48106

TEL: (734) 994-6088

FAX: (734) 994-3338

www.roboticsonline.com

Ultimately, well-trained personnel are the best safeguard against

accidents and damage that can result from improper operation of the

equipment. The customer is responsible for providing adequately trained

personnel to operate, program, and maintain the equipment. NEVER

ALLOW UNTRAINED PERSONNEL TO OPERATE, PROGRAM, OR

REPAIR THE EQUIPMENT!

We recommend approved Yaskawa training courses for all personnel

involved with the operation, programming, or repair of the equipment.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC rules. These limits

are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications.

iv

HW1482870

Page 5

170904-1CD

CAUTION

MANDATORY

PROHIBITED

NOTE

DANGER

5 of 81

MPL80 II

Notes for Safe Operation

Read this manual carefully before installation, operation, maintenance, or

inspection of the MOTOMAN-MPL80 II.

In this manual, the Notes for Safe Operation are classified as “DANGER”,

“WARNING”, “CAUTION”, “MANDATORY”, or “PROHIBITED”.

DANGER

WARNING

Indicates an imminent hazardous

situation which, if not avoided, could

result in death or serious injury to

personnel.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury to

personnel.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury to

personnel and damage to

equipment. It may also be used to

alert against unsafe practices.

Always be sure to follow explicitly

the items listed under this heading.

Must never be performed.

Even items described as “CAUTION” may result in a serious accident in

some situations.

At any rate, be sure to follow these important items.

To ensure safe and efficient operation at all times, be sure

to follow all instructions, even if not designated as

“DANGER”, “WARNING” and “CAUTION” .

• Maintenance and inspection must be performed by specified

personnel.

Failure to observe this caution may result in electric shock or injury.

• For disassembly or repair, contact your Yaskawa representative.

• Do not remove the motor, and do not release the brake.

Failure to observe these safety precautions may result in death or

serious injury from unexpected turning of the manipulator's arm.

v

HW1482870

Page 6

MPL80 II

TURN

6 of 81

170904-1CD

WARNING

• Before operating the manipulator, check that servo power is turned

OFF pressing the emergency stop buttons .

When the servo power is turned OFF, the SERVO ON LED on the

programming pendant is turned OFF.

Injury or damage to machinery may result if the emergency stop circuit

cannot stop the manipulator during an emergency. The manipulator

should not be used if the emergency stop buttons do not function.

Fig. : Emergency Stop Button

• Once the emergency stop button is released, clear the cell of all

items which could interfere with the operation of the manipulator.

Then turn the servo power ON.

Injury may result from unintentional or unexpected manipulator motion.

Fig. : Release of Emergency Stop

• Observe the following precautions when performing teaching

operations within the P-point maximum envelope of the

manipulator:

– Be sure to use a lockout device to the safeguarding when going

inside. Also, display the sign that the operation is being

performed inside the safeguarding and make sure no one closes

the safeguarding.

– View the manipulator from the front whenever possible.

– Always follow the predetermined operating procedure.

– Keep in mind the emergency response measures against the

manipulator’s unexpected motion toward you.

– Ensure that you have a safe place to retreat in case of

emergency.

Improper or unintended manipulator operation may result in injury.

• Confirm that no person is present in the P-point maximum envelope

of the manipulator and that you are in a safe location before:

– Turning ON the power for the DX200.

– Moving the manipulator with the programming pendant.

– Running the system in the check mode.

– Performing automatic operations.

Injury may result if anyone enters the P-point maximum envelope of the

manipulator during operation. Always press an emergency stop button

immediately if there is a problem.

vi

HW1482870

Page 7

170904-1CD

CAUTION

7 of 81

MPL80 II

• Perform the following inspection procedures prior to conducting

manipulator teaching. If problems are found, repair them

immediately,

and be sure that all other necessary processing has been

performed.

– Check for problems in manipulator movement.

– Check for damage to insulation and sheathing of external wires.

• Always return the programming pendant to the hook on the cabinet

of the DX200 after use.

The programming pendant can be damaged if it is left in the

manipulator's work area, on the floor, or near fixtures.

• Read and understand the Explanation of Warning Labels in the

DX200 Instructions before operating the manipulator:

Definition of Terms Used Often in This Manual

The MOTOMAN is the YASKAWA industrial robot product.

The MOTOMAN usually consists of the manipulator, the controller, the

programming pendant, and supply cables.

In this manual, the equipment is designated as follows:

Equipment Manual Designation

DX200 controller DX200

DX200 programming pendant Programming pendant

Cable between the manipulator and the

controller

Manipulator cable

Description of the Operation Procedure

In the explanation of the operation procedure, the expression “Select • • •”

means that the cursor is moved to the item and the SELECT key is

pressed, or that the item is directly selected by touching the screen.

Registered Trademark

In this manual, names of companies, corporations, or products are

trademarks, registered trademarks, or bland names for each company or

corporation. The indications of

® and

TM

are omitted.

vii

HW1482870

Page 8

MPL80 II

8 of 81

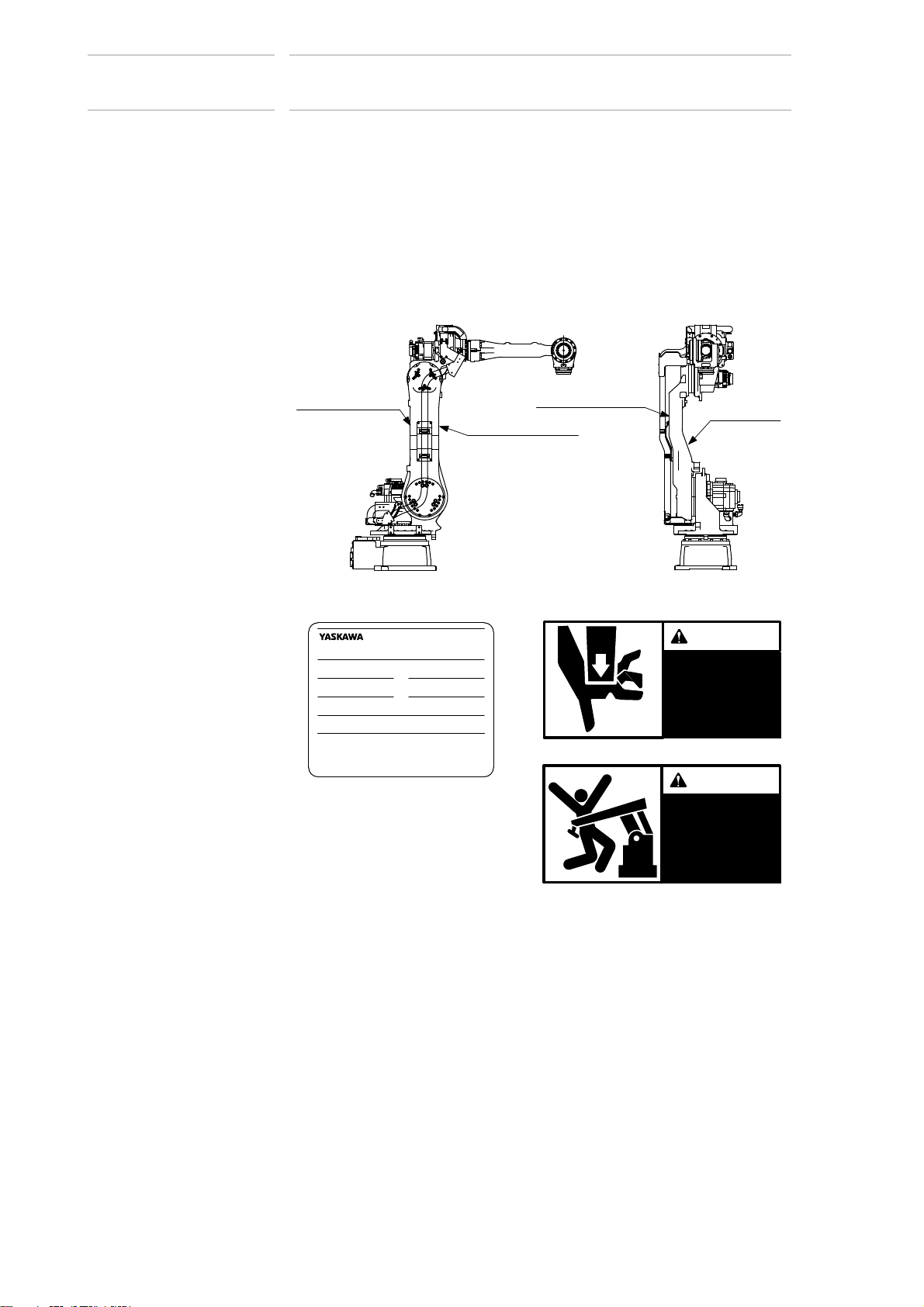

Explanation of Warning Labels

The following warning labels are attached to the manipulator.

Always follow the warnings on the labels.

Also, an identification label with important information is placed on the

body of the manipulator. Prior to operating the manipulator, confirm the

contents.

Fig. : Warning Label Locations

170904-1CD

WARNING label B

Nameplate

MODEL

MOTOMANTYPE

PAYLOAD

ORDERNO.

SERIALNO.

YASKAWAELECTRICCORPORATION

2-1Kurosakishiroishi,Yahatanishi-ku,

Kitakyushu806-0004Japan

MADEINJAPAN

kg

MASS

DATE

WARNING label A

kg

NJ3878

WARNING label A

WARNING Label A:

WARNING Label B:

Nameplate

WARNING

Moving parts

may cause

injury

WARNING

Do not enter

robot

work area.

viii

HW1482870

Page 9

170904-1CD

9 of 81

MPL80 II

Safeguarding Tips

All operators, programmers, maintenance personnel, supervisors, and

anyone working near the system must become familiar with the operation

of this equipment. All personnel involved with the operation of the

equipment must understand potential dangers of operation. General

safeguarding tips are as follows:

• Improper operation can result in personal injury and/or damage to

the equipment. Only trained personnel familiar with the operation of

this equipment, the operator's manuals, the system equipment, and

options and accessories should be permitted to operate this

equipment.

• Improper connections can damage the equipment. All connections

must be made within the standard voltage and current ratings of the

equipment.

• The system must be placed in Emergency Stop (E-Stop) mode

whenever it is not in use.

• In accordance with ANSI/RIA R15.06-2012, section 4.2.5, Sources of

Energy, use lockout/tagout procedures during equipment

maintenance. Refer also to Section 1910.147 (29CFR, Part 1910),

Occupational Safety and Health Standards for General Industry

(OSHA).

Mechanical Safety Devices

The safe operation of this equipment is ultimately the users responsibility.

The conditions under which the equipment will be operated safely should

be reviewed by the user. The user must be aware of the various national

codes, ANSI/RIA R15.06-2012 safety standards, and other local codes

that may pertain to the installation and use of this equipment.

Additional safety measures for personnel and equipment may be required

depending on system installation, operation, and/or location. The following

safety equipment is provided as standard:

• Safety barriers

• Door interlocks

• EMERGENCY STOP button

Check all safety equipment frequently for proper operation. Repair or

replace any non-functioning safety equipment immediately.

ix

HW1482870

Page 10

MPL80 II

10 of 81

Programming, Operation, and Maintenance Safety

All operators, programmers, maintenance personnel, supervisors, and

anyone working near the system must become familiar with the operation

of this equipment. Improper operation can result in personal injury and/or

damage to the equipment. Only trained personnel familiar with the

operation, manuals, electrical design, and equipment interconnections of

this equipment should be permitted to program, or maintain the system.

All personnel involved with the operation of the equipment must

understand potential dangers of operation.

• Inspect the equipment to be sure no potentially hazardous conditions

exist. Be sure the area is clean and free of water, oil, debris, etc.

• Be sure that all safeguards are in place. Check all safety equipment

for proper operation. Repair or replace any non-functioning safety

equipment immediately.

• Check the EMERGENCY STOP buttons for proper operation before

programming. The equipment must be placed in the Emergency

Stop (E-Stop) mode whenever it is not in use.

170904-1CD

• Back up all programs and jobs onto suitable media before making

program changes. To avoid loss of information, programs, or jobs, a

backup must always be made before performing any service

procedures or making any changes to options, accessories, or

equipment.

• Any modifications to the Controller can cause severe personal injury

or death, as well as damage to the Manipulator! Do not make any

modifications to the Controller unit. Making any changes without

written permission from Yaskawa will void the warranty.

• Some operations require a standard passwords and some require

special passwords.

• The equipment allows modifications of the software for maximum

performance. Use Care when making these modifications. All

modifications made to the software will change the way the

equipment operates and can cause severe personal injury or death,

as well as damage parts of the system. Double check all

modifications under every mode of operation to ensure changes do

not create a hazard or dangerous situation.

• This equipment has multiple sources of electrical supply. Electrical

interconnections are made between the Controller and other

equipment. Disconnect and lockout/tagout all electrical circuits

before making any modifications or connections.

• Do not perform any maintenance procedures before reading and

understanding the proper procedures in the appropriate manual.

• Use proper replacement parts.

• Improper connections can damage equipment. All connections must

be made within the standard voltage and current ratings of the

equipment.

x

HW1482870

Page 11

170904-1CD

11 of 81

MPL80 II

Maintenance Safety

Turn power OFF and disconnect and lockout/tagout all electrical circuits

before making any modifications or connections.

Perform only the maintenance described in this manual. Maintenance

other than specified in this manual should be performed only by Yaskawatrained, qualified personnel.

Summary of Warning Information

This manual is provided to help users establish safe conditions for

operating the equipment. Specific considerations and precautions are also

described in the manual, but appear in the form of DANGERS,

WARNINGS, CAUTIONS, and Notes.

It is important that users operate the equipment in accordance with this

instruction manual and any additional information which may be provided

by Yaskawa. Address any questions regarding the safe and proper

operation of the equipment to Customer Support.

xi

HW1482870

Page 12

MPL80 II

NOTE

(937) 847-3200

12 of 81

Customer Support Information

If you need assistance with any aspect of your MPL80 II system, please

contact Customer Support at the following 24-hour telephone number:

For routine technical inquiries, you can also contact Customer Support at

the following e-mail address:

When using e-mail to contact Customer Support, please provide a

detailed description of the issue, along with complete contact information.

Please allow approximately 24 to 36 hours for a response.

170904-1CD

techsupport@motoman.com

Please use e-mail for routine inquiries only. If you have an

urgent or emergency need for service, replacement parts,

or information, contact Customer Support at the telephone

number shown above.

Please have the following information ready before you call Customer

Support:

• System MPL80

• Primary Application

• Controller DX200

• Software Version

Access this information on the Programming

Pendant’s LCD display screen by selecting {MAIN

MENU} - {SYSTEM INFO} - {VERSION}

• Manipulator Serial Number

Located on the Manipulator data plate

• Manipulator Sales Order

Number

II

• Positioner

xii

Located on the Controller data plate

HW1482870

Page 13

170904-1CD

13 of 81

MPL80

II

Table of Contents

Table of Contents

1 Product Confirmation ...................................................................................................................... 1-1

1.1 Contents Confirmation ....................................................................................................... 1-1

1.2 Order Number Confirmation .............................................................................................. 1-2

2 Transport......................................................................................................................................... 2-1

2.1 Transport Method .............................................................................................................. 2-1

2.1.1 Using a Crane ...................................................................................................... 2-2

2.1.2 Using a Forklift...................................................................................................... 2-3

2.2 Shipping Bolts and Brackets..............................................................................................2-3

3 Installation....................................................................................................................................... 3-1

3.1 Installation of the Safeguarding .........................................................................................3-2

3.2 Mounting Procedures for Manipulator Base ...................................................................... 3-2

3.2.1 Mounting Example................................................................................................ 3-3

3.2.2 When the Manipulator is Mounted Directly on the Floor....................................... 3-4

3.3 Protection Class................................................................................................................. 3-5

3.4 Location ............................................................................................................................. 3-5

4 Wiring.............................................................................................................................................. 4-1

4.1 Grounding .......................................................................................................................... 4-1

4.2 Cable Connection .............................................................................................................. 4-2

4.2.1 Connection to the Manipulator.............................................................................. 4-2

4.2.2 Connection to the DX200 ..................................................................................... 4-2

5 Basic Specifications ........................................................................................................................ 5-1

5.1 Basic Specifications........................................................................................................... 5-1

5.2 Part Names and Working Axes.......................................................................................... 5-2

5.3 Baseplate Dimensions ....................................................................................................... 5-2

5.4 Dimensions and P-Point Maximum Envelope.................................................................... 5-3

5.5 B-Axis Operating Range .................................................................................................... 5-4

5.6 Stopping Angle and Time at the Emergency Stop............................................................. 5-5

5.6.1 Stop Category 0: Emergency Stop ....................................................................... 5-5

5.6.1.1 Position 100% ......................................................................................... 5-5

5.6.1.2 Position 66% ........................................................................................... 5-6

5.6.1.3 Position 33% ........................................................................................... 5-7

xiii

HW1482870

Page 14

170904-1CD

14 of 81

MPL80 II

5.6.2 Stop Category 1: Emergency Stop ....................................................................... 5-8

5.7 Alterable Operating Range ................................................................................................5-9

5.7.1 Necessary Parts ................................................................................................... 5-9

5.7.2 Notes on the S-Axis Mechanical Stopper Installation ......................................... 5-10

5.7.3 Alteration of the S-Axis Pulse Soft Limit ............................................................. 5-11

6 Allowable Load for Wrist Axis and Wrist Flange .............................................................................6-1

6.1 Allowable Wrist Load ......................................................................................................... 6-1

6.2 Wrist Flange....................................................................................................................... 6-2

7 System Application.......................................................................................................................... 7-1

7.1 Peripheral Equipment Mounts............................................................................................ 7-1

7.2 Internal User I/O Wiring Harness and Air Line................................................................... 7-2

Table of Contents

8 Electrical Equipment Specification .................................................................................................. 8-1

8.1 Position of Limit Switch ...................................................................................................... 8-1

8.1.1 Specification of Limit Switch ................................................................................. 8-1

8.1.2 Location of Limit Switch ........................................................................................ 8-1

8.1.3 Setting of Operation Range .................................................................................. 8-2

8.1.3.1 S-Axis Operation Range.......................................................................... 8-2

8.1.3.2 L-Axis Operation Range .......................................................................... 8-2

8.1.3.3 Setting Range of LU-Axes Interference Angle......................................... 8-3

8.2 Internal Connections .......................................................................................................... 8-4

9 Maintenance and Inspection ........................................................................................................... 9-1

9.1 Inspection Schedule........................................................................................................... 9-1

9.2 Notes on Maintenance Procedures.................................................................................... 9-5

9.2.1 Battery Pack Replacement ................................................................................... 9-5

9.3 Grease Replenishment/Exchange ..................................................................................... 9-7

9.3.1 Notes on Grease Replenishment/Exchange Procedures ..................................... 9-7

9.3.2 Grease Replenishment/Exchange for S-axis Speed Reducer.............................. 9-8

9.3.2.1 Grease Replenishment............................................................................ 9-8

9.3.2.2 Grease Exchange.................................................................................... 9-9

9.3.3 Grease Replenishment/Exchange for L-Axis Speed Reducer............................ 9-10

9.3.3.1 Grease Replenishment.......................................................................... 9-10

9.3.3.2 Grease Exchange.................................................................................. 9-11

9.3.4 Grease Replenishment/Exchange for U-Axis Speed Reducer ........................... 9-12

9.3.4.1 Grease Replenishment.......................................................................... 9-12

9.3.4.2 Grease Exchange.................................................................................. 9-13

xiv

HW1482870

Page 15

170904-1CD

15 of 81

MPL80

10 Recommended Spare Parts....................................................................................................... 10-1

11 Parts List ..................................................................................................................................... 11-1

II

9.3.5 Grease Replenishment for B- and T-Axis Gears................................................ 9-14

9.3.5.1 Grease Replenishment.......................................................................... 9-14

9.3.5.2 Grease Exchange ................................................................................. 9-15

9.3.6 Grease Replenishment for B- and T-Axis Speed Reducers and Gears ............. 9-16

9.3.6.1 Grease Replenishment.......................................................................... 9-16

9.3.6.2 Grease Exchange ................................................................................. 9-17

9.4 Notes for Maintenance..................................................................................................... 9-18

9.4.1 Battery Pack Connection .................................................................................... 9-18

11.1 S-Axis Unit ..................................................................................................................... 11-1

11.2 L-Axis Unit ..................................................................................................................... 11-3

Table of Contents

11.3 U-Axis Unit..................................................................................................................... 11-5

11.4 B-,T-Axes Unit ............................................................................................................... 11-7

11.5 Wrist Unit ..................................................................................................................... 11-10

xv

HW1482870

Page 16

MPL80 II

CAUTION

16 of 81

1 Product Confirmation

1.1 Contents Confirmation

1 Product Confirmation

• Confirm that the manipulator and the DX200 have the same order

number. Special care must be taken when more than one

manipulator is to be installed.

If the numbers do not match, manipulators may not perform as

expected and cause injury or damage.

1.1 Contents Confirmation

Confirm the contents of the delivery when the product arrives.

Standard delivery includes the following four items (Information for the

content of optional goods is given separately):

170904-1CD

• Manipulator

• DX200

• Programing Pendant

• Manipulator Cable

1-1

HW1482870

Page 17

170904-1CD

17 of 81

MPL80

II

1 Product Confirmation

1.2 Order Number Confirmation

1.2 Order Number Confirmation

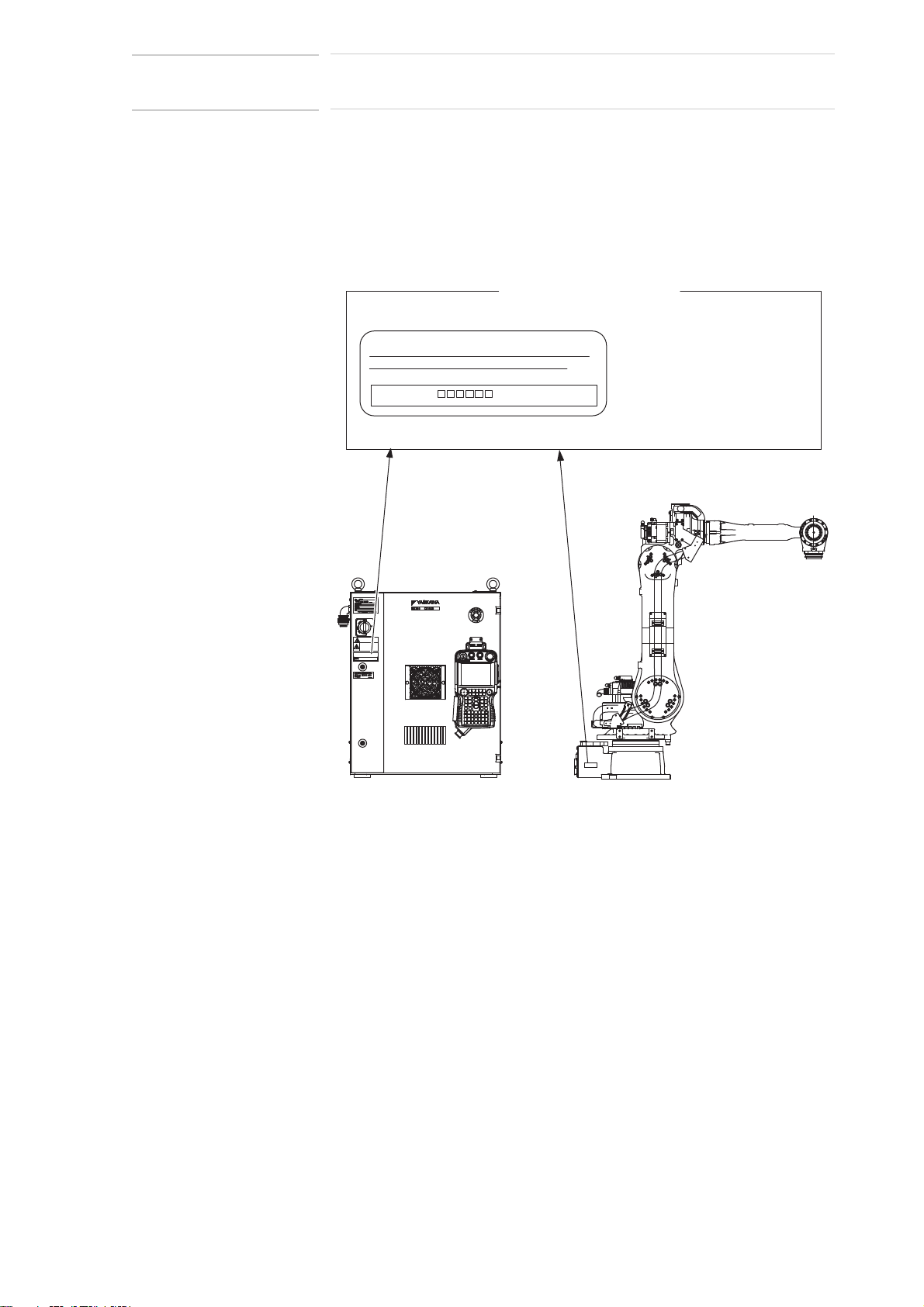

Check that the order number of the manipulator corresponds to the

DX200. The order number is located on a label as shown below.

Fig. 1-1: Location of Order Number Labels

Label (Enlarged View)

THE MANIPULATOR AND THE CONTROLLER

SHOULD HAVE SAME ORDER NUMBER.

ORDER NO.

Check that the manipulator

and the DX200 have the

same order number.

(a) DX200 (Front View) (b) Manipulator (Side View)

1-2

HW1482870

Page 18

MPL80 II

CAUTION

NOTE

18 of 81

2 Transport

170904-1CD

2 Transport

2.1 Transport Method

• Sling applications and crane or forklift operations must be

performed by authorized personnel only.

Failure to observe this caution may result in injury or damage.

• Avoid excessive vibration or shock during transport.

The system consists of precision components. Failure to observe this

caution may adversely affect performance.

2.1 Transport Method

• Check that the eyebolts are securely fastened.

• The weight of the manipulator is approximately 580 kg

including the shipping bolts and brackets. Use a wire rope

strong enough to withstand the weight.

• Attached eyebolts are designed to support the manipulator

weight. Do not use them for anything other than

transporting the manipulator.

• Mount the shipping bolts and brackets for transporting the

manipulator.

• Avoid putting external force on the arm or motor unit when

transporting by a crane, forklift, or other equipment.

Failure to observe this instruction may result in injury.

2-1

HW1482870

Page 19

170904-1CD

19 of 81

MPL80

II

2 Transport

2.1 Transport Method

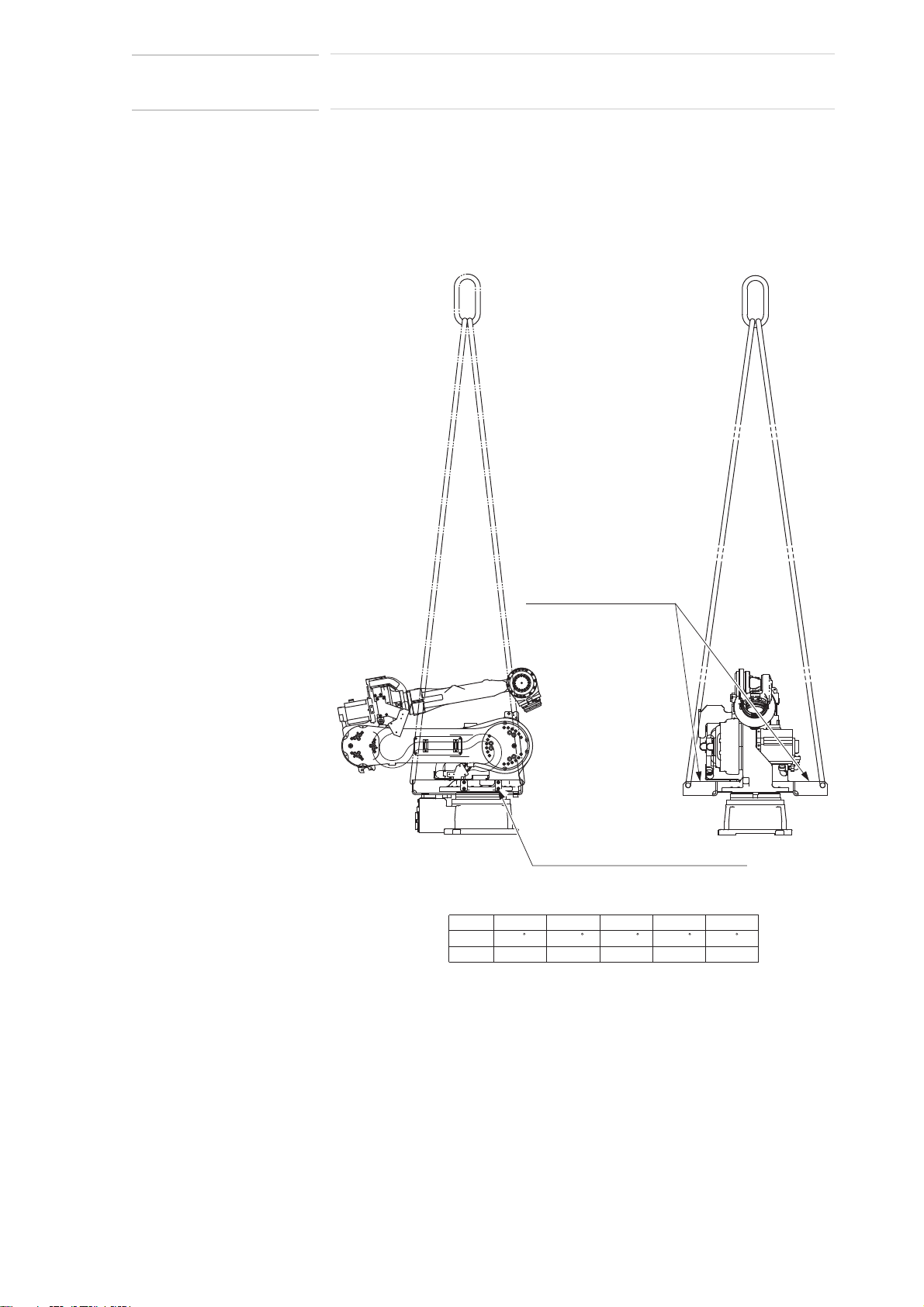

2.1.1 Using a Crane

As a rule, the manipulator should be lifted by a crane with four wire ropes

when removing it from the package and moving it. Be sure that the

manipulator is fixed with the shipping bolts and brackets before transport,

and lift it in the posture as shown in Fig. 2-1 “Transporting Position”.

Fig. 2-1: Transporting Position

Shipping bracket

Delivered with the manipulator

Hexagon socket head cap screw M12

(8 screws)

Factory setting for angle and pulse of each axis

Axis

Angle

Pulse

SLUBT

0

-90 +5

-144384 3826

0

-80 0

-159547

0

2-2

HW1482870

Page 20

MPL80 II

Delivered with the manipulator

Shipping bracket

Forklift claw entry

Pallet

Bolt M20 (8 bolts)

NOTE

20 of 81

170904-1CD

2 Transport

2.2 Shipping Bolts and Brackets

2.1.2 Using a Forklift

When using a forklift, the manipulator should be fixed on a pallet with bolts

as shown in Fig. 2-2 “Using a Forklift”. Insert claws under the pallet and lift

it. The pallet must be strong enough to support the manipulator. Transport

the manipulator slowly with due caution in order to avoid overturning or

slippage.

Fig. 2-2: Using a Forklift

2.2 Shipping Bolts and Brackets

The manipulator is provided with shipping bolts and a shipping brackets.

(See Fig. 2-1 “Transporting Position”.)

• The shipping bolts and bracket are painted yellow.

Before turning ON the power, make sure that the shipping

bolts and brackets are removed. The shipping bolts and

brackets then must be stored for future use, in the event

that the manipulator must be moved again.

2-3

HW1482870

Page 21

170904-1CD

CAUTION

21 of 81

MPL80

II

3 Installation

3 Installation

WARNING

• Install the safeguarding.

Failure to observe this warning may result in injury or damage.

• Install the manipulator in a location where the tool or the workpiece

held by its fully extended arm will not reach the wall, safeguarding,

or controller.

Failure to observe this warning may result in injury or damage.

• Do not start the manipulator or even turn ON the power before it is

firmly anchored.

The manipulator may overturn and cause injury or damage.

• Do not install or operate a manipulator that is damaged or lacks

parts.

Failure to observe this caution may cause injury or damage.

• Before turning ON the power, check to be sure that the shipping

bolts and brackets are removed.

Failure to observe this caution may result in damage to the driving

parts.

3-1

HW1482870

Page 22

MPL80 II

22 of 81

170904-1CD

3 Installation

3.1 Installation of the Safeguarding

3.1 Installation of the Safeguarding

To insure safety, be sure to install safeguarding. It prevents unforeseen

accidents with personnel and damage to equipment. Refer to the quoted

clause for your information and guidance.

Responsibility for Safeguarding (ISO10218)

The user of a manipulator or robot system shall ensure that safeguarding

is provided and used in accordance with Sections 6, 7, and 8 of this

standard. The means and degree of safeguarding, including any

redundancies, shall correspond directly to the type and level of hazard

presented by the robot system consistent with the robot application.

Safeguarding may include but not be limited to safeguarding devices,

barriers, interlock barriers, perimeter guarding, awareness barriers, and

awareness signals.

3.2 Mounting Procedures for Manipulator Base

The manipulator should be firmly mounted on a baseplate or foundation

strong enough to support the manipulator and withstand repulsion forces

during acceleration and deceleration.

Construct a solid foundation with the appropriate thickness to withstand

maximum repulsion forces of the manipulator referring to Table 3-1

“Manipulator Repulsion Force and Torque” .

A baseplate flatness must be kept at 0.5 mm or less: insufficient flatness

of installation surface may deform the manipulator shape and affect its

functional abilities. Mount the manipulator base as instructed in section

3.2.1 “Mounting Example” or section 3.2.2 “When the Manipulator is

Mounted Directly on the Floor”.

Table 3-1: Manipulator Repulsion Force and Torque

Horizontal rotation Vertical rotation

Repulsion force F

Emergency stop 23544 N

(2400kgf)

Acceleration/deceleration 5886 N

(600 kgf)

Torque M

H

24525 N•m

(2500 kgf•m)

6131 N•m

(625 kgf•m)

Fig. 3-1: Manipulator Repulsion Force and Torque

H

Repulsion force FVTorque M

27468 N

(2800 kgf)

5396 N

(550 kgf)

M

V

45126 N•m

(4600 kgf•m)

11282 N•m

(1150 kgf•m)

V

3-2

F

V

M

H

F

H

HW1482870

Page 23

170904-1CD

50

30

Flatness:

0.5mm or less

Hexagon head screw

M20 (8 screws)

Manipulator base

Spring washer

Washer

Baseplate

Anchor bolt M20 or more

Baseplate

23 of 81

MPL80

II

3 Installation

3.2 Mounting Procedures for Manipulator Base

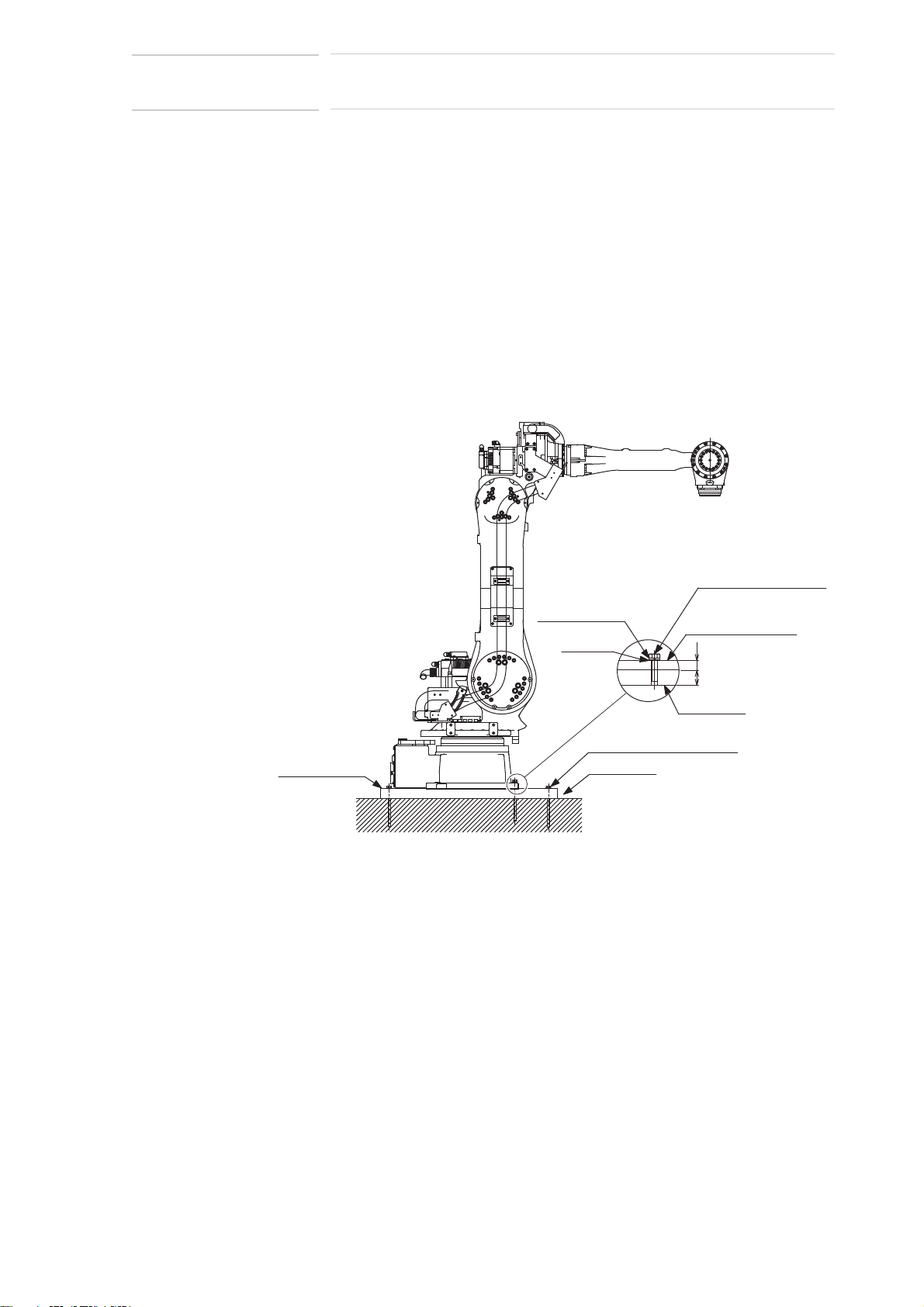

3.2.1 Mounting Example

For the first process, anchor the baseplate firmly to the ground. The

baseplate should be rugged and durable to prevent shifting of the

manipulator or the mounting fixture. It is recommend to prepare a

baseplate of 50 mm or more thick, and anchor bolts of M20 or larger size.

Next, fix the manipulator base to the baseplate. The manipulator base is

tapped for eight mounting holes; securely fix the manipulator base to the

baseplate with hexagon head screws M20 (70 mm long is recommended).

Tighten the hexagon head screws and anchor bolts firmly so that they will

not work loose during the operation.

Refer to Fig. 3-2 “Mounting the Manipulator Baseplate”.

Fig. 3-2: Mounting the Manipulator Baseplate

3-3

HW1482870

Page 24

MPL80 II

600

900

800

720

385

320

300300

400

230

Bolt A

Tapped hole M20 (8 holes)

Bolt B

Tapped hole M24 (4holes) (Base B)

28dia. (4 holes) (Base A)

28dia. (4 holes) (Base B)

Base B

Base A

Bolt A: Bolt M20 X 70 mm (8 bolts),Spring Washer, Flat Washer

Tightening bolts or bases are prepared by the customer.

FL

Leveling is required

32

36250

350

200

100

100

200

JA Base bolt

M24 X315mm

Weld after adjusting

the installation

10

Manipulator base

Units: mm

Bolt B: Bolt M24 X 70 mm (4 bolts),Spring Washer, Flat Washer

24 of 81

3 Installation

3.2 Mounting Procedures for Manipulator Base

3.2.2 When the Manipulator is Mounted Directly on the Floor

The floor should be strong enough to support the manipulator. Construct

a solid foundation with the appropriate thickness to withstand maximum

repulsion forces of the manipulator. As a rough standard, when there is a

concrete thickness (floor) is 200 mm or more, the manipulator base can

be fixed directly to the floor with M 20 anchor bolts. Before mounting the

manipulator, however, check that the floor is level and that all cracks, etc.

are repaired. Any thickness less than 200 mm is insufficient for mounting,

even if the floor is concrete.

Fig. 3-3: Direct Mounting on the Floor

170904-1CD

3-4

HW1482870

Page 25

170904-1CD

25 of 81

MPL80

II

3 Installation

3.3 Protection Class

3.3 Protection Class

For the standard type, environmental resistance for main part of the

manipulator conforms to IP54; the wrist part conforms to IP67.

For the main part of environmental resistance, IP65 is also available as

optional.

3.4 Location

When installing a manipulator, it is necessary to satisfy the following

environmental conditions:

• Ambient Temperature: 0 to +45C

• Humidity: 20 to 80%RH (non-condensing)

• Free from dust, soot, oil, or water

• Free from corrosive gas or liquid, or explosive gas or liquid.

• Free from excessive vibration (4.9 m/s

2

[0.5G] or less)

• Free from large electrical noise (plasma)

• The flatness for installation is 0.5 mm or less

3-5

HW1482870

Page 26

MPL80 II

CAUTION

NOTE

A

5.5mm or more

2

Delivered with the manipulator

Bolt M8 (for grounding)

View A

26 of 81

4 Wiring

170904-1CD

4 Wiring

4.1 Grounding

WARNING

• Ground resistance must be 100 or less.

Failure to observe this warning may result in fire or electric shock.

• Before wiring, make sure to turn the primary power supply off, and

put up a warning sign. (ex. DO NOT TURN THE POWER ON.)

Failure to observe this warning may result in fire or electric shock.

• Wiring must be performed by authorized or certified personnel.

4.1 Grounding

Fig. 4-1: Grounding Method

Failure to observe this caution may result in fire or electric shock

Follow the local regulations and electrical installation standards for

grounding. A wire of 5.5 mm

Refer to Fig. 4-1 “Grounding Method” to connect the ground line directly to

the manipulator.

• Never use this wire sharing with other ground lines or

grounding electrodes for other electric power, motor

power, welding devices, etc.

• Where metal ducts, metallic conduits, or distributing racks

are used for cable laying, ground in accordance with

electrical installation standards.

2

or more is recommended.

4-1

HW1482870

Page 27

170904-1CD

2BC

X11

1BC

X21

2BC

DX200 side

X11

1BC

X21 2BC

DX200 side

1BC

Manipulator side

Encoder cable

Power cable

Manipulator side

27 of 81

MPL80

II

4 Wiring

4.2 Cable Connection

4.2 Cable Connection

Two manipulator cables are delivered with the manipulator; an encoder

cable (1BC) and a power cable (2BC). (Refer to Fig. 4-2 “Manipulator

Cables”.)

Connect these cables to the manipulator base connectors and to the

DX200. Refer to Fig. 4-3(a) “Manipulator Cable Connectors (Manipulator

Side)” and Fig. 4-3(b) “Manipulator Cable Connectors (DX200 Side)”.

4.2.1 Connection to the Manipulator

Before connecting cables to the manipulator, verify the numbers on both

manipulator cables and the connectors on the connector base of the

manipulator. When connecting, adjust the cable connector positions to

the main key positions of the manipulator, and insert cables in the order of

2BC, then 1BC. After inserting the cables, depress the lever until it clicks.

4.2.2 Connection to the DX200

Before connecting cables to the DX200, verify the numbers on both

manipulator cables and the connectors on the DX200. When connecting,

insert the cables in the order of X21, then X11, and depress each lever low

until it clicks.

Fig. 4-2: Manipulator Cables

4-2

HW1482870

Page 28

MPL80 II

28 of 81

170904-1CD

4 Wiring

4.2 Cable Connection

Fig. 4-3(a): Manipulator Cable Connectors (Manipulator Side)

AIR

1BC

2BC

Fig. 4-3(b): Manipulator Cable Connectors (DX200 Side)

X11

X21

AIR

1BC

2BC

4-3

HW1482870

Page 29

170904-1CD

29 of 81

MPL80

II

5 Basic Specifications

5.1 Basic Specifications

5 Basic Specifications

5.1 Basic Specifications

Table 5-1: Basic Specifications

Item Model MOTOMAN-MPL80 II

Structure Vertically Articulated

Degree of Freedom 5

Payload 80 kg

Repeatability

Range of Motion S-Axis (turning) -180+180

Maximum Speed S-Axis 2.97 rad/s, 170/s

Allowable Moment

Allowable Inertia

2

/4)

(GD

Approx. Mass 550 kg

Protective Structure Basic axis: IP54 or equivalent

Ambient Conditions Temperature 0 to 45C

Power Capacity 4.0 kVA

Noise

1 SI units are used in this table. However, gravitational unit is used in ( ).

2 Conformed to ISO9283

3 The range of motion of the B-axis indicates the angle to the ground. With certain postures,

however, motion may be limited by the relative angle between the B-axis and the upper arm.

Refer to section 5.5 “B-Axis Operating Range”.

4 Refer to section 6.1 “Allowable Wrist Load” for details on the permissible moment of inertia.

5 Conformed to ISO6926

1, Measurement is carried out when the maximum load is mounted to the manipulator and

operated in the maximum speed.

2, Measurement is carried out:

- between 1.2m and 1.5m above the ground.

- 400mm away from the P-point maximum envelope.

2)

4)

5)

1)

±0.07 mm

L-Axis (lower arm) -90+135

U-Axis (upper arm) -160+35

B-Axis (wrist pitch/yaw) -15+15

T-Axis (wrist twist) -360+360

L-Axis 2.97 rad/s, 170/s

U-Axis 2.97 rad/s, 170/s

B-Axis 2.97 rad/s, 170/s

T-Axis 6.11 rad/s, 350/s

B-Axis 78.4 N•m (8 kgf•m)

T-Axis 20.5 N•m (2.1 kgf•m)

B-Axis 16 kg•m

T-Axis 6.1 kg•m

Wrist axis only: IP67 or equivalent

Humidity 20 to 80% RH at constant temperature

Vibration Acceleration Less than 4.9 m/s

Others Free from corrosive gas or liquid, or explosive gas.

Free from water, oil, or dust.

Free from excessive electrical noise (plasma).

70 dB

3)

2

2

2

(0.5 G)

5-1

HW1482870

Page 30

MPL80 II

30

A

153

455

608

455

195

385

320

195

±0.1

195

230

22 dia.(8 holes)

View A

+0.018

0

12 dia. (2 holes)

230

400

195

Base dimensions

30 of 81

170904-1CD

5 Basic Specifications

5.2 Part Names and Working Axes

5.2 Part Names and Working Axes

Fig. 5-1: Part Names and Working Axes

Rotary head

S-head

L- L+

S+

Upper arm

U+

U-

Lower arm

L-arm

Manipulator base

U-arm

B-

T-

Wrist

B+

T+

Wrist flange

5.3 Baseplate Dimensions

Fig. 5-2: Baseplate Dimensions

S-

5-2

HW1482870

Page 31

170904-1CD

31 of 81

MPL80

II

5 Basic Specifications

5.4 Dimensions and P-Point Maximum Envelope

5.4 Dimensions and P-Point Maximum Envelope

Fig. 5-3: Dimensions and P-Point Maximum Envelope

1807

210870540 187

180°

R377

180°

145

90°

1025

R543

R2061

P-point maximum envelope

55°

57

175

P-point

276

253343

135°

85°

131

3291

15°

15°

65°

6231121 312 925 1300 2170

160°

471

248

6

543

2192

2061

234234

5-3

HW1482870

Page 32

MPL80 II

15°

15°

15°

32 of 81

5 Basic Specifications

5.5 B-Axis Operating Range

5.5 B-Axis Operating Range

The operating range of the B-axis maintaining a constant angle to the

center of U-axis is shown in Fig. 5-4 “B-Axis Operating Range”.

By “B-axis adjustable motion function”, the B-axis maintains the same

posture to the ground regardless of the L- or U-axis angle.

The operating range is ±15° (0 degree is defined as the angle when the

wrist flange is horizontal and facing to the ground.) When the B-axis

position exceeds this limit, ”Special Soft Limit” occurs.

Note: In relation with interference with the upper arm, the range of motion

can be limited.

Fig. 5-4: B-Axis Operating Range

U-axis rotation center

55°

170904-1CD

(*1)

15°

L-axis rotation center

S-axis rotation center

55°

(*1)

15°

15°

15°

15

15

15°

15

15°

Upper arm

(U-arm)

15°

15°

15°

15°

B-axis rotation center

Wrist flange

15°

15°

15°

15°

5-4

HW1482870

Page 33

170904-1CD

Stop position of S -axis category0 100%

0

5

10

15

20

25

30

35

0 30 60 90 120 150 180

Speed[deg/s]

Stopping angle[deg]

Load100% Load66% Load33%

Stop position of S -axis category0 100%

0.0

0.1

0.2

0.3

0.4

0.5

0 30 60 90 120 150 180

Speed[deg/s]

Stopping time[sec]

Load100% Load66% Load33%

Stop position of L-axis category0 100%

0

5

10

15

20

25

30

35

0 30 60 90 120 150 180

S peed[deg/s]

Stopping angle[deg]

Load100% Load66% Load33%

Stop position of L-axis category0 100%

0.0

0.1

0.2

0.3

0.4

0.5

0 30 60 90 120 150 180

Speed[deg/s]

Stopping time[sec]

Load100% Load66% Load33%

Stop position of U -axis category0 100%

0

5

10

15

20

25

30

35

0 30 60 90 120 150 180

Speed[deg/s]

Stopping angle[deg]

Load100% Load66% Load33%

Stop position of U -axis category0 100%

0.0

0.1

0.2

0.3

0.4

0.5

0 30 60 90 120 150 180

Speed[deg/s]

Stopping time[sec]

Load100% Load66% Load33%

33 of 81

MPL80

II

5 Basic Specifications

5.6 Stopping Angle and Time at the Emergency Stop

5.6 Stopping Angle and Time at the Emergency Stop

Following data on stopping angle and time at the emergency stop are

measured under the standard of ISO10218.

5.6.1 Stop Category 0: Emergency Stop

5.6.1.1 Position 100%

Fig. 5-5: Category 0, Position 100%: Stopping Angle and Time for each Axis at the Emergency Stop

(a)S-Axis

(b)L-Axis

(c)U-Axis

5-5

HW1482870

Page 34

170904-1CD

Stop position of S -axis category0 66%

0

5

10

15

20

25

30

35

0 306090120150180

Speed[deg/s]

Stopping angle[deg]

Load100% Load66% Load33%

Stop positio n o f S - ax is category0 66%

0.0

0.1

0.2

0.3

0.4

0.5

0 30 60 90 120 150 180

Speed[deg/s]

Stopping time[sec]

Load100% Load66% Load33%

Stop position of L-axis category0 66%

0

5

10

15

20

25

30

35

0 20 40 60 80 100 120 140 160 180

Speed[deg/s]

Stopping angle[deg]

Load100% Load66% Load33%

Stop position of L-axis category0 66%

0.0

0.1

0.2

0.3

0.4

0.5

0 30 60 90 120 150 180

Speed[deg/s]

Stopping time[sec]

Load100% Load66% Load33%

34 of 81

MPL80 II

5 Basic Specifications

5.6 Stopping Angle and Time at the Emergency Stop

5.6.1.2 Position 66%

Fig. 5-6: Category 0, Position 66%: Stopping Angle and Time for each Axis at the Emergency Stop

(a)S-Axis

(b)L-Axis

note: U axis is only one pose for its structure.

5-6

HW1482870

Page 35

170904-1CD

Stop position of S -axis category0 33%

0

5

10

15

20

25

30

35

0 30 60 90 120 150 180

Speed[deg/s]

Stopping angle[deg]

Load100% Load66% Load33%

Stop positio n o f S - ax is category0 33%

0.0

0.1

0.2

0.3

0.4

0.5

0 30 60 90 120 150 180

Speed[deg/s]

Stopping time[sec]

Load100% Load66% Load33%

Stop position of L-axis category0 33%

0

5

10

15

20

25

30

35

0 30 60 90 120 150 180

Speed[deg/s]

Stopping angle[deg]

Load100% Load66% Load33%

Stop position of L-axis category0 3 3%

0.0

0.1

0.2

0.3

0.4

0.5

0 30 60 90 120 150 180

Speed[deg/s]

Stopping time[sec]

Load100% Load66% Load33%

35 of 81

MPL80

II

5 Basic Specifications

5.6 Stopping Angle and Time at the Emergency Stop

5.6.1.3 Position 33%

Fig. 5-7: Category 0, Position 33%: Stopping Angle and Time for each Axis at the Emergency Stop

(a)S-Axis

(b)L-Axis

note: U axis is only one pose for its structure.

5-7

HW1482870

Page 36

MPL80 II

Stop position of S -axis category1

0

10

20

30

40

50

60

0 30 60 90 120 150 180

Speed[deg/s]

Stopping angle[deg]

Stop position of S -axis category1

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0 30 60 90 120 150 180

Speed[deg/s]

Stopping time[sec]

Stop position of L-axis ca te g ory 1

0

10

20

30

40

50

60

0 30 60 90 120 150 180

Speed[deg/s]

Stopping angle[deg]

Stop position of L-axis category1

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0 30 60 90 120 150 180

Speed[deg/s]

Stopping time[sec]

Stop position of U -axis c a tego ry 1

0

10

20

30

40

50

60

0 30 60 90 120 150 180

Speed[deg/s]

Stopping angle[deg]

Stop position of U -axis c ate go ry 1

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0 30 60 90 120 150 180

Speed[deg/s]

Stopping time[sec]

36 of 81

5 Basic Specifications

5.6 Stopping Angle and Time at the Emergency Stop

5.6.2 Stop Category 1: Emergency Stop

The stopping angle and time at the emergency stop in category 1 are not

subjected to the manipulator position and the load.

Stop of category1 doesn't depend on the robot position and the load.

Fig. 5-8: Category 1: Stopping Angle and Time for each Axis at the Emergency Stop

(a)S-Axis

170904-1CD

(b)L-Axis

(c)U-Axis

5-8

HW1482870

Page 37

170904-1CD

37 of 81

MPL80

II

5 Basic Specifications

5.7 Alterable Operating Range

5.7 Alterable Operating Range

The operating range of the S-axis can be altered in accordance with the

operating conditions as shown in Table 5-2 “S-Axis Operating Range”.

If alteration is necessary, contact your Yaskawa representative in

advance.

Table 5-2: S-Axis Operating Range

Item Specifications

S-Axis Operating Range -180° - +180°(standard)

-165° - +165°

-150° - +150°

-135° - +135°

-120° - +120°

-105° - +105°

-90° - +90°

-75° - +75°

-60° - +60°

-45° - +45°

-30° - +30°

-15° - +15°

5.7.1 Necessary Parts

When altering the operating range of the S-axis, following parts shown in

Fig. 5-9 “S-Axis Mechanical Stopper” are necessary in addition to the

already delivered parts.

(1) Hexagon socket head cap screw M20 (length: 40 mm)

(2) Collar (drawing No. HW9405875-2) x 1

(3) Pin (drawing No. HW9405032-2) x 1

(4) Washer M6X3

Note:((3), (4) only): Necessary only when the manipulator is equipped with

Fig. 5-9: S-Axis Mechanical Stopper

(Tensile strength: 1200N/mm

stopper)

the S-axis overrun limit switch.

Collar

HW9405875-2

Hexagon socket head cap screw M20 (length: 40 mm)

(Stopper)

2

) x 1 screw (for the mechanical

Washer M6×3

(Necessary only when the manipulator is equipped

with the S-axis overrun limit switch)

Pin

HW9405032-2

(Necessary only when the manipulator is equipped

with the S-axis overrun limit switch)

5-9

HW1482870

Page 38

MPL80 II

38 of 81

170904-1CD

5 Basic Specifications

5.7 Alterable Operating Range

5.7.2 Notes on the S-Axis Mechanical Stopper Installation

Mount the collar (drawing No. HW9405785-2) to the hexagon socket head

screws M20 (length: 40 mm) (Tensile strength: 1200N/mm

shown in Fig. 5-9 “S-Axis Mechanical Stopper”, mount the S-axis

mechanical stopper to the S-head using the collar with the screws with the

tightening torque of 167 N•m (17 kgf•m).

The S-axis mechanical stopper can be mounted in every 15-degree pitch

as shown in Fig. 5-10 “S-Axis Stopper Mounting Position”.

When the manipulator is equipped with the S-axis overrun limit switches,

install the pins (drawing No. HW9405032-2) and washer M6 to the same

degree positions as the hexagon socket head screws.

Fig. 5-10: S-Axis Stopper Mounting Position

2

). Then, as

Section A-A

A

5-10

A

HW1482870

Page 39

170904-1CD

NOTE

39 of 81

MPL80

II

5 Basic Specifications

5.7 Alterable Operating Range

5.7.3 Alteration of the S-Axis Pulse Soft Limit

Apply the Instruction for “DX200 Instructions section 8.17 Changing the

Parameter Setting (manual No. RE-CTO-A220)” as part of reference

materials for adjusting the programming pendant when modifying the

range of motion of S-Axis.

Pulse limit (positive (+) direction of the S-axis): S1CxG400

Pulse limit (negative (-) direction of the S-axis): S1CxG408

D e g r e e 0 -1515 -3030 -4545 -6060

Pulse 0 -21203

-

+21203

Degree -7575 -9090 -105105 -120120 -135135

Pulse -106015

-

+106015

-127217

-

+127217

-42406

-

+42406

-148420

-

+148420

-63609

-

+63609

-169623

-

+169623

-84812

-

+84812

-190826

-

+190826

D e g r e e -150150 -165165 -180180(Standard)

Pulse -212029

-

+212029

-233232

-

+233232

-254434

-

+254434

Please do not alter the range of motion with the software

only, but in combination with the mechanical stopper.

Also, when executing the alteration, be sure to uniform the

range.

5-11

HW1482870

Page 40

MPL80 II

800 600 400

20kg

1200

1000

800

600

400

800600400

LT(mm)

10kg

40kg

60kg

80kg

LB(mm)

LT(mm)

T- and R-axes

center of rotation

B-axis center of rotation

40 of 81

6 Allowable Load for Wrist Axis and Wrist Flange

6.1 Allowable Wrist Load

6 Allowable Load for Wrist Axis and Wrist Flange

6.1 Allowable Wrist Load

The allowable wrist load is 80 kg. If force is applied to the wrist instead of

the load, force on R-, B-, and T-axes should be within the value shown in

Table 6-1 “Allowable Wrist Load”. Contact your Yaskawa representative

for further information or assistance.

Table 6-1: Allowable Wrist Load

Axis Moment N•m (kgf•m)

B-Axis 78.4 (8) 16

T-Axis 20.5 (2.1) 6

1 ( ): Gravitational unit

1)

GD

kg•m

170904-1CD

2

/4 Total Moment of Inertia

2

When the volume load is small, refer to the moment arm rating shown in

Fig. 6-1 “Moment Arm Rating”.

The allowable total moment of inertia is calculated when the moment is at

the maximum. Contact your Yaskawa representative beforehand when

only the moment of inertia is created, or when the load moment is small

while the moment of inertia is large. Also, when the load mass is

combined with an outside force, contact your Yaskawa representative

beforehand.

Fig. 6-1: Moment Arm Rating

6-1

HW1482870

Page 41

170904-1CD

Unit: mm

axis

Tapped hole M8

8 dia

Alignment mark

6 dia.

+0.012

0

50 dia.

0

-0.025

(depth: 10mm)

(depth:14 mm) (pitch:1.25) (6 holes)

(depth: 14mm)

+0.015

0

100 dia.

0

-0.022

P.C.D.80

4240

6

8

NOTE

41 of 81

MPL80

II

Fig. 6-2: Wrist Flange

6 Allowable Load for Wrist Axis and Wrist Flange

6.2 Wrist Flange

6.2 Wrist Flange

The wrist flange dimensions are shown in Fig. 6-2 “Wrist Flange”. In order

to see the alignment marks, it is recommended that the attachment be

mounted inside the fitting. Fitting depth of inside and outside fittings must

be 5 mm or less.

Wash off anti-corrosive paint (yellow) on the wrist flange

surface with thinner or light oil before mounting the tools.

6-2

HW1482870

Page 42

MPL80 II

42 of 81

7 System Application

7.1 Peripheral Equipment Mounts

7 System Application

7.1 Peripheral Equipment Mounts

The peripheral equipment mounts are provided on the U-axis (upper arm)

and S-axis (rotary head) as shown in Fig. 7-1 “Installing Peripheral

Equipment” for easier installation of the users’ system applications. The

following conditions should be observed to attach or install peripheral

equipment.

Fig. 7-1: Installing Peripheral Equipment

A

Tapped hole M8 (4 holes)

(pitch: 1.25) (depth: 16)

100

170904-1CD

100

50

200

200

57

B

Tapped hole M8 (4 holes)

(pitch: 1.25) (depth: 16)

100

100

611.5

223.5

223.5

105

105

C

Tapped hole M12 (4 holes)

(pitch: 1.75) (depth: 20)

40

105

105

40

Table 7-1: Conditions for Installation

Section Application Note

A Cable processing 80 kg max. for attaching load mass including

wrist load.

B Cable processing and

valve load

10 kg max.

N•m (5 kgf•m) max. for increased

49

moment amount of upper arm

C Others 30 kg max.

7-1

HW1482870

Page 43

170904-1CD

A

Exhaust port

Tapped hole PT3/8 with pipe plug

Connector for Internal User I/O Wiring Harness

Pins used

Internal user I/O wiring harness :

0.5 mm

2

, 23 lead wires

8

4

9

6517

23

14

19

20

15

17

11 121813

21 22 23

10

16

P

P

P

P

P

P

P

P

P

P

P

1

6

5

3

4

2

7

8

9

10

15

14

13

12

11

20

19

17

18

16

22

23

21

Air inlet Tapped hole PT3/8 with pipe plug

Connector for internal user I/O wiringharness:

JL05-2A24-28SC (socket connector with a cap)

Prepare pin connector JL05-6A24-28P.

Connector for internal user I/O wiringharness:

JL05-2A24-28PC (socket connector with a cap)

Prepare pin connector JL05-6A24-28S.

Tube for field bus cable (inside dia.:12)

(inside of the manipulator base)

View A

Tapped hole M4x3 (4 holes)

(pitch: 0.7) (depth: 3)

Tapped hole M4x3 (4 holes)

(pitch: 0.7) (depth: 3)

43 of 81

MPL80

II

7 System Application

7.2 Internal User I/O Wiring Harness and Air Line

7.2 Internal User I/O Wiring Harness and Air Line

Internal user I/O wiring harness (0.5 mm2 x 23 wires), and an air line are

incorporated in the manipulator for the drive of peripheral device mounted

on the upper arm as shown in Fig. 7-2 “Connectors for Internal User I/O

Wiring Harness and Air Line”.

The connector pins 1 to 23 are assigned as shown in Fig. 7-2. Wiring

must be performed by users.

The allowable current for internal user

I/O wiring harness

The maximum pressure for the air line 490 kPa (5 kgf/cm

Fig. 7-2: Connectors for Internal User I/O Wiring Harness and Air Line

5.1 A or less for each wire

(The total current value for pins 1 to 23

must be 34.5 A or less.)

2

) or less

(The air line inside diameter: 8.0 mm.)

The same numbered pins (1 to 23) of the two connectors are connected

with a single lead wire of 0.5 mm

7-2

2

.

HW1482870

Page 44

MPL80 II

NOTE

44 of 81

8 Electrical Equipment Specification

8.1 Position of Limit Switch

8 Electrical Equipment Specification

8.1 Position of Limit Switch

8.1.1 Specification of Limit Switch

1. The interference limit switch at S-, L- and U-axes electrically limit the

operating range of respective axes by adjusting the position of the dog

using the limit switch.

The positions of the mechanical limits (mechanical stoppers) at S-axis

is changeable.

When the limit switch is activated, the power supply to the manipulator

is interrupted, then the manipulator makes an emergency stop as a

result. Refer to section 8.9 “Overrun/Tool Shock Sensor Releasing” in

“DX200 INSTRUCTIONS” for releasing the status of this overrun.

2. The range of S-, L- and U-axes limit switches are set to the maximum

operating range before shipping.

170904-1CD

In case of re-adjusting the operating range of each subject

axis, it is also required to change the dog location and limit

values in software. Contact your Yaskawa representative if

re-adjustment is required.

8.1.2 Location of Limit Switch

The limit switches are optional. See Fig. 8-1 “Location of Limit Switches”.

Fig. 8-1: Location of Limit Switches

L-and U-axes interference L.S.

S-axis overrun L.S.

8-1

L-axis overrun L.S.

$,5

%&

%&

HW1482870

Page 45

170904-1CD

45 of 81

MPL80

II

8.1.3 Setting of Operation Range

8.1.3.1 S-Axis Operation Range

8.1.3.2 L-Axis Operation Range

8 Electrical Equipment Specification

8.1 Position of Limit Switch

By the S-axis limit switch, S-axis operation range can be set to those

ranges mentioned in Table 5-2 “S-Axis Operating Range”.

By the L-axis limit switch, the L-axis operation range can be set to any

angles within -91° to +136° as mentioned in the figure below.

Fig. 8-2: L-Axis Overrun Limit Switch Setting Range

Positive side

Negative side

L-axis center of rotation

8-2

HW1482870

Page 46

MPL80 II

46 of 81

170904-1CD

8 Electrical Equipment Specification

8.1 Position of Limit Switch

8.1.3.3 Setting Range of LU-Axes Interference Angle

L- and U-axes interference limit switches are designed to check the

interference angle of L- and U-axes.

As shown in Fig. 8-3 “LU-Axes Interference Angle”, the operation range of

U-axis can be set to any angles within +9° to +276° as the interference

angle with L-axis.

Fig. 8-3: LU-Axes Interference Angle

U-axis center of rotation

8-3

HW1482870

Page 47

170904-1CD

47 of 81

MPL80 II

8.2 Internal Connections

Fig. 8-4(a): Internal Connection Diagram

Controller

CN1-5

CN1-4

CN1-10

CN1-9

CN1-1

CN1-2

CN1-3

CN1-6

CN1-7

CN1-8

CN2-1

CN2-2

CN2-3

CN3-1

CN3-2

CN3-3

CN3-6

CN3-7

CN3-8

CN4-10

CN2-10

CN4-3

CN4-1

CN4-6

CN2-4

CN2-5

+24V

0V

+24V

0V

SPG+1

SPG-1

FG1

SPG+2

SPG-2

FG2

SPG+3

SPG-3

FG3

SPG+5

SPG-5

FG5

SPG+6

SPG-6

FG6

0V

+24V

BC2

+24V

LB1

+24V

LD1

8 Electrical Equipment Specification

8.2 Internal Connections

<Notes>

1.For the limit switch specification, the connection of the section A B are changed as follows:

LA1

LA1

LB1

0BT

1

0BAT11

BATRKP

2

BAT11

0BT

3

0BAT12

4BATRK P BAT12

0BT

5 0BAT21

6BATRK P BAT21

7

0BAT22

0BT

8

BAT22

BAT

RKP

1

2

3

4

5

6

7

8

1BC(10×4)

CN1-5

+24V

CN1-4

P

P

P

P

P

P

P

P

P

CN1-10

CN1-9

CN1-1

CN1-2

CN1-3

CN1-6

CN1-7

CN1-8

CN2-1

CN2-2

CN2-3

CN3-1

CN3-2

CN3-3

CN3-6

CN3-7

CN3-8

CN4-10

CN2-10

CN4-3 BC2

CN4-1

CN4-6

CN2-4

CN2-5

S1(24-28)

1

0V

+24V

0V

SPG+1

SPG-1

FG1

SPG+2

SPG-2

FG2

SPG+3

SPG-3

FG3

SPG+5

SPG-5

FG5

SPG+6

SPG-6

FG6

0V

+24V

+24V

LB1

+24V

LD1

E

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

No.24CN

X

+24V-1

0V

-3

+24V

-2 2

0V

-4

1

3

4

E

Base

E

17

0BAT1

18

BAT1

19

0BAT2

20 BAT2

21

0BAT3

22

BAT3

23

24

25

26

27

0BAT5

28

BAT5

29

0BAT6

30

BAT6

31

32

1

PG0V1

2

PG5V1

3

PG0V2

4

PG5V2

PG0V3

5

6PG5V3

7

8

9

PG0V5

10

PG5V5

11

PG0V6

12

PG5V6

13

14

15

16

LA1

LC1

P

P

P

P

P

P

P

P

P

P

P

LB1

LD1

MANIPULATOR

A1

B1

LC1

LD1

LC1

LD1

LA1

LB1

No.18CN

-1

-2

-3

-4

No.19CN

-1

-3

-4

No.20CN

-1

-2

-4

No.22CN

-1

-2

-3

-4

No.23CN

-1

-2

-3

-4

BAT1

0BAT1

PG5V1

PG0V1

BAT2

PG5V2

PG0V2

BAT3

0BAT3

PG5V3-3

PG0V3

BAT5

0BAT5

PG5V5

PG0V5

BAT6

0BAT6

PG5V6

PG0V6

LB1

LB1

LB2

LB2

LB1

LC1

LD1

LD1

LD2

LD2

LD1

LA2

LB2

LC2

LD2

LC3

LD3

S-axis overrun L.S.

LA3

LB3

S-axis overrun L.S.

SLU-axes with Limit Switch Specification

LC1

LD1

LA1

LB1

S-axis overrun L.S.

S-axis overrun L.S.

S-axis with Limit Switch Specification

S

P

P

P

L

P

P

U

P

P

P

B

P

P

P

T

P

P

P

LB1

LB2

LD1

LD2

LB2

LB1

LD2

LD1

LA2

A2

LB2

LC2

LD2

Casing

L-axis overrun L.S.

L-axis overrun L.S.

No.1CN

1CN-1

-6

-5

-4

-9

-10

No.2CN

2CN-1

-6

-4

-10

No.3CN

3CN-1

-2

-6

-5

-9

-10

B2

No.8CN(24-28)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Connected to

Connected to

Connected to

Connected to

DATA+1

DATA-1-2

BAT

OBT

+5V

0V

FG1

OBT

BAT

DATA+2

DATA-2-2

BAT

OBT-5P0BAT2-2

+5V

0V-9

FG2

OBT

BAT

DATA+3

DATA-3

BAT

OBT

+5V-4

0V

FG3

OBT

BAT

SP1

SP2

SP3

SP4

SP5

SP6

SP7

SP8

SP9

SP10

SP11

SP12

SP13

SP14

SP15

SP16

SP17

SP18

SP19

SP20

SP21

SP22

SP23

A1

Connected to

A2

L and U-axes interference L.S.

B1

B2Connected to

L and U-axes interference L.S.

B1

A1

PG S-AXIS

PG L-AXIS

PG

No.5CN

5CN-1

DATA+5

-2

DATA-5

-6

BAT

-5

OBT

-4

+5V

-9

0V

-10 FG5

OBT

BAT

No.6CN

6CN-1

DATA+6

-2

DATA-6

-6

BAT

-5

OBT

-4

+5V

-9

0V

-10

FG6

OBT

BAT

BC1

BC2

LA3

A3

LB3

LC3

LD3

U-AXIS

Connected to

Connected to

FOR LAMP(OPTION)

B3

A3

B3

PG

B-AXIS

T-AXIS

PG

8-4

HW1483872

Page 48

MPL80 II

YB

SM

B-AXIS

SM

YB

T-AXIS

13CN-3

No.13CN

MU5

-2

-1

-5

-4

-PE

MV5

MW5

BB5

BA5

ME5

-2

14CN-3

No.14CN

MU6

MV6

-1

-4

-5

-PE

MW6

BA6

BB6

ME6

EE

2BC

2BC(8X4+12X2)

PE

ME6

BB1

BA1

BA3

BA6

BA5

BB5

BA2

ME5

ME3

ME2

ME2

ME1

ME1

MW5

MV5

MU5

MU6

MW6

MV6

MV2

MV2

MW2

MU3

MV3

MW2

MU1

MV1

MV1

MW1

MU1

MU2

MU2

MW1

MW3

ME6

BB1

BA1

BA3

BA6

BA5

BB5

BA2

CN6-9

CN6-10

CN6-12

CN6-11

CN6-2

CN6-1

CN6-4

CN6-7

CN6-8

CN6-6

CN6-5

CN6-3

ME5

ME3

ME2

ME2

ME1

ME1

CN5-5

CN5-8

CN5-7

CN5-6

CN5-4

CN5-3

CN5-2

CN5-1

CN4-2

CN4-1

CN4-6

CN4-7

CN4-3

CN4-5

CN4-4

CN4-8

MW5

MV5

MU5

MU6

MW6

MV6

CN3-1

CN3-2

CN3-5

CN3-4

CN3-7

CN3-8

CN3-6

CN3-3

CN5-5

CN5-8

CN5-7

CN5-6

CN5-4

CN5-3

CN5-2

CN2-8

CN2-7

CN2-8

CN2-7

MV2

MV2

MW2

MU3

MV3

MW2

CN2-1

CN2-3

CN2-2

CN2-5

CN2-6

CN2-4

CN1-8

CN1-7

CN1-6

CN1-5

CN1-4

CN1-3

CN1-2

CN1-8

CN1-7

CN1-6

CN1-5

CN1-4

CN1-3

CN1-2

CN6-9

CN6-10

CN6-12

CN6-1

1

S-AXISSM

YB

L-AXIS

YB

SM

U-AXISSM

YB

-C

No.9CN

9CN-A

-B

MW1

MU1

MV1

-1

-D

-2

BA1

ME1

BB1

CN1-1

MU1

MV1

MV1

MW1

MU1

MU2

MU2

MW1

CN1-1

CN2-1

CN2-3

CN2-2

10CN-A

No.10CN

MU2

-2

-C

-1

-D

BB2

MW2

BA2

ME2

MV2-B

-C

-B

No.11CN

11CN-A

MW3

MV3

MU3

-2

-1 BA3

BB3

ME3-D

MW3

CN2-5

CN2-6

CN2-4

CN3-1

CN3-2

CN3-5

CN3-4

CN4-2

CN3-7

CN4-1

CN3-8

CN3-6

CN3-3

CN4-6

CN4-7

CN4-3

CN4-5

CN4-4

CN4-8

CN5-1

CN6-2

CN6-1

CN6-4

CN6-7

CN6-8