Page 1

TX100/200-SERIES

INSERTION TURBINE

INSTRUCTIONS

TX100/200-SERIES INSERTION TURBINE INSTRUCTIONS

TX101/201

ISO

TX115/215

9001:2008

CERTIFIED COMPANY

Page 2

TABLE OF CONTENTS

General Information

Features, Specications ......................................................................................................................................Page 1

Installation

Piping, Immersion, Positioning the Meter ..........................................................................................................Page 2

Straight Pipe Recommendations ........................................................................................................................

Full Pipe Recommendations ................................................................................................................................Page 4

Fitting Installation, Meter Installation .................................................................................................................Page 5

Proper Depth Setting, Dimension C, Pipe Wall Thickness .................................................................................Page 6

Set-Up

Connection, Calibration, K-Factors .....................................................................................................................Page 7

Operation

Flow Range, Flow Rates .......................................................................................................................................Page 8

Parts List

Parts Exploded View.............................................................................................................................................Page 9

Troubleshooting & Repair

Troubleshooting, Repair, Rotor Replacement ........................................................................................................ Back

Page 3

TABLES AND DIAGRAMS

Features ............................................................................................................................................................... Page 1

Specifications ...................................................................................................................................................... Page 1

Positioning the Meter .......................................................................................................................................... Page 2

Piping ................................................................................................................................................................... Page 2

Straight Pipe Recommendations .......................................................................................................................

Full Pipe Recommendations ...............................................................................................................................Page 4

Meter Installation ................................................................................................................................................ Page 5

Depth Setting ...................................................................................................................................................... Page 6

Pipe Wall Thickness ............................................................................................................................................ Page 6

Connection Diagram ........................................................................................................................................... Page 7

Parts Exploded View............................................................................................................................................ Page 9

Page 3

Parts List .............................................................................................................................................................. Page 9

Rotor Replacement ................................................................................................................................................ Back

Page 3

GENERAL INFORMATION

The TX100/200-Series are adjustable depth insertion turbines

that come in brass or 316 stainless models to t 3” to 40”

pipe. Adapters mate with standard 1-1/2" (101/201) or 2”

(115/215) FNPT ttings such as saddles and weldolets which

may be purchased either locally or from Seametrics.

Ruby bearings and a non-drag pickoff give these adjustable

insertion turbine ow sensors a wide ow range and long life.

A sensor detects the passage of miniature magnets in the rotor blades. The resulting square-wave signal can be sent for

hundreds of feet without a transmitter, over unshielded cable.

This signal can be connected directly to many PLC’s and other

controls without any additional electronics.

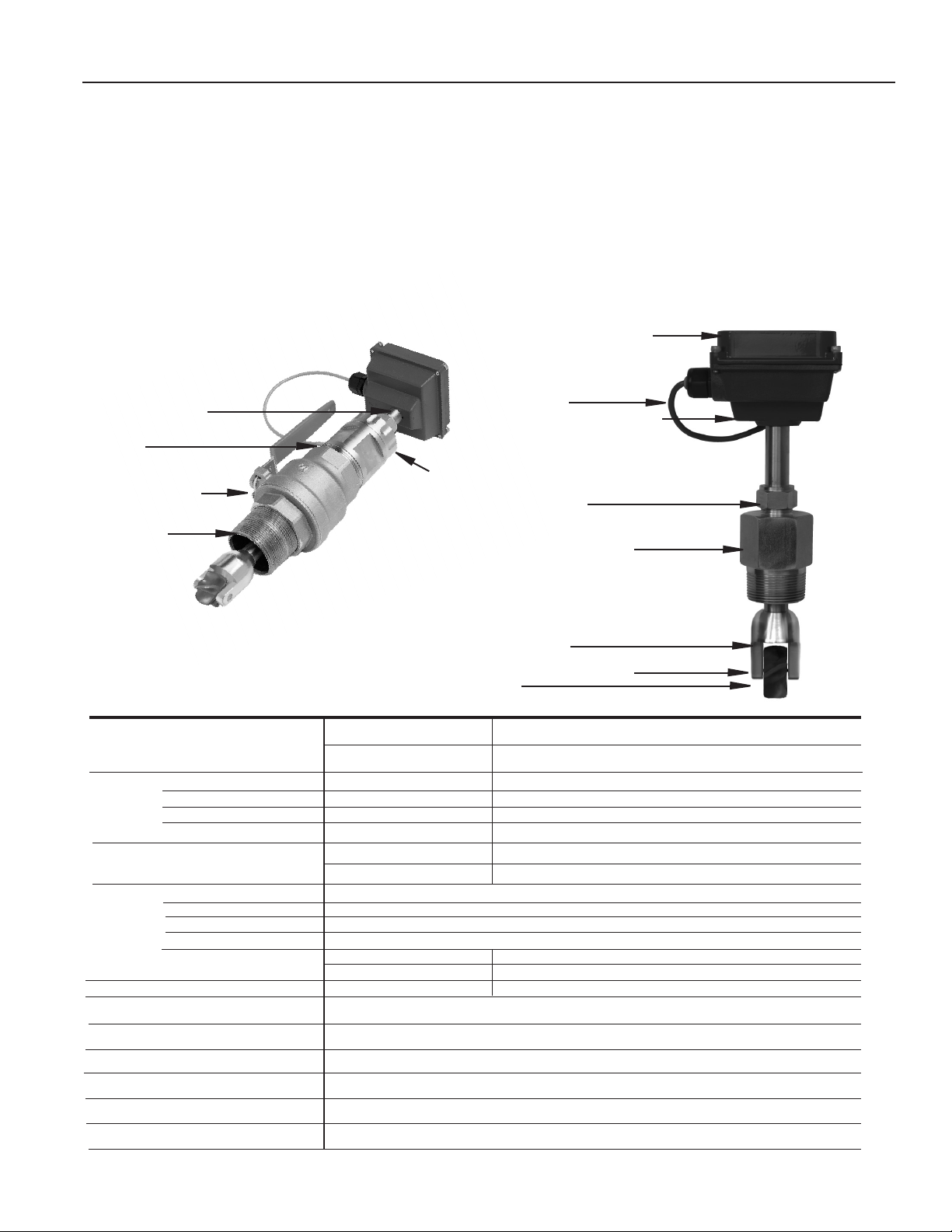

FEATURES

3/4” diameter tubing

for low insertion force

2” Adapter

removes to mount

hot-tap machine

Full-port 2” ball valve

for sensor removal

Adapter mates

with 2” FNPT

threaded ttings

Locking collar

If desired, a modular system of electronics can be installed

directly on the ow sensor or mounted remotely. The FT415

(battery powered) or FT420 (loop powered) provides digital rate

and total display, as well as programmable pulse; the FT420

also provides a 4-20 mA analog output. The AO55 is a blind

analog (4-20 mA) transmitter. Programmable pulse for pump

pacing is available with the PD10.

The “hot-tap” models (TX115/215) can be installed or serviced

without shutting down the line by means of a 2” full-port isolation valve that comes with a nipple for installation on the pipe

tting. In most circumstances, no special tool is required.

Modular electronics (optional)

• rate/total/pulse/4-20 mA

• blind 4-20 transmitter

• pulse divider

18 Foot Cable

Rugged cast aluminum housing

Compression nut

for easy adjustment, secure locking

Adapter mates with 1-1/2”

FNPT threaded ttings

SPECIFICATIONS*

Power Source

Supply Voltage/Current

Sensor Type

Output

Sinking Current

External Pull-up Resistor

Pipe Size

Materials Housing

Sensor Body

Rotor

Shaft/Bearings

Isolation Valve

Fitting Size Required

Flow Range

Accuracy

Maximum Temperature

Maximum Pressure

Insertion Force

Cable

TX115/215

Rotor housing

Removable jewel bearings

Rotor

Standard Micropowered (-04 Option)

6-40 Vdc/< 2 mA 3.5-16 Vdc/60 µA @ 3.5 Vdc

Magnetoresistive Magnetoresistive

Current Sinking Pulse Current Sinking Pulse

100 mA max 2 mA max

3-40 Vdc ≤ Supply Voltage

TX101/115 TX201/215

3” - 12” (50 - 300mm) 12” - 40” (300 - 890mm)

Cast aluminum

Brass or 316 SS

PVDF standard

Nickel-bound tungsten carbide/Ruby

TX101/201 TX115/215

None Bronze (316SS optional)

1-1/2” FNPT 2” FNPT

0.5 - 30 feet/sec (0.15 - 9.14 meter/sec)

+/-1.5% of full scale

200˚ F (93˚ C)

200 psi (14 bar)

0.44 x pressure in pipe

#22 AWG 3-con, 18’ (6m); 2,000’ (650m) maximum cable run

TX101/201

Note: For larger pipe sizes contact factory

*Specications subject to change. Please consult our website for the most current data (www.seametrics.com).

Page 1

Page 4

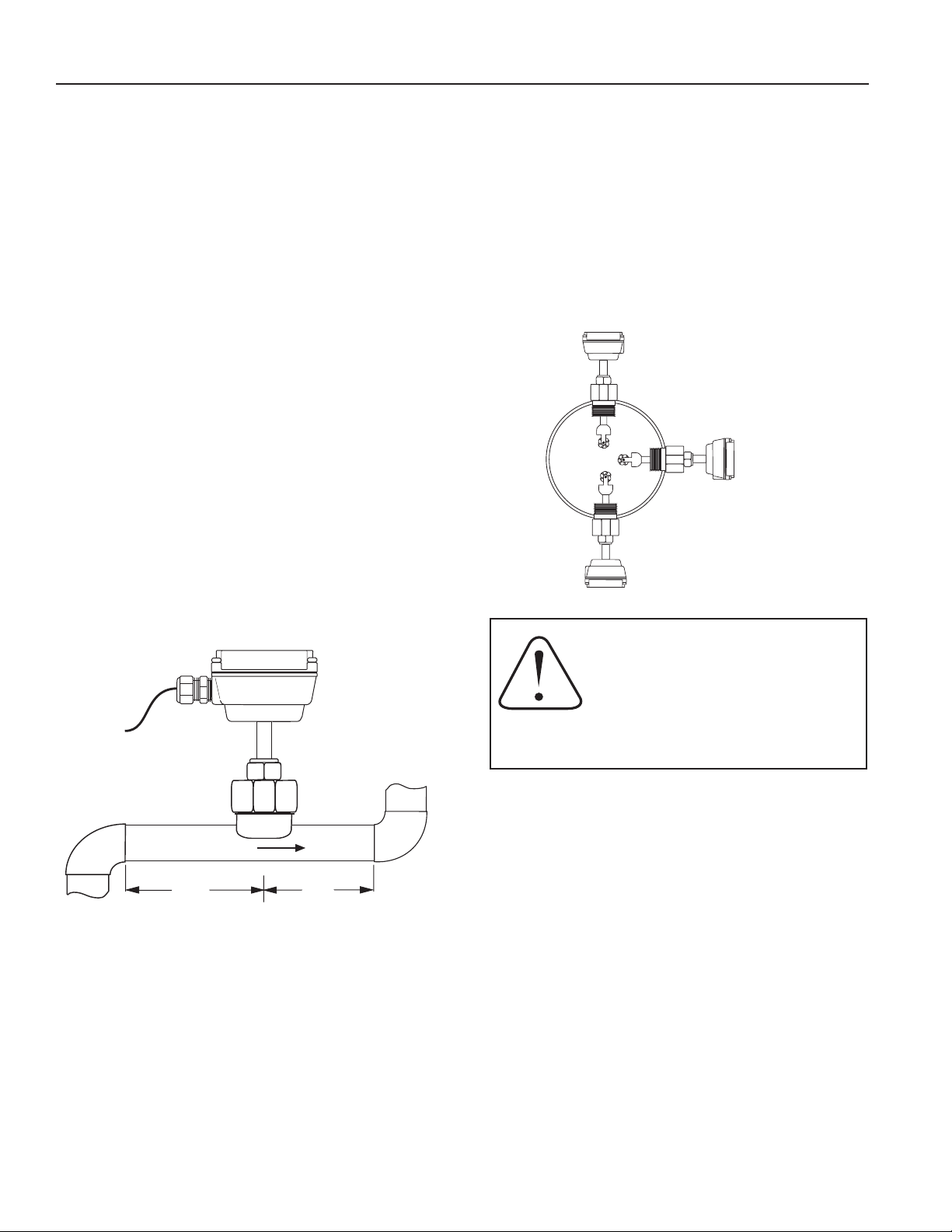

INSTALLATION

10

x Dia.

5

x Dia.

FLOW

An insertion ow sensor measures the velocity of ow at one

point in the pipe; ow rate and total can be inferred from this

one point. Accuracy is decreased by any factor which makes

the ow at the measured point unrepresentative of the entire

ow stream. This includes distorted ow patterns caused by

upstream ttings too close to the sensor. The worst offenders

are ttings that increase the ow on one side of the pipe, such

as partially-opened gate or buttery valves. Fluid moving in a

pipe does not ow at the same velocity. Toward the center of

the pipe, uid moves faster than at the wall, and the relationship between the two changes as overall ow rate increases.

This change in the “velocity prole” can result in non-linearity,

which means that the K-factor (see page 7) that is correct for

one ow rate may be incorrect for another. Recommended

depth settings (see page 6) have been carefully chosen to

minimize this source of error, and should be followed carefully,

especially in the smaller pipe sizes.

Piping. For best results, the TX sensor should be installed with at least ten diameters of straight pipe

upstream and ve downstream. Certain extreme situations

such as partially-opened valves are particularly difcult and

may require more straight diameters upstream. See Straight

Pipe and Full Pipe recommendations on following pages.

Immersion. The TX100/200-Series standard sensors are

not designed for continuous underwater operation. If your

meter may experience occasional temporary immersion, as

in a ooded vault, a unit modied for immersion should be

specied (Option -40).

Positioning the Meter. Horizontal is the preferred installation orientation, since it improves low-ow performance

slightly and avoids problems with trapped air. Bottom, top,

and vertical pipe installaations are all acceptable if required

by the piping layout.

Fair (unacceptable if air is

present)

Best

Fair (unacceptable if uid

contains sediment)

CAUTION: These water meters are

not recommended for installation

downstream of the boiler feedwater

pump where installation fault may

expose the meter to boiler pressure

and temperature. Maximum recom-

mended temperature is 200ºF.

Page 2

Page 5

INSTALLATION

STRAIGHT PIPE RECOMMENDATIONS

(X = diameter)

Reduced Pipe

Two Elbows In Plane

Two Elbows, Out Of Plane

10X

20X

5X

5X10X

5X

Expanded Pipe

Spiral Flow

Swirling Flow

Propeller Meter

Partially Open

Buttery Valve

20X

5X

30X

50X

Page 3

Page 6

INSTALLATION

FULL PIPE RECOMMENDATIONS

Allows air pockets to form at sensor

Better InstallationPossible Problem

Ensures full pipe

Better InstallationPossible Problem

Post-valve cavitation can create air pocket Keeps pipe full at sensor

Better InstallationPossible Problem

Air can be trapped

Allows air to bleed off

Page 4

Page 7

INSTALLATION

TX101/201 INSTALLATION

Fitting Installation. TX101/201 adapters mate with a 1-1/2” female

NPT pipe thread adapter tting. Any tting that provides the matching

NPT female thread may be used. Installation procedure compensates

for tting height differences. Cut a minimum 1-3/4” hole in the pipe. If

possible, measure the wall thickness and write it down for use in depth

setting. Then install the threaded tting (saddle, weldolet, etc.) on the

pipe.

Meter Installation. Loosen the compression nut so that the adapter

slides freely. Pull the meter fully upward and nger-tighten the compression nut. Using a thread sealant, install the adapter in the pipe tting.

Do not overtighten. Now loosen the compression nut, lower the meter to

the appropriate depth setting (see diagram and instructions that follow).

Caution: Do not allow the meter to fall into the pipe uncontrolled, as this

may damage the meter. Be sure ow is in the direction of the arrow on

the housing. Tighten compression nut fully.

Compression nut

Adapter mates

with 1-1/2"

FNPT threads

TX115/215 INSTALLATION

‘Hot tap’ TX meters are designed to be installed and serviced without

depressurizing the pipe.

Fitting Installation. The TX115/215 adapters mate with a 2” FNPT

threaded tting for compatibility with the 2” isolation valve. Any tting

that provides matching NPT female thread may be used. The installation

procedure compensates for differences in tting height.

If initial installation is performed on an unpressurized pipe, cut a

minimum 1-3/4” hole in the pipe. If possible, measure the wall thickness

and write it down for use in depth setting. Then install the threaded tting

(saddle, weldolet, etc.) on the pipe.

If it is necessary to do the initial installation under pressure, any standard

hot tap drilling machine with 2” NPT adapter, such as a Transmate or a

Mueller, can be used. Ordinarily, it is not necessary to use an installation

tool, since the small-diameter tube can be controlled by hand at all but

the highest pressures.

Compression nut

Locking collar

2” adapter removes

to mount hot-tap

machine

Full-port 2” ball

valve allows sensor

removal

Mates with 2”

FNPT threads

Meter Installation. Remove the sensor unit from the valve assembly.

Using a thread sealant, install the valve assembly on the pipe tting. If

the initial installation is a pressure (“hot”) tap, remove the 1-1/2” x 2”

adapter bushing at the back of the valve. Thread the tapping machine

on, open the valve, and tap using a minimum of 1-3/4” or maximum

1-7/8” cutter. After retracting the machine and closing the valve, reinstall

the ow sensor. When the sensor is secure, open the valve and adjust

depth setting (see diagram and instructions that follow). Be sure ow is

in the direction of the arrow on the housing. Tighten locking collar and

compression nut fully.

TX115/215 Sensor

Removal

Page 5

Page 8

INSTALLATION

"D"

2. Measuring from the outside of the pipe to the joint

in the housing, as shown in the diagram above,

adjust the sensor to Dimension D and hand-tighten

compression nut.

3. Align the conduit housing with the centerline of the

pipe, as shown. Be sure the arrow on the housing

points in the direction of ow.

Proper Depth Setting. It is important for accuracy that

the sensor be inserted to the correct depth into the pipe.

1. Please visit www.seametrics.com and select the

K-factor Calculator located on the lower left of

the homepage to nd dimension 'D' (insertion depth

setting) above.*

TABLE 1: PIPE WALL THICKNESS

NOMINAL PIPE SIZE

3” 4” 6” 8” 10” 12” 14” 16” 18” 20” 24” 30” 36”

PVC/Steel

Sch. 40

0.216 0.237 0.280 0.322 0.365 0.406 0.438 0.500 0.562 0.593 0.687

strain

relief

FLOW

4. Check Dimension D one more time.

5. Tighten the compression nut fully.

RECORD YOUR SETTINGS

Once you have the meter set up and operational, it

is important to record your meter setttings and save

them for future reference.

K-Factor

Insertion Depth (Dim. D)

*For pipe sizes larger than 50”, please consult factory.

PVC/Steel

Sch. 80

Stainless

Steel (10S)

Stainless

Steel (40S)

Copper Tubing

(Type L)

Copper Tubing

(Type K)

Brass Pipe

Duct. Iron

(Class 52)

Page 6

0.300 0.337 0.432 0.500 0.593 0.687 0.750 0.843 0.937 1.031 1.218

0.120 0.120 0.134 0.148 0.165 0.180 0.188 0.188 0.188 0.218 0.250 0.312 0.312

0.216 0.237 0.280 0.322 0.365 0.375 0.375 0.375 0.375 0.375 0.375 0.375 0.375

0.090 0.110 0.140 0.200 0.250 0.280

0.109 0.134 0.192 0.271 0.338 0.405

0.219 0.250 0.250 0.312 0.365 0.375

0.280 0.290 0.310 0.330 0.350 0.370 0.390 0.400 0.410 0.420 0.440 0.470 0.530

Page 9

SET-UP

Connection. Sensors are supplied with 18 ft. of cable. For

sensors with no additional electronics, see diagram for color

coding. For sensors with on-board electronics, see the manual

accompanying the electronics module.

RED (+) 5-24 Vdc

WHITE (signal)

BLACK (-) Power

18' cable standard

Calibration (“K-Factor”). In order to properly process pulses

from the ow sensor, a number must be entered into the control

to which the sensor is connected. This number, called the Kfactor, is the number of pulses the sensor puts out per unit of

uid passing through the pipe. It is normally provided for Seametrics sensors in pulses per gallon, and can be ascertained

by using the “K-Factor Calculator” on the Seametrics website.

These numbers are based on extensive testing, which has shown

close agreement between different TX sensors in the same

installation. Most K-factor error can be attributed to installation variables, such as depth setting and tting conguration.

It is possible to eld calibrate a sensor by catching the uid

in a measured container and comparing with the number of

pulses recorded. (To record individual pulses, set the K-factor on the control to 1.00.) This is especially desirable if the

installation has less than the recommended length of straight

pipe upstream of the sensor. For detailed intructions on eld

calibration, please refer to the technical bulletin on our website

(www.seametrics.com/pdf/LT-13276-A.pdf).

Page 7

Page 10

OPERATION

Flow Range. These sensors are designed to operate at ow

velocities of 0.5 to 30 feet per second (see Table 2, below).

If erratic readings are encountered at low ows, check the

chart to see if ow is below minimum for the pipe size. The

standard shaft and bearings should have a long life at continuous high ow.

TABLE 2: Flow Rates converted from Feet/Sec to Gallons/Minute at various velocities: Schedule 40 pipe

Nominal pipe size

Feet / Sec

3" 4" 5" 6" 8" 10" 12" 16" 24" 36" 38" 40"

▲

(0.5)

11.5 19.8 31.2 45 78 123 176 313 704 1585 1770 1960

(1.0)

23 39.7 62.4 90 156 246 349 551 1250 2910 3530 3915

(2.0)

46.1 79.4 125 180 312 492 698 1100 2510 5830 7070 7825

(5.0)

115 198 312 450 780 1230 1740 2750 6270 14570 17670 19560

(10.0)

230 397 624 900 1560 2460 3490 5510 12530 29140 35350 39120

(20.0)

461 794 1250 1800 3120 4920 6980 11020 25060 58270 70700 78240

691 1190 1870 2700 4680 7370 10470 16520 37600 87410 106050 117500

(30.0)

Page 8

Page 11

PARTS LIST

4

1

2

3

7

8

9

10

TX101/201

5

6

TX115/215

17

18

19

TX 101/201 Parts

1 Upper housing assembly 30475

2 Housing Gasket 26211

3 Lower housing Not Field Replaceable

4 Housing screw assembly 26229 (4 required)

5 Plug, steel 26073

6 Strain relief 07655

7 Sensor w/cable

8 Tube Not Field Replaceable

9 Compression nut

10 Compression Ferrule 26065

11 Adapter

12 Rotor housing O-ring 16454

13 Rotor housing

26310 (Standard - FT420)

29953 (Micropower - FT415)

14199 (Brass)

15064 (SS)

30998 (Brass)

30999 (SS)

After Jan 1, 2011

33023 (Brass)

33024 (SS)

11

7

12

13

14

16

20

Jewel bearing assembly

14

(for carbide shaft)

15 Turbine Rotor assembly

Rotor repair kit

16

(consists of #15 & #16)

25901 (2 required)

After Jan 1, 2011

33015 (Kynar)

After Jan 1, 2011

33087 (Kynar/Carb)

TX 115/215 Parts (hot tap)

All part numbers are the same except those below

17 Locking Collar

18 Adapter tting O-ring 26029

19 Adapter, hot tap

Valve assembly

20

(inlcudes Adapter, #20)

14190 (Brass)

15170 (SS)

26130 (Brass)

26131 (SS)

14225 (Brass)

15225 (SS)

15

Page 9

Page 12

TROUBLESHOOTING and REPAIR

Troubleshooting

CAUTION! Never attempt to remove a

ow sensor when there is pressure in

the pipe. Loosen the compression nut

slowly to release any trapped pressure.

If uid sprays out when removing the

sensor, stop turning and depressurize the pipe. Failure to do so could result in the sensor being thrown

from the pipe, resulting in damage or serious injury.

The ow sensor has only one moving part, the rotor. If this is

turning properly and there is no signal, the Hall-effect sensor

is not operating properly. To check the signal, apply 12 Vdc

regulated* power to the red (+) and black (-) leads. Set a

multimeter to voltage reading. Put the positive multimeter

lead on the red wire and the negative lead on the white

wire. Slowly turn the rotor. Voltage reading should swing

between +12 Volts and 0 Volts as the rotor turns. If it does

not, the Hall effect sensor is not working properly. Checking

for continuity is not a useful test of these sensors.

*NOTE: An unregulated power supply can exceed max voltage of

micro powered sensor (gray cable) and damage sensor.

Rotor Replacement. Rotors are easily eld-replaced. Shaft

and rotor are a single unit, and are not replaced separately.

If replacement is due only to normal shaft wear, bearing replacement is probably not necessary. If the rotor has been

damaged by impact, the bearings should also be replaced.

Rotor and bearings can be ordered as a kit (see parts listing).

Follow these steps:

1. Unscrew the threaded bearing housings to expose the

shaft ends. If bearings are being replaced, back them

completely out.

2. Remove the rotor. Put the new rotor in its place.

3. Thread in one bearing housing part way, then the

other. Take care to start the end of the shaft into

the bearing hole before tightening further.

4. Screw in bearing housings until they bottom.

Note: Do not use excessive force.

5. Check for free spin. Blowing lightly on the rotor

should result in it spinning rapidly and coasting

to a smooth stop.

Turbine Rotor

Repair

All Seametrics ow sensors are repairable, and can be

returned to the factory or distributor for repair.

Please rst obtain a Return Material Authorization

(RMA) number.

Bearing

Housing

Shaft

Seametrics Incorporated • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • www.seametrics.com

LT-65200050-061213

6/12/2013

Loading...

Loading...