Xylem TX100, TX200 User Manual

TX100/200-SERIES

INSERTION TURBINE

INSTRUCTIONS

TX100/200-SERIES INSERTION TURBINE INSTRUCTIONS

TX101/201

ISO

TX115/215

9001:2008

CERTIFIED COMPANY

TABLE OF CONTENTS

General Information

Features, Specications ......................................................................................................................................Page 1

Installation

Piping, Immersion, Positioning the Meter ..........................................................................................................Page 2

Straight Pipe Recommendations ........................................................................................................................

Full Pipe Recommendations ................................................................................................................................Page 4

Fitting Installation, Meter Installation .................................................................................................................Page 5

Proper Depth Setting, Dimension C, Pipe Wall Thickness .................................................................................Page 6

Set-Up

Connection, Calibration, K-Factors .....................................................................................................................Page 7

Operation

Flow Range, Flow Rates .......................................................................................................................................Page 8

Parts List

Parts Exploded View.............................................................................................................................................Page 9

Troubleshooting & Repair

Troubleshooting, Repair, Rotor Replacement ........................................................................................................ Back

Page 3

TABLES AND DIAGRAMS

Features ............................................................................................................................................................... Page 1

Specifications ...................................................................................................................................................... Page 1

Positioning the Meter .......................................................................................................................................... Page 2

Piping ................................................................................................................................................................... Page 2

Straight Pipe Recommendations .......................................................................................................................

Full Pipe Recommendations ...............................................................................................................................Page 4

Meter Installation ................................................................................................................................................ Page 5

Depth Setting ...................................................................................................................................................... Page 6

Pipe Wall Thickness ............................................................................................................................................ Page 6

Connection Diagram ........................................................................................................................................... Page 7

Parts Exploded View............................................................................................................................................ Page 9

Page 3

Parts List .............................................................................................................................................................. Page 9

Rotor Replacement ................................................................................................................................................ Back

GENERAL INFORMATION

The TX100/200-Series are adjustable depth insertion turbines

that come in brass or 316 stainless models to t 3” to 40”

pipe. Adapters mate with standard 1-1/2" (101/201) or 2”

(115/215) FNPT ttings such as saddles and weldolets which

may be purchased either locally or from Seametrics.

Ruby bearings and a non-drag pickoff give these adjustable

insertion turbine ow sensors a wide ow range and long life.

A sensor detects the passage of miniature magnets in the rotor blades. The resulting square-wave signal can be sent for

hundreds of feet without a transmitter, over unshielded cable.

This signal can be connected directly to many PLC’s and other

controls without any additional electronics.

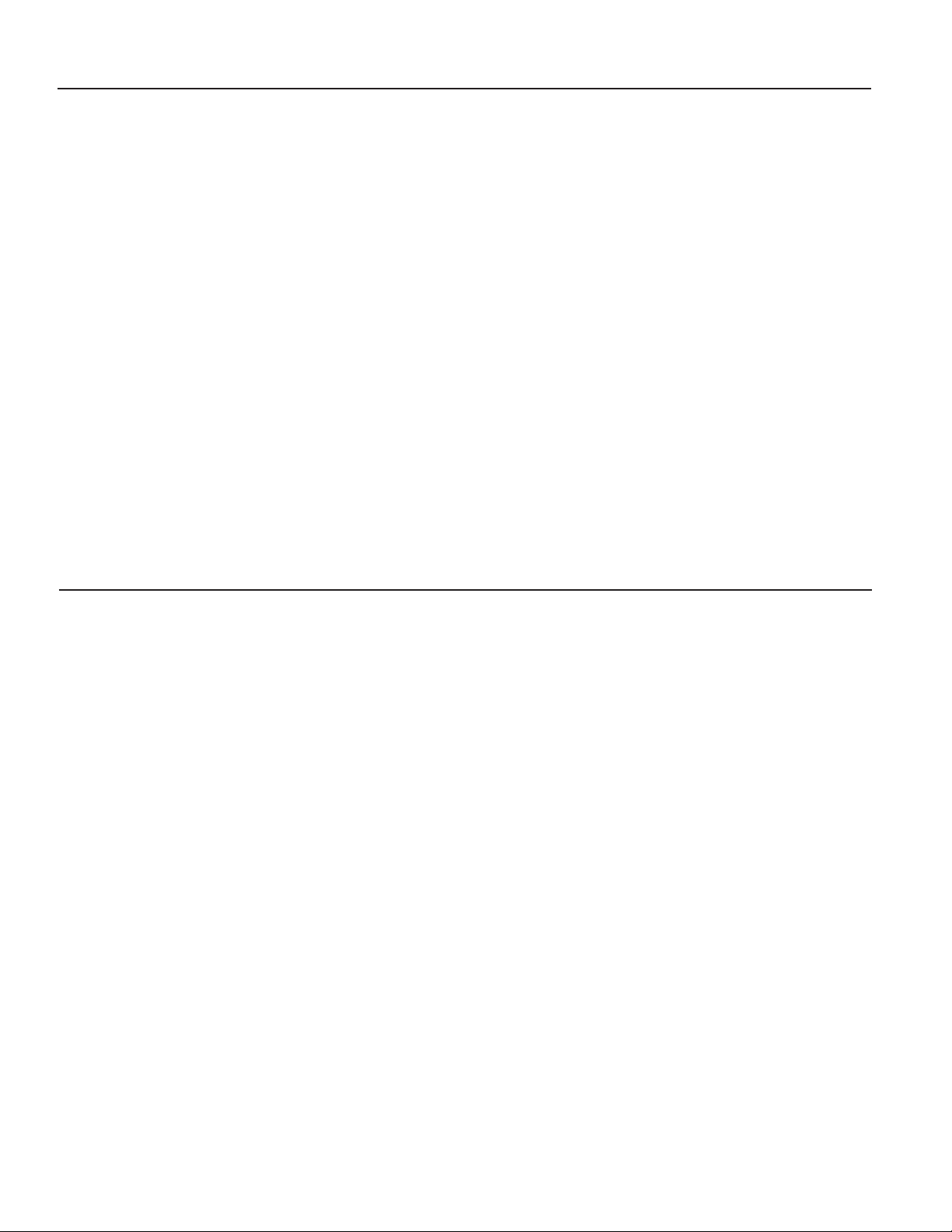

FEATURES

3/4” diameter tubing

for low insertion force

2” Adapter

removes to mount

hot-tap machine

Full-port 2” ball valve

for sensor removal

Adapter mates

with 2” FNPT

threaded ttings

Locking collar

If desired, a modular system of electronics can be installed

directly on the ow sensor or mounted remotely. The FT415

(battery powered) or FT420 (loop powered) provides digital rate

and total display, as well as programmable pulse; the FT420

also provides a 4-20 mA analog output. The AO55 is a blind

analog (4-20 mA) transmitter. Programmable pulse for pump

pacing is available with the PD10.

The “hot-tap” models (TX115/215) can be installed or serviced

without shutting down the line by means of a 2” full-port isolation valve that comes with a nipple for installation on the pipe

tting. In most circumstances, no special tool is required.

Modular electronics (optional)

• rate/total/pulse/4-20 mA

• blind 4-20 transmitter

• pulse divider

18 Foot Cable

Rugged cast aluminum housing

Compression nut

for easy adjustment, secure locking

Adapter mates with 1-1/2”

FNPT threaded ttings

SPECIFICATIONS*

Power Source

Supply Voltage/Current

Sensor Type

Output

Sinking Current

External Pull-up Resistor

Pipe Size

Materials Housing

Sensor Body

Rotor

Shaft/Bearings

Isolation Valve

Fitting Size Required

Flow Range

Accuracy

Maximum Temperature

Maximum Pressure

Insertion Force

Cable

TX115/215

Rotor housing

Removable jewel bearings

Rotor

Standard Micropowered (-04 Option)

6-40 Vdc/< 2 mA 3.5-16 Vdc/60 µA @ 3.5 Vdc

Magnetoresistive Magnetoresistive

Current Sinking Pulse Current Sinking Pulse

100 mA max 2 mA max

3-40 Vdc ≤ Supply Voltage

TX101/115 TX201/215

3” - 12” (50 - 300mm) 12” - 40” (300 - 890mm)

Cast aluminum

Brass or 316 SS

PVDF standard

Nickel-bound tungsten carbide/Ruby

TX101/201 TX115/215

None Bronze (316SS optional)

1-1/2” FNPT 2” FNPT

0.5 - 30 feet/sec (0.15 - 9.14 meter/sec)

+/-1.5% of full scale

200˚ F (93˚ C)

200 psi (14 bar)

0.44 x pressure in pipe

#22 AWG 3-con, 18’ (6m); 2,000’ (650m) maximum cable run

TX101/201

Note: For larger pipe sizes contact factory

*Specications subject to change. Please consult our website for the most current data (www.seametrics.com).

Page 1

INSTALLATION

10

x Dia.

5

x Dia.

FLOW

An insertion ow sensor measures the velocity of ow at one

point in the pipe; ow rate and total can be inferred from this

one point. Accuracy is decreased by any factor which makes

the ow at the measured point unrepresentative of the entire

ow stream. This includes distorted ow patterns caused by

upstream ttings too close to the sensor. The worst offenders

are ttings that increase the ow on one side of the pipe, such

as partially-opened gate or buttery valves. Fluid moving in a

pipe does not ow at the same velocity. Toward the center of

the pipe, uid moves faster than at the wall, and the relationship between the two changes as overall ow rate increases.

This change in the “velocity prole” can result in non-linearity,

which means that the K-factor (see page 7) that is correct for

one ow rate may be incorrect for another. Recommended

depth settings (see page 6) have been carefully chosen to

minimize this source of error, and should be followed carefully,

especially in the smaller pipe sizes.

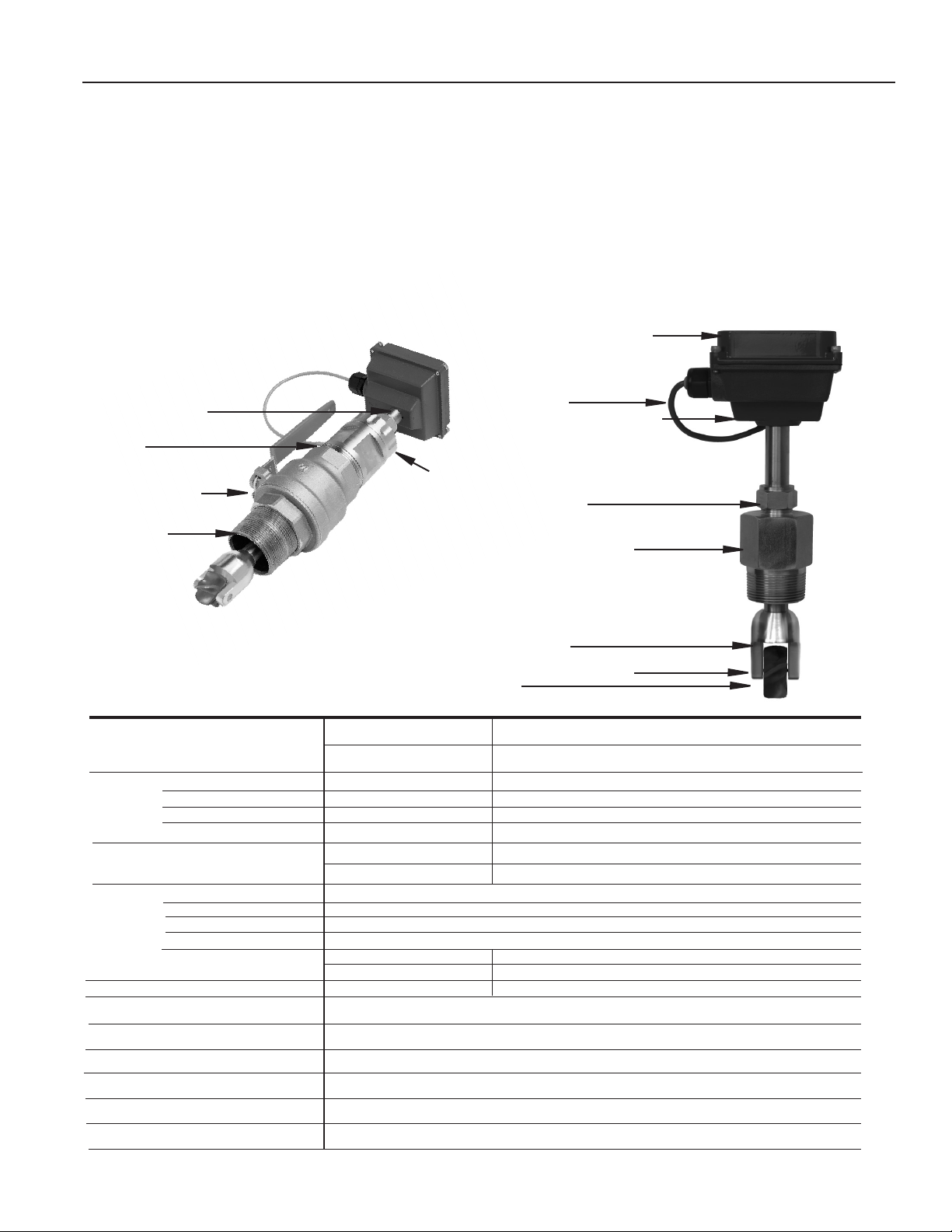

Piping. For best results, the TX sensor should be installed with at least ten diameters of straight pipe

upstream and ve downstream. Certain extreme situations

such as partially-opened valves are particularly difcult and

may require more straight diameters upstream. See Straight

Pipe and Full Pipe recommendations on following pages.

Immersion. The TX100/200-Series standard sensors are

not designed for continuous underwater operation. If your

meter may experience occasional temporary immersion, as

in a ooded vault, a unit modied for immersion should be

specied (Option -40).

Positioning the Meter. Horizontal is the preferred installation orientation, since it improves low-ow performance

slightly and avoids problems with trapped air. Bottom, top,

and vertical pipe installaations are all acceptable if required

by the piping layout.

Fair (unacceptable if air is

present)

Best

Fair (unacceptable if uid

contains sediment)

CAUTION: These water meters are

not recommended for installation

downstream of the boiler feedwater

pump where installation fault may

expose the meter to boiler pressure

and temperature. Maximum recom-

mended temperature is 200ºF.

Page 2

Loading...

Loading...