Page 1

INSTRUCTION MANUAL

HS-613

REVISION B

Hoffman Specialty

®

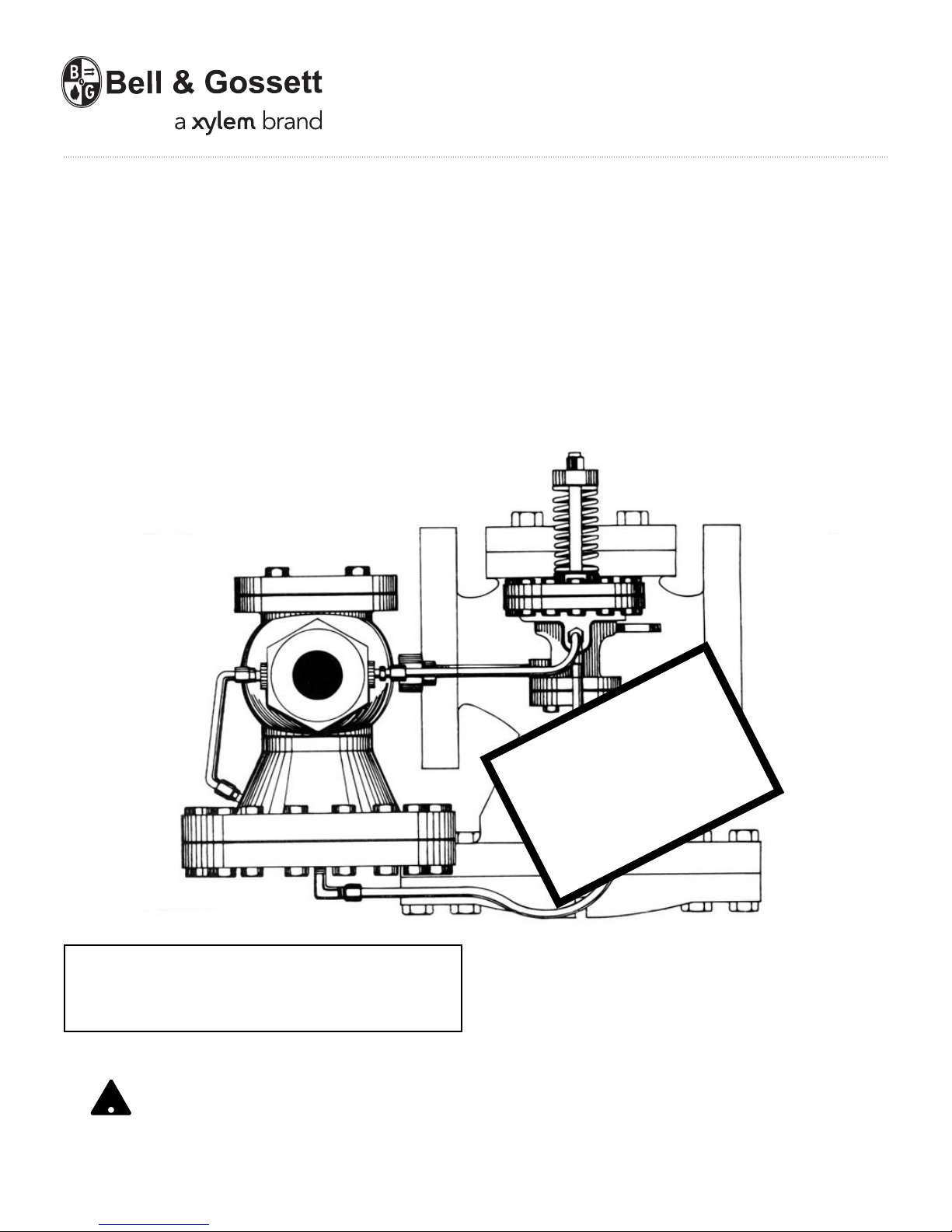

Series 2000 Air and Spring

Pilot Replacement Parts

Models AP-1, AP-3, AP-5

and SP-12, SP-30, SP-60, SP-175, SP225

(Not currently manufactured)

PLEASE READ INSTRUCTIONS CAREFULLY BEFORE

STARTING WORK. ALL WORK MUST BE PERFORMED

BY QUALIFIED PERSONNEL IN ACCORDANCE WITH

ALL APPLICABLE CODES AND ORDINANCES.

CAUTION:

!

BEFORE ANY VALVE SYSTEM IS DISASSEMBLED CLOSE ALL STEAM

LINES WHICH COULD PRESSURIZE

ANY OF THE VALVE CHAMBERS. ANY

VALVE CHAMBER MAY HAVE HOT CONDENSATE TRAPPED, USE CAUTION

WHEN OPENING ANY SECTION OR

CHAMBER.

NOTICE!

No regulator will work satisfactorily if

improperly installed. Read these

instructions carefully before making the

installation and follow directions as

outlined. Handle the regulator with

extreme care. Do not lift a regulator by

any external tubing.

Pressure Pilots

(SPRING AND AIR)

Remove the pilot from the main valve. In order to determine the malfunction before disassembling the valve, hook

the pilot to air and test. Attach shop air to the pilot inlet,

install a line with a shutoff valve and a pressure gauge at

the pilot outlet and plug the feed back port.

Page 2

Pressure Pilot Test

Pressure Pilot Repair

SEAT AND BALL LEAKAGE

Release the loading force. (Spring tension or air presure).

Open the inlet and outlet valves.

LOOK FOR: Leakage at the outlet, allow only a

very small leakage.

INDICATES: Seat and Ball are worn or held

open by dirt.

ACTION: Clean parts and retest, replace

parts if cleaning fails.

STICKING VALVE MOVEMENT

Close the outlet valve and adjust outlet pressure to half of

the inlet. Open and close the outlet valve several times.

LOOK FOR: Outlet pressure on valve closure,

the pressure should be approximately the same each time.

INDICATES: Moving parts are sticking.

ACTION: Clean parts and retest,

replace parts if cleaning fails.

DIAPHRAGM DAMAGE

Close the outlet valve pressurizing the downstream side

of the pilot.

LOOK FOR: Leakage to atmosphere at spring

button and cover or middle

diaphragm case vent, allow none.

INDICATES: Broken diaphragms.

ACTION: Replace diaphragms.

The instructions describe how to disassemble and rebuild

a pilot. For assembly the steps are reversed. Please note

that if the air test has indicated a specific problem some

of the steps may be skipped. For example, if the test

indicates a bad diaphragm, there is no need to open the

cover at the other end.

1. Unbolt Lower Cover.

REASSEMBLY TORQUE 175 in-lb.

2. Remove; Screen, Spring Ball Button, Ball and Stem.

Stem should drop out when the valve is inverted.

3. Clean the parts and inspect for wear on seat, ball and

stem. If there is no wear and it appears dirt was the

problem, assemble and retest the valve.

4. On the Spring Pilot remove the nuts and washers,

yoke, spring and spring button.

4a. On the air pilots unbolt the large diaphragm case.

Remove the case, diaphragms and button.

REASSEMBLY TORQUE 425 in-lb.

5. Move the pilot valve diaphragm button up and down

by hand. Movement should be smooth and free.

6. Unbolt the diaphragm cover. Remove it and the

diaphragm button.

REASSEMBLY TORQUE 175 in-lb.

7. Lift off the diaphragms and inspect for damage.

USE NEW DIAPHRAGMS FOR REASSEMBLY.

8. Lift out the cup and unthread the seat.

ASSEMBLY - THREAD IN UNTIL SEAT BOTTOMS.

9. Clean all gasket and diaphragm sealing surfaces. Use

steel wool or fine (400 grit) paper to clean diaphragm

seal areas.

IF PILOT PASSES

If the pilot valve passes the above tests it is functional

and the problem is somewhere else, proceed to main

valve.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. HS-613B October 2012 Part No. 514306

10. Clean all parts before reassembly. Polish sliding

surface with steel wool until movement is free.

REPLACE ALL WORN PARTS.

11. Reassemble the valve. Insert seat gasket and apply

non-hardening sealant to seat threads. Start at number 8

above and work backwards.

REASSEMBLY COMPLETED

When the assembly is completed retest with air.

Loading...

Loading...