Page 1

MotionWorks IEC

PLCopenPlus Function Blocks for

Motion Control - 2013-04-12

Page 2

Page 3

Table Of Contents

Overview .................................................................................... 1

Introduction ............................................................................. 1

The State Diagram .................................................................... 3

Error Handling .......................................................................... 6

Function block interface ............................................................. 8

Data Types ................................................................................ 29

Data Types ............................................................................. 29

Data Type: AXIS_REF ............................................................... 30

Data Type: CONTINUOUS_REF .................................................. 32

Data Type: INPUT_REF ............................................................. 34

Data Type: OUTPUT_REF .......................................................... 36

Data Type: PATTERN _REF ......................................................... 38

Data Type: PrmStruct .............................................................. 39

Data Type: RTC_STRUCT .......................................................... 40

Data Type: TRIGGER_REF ......................................................... 41

Data Type: Y_DISENGAGE_DATA ............................................... 43

Data Type: Y_ENGAGE_DATA .................................................... 44

Data Type: Y_MS_CAM_STRUCT ................................................ 45

iii

Page 4

Enumerated Types ...................................................................... 47

Function Block List ...................................................................... 49

Function Block List ................................................................... 49

Function Blocks for Motion Control ................................................ 61

MC_AbortTrigger ..................................................................... 61

MC_FinishHoming .................................................................... 65

MC_GearIn ............................................................................. 68

MC_GearInPos ......................................................................... 74

MC_GearOut ........................................................................... 83

MC_MoveAbsolute .................................................................... 86

MC_MoveRelative..................................................................... 92

MC_MoveSuperImposed ........................................................... 97

MC_MoveVelocity ................................................................... 109

MC_Power ............................................................................. 114

MC_ReadActualPosition ........................................................... 121

MC_ReadActualTorque ............................................................ 123

MC_ReadActualVelocity .......................................................... 126

MC_ReadAxisError ................................................................. 128

MC_ReadBoolParameter.......................................................... 132

iv

Page 5

MC_ReadParameter ................................................................ 135

MC_ReadStatus ..................................................................... 138

MC_Reset ............................................................................. 142

MC_SetPosition...................................................................... 146

MC_StepLimitSwitch ............................................................... 150

MC_StepRefPulse ................................................................... 155

MC_Stop ............................................................................... 160

MC_TorqueControl ................................................................. 165

MC_TouchProbe ..................................................................... 176

MC_WriteBoolParameter ......................................................... 185

MC_WriteParameter ............................................................... 188

Y_CamFileSelect .................................................................... 191

Y_CamIn .............................................................................. 197

Y_CamOut ............................................................................ 210

Y_CamScale .......................................................................... 215

Y_CamShift ........................................................................... 220

Y_CamStructSelect ................................................................ 227

Y_ClearAlarms ....................................................................... 231

Y_DirectControl ..................................................................... 233

v

Page 6

Y_HoldPosition ...................................................................... 239

Y_ProbeContinuous ................................................................ 242

Y_ReadAlarm ........................................................................ 248

Y_ReadCamTable ................................................................... 250

Y_ReadDriveParameter ........................................................... 254

Y_ReadMultipleParameters ...................................................... 258

Y_ReadStringParameter .......................................................... 261

Y_RebootController ................................................................ 264

Y_ReleaseCamTable ............................................................... 266

Y_ResetAbsoluteEncoder ......................................................... 268

Y_ResetMechatrolink .............................................................. 273

Y_SetRTC ............................................................................. 276

Y_SlaveOffset ........................................................................ 278

Y_VerifyParameters ................................................................ 285

Y_WriteCamTable .................................................................. 290

Y_WriteDriveParameter .......................................................... 293

Y_WriteParameters ................................................................ 297

Controller AlarmID List .............................................................. 301

Function Block ErrorID List ........................................................ 333

vi

Page 7

Axis Parameter List ................................................................... 341

High Speed Output ................................................................... 349

Timing Diagram ........................................................................ 350

Camming ................................................................................. 353

Camming Introduction ............................................................ 353

CamState ............................................................................. 353

Cam Masters ......................................................................... 355

Master Cycle ......................................................................... 355

Camming Function Blocks ....................................................... 356

Creating a Cam Table ............................................................. 357

Externally Created Cam Data .................................................. 358

Transferring Cam Files to an MPiec Controller ............................ 359

User File Storage ................................................................... 362

Configuring FileName Input for Y_CamFileSelect ........................ 363

Internally Created Cam Data ................................................... 365

Cam Table Types ................................................................... 367

On-The-Fly Adjustments ......................................................... 368

Camming Block Diagram ......................................................... 369

Engage / Disengage Window ................................................... 370

vii

Page 8

Cam Transitions Matrix ........................................................... 371

Motion Details .......................................................................... 375

Acceleration/Deceleration Limits .............................................. 375

Position Limits ....................................................................... 377

Velocity Limits ....................................................................... 379

Moving Average Filter (S-Curve) .............................................. 380

Determining When Motion is Complete ..................................... 383

External Encoder Block Diagram .............................................. 385

Commanded Position Output ................................................... 386

Command Filtering (MPiec with MECHATROLINK interface) .......... 387

Command Filtering (MP2600iec - Dual Port RAM interface) .......... 388

viii

Page 9

Overview

This document contains instructions for using the PLCopenPlus and

YMotion firmware library function blocks integrated in the MPiec Series

Controllers.

Introduction

This manual is adopted from the PLCopen for motion control specification

at www.plcopen.org, and includes additional information for functionality

with Yaskawa and other components.

Each function block is listed in alphabetical order, and is also linked to the

feature or function from the software environment. A comprehensive list

of axis parameters and error codes is at the back of the manual. A subset

of specific errors that each function block may generate is included under

each function block description.

The other main concepts covered in this manual are the Motion State

Diagram, and documentation concerning the Data Types supplied with the

PLCopenPlus Firmware Library.

The Firmware Library is the set of all PLCopen function blocks, plus

Yaskawa specific functions. The firmware library is called PLCopen Plus,

and is automatically loaded when a new project is created.

Model

The PLCopenPlus Function Block (FB) library is designed for the purpose of

controlling axes via the language elements consistent with those defined in

the IEC 61131-3 standard. It provides a set of command oriented function

PLCopenPlus Function Blocks for Motion Control 2013-04-13 1

Page 10

blocks that have a reference to the axis, e.g. the abstract data type ‘Axis’,

which offers flexibility, ease of use and reusability.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 2

Page 11

The State Diagram

The state diagram shown defines the behavior of the axis at a high level

when motion control function blocks are "simultaneously" activated. This

combination of motion profiles is useful in building a more complicated

profile or to treat exceptions within a program.

The basic rule is that motion commands are always taken sequentially.

These commands act on the axis' state diagram. The axis is always in one

of the following defined states:

Standstill (no movement)

Homing (movement to reference position)

Discrete Motion (movement towards target position)

Continuous Motion (jogging)

Synchronized Motion (synchronized movement of master and slave)

Stopping (axis is stopped)

ErrorStop (axis error occurred)

Any motion command is a tr ansitio n th at change s the sta t e of the axis and ,

as a consequence, modifies the way the current motion is computed. A

normal procedure would start in Standstill. In this state, the power can be

switched on per axis (via the Power command). Also, one can access the

Homing state (via the issue of the Home command per axis), which after

normal completion returns to Standstill. From here, one can transfer an

axis to either Disc re te M otion o r Co ntin uo us Motio n. V ia th e Stoppi ng sta te,

one can return to Standstill. ErrorStop is a state to which the axis

transfers in case of an error. Via a Reset command, one can return to

Standstill, from which the machine can be moved to an operational state

again. Please note that the states define the functionality of the Function

Blocks.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 3

Page 12

The diagram is focused on the states of a single axis. The multiple axis

function blocks such as MC_CamIn and MC_GearIn change the state

whereas these axis can have specific states.

Connecting a slave axis to a master axis has no influence on the master

axis.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 4

Page 13

PLCopenPlus Function Blocks for Motion Control 2013-04-13 5

Page 14

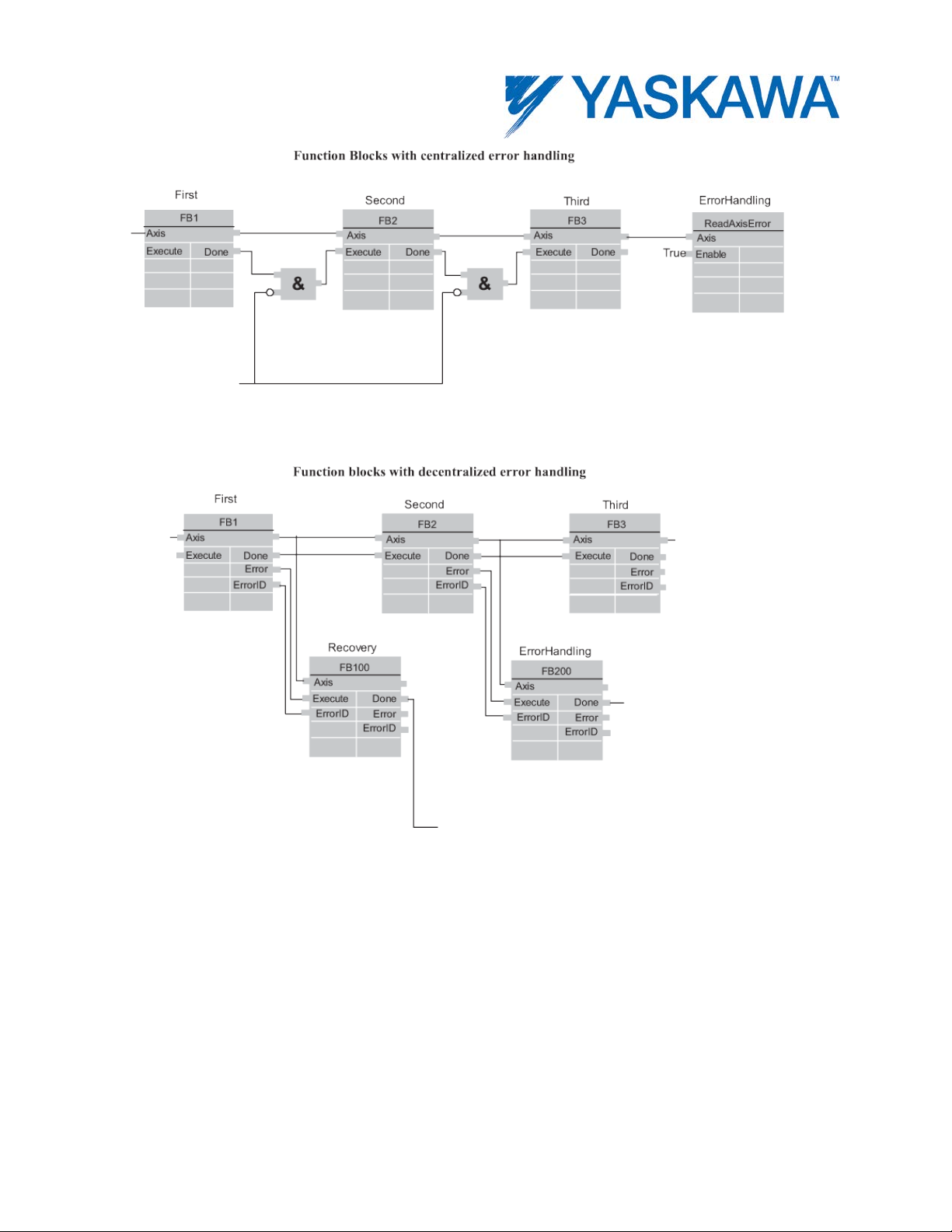

Error Handling

All access to the drive/motion control is via Function Blocks. Internally

these Function Blocks provide basic error checking on the input data.

If the device itself has an error, it can be read using the MC_ReadAxisError

block.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 6

Page 15

PLCopenPlus Function Blocks for Motion Control 2013-04-13 7

Page 16

Rule applies to

Rule

Output exclusivity

When 'Execute' is true, the outputs ‘Busy’,

Output status

The 'Done', 'InGear', 'InSync', 'InVelocity',

Missing input

According to IEC 61131-3, if any parameter of a

Function block interface

General rules

The following table provides general rules about the interface of the Motion

Control function blocks.

‘Done’, ‘Error’, and ‘CommandAborted’ are

mutually exclusive.

'Error', 'ErrorID' and 'CommandAborted' output s

are reset with the falling edge of

'Execute'. However, the falling edge of 'Execute'

does not stop or even influence the execution of

the actual FB. The corresponding outputs are

set for at least one cycle if the situation occurs,

even if execute was reset before the FB

completed. If an instance of a FB receives a

new 'Execute' before it finishes (as a series of

Input parameters The parameters are read at the rising edge of

commands on the same instance), the FB won’t

return any feedback, like ‘Done’ or

‘CommandAborted’, for the previous action.

the 'Execute' input. To modify any parameter, it

is necessary to change the input parameter(s)

and trigger the 'Execute' again.

parameters

PLCopenPlus Function Blocks for Motion Control 2013-04-13 8

function block input is missing (“open”) then the

Page 17

value from the previous invocation of this

instance will be used. In the first invocation the

Sign rules

The 'Velocity', 'Acceleration', 'Deceleration' and

Error Handling

All blocks have two outputs , whic h dea l w ith

Error: Rising edge of 'Error' indicates that an

'Done', 'InVelocity', 'InGear', and 'InSync'

default value is applied .

Position versus

distance

Behavior

'Position' is a value defined within a coordinate

system. 'Distance' is a relative measure, the

difference between two positions.

'Jerk' are always positive values. 'Position' and

'Distance' can be positive or negative.

errors that can occur while executing that

Function Block. These outputs are defined as

follow:

error occurred during the execution of the

Function Block.

ErrorID: Error number - see the Error Code List

at the end of the manual.

indicate successful completion, so these signals

are logically exclusive to “Error”.

Types of errors:

• Function Block Error (e.g. parameters out of

range, state machine violation attempted)

• Communication Error

• Amplifier/Axis Error

Instance errors do not always result in an axis

error (forcing the axis to 'StandStill'). The error

outputs of the relevant FB are reset with falling

PLCopenPlus Function Blocks for Motion Control 2013-04-13 9

Page 18

edge of 'Execut e' .

Inputs exceeding

If a FB is commanded with parameters which

Behavior of Done

output

Behavior of

CommandAborted

output

The “Done” output (as well as 'InGear',

'InSync', ..) is set when the commanded action

has been completed successfully. With multiple

Function Blocks working on the same axis in a

sequence, the following applies:

When one movement on an axis is interrupted

with another movement on the same axis

without having reached the final goal, 'Done' of

the first FB will not be set.

'CommandAborted' is set when a commanded

motion is interrupted by another motion

command. The reset-behavior of

'CommandAborted' is like that of 'Done'. When

'CommandAborted' occurs, the other outputsignals such as 'InVelocity' are reset.

application limits

result in a violation of application limits, the

instance of th e FB generates an error. The

consequences of this error for the axis are

application specific and thus should be handled

by the application program.

Behavior of Busy

output

'Busy' output indicates that the FB is not

finished. 'Busy' is SET at the rising edge of

'Execute' and RESET when one of the outputs

'Done', 'Aborted', or ' Error' is set. It is

recommended that this FB should be kept in the

active loop of the application program for at

least as long as ‘Busy’ is true, because the

PLCopenPlus Function Blocks for Motion Control 2013-04-13 10

Page 19

outputs may still change. For one axis, several

Function Blocks might be busy, but only one can

Output ‘Active’

The 'Active' output is available on Function

Enable and Valid

The 'Enable' input is coupled to a 'Valid' output.

be active at a time. Exceptions are

'MC_SuperImposed' and 'MC_Phasing', where

more than one FB related to one axis can be

active.

Blocks with buffering capabilities. This output is

set at the moment the function block takes

control of the axis. For unbuffered mode the

outputs “Active” and “Busy” can have the same

value.

Status

'Enable' is level sensitive, and 'Valid' shows that

a valid set of outputs is available at the FB. The

'Valid' output is TRUE as long as a valid output

value is available and the 'Enable' input is

TRUE. The relevant output values are refreshed

while the input 'Enable' is TRUE. If there is a FB

error, the output is not valid (“Valid” set to

FALSE). When the error condition disappears,

the values will reappear and 'Valid' output will

be set again.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 11

Page 20

The behavior of the “Execute” / “Done” style FBs is as follows:

Why the command input is edge sensitive

The “Execute” input always triggers the function with its rising edge. New

input values may be commanded during execution of a previous command

because the inputs are only read once. The 'Done' output can be used to

trigger the next part of the movement. The example given below is

intended to explain the behavior of the Function Block execution.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 12

Page 21

The figure illustrates the sequence of three Function Blocks, 'First',

'Second' and 'Third', controlling the same axis. These three Function

Blocks could be for instance various absolute or relative move

commands. When “First” has completed, the output 'First.Done' triggers

'Second.Execute'. The output 'Second.Done' AND “In13” trigger

'Third.Execute'.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 13

Page 22

Example 1: Same Function Block instance controls different motions of an axis

The figure below shows an example where the Function Block FB1 is used

to control “AxisX” with three different values of Velocity. In a Sequential

Function Chart (SFC) the velocity 10, 20, and 0 is assigned to V. To trigger

the Execute input with a rising edge the variable E is stepwise set and

reset.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 14

Page 23

PLCopenPlus Function Blocks for Motion Control 2013-04-13 15

Page 24

Example 2: Different FB instances control the motions of an axis

Different instances related to the same axis can control the motions on an

axis. Each instance will then be responsible for one part of the global

profile.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 16

Page 25

PLCopenPlus Function Blocks for Motion Control 2013-04-13 17

Page 26

Aborting Versus Buffered Modes: Input BufferMode

Buffer mode

Short description Im portant

descriptions!

Input value at

Aborting

This is the Default mode. The FB

immediately.

INT#0

Buffered

The FB affects the axis as soon as

between the movements.

INT#1

BlendingLow

The FB controls the axis after the

INT#2

Some of the FBs provide the input 'BufferMode'. By setting this input, the

FB can either be run in "non-buffered mode" (default behavior) or in

buffered mode. The transition behavior (blending) between two motions

can be set by defining when the FB starts its action. The difference

between these two modes is as follows:

A Function Block in non-buffered mode is applied immediately, even

when this interrupts a motion which is currently executed.

A Function Block in buffered mode is not executed until the current

FB has finished the motion it is currently executing and indicates this

by setting the corresponding output (Done or InPosition or InVelocity see table below).

Up to 16 motion blocks can be buffered before error 4369 would be

generated. Axis Parameter 1600 indicates the number of buffered

motion blocks.

Possible options for the buffered mode

The input BufferMode must be connected with a INT data type which can

have the following values:

note: The meaning of each value

BufferMode *

may vary depending on the

FB(s) involved. For this reason,

please also refer to the

individual parameter

aborts an ongoing motion and the

command affects the axis

the previous movement is

complete. The axis will stop

PLCopenPlus Function Blocks for Motion Control 2013-04-13 18

Page 27

previous FB has finished, but the

axis will not stop between the

commands.

BlendingPrevious

The FB controls the axis after the

velocity of the previous move.

INT#3

of this (next) function.

(next) function.

movements. The velocity is blended

with the lowest velocity of both

previous FB has finished

(equivalent to buffered), but the

axis will not stop between the

movements. Blending with the

BlendingNext The FB controls the axis after the

previous FB has finished, but the

axis will not stop between the

movements. Blending with velocity

BlendingHigh The FB controls the axis after the

previous FB has finished

(equivalent to buffered), but the

axis will not stop between the

movements. Blending with highest

velocity of the previous and this

INT#4

INT#5

PLCopenPlus Function Blocks for Motion Control 2013-04-13 19

Page 28

Example 1: Standard behavior of 2 following absolute movements

PLCopenPlus Function Blocks for Motion Control 2013-04-13 20

Page 29

Example 2: Aborting motion

PLCopenPlus Function Blocks for Motion Control 2013-04-13 21

Page 30

Example 3: Buffered motion

PLCopenPlus Function Blocks for Motion Control 2013-04-13 22

Page 31

Example 4: BlendingLow motion

PLCopenPlus Function Blocks for Motion Control 2013-04-13 23

Page 32

Example 5: BlendingPreviou s motion

PLCopenPlus Function Blocks for Motion Control 2013-04-13 24

Page 33

Example 6: BlendingNext motion

PLCopenPlus Function Blocks for Motion Control 2013-04-13 25

Page 34

Example 7: BlendingHi gh motion

PLCopenPlus Function Blocks for Motion Control 2013-04-13 26

Page 35

Rules for the definition of Motion Control function blocks according to PLCopen

The input/output variables of the function blocks mandatory according to

the PLCopen Standard are marked with the letter 'B' in the defined tables

in the definition of the function blocks.

Input/output variables marked with the letter 'E' are optional, i.e. they can

be implemented but are not mandatory.

Vendor specific input / output variables, i.e. added by the vendor, are

marked with the letter 'V'.

According to the IEC 61131-3 specification, the input variables may be

unconnected or not parameterized by the user. In this case, the function

block will use the value from the previous invocation of the function block

instance, or in case of the first invocation, the initial value will be used.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 27

Page 36

Page 37

Data Types

Data Types

A data type can be any simple or complex set of data consisting of multiple data types.

The following data types are supplied by Yaskawa as part of the PLCopenPlus firmware

library and will appear in the project tree when a new project is created. The DataType

file is named below.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 29

Page 38

Data Type: AXIS_REF

The AXIS_REF data type identifies an axis and thus provides the interface

to the hardware or virtual axes. AXIS_REF is used as VAR_IN_OUT in all

Motion Control Function Blocks described in this Online help. It is

represented as an input and an output connected by a horizontal line in

the graphical representation of a function block.

The value of AxisNum is determined by the logical axis number assigned in

the Hardware Configuration. See the Configuration tab under each axis.

Data Type Declaration

TYPE

AXIS_REF:STRUCT

AxisNum:UINT;

END_STRUCT;

END_TYPE

Variable Declaration Example

PLCopenPlus Function Blocks for Motion Control 2013-04-13 30

Page 39

Code Example

AxisX.Number:=UINT#0;

MCMoveAbsoluteX(Axis:=AxisX, Execute:=FALSE);

AxisX:=MCMoveAbsolutX.Axis;

AxisY.Number:=UINT#0;

MCMoveAbsoluteY(Axis:=AxisY, Execute:=FALSE);

AxisX:=MCMoveAbsolutY.Axis;

PLCopenPlus Function Blocks for Motion Control 2013-04-13 31

Page 40

Data Type: CONTINUOUS_REF

This datatype is for use with the Y_ProbeContinuous function block

Data Type Declaration

CONTINUOUS_LATCH_RECORD : STRUCT

ValueCyclic : LREAL; (* Cyclic latch value (rotary

modulus)*)

ValueNonCyclic : LREAL; (* Non-cyclic latch value *)

InputID : INT; (* Input signal ID corresponding

to the latch data

Indicates C-Channel, EXT1,

EXT2, EXT3 *)

PatternIndex : UINT; (* Signal pattern array index *)

PatternCount : UINT; (* Signal pattern repeat count

*)

Reserved : UINT;

END_STRUCT;

LATCH_BUFFER_TYP : ARRAY(0..127) OF CONTINUOUS_LATCH_RECORD

CONTINUOUS_REF : STRUCT

BufferSize : UINT; (* Maximum number of

registration marks that will be

tracked by the application at

any one time *)

BufferLevel : UINT; (* Number of registration marks

in the buffer and

not yet processed by the

application *)

PLCopenPlus Function Blocks for Motion Control 2013-04-13 32

Page 41

StorePointer : UINT; (* Array index of the

LATCH_BUFFER_TYP last stored by

Y_ProbeContinuous *)

UsePointer : UINT; (* Array index of the next

LATCH_BUFFER_TYP to be

used by the application *)

Buffer : LATCH_BUFFER_TYP; (* Array of continuous latch

data *)

END_STRUCT;

PLCopenPlus Function Blocks for Motion Control 2013-04-13 33

Page 42

Data Type: INPU T_REF

This datatype is for use with the MC_ReadDigitalInput function block

Data Type Declaration

TYPE

(* Inputs and outputs are referenced via a variable of the

type INPUT_REF or OUTPUT_REF *)

INPUT_REF: STRUCT

ID: UINT; (* Mapping may be required for drive

inputs and C-pulse. These inputs must not been neglected *)

END_STRUCT;

END_TYPE

Variable Declaration Example

PLCopenPlus Function Blocks for Motion Control 2013-04-13 34

Page 43

Code Example

PLCopenPlus Function Blocks for Motion Control 2013-04-13 35

Page 44

Data Type: OUTPUT_REF

This data type is for use with the MC_WriteDigitalOutput function block.

Data Type Declaration

TYPE

(* Inputs and outputs are referenced via a variable of the

type INPUT_REF or OUTPUT_REF *)

OUTPUT_REF: STRUCT

ID: UINT; (* The user may output to memory or

hardware. *)

END_STRUCT;

END_TYPE

Variable Declaration Example

PLCopenPlus Function Blocks for Motion Control 2013-04-13 36

Page 45

Code Example

PLCopenPlus Function Blocks for Motion Control 2013-04-13 37

Page 46

Data Type: PAT TERN_REF

This datatype is for use with the Y_ProbeContinuous function block

Data Type Declaration

PATTERN_ARRAY_TYP : ARRAY(0..7) OF UINT;

PATTERN_REF : STRUCT

PatternSize : UINT; (* Number of sensors that will

operate in a repeating

pattern. Sent to Sigma-5 Pn850

*)

PatternCount : UINT; (* Number of times the pattern

repeats until the FB

will be done. UINT#0 =

infinite. Sent to Sigma-5

Pn 851 *)

PatternArray : PATTERN_ARRAY_TYPE;

(* Array of signal ID pattern,

indicating C Channel,

EXT1, EXT2, EXT3. Sent to Sigma5 Pn853 and Pn854 *)

END_STRUCT;

PLCopenPlus Function Blocks for Motion Control 2013-04-13 38

Page 47

Data Type: PrmStruct

This datatype is for use with the Y_ReadMultipleParameters function block

Data Type Declaration

Params : STRUCT

Number : UINT; (* The parameter number to read *)

Reserved : UDINT;

Value : LREAL; (* The value of the parameter *)

END_STRUCT;

ParamList : ARRAY[0..99] OF Params;

PrmStruct : STRUCT

LastParam : INT; (* Indicates the last parameter

in the list *)

Reserved : UDINT;

ParamData : ParamList; (* The array of parameter numbers

and values *)

END_STRUCT;

PLCopenPlus Function Blocks for Motion Control 2013-04-13 39

Page 48

Data Type: RTC_STRUCT

This datatype is for use with the Y_SetRTC function block

Data Type Declaration

RTC_Struct:STRUCT

Year:INT;

Month:INT;

Day:INT;

Hour:INT;

Minute:INT;

Second:INT;

Millisecond:INT;

END_STRUCT;

PLCopenPlus Function Blocks for Motion Control 2013-04-13 40

Page 49

Data Type: TRIGGER_REF

This data type is for use with the MC_TouchProbe and MC_AbortTrigger

function blocks.

Data Type Declaration

TYPE

(* MC_TouchProbe requires a trigger referenced via a variable

of the type TRIGGER_REF *)

Detection_Pattern:(Rising_Edge, Falling_Edge); (* Not

used *)

TRIGGER_REF: STRUCT

Input: INPUT_REF;

Bit: UINT;

Pattern:

ID: UINT; (* Unique identification of the trigger;

used for MC_AbortTrigger *)

END_STRUCT;

END_TYPE

DETECTION_PATTERN;

PLCopenPlus Function Blocks for Motion Control 2013-04-13 41

Page 50

Variable Declaration Example

The following chart details the correct values for the TRIGGER_REF

structure based on the hardware latch to be detected.

Code Example

PLCopenPlus Function Blocks for Motion Control 2013-04-13 42

Page 51

Data Type: Y_DISENGAGE_DATA

This data type is for use with the Y_CamOut function block.

Data Type Declaration

TYPE

Y_Disengage_Data : STRUCT

EndMode : INT; (* Possible values are

described in Y_DisengageMethod *)

RampOut : INT; (* Reserved for future use *)

RampOutData1 : LREAL; (* Reserved for future use *)

RampOutData2 : LREAL; (* Reserved for future

use *)

RampOutData3 : LREAL; (* Reserved for future

use *)

RampOutData4 : LREAL; (* Reserved for future

use *)

END_STRUCT;

END_TYPE;

Y_DisengageMethod: (AtPosition, Immediate, EndOfProfile);

(* Immediate and EndofProfile Reserved for

future use *)

PLCopenPlus Function Blocks for Motion Control 2013-04-13 43

Page 52

Data Type: Y_ENGAGE_DATA

This data type is for use with the Y_CamIn function block.

Data Type Declaration

TYPE

Y_Engage_Data : STRUCT

StartMode : INT; (* Possible values are

described in Y_EngageMethod *)

MasterRelative : BOOL;

SlaveAbsolute : BOOL;

RampIn : INT; (* Reserved for future use

*)

RampInData1 : LREAL; (* Reserved for future use

*)

RampInData2 : LREAL; (* Reserved for future use

*)

RampInData3 : LREAL; (* Reserved for future use

*)

RampInData4 : LREAL; (* Reserved for future use

*)

END_STRUCT;

END_TYPE;

Y_EngageMethod: (AtPosition, Immediate, Linked);

PLCopenPlus Function Blocks for Motion Control 2013-04-13 44

Page 53

Data Type: Y_MS_CAM_STRUCT

This data type is for use with the Y_CamStructSelect, Y_ReadCamTable,

and Y_WriteCamTable function blocks. Y_MS_CAM_STRUCT consists of

the sub-structures found below. Refer to the Internally Created Cam Data

diagram in the Cam Data Management section.

Data Type Declaration

TYPE

Y_CAM_HEADER:STRUCT

TableType:INT; (* INT#1 = Master/Slave

pair *)

Reserved1:UINT;

DataSize:UDINT; (* Size of cam table in bytes.

There are 16 bytes

(8 Master/8 Slave)per

Y_MS_PAIR. For example, if

your CAM profile has 360

data pairs, then the data

size is 360 pairs x 16 bytes =

5760 bytes *)

END_STRUCT;

Y_MS_PAIR: STRUCT

Master:LREAL; (* Master position *)

Slave:LREAL; (* Slave position *)

END_STRUCT;

PLCopenPlus Function Blocks for Motion Control 2013-04-13 45

Page 54

Y_MS_HEADER:STRUCT

SlaveIncremental:BOOL;

MasterIncremental:BOOL;

Reserved1:UINT;

Reserved2:UINT;

Reserved3:UINT;

END_STRUCT;

MS_Array_Type:ARRAY[0..512] OF Y_MS_PAIR;

Y_MS_CAM_STRUCT:STRUCT

Header:Y_CAM_HEADER;

MS_Header:Y_MS_HEADER;

MS_Data:MS_Array_Type;

END_STRUCT;

END_TYPE

PLCopenPlus Function Blocks for Motion Control 2013-04-13 46

Page 55

Enumerated Types

Some blocks accept an enumerated type, which is a keyword (or constant)

representing a value which will configure the operation of the function

block. Enumerated types are equivalent to zero-based

integers. Therefore, the first value equates to zero, the second to 1,

etc. The format for enumerated types is as follows: ENUM:(0, 1, 2...) as

displayed in the example below (MC_BufferMode#Aborting).

MC_BufferMode:(Aborting, Buffered, BlendingLow, BlendingPrevious,

BlendingNext, BlendingHigh)

MC_Detection_Pattern: (Rising_Edge, Falling_Edge)

MC_Direction: (Positive_Direction, Shortest_Way, Negative_Direction,

Current_Direction)

(* MC_Direction#ShortestWay and MC_Direction#Current_Direction are

designed for use in applications where the Load Type is configured as a

rotary or modularized axis. Additionally, MC_Direction#Current_Direction

only applies if an existing move is in progress and another function block

such as MC_MoveAbsolute or MC_MoveRela tive is executed. Once the axis

PLCopenPlus Function Blocks for Motion Control 2013-04-13 47

Page 56

is at StandStill, using MC_Direction_CurrentDirection will default to the

positive direction. *)

MC_SwitchMode:(On, Off, EdgeOn, EdgeOff, EdgeSwitchPositive,

EdgeSwitchNegative) (* Only MC_SwitchMode#EdgeOn is supported *)

Y_AdjustMode: (MasterDistance, ElapsedTime, WithinRange)

• If AdjustMode=Y_AdjustMode#MasterDistance, then the cam

adjustment starts immediately, and completes when the master has

travelled the specified distance. If MasterDistance is 0.0, then the cam

adjustment finishes in the same scan it starts.

• If AdjustMode=Y_AdjustMode#ElapsedTime, then the cam adjustment

starts immediately, and completes within the specified time. If time=0 .0 ,

then the adjustment completes in the same scan it starts.

• If AdjustMode=Y_AdjustMode#WithinRange, then the cam adjustment

starts when the master is crosses the StartPosition, and completes when

the master reaches the EndPosition. If the master position is already

between StartPosition and EndPosition, then the adjustment starts

immediately, but still completes at the EndPosition, which means that the

correction speeds may be higher.

Y_RampIn:(None, Accel, SCurve) - Reserved for future use.

Y_RampOut: Reserved for future use.

Y_EngageMethod:(AtPosition, Immediate, Linked): This enumerated type

is reserved for Y_CamIn

Y_DisengageMethod:(AtPosition, Immediate, EndOfProfile): This

enumerated ty pe is reserved for Y_CamOut

PLCopenPlus Function Blocks for Motion Control 2013-04-13 48

Page 57

Function Block List

Function Block

Support

Short

Single-Axis Motion Function Blocks

MC_AccelerationProfile

None

Commands an

MC_GroupSyncOut

None

Function Block List

This online help provides information about the function blocks which can

be used for motion control. The function blocks are divided into single-axis

and multi-axis motion blocks and administrative function blocks which do

not generate a movement.

Single-Axis Motion Function Blocks

Single-Axis Administrative Function Blocks

Multi-Axis Motion Function Blocks

Multi-Axis Administrative Function Blocks

Homing Function Blocks

description

activation of a

positioning task

as an array which

describes the

acceleration of an

axis depending on

the time.

MC_Halt Future

PLCopenPlus Function Blocks for Motion Control 2013-04-13 49

Page 58

MC_Home

None

Obsolete function

MC_MoveAbsolute

Ver. 1.0

Commands a

MC_MoveAdditive

Future

Commands a

MC_MovePath

None

block. Please

use Part 5

Homing Function

Blocks to perform

Homing Functions

(i.e. MC_Step...)

controlled motion

of the axis at a

specified absolute

position.

MC_MoveContinuous Future

MC_MoveRelative Ver. 1.0 Commands a

controlled motion

of a specified

relative distance

additional to the

original

commanded

position in the

discrete motion

state.

controlled motion

of a specified

distance relative

to the actual

PLCopenPlus Function Blocks for Motion Control 2013-04-13 50

Page 59

position at the

time of the

MC_MoveVelocity

Ver. 1.0

Commands a

MC_PathGearIn

None

MC_PositionProfile

Future

Commands an

MC_TorqueControl

Ver. 1.0

execution.

MC_MoveSuperImposed Ver. 1.0 Commands a

controlled motion

of a specified

relative distance

additional to an

existing motion.

never ending

controlled motion

at a specified

MC_Stop Ver. 1.0 Commands a

velocity.

controlled motion

stop of an axis.

activation of a

positioning task

as an array which

describes the

positions of an

axis depending on

the time.

MC_VelocityProfile Future Commands an

activation of a

PLCopenPlus Function Blocks for Motion Control 2013-04-13 51

Page 60

positioning task

Y_HoldPosition

Ver. 1.0.5.1

Puts the servo in

Single-Axis Administrative Function Blocks

MC_AbortTrigger

Ver. 1.0

Aborts function

MC_Power

Ver. 1.0

Sets or resets the

MC_ReadActualTorque

Ver. 1.0

Reads the actual

as an array which

describes the

velocity of an axis

depending on the

time.

position mode and

freezes the

profiler.

blocks which are

connected to

trigger events.

MC_DigitalCamSwitch Refer to the

PLCopen Toolbox

available on

www.yaskawa.com

Provides output

control based on

a position input

and speed.

enabling for an

axis.

MC_ReadActualPosition Ver. 1.0 Reads the actual

position of the

axis.

torque of the axis.

MC_ReadActualVelocity Ver. 1.0 Reads the actual

PLCopenPlus Function Blocks for Motion Control 2013-04-13 52

velocity of the

Page 61

axis.

MC_ReadBoolParameter

Ver. 1.0

Reads the axis

MC_ReadDigitalInput

Future

Function block not

MC_ReadParameter

Ver. 1.0

Reads the axis

MC_SetOverride

Future

Sets the values of

MC_ReadAxisError Ver. 1.0 Indicates an axis

error and allows

to read the error.

parameters of the

data type BOOL.

necessary to read

inputs.

MC_ReadDigitalOutput Future Function block not

necessary to set

outputs.

MC_ReadStatus Ver. 1.0 Returns the status

MC_Reset Ver. 1.0 Acknowledges an

parameters.

of the axis with

respect to the

motion currently

in progress.

existing error

message.

override for the

whole axis, and

all functions that

are working on

PLCopenPlus Function Blocks for Motion Control 2013-04-13 53

that axis.

Page 62

MC_SetPosition

Ver. 1.0

Sets the current

MC_TouchProbe

Ver. 1.0

Record an axis

MC_WriteBoolParameter

Ver. 1.0

Writes the axis

MC_WriteDigitalOutput

Future

Writes a value to

Y_DirectControl

Ver. 1.0.7.4

Allows direct

position of an axis

to a new position

and thus shifts

the coordinate

system.

position at a

trigger event.

parameters of the

data type BOOL.

MC_WriteParameter Ver. 1.0 Writes the axis

Y_ClearAlarms Ver. 1.0 Clears non-axis-

the output

referenced by the

argument

'Output'. Function

block not

necessary to write

outputs.

parameters.

related controller

alarms

access to any of

PLCopenPlus Function Blocks for Motion Control 2013-04-13 54

three possible

control modes

Page 63

available on the

Y_ReadAlarm

Ver. 1.0

Reads non-axis-

Y_ReadDriveParameter

Ver. 1.0.5.1

Reads a

Y_VerifyParameters

Ver. 1.1

Compares

Y_WriteDriveParameter

Ver. 1.0.5.1

Writes a

Multi-Axis Motion Function Blocks

MC_GearIn

Ver. 1.0

Activates an

MECHATROLINK

network servo

control system.

related controller

alarms

parameter from

the associated

motor driver

parameters in the

drive with those

stored in the

controller

parameter from

the associated

motor driver

Y_WriteParameters Ver. 1.1 Sends parameters

stored in the

controller to the

drive

electronic velocity

PLCopenPlus Function Blocks for Motion Control 2013-04-13 55

gearing between

a slave and

Page 64

master axis.

MC_GroupHome

None

MC_MoveCircularAbsolute

None

MC_MoveDirectAbsolute

None

MC_MoveDirectRelative

None

MC_MoveLinearRelative

None

MC_MovePositionDirectRelative

None

MC_GearInPosition Ver. 1.0 Commands a gear

ratio between the

position of the

slave and master

axes from the

synchronization

point onwards.

MC_GearOut Ver. 1.0 Deactivates the

electronic velocity

gearing between

a slave and

master axis.

MC_GroupHalt None

MC_GroupStop None

MC_MoveCircularRelative None

MC_MoveLinearAbsolute None

MC_MovePathSynchronized None

MC_Phasing Future Creates a phase

shift in the master

PLCopenPlus Function Blocks for Motion Control 2013-04-13 56

position of a slave

axis.

Page 65

MC_TrackConveyorBelt

None

MC_TrackRotaryTable None

Y_CamFileSelect

Ver. 1.1

Y_CamOut

Ver. 1.1

Deactivates the

Y_CamScale

Ver. 1.1

Multiplication

Y_CamShift

Ver. 1.1

Y_ReleaseCamTable

Ver. 1.1

Frees motion

Y_CamIn Ver. 1.1 Activates the

coupling between

master and slave

axis.

coupling of the

slave axis with

the master axis.

factor applied to

the slave data

Y_CamStructSelect Ver. 1.1 Loads cam data

from the

application

program into

motion memory

Y_ReadCamTable Ver. 1.1 Copies cam data

from motion

memory into the

application

program

memory and

PLCopenPlus Function Blocks for Motion Control 2013-04-13 57

CamTableID

Page 66

Y_ResetMechatrolink

Ver. 1.0.5.1

Restarts the

MECHATROLINK

Multi-Axis Administrative Function Blocks

MC_AddAxisToGroup

None

MC_CamTableSelect

None

See

MC_GroupDisable

None

MC_GroupReadActualAcceleration

None

MC_GroupReadActualVelocity

None

MC_GroupReadConfiguration

None

MC_GroupReadStatus

None

MC_GroupSetOverride

None

MC_PathSelect

None

MC_RemoveAxisFromGroup

None

network

Y_SlaveOffset Ver. 1.1 Adds an offset to

the slave data

Y_WriteCamTable Ver. 1.1 Copies cam data

from the

application

program to the

motion memory

MC_GroupEnable None

MC_GroupReadActualPosition None

MC_GroupReadError None

MC_GroupReset None

MC_GroupSetPosition None

Y_CamTableSelect

PLCopenPlus Function Blocks for Motion Control 2013-04-13 58

Page 67

MC_SetCartesianTransform

None

MC_SetCoordinateTransform None

MC_SetDynCoordTransform

None

MC_SyncAxisToGroup

None

Homing Function Blocks

MC_AbortPassiveHoming

Future

MC_StepAbsolute

None

This function is

MC_StepAbsSwitch

Future

MC_StepDirect

Future

MC_StepLimitSwitch

Ver. 1.0

Performs homing

MC_StepReferenceFlyingSwitch

Future

MC_SetKinTransform None

MC_UngroupAllAxes None

MC_FinishHoming Ver. 1.0 Transfers an axis

from 'Homing'

state to

'Standstill' state.

not required with

Yaskawa absolute

encoders.

MC_StepBlock Future

by searching for a

limit switch.

MC_StepReferenceFlyingRefPulse Future

MC_StepRefPulse Ver. 1.0 Performs homing

by searching for a

Zero pulse.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 59

Page 68

Page 69

Function Blocks for Motion Control

Parameter

Data type

Description

B

Axis

AXIS_REF

Logical axis reference. This value

E

TriggerInput

TRIGGER_REF

Reference to the trigger signal

MC_AbortTrigger

The Function Block aborts function blocks which are associated with trigger

events (e.g. MC_TouchProbe).

Parameters

VAR_IN_OUT

can be located on the Configuration

tab in the Hardware Configuration

(logical axis number).

PLCopenPlus Function Blocks for Motion Control 2013-04-13 61

Page 70

source. See MC_TouchProbe

VAR_INPUT Default

B

Execute

BOOL

Upon the rising

FALSE

VAR_OUTPUT

B

Done

BOOL

Set high when the commanded

B

Busy

BOOL

Set high upon the rising edge of the

B

Error

BOOL

Set high if error has occurred during

edge, all other

function block inputs

are read and the

function is initiated.

To modify an input,

change the value

and re-trigger the

execute input.

action has been completed

successfully. If another block takes

control before the action is

completed, the Done output will not

be set. This output is reset when

execute goes low.

'Execute' or 'Enable' input, and

reset if Done, CommandAborted, or

Error is true.

the execution of the function block.

This output is cleared when

'Execute' or 'Enable' goes low.

E ErrorID UINT If error is true, this output provides

PLCopenPlus Function Blocks for Motion Control 2013-04-13 62

the Error ID. This output is reset

Page 71

when 'Execute' or 'Enable' goes low.

ErrorID

Meaning

4391

The function block can not be used with a virtual axis.

4625

Axis ID does not correspond to an axis configured on the

4630

Trigger or pattern reference is not valid

57620

The structure size does not match.

Notes

The following chart details the correct values for the TRIGGER_REF

structure based on the hardware latch to be detected.

Related Function Blocks

MC_TouchProbe

Error Description

0 No Error

system. Verify the value of AxisNum matches a logical axis

number in the configuration. Tip: Make sure AXIS_REF is

properly declared as a VAR or VAR_GLOBAL in all relevant

POUs.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 63

Page 72

Example

The following example shows how MC_AbortTrigger cancels (Aborts) a

busy MC_TouchProbe.

Timing Diagram for MC_AbortTrigger

PLCopenPlus Function Blocks for Motion Control 2013-04-13 64

Page 73

MC_FinishHoming

VAR_IN_OUT

This FB transfers an axis from the ‘Homing’ state to the ‘StandStill’ state.

It does not perform any movement. This block is necessary after the user

builds a homing procedure containing any number of MC_StepXXXX

homing blocks (See Notes ).

Parameters

Parameter Data type Description

B Axis AXIS_REF Logical axis reference. This value can be locate d on the

Configuration tab in the Hardware Confi g uration (logical axis

number).

VAR_INPUT Default

B Execute BOOL Upon the rising edge, all other

function block inputs are read and

the function is initiated. To modify

an input, change the value and

re-trigger the execute input.

False

PLCopenPlus Function Blocks for Motion Control 2013-04-13 65

Page 74

VAR_OUTPUT

E

ErrorID

UINT

If error is true, this output provides the Error ID. This outp ut is

E BufferMode MC_BufferMode Defines the behavior of the axis -

allowable modes are Aborting,

Buffered, BlendingLow,

BlendingPrevious, BlendingNext,

and BlendingHigh.MC_BufferMode#Aborting

MC_BufferMode#Buffered

MC_BufferMode#BlendingLow

MC_BufferMode#BlendingPrevious

MC_BufferMode#BlendingNext

MC_BufferMode#BlendingHigh

B Done BOOL Set high when the commanded action has been completed

successfully. If another block takes control before the action is

completed, the Done output will not be set. This outp ut is rese t

when execute goes low.

E Busy BOOL Set high upon the rising edge of the 'Execute' or 'Enable' input,

and reset if Done, CommandAborted, or Error is true.

E Active BOOL For buffered modes, this output is set high at the moment the

block takes control of the axis. For non buffered modes, the

outputs Busy and Active have the same value.

E CommandAborted BOOL Set high if motion is aborted by another motion command or

MC_Stop. This output is cleared with the same behav ior as the

Done output.

B Error BOOL Set high if error has occurred during the execution of the

function block. This output is cleared w hen 'Exec ute ' or 'Enable'

goes low.

MC_BufferMode#Aborting

Notes

This block is not necessary if the last homing block executed is

MC_StepRefPulse, MC_StepDirect, or MC_StepAbsolute because these

blocks will change the motion state back to 'Standstill' when complete.

This block is only necessary if the following homing blocks are last in a

homing sequence:

• MC_StepAbsSwitch

PLCopenPlus Function Blocks for Motion Control 2013-04-13 66

reset when 'Execute' or 'Enable' goes low.

Page 75

• MC_StepLimitSwitch

ErrorID

Meaning

0

No Error

4378

The function block is not applicable for the external axis

4381

Motion aborted due to axis alarm.

4893

The specified external axis may not be used. A physical axis is

57620

The structure size does not match.

• MC_StepBlock.

Error Description

specified

4625 Axis ID does not correspond to an axis configured on the

system. Verify the value of AxisNum matches a logical axis

number in the configuration. Tip: Make sure AXIS_REF is

properly declared as a VAR or VAR_GLOBAL in all relevant

POUs.

4641 Buffer mode does not correspond to a valid enumeration value.

required

PLCopenPlus Function Blocks for Motion Control 2013-04-13 67

Page 76

MC_GearIn

Parameter

Data type

Description

B

Slave

AXIS_REF

A logical reference to the slave axis

B

Execute

BOOL

Upon the rising edge, all other

FALSE

This Function Block commands a velocity ratio between the master and

slave axes. If the gearing mode is executed while the master is already in

motion, position synchronization will not be achieved unless some other

method (MC_MoveSuperimposed or MC_GearInPos) is employed.

Parameters

VAR_IN_OUT

B Master AXIS_REF A logical reference to the master axis

VAR_INPUT Default

function block inputs are read and

the function is initiated. To modify

an input, change the value and

PLCopenPlus Function Blocks for Motion Control 2013-04-13 68

Page 77

re-trigger the execute input.

B

RatioNumerator

DINT

Gear ratio numerator

DINT#0

VAR_OUTPUT

B

InGear

BOOL

Set high upon successful completion of the functio n. Thi s output

B

Error

BOOL

Set high if error has occurred during the execution of the

E

ErrorID

UINT

If error is true, this output provides the Error ID. This outp ut is

B RatioDenominator DINT Gear ratio denominator DINT#1

E Acceleration LREAL Value of the acceleration in user

units/second^2 (acceler ation is

applicable with same sign of

torque and velocity)

E Deceleration LREAL Value of the deceleration in user

units/second^2 (deceleration is

applicable with opposite signs of

torque and velocity)

E Jerk LREAL Value of the Jerk [u/s3]. Value o f

the jerk in user units/second^3.

Jerk not supported . Reserved for

future use.

E BufferMode MC_BufferMode D e fines the behavior of the axis -

allowable modes are Aborting,

Buffered, BlendingLow,

BlendingPrevious, BlendingNext,

and BlendingHigh.MC_BufferMode#Aborting

MC_BufferMode#Buffered

MC_BufferMode#BlendingLow

MC_BufferMode#BlendingPrevious

MC_BufferMode#BlendingNext

MC_BufferMode#BlendingHigh

LREAL#0.0

LREAL#0.0

LREAL#0.0

MC_BufferMode#Aborting

E Busy BOOL Set high upon the rising edge of the 'Execute' or 'Enable' input,

E Active BOOL For buffered modes, this output is set high at the moment the

E CommandAborted BOOL Set high if motion is aborted by another motion command or

PLCopenPlus Function Blocks for Motion Control 2013-04-13 69

is reset when execute goes low.

and reset if Done, CommandAborted, or Error is true.

block takes control of the axis. For non buffered modes, the

outputs Busy and Active have the same value.

MC_Stop. This output is cleared with the same behav ior as the

Done output.

function block. This output is cleared w hen 'Exec ute ' or 'Enable'

goes low.

reset when 'Execute' or 'Enable' goes low.

Page 78

Notes

ErrorID

Meaning

0

No Error

1. The slave accelerates up to the ratio of the master velocity and become

"InGear" when ratio is reached. Compensation for any position

relationship lost during the acceleration phase is not provided during

synchronization. Use MC_GearInPos when maintaining a position

relationship is important.

2. The gearing ratio can be changed while MC_GearIn is running, using a

consecutive MC_GearIn command or re-triggering the 'Execute' input

without the necessity to MC_GearOut first.

3. The InGear output is set the first time the specified ratio is reached.

Related Function Blocks

MC_GearOut: disengages the Slave axis from the master axis.

Error Description

4369 The move could not be buffered because the axis motion

queue is full. 16 moves is the maximum which can be

buffered.

4370 The move could not be started because motion is prohibited.

MC_Stop.Execute might be held high, preventing motion. If

MC_Stop has control of the axis, no other function block can

override the "Stopping" state. Other blocks that try to cause

motion while MC_Stop has control of the axis will generate

this error. Also verify that the limit switches are not active by

checking the Global Variables for the axis. Also, a motion

PLCopenPlus Function Blocks for Motion Control 2013-04-13 70

Page 79

block may be attempting to abort an MC_TorqueControl

move.

4378

The function block is not applicable for the external axis

4381

Motion aborted due to axis alarm.

4641

Buffer mode does not correspond to a valid enumeration

4659

Acceleration is less than or equal to zero.

4666

Denominator is zero.

4891

The slave axis can not be the same as the master axis.

57620

The structure size does not match.

specified

4625 Axis ID does not correspond to an axis configured on the

system. Verify the value of AxisNum matches a logical axis

number in the configuration. Tip: Make sure AXIS_REF is

properly declared as a VAR or VAR_GLOBAL in all relevant

POUs.

4626 The master slave relationship is defined. A slave cannot be a

master to another axis.

value.

4660 Deceleration is less than or equal to zero.

4667 Jerk is less than or equal to zero

PLCopenPlus Function Blocks for Motion Control 2013-04-13 71

Page 80

Timing Diagram

PLCopenPlus Function Blocks for Motion Control 2013-04-13 72

Page 81

Example

PLCopenPlus Function Blocks for Motion Control 2013-04-13 73

Page 82

MC_GearInPos

This Function Block commands a gear ratio between the master and slave

axes. Position synchronization is achieved over a defined region of travel

for both master and slave.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 74

Page 83

Parameters

VAR_IN_OUT

VAR_INPUT

Default

B

SlaveSyncPosition

LREAL

Slave position at which the axes

LREAL#0.0

E

Jerk

LREAL

Value of the Jerk [u/s3]. Value o f

LREAL#0.0

Parameter Data type Description

B Master AXIS_REF A logical reference to the master axis

B Slave AXIS_REF A logical reference to the slave axis

B Execute BOOL Upon the rising edge, all other

function block inputs are read and

the function is initiated. To modify

an input, change the value and

re-trigger the execute input.

B RatioNumerator DINT Gear ratio numer ator DINT#0

B RatioDenominator DINT Gear ratio denominator DINT#1

B MasterSyncPosition LREAL Master Position at which the axes

are synchronized

are synchronized

E SyncMode INT Reserved for future use INT#0

E MasterStartDistance LREAL Master Distance for

synchronization procedure. See

Note Below

E Velocity LREAL Maximum Velocity allowed by the

slave during 'StartSync' to the

'InSync' event

E Acceleration LREAL Acceleration limit while

attempting to Engage

E Deceleration LREAL Deceleration limit while

attempting to Engage

FALSE

LREAL#0.0

LREAL#0.0

LREAL#0.0

LREAL#0.0

LREAL#0.0

E BufferMode MC_BufferMode Defines the behavior of the axis -

PLCopenPlus Function Blocks for Motion Control 2013-04-13 75

the jerk in user units/second^3.

Jerk not supported . Reserved for

future use.

MC_BufferMode#Aborting

allowable modes are Aborting,

Buffered, BlendingLow,

BlendingPrevious, BlendingNext,

and BlendingHigh.MC_BufferMode#Aborting

MC_BufferMode#Buffered

Page 84

VAR_OUTPUT

E

Busy

BOOL

Set high upon the rising edge of the 'Execute' or 'Enable ' input,

B

CommandAborted

BOOL

Set high if motion is aborted by another motion command or

B

Error

BOOL

Set high if error has occurred during the execution of the

MC_BufferMode#BlendingLow

MC_BufferMode#BlendingPrevious

MC_BufferMode#BlendingNext

MC_BufferMode#BlendingHigh

E StartSync BOOL The slave has started to synchronize, but not yet synchronized

with the master

B InSync BOOL Set high when the slave first synchronizes with the master. This

output is reset when execute goes low.

and reset if Done, CommandAborted, or Error is true.

E Active BOOL For buffered modes, this output is set high at the moment the

block takes control of the axis. For non buffered modes, the

outputs Busy and Active have the same value.

MC_Stop. This output is cleared with the same behav ior as the

Done output.

function block. This output is cleared w hen 'Exec ute ' or 'Enable'

goes low.

E ErrorID UINT If error is true , this outp ut provid e s the Error ID. This output is

reset when 'Execute' or 'Enable' goes low.

Notes

• If the master is stationary when the MC_GearInPos function is

• Only one SyncMode is supported: MC_SyncMode#Acc_Vel_Dec uses

• MasterStartDistance and MasterSyncPosition are in units of the

executed, it will remain busy until motion occurs.

the input parameters Acceleration, Velocity, & Deceleration to make

a move to the SlaveSyncPosition. The slave may attain

synchronization early if these parameters are set higher than

optimally required. If these parameters will not allow the slave to

engage by the time the master reached the MasterSyncPosition, an

error will result.

specified master.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 76

Page 85

MasterDistance is a relative distance from the desired

ErrorID

Meaning

4369

The move could not be buffered because the axis motion

4370

The move could not be started because motion is prohibited.

4378

The function block is not applicable for the external axis

4625

Axis ID does not corresp ond to an axis configured on the

4626

The master slave relationship is defined. A slave cannot be a

•

synchronization point. The slave will start the synchronization

process when the master is within this range of the

MasterSyncPosition.

Error Description

0 No Error

queue is full. 16 moves is the maximum which can be

buffered.

MC_Stop.Execute might be held high, preventing motion. If

MC_Stop has control of the axis, no other function block can

override the "Stopping" state. Other blocks that try to cause

motion while MC_Stop has control of the axis will generate

this error. Also verify that the limit switches are not active by

checking the Global Variables for the axis. Also, a motion

block may be attempting to abort an MC_TorqueControl

move.

specified

4381 Motion aborted due to axis alarm.

system. Verify the value of AxisNum matches a logical axis

number in the configuration. Tip: Make sure AXIS_REF is

properly declared as a VAR or VAR_GLOBAL in all relevant

POUs.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 77

Page 86

master to another axis.

4641 Buffer mode does not correspond to a valid enumeration

4659

Acceleration is less than or equal to zero.

4660

Deceleration is less than or equal to zero.

4669

Engage position is outside the cam table domain.

57620

The structure size does not match.

value.

4647 The synch mode does not correspond to a valid enumeration

value.

4657 Distance parameter is less than or equal to zero.

4666 Denominator is zero.

4889 The engage phase exceeded the distance limit. Slave axis

could not attain the target position and velocity within the

user specified master distance.

4891 The slave axis can not be the same as the master axis.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 78

Page 87

Usage Matrix Chart

Examples

Scenario 22:

A logic analyzer plot of the commanded position (Prm 1010) of the master

and the slave before and after' InSync' in is shown below.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 79

Page 88

Scenario 30:

A logic analyzer plot of the commanded position (Prm 1010) of the master

and the slave before and after' InSync' in is shown below.

Recall that the requirements for this scenario state that the

MasterStartDistance and the MasterSyncDistance must be negative.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 80

Page 89

PLCopenPlus Function Blocks for Motion Control 2013-04-13 81

Page 90

Timing Diagram

PLCopenPlus Function Blocks for Motion Control 2013-04-13 82

Page 91

MC_GearOut

Parameter

Data

Description

B

Slave

AXIS_REF

A logical reference to the slave axis

VAR_OUTPUT

This Function Block disengages the Slave axis from the Master axis. The

slave will continue to move at the last commanded velocity.

Parameters

Type

VAR_IN_OUT

VAR_INPUT Default

B Execute BOOL Upon the rising edge, all other func tio n blo ck inp uts are

read and the function is initiated. To modify an input,

change the value and re-trigger the execute input.

B Done BOOL Set high when the commanded action has been completed

successfully. If another block takes control before the action is

completed, the Done output will not be set. This outp ut is reset when

execute goes low.

E Busy BOOL Set high upon the rising edge of the 'Execute' or 'Enable' input, and

reset if Done, CommandAborted, or Error is true.

B Error BOOL Set high if error has occurred during the execution of the function

block. This output is cl e ared when 'Exe c ute ' or 'Enable ' goes low .

E ErrorID UINT If error is true, this output provides the Error ID. This outp ut is res e t

FALSE

PLCopenPlus Function Blocks for Motion Control 2013-04-13 83

Page 92

when 'Execute' or 'Enable' goes low.

ErrorID

Meaning

4378

The function block is not applicable for the external axis

4381

Motion aborted due to axis alarm.

4625

Axis ID does not correspond to an axis configured on the

4376

The master slave relationship can not be modified because the

4404

Can not execute MC_GearOut because axis is not in gear

Notes

It is assumed that this command is followed by another command, for

instance MC_Stop, MC_GearIn, or any other command. If there is no new

command, the defa ult con dit ion wi ll be to ma intain the la st gea red v eloc ity.

Related Function Blocks

MC_GearIn: Commands a velocity ratio between the master and slave

axes.

Error Description

0 No Error

specified

system. Verify the value of AxisNum matches a logical axis

number in the configuration. Tip: Make sure AXIS_REF is

properly declared as a VAR or VAR_GLOBAL in all relevant

POUs.

master axis has not been set yet.

57620 The structure size does not match.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 84

Page 93

Example

In the example shown below, an MC_Stop function block is used to bring

the slave axis to a standstill after the gear relation is broken using

MC_GearOut

PLCopenPlus Function Blocks for Motion Control 2013-04-13 85

Page 94

VAR_IN_OUT

B

Axis

AXIS_REF

Logical axis reference. This value can be locate d on the Config ur a tio n

VAR_INPUT

Default

MC_MoveAbsolute

This Function Block commands a controlled motion to the specified

absolute position.

Parameters

Parameter Data Type Description

tab in the Hardware Configuration (logical ax is numb er ).

B Execute BOOL Upon the rising edge, all other

function block inputs are read and

the function is initiated. To modify

an input, change the value and

re-trigger the execute input.

FALSE

PLCopenPlus Function Blocks for Motion Control 2013-04-13 86

Page 95

E

Deceleration

LREAL

Value of the deceleration in user

LREAL#0.0

E

Direction

MC_Direction

Specifies the direction of motion.

MC_Direction#Positive_Direction

VAR_OUTPUT

B Position LREAL A po s itive or negative value

within the coordinate system in

user units.

E Velocity LREAL Absolute value of the velocity in

user units/second

E Acceleration LREAL Value of the acceleration in user

units/second^2 (acceler ation is

applicable with same sign of

torque and velocity)

units/second^2 (deceleration is

applicable with opposite signs of

torque and velocity)

E Jerk LREAL Value of the Jerk [u/s3]. Value o f

the jerk in user units/second^3.

Jerk not supported . Reserved for

future use.

Allowable modes are

positive_direction, s hor test_way,

negative_direction,

current_direction.

MC_Direction#Positive_Direction

MC_Direction#Shortest_Way

MC_Direction#Negative_Direction

MC_Direction#Current_Direction

E BufferMode MC_BufferMode Defines the behavior of the axis -

allowable modes are Aborting,

Buffered, BlendingLow,

BlendingPrevious, BlendingNext,

and BlendingHigh.MC_BufferMode#Aborting

MC_BufferMode#Buffered

MC_BufferMode#BlendingLow

MC_BufferMode#BlendingPrevious

MC_BufferMode#BlendingNext

MC_BufferMode#BlendingHigh

LREAL#0.0

LREAL#0.0

LREAL#0.0

LREAL#0.0

MC_BufferMode#Aborting

B Done BOOL Set high when the commanded action has been completed successfully.

E Busy BOOL Set high upon the rising edge of the 'Execute' or 'Enable' input, and

PLCopenPlus Function Blocks for Motion Control 2013-04-13 87

If another block takes control before the actio n is comp le ted, the Done

output will not be set. This output is reset when execute goes low.

reset if Done, CommandAborted, or Error is true.

Page 96

E Active BOOL For buffered modes, this output is set high at the moment the block

takes control of the axis. For non buffered modes, the outputs Bus y

and Active have the same value.

E CommandAborted BOOL Set high if motion is aborted by another motion command or MC_Stop.

This output is cleared with the same behavior as the Done output.

B Error BOOL Set high if error has occurred during the execution of the function

block. This output is cleared when 'Execute ' or 'Enable ' goes low .

E ErrorID UINT If error is true, this output provides the Error ID. This output is reset

when 'Execute' or 'Enable' goes low.

Notes

• The absolute position, as with all other inputs, can be updated while in

motion by retriggering the Execute input.

• This action completes with velocity zero if no further blocks are pending.

• Regarding the use of the 'Direction' input:

• If there is only one mathematical solution to reach the commanded

position (like in linear systems), the value of the input Direction is

ignored.

• For rotary axis - valid absolute position values are in the range of the

machine cycle. It is possible to specify a relative move of more than one

machine cycle using MC_MoveRelative. When motion is complete, the

position will be reported as somewhere between 0 and machine cycle.

• The Enum type MC_Direction#Shortest_Way will cause motion through

the shortest route. The controller will decide based on the current

position when the function block is executed.

• For further information about the Done output, Profile Complete, and

Motion Complete, see the Determining when motion is complete section.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 88

Page 97

Error Description

ErrorID

Meaning

4369

The move could not be buffered because the axis motion

4378

The function block is not applicable for the external axis

4381

Motion aborted due to axis alarm.

4659

Acceleration is less than or equal to zero.

4660

Deceleration is less than or equal to zero.

4641

Buffer mode does not correspond to a valid enumeration

0 No Error

queue is full. 16 moves is the maximum which can be

buffered.

4370 The move could not be started because motion is prohibited.

MC_Stop.Execute might be held high, preventing motion. If

MC_Stop has control of the axis, no other function block can

override the "Stopping" state. Other blocks that try to cause

motion while MC_Stop has control of the axis will generate

this error. Also verify that the limit switches are not active by

checking the Global Variables for the axis. Also, a motion

block may be attempting to abort an MC_TorqueControl

move.

specified

4625 Axis ID does not corresp ond to an axis configured on the

system. Verify the value of AxisNum matches a logical axis

number in the configuration. Tip: Make sure AXIS_REF is

properly declared as a VAR or VAR_GLOBAL in all relevant

POUs.

4658 Velocity parameter is less than or equal to zero.

PLCopenPlus Function Blocks for Motion Control 2013-04-13 89

Page 98

value.

4642 Direction does not correspond to a valid enumeration value.

4667

Jerk is less than or equal to zero

4893

The specified external axis may not be used. A physical axis is

57617

Instance object is NULL.

57620

The structure size does not match.

4378 The function block is not applicable for the external axis

specified

4369 The move could not be buffered because the axis motion

queue is full. 16 moves is the maximum which can be

buffered.