Page 1

ITT

Installation, Operation and Maintenance Instructions

SERIES VTP™

Vertical Turbine Pumps

Bell & Gossett

VTP2006-IOM

®

www.bellgossett.com

Engineered for life

®

Page 2

Foreward

Foreward

This manual provides instructions for the Installation, Operation, and Maintenance of the Bell & Gossett Vertical

Turbine Pumps. This manual covers a standard product. For special options, supplemental instructions are

available. This manual must be read and understood before installation and start-up.

This instruction manual covers several different pump models. Most assembly, disassembly, and inspection

procedures are the same for all the pumps. However, where there are differences, these differences will be

noted within the manual. The design, materials and workmanship incorporated in the construction of the

Bell & Gossett VTP pumps makes them capable of giving long, trouble-free service. The life and satisfactory

service of any mechanical unit, however, is enhanced and extended by correct application, proper installation,

periodic inspection, condition monitoring and careful maintenance. This instruction manual was prepared

to assist operators in understanding the construction and the correct methods of installing, operating, and

maintaining these pumps.

The information contained in this book is intended to assist operating personnel by providing information on the

characteristics of the purchased equipment. It does not relieve the user of their responsibility for using accepted

safe engineering practices in the installation, operation and maintenance of this equipment.

ITT shall not be liable for physical injury, death, damage, or delays caused by a failure to observe the

instructions for installation, operation and maintenance contained in this manual.

Warranty is valid only when genuine Bell & Gossett parts are used.

Use of the equipment on a service other than stated in the order will nullify the warranty, unless written approval

is obtained in advance from Bell & Gossett.

For information or questions not covered in this manual, contact ITT at (806) 763-7867.

THIS MANUAL EXPLAINS :

• Proper Installation • Pump Overhaul

• Start-up Procedures • Trouble Shooting

• Operation Procedures • Ordering Spare or Repair Parts

• Routine Maintenance

Owner’s Information

Owner’s Information

Pump Model Number:

Pump Serial Number:

Motor Model Number:

Motor Serial Number:

Dealer:

Dealer Telephone:

Purchase Date:

Installation Date:

2

Page 3

Table of Contents

Table of Contents

SUBJECT PAGE

SECTION 1 – Safety ...................................................................................................................................................4

Safety Instructions ..................................................................................................................................................... 4

General Precautions ...................................................................................................................................................4

SECTION 2 – General Information ............................................................................................................................. 4

Introduction ..............................................................................................................................................................4

Receiving and Checking ............................................................................................................................................4

Materials and Equipment Required ...........................................................................................................................5

Storage ......................................................................................................................................................................5

General Description ..................................................................................................................................................6

Typical Drawings ..................................................................................................................................................7-10

SECTION 3 – Installation .........................................................................................................................................11

Foundation / Piping .................................................................................................................................................11

Pump Installation ....................................................................................................................................................12

Installing the Bowl Assembly ...................................................................................................................................12

Installing the Column ..............................................................................................................................................13

Installing the Discharge Head ..................................................................................................................................15

Installing the Stuffing Box........................................................................................................................................15

Installing the Mechanical Seal ..................................................................................................................................16

Installing the Tension Plate ...................................................................................................................................... 16

Installing the Driver ................................................................................................................................................18

Installing the Thrust Pot .......................................................................................................................................... 22

SECTION 4 – Pump Start Up and Operation ............................................................................................................24

SECTION 5 – Maintenance ...................................................................................................................................... 25

Preventive Maintenance ..........................................................................................................................................25

Packing Adjustment and Replacement ......................................................................................................................25

Seasonal Shutdown .................................................................................................................................................. 25

Thrust Pot Lubrication and Maintenance .................................................................................................................26

Recommended Lubricants .......................................................................................................................................27

Troubleshooting ......................................................................................................................................................28

SECTION 6 – Disassembly and Reassembly ..............................................................................................................30

Disassembly ............................................................................................................................................................. 30

Inspection and Reassemble ...................................................................................................................................... 31

SECTION 7 – Repair Parts ........................................................................................................................................ 33

Limited Warranty ......................................................................................................................................................34

3

Page 4

DANGER

WARNING

CAUTION

WARNING

Hazardous voltage

can shock, burn or

cause death.

Safety Instructions – SECTION 1

WARNING

CAUTION

WARNING

CAUTION

Safety Instructions – SECTION 1

• Other personal protective equipment to protect against

hazardous/toxic fluid.

TO AVOID SERIOUS OR FATAL PERSONAL INJURY

OR MAJOR PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS IN THE

MANUAL AND ON THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump or

in the manual, look for one of the following signal words and be alert to the potential for personal injury or property damage.

Warns of hazards that WILL cause serious

personal injury, death or major property

damage.

Warns of hazards that CAN cause serious

personal injury, death or major property

damage.

Warns of hazards that CAN cause personal

injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND MUST BE

FOLLOWED.

THIS MANUAL IS INTENDED TO ASSIST IN

THE INSTALLATION AND OPERATION OF

THIS UNIT. THOROUGHLY REVIEW ALL

INSTRUCTIONS AND WARNINGS PRIOR TO

PERFORMING ANY WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

Install, ground and wire according

to local and National Electrical Code

Requirements.

Install an all leg disconnect switch

near the pump.

Disconnect and lockout electrical

power before installing or servicing

the pump.

Electrical supply must match motor’s

nameplate specifications. Incorrect

voltage can cause fire, damage motor

and void the warranty.

Single phase pump motors are equipped with an

automatic thermal protector, which opens the motor’s

electrical circuit when an overload condition exists.

This can cause the pump to start unexpectedly.

General Precautions

General Precautions

Personal injuries will result if procedures

outlined in this manual are not followed

Electric supply MUST match pump’s

nameplate specifications. Incorrect

voltage can cause fire, damage to motor and voids

warranty.

Safety Apparel:

• Insulated work gloves when handling hot sand collar.

• Heavy work gloves when handling parts with sharp

edges, especially impellers.

• Safety glasses (with side shields) for eye protection.

• Steel-toed shoes for foot protection when handling

parts, heavy tools, etc.

4

Maintenance Safety:

• Always lock out power.

• Ensure pump is isolated from system and the pressure

is relieved before disassembling the pump, removing

plugs, or disconnecting the piping.

• Use proper lifting and supporting equipment to prevent

serious injury or death.

• Observe all decontamination procedures.

General Information – SECTION 2

General Information – SECTION 2

INTRODUCTION

NOTE: The information in this manual intends to be

used as a guide only. If you are in doubt, consult

your Bell & Gossett Representative for specific

information about your pump.

The design, material, and workmanship incorporated in

the construction of Bell & Gossett VTP pumps makes

them capable of giving long, trouble free service. The life

and satisfactory service of any mechanical unit, however,

is enhanced and extended by correct application, proper

installation, periodic inspection and careful maintenance.

This instruction manual was prepared to assist operators

in understanding the construction and the correct

methods of installing, operating and maintaining these

pumps.

Rotating components of the pump

assembly must be covered with a suitable

rigid guard to prevent injury to personnel.

Study thoroughly Sections 1 through 6 and carefully

follow the instructions for installing and operating.

Sections 5 contains answers to troubleshooting and

maintenance questions. Keep this instruction manual

handy for reference.

Bell & Gossett will not be liable for any

damages or delay caused by failure to

comply with the provisions of this instruction manual.

RECEIVING AND CHECKING

The pump should be carefully supported prior to

unloading from the carrier. Handle all components

carefully. Inspection for damage of the shipping crate

should be made prior to unpacking the pump. After

unpacking, visually inspect the pump and check the

following:

1. Contents of the pump assembly against the

packing list.

2. All components against damage.

3. All shafting for damage, should the crate be

broken or show careless handling. All shafting

must be checked for straightness.

Any shortages or damages should be immediately called

to the attention of the local freight agent of the carrier by

which the shipment arrived and proper notation made on

the bill. This will prevent any controversy when a claim is

made and facilitate prompt and satisfactory adjustment.

Page 5

MATERIALS AND EQUIPMENT REQUIRED

The material and equipment necessary for installation

of the pump will vary with the size of the pump and the

type of installation.

The following list of standard tools and supplies is

offered only as a guide.

BULK MATERIAL

• Anti-Galling lubricant

(such as Dow Corning “MOLYKOTE”)

• Thread Compound

• Lubrication Oil

• Turbine Oil

• Grease

RIGGING EQUIPMENT

• Mobile power hoist, traveling crane or derrick.

• Drag line and blocks.

• Elevator clamps, if unit is unassembled.

• Clevises – for use with eyebolts.

• Timbers – size, length and quantity to support long

pump parts on the floor.

• I-Beams or timbers to support pump over

installation.

HAND TOOLS

• Pipe wrenches.

• Feeler gauges.

• Set of mechanics tools including: files, wire brush,

pliers, wire cutters and pocket knife.

• Clean rags.

• Dial indicator to assist in motor and pump

alignment.

OPTIONAL TOOLS TO FACILITATE PUMP

ASSEMBLY AND DISASSEMBLY

• Taperlock driver to assist in bowl assembly and

disassembly for pumps with taper lock impellers

only.

STORAGE

Bell & Gossett carefully preserves and protects its

products for shipment. However, the effective life of the

preservatives applied at the factory can vary from 3 to

18 months depending on the severity of the environment

in which the equipment is stored. This section provides

procedures for preparation prior to storage and

maintenance during storage of Bell & Gossett VTP

pumps. These procedures are necessary to protect the

precision parts of the pumps. Specific procedures for

storing motors, gear drivers, and engines, should be

obtained from the equipment manufacturer. This section

is intended to be of general assistance to users of Bell &

Gossett VTP pumps. It shall not modify, amend and/or

otherwise alter the scope of Bell & Gossett VTP pumps

warranty responsibilities to the purchaser in any way

whatsoever.

Storage Preparation

Bell & Gossett VTP pumps require proper preparation

for storage and regular maintenance during storage. The

pump shall be considered in storage when it has been

delivered to the job site and is awaiting installation.

Preferably, the storage area shall be paved, well drained

and free from flooding, and be indoors whenever

possible.

Weatherproof coverings used for outdoor storage shall be

flame resistant type sheeting or tarpaulins. They shall be

placed so as to provide good drainage and air circulation

and shall be tied down to protect from wind damage.

Storage area shall be maintained in a clean condition at

all times.

Pumps and/or component parts shall be placed on skids,

pallets, or shoring to permit good air circulation.

Pumps and/or component parts shall be sorted so as to

permit ready access for inspection and/or maintenance

without excessive handling.

Pumps and/or component parts stacked during storage

shall be arranged so that the racks, containers, or crates

bear full weight without distortion of pumps or parts.

Identification markings must be readily visible. Any

cover removed for internal access shall be replaced

immediately.

Pump and bowl assembly shafting shall be rotated

counter clockwise, as a minimum, once a month. Shaft

shall not be left in the same previous position, nor in the

extreme raised or lowered lateral position. Shaft should

rotate freely.

NOTE: For further information on these procedures

contact your Bell & Gossett Representative.

Recommended Storage Procedures

Controlled storage facilities should be maintained at an

even temperature 10º F (6º C) or more above the dew

point with relative humidity less than 50% and little or

no dust. (If these requirements can not be met the pump

is to be considered in uncontrolled storage.)

For uncontrolled storage periods of 6 months or less,

the pump is to be inspected periodically to insure that all

preservatives are intact.

All pipe threads and flanged pipe covers are to be sealed

with tape.

The pump must not be stored closer than six inches

(15 cm) from the ground.

5

Page 6

Uncontrolled Long Term Storage Preparations

When applicable to the pump, storage periods over six

months require the preceding storage procedure and

storage preparation plus the following:

Inspect the lube oil and seal flush piping and either

fill the piping with rust preventative oil, or re-coat the

piping periodically to prevent corrosion.

Discharge Head

The discharge head is either a cast iron head or

a fabricated ‘F’ type head. Ports are provided for

connecting the pressure gauge, stuffing box bypass return

and lubricator connections. The driver support portion

of the discharge head is designed with large windows

for easy stuffing box or tension plate adjustment. The

windows are covered with guards for safe operation.

Place 10 pounds (4.5 kg) of moisture absorbing desiccant

or 5 pounds (2.3 kg) of vapor phase inhibitor crystals

near the center of the pump. If the pump is assembled,

place an additional one pound (0.5 kg) in the discharge

nozzle securely fastened to the discharge elbow.

Install a moisture indicator near the perimeter of the

pump. Cover the pump with 6 mil (0.15 mm) minimum

thickness black polyethylene or equal and seal it with

tape. Provide a small ventilation hole approximately

½ inch (12 mm) diameter.

Provide a roof or shed shelter to protect from direct

exposure to the elements.

GENERAL DESCRIPTION

The model VTP pump is a vertical turbine lineshaft

pump, which is designed to meet wide ranges of service

with maximum dependability. See Figure 1 or Figure 2

for open lineshaft pump and Figure 3 and Figure 4 for

enclosed lineshaft pump.

Drivers

Hollow shaft motors or right angle gear drives, are often

used with a separate head shaft through the driver and

connected to the pump by a threaded coupling.

Column

Threaded or flanged column construction provides

positive shaft and bearing alignment. Bearings are spaced

to provide vibration free operation away from the

shaft critical speed in order to insure long bearing life

and reduced shaft wear. For open lineshaft, the shaft is

supported within the column by using bearing retainers

in the column assembly. For enclosed lineshaft, the

bearings are also the tube couplings of the shaft-enclosing

tube. The shaft-enclosing tube is stabilized in the column

pipe by tube stabilizer.

Bowl Assembly

The bowls are generally of flanged construction for

accurate alignment and ease of assembly and disassembly.

Impellers may be either open or enclosed depending on

the design requirements. They are fastened to the pump

shaft by taperlocks. For temperatures over 180º F (82º

C) and in the larger size bowls (over 18”), impellers

are keyed to the shaft. A special first stage low NPSH

impeller may be provided on some pump for certain

special application.

Thrust Pot

A thrust pot is utilized when the driver is not designed to

carry the pump thrust.

6

Page 7

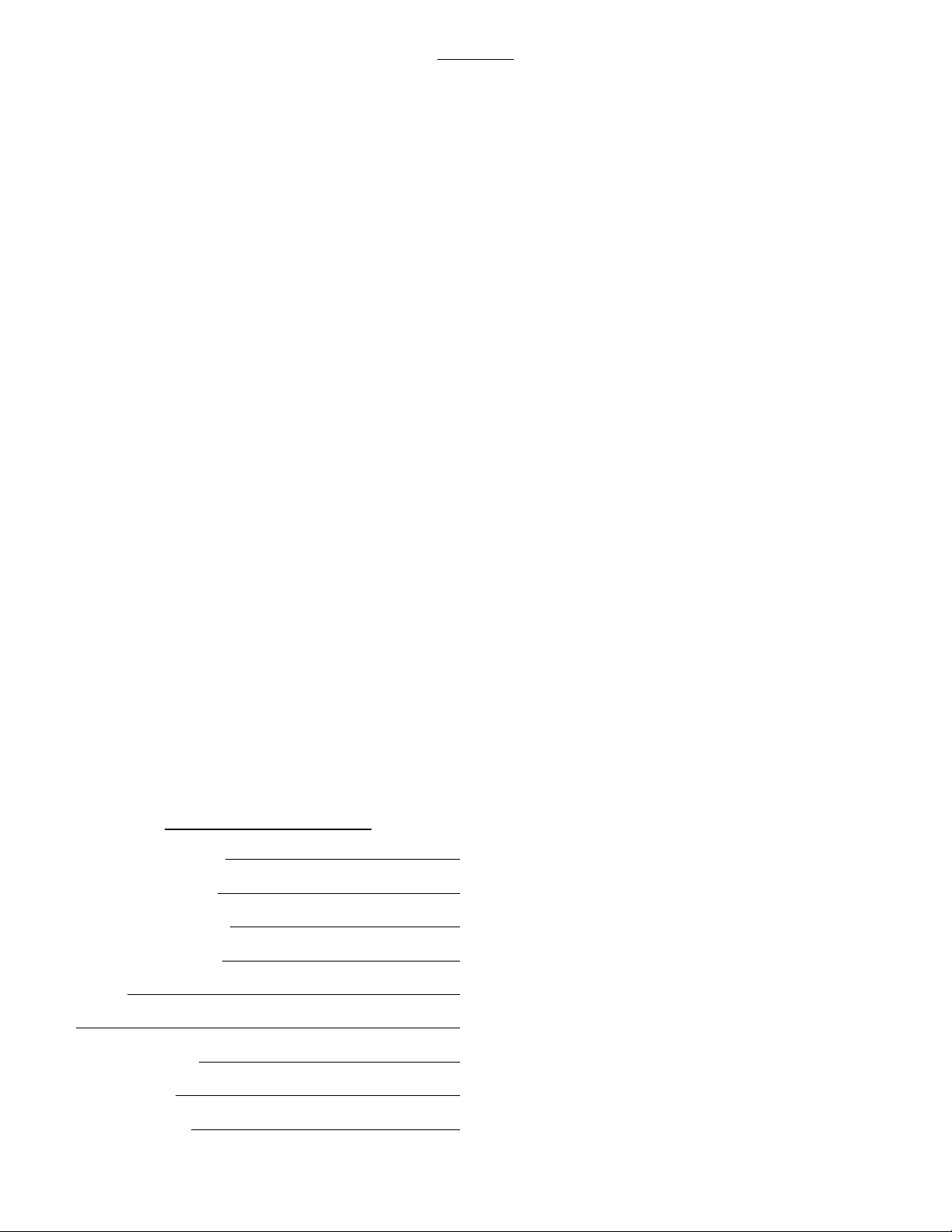

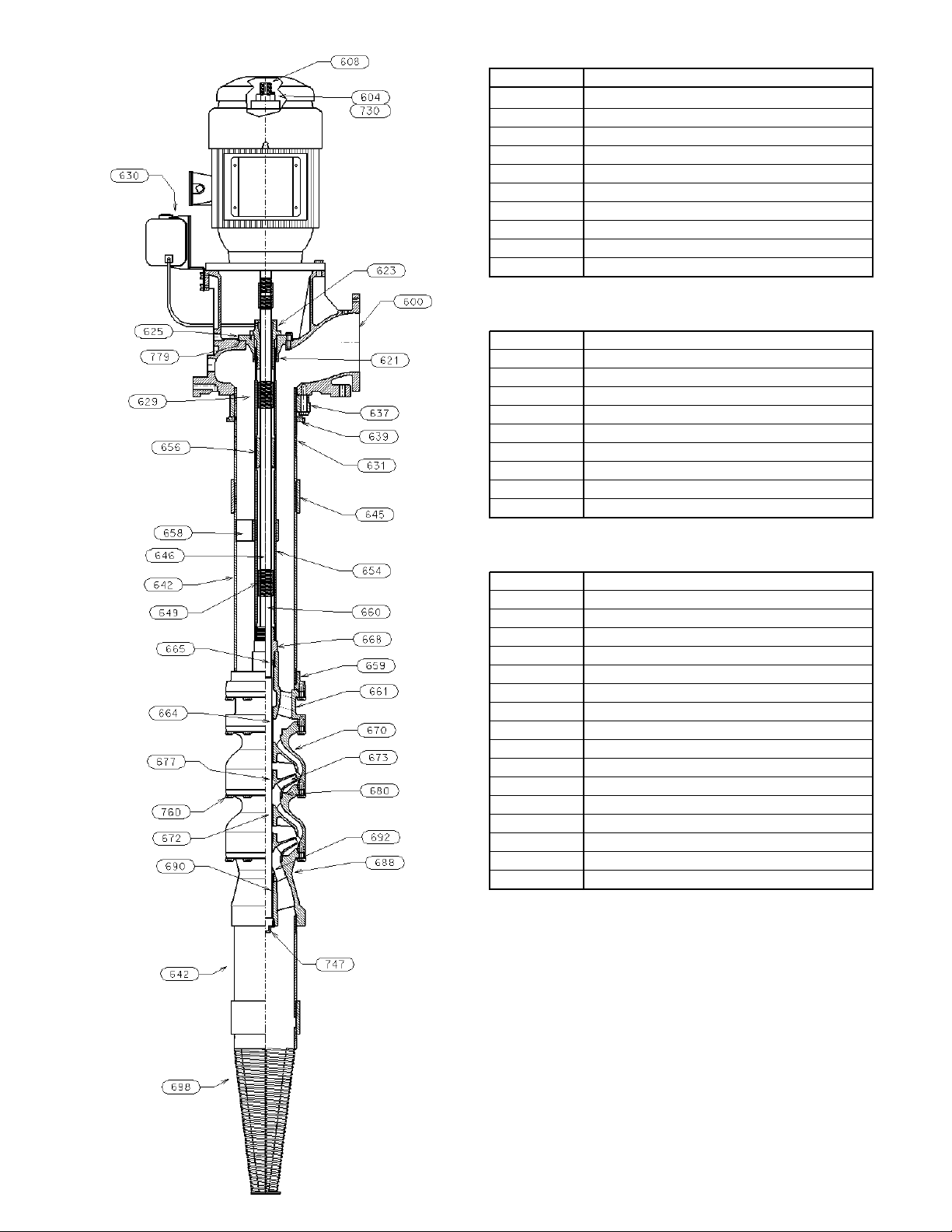

DISCHARGE HEAD ASSEMBLY

ITEM DESCRIPTION

600 DISCHARGE HEAD

601 MOTOR SUPPORT

608 HEADSHAFT

610 COUPLING ASSEMBLY

616 SEAL HOUSING

617 SEAL HOUSING BEARING

620 MECHANICAL SEAL

637 COLUMN FLANGE

779 SEAL HOUSING GASKET

COLUMN ASSEMBLY

642 COULMN PIPE

645 COLUMN COUPLING

646 LINESHAFT

649 LINESHAFT COUPLING

652 BEARING RETAINER

656 LINESHAFT BEARING

BOWL ASSEMBLY

660 BOWL SHAFT

661 DISCHARGE BOWL

664 DISCHARGE BEARING

670 INTERMEDIATE BOWL

672 INTERMEDIATE BOWL BEARING

673 IMPELLER

677 TAPERLOCK

680 WEAR RING (OPTIONAL)

760 HEX BOLT

692 SAND COLLAR

688 SUCTION BOWL/BELL

690 SUCTION BEARING

698 SUCTION STRAINER

747 PLUG

Figure 1 Open Lineshaft Pump with

Threaded Column Pipe

7

Page 8

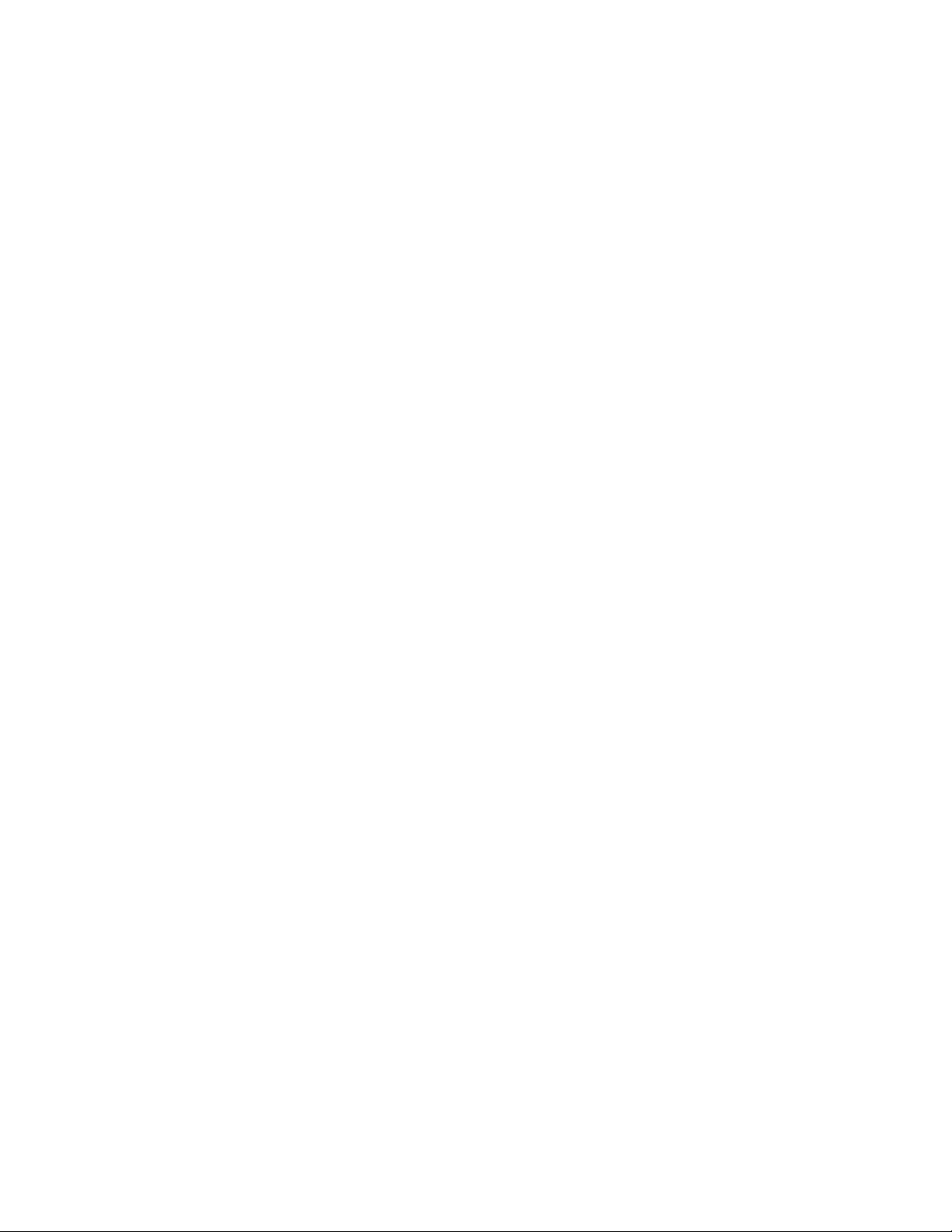

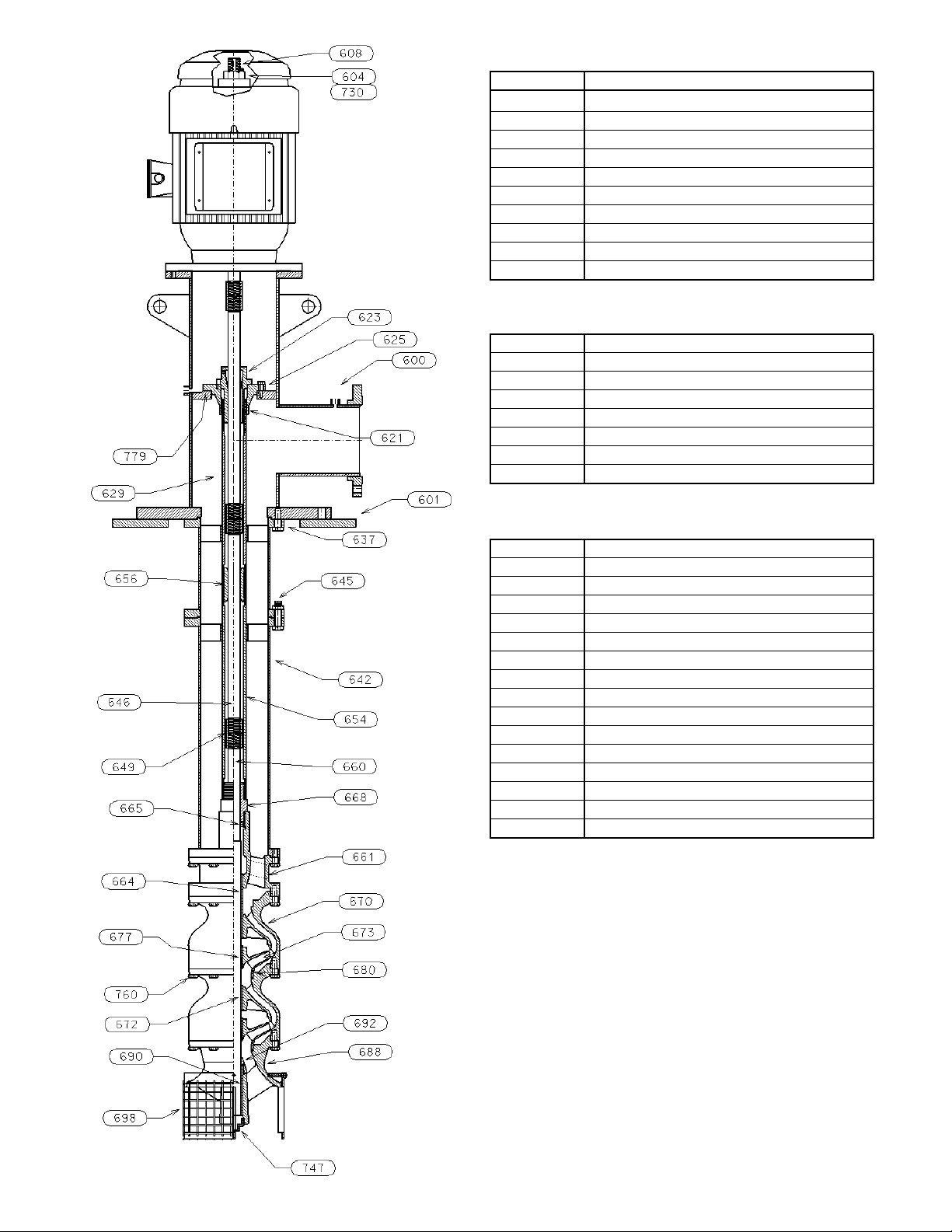

DISCHARGE HEAD ASSEMBLY

ITEM DESCRIPTION

600 DISCHARGE HEAD

608 HEADSHAFT

610 COUPLING ASSEMBLY

616 SEAL HOUSING

617 SEAL HOUSING BEARING

620 MECHANICAL SEAL

COLUMN ASSEMBLY

642 COULMN PIPE

645 COLUMN BOLTING

646 LINESHAFT

649 LINESHAFT COUPLING

652 BEARING RETAINER

656 LINESHAFT BEARING

BOWL ASSEMBLY

660 BOWL SHAFT

670 INTERMEDIATE BOWL

672 INTERMEDIATE BOWL BEARING

673 IMPELLER

677 TAPERLOCK

680 WEAR RING (OPTIONAL)

760 HEX BOLT

692 SAND COLLAR

688 SUCTION BOWL/BELL

690 SUCTION BEARING

698 SUCTION STRAINER

747 PLUG

Figure 2 Open Lineshaft Pump

8

with Flanged Column

Page 9

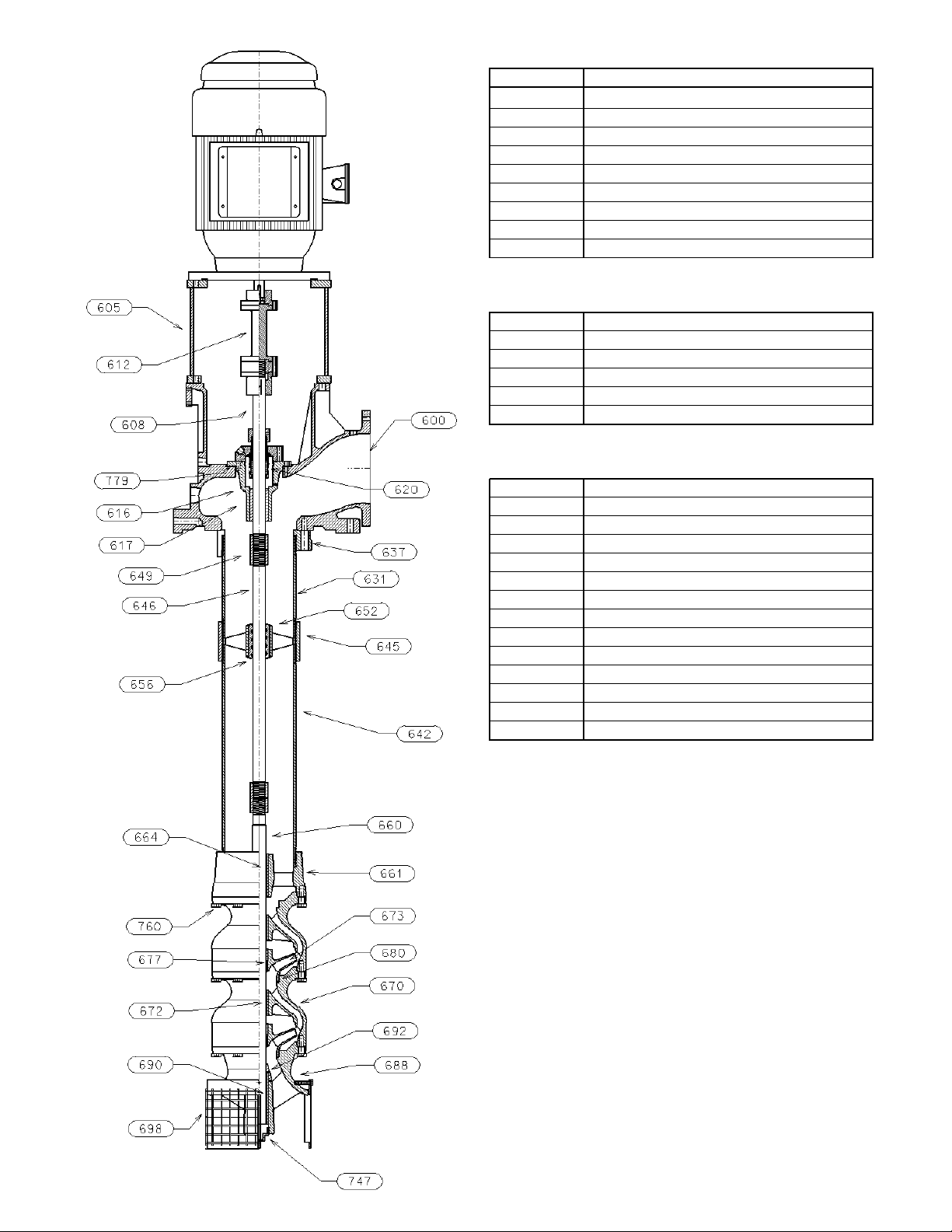

HEAD ASSEMBLY

ITEM DESCRIPTION

600 DISCHARGE HEAD

604 ADJUSTING NUT

608 HEADSHAFT

620 O-RING

623 TENSION NUT

625 TENSION PLATE

630 OILER

637 COLUMN FLANGE

730 GIB KEY

779 TENSION PLATE GASKET

COLUMN ASSEMBLY

629 TUBE NIPPLE

631 COLUMN NIPPLE

639 COLUMN LOCK RING

642 COULMN PIPE

645 COLUMN COUPLING

646 LINESHAFT

649 LINESHAFT COUPLING

654 OIL TUBE

656 LINESHAFT BEARING

658 TUBE STABILIZER

BOWL ASSEMBLY

659 COLUMN ADAPTER

660 BOWL SHAFT

661 DISCHARGE BOWL

664 DISCHARGE BEARING

665 OIL SEAL

668 TUBE ADAPTER BEARING

670 INTERMEDIATE BOWL

672 INTERMEDIATE BOWL BEARING

673 IMPELLER

677 TAPERLOCK

680 WEAR RING (OPTIONAL)

688 SUCTION BOWL/BELL

690 SUCTION BEARING

692 SAND COLLAR

698 SUCTION STRAINER

747 PLUG

760 HEX BOLT

Figure 3 Enclosed Lineshaft Pump with

Threaded Column Pipe

9

Page 10

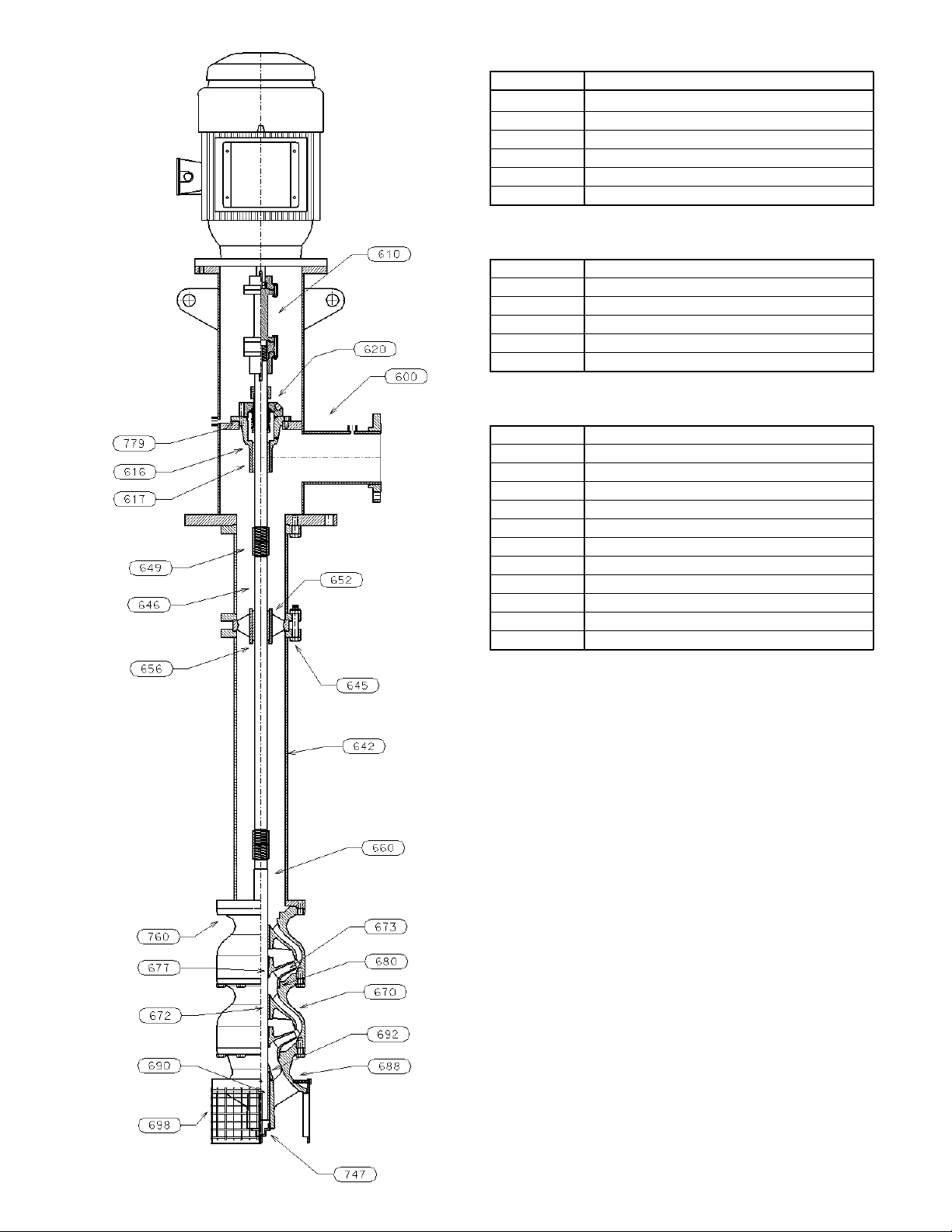

HEAD ASSEMBLY

ITEM DESCRIPTION

608 HEADSHAFT

604 ADJUSTING NUT

730 GIB KEY

600 DISCHARGE HEAD

630 OIL RESERVOIR

623 TENSION NUT

625 TENSION PLATE

779 TENSION PLATE GASKET

620 O-RING

637 COLUMN FLANGE

COLUMN ASSEMBLY

629 TUBE NIPPLE

642 COLUMN PIPE

645 COLUMN BOLTING

646 LINESHAFT

649 LINESHAFT COUPLING

654 OIL TUBE

656 LINESHAFT BEARING

658 TUBE STABLIZER

BOWL ASSEMBLY

660 BOWL SHAFT

661 DISCHARGE BOWL

664 DISCHARGE BEARING

665 OIL SEAL

668 TUBE ADAPTER BEARING

670 INTERMEDIATE BOWL

672 INTERMEDIATE BOWL BEARING

673 IMPELLER

677 TAPERLOCK

680 WEAR RING (OPTIONAL)

688 SUCTION BOWL/BELL

690 SUCTION BEARING

692 SAND COLLAR

698 SUCTION STRAINER

747 PLUG

760 HEX BOLT

10

Figure 4 Enclosed Lineshaft Pump with

Flanged Column

Page 11

Installation – SECTION 3

Installation – SECTION 3

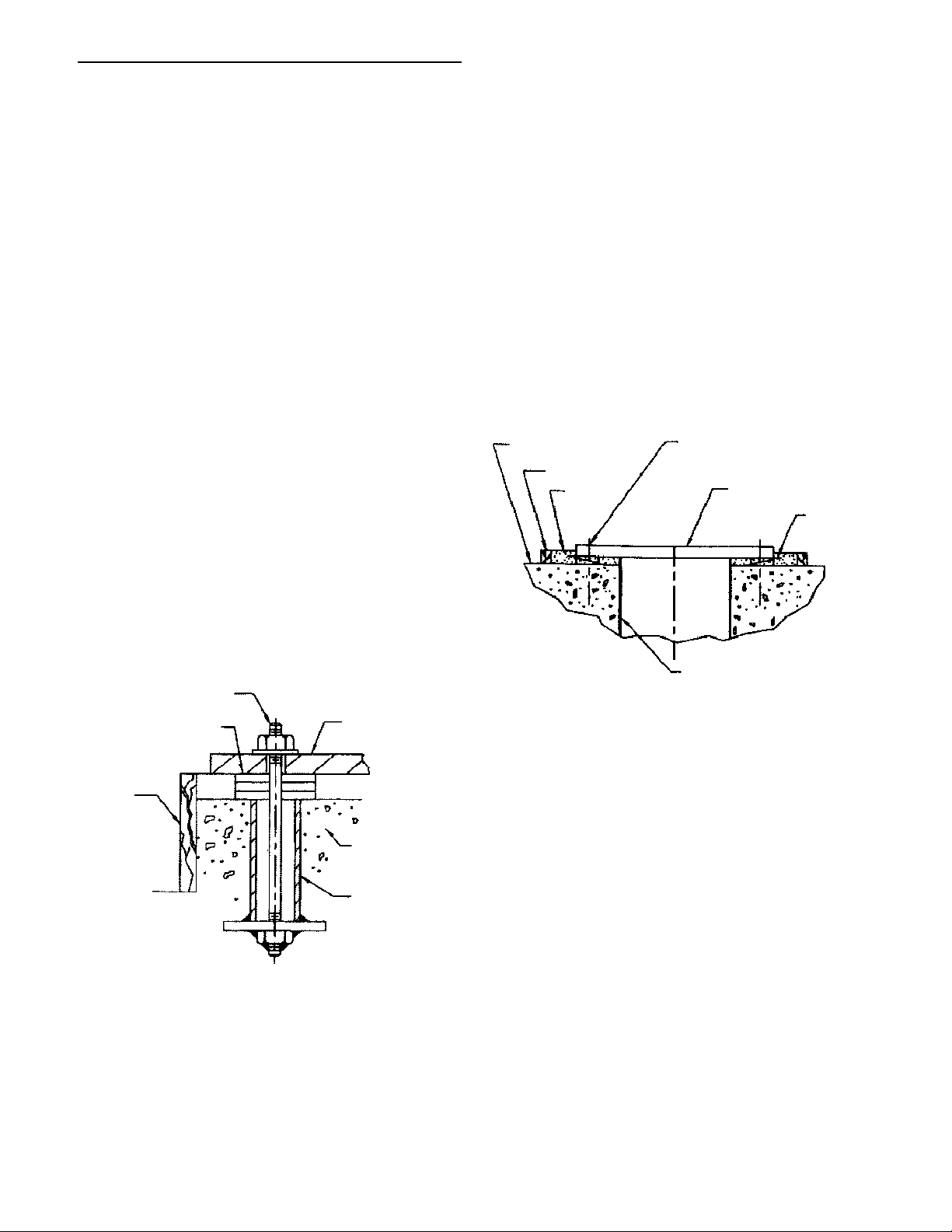

FOUNDATION AND PIPING

SUB BASE (SOLE PLATE) INSPECTION

Sub base and sole plate are terms in common use to

describe a general class of solid steel plates mounted

in grout (or bolted to steel structures) at the pumpfoundation interface.

5. Carefully lower the sub base onto the foundation

bolts. Hand tighten the nuts.

6. Leveling the sub base may be done by several

methods. Two common methods are:

A. Using leveling wedges. This is shown in

Figure 6.

B. Leveling nuts on the anchor bolts.

1. Remove the sub base from the pump discharge head,

when shipped assembled.

2. Completely clean the underside of the sub base. It is

sometimes necessary to coat the underside of the sub

base with an epoxy primer. (This is available as an

option.)

3. Remove the rust preventative solution from the

machined topside with an appropriate solution.

SITE WITH CONCRETE FOUNDATION

1. A pump should have adequate space for operation,

maintenance and inspection.

2. Sub base mounted pumps are normally grouted

on a concrete foundation, which has been poured

on a solid footing. The foundation must be able to

absorb any vibration and to form a permanent, rigid

support for the pumping unit.

3. The foundation must be of adequate strength to

support the complete weight of the pump, plus the

weight of the liquid passing through it. A typical

installation will have bolts with a pipe sleeve 2½

times the bolt diameter embedded in the concrete.

BOLT

SHIMS

SUB BASE

Regardless of the method, a machinist level must be

used for leveling.

NOTE: When using a machinist level, it is important

that the surface being leveled is free of all

contaminants, such as dust, to ensure an

accurate reading.

7. Level the sub base in two directions at 90 degrees

on the machined surface. The levelness tolerance

is 0.005 inches per foot for commercial, and 0.001

inches per foot for API.

FOUNDATION

DAM

GROUT

CENTERLINE

ANCHOR BOLT

SUB BASE

LEVELING

WEDGES

FLOOR SLEEVE

(OPTIONAL)

Figure 6

DAM

FOUNDATION

SLEEVE

Figure 5

Bolts should be sized and located in accordance

with the dimensions given on the Certified Pump

Outline Drawing, if provided. The pipe sleeve

allows movement for the final positioning of the

foundation bolts to conform to the holes in the sub

base flange. See Figure 5.

4. Remove water and/or debris from anchor bolt holes/

sleeves prior to grouting. If the sleeve type bolts are

being used, fill the sleeves with packing or rags to

prevent grout from entering.

SUB BASE GROUTING

1. Inspect foundation for dust, dirt, oil, chips, water,

etc. and remove any contaminants. Do not use oilbased cleaners as grout will not bond to them. Refer

to grout manufacturer’s instructions.

2. Build dam around foundation (See Figure 6).

Thoroughly wet foundation. Refer to grout

manufacturer’s instructions.

3. Pour grout between sub base and concrete

foundation, up to level of dam. Remove air bubbles

from grout as it is poured by puddling, using a

vibrator, or pumping the grout into place. Nonshrink grout is recommended. Refer to grout

manufacturer’s instructions.

4. Allow grout to set at least 48 hours.

5. Tighten foundation bolts.

PIPING

Guidelines for piping are given in the “Hydraulic

Institute Standards”, available from: Hydraulic Institute,

11

Page 12

9 Sylvan Way, Parisppany, NJ 07054-3802 and must be

WARNING

WARNING

CAUTION

reviewed prior to pump installation.

and rests firmly on the plate, then secure with

capscrews provided.

Never draw piping into place by forcing

the flange connections of the pump. Pipe

strain will adversely effect the operation of the pump

resulting in damage to the equipment and possible

physical injury.

1. All piping must be supported independently of, and

line up naturally with the pump flange so that undue

pipe strain is not imposed on the pump.

2. DO NOT connect piping to pump until grout has

hardened and pump hold-down bolts have been

tightened.

3. It is suggested that expansion loops or joints, if used,

be properly installed in the discharge line. When

handling liquids at elevated temperatures expansion

joints are used, so linear expansion of piping will

not draw pumps out of alignment.

4. Carefully clean all pipe parts, valves and fittings, and

piping branches prior to assembly.

5. Isolation and check valves should be installed in

discharge line. Locate the check valve between

isolation valve and pump, this will permit inspection

of the check valve. The isolation valve is required

for regulation of flow, and for inspection and

maintenance of pump. The check valve prevents

pump or seal damage due to reverse flow through

the pump when the driver is turned off.

6. Increasers, if used, should be placed between pump

and check valves.

7. Cushioning devices should be used to protect the

pump from surges and water hammer if quickclosing valves are installed in the system.

5. When a lineshaft is shipped separately check shaft

for straightness; average total run out should not

exceed 0.005” TIR (0.127mm) for 10 feet (3m).

Shaft must be within tolerance prior to installation.

6. Remove stuffing box (if installed) and carefully slide

shaft through top column bearing retainer and tread

into coupling after replacing stuffing box or seal

housing. Use extreme care not to damage bearing

retainer.

7. Refer to remainder of this manual for complete

assembly, startup, maintenance, disassembly and

recommended lubricants for the pump.

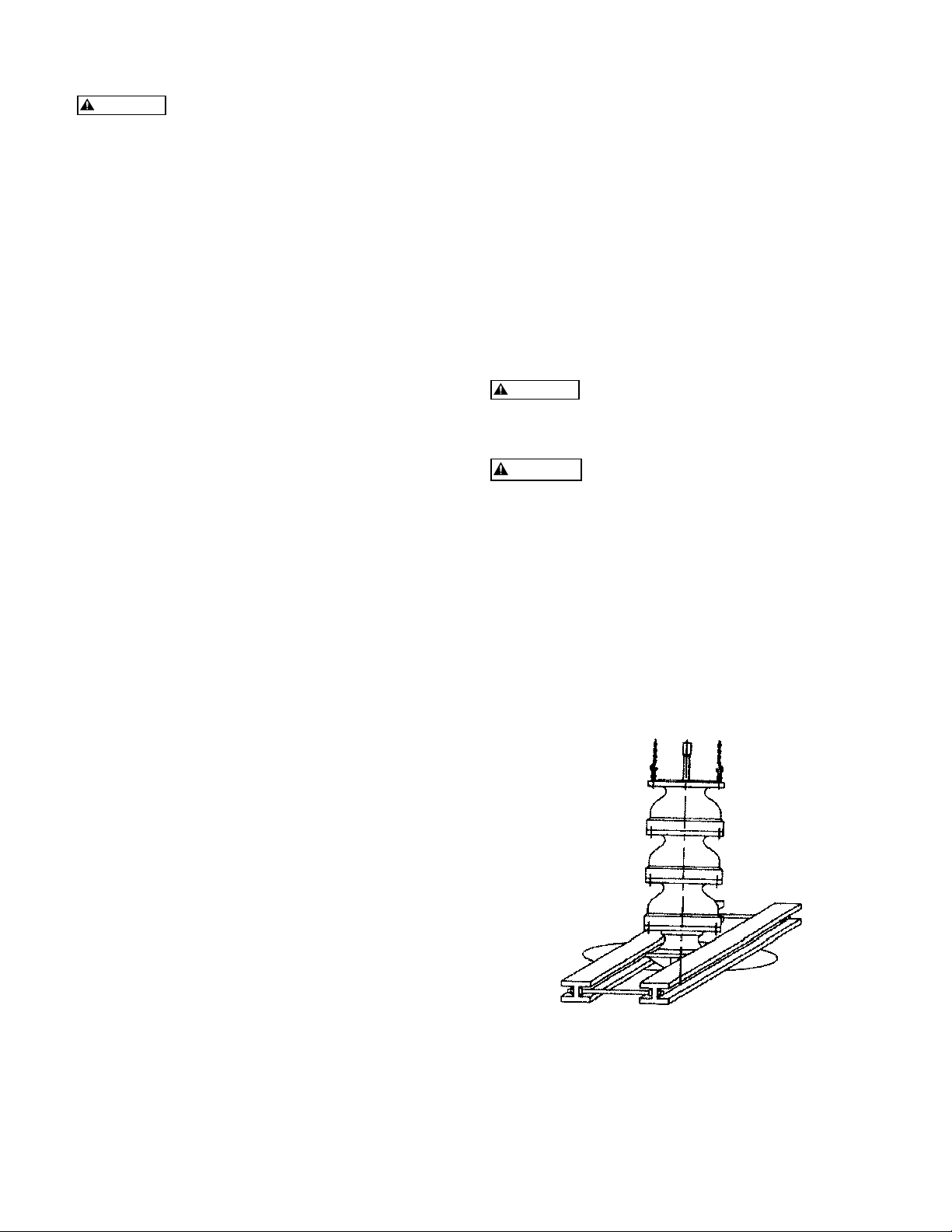

INSTALLING A PARTIALLY ASSEMBLED PUMP

Do not work under a heavy suspended

object unless there is positive support and

safe guards, which will protect personnel, should a hoist

or sling fail.

Do not attempt to lift bowl assembly

by the pump shaft. This can result in

damaging the pump shaft.

1. Prior to installing the bowl assembly, check that

all capscrews are tight. Turn the pump shaft by

hand and make sure it turns freely. Remove all

accumulated dust, oil or other foreign material from

the external surfaces.

2. Place two I-beam supports across the base plate

opening, strong enough to safely support the weight

of the entire pump assembly. These I-beams should

be connected by threaded rods and nuts so as to

clamp them firmly together to support the pump.

(See Figure 7).

PUMP INSTALLATION

Pumps of 20 feet (6M) or less in length are usually

shipped assembled, with the exception of the driver,

mechanical seal with tubing and coupling assembly,

spacer or non spacer type. When provided, refer to the

Certified Pump Outline for the applicable base plate plan

for the location of anchor bolt holes.

INSTALLING AN ASSEMBLED PUMP

1. If a base plate was supplied, install as described in

Foundation/Piping Section (page 13-14).

2. Clean the mounting surface of the plate and clean

bottom surface of discharge head mounting flange.

3. Sling through discharge head holes or thread two

eyebolts through bolt holes in the mounting flange

and hoist unit into position over foundation.

NOTE: Eyebolts or sling should be rated to handle

in excess of the pump weight (See Outline Drawing).

4. Lower the unit and carefully guide it so that unit

does not strike the side of the base plate. Continue

to lower unit until the discharge head flange engages

12

Figure 7

3. Place a suitable hoist or derrick over base plate

opening with the hook in the center.

4. If a suction strainer is provided, assemble it to the

suction bell (or suction bowl).

5. Place the elevator clamps just below the discharge

bowl. For flanged discharge, install two threaded eye

bolts through bolt holes in the flange 180º apart.

Page 13

6. Attach sling to elevator clamps or eye bolts and hoist

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

into position over foundation opening (See Figure

7).

7. Carefully lower bowl assembly, guiding the unit so it

does not strike the sides of the opening. Continue

to lower bowl assembly until the elevator clamps

or discharge bowl flange rests firmly on the I-beam

supports.

8. Place a cover over the discharge bowl opening to

prevent entrance of dirt or other foreign matter

until ready for installation of the column assembly.

Do not drop any foreign object into the

bowl assembly. Such an object can cause

serious damage to the pump and any downstream

components. Any foreign object dropped into the bowl

assembly must be retrieved prior to continuing assembly.

COLUMN

OPEN LINESHAFT

Lineshafts are coupled with threaded couplings. Column

pipe may be threaded or flanged. When provided, see

the Certified Pump Outline Drawing for the number of

column and shaft sections required. The top and bottom

sections may be special lengths:

1. Check the lineshaft (646) for straightness. Average

total runout should be less than 0.0005” TIR per

foot, not to exceed 0.005” T.I.R. for every 10 feet of

shafting.

NOTE: Bottom section of column pipe

should not be longer than 5 feet.

4. For threaded column, secure a friction clamp

immediately below the column coupling. Hoist

column section over bowl assembly. Lower

column over lineshaft until column pipe engages

the discharge bowl. Manually screw the column

into discharge bowl. Complete joint by tightening

column with chain tongs until the end of the column

butts firmly against discharge bowl.

5. For flanged column, install two eyebolts

diametrically opposite the upper flange of the

bottom column. Attach a sling to the eyebolts and

to the hoist hook. Lower column section until the

flange engages the flanged top bowl register. Insert

as many bolts through both flanges as possible. Lift

column assembly high enough to allow rotation

of the supports. Install and tighten remaining

capscrews gradually in diametrically opposite pairs

until all are uniformly tightened.

6. Lift the assembly and remove the elevator clamp

or supports and slowly lower the bowl and the

column assembly. Place supports on the base plate

and continue to lower the assembly until the column

elevator clamps or column flange comes to rest on

the supports. Place an elevator clamp under the

column pipe and allow it to butt firmly against the

column pipe coupling.

7. Place the bearing retainer over the shaft and locate

it in the column coupling recess. Make sure the

end faces of the column pipe are clean. For flanged

columns, fit the retainer in the female register of the

flange. Make sure the contact faces in the flanges are

clean.

2. Hoist the first piece of lineshaft over the bowl

assembly. Lower the lineshaft until the bottom end

is properly aligned with the coupling of the pump

shaft. Apply a thin film of oil to the threads on the

lineshaft (646) and the coupling (649) (for nongalling material, or Molykote if galling material).

Use “MOLYKOTE” Dow Corning or

equal for all galling material such as

316 stainless steel.

3. With lineshaft in the proper position on the

coupling, screw lineshaft into the coupling manually

until resistance is felt. A fine wire inserted in the

hole at the center of the coupling can be used as a

gage to determine when the coupling is correctly

positioned on the shaft. Remove the wire after

installing the coupling. Completely tighten the

joint by using a pair of pipe wrenches. Use care not

to damage any bearing journal areas on the shaft.

NOTE: Shaft threads are left-handed.

Make up threaded joints manually to

verify that the threads are properly

engaged prior to applying a wrench. If cross-threading

occurs, break the joint and repair the threads. If the

threads are beyond repair, replace the damaged part.

8. Check that the shaft is approximately centered in

the bearing. Move the shaft around slightly so as to

center it in its bearing. Only a slight amount of force

should be required. If an excessive amount of force

is required, the pipe or shaft may not be butted

properly or the shaft may be bent. In any case, the

problem must be corrected prior to proceeding

further.

9. Repeat the preceding procedures until all column

sections required have been installed.

10. Install the top shaft or stub shaft and coupling. If

the pump is equipped with column adjusting nipple,

install it with longer threaded end upward. Screw

the lock ring on to the nipple until you reach the

end of the thread.

Do not drop any foreign object into the

column assembly. Such an object can

cause serious damage to the pump and any downstream

components. Any foreign object dropped into the column

assembly must be retrieved prior to continuing assembly.

13

Page 14

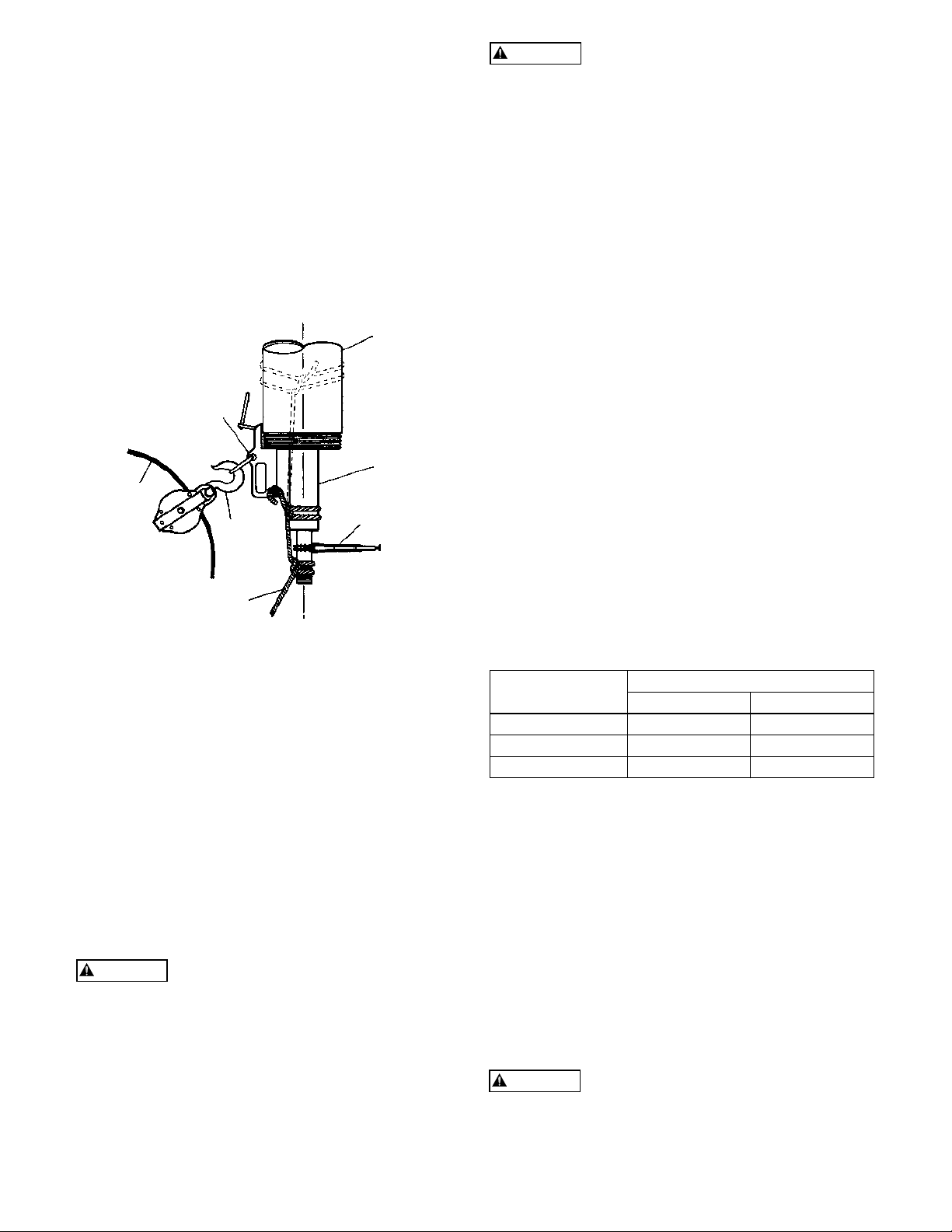

ENCLOSED LINESHAFT

CAUTION

CAUTION

CAUTION

1. Insert tube (654) and shaft (646) sections into

column section.

2. Place an elevator clamp near top of column just

below and butt firmly against column pipe coupling

(645). For flanged columns, place the elevator clamp

just below the flange.

3. Attach a sling to hoist hook. Attach bottom of shaft

(646) to column (644), by tying a tail rope to deepthroated clamp attached to bottom of column. (See

Figure 8). Tie a clove hitch or double half hitch

around the enclosing tube and then around the shaft

in threaded area. Figure 8 also shows the alternate

method (dotted lines).

DEEP THROATED CLAMP

DRAG LINE

HOIST

HOOK

COLUMN

ENCLOSING

TUBE

CHAIN WRENCH

(CLAMP)

Make up threaded joints manually to

verify that the threads are properly

engaged prior to applying a wrench. If cross-threading

occurs, break the joint and repair the threads. If the

threads are beyond repair, replace the damaged part.

8. Carefully lower column section until lower end

of the tube section rests on the adapter bearing

(668). The end faces of the tube should be clean

and free of nicks. Remove tail rope, clean outside

of the adapter bearing and lubricate with thread

compound. Screw tube section onto adapter bushing

manually, until resistance is felt. Complete tube joint

by utilizing a pair of pipe wrenches or chain tongs,

butting the end of tube against the upper end of the

tube adapter bearing.

9. Clean column threads and lubricate with thread

compound.

10. Lower column until column pipe engages in the

discharge bowl. Manually thread the column into

discharge bowl. Complete joint by tightening

column, utilizing chain tongs until the end of the

column butts firmly against discharge bowl.

11. Lift the pump assembly and remove elevator clamp

secured to discharge bowl. Slowly lower assembly

into well or sump until elevator clamp gently comes

to rest on timbers or I-beam supports and remove

the sling.

ROPE

Figure 8

4. Utilize the remaining tail rope to keep tension on

the knots during hoisting. Lower end of column

section shall be guided by a drag line which is pulled

by the hoist. A traveling block for the drag-line

shall be attached to a deep-throated clamp, which is

secured to bottom of the column threads.

5. Hoist column section over pump, keeping tension

on tail rope. With column in a vertical position,

remove drag-line and traveling block, lower column

until bottom line shaft is properly aligned with

pump shaft coupling.

6. Apply a thin film of oil to the threads on the

lineshaft (646) and the coupling (649) (for nongalling material or Molykote if galling material).

Use “MOLYKOTE” Dow Corning or

equal for all galling material such as 316

stainless steel.

7. With lineshaft in proper position on the coupling,

remove tail rope and screw lineshaft into coupling

until resistance is felt. A fine wire inserted in the

hole at the center of the coupling can be used as a

gage to determine when the coupling is correctly

positioned on the shaft. Remove the wire after

installing the coupling. Completely tighten the

joint by using a pair of pipe wrenches. Use care not

to damage any bearing journal areas of the shaft.

NOTE: Shaft threads are left-handed.

14

12. Remove the exposed lineshaft bearing, pour oil into

the tubing and reinstall the bearing. The amount of

oil to be poured is given in the following table:

Tube Size

10 ft. Sections 20 ft. Sections

Amount of oil per section

1¼, 1½, 2 ½ Cup 1 Cup

2½, 3, 3½ 1 Cup ½ Qt.

4 and larger ½ Qt. 1 Qt.

See page 27 for recommended oil.

13. Repeat the preceding procedures. Throughout the

column assembly, install tube stabilizer (658) over

the enclosing tube (654) every 40 feet. The last one

should be less than 20 feet below the bottom of the

discharge head. Use soapy water as lubricant when

sliding the stabilizer over the tube.

14. Continue the procedure until all column sections

for the proper setting have been installed, excluding

the column adjusting nipple (631) and tube nipple

(629), if provided.

15. Install the top shaft or stub shaft and coupling.

Do not drop any foreign object into the

bowl assembly. Such an object can cause

serious damage to the pump and any downstream

components. Any foreign object dropped into the bowl

assembly must be retrieved prior to continuing assembly.

Page 15

INSTALLING THE DISCHARGE HEAD

CAUTION

CAUTION

VTP pumps are provided with either a cast iron or

fabricated steel type head. For pump with below

ground discharge, a motor stand is provided instead the

discharge head. Install the discharge head as follows:

1. If the stuffing box (See Fig. 9) or tension nut (See

Fig. 10) is assembled to the head, remove it and all

the attached piping.

2. For threaded column, check to be sure that the

flange column (637) is securely attached to the

bottom of the discharge head. Check and tighten

the capscrews (or socket head screw) gradually in

diametrically opposite pairs.

3. Remove coupling guard if provided. Attach a sling

to the lifting lugs on the side of the discharge head

through windows and hoist discharge head over the

protruding top shaft (or stub shaft).

Do not bump or scrape the shaft

protruding above the column. This could

result in bending or damaging the shaft.

4. Orient the discharge head in the required position

and lower the head. Center the vertical hole with

the top shaft protruding above the column. For

threaded column, continue to lower the discharge

head until the large threaded hole in the bottom

of the discharge head rests squarely on top of

column. Clean the threads at upper end of column

assembly and lubricate with thread compound.

Rotate discharge head, screw it onto the column,

for short set-pump, (without the column adjusting

nipple) butting the top of column tightly against the

discharge head.

be centered by shimming the head base and the sub

base (or the foundation).

10. Rotate the shaft approximately 90 degrees. Check

again whether the shaft is at the center of the

stuffing box bore or not. If not, either the top

shaft is bent or the first shaft below it did not butt

properly. Correction must be made before the

installation procedures can proceed.

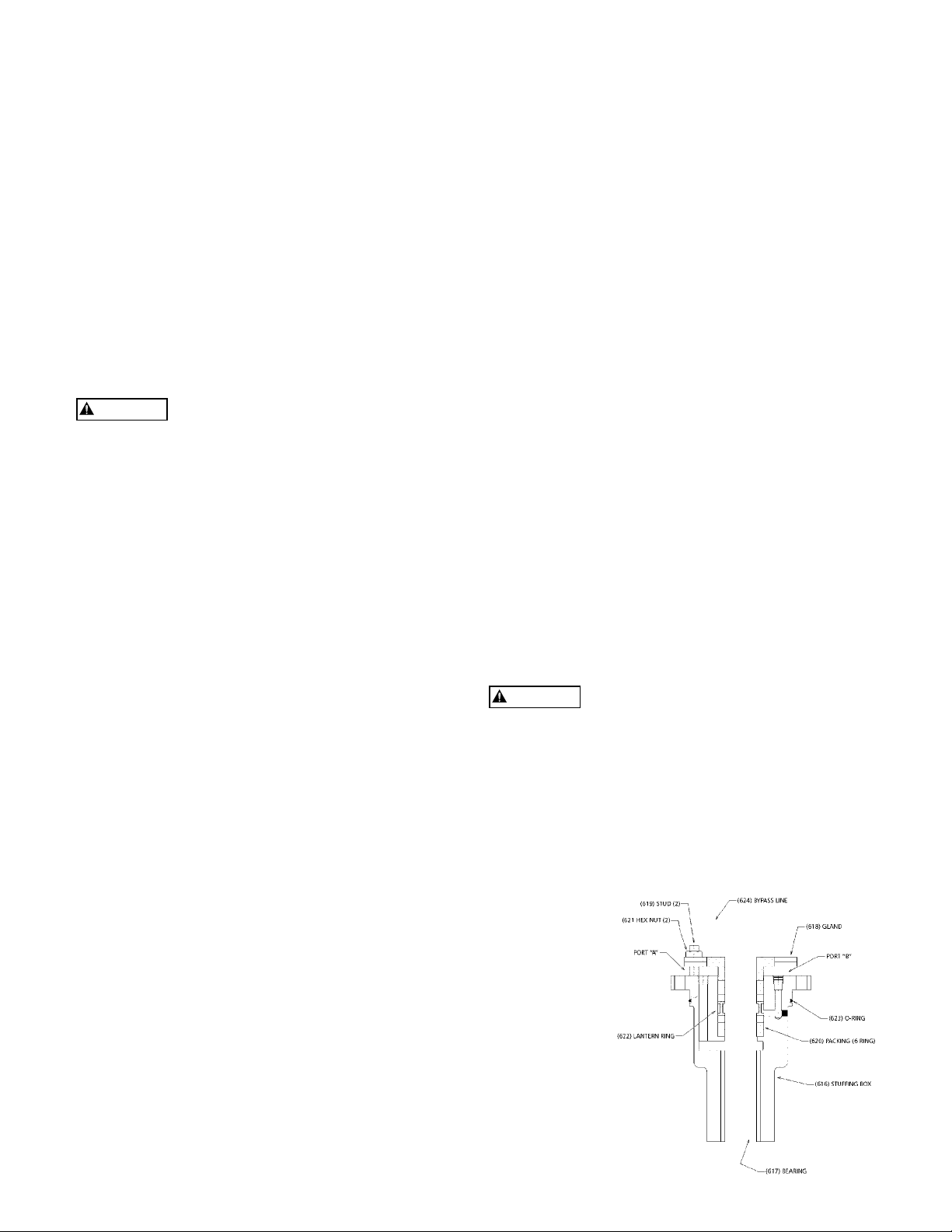

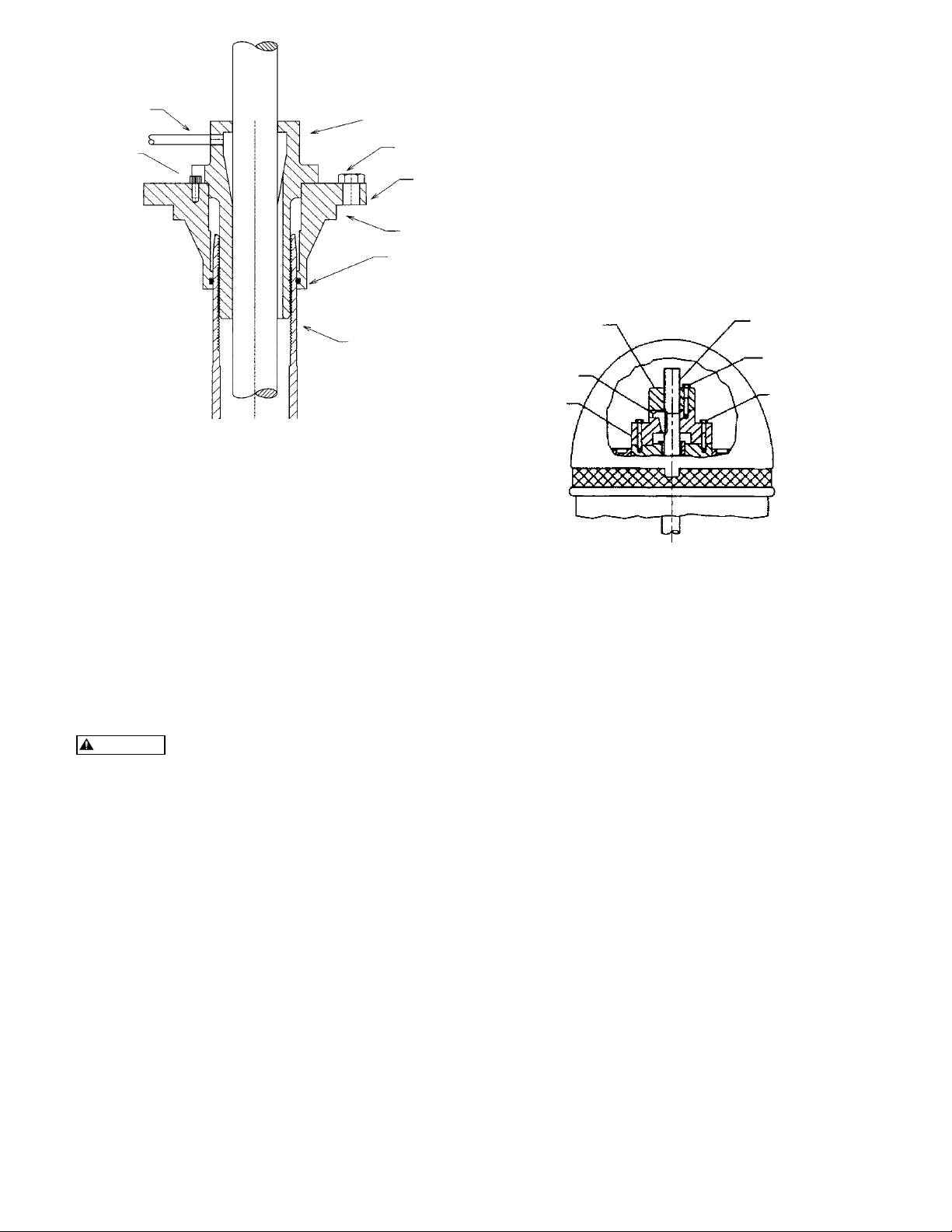

INSTALLING THE STUFFING BOX

Assemble stuffing box as shown in Figure 9.

1. Clean the surface of the discharge head where

the stuffing box will be mounted and remove

any nicks or burrs with a fine flat file. Position

gasket on surface. Slide stuffing box (616) down

over headshaft and into position on the gasket.

Secure stuffing box with capscrews. Make sure

the capscrews are torqued equally to prevent

misalignment.

2. Grease the packing ring (620) for easier installation.

3. Twist the packing ring sideways to get it around the

shaft easily. Start the first ring into the stuffing box.

When the entire ring is worked in using the fingers,

tamp it down using a split wood bushing (or equal)

and push the packing ring down firmly. It must seal

on the shaft and bore of the stuffing box. Install all

six (6) rings and lantern ring as shown in the Figure

9. Stagger ring joints 90 degrees apart. The split

gland may be used as a tamper for the top ring.

4. Install the split gland and screw nuts on the split

gland studs. Tighten nuts then relieve the nuts and

tighten finger tight.

5. For flanged column, continue to lower the discharge

head until the discharge head engages the column

flange. Install capscrews and secure discharge head

to the column flange. Tighten capscrews gradually

in diametrically opposite pairs. Lift the pump

assembly high enough to allow rotation of the

supports. Realign and lower assembly. Install and

tighten remaining capscrews. Repeat the rotating

and the tightening procedure until all capscrews are

uniformly tight.

6. Hoist the discharge head by lifting lug and remove

the elevator clamp attached to column.

7. Remove the support timbers or I-beams and clean

the top of foundation or base plate. Orient the

discharge head in the required position.

NOTE: Sling should be rated to handle in excess of the

pump weight.

8. Lower bowl, column and head assembly, until

discharge head mounting flange engages base plate.

Secure discharge head to the foundation or base

plate. Check the levelness of the discharge head in

all directions, utilizing a machinist level across the

driver’s mounting surface of the discharge head.

9. Check whether the top shaft (or stub shaft) is in the

center of the stuffing box bore. If not, the shaft must

Check that the split gland is square in the

stuffing box. Cocking can cause uneven

compression of packing and damage to the shaft or sleeve

and heat up the shaft and stuffing box.

5. The stuffing box is shipped with both ports plugged.

If discharge pressure over 100 PSI, remove the plug

on port “A” and attach bypass line. If the discharge

pressure is over 200 PSI the Port “B should also be

opened and attached another relief line.

6. Final adjustment of the stuffing box must be made

at pump

start up. A

properly

packed

stuffing box

should be

loose enough

to allow

the shaft to

be turned

manually.

Also, packing

must allow

leak. See

page 24,

Pump Start

Up #5.

Figure 9

15

Page 16

Do not over tighten packing or excessive

CAUTION

CAUTION

CAUTION

wear can occur on the shaft or sleeve.

Do not bump carbon members against the

shaft as they may chip, crack or break.

INSTALLING THE MECHANICAL SEAL

Vertical turbine pumps are usually supplied with cartridge

type mechanical seals, shipped assembled - ready

for installation, when mechanical seals are supplied.

Instructions for installing mechanical seals are provided

by the seal manufacturer. Consult the seal manufacturer’s

instructions (furnished with the seal) for information

on the type of seal used. Additionally, refer to factory

furnished outline drawing and seal piping schematic on

complex seal piping arrangements.

GENERAL REQUIREMENTS FOR INSTALL SEALS

1. Check surfaces at the face of the seal housing and

at the bottom of the seal housing to insure that they

are clean, flat and free of burrs. The face surface

must be smooth to form a good sealing surface for a

gasket or O-ring.

2. Check that shaft is smooth, and free of burrs, nicks

and sharp corners that could nick or cut the O-ring

or shaft packing. When further clean up is required,

protect by covering the inside of the pump seal

housing. Remove burrs, nicks and sharp corners by

using a strip of emery cloth “shoeshine fashion” over

the shaft threads. File threads around the keyway

with a smooth mill file or emery cloth. Sharp edges

must be rounded.

3. Remove all chips and dust from the shaft area.

8. Position seal gland on discharge head seal housing

and secure with capscrews (or nuts for studs)

provided. Tighten capscrews gradually and

uniformly in a criss-cross pattern, taking 2 or 3

passes.

Do not over tighten capscrews on gland.

This can distort seal seat and cause seal

failure.

9. Install all seal piping as required. Prior to making

final connections of sealing liquid pressurizing

lines, make sure the seal housing and all sealing

liquid lines are flushed free of dirt, scale and other

particles that would be abrasive to the sealing faces.

10. The Driver and Coupling must now be installed

per instruction. (See page 24 - INSTALLING

THE HOLLOW SHAFT DRIVER or page 26 INSTALLING THE SOLID SHAFT DRIVER).

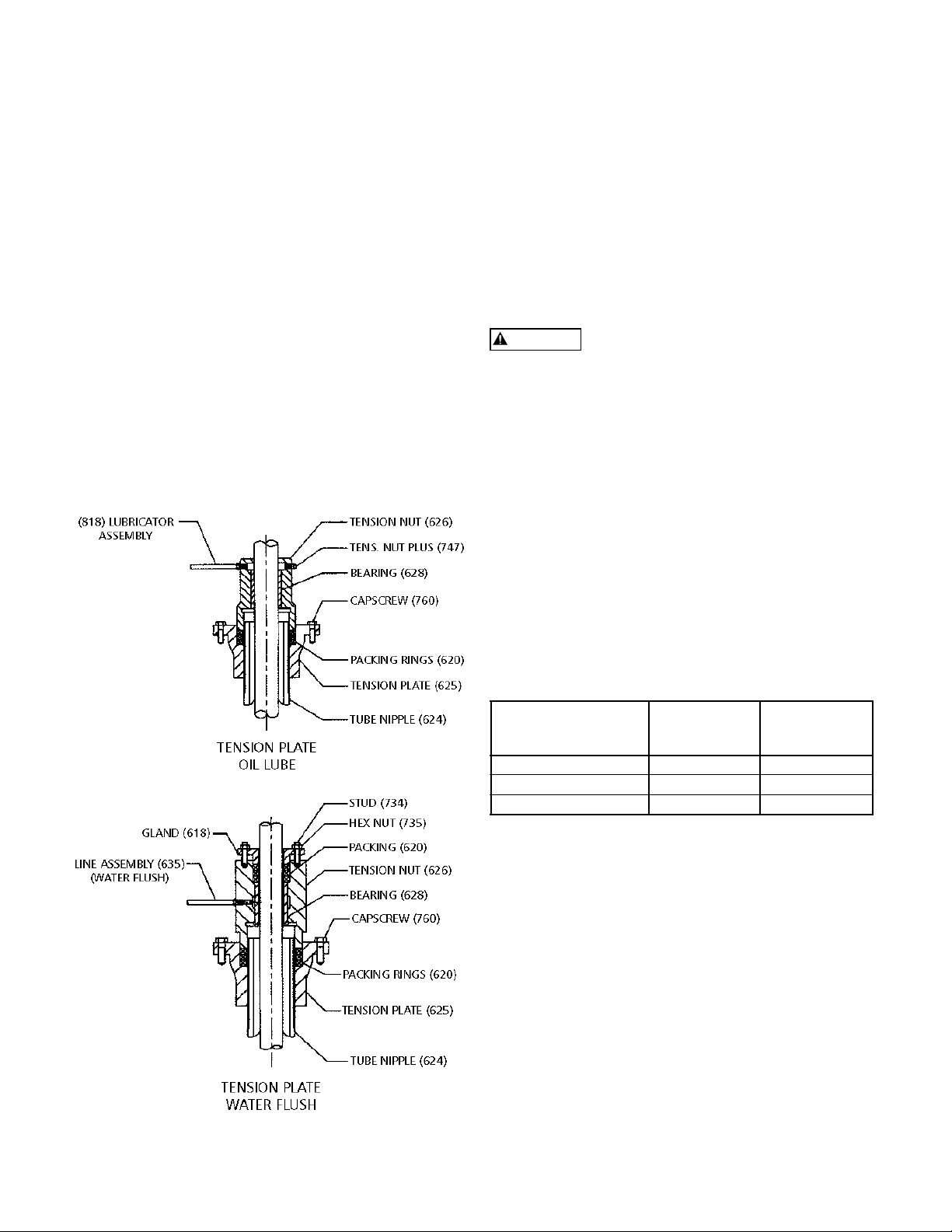

INSTALLING THE TENSION PLATE WITH CAST IRON

TENSION NUT

INSTALLING THE TUBE TENSION PLATE

1. (See Figure 10). Lubricate tube threads and

underside of tension plate flange with thread

compound. Thread the tension plate (625) onto

the enclosing tube nipple (629) manually until its

shoulder rests on the discharge head.

4. Check that all rotary unit parts of the seal fit over

the shaft. A pre-check may be made by removing the

O-ring(s) from the cartridge sleeve Inside Diameter

(ID) and then installing the seal on the shaft. Further

shaft clean up will be necessary when the seal will

not pass all the way into the seal housing.

5. Remove the seal after the pre-check and re-install

the sleeve O-ring(s).

6. Sparingly lubricate the shaft and sleeve ID with

the lubricant included with the mechanical seal or

recommended by the mechanical seal manufacturer.

The following lubricants may be used, for

water service, when no lubricant is supplied or

recommended by the mechanical seal manufacturer.

• Light oil (SAE #10 or 20)

• Dow Corning #4 Grease

• Silicone lubricant

• Wax or Clay

• Soapy water

Oil based lubricants will damage EPR / EPDM

elastomer O-rings. Silicone lube and soapy water are

safe for EPR / EPDM elastomer O-rings.

7. Install the O-ring or gasket, between the seal

housing and seal. Install the seal over the shaft and

ease it into position against the face of the seal box.

Take care when passing the sleeve and O-ring over

keyways or threads to avoid damaging the O-ring.

TENSIONING THE ENCLOSING TUBE

The enclosing tube sags from its own weight as it is

installed and must be pulled tight (tensioned) to make

it straight. This section describes two methods of

tensioning the tube. The direct pull method is more

precise and is preferred. The second method--the

wrenching method--is given as an alternate.

NOTE: The correct tension is equal to the weight of the

enclosing tube plus 10%.

Weights per unit length for each tube size are given in the

Table 1. Multiply by total length of the tube to determine

the total weight.

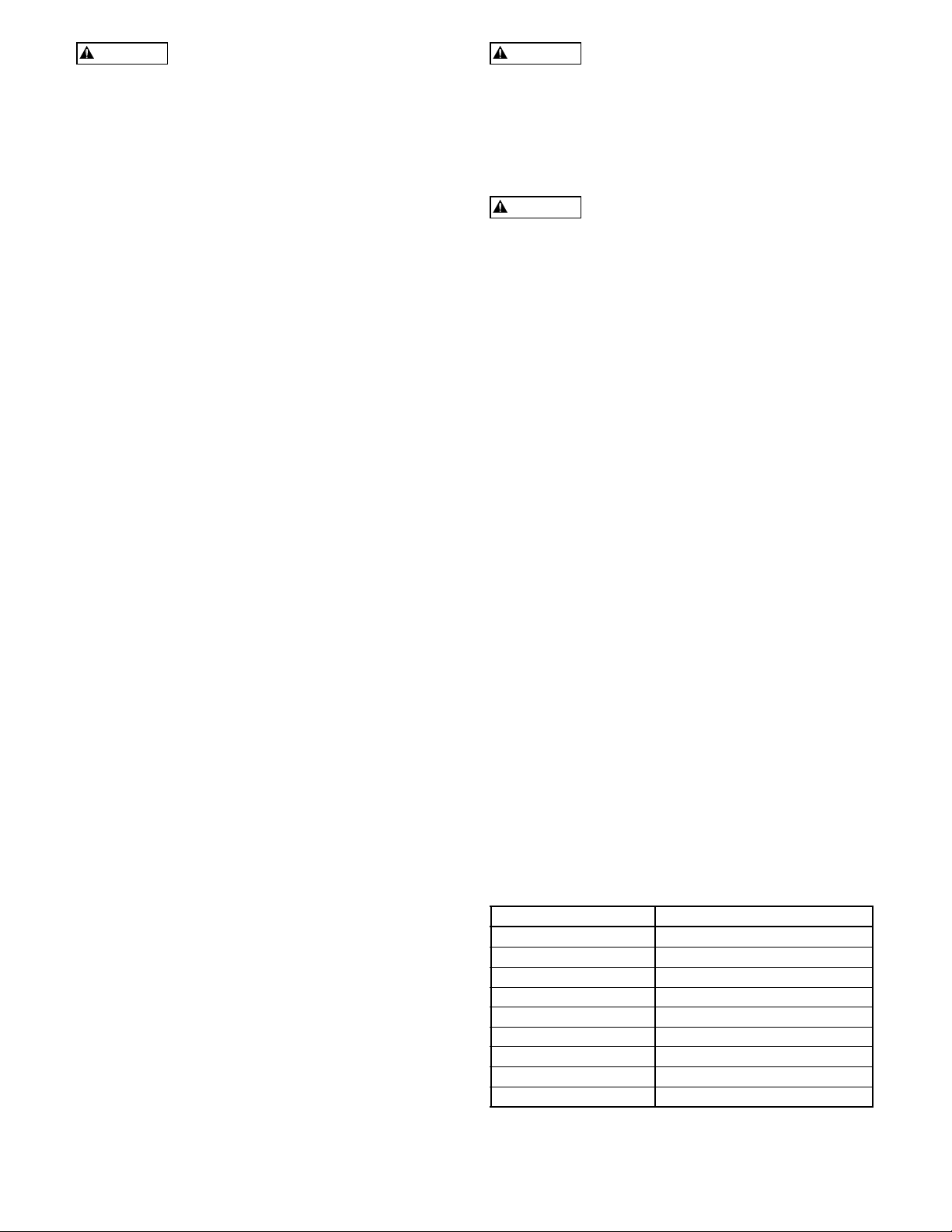

TABLE 1 – Weight-per-foot of Enclosing Tubing

TUBE SIZE (INCH) WEIGHT PER FOOT (LB.)

1¼ 2.99

1½ 3.63

2 5.02

2½ 7.66

3 10.25

3½ 12.50

4 14.98

5 20.78

6 28.57

DIRECT PULL METHOD

1. The upper end of the tube may be pulled by the

hoist to obtain the predetermined tension value.

16

Page 17

This requires the use of a dynamometer scale and

CAUTION

an adapter fitting to grip the tube. TUBE TENSION

ADAPTER AVAILABLE THROUGH FACTORY.

With the tension plate installed manually but

not tightened, thread the special fitting onto the

top of the tube to full engagement. Attach the

dynamometer scale to the fitting, and connect the

upper end of the scale to the hoist hook. Operate

the hoist hook to apply the required tension. This

should pull the tension plate off the discharge head.

Manually thread the tension plate to reset it. Release

tension, remove dynamometer scale and special

fitting.

WRENCHING METHOD

1. If a dynamometer is not available, the tube can

be tensioned by wrenching the tube tension

plate. Make up a spanner wrench to straddle the

projecting threaded tube end and to engage the tube

tension plate capscrew holes by two lugs. Torque

the tension plate to take all the slack out of the shaft

tubing and induce a reasonable amount of tension

by turning the tension plate counterclockwise.

For tubing 2½” (63.5mm) and larger, a man’s full

strength on a 3 foot (915mm) lever arm is sufficient.

For smaller sizes, less pull must be exercised.

INSTALLING TENSION NUT

1. (See Figure 10). Install capscrews (760) in the

tension plate. Pour one pint of oil down the oil

tube. Note: Factory assembled unit has no oil in it.

Oil must added in the field.

2. Install packing (620) in the tension plate and thread

the tension nut (626), tightening it firmly against the

packing.

3. If a packed type tension nut (626) is used (for water

flush), install packing (620), packing gland (618)

and secure with stud (739) and nut (735). Screw

nut finger tight. Install line assembly (635) and

connect to flush liquid supply (see Figure 10).

Be sure that the top of the enclosing tube

does not interference with the tension nut.

4. If the top of the tube interferes with the tension nut,

determine the distance, if the tube is too long or too

short. If the tube is too short, it must be replaced

with a longer tube of the correct length. If the tube

is too long, it must be cut to the correct length and

re-threaded. Reinstall and re-level pump.

LUBRICATION SYSTEM

1. Connect solenoid valve (if provided), oil lines, and

fill the oil reservoir with oil.

2. Check the lubricator feed and see that the oil

reservoir is flowing freely. (In the case of a solenoid

valve, temporary power connections are required.)

Set the proper drops per minute on the regulator.

Table 2 shows recommended regulator setting.

TABLE 2 – Regulator Setting

DROPS PER MINUTE

PER 100 FEET

(30.48 m) OF SETTING

8 0.75 to 1.00 19 to 25

16 1.19 to 1.94 30 to 50

20 2.19 and larger 55 and larger

SHAFT SIZE SHAFT SIZE

(INCH) (mm)

INSTALLING THE TENSION PLATE WITH BRONZE

TENSION NUT

Assemble Tension Plate Assembly as shown in Figure 11.

1. Remove the lock bolt (636) and o-ring (620).

Thoroughly clean the tension plate (625) include

the o-ring groove. Lightly grease the o-ring and reinstall it.

Figure 10

NOTE: Do not turn clockwise to align holes in tension

plate and discharge head.

2. Clean the surface of the discharge head where the

tension plate will be mounted and remove any nicks

or burrs with a fine flat file. Clean the O.D. of the

tube nipple. Carefully install the tension plate and

gasket (779). Evenly tighten the mounting capscrews

(759F).

3. Pour one pint of recommended oil down the tube

nipple (629). (See page 27 for recommended

lubricants.) Note: Factory assembled unit has no oil

in it. Oil must added in the field.

17

Page 18

LUBE LINE

WARNING

(635)

LOCK BOLT

(636)

TENSION NUT

(623)

CAPSCREWS

TENSION PLATE

(625)

GASKET

(779)

O-RING

(620)

and clean these surfaces thoroughly. If any burrs

are found, remove burrs with a smooth mill file,

cleaning thoroughly afterward.

4. For motor, orient the motor conduit box in the

required position. For the right angle gear, orient

the input shaft to the desire position. Align the

driver mounting holes with the mating tapped holes

on the discharge head. Lower the driver until the

registers engage and the driver rests on the discharge

head. Secure driver with capscrews provided.

5. Lubricate the driver bearings in accordance with

instructions given on lubrication plate attached to

the driver case (or in the motor IOM).

TUBE NIPPLE

(629)

Figure 11

4. Clean the tension nut (623) and lightly oil its bore

and the threads. Screw the tension nut into the tube

nipple until the flange face of the nut contact the

tension plate.

5. For setting less than 100 feet, tighten the tension nut

until a slot aligns with the nearest locking position.

Install the locking bolt.

INSTALLING THE DRIVER

INSTALLATION OF A HOLLOW SHAFT DRIVER

This refers to either VHS type electric motors or hollow

shaft type gear drives. A small paragraph will be devoted

to combination electric motor and right angle gear

drives.

Do not work under a heavy suspended

object unless there is a positive support

and safe guards which will protect personnel should a

hoist or sling fail.

1. The driving mechanism of all hollow shaft driver is

shown on Figure 12. The head shaft (608) extends

up through the quill or hollow shaft of the driver

and is held in place by an adjusting nut (604), which

not only carries all the static and hydraulic thrust

of the impellers and shaft, but also provides the

adjustment for the impeller clearances. The head

shaft is connected to top shaft (or stub shaft) by a

threaded coupling or a rigid flange coupling.

2. When a motor stand is furnished and not installed,

proceed as follows:

(604) ADJUSTING

NUT

(730) GIB KEY

DRIVE

COUPLING

HEADSHAFT (608)

CAPSCREW (760)

ADJUSTING NUT

HOLD DOWN

BOLT

Figure 12

6. After lowering and orienting the driver as explained

above, remove the drive coupling and the hold

down bolts (See Figure 12). Be sure to mark the

location of the coupling before removing it.

7. Lower the head shaft through the motor quill shaft

to meet the shaft coupling. Apply a thin film of oil

to head shaft threads (if non-galling material) and

screw into the shaft coupling (located above the

stuffing box). Make sure the shaft is not damaged in

any way. Tighten the joint.

8. Check that the head shaft centers inside the driver

quill shaft within 0.06” (1.5 mm). If it does not,

misalignment is indicated.

9. Any head shaft misalignment with driver quill

shaft could be caused by a bent headshaft, burrs,

or foreign matter between shaft ends or any of the

mounting flanges: motor flange to discharge head

top flange, discharge head base flange to base plate

or the base plate itself could be out of level. If the

latter, shim between base plate and discharge head

base, will correct it. Also, check concentricity of

motor to motor-stand (if provided) to discharge

head.

A. Hoist the motor stand, inspect the mounting

surfaces, register and clean these surfaces

thoroughly.

B. Install the motor stand on discharge head and

secure with capscrews provided.

3. Attach a sling to the lifting lugs of driver and hoist

the driver up. Inspect the mounting surface, register

18

10. With the motor in place and the head shaft

projecting through the motor quill shaft, make

temporary electrical connection to check the motor

rotation. (Be sure to remove the ratchet pins or balls

before checking motor rotation.) Motor must rotate

counter-clockwise when viewed from the top. See

arrow on pump name plate. If motor does not rotate

counter-clockwise, you can change the rotation by

Page 19

CAUTION

WARNING

interchanging any two leads. (For three phase only.

For single phase motors see motor manufacturer’s

instructions.)

Never check motor rotation with the drive

coupling in place. The bore clearance

between the drive coupling and the pump shaft O. D.

is so close that should the motor spin with this shaft

stationary, galling and locking together is very likely to

take place.

11. Install motor drive coupling. (Be sure to line up the

match mark made at step 6.) Inserting the ratchet

pins if a non-reverse ratchet is used. Match the

coupling lugs with corresponding holes in motor.

Tighten hold down bolts evenly, making sure driver

coupling is properly seated in the register fit.

12. Fit gib key (730) into keyway, by filing if necessary,

to where there is a snug but sliding fit. This key

must be able to be removed by gentle leverage with

a screwdriver under it.

13. Be careful that the gib key (730) is not too high so

as to hold up the adjusting nut (604) from seating

on the drive coupling. If it is, cut off some length of

the key.

14. Install adjusting nut (604) to hand tight.

COMBINATION ENGINE AND MOTOR DRIVES

1. On combination drivers, the motor is invariably on

top with a projecting head shaft extension.

2. Follow all procedures outlined in the previous

paragraph, except that the motor must be lowered

over this extended head shaft and great care must be

taken to center it exactly so as not to bump or missalign the shaft while the motor is being lowered into

place.

3. There are several methods of running engines

without electric motors and vise versa, requiring

simple adjustment to the combination drive, but

they are too numerous to mention here and can be

obtained from the gear manufacturers instructions

included with the shipment.

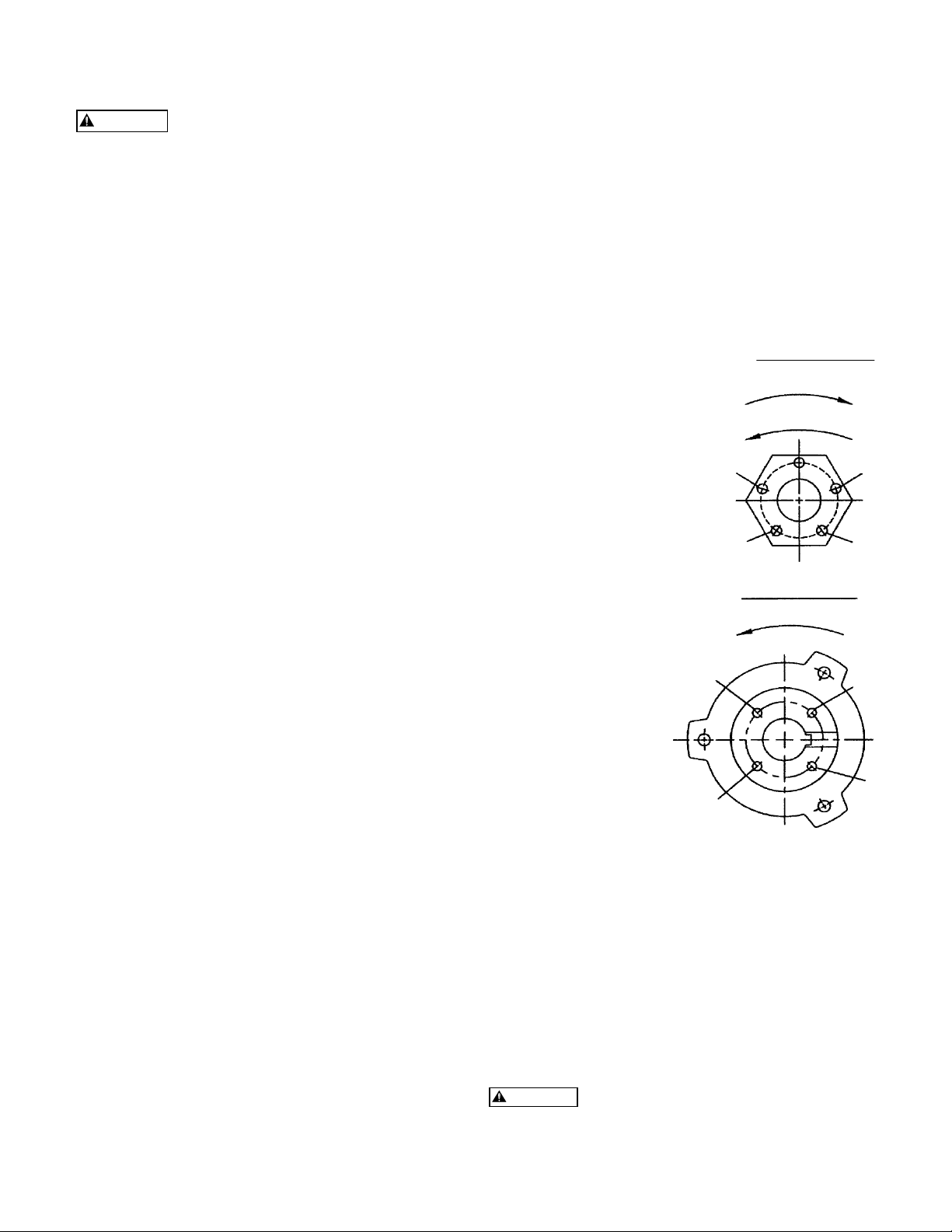

IMPELLER ADJUSTMENT FOR ALL

HOLLOW SHAFT DRIVERS

NOTE: Shaft adjustment up or down is accomplished by

turning the adjusting nut (604) Figure 13.

NOTE: There are five holes in the adjusting nut and only

four in the motor coupling. See Figure 13.

1. With shafting all the way down and the impellers

resting on their seats, turn the adjusting nut (604)

in counter-clockwise direction, thus lifting the shaft,

until the impellers just clear their seats and the

shaft/motor turns free by hand. This removes all

deflection from the shaft.

2. If pump setting is 200 ft. or less, make another two

turns on the adjusting nut for the first 100 ft. (3

turns for 12 thread/inch shaft). Line-up one of the

holes in the adjusting nut with the nearest hole in

the driver coupling. Insert the capscrew in the hole

and tighten it.

NOTE: 1.00” and 1.18” diameter shafts are 12 thread

per inch. All the larger sizes are 10 thread per

inch.

3. For pump setting over 200 ft. see IOM for DWT.

FOR OPEN IMPELLERS

1. With shafting all the way down and the impellers

resting on their seats, turn the adjusting nut (604)

in counter-clockwise direction, thus lifting the shaft,

until the impellers just clear their seats and the

shaft/motor turns free by hand. This removes all

deflection from the shaft.

2. Align hole “A” in the

(604) ADJUSTING NUT

adjusting nut (604) and

hole “C” in the driver

LOWER IMPELLER

coupling (See Figure13) or

whatever similar holes are

in like position. If care is

RAISE IMPELLER

exercised, this will give an

initial impeller clearance

of 0.001” to 0.003”

A

depending on shaft size or

the pitch of the thread.

3. Insert capscrew into hole

B

“B” provided these are the

nearest matching holes

for counter-clockwise

rotation of adjusting nut,

MOTOR COUPLING

ROTATION

turn adjusting nut counterclockwise until holes “B”

and “D” line up. This

gives 1/20 of a turn

C

which is 0.004” on

12 threads per inch

shaft or 0.005” on

10 threads per inch

shaft.

4. Normal impeller

Figure 13

D

clearance for the open

impeller is consider to be 0.015” for the first 10

ft of the column length and 0.010” additional

clearance for each 10 ft of length thereafter. This

can be reduced in some instances where is necessary,

but should not be attempted without consulting the

factory or factory serviceman is present.

INSTALLATION OF A SOLID SHAFT DRIVER

NOTE: When pump is supplied with an oil lubricated

thrust pot, do not secure driver to discharge

head until after the thrust pot and flexible

coupling are installed. (See page 22 for thrust

pot installation instruction.)

Do not work under a heavy suspended

object unless there is a positive support

and safe guard which will protect personnel should a

hoist or sling fail.

F

E

H

G

19

Page 20

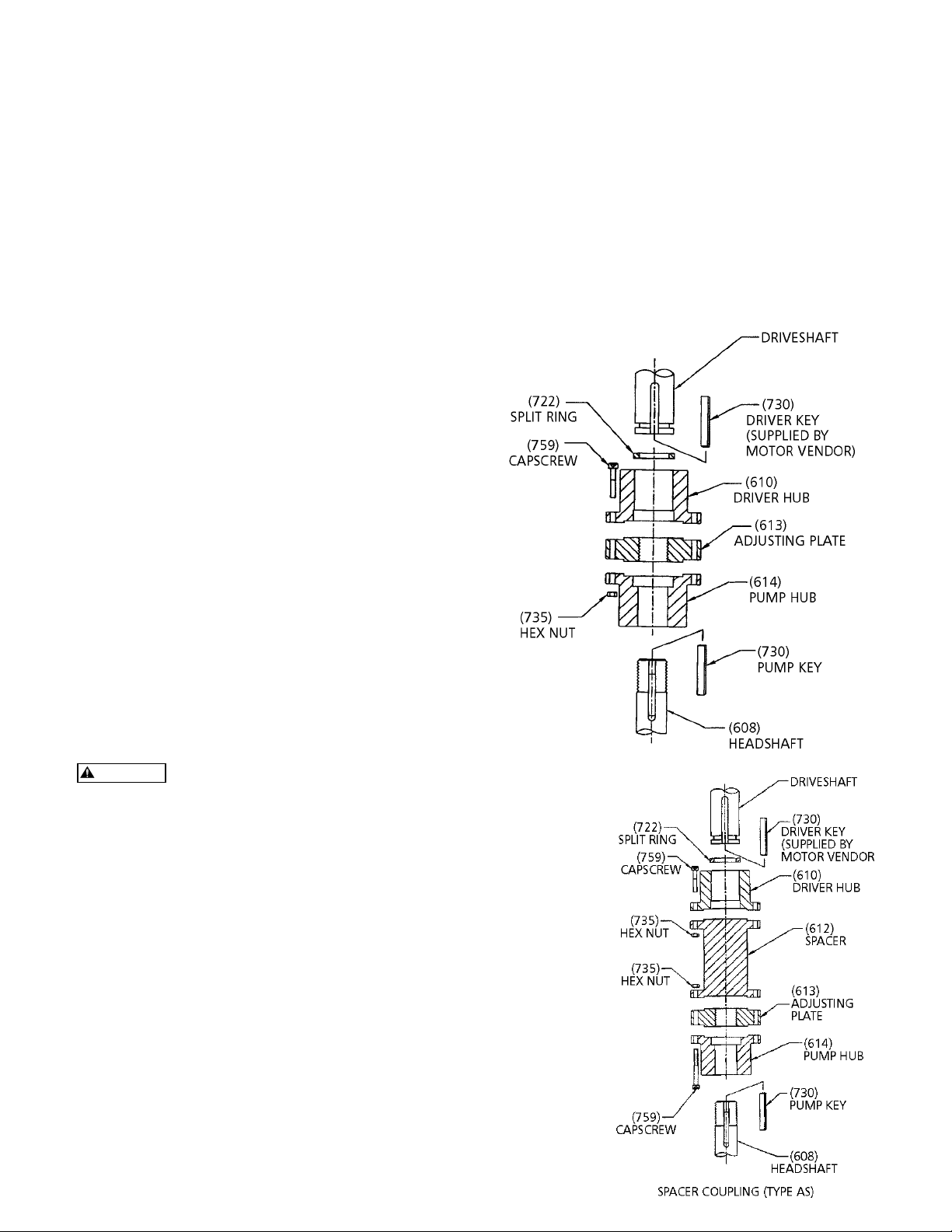

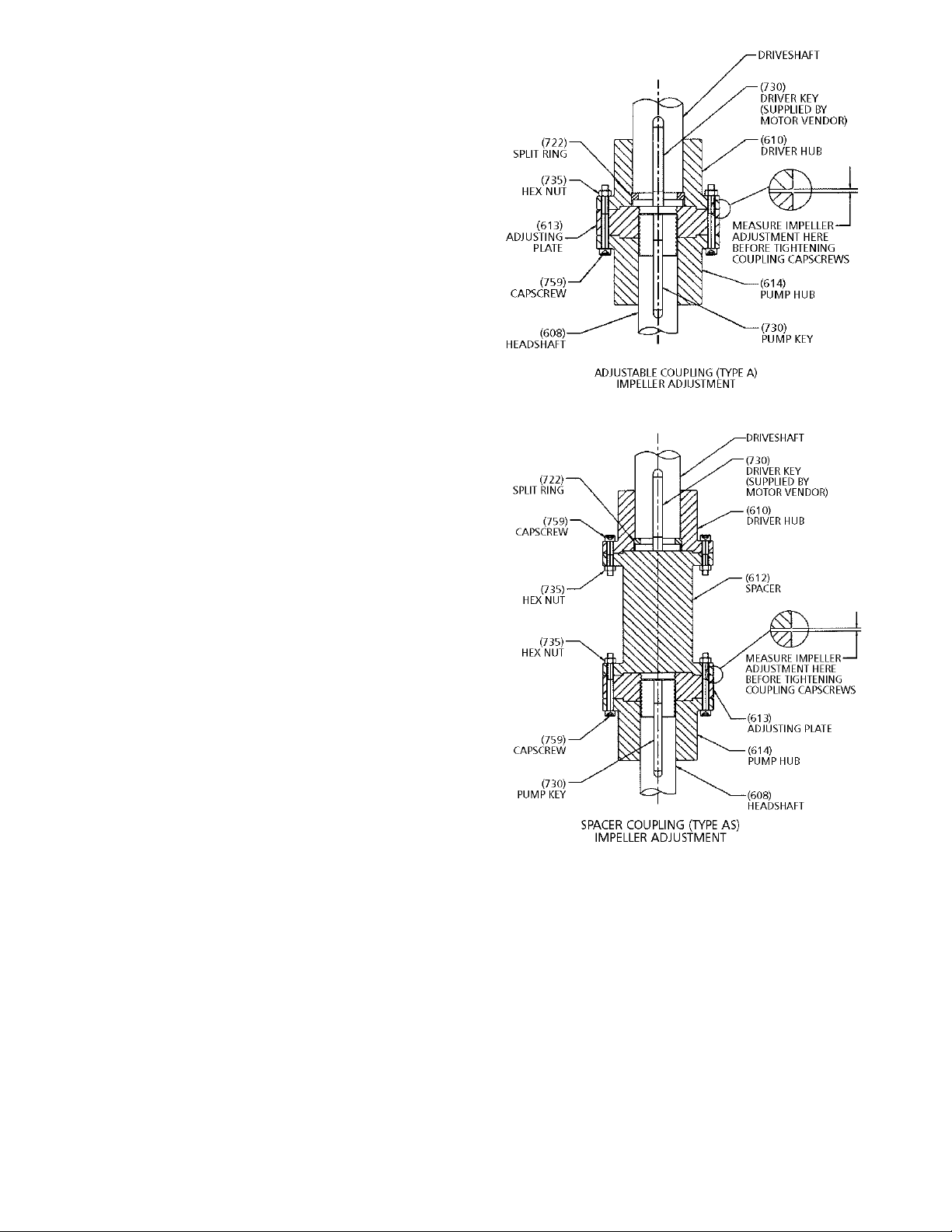

The coupling between the driveshaft and discharge head

WARNING

shaft may be a non-spacer type (see Figure 14), or a

spacer type (see Figure 15). The latter is used on pumps

furnished with a mechanical seal to permit servicing of

the seal without removal of the driver.

1. Driver support. When a driver support is furnished

and not installed, proceed as follows.

A. Hoist driver support, inspect the mounting

surfaces, register and clean these surfaces

thoroughly.

B. Install driver support on discharge head and

secure with capscrews provided.

2. Attach a sling to the lifting lugs of driver, hoist

motor, inspect the mounting surface, register, and

shaft extension, and clean these surfaces thoroughly.

If any burrs are found, remove burrs with a smooth

mill file, cleaning thoroughly afterward.

3. Orient the motor conduit box in the required

position. Align the motor mounting holes with the

mating tapped holes on the discharge head. Lower

the motor until the registers engage and the motor

rests on the discharge head. Secure motor with

capscrews provided.

COUPLING INSTALLATION: (SEE FIGURES 14 and 15)

1. Apply a thin film of oil on the pump key (730) and

insert key into headshaft keyway seat.

2. Gently lower pump hub of coupling (614) onto

headshaft.

3. Thread on the adjusting plate (613) onto the

headshaft until flush with top of the headshaft.

4. Apply a thin film of oil to the driver key (730) and

insert key into drive shaft keyway seat. Place the

driver hub (610) onto the drive shaft and with key

slide it up the drive shaft until the annular grove is

exposed. Install split ring (722) in the groove and

slide driver hub down over the split ring to capture

it.

4. On drivers having a non-reverse ratchet or pins,

manually turn the driver shaft clockwise viewed

from the top until the non-reverse ratchet or pins

fully engage.

5. Lubricate motor bearings in accordance with

instructions given on lubrication plate attached to

the motor case.

NOTE: Please read and follow the motor manufacturer’s

instructions before lubricating the motor

bearings. Too much lubricant can cause the

bearings to overheat prematurely fail.

The motor must not be tested for direction

of rotation when coupled to the pump.

If pump should rotate in the wrong direction, serious

damage to the pump and motor would result. Also

serious injury to personnel could result.

6. Make temporary electrical connections according

to tagged leads or diagram attached to the motor.

Motor must rotate counter-clockwise when viewed

from the top. See arrow on pump name plate. If

motor does not rotate counter-clockwise, you can

change the rotation by interchanging any two leads

(For three phase only, for single phase motors see

motor manufacturer’s instructions.)

7. Motor shaft end play adjustment: if required,

motor shaft end play shall be checked with a dial

indicator prior to connecting the pump coupling to

the solid shaft motor. Consult the applicable motor

manufacturer’s instruction manual for detailed

information on motor shaft end play.

Figure 14

5. If the pump

is supplied

with an

adjustable

spacer

coupling

(see Figure

15), install

spacer (612)

between

headshaft

and

driveshaft

hubs.

Secure with

capscrews

(759) and

hex nuts

(735).

20

Figure 15

Page 21

IMPELLER ADJUSTMENT

Impeller adjustment is identical for all motors and right

angle gear drives. Adjustment is accomplished by turning

the adjusting plate (613). (See Figure 16 or 17). The

correct adjustment is listed on the Outline Drawing for

the specific unit. If the pump has a thrust pot, do not

adjust the impeller position until the thrust pot has been

installed and adjust the impeller position by using the

adjust nut on the thrust pot.

NOTE: Mechanical seal, when provided, must not be

secured to the shaft prior to impeller adjustment.

(open or enclosed type impellers). Shaft must

move up or down within the seal Assembly.

For pumps handing liquids between –50º to

200º F, impeller adjustment can be made under

ambient conditions. For liquids in excess of

this range, it is recommended that impeller

adjustment be made after the pump surface

temperature has reached an equilibrium when

charged with the pumpage. In those cases, where

this is not feasible due to safety consideration

or impossible due to external ice build up in

cryogenic applications, refer to factory for

specific instructions.

Figure 16

OPEN IMPELLERS

1. With the impellers touching the bottom of the

bowls, turn the adjusting plate (613) towards the

driver hub (610) or spacer (612) obtain 0.015 inch

clearance between the adjusting plate and driver hub

or spacer for the first 10 feet of column. Add 0.010”

for each additional 10 feet of column. See figure

20 or 21. Note: The determination of driver shaft

end play can be critical and should be added to this

setting. For larger pumps over 8”, this amount may

be too little; please refer to Outline Drawing.

Example: total pump length is 50 feet - set impellers

at 0.055 inch.

2. After impeller adjustment, align adjusting plate

(613) with the pump hub (614), and tightly draw

coupling flanges together with capscrews (759) and

nuts (735). (See Figures 14 and 15.)

3. Set seal after impeller adjustment. Securely tighten

all set screws in the collar. Remove the spacer

between the gland plate and collar. Retain spacer for

future resetting of seal.

NOTE: When impellers are reset, the seal must also be

reset.

Figure 17

ENCLOSED IMPELLERS

For enclosed impellers obtain the clearance between the

adjusting plate and driver hub or spacer as specified on

the outline drawing. See Figure 16 or 17.

INSTALLING THE GREASE LUBRICATED THRUST POT

This type of thrust pot and the motor stand are

assembled on the discharge head by the factory. This

thrust pot is designed to be used with NEMA Vertical

C-face motors. The motor shaft and the pump shaft to be

coupled with flexible coupling.

INSTALLATION:

1. Install both coupling halves prior to mounting

the motor. Refer to the coupling manufacturer’s

instructions.

21

Page 22

2. Using the lifting lugs on the motor, carefully lower

WARNING

the motor onto to the motor stand of the thrust pot

(See Figure 18) and align the bolt holes.

3. Install the bolts finger tight.

4. Make temporary electrical connections according

to tagged leads or diagram attached to the motor.

Motor must rotate counter-clockwise when viewed

from the top. See arrow on pump name plate. If

motor does not rotate counter-clockwise, you can

change the rotation by interchanging any two leads.

Before beginning any alignment procedure,

make sure driver power is locked out.

Failure to lock out driver power will result in serious

physical injury.

INSTALLING THE OIL LUBRICATED THRUST POT

If the unit is supplied with a thrust pot (see Figure 19),

the thrust pot should be installed on top of the discharge

head or motor stand before installing the driver. The

driving mechanism of the thrust pot assembly is similar

to the hollow shaft motor. (See Figure 12)

1. Attach a sling to the thrust pot assembly through

the windows on the motor adapter and hoist the

assembly over the top of the discharge head.

2. Clean the mounting face of the discharge head

and the thrust pot. Lower the thrust pot assembly

and orient it so that the bolt hole on the base of

the thrust pot and the top flange of the discharge

head are line up. Install all the bolts to secure the

assembly to the discharge head.

ALIGNMENT OF FLEXIBLE COUPLING:

Alignment of the pump and motor is extreme importance

for trouble-free mechanical operation. Straight edge

alignment by an experienced installed proves adequate

for most installation.

1. Check for coupling alignment by laying a straight

edge across both coupling rims at four points 90

degree apart.

2. Move motor until straight edge rests evenly at each

position. Repeat procedure until correct alignment is

achieved.

3. Install flexible sleeve between the hubs per the

manufacture’s instructions.

4. Tighten all motor bolts.

NOTE: Be sure the relief fitting (#11 in Figure 18) is

clear of paint or any other obstructive material.

Otherwise it will cause premature failure of the

thrust pot and is not covered under warranty.

3. Lower the drive shaft through the quill of the thrust

pot assembly to meet the shaft coupling. Apply a

thin film of oil to the head shaft thread and screw

into the shaft coupling.

4. For unit with mechanical seal and flanged coupling,

install the spacer flange coupling as instructed on

page 20.

5. Install the gib key (#16) into the drive shaft and the

hollow shaft clutch.

6. Install the adjusting nut (#17) to hand tight.

7. With shafting all the way down and the impellers

resting on their seats, turn the adjusting nut (#17)

in counter-clockwise direction, thus lifting the shaft,

until the impellers just clear their seats and the

shaft/motor turns free by hand. This removes all

deflection from the shaft.