Page 1

USER MANUAL

V2.0

(FOR FIRMWARE V2.0)

SDI-12 RADAR

WATER LEVEL SENSOR

D36 0514

Page 2

CONTENTS & WARRANTY

Warranty.................................................................................1

Chapter 1: Introduction.......................................................2

Features................................................................................

Built-in LCD Display............................................................

Communications.................................................................

Fast Mode Data Logging....................................................

“NOAA” Mode measurement............................................

Fast Measure Mode............................................................

FCC Approval......................................................................

Chapter 2: Installation & Maintenance............................6

Installation Techniques.......................................................

General Installation Recommendations...........................

Mounting the Radar Unit - Vertical Alignment................

Making Connections..........................................................

Grounding Your Radar.......................................................

Over Cable.....................................................................

Wireless Radio..............................................................

Connecting Your Data Logger.........................................

Programming Your SDI-12 Data Recorder.....................

Programming the SDI-12 Interface.................................

Setup and Test Procedure...............................................

Programming the Radar Sensor......................................

Built-in LCD Display..........................................................

Chapter 3: SDI-12 Command & Response Protocol...17

Command Summary.........................................................

Measure Command..........................................................

“aM1” (NOAA) Measure Command...............................

“aM2” 1 Minute Average Measure Command..............

“aM3” 15 Second Average Measure Command...........

Concurrent Measurement Command............................

Concurrent “aC1!” Command.........................................

Concurrent “aC2!” Command.........................................

Send Data Command......................................................

Measurements with CRC.................................................

Continuous Measurements.............................................

Send Acknowledge Command......................................

Initiate Verify Command..................................................

Send Identification Command........................................

Change Sensor Address Command..............................

Extended Set_Current_Stage Command......................

Extended Read/Write Stage_Offset and Stage_Slope.

Extended Read Number_of_Measurements.................

Extended Write Number_of_Measurements................

Extended “XTEST”.............................................................

Chapter 4: Appendix.........................................................35

Appendix A: Specifications.............................................

Appendix B: FCC Equipment Authorization.................

3

4

4

4

4

5

5

7

8

8

9

9

9

11

12

13

13

13

14

15

19

19

21

23

24

25

26

26

27

28

28

28

28

29

30

31

31

33

33

34

36

37

Page 3

Contents & Warranty

“WATERLOG™ PRODUCTS MANUFACTURED BY YELLOW SPRINGS INSTRUMENTS CO., INC.

are warranted by Yellow Springs Instruments Co., Inc. (“YSI”) to be free from defects in materials

and workmanship under normal use and service for twelve (12) months from date of shipment

unlessotherwise specified in the corresponding YSI pricelist or product manual.

WaterLOG™ products not manufactured, but that are re-sold by YSI, are warranted only to the

limits extended by the original manufacturer. Batteries, desiccant, and other consumables have

no warranty. YSI’s obligation under this warranty is limited to repairing or replacing (YSI’s option)

defective products,which shall be the sole and exclusive remedy under this warranty.

The customer shall assume all costs of removing, reinstalling, and shipping defective products to YSI.

YSI will return such products by surface carrier prepaid within the continental United States of America.

To all other locations, YSI will return such products best way CIP (Port of Entry) INCOTERM® 2010,

prepaid. This warranty shall not apply to any products which have been subjected to modification,

misuse, neglect, improper service, accidents of nature, or shipping damage. This warranty is in lieu

of all other warranties, expressed or implied. The warranty for installation services performed by YSI

such as programming to customer specifications, electrical connections to products manufactured by

YSI, and product specific training, is part of YSI’s product warranty. YSI EXPRESSLY DISCLAIMS AND

EXCLUDES ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. YSI is not liable for any special, indirect, incidental, and/or consequential damages.”

A complete TERMS AND CONDITIONS OF SALE can be viewed at:

http://www.ysi.com/terms-and-conditions.php

This user manual is a guide for the H-3611/12/13 Radar Level Series

. For more information, updated

manuals, brochures, technical notes, and supporting software on the H-3611/12/13 Radar

refer to waterlog.com/radar or contact your sales representative.

For additional assistance, please contact us at +1.435.753.2212 or sales@waterlog.com

, please

1

Page 4

01 /

INTRODUCTION

2

Page 5

Introduction

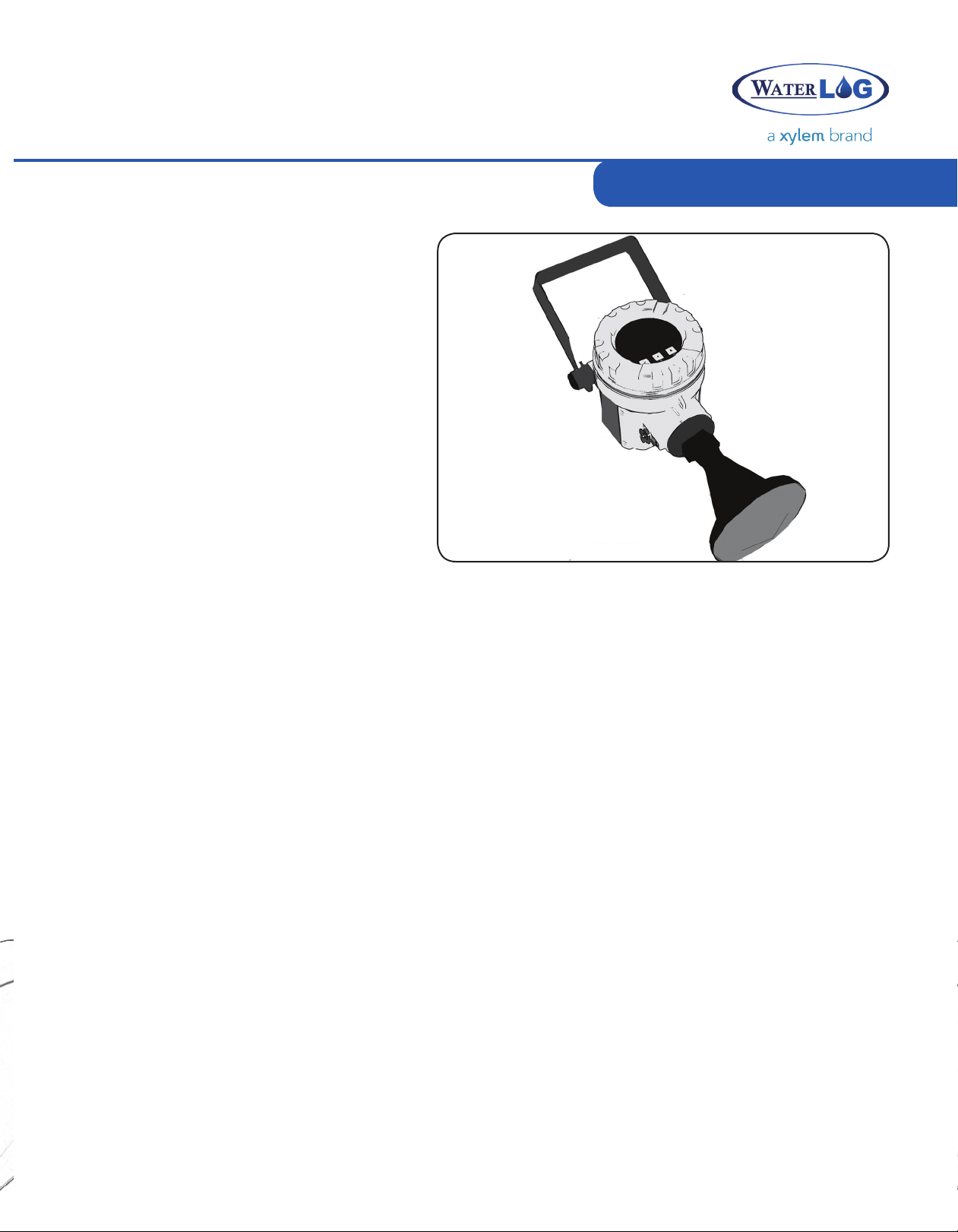

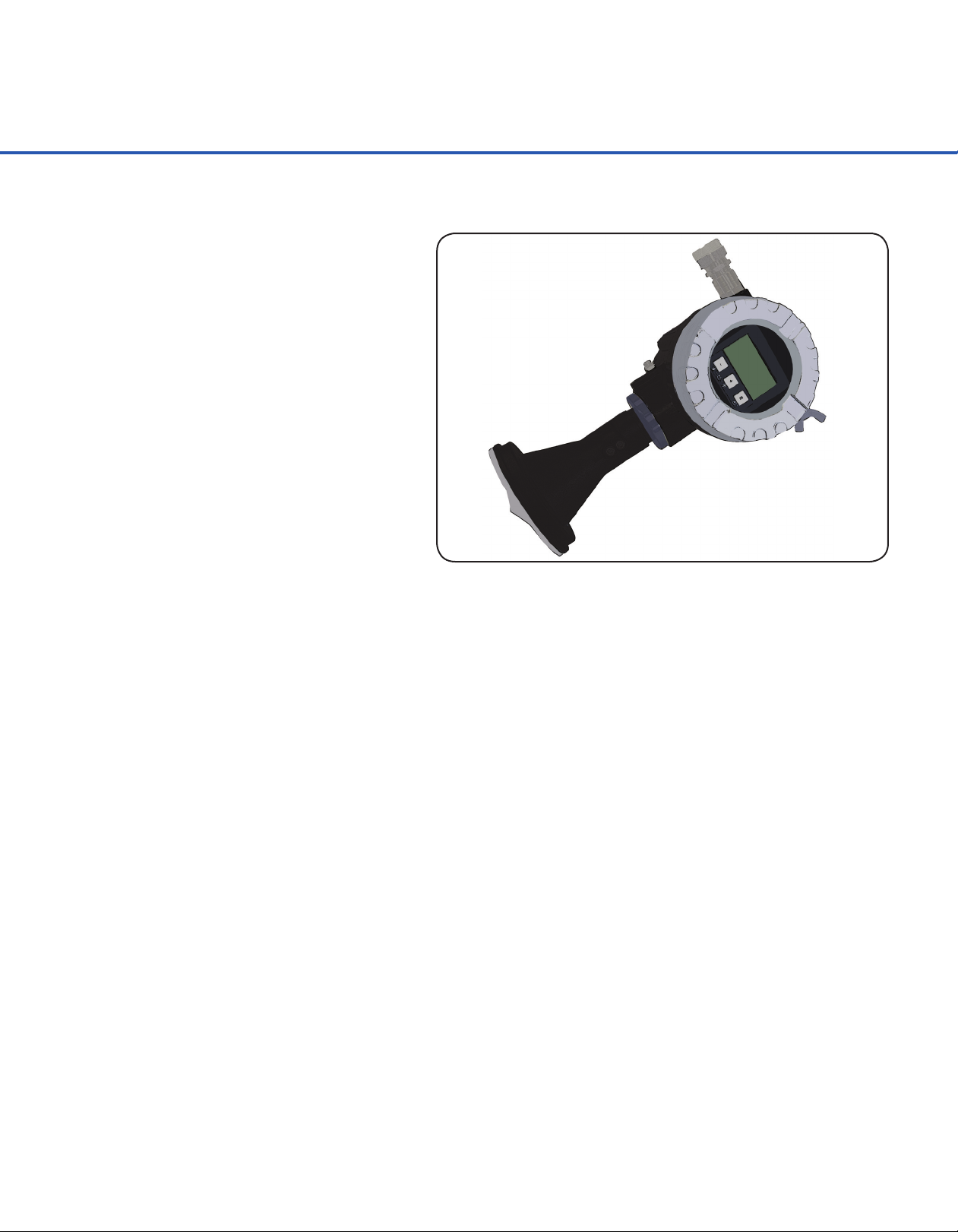

The WaterLOG® Radar Series consist of

the H-3611, H-3612 and H-3613 products.

Typical applications include non-contact

measurement of river, lake and reservoir

water level. The sensor makes multiple

distance measurements, averages the

results and converts the measurement

data into Stage in units of Feet, Meters or

other engineering units.

The Radar Series is easy to use and works

with any data recorder/logger with a SDI12 interface. They are powered from the

+12V wire of the 3-wire SDI-12 bus. The

Serial-Digital Interface (SDI-12) is ideal

for data logging applications with the

following requirements:

Battery powered operation with minimal current drain

•

• Measurement data is transmitted digitally over long cable lengths without error

• Multiple sensors on a simple three-wire cable

• Up to 250 feet of cable between a sensor and the data recorder (Use of an H-423, SDI-12 to RS485 or an

H-4500 fiberoptic media converter extends the range to 1000’s of feet)

Features

Below is a quick overview of the common features of all Radar series products.

•

Simple to install, use, and maintain

• Non-contact level measurement eliminates the need for stilling wells and other infrastructure.

• Undamaged by ice, logs or debris

• ±3.0mm accuracy with standard model

• -40 ° C to +80 ° C operation

• NEMA 4x enclosure is suitable for outdoor installations

• Stainless steel horn (H-3611/ H-3612)

• Frequency range - approx 26 Ghz

• Built-in LCD screen for monitor and setup

• Low current operation (8.0 mA typical standby)

• Continuous operation, no warmup or “lock on” needed

• Extended SDI-12 commands for setting the Stage to the current water elevation.

• Built in 3 or 6 minute “NOAA” mode measurements.

• Optional fast mode sends the service request within 55mS for sustained 1-second data logging.

Description

The Radar Level gauge consists of an integrated microwave transmitter and sensor together with a

horn antenna. The horn antenna serves to focus the transmitted signal as well as to receive the

reflected echo. A built-in SDI-12 interface provides low power operation, data processing and

SDI-12 communications with the data logger.

3

Page 6

INTRODUCTION

Built-in LCD Display

The Radar sensor has a built-in LCD

display which normally shows Distance

(distance from the radar unit to the

water). The display has three buttons and

can be used to monitor or edit the radar

unit configuration. The LCD display has

a short cord and can be detached from

the radar housing for convenience.

Communications

The Radar sensor is a stand-alone

instrument that provides an SDI-12

output for communications with a

datalogger. The sensor is supplied with

a liquid-tight fitting and two 6- foot cables. One cable is convenient for making connections to

your data logger, the second cable used to connect to a laptop computer when using the TofTool

configuration and diagnostic program.

Fast Mode Data Logging

The Radar response to an “aM!” command is “0044” (4-seconds, 4-parameters). The actual

measurement completes very quickly and the service request is sent within 530ms. The reported

4-second value allows time for retries when troubleshooting the internal connection between the

SDI-12 interface and the radar unit. Unfortunately most data loggers cannot sustain a 1-second

logging interval even if the sensor responds within 500mS. For making measurements at a

sustained 1-second measurement interval two options are available as explained below.

“NOAA” Mode Measurement

The Radar supports the “aM1” measurement. The H-3611 internally performs the following

measurement sequence.

1. Makes 181 measurements at a precise 1 second interval.

2. Computes the standard deviation for the data set.

3. Multiplies the standard deviation by 3 to obtain a High and Low outlier threshold.

4. Sifts through the data set and discards data points above and below the outlier thresholds.

5. Computes the standard deviation again for the data set with the outliers removed.

The standard deviation is computed as follows:

1. Compute the mean for the data set

2. Compute the deviation by subtracting the mean from each value

3. Square each individual deviation

4

Page 7

Introduction

4. Divide by one less than the sample size

5. Take the square root

The “aM1” command response is “01844” (184 seconds, 4- parameters). The sensor buffer will

contain 4 parameters; mean, standard deviation, number of outliers and battery voltage.

If the built in “NOAA” mode is not workable, the H-3611 supports an alternate “fast measure”

mode.

Fast Measure Mode

Normally, the Radar transmits the service request within 530mS of receipt of the command. As

with many data loggers, this leaves insufficient time to sustain continuous measurements once

per second. The Power_Mode is an internal setting which places the H-3611 in a fast measure

mode. In this mode, the Radar is always awake and automatically collecting data from the

radar unit at a 1-second interval and stores the previous six minutes of data in the stack. In this

mode the sensor uses additional power. When an “aM!” measurement is received, the sensor

response is “0014” (1-seconds, 4-parameters). The service request is sent within 55mS of receipt

of the command (170mS of receipt of the break). This leaves plenty of time for a data logger to

collect the data while sustaining a 1-second logging interval. The data placed in the sensor buffer

is the results of the previous internal measurement (1-second old). The data logger must

implement its own internal NOAA or other filtering and averaging computations.

When in fast measure mode the radar makes continuous measurements which allows a different

type of NOAA mode measurement to take place. When in fast measure mode the “aM1!”

command is replaced with a command that takes the data from the previous six minutes and

performs the same procedure as the NOAA mode measurements, namely:

1. Collect a set of 1-Hz samples centered in the previous six minute time block, the

length of which is selected by the user (ranging from 1-360)

2. Computes the standard deviation for the data set.

3. Multiplies the standard deviation by 3 to obtain a High and Low outlier threshold.

4. Sifts through the data set and discards data points above and below the outlier thresholds.

5. Computes the mean and standard deviation again for the data set with the outliers removed.

In addition to the “aM1!” command, the “aM2!” and “aM3!” commands have been added which

take the simple average and standard deviation of the previous 1 minute and 15 second data sets

respectively. All of these commands have concurrent counterparts as well.

FCC Approval

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

5

Page 8

INSTALLATION

02 /

& MAINTENANCE

6

Page 9

Installation & Maintenance

The Radar is a time-of-flight microwave radar level sensor. It excels in applications where ice, logs,

floating debris and boat traffic can damage stilling wells and other infrastructure. When installed

on a bridge over shallow streams having sandy bottoms the radar can be moved from location to

location as the river shifts channel position after storm events.

Installation Techniques

For installations where vandalism is of concern or additional protection is needed, many users

prefer to install the radar unit in a protective housing. The housing provides a convenient location

for installing other gauge station equipment such as a battery or data logger. Several housings

are available from WaterLOG, please contact the factory for further information. WaterLOG also

offers optional installation packages that have a solar panel, battery and short range

telemetry radio for communicating with a nearby gauge station.

Several typical installations are shown below.

7

Page 10

INSTALLATION & MAINTENANCE

General Installation Recommendations

Before proceeding with the installation, please consider several site preparation and maintenance

issues. The Radar Series has been designed to operate safely in accordance with current technical,

safety and EU standards. Personnel must be authorised and suitably qualified. The manual must

have been read and understood, and the instructions followed.

Warning: Working over water or on tall structures can be dangerous. Use a safety harness,

fall arrest device, life saver and/or other safety equipment when conditions warrant.

Follow these guidelines when selecting a location for the radar gauge:

• The radar unit is a precision instrument and should not be jarred or dropped.

• The sensor must be mounted rigidly to prevent movement from wind and vibration.

• The antenna horn must be aligned within 1 ° of vertical to prevent trigonometric measurement errors.

• Make certain the sensor is mounted high enough to avoid being submerged during high water or ood

conditions.

• The sensor is rated NEMA 4x and can be mounted outdoors in unprotected locations.

• The operating temperature range for the sensor is –40 ° C to 80 ° C.

• The sensor should be mounted above the smoothest portion of the water surface. Generally between piers

of a bridge structure. However on bridges with long spans between the piers there will be more vibration

on the bridge. To moderate the vibration in these situations mount the radar 1/4 to 1/3 the span distance

from the pier.

• There should be a clear path between the sensor and the water to avoid false reections. Try to locate the

sensor to keep the beam path (8 ° for 4-inch horn, 10 ° for 3-inch horn) clear of excessive turbulence,

splashing, waves, pipes, wires and other obstructions.

• Avoid submerged obstructions such as rocks or bridge piers that disturb or distort the water level.

• The mounting location should also avoid horizontal structural surfaces such as beams, brackets, and side

wall joints because these surfaces tend to reflect a strong false signal. If these cannot be avoided the display

can be used to map the radar beam profile and optimize the profile by means of electronic suppression of

interference echoes.

• Be aware that bridges and other large structures expand and contract with temperature. The bridge height

can change a few inches with diurnal temperature changes. Trucks and other traffic loads can cause transient

changes to the bridge height.

Mounting the Radar Unit - Vertical Alignment

Make certain the horn antenna is aligned within 1 ° of vertical. If the antenna is not vertical a

trigonometric measurement error with respect to the water will occur and the maximum range will

be reduced due to the off-axis return signal.

8

Page 11

Installation & Maintenance

Making Connections

Since the Radar can be exposed to the

sun and weather, a cable rated for water

immersion (rain) and sunlight resistance

is required. A polyurethane or similar

sunlight and waterproof rated cable is

recommended. Do not use utility PVC

or other wiring materials which can

become brittle or crack when exposed to

ultraviolet radiation from the sun.

If conduit is used to connect to the Radar,

remove and discard the liquid-tight cord

retainer. If metal conduit is used, the

conduit must be grounded. When using

conduit the entry must be sealed with

silicone or other sealant to prevent moisture from entering the Radar enclosure via the conduit piping.

The thermal mass of the casting will cause water vapor to internally condense and accumulate with

changes in the weather.

Caution: Remove all power from the unit before making any connections.

Liquid Tight Fitting

SDI-12 Connections

Warning: All wiring must be done by qualified individuals in accordance with applicable

codes such as the ANSI/NFPA 70 specifications or the

Canadian Electrical Code Part 1.

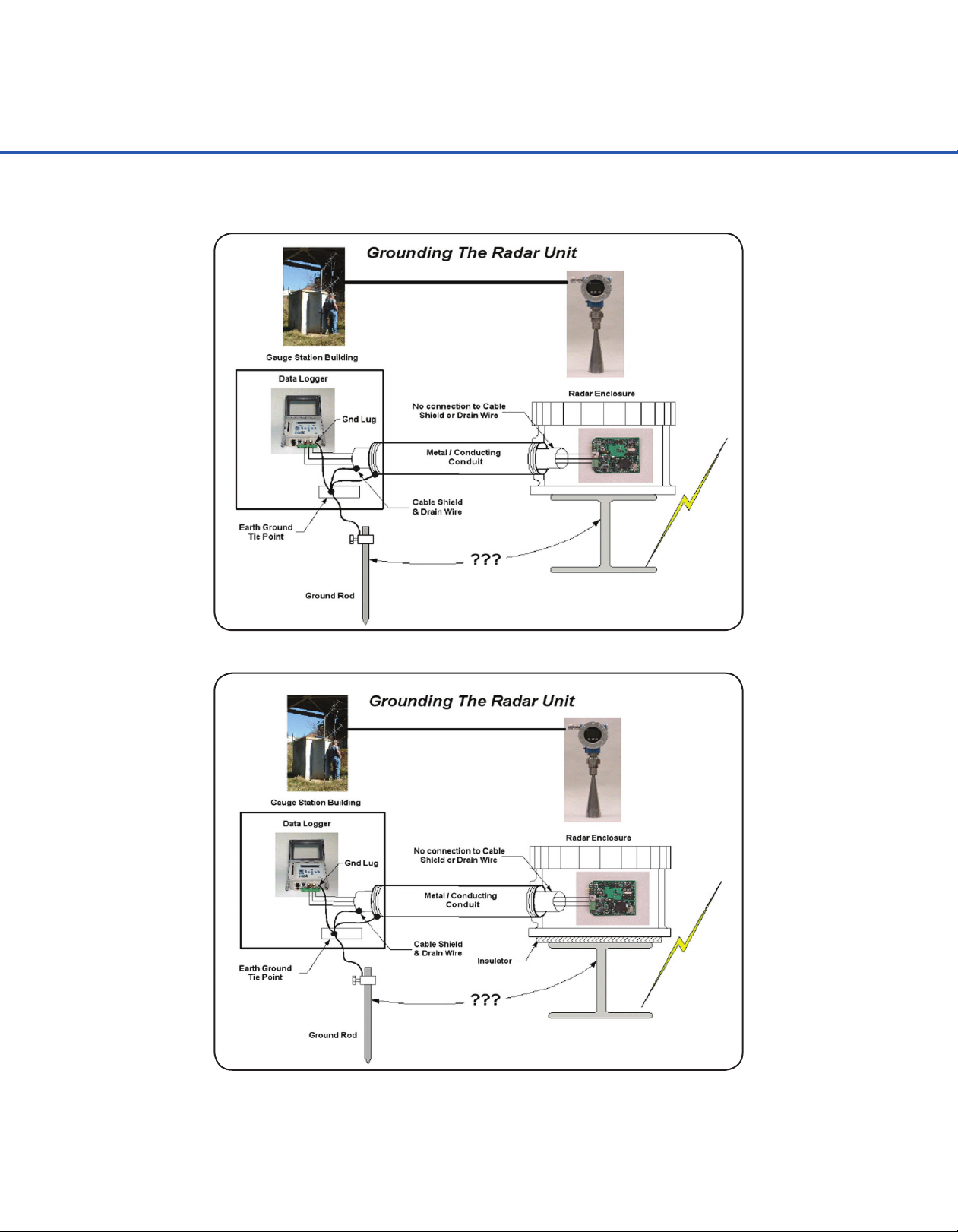

Grounding Your Radar

The following graphic illustrations are the recommended methods for grounding the Radar. These

grounding methods will work if the guidelines are strictly followed. It should be mentioned that not

much can protect your site if it suffers a direct lightning strike. However, these general grounding

techniques can certainly help protect the equipment from normal occurrences. It is hoped that this

information will serve as a reference guide to grounding your Radar.

Grounding Your Radar Over Cable

Grounding the Radar is a simple yet subtle thing to do. Figures on page 10 show the preferred

methods for grounding a radar gauge over a cable. A metal conduit is to be used. If junction

boxes or pull boxes are used, they are to be metal as well. The metal conduit will provide a

conducting path to ground for the radar enclosure and also act as a shield that will conduct away

electrical noise. If a flex conduit is used at the radar enclosure or at the gauge house, this

conduit must be a conducting type of conduit. Note: you must also use a conducting

connector for conducting flex conduit. The electrical cable is to have a shield and at least 3

conductors. The wire conductor gauge of 20awg is recommended for most applications, but

you may certainly use 18 or 16 gauge conductors as well.

9

Page 12

INSTALLATION & MAINTENANCE

Layout of Hard Wire Radar Installation

10

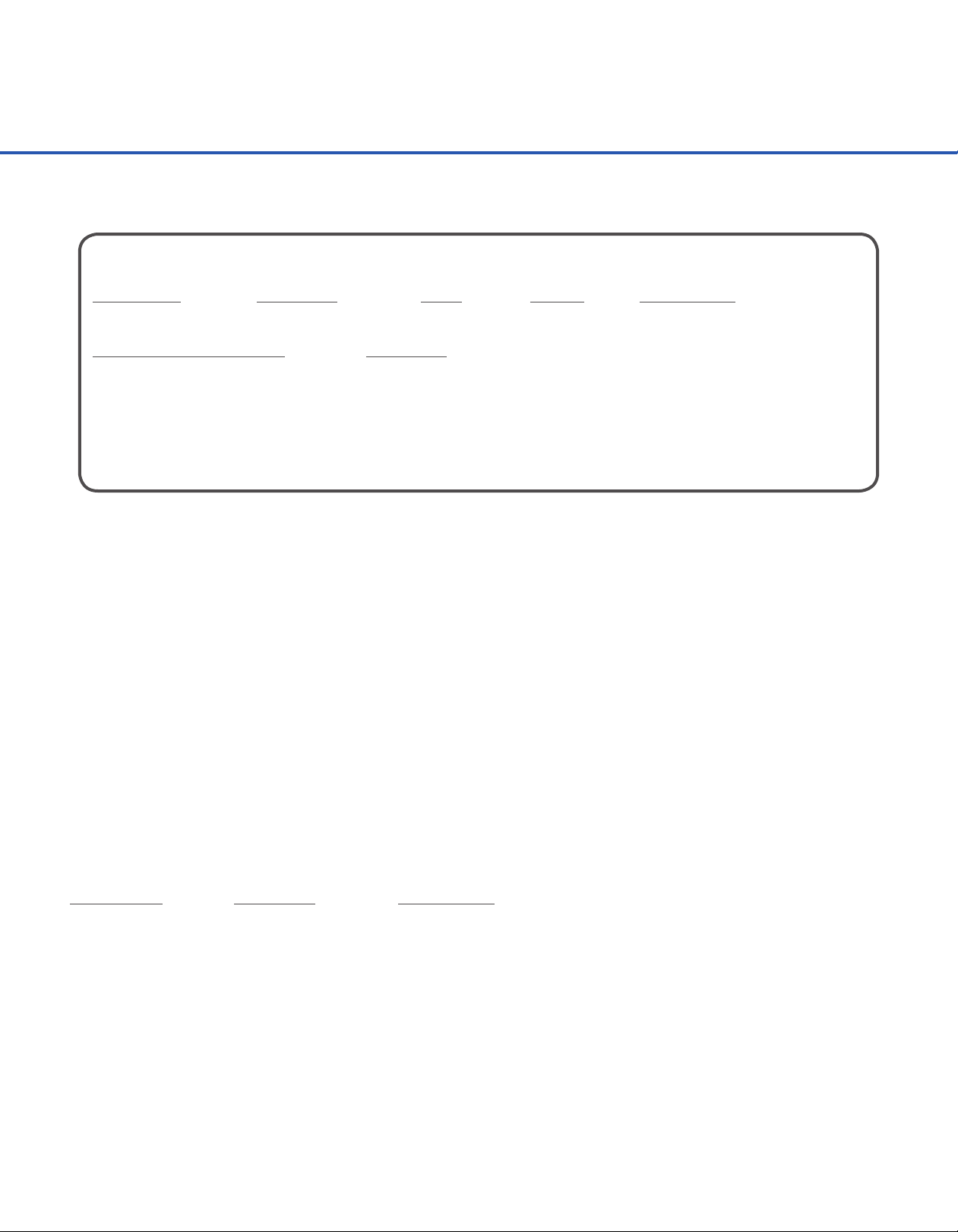

Layout of Hard Wire Radar Installation with Insulator

Page 13

Installation & Maintenance

The main difference between the figures on page 10, is that the radar enclosure in the second

figure is insulated from the bridge structure. Typically bridges are constructed of steel and other

conducting materials which act as very good earth grounds. The insulator in this picture could be

the concrete you are mounting the radar to or some other nonconducting surface. You can also

choose to use a piece of nonconducting material to mount the radar to. Using this type of

installation, the same rules are followed for both. You must provide a metal conducting conduit

from the enclosure all the way back to the gauge house. No earth grounding is done at the radar.

All earth ground connections are made at the gauge house. Using these techniques will help

solve many of your grounding related issues.

Grounding Your Radar Using a Wireless Radio

This type of equipment installation by its nature is ideal, because the cabling that causes many of

the grounding problems has been removed. The cable has been replaced by a radio transmitter/

receiver pair. Thus there is no common powering or grounding required between these two

systems. All the equipment at the remote end or radar installation is connected to a local battery,

and there are no long cables and conduit to deal with or grounding issues that need to be

worked out. This type of installation electrically isolates the remote radar equipment from the

datalogger equipment. Thus, lightning and other electrical events will have little effect on this

type of installation.

Radio Bridge

11

Page 14

INSTALLATION & MAINTENANCE

Remember that grounding should be simple. If your system grounding is getting complicated,

something is wrong. The purpose of grounding is to remove ground loops. Ground loops without

getting into a technical physics discussion, are the source of most equipment field failures. At the

gauge house, use a simple Single Point Ground as shown in the above illustrations. Remove any

multiple or redundant ground wires. Keep your wires neat and clean. Things that look good seem

to work good.

Connecting Your Data Logger

The Radar is supplied with a 6-foot, 4-conductor polyurethane cable for making convenient

connections to your data logger. The cable is routed thru a liquid tight cord connector on the radar

housing and is waterproof and sunlight resistant. The Radar is a SDI-12 V1.3 compliant sensor and

connects directly to any data recorder with SDI-12 capability.

4-Conductor Cable

Color Function

Red

White

Black

Green

If the 6-foot cable is unsuitable for your application it may be removed and replaced with a longer

cable. Internal to the radar housing, the SDI-12 interface module has a removable 3-position

connector for making the SDI-12 connections. The SDI-12 connections provides both +12V power

and SDI-12 serial data communications. You will need a 1/8 inch blade screwdriver to connect the

wires to the plug-in connector. The connections inside the radar housing may be accessed with the

following procedure:

1. Disconnect the power supply

2. Unscrew the housing cover (the round casting with the glass window). Do not contaminate

or dislodge the o-ring seal in the cover

3. Remove and unplug the LCD display module

4. Remove the cover plate from the terminal compartment

5. Disconnect the 3-position green connector

6. Loosen the nut on the liquid tight connector

7. Unseat (loosen) the rubber grommet in the liquid tight connector

8. Remove the existing 4-conductor cable

+12V Power

SDI-12 Data

Gnd

Gnd

If your cable has a dedicated ground wire, connect it to the internal ground screw on the bracket

(the bracket is grounded to the enclosure).

NOTE: This device must not include, or make provisions for, the use of battery chargers which permit

operating while charging, AC adapters or battery eliminators and must not connect to the AC power lines

indirectly, obtaining power through another device.

12

Page 15

Installation & Maintenance

Programming Your SDI-12 Data Recorder

You must prepare your data recorder to receive and record the Radar data. Since data recorders

differ widely, refer to your data recorder manufacturer’s directions. In general, program the data

recorder to input four values via the SDI-12 port. Usually only one or two of the parameters are

actually recorded. Your data recorder must issue an “aM!” command, then collect the data with a

“aD0” command, as explained in Chapter 3. The Radar places four parameters in its data buffer:

a+AA.AAA+BB.BBB+CC+DD.D<cr><lf>

Where:

a = SDI-12 address 0-9, A-Z

AA.AAA = Stage (feet, inches, meters etc.)

BB.BBB = Distance (feet, i.e. raw radar measurement)

CC = Measurement Status (0 = success)

DD.D = Power Supply Voltage (Volts)

Programming The SDI-12 Interface

The radar unit measures the distance between the mounting flange of the horn to the water surface.

The SDI-12 interface (internal or external) processes the raw Distance measurement with a Stage

= m * Distance + b equation. The Slope (m) and Offset (b) terms are programmable, allowing the

user to scale the reading into other engineering units. The Radar comes from the factory with the

following settings:

SDI Address: 0

Slope: -1.0

Offset 0.0

With these values the Stage measurement data will be in units of feet. The reason for a negative

slope is that the radar measures Distance, as the water rises Distance decreases. These setups are

stored in FLASH memory within the Radar and will not be lost if the power is disconnected. The

extended commands for changing the address, slope and offset are described in detail in Chapter 3.

If more than one sensor is to be connected to the SDI-12 bus, make certain each sensor has a unique

address.

Setup and Test Procedure

Step 1:

Double check all wiring connections. Connect the Radar to your data recorder and apply +12V

power.

Step 2:

The Radar comes from the factory with it’s SDI-12 address set to “0”. Verify the Radar is responding

by issuing a “0I!” Send Identification command. If more than one sensor is to be connected to the

SDI-12 bus, make certain each sensor has a different sensor address. If needed, the address can

be changed with an SDI-12 command (see Chapter 3).

13

Page 16

INSTALLATION & MAINTENANCE

Step 3:

Make several measurements (“aM!” and “aD0!”) and verify the Distance measurement is correct.

Do not be concerned if the Distance measurement is several inches in error, the radar sensor may

have a small distance offset and it’s often difficult to directly measure between the mount flange

and the water surface . The Distance value is continually displayed on the built-in LCD display.

Step 4:

With the Slope set to -1.0 the Stage will be in units of feet. If other engineering units are wanted

change the Slope as described in Chapter 3.

Step 5: Setting the Stage

When the Radar is first installed, you will want to adjust the Offset such that the SDI-12 measurement

data (Stage) corresponds to the current water elevation or stage as determined with a staff gauge

or other datum.

An extended SDI-12 command is convenient to quickly set the Radar Stage reading to match the

current water level. The “aXSCSdd.d!” command causes the Radar to make a fresh measurement and

automatically update the Offset as needed to produce the desired Stage. See Chapter 3 for details.

Example of a H-3611 Extended “Set Current Stage” command:

Command Response Time Values Description

“aXSCS2.3!” “a0041<cr><lf>” 4sec 1 Set the Stage to 2.3

Subsequent Command Response Description

“aD0” a+12.80<cr><lf> The new Offset

Step 6:

Make several measurements and make certain the Stage reading is correct and the measurements

are stable for the current water level and conditions.

If available, a H-4191 SDI-12 to RS-232 interface can be used to observe the “XTEST” mode.

The “XTEST” mode causes the Radar to transmit unsolicited real-time data for testing purposes. The

test mode is used to help troubleshoot the installation by providing a continuous readout of sensor

data. This is not compliant with the SDI-12 specification and is not used with data loggers.

Programming the Radar Sensor

The radar unit has many setups and configurations including measurement units, max/min distance,

averaging and media conditions. For most users the Radar comes from the factory pre-configured

for most hydrological applications and can be used “out of the box”. For special applications and

when performing maintenance and diagnostics the radar unit configuration can be monitored and

changed by either the built-in LCD display or a Windows™ based PC program called TofTool (Time-

Of-Flight-Tool)

14

Page 17

Built-in LCD Display

The built-in LCD display normally displays

Distance (distance from the radar unit to

the water). The display has three buttons

and can be used to monitor and edit the

radar unit configuration. To access the

display, unscrew the housing cover (the

round casting with the glass window).

Take precautions to not contaminate or

dislodge the o-ring seal in the cover. The

LCD display has a short cord and can be

detached from the radar for convenience.

Each function menu has a Function Group

and Function number in the upper right

hand corner of the screen. Together they

provide orientation within the menu map.

Installation & Maintenance

15

Page 18

INSTALLATION & MAINTENANCE

The radar unit supports other configurations such as tank volume gauging which are not used for

stream gauging applications. When using the LCD setup menus, be careful to not indiscriminately

alter the setup parameters. For special applications or problematic installations such as having false

echoes from a bridge pier please contact WaterLOG for advice.

16

Page 19

SDI-12 COMMAND &

03 /

RESPONSE PROTOCOL

17

Page 20

SDI-12 COMMAND & RESPONSE

This is a brief description of the Serial Digital Interface (SDI-12) Command and Response Protocol

used by the WaterLOG® Radar Series. Included is a description of the commands and data format

supported by the Radar.

Refer to the document "A SERIAL DIGITAL INTERFACE STANDARD FOR HYDROLOGIC AND

ENVIRONMENTAL SENSORS". Version 1.3 January 12, 2009 Coordinated by the SDI-12 Support

Group, 135 East Center, Logan, Utah.

During normal communication, the data recorder sends an address together with a command to

the Radar SDI-12 sensor. The Radar then replies with a "response." In the following descriptions,

SDI-12 commands and responses are enclosed in quotes. The SDI-12 address and the command/

response terminators are defined as follows:

“a” Is the sensor address. The following ASCII Characters are valid addresses:

“0-9”, “A-Z”, “a-z”, “*”, “?”. Sensors will be initially programmed at the factory with

the address of “0” for use in single sensor systems. Addresses “1 to 9” and “A to

Z” or “a to z” can be used for additional sensors connected to the same SDI-12

bus. Address “*” and “?” are “wild card” addresses which select any sensor,

regardless of its actual address.

“!” Is the last character of a command block.

“<cr><lf>” Are carriage return (0D) hex and line feed (0A) hex characters. They are the last

two characters of a response block.

Notes:

• All commands/responses are upper-case printable ASCII characters.

• Commands must be terminated with a “!” character.

• Responses are terminated with <cr><lf> characters.

• The command string must be transmitted in a contiguous block with no gaps of more than 1.66 milliseconds

between characters.

To enhance the error detection capability in SDI-12 data collection systems, a variation of the Start

Measurement Commands (M!, M1! ... M9!), Start Concurrent Measurement Commands (C!, C1! ...

C9!), and Continuous Measurement Commands (aR0! ... aR9!) request that the data be returned

with a 16 bit Cyclic Redundancy Check (CRC) appended to it. These commands use the existing

command letters with a C appended, namely: aMC!, aMC1! ... aMC9!, aCC!, aCC1! ... aCC9!, and

aRC0! ... aRC9!. When these commands are used, the data returned in response to the D commands,

or R commands, have a CRC code appended to it.

18

Page 21

SDI-12 Command & Response

Command Summary

The Radar supports the following SDI-12 commands:

Standard Commands:

aM! Make measurement

aM1! Make NOAA measurement

aM2! Make 1 minute average measurement

aM3! Make 15 second average measurement

aD0! Send Data

aV! Verify

aI! Send Identification

a! Send Acknowledge

aAn! Change Address

Extended Commands:

aXRS! Read Slope

aXWSnn! Write Slope

aXRO! Read Offset

aXWOnn! Write Offset

aXRPM! Read Power Mode (0=Sleep, 1=Fast Measure)

aXWPMn! Write Power Mode (0=Sleep, 1=Fast Measure)

aXWNM! Write the number of measurements used in the fast mode “aM1” command

aXRNM! Read the number of measurements used in the fast mode “aM1” command

aXTEST! Displays the current settings, then displays data at a fast rate

aXHELP! Displays the supported commands

Measure Command

The Measure Command causes a measurement sequence to be performed. Data values generated

in response to this command are stored in the sensor’s buffer for subsequent collection using “D”

commands. The data will be retained in the sensor until another “M”, “ C”, or “V” command is

executed.

Command Response Description

“aM!” “atttn<cr><lf>” Initiate measurement

Where:

a is the sensor address (“0-9”, “A-Z”, “a-z”, “*”, “?”).

M is an upper-case ASCII character

ttt is a three digit integer (000-999) specifying the maximum time, in seconds, the sensor

will take to complete the command and have measurement data available in its buffer.

n is a single digit integer (0-9) specifying the number of values that will be placed

in the data buffer. If “n” is zero (0), no data will be available using subsequent “D”

commands.

19

Page 22

SDI-12 COMMAND & RESPONSE

Upon completion of the measurement, a service request “a<cr><lf>” is sent to the data recorder

indicating the sensor data is ready. The data recorder may wake the sensor with a break and collect

the data any time after the service request is received or the specified processing time has elapsed.

Example of an "aM!" command:

Command Response Time Values Description

"aM!" "a0044<cr><lf>" 4 sec 4 Make measurement

Note: The service request is normally sent within 530mS of receipt of the break.

Subsequent Command Response

"aD0" a+AA.AAA+BB.BBB+CC+DD.D<cr><lf>

Where:

AA.AAA = Stage (feet, inches, meters etc.)

BB.BBB = Distance (feet)

CC = Measurement Status:

0 = No errors

1 = 500ms response timeout

2 = Response overflowed the buffer

3 = No preamble FF's

4 = Missing start byte (delimiter)

5 = Wrong delimiter

6 = Wrong command byte

7 = Response code not zero

8 = Field Device Malfunction (Device Status = $80)

9 = Wrong byte count byte

10 = Not enough bytes received

11 = Frame parity error

DD.D = Power Supply Voltage (Volts)

Each SDI-12 data point or “measurement” is input from the radar subsystem. The “aM!” command

does not filter or average the measurement data. The radar unit internally processes raw distance

measurements with a damping factor and other filtering algorithms.

20

Page 23

SDI-12 Command & Response

“aM1” (NOAA) Measure Command

The Radar supports two different “aM1” measurement commands based on the Power Mode.

Data values generated in response to this command are stored in the sensor’s buffer for subsequent

collection using “D” commands. The data will be retained in the sensor until another “M”, “ C”,

or “V” command is executed.

When Power Mode = 0, the Radar internally performs the following measurement sequence:

1. Makes 181 measurements at a precise1.0 second interval.

2. Computes the standard deviation for the data set.

3. Multiplies the standard deviation by 3 to obtain a High and Low outlier threshold.

4. Sifts through the data set and discards data points above and below the outlier thresholds.

5. Computes the mean and standard deviation again for the data set with the outliers removed.

When Power Mode = 1, the Radar internally performs the following measurement sequence:

1. Collect a set of 1-Hz samples centered in the previous six minute time block, the length of

which is selected by the user (ranging from 1-360 data points)

2. Computes the standard deviation for the data set.

3. Multiplies the standard deviation by 3 to obtain a High and Low outlier threshold.

4. Sifts through the data set and discards data points above and below the outlier thresholds.

5. Computes the mean and standard deviation again for the data set with the outliers removed.

The standard deviation is computed as follows:

1. Compute the mean for the data set

2. Compute the deviation by subtracting the mean from each value

3. Square each individual deviation

4. Divide by one less than the sample size

5. Take the square root

Command Response Description

“aM1!” “atttn<cr><lf>” Initiate measurement

Where:

a is the sensor address (“0-9”, “A-Z”, “a-z”, “*”, “?”).

M is an upper-case ASCII character

ttt is a three digit integer (000-999) specifying the maximum time, in seconds, the sensor

will take to complete the command and have measurement data available in its buffer.

n is a single digit integer (0-9) specifying the number of values that will be placed in the

data buffer. If “n” is zero (0), no data will be available using subsequent “D” commands.

21

Page 24

SDI-12 COMMAND & RESPONSE

Upon completion of the measurement, a service request “a<cr><lf>” is sent to the data recorder

indicating the sensor data is ready. The data recorder may wake the sensor with a break and collect

the data any time after the service request is received or the specified processing time has elapsed.

Example of an "aM1!" command when Power Mode = 0:

Command Response Time Values Description

"aM1!" "a1844<cr><lf>" 184 sec 4 Make measurement

Note: The service request is normally sent within 182 seconds of receipt of the command. The

184-second value reported allows time for a few retries when communicating with the radar

subsystem.

Subsequent Command Response

"aD0" a+AA.AAA+BB.BBB+CC+DD.D<cr><lf>

Where:

AA.AAA = Stage (feet, inches, meters etc.)

BB.BBB = Standard Deviation (feet, inches, meters etc.)

CC = Number of outlier data points discarded

DD.D = Power Supply Voltage (Volts)

Example of an “aM1!” command when Power Mode = 1:

Command Response Time Values Description

"aM1!" “a0014<cr><lf>” 1 sec 4 Make measurement.

Subsequent Command Response

"aD0" a+AA.AAA+BB.BBB+CC+DD.D<cr><lf>

Where:

AA.AAA = Stage (feet, inches, meters etc.)

BB.BBB = Standard Deviation (feet, inches, meters etc.)

CC = Number of outlier data points discarded

DD.D = Power Supply Voltage (Volts)

22

Page 25

SDI-12 Command & Response

“aM2” 1 Minute Average Measure Command

The Radar only supports the”aM2” measurement command when the Power Mode = 1. Data

values generated in response to this command are stored in the sensor’s buffer for subsequent

collection using “D” commands. The data will be retained in the sensor until another “M”, “ C”,

or “V” command is executed.

When Power Mode = 0, the Radar returns “a0000” signifying the command is not supported in

this mode.

When Power Mode = 1, the H-3611 averages the data collected from the previous minute and

returns the mean and standard deviation

.

The standard deviation is computed as follows:

1. Compute the mean for the data set

2. Compute the deviation by subtracting the mean from each value

3. Square each individual deviation

4. Divide by one less than the sample size

5. Take the square root

Command Response Description

“aM1!” “atttn<cr><lf>” Initiate measurement

Where:

a is the sensor address (“0-9”, “A-Z”, “a-z”, “*”, “?”).

M is an upper-case ASCII character

ttt is a three digit integer (000-999) specifying the maximum time, in seconds, the sensor

will take to complete the command and have measurement data available in its buffer.

n is a single digit integer (0-9) specifying the number of values that will be placed in the

data buffer. If “n” is zero (0), no data will be available using subsequent “D” commands.

Upon completion of the measurement, a service request “a<cr><lf>” is sent to the data recorder

indicating the sensor data is ready. The data recorder may wake the sensor with a break and collect

the data any time after the service request is received or the specified processing time has elapsed.

23

Page 26

SDI-12 COMMAND & RESPONSE

Example of an “aM2!” command:

Command Response Time Values Description

"aM2!" “a0013<cr><lf>” 1 sec 3 Make measurement.

Subsequent Command Response

"aD0" a+AA.AAA+BB.BBB+CC.C<cr><lf>

Where:

AA.AAA = Stage (feet, inches, meters etc.)

BB.BBB = Standard Deviation (feet, inches, meters etc.)

CC.C = Power Supply Voltage (Volts)

“aM3” 15 Second Average Measure Command

The Radar only supports the”aM3” measurement command when the Power Mode = 1. Data

values generated in response to this command are stored in the sensor’s buffer for subsequent

collection using “D” commands. The data will be retained in the sensor until another “M”, “ C”, or “V”

command is executed.

When Power Mode = 0, the Radar returns “a0000” signifying the command is not supported in this

mode.

When Power Mode = 1, the Radar averages the data collected from the previous fifteen seconds

and returns the mean and standard deviation

The standard deviation is computed as follows:

1. Compute the mean for the data set

2. Compute the deviation by subtracting the mean from each value

3. Square each individual deviation

4. Divide by one less than the sample size

5. Take the square root

Command Response Description

“aM3!” “atttn<cr><lf>” Initiate measurement

Where:

a is the sensor address (“0-9”, “A-Z”, “a-z”, “*”, “?”).

M is an upper-case ASCII character

ttt is a three digit integer (000-999) specifying the maximum time, in seconds, the sensor

will take to complete the command and have measurement data available in its buffer.

n is a single digit integer (0-9) specifying the number of values that will be placed in the

24

data buffer. If “n” is zero (0), no data will be available using subsequent “D” commands.

Page 27

SDI-12 Command & Response

Upon completion of the measurement, a service request “a<cr><lf>” is sent to the data recorder

indicating the sensor data is ready. The data recorder may wake the sensor with a break and collect

the data any time after the service request is received or the specified processing time has elapsed.

Example of an “aM3!” command:

Command Response Time Values Description

"aM3!" “a0013<cr><lf>” 1 sec 3 Make measurement.

Subsequent Command Response

"aD0" a+AA.AAA+BB.BBB+CC.C<cr><lf>

Where:

AA.AAA = Stage (feet, inches, meters etc.)

BB.BBB = Standard Deviation (feet, inches, meters etc.)

CC.C = Power Supply Voltage (Volts)

Concurrent Measurement Command

A concurrent measurement is one which occurs while other SDI-12 sensors on the bus are also

taking measurements. This command is similar to the “aM!” command, however, the nn field has

an extra digit and the sensor does not issue a service request when it has completed the

measurement. Communicating with other sensors will NOT abort a concurrent measurement.

Data values generated in response to this command are stored in the sensor’s buffer for subsequent

collection using “D” commands. The data will be retained in the sensor until another “M”, “C”, or

“V” command is executed.

Command Response Description

“aC!” “atttnn<cr><lf>” Initiate measurement

Where:

a is the sensor address (“0-9”, “A-Z”, “a-z”, “*”, “?”).

C is an upper-case ASCII character

ttt is a three digit integer (000-999) specifying the maximum time, in seconds, the sensor

will take to complete the command and have measurement data available in its buffer.

nn is a two digit integer (00-99) specifying the number of values that will be placed in the

data buffer. If “n” is zero (0), no data will be available using subsequent “D” commands.

The data recorder may wake the sensor with a break and collect the data anytime after the specified

processing time has elapsed.

25

Page 28

SDI-12 COMMAND & RESPONSE

Concurrent “aC1!” Command

This command is similar to the “aM1!” command, however, the nn field has an extra digit and the

sensor does not issue a service request when it has completed the measurement. Data values

generated in response to this command are stored in the sensor’s buffer for subsequent collection

using “D” commands. The data will be retained in the sensor until another “M”, “C”, or “V”

command is executed.

Command Response Description

“aC1!” “atttnn<cr><lf>” Initiate measurement

Where:

a is the sensor address (“0-9”, “A-Z”, “a-z”, “*”, “?”).

C is an upper-case ASCII character

ttt is a three digit integer (000-999) specifying the maximum time, in seconds, the sensor

will take to complete the command and have measurement data available in its buffer.

nn is a two digit integer (00-99) specifying the number of values that will be placed in the

data buffer. If “n” is zero (0), no data will be available using subsequent “D” commands.

The data recorder may wake the sensor with a break and collect the data anytime after the specified

processing time has elapsed. This command may not work for some applications, as the data logger

must wait 1 second before collecting data, which may not work for applications requiring a faster

response.

Concurrent “aC2!” Command

This command is similar to the “aM2!” command, however, the nn field has an extra digit and the

sensor does not issue a service request when it has completed the measurement. Data values

generated in response to this command are stored in the sensor’s buffer for subsequent collection

using “D” commands. The data will be retained in the sensor until another “M”, “C”, or “V” command

is executed..

Command Response Description

“aC2!” “atttnn<cr><lf>” Initiate measurement

Where:

a is the sensor address (“0-9”, “A-Z”, “a-z”, “*”, “?”).

C is an upper-case ASCII character

ttt is a three digit integer (000-999) specifying the maximum time, in seconds, the sensor

will take to complete the command and have measurement data available in its buffer.

26

nn is a two digit integer (00-99) specifying the number of values that will be placed in the

data buffer. If “n” is zero (0), no data will be available using subsequent “D” commands.

Page 29

SDI-12 Command & Response

The data recorder may wake the sensor with a break and collect the data anytime after the specified

processing time has elapsed.

Send Data Command

The Send Data command returns sensor data generated as the result of previous “aM!”, “aM1!”,

“aC!”, or “aV!” commands. Values returned will be sent in 33 characters or less. The sensor’s data

buffer will not be altered by this command.

Command Response

“aD0!” through “aD9!” “apd.d ... pd.d<cr><lf>”

Where:

a is the sensor address (“0-9”, “A-Z”, “a-z”, “*”, “?”).

D0...D9 areupper-case ASCII character

p Is a polarity sign (+ or -)

d.d represents numeric digits before and/or after the decimal. A decimal may be

used in any position in the value after the polarity sign. If a decimal is not used,

it will be assumed to be after the last digit.

For example: +3.29 +23.5 -25.45 +300

If one or more values were specified and a “aD0!” returns no data (<CR><LF> only), it means that the

measurement was aborted and a new “M” command must be sent.

Example of an “aD0!” command:

Previous Command Response

"aM!" “a0044<cr><lf>”

Note: The service request is normally sent within 530mS of receipt of the break.. The 4-second

value reported allows time for a few retries when communicating with the radar subsystem.

Subsequent Command Response

"aD0" a+AA.AAA+BB.BBB+CC.C<cr><lf>

Where:

AA.AAA = Stage (feet, inches, meters etc.)

BB.BBB = Distance (feet)

CC = Measurement Status

DD.D = Power Supply Voltage (Volts)

27

Page 30

SDI-12 COMMAND & RESPONSE

Measurements with CRC

To enhance the error detection capability in SDI-12 data collection systems, a variation of the Start

Measurement Commands (M!, M1! ... M9!), Start Concurrent Measurement Commands (C!, C1! ...

C9!), and Continuous Measurement Commands (aR0! ... aR9!) request that the data be returned

with a 16 bit Cyclic Redundancy Check (CRC) appended to it. These commands use the existing

command letters with a C appended, namely: aMC!, aMC1! ... aMC9!, aCC!, aCC1! ... aCC9!, and

aRC0! ... aRC9!. When these commands are used, the data returned in response to the D commands,

or R commands, have a CRC code appended to it.

All Measure and Concurrent Measure Commands support the CRC functionality. In order to have

the CRC appended to the data of, for example, the “aM!” command the command would change

to “aMC!” The Concurrent Measurements also support the CRC, so for a CRC to be appended onto

the “aC1!” command, the variant would be “aCC1!”

Continuous Measurements

This is a command for the Version 1.2 SDI-12 Specification. Sensors that are able to continuously

monitor the phenomena to be measured, such as a cable position, do not require a start measurement

command. They can be read directly with the R commands (R0!...R9!). The R commands work exactly

like the D (D0!...D9!) commands. The only difference is that the R commands do not need to be

preceded with an M command.

The Radar does not support the aR0! continuous measurement commands because the measurement

and math operations require more than 10mS to complete.

Send Acknowledge Command

The Send Acknowledge Command returns a simple status response which includes the address of

the sensor. Any measurement data in the sensor’s buffer is not disturbed.

Command Response

“a!” “a<cr><lf>”

Where:

a Is the sensor address (“0-9”, “A-Z”, “a-z”, “*”, “?”).

Initiate Verify Command

The Verify Command causes a verify sequence to be performed. The result of this command is

similar to the “aM!” command except that the values generated are fixed test data and the results of

diagnostic checksum tests. The data generated in response to this command is placed in the sensor’s

buffer for subsequent collection using “D” commands. The data will be retained in the sensor until

another “M”, “C”, or “V” command is executed.

Command Response Description

“aV!” “atttn<cr><lf>” Initiate verify sequence

28

Page 31

SDI-12 Command & Response

Where:

a is the sensor address (“0-9”, “A-Z”, “a-z”, “*”, “?”).

V is an upper-case ASCII character.

ttt is a three digit integer (000-999) specifying the maximum time, in seconds, the sensor

will take to complete the command and have data available in its buffer.

n is a single digit integer (0-9) specifying the number of values that will be placed in the

data buffer. If “n” is zero (0), no data will be available using subsequent “D” commands

Example of an “aV!” command:

Command Response Time Values Description

"aV!" “a0013<cr><lf>” 1 sec 3 Return fixed data and

diagnostic data for testing

purposes.

Subsequent Command Response

"aD0" a+123.456+78.9+y<cr><lf>

Key Description Units

+123.456 Fixed test data

+78.9 Fixed test data

y ROM checksum test 0 = Failed, 1 = Passed

Send Identification Command

The Send Identification Command responds with sensor vendor, model, and version data. Any

measurement data in the sensor’s buffer is not disturbed.

Command Response

“aI!” “allccccccccmmmmmmvvvxx...xx<cr><lf>”

Where:

a is the sensor address (“0-9”, “A-Z”, “a-z”, “*”, “?”).

I is an upper-case ASCII character.

ll is the SDI-12 version compatibility level, e.g. version 1.2 is represented as “12”.

cccccccc is an 8 character vendor identification to be specified by the vendor and usually

in the form of a company name or its abbreviation.

mmmmmm is a 6 character field specifying the sensor model number.

vvv is a 3 character field specifying the sensor version number.

29

Page 32

SDI-12 COMMAND & RESPONSE

xx...xx is an optional field of up to a maximum of 13 characters to be used for serial number

or other specific sensor information not relevant to operation of the data recorder.

Example of a “aI!” command:

“a12 DAA H-3611vvvS#nnnnnnVkkk<cr><lf>”

Radar implementation of the optional 13 character field:

S#nnnnnnVkkk (12 bytes total)

Where:

“nnnnnn is a six character sensor serial number

“kkk” is a three digit sensor firmware revision level

Change Sensor Address Command

The Change Sensor Address Command allows the sensor address to be changed. The address is

stored in non-volatile EEPROM within the sensor. The Radar will not respond if the command was

invalid, the address was out of range, or the EEPROM programming operation failed.

Command Response Description

“aAn! “n<cr><lf>” Change sensor address

Where:

a is the current (old) sensor address (“0-9”, “A-Z”, “a-z”, “*”, “?”). An ASCII “*” may be used

as a “wild card” address if the current address is unknown and only one sensor is

connected to the bus.

A is an upper-case ASCII character.

n is the new sensor address to be programmed (“0-9”, “A-Z”).

NOTE: To verify the new address use the “Identify Command.”

Example of a “Change Sensor Address” command:

Command Response Description

“aA2! “2<cr><lf>” Change sensor address to “2”

30

Page 33

SDI-12 Command & Response

Extended Set_Current_Stage Command

The Radar processes Distance data and computes Stage = m * Distance + b. During installation it is

convenient to quickly set the Radar’s Stage reading to match the current stage or elevation of the

water as determined by a staff gauge or other datum. This command causes the Radar to make a

fresh measurement and automatically update the Offset (b) term as needed to produce the desired

Stage.

Example of an Extended “Set Current Stage” command:

Command Response Time Values Description

“aXSCS2.3!” “a0041<cr><lf>” 4 sec 1 Set the Stage to 2.3

Subsequent Command Response Description

“aD0” a+12.80<cr><lf> The new Offset

Extended Read/Write Stage_Offset and Read/Write Stage_Slope

The Radar processes the Distance data and computes Stage = m * Distance + b. The Slope (m) and

Offset (b) terms are programmable, allowing the user to scale the reading into other engineering

units. These commands allow the user to read or write (change) the Slope and Offset terms. The

Slope is set to -1.0 and the Offset to 0.00 at the factory. With the factory default (-1.0) the Stage will be

in units of water depth (in feet). The reason for a negative slope is that the radar measures Distance,

as the water rises Distance decreases. These values are stored in non-volatile FLASH memory within

the sensor. Once the new Slope or Offset value is written to the FLASH memory, a copy is sent to the

sensor data buffer for verification. This data can be viewed by using a subsequent “D” command. To

verify these settings any other time, use the “XRS” or “XRO” commands. This command takes 001

seconds to complete and places 1 value in the data buffer. Use the “aD0” command to collect and

view the new slope or offset.

Command Response Description

“aXRS!” “a0011<cr><lf>” Read Slope

“aXRO!” “a0011<cr><lf>” Read Offset

“aXWSddd!” “a0011<cr><lf>” Write Slope

“aXWOddd!” “a0011<cr><lf>” Write Offset

Where:

a is the sensor address (“0-9”, “A-Z”, “a-z”, “*”, “?”)

XRS are upper case characters

XRO are upper case characters

XWS are upper case characters

XWO are upper case characters

ddd is the new slope or offset value (For example: 20.0, 195)

31

Page 34

SDI-12 COMMAND & RESPONSE

Example of an Extended “Read Slope” command:

Command Response Time Values Description

“aXRS!” “a0011<cr><lf>” 1 sec 1 Read Slope

Subsequent Command Response Description

“aD0!” “a+1.00<cr><lf>” Slope is 1.00

Example of an Extended “Write Slope” command:

Command Response Time Values Description

“aXWS1.234!” “a0011<cr><lf>” 1 sec 1 Write Slope

Subsequent Command Response Description

“aD0!” “a+1.234<cr><lf>” Slope is 1.234

Extended Read Power_Mode and Write Power_Mode

Normally, the Radar transmits the service request within 530mS of receipt of the break. As with some

data loggers, this leaves insufficient time to sustain continuous measurements once per second.

The Power_Mode is an internal setting which puts the Radar in a fast measure mode. In this mode

the Radar is always awake and automatically collecting data from the radar unit and storing it at

1-second intervals. In this mode the sensor uses additional power. Changing this mode will allow

and disallow the use of some measurement types.

This command is used to change the power mode. The Radar comes from the factory with the power

mode set to the Sleep mode. This setting is stored in non-volatile FLASH memory within the sensor.

Once a new value is written, a copy is sent to the sensor data buffer for verification. This data can

be viewed by using a subsequent “D” command. To read or verify the value any other time, use the

“XRPM” command.

Command Response Description

“aXRPM!” “a0011<cr><lf>” Read Power_Mode

“aXWPMn!” “a0011<cr><lf>” Write Power_Mode

Where:

a is the sensor address (“0-9”, “A-Z”, “a-z”, “*”, “?”).

XRPM are upper case characters.

XWPM are upper case characters.

n is the new setting (0 or 1)

32

0 = Sleep between measurements

1 = Make continuous measurements

Page 35

SDI-12 Command & Response

This command takes 001 seconds to complete and places 1 value in the data buffer. Use the “aD0”

command to collect and view the current value.

Extended Read Number_of_Measurements and Write Number_of_Measurements

This command is used to change the number of measurements used in the “aM1!” command when

the Power Mode is set to 1. The Radar comes from the factory with the number of measurments set

to 360. This setting is stored in non-volatile FLASH memory within the sensor. The minimum and

maximum values that can be written are 1 and 360, respectively, anything beyond these values will

be set to one of the endpoints.

Once a new value is written, a copy is sent to the sensor data buffer for verification. This data can

be viewed by using a subsequent “D” command. To read or verify the value any other time, use the

“XRPM” command.

Command Response Description

“aXRNM!” “a0011<cr><lf>” Read Number_of_Measurements

“aXWNMnn!” “a0011<cr><lf>” Write Number_of_Measurements

Where:

a is the sensor address (“0-9”, “A-Z”, “a-z”, “*”, “?”).

XRNM are upper case characters.

XWNM are upper case characters.

nn is the new setting (1 - 360)

This command takes 001 seconds to complete and places 1 value in the data buffer. Use the “aD0”

command to collect and view the current value.

Example of an Extended “Read Number_of_Measurements “ command:

Command Response Time Values Description

“aXRNM!” “a0011<cr><lf>” 1 sec 1 Read Number_of_Measurements

Subsequent Command Response Description

“aD0!” “a+360<cr><lf>” Number_of_Measurements = 360

Example of an Extended “Write Number_of_Measurements “ command:

Command Response Time Values Description

“aXWNM181!” “a0011<cr><lf>” 1 sec 1 Write Number_of_Measurements

Subsequent Command Response Description

“aD0!” “a+181<cr><lf>” Number_of_Measurements = 181

33

Page 36

SDI-12 COMMAND & RESPONSE

Extended “XTEST”

This command is used for installation or production testing and requires the use of a H-4191

Sidekick interface and a PC or an XL Series Data Logger. This command causes the Radar to transmit

unsolicited real-time data for testing purposes. The test mode is used to help troubleshoot the

installation by providing a continuous readout of measurement data. This is not compliant with the

SDI-12 specification and cannot used with most data loggers. This command returns different data

based on the Power Mode setting. To activate the test mode, send the command “aXTEST!”.

In Power Mode = 0, The Radar will enter the test mode and make continuous measurements. The test

mode is exited by sending a break or any new command on the SDI-12 bus. It may take a few tries

to exit if the command is sent at the same time data is being sent from the Radar. Removing power

from the Radar also causes it to exit this mode.

In Power Mode = 1, the Radar will enter the test mode and take the raw data that would otherwise

be used for an “aM1!” command and outputs it to the SDI-12 bus one piece at a time in order from

newest to oldest. After the data is sent it waits for 2 seconds and then starts over as if a new “aXTEST!”

Command were sent The test mode is exited by sending a break or any new command on the SDI-

12 bus. It may take a few tries to exit if the command is sent at the same time data is being sent from

the Radar. Removing power from the Radar also causes it to exit this mode.

Format:

SensorAdr + Stage + Distance + Status

“XTEST” displays the following data:

0: +1.202 +3.222 +0

0: +1.212 +3.232 +0

0: +1.222 +3.342 +0

0: +1.232 +3.352 +0

0: +1.232 +3.352 +0

etc.

34

Page 37

04 /

APPENDIX

35

Page 38

APPENDIX

Appendix A: Specifications

PERFORMANCE

Accuracy

Frequency

Range

General

±0.01 ft (±3 mm) (H-3611/3613)

(including linearity, repeatability and hysteresis)

~26 GHz

Electromagnetic

Compatibility

Pulse Energy 1mW max (1W average)

Radar Unit

Measuring

Distance

10 ft (3.0 m) 0.87 ft (0.27 m) 0.69 ft (0.21 m)

20 ft (6.1 m) 1.75 ft (0.53 m) 1.4 ft (0.427 m)

30 ft (9.1 m) 2.62 ft (0.80 m) 2.1 ft (0.64 m)

40 ft (12.2 m) 3.50 ft (1.07 m) 2.8 ft (0.85 m)

50 ft (15.2 m) 4.37 ft (1.33 m) 3.5 ft (1.06 m)

75 ft (22.9 m) 6.56 ft (2.00 m) 5.24 ft (1.6 m)

100 ft (30.5 m) 8.75 ft (2.67 m) 6.99 ft (2.13 m)

131 ft (40 m) 11.46 ft (3.49 m) 9.16 ft (2.8 m)

H-3612

Measuring

Distance

150 ft (45.72 m) 13.12 ft (4 m) 10.49 ft (3.2 m)

175 ft (53.34 m) 15.31 ft (4.66 m) 12.34 ft (3.73 m)

200 ft (60.96 m) 17.5 ft (5.33) 13.99 ft (4.62 m)

230 ft (70 m) 20.12 ft (6.13 m) 16.1 ft (4.89 m)

Rating NEMA 4x

Internal Display LCD with back light

MECHANICAL / POWER

Size

Weight

Housing

H-3611/3612

Housing

H-3613

Horn

H-3611/3612

Horn H-3613 5.5 in. L x 4.5 in. W

H-3611/3612 8 lbs. (3.6 kg)

H-3613 7 lbs. (3.18 kg)

Emission to EN 61326

Electrical Equipment Class B

Radar Unit

Beam Radius

3 in. Horn (76.2

mm)

H-3612

Beam Radius 3 in.

Horn (76.2 mm)

17 in. L x 6 in. W x 6 in. H

(431.8 mm L x 152.4 mm W x 152.4 mm

H)

13 in. L x 6 in. W x 6 in. H

(330 mm L x 150 mm W x 150 mm H)

8.3 in. L x 3 in. W

(211mm L x 75 mm W) standard

11 in. L x 4 in. W

(282 mm L x95 mm W) optional

(140 mm L x 114 mm W)

Radar Unit

Beam Radius

4 in. Horn (101.6

mm)

H-3612

Beam Radius 4 in.

Horn (101.6 mm)

Material Housing Aluminum coated IP65

Horn

H-3611/3612

Horn

H-3613

Power

Requirements

Connection

General Beam Angle 10°

COMMUNICATIONS

SDI-12 Baud Rate 1200

ENVIRONMENTAL

General Operating

MISCELLANEOUS

Warranty

Notes

Voltage Input 10 to 16 volts DC

Surge

Protection

Supply Current Standby: 8 mA

+12V & SDI-12 Internal 3-position connector.

Cables 6 ft (1.8 m) cable with RS-232

Protocol SDI-12, V1.2 7-bit even parity, 1 stop bit

Output Voltage

Levels

Temperature

Storage

Temperature

Temperature

Sensitivity

The WaterLOG® H-3611/H-3612/H-3613 series radars

are warranted against defects in materials and

workmanship for two years from date of shipment.

Specifications subject to change without prior notice

due to ongoing commitment to product testing and

improvement. LR June 17, 2013 (D4 0613)

Stainless steel

PTB

Built in, 1.5 KVA

Active: 15 mA

Startup: 20 mA

6 ft (1.8 m) polyurethane pigtail is

provided.

connector for TofTool® connection.

3 in. (76.2 mm) Standard Horn

8°

4 in. (101.6 mm) Extended Horn

10°

3 in. (76.2 mm) PTB Horn

Minimum high level: 3.5 volts

Maximum low level: 0.8 volts

-40° C to + 80° C

-40° C to + 80° C

Average TK: 2 mm/10 K, max 5 mm

over the entire temperature range

-40° C to +80° C

36

Page 39

Appendix B: FCC Equipment Authorization

Information For User:

NOTE: This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own

expense.

Appendix

Declaration of Conformity to Part 15, subpart B

This device complies with part 15 of the FCC rules. Operation is subject

to the following conditions:

1) This equipment complies with Part 15 of the FCC rules. Any changes

or modifications not expressly approved by the manufacturer could

void the user’s authority to operate the equipment.

2) This device complies with Part 15 of the FCC rules subject to the

following two conditions:

1) This device may not cause harmful interference

2) This device must accept all interference received, including

interference that may cause undesired operation.

37

Page 40

Xylem

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,000 people unified in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem—WaterLOG

95 W 100 S, Suite 150

Logan, UT 84321

Tel +1.435.753.2212

Fax +1.435.753.7669

www.waterlog.com

Radar Series is a trademark of Xylem Inc. or one of its subsidiaries.

© 2014 Xylem, Inc. D36 0514

Loading...

Loading...