Page 1

Operating manual

ProLab 4000

ba75646e03 12/2012

DRAFT December 10, 2012 1:25 pm

pH/ISE/Conductivity measuring instrument

with automatic sensor recognition

and electronic access control

Page 2

Accuracy when

going to press

Warranty We guarantee the meter described for 3 years from the date of pur-

The use of advanced technology and the high quality standard of our

instruments are the result of a continuous development. This may

result in differences between this operating manual and your instrument. Also, we cannot guarantee that there are absolutely no errors in

this manual. Therefore, we are sure you will understand that we cannot

accept any legal claims resulting from the data, figures or descriptions.

chase.

The meter warranty covers manufacturing faults that are discovered

within the warranty period.

The warranty does not cover components that are replaced during

maintenance work, e. g. batteries.

The warranty claim extends to restoring the instrument to readiness for

use but not, however, to any further claim for damages. Improper handling or unauthorized opening of the meter invalidates any warranty

claim.

To ascertain the warranty liability, return the instrument and proof of

purchase together with the date of purchase freight paid or prepaid.

CE conformity

Radio data transmission

Copyright

SI Analytics GmbH hereby declares that the ProLab 4000 meter is in

compliance with the basic requirements and the other relevant regulations of the directive 1999/5/EC.

The EC declaration of conformity can be requested from SI Analytics

GmbH.

© 2012, SI Analytics GmbH

Reprinting - even in the form of excerpts - is only allowed with the

explicit written authorization of SI Analytics GmbH.

Printed in Germany.

Page 3

ProLab 4000

KONFORMITÄTSERKLÄRUNG

DECLARATION OF CONFORMITY

DÉCLARATION DE CONFORMITÉ

Wir erklären in alleiniger

Verantwortung, dass das

Produkt

pH-/ISE-/

Leitfähigkeits-

Messgerät

ProLab 4000

auf das sich diese Erklärung

bezieht, übereinstimmt mit

den Angaben im Kapitel

We declare under our sole

responsibility that the

product

pH / ISE /

conductivity

measuring

instrument

ProLab 4000

to which this declaration

relates is in conformity with

the specifications in the

chapter

Nous déclarons sous notre

seule responsabilité que le

produit

Appareil de mesure

pour pH/ISE/

conductivité

ProLab 4000

auquel se réfère cette

déclaration est conforme aux

indications du chapitre

30. Oktober, October 30, 30 octobre 2005

AGQSF 0000-A108-01/091030

SI Analytics GmbH

Hattenbergstr. 10

D-55122 Mainz

Deutschland, Germany, Allemagne

Technische Daten

pH-/ISE-/Leitfähigkeits-Messgerät

ProLab 4000

30. Oktober 2009

ba75646e03 12/2012

3

Page 4

ProLab 4000

4

ba75646e03 12/2012

Page 5

ProLab 4000 Contents

ProLab 4000 - Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1 General features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2 Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4 Socket field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.5 Automatic sensor recognition . . . . . . . . . . . . . . . . . . . . . 16

1.5.1 ID sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.5.2 Sensor data from ID sensors . . . . . . . . . . . . . . . 18

1.6 Electronic access control . . . . . . . . . . . . . . . . . . . . . . . . 19

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.1 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . 22

3 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1 Scope of delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2 Initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3 Connecting the power pack. . . . . . . . . . . . . . . . . . . . . . . 24

3.4 Switching on the ProLab 4000 . . . . . . . . . . . . . . . . . . . . 25

3.5 Connecting the USB mouse . . . . . . . . . . . . . . . . . . . . . . 26

3.6 Connecting sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.6.1 Connecting an ID sensor . . . . . . . . . . . . . . . . . . 27

3.6.2 Connecting a non ID sensor. . . . . . . . . . . . . . . . 28

3.7 Connecting optional accessories . . . . . . . . . . . . . . . . . . 28

3.7.1 RS232 interface (serial port) . . . . . . . . . . . . . . . 29

3.7.2 USB-B interface (USB Device). . . . . . . . . . . . . . 31

3.7.3 USB-A interface (USB Host) . . . . . . . . . . . . . . . 32

4 Operating principles. . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1 Operating and display elements . . . . . . . . . . . . . . . . . . . 33

4.2 File system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.3 Entry of numerals, letters and characters . . . . . . . . . . . . 38

4.4 Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.4.1 Navigation in the measured value display . . . . . 41

4.4.2 Navigation in menus. . . . . . . . . . . . . . . . . . . . . . 42

4.4.3 Navigation in dialog boxes . . . . . . . . . . . . . . . . . 44

4.4.4 Navigation in the file selection dialog box . . . . . 45

ba75646e03 12/2012

5

Page 6

Contents ProLab 4000

5 Access to the meter . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.1 Switch the meter on and off. . . . . . . . . . . . . . . . . . . . . . . 47

5.2 Login as a user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.3 Password for login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3.1 Changing the password . . . . . . . . . . . . . . . . . . . 49

5.3.2 Assigning a password. . . . . . . . . . . . . . . . . . . . . 49

5.3.3 Forgotten the password? . . . . . . . . . . . . . . . . . . 49

5.4 Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.5 Access control and user rights. . . . . . . . . . . . . . . . . . . . . 51

5.5.1 Access control . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.5.2 User management and assigning user rights . . . 53

5.6 Lost your electronic key? . . . . . . . . . . . . . . . . . . . . . . . . . 55

6 System functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.1 Overview: System settings . . . . . . . . . . . . . . . . . . . . . . . 56

6.2 Selecting the language . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.3 Selecting the country . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.4 Setting the date and time. . . . . . . . . . . . . . . . . . . . . . . . . 59

6.5 Selecting the channels for measured value display. . . . . 60

6.6 Interfaces for data download . . . . . . . . . . . . . . . . . . . . . . 60

6.7 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.7.1 Temperature unit . . . . . . . . . . . . . . . . . . . . . . . . 61

6.7.2 Temperature measurement . . . . . . . . . . . . . . . . 62

6.8 Automatic stability control . . . . . . . . . . . . . . . . . . . . . . . . 63

6.9 Color assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.10 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.10.1 Resetting the sensor settings . . . . . . . . . . . . . . . 65

6.10.2 Resetting the system settings. . . . . . . . . . . . . . . 66

6.11 List of open windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7 pH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.2 Measuring the pH value. . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.2.1 Preparatory activities . . . . . . . . . . . . . . . . . . . . . 70

7.2.2 Measuring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.2.3 Measurement settings . . . . . . . . . . . . . . . . . . . . 73

7.3 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.3.1 Carrying out a calibration procedure

(example: AutoCal DIN) . . . . . . . . . . . . . . 79

7.3.2 Carrying out a calibration procedure

(example: VariCal) . . . . . . . . . . . . . . . . . . . . . . . 83

7.3.3 Calibration settings and calibration data. . . . . . . 87

7.3.4 Calibration interval . . . . . . . . . . . . . . . . . . . . . . . 88

6

ba75646e03 12/2012

Page 7

ProLab 4000 Contents

8 ORP voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

8.1 General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

8.2 Measuring the ORP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

8.2.1 Preparatory activities . . . . . . . . . . . . . . . . . . . . . 90

8.2.2 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.2.3 Measuring the relative ORP . . . . . . . . . . . . . . . . 93

8.2.4 Measurement settings . . . . . . . . . . . . . . . . . . . . 96

9 Ion concentration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

9.1 General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

9.2 Measuring the ion concentration . . . . . . . . . . . . . . . . . . 98

9.2.1 Preparatory activities . . . . . . . . . . . . . . . . . . . . . 98

9.2.2 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

9.2.3 Measurement settings . . . . . . . . . . . . . . . . . . . 101

9.3 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

9.3.1 Carrying out calibration . . . . . . . . . . . . . . . . . . 106

9.3.2 Calibration data . . . . . . . . . . . . . . . . . . . . . . . . 110

9.4 Blank value correction. . . . . . . . . . . . . . . . . . . . . . . . . . 111

9.5 Reference measurement. . . . . . . . . . . . . . . . . . . . . . . . 112

9.6 Measuring with increment procedure (methods). . . . . . 113

9.6.1 Selecting the measuring method . . . . . . . . . . . 113

9.6.2 Standard addition . . . . . . . . . . . . . . . . . . . . . . . 114

9.6.3 Double standard addition . . . . . . . . . . . . . . . . . 118

9.6.4 Standard subtraction . . . . . . . . . . . . . . . . . . . . 122

9.6.5 Sample addition . . . . . . . . . . . . . . . . . . . . . . . . 126

9.6.6 Sample subtraction . . . . . . . . . . . . . . . . . . . . . 130

9.6.7 Blank value addition

(Standard addition with blank value correction) 134

ba75646e03 12/2012

10 Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

10.1 General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

10.2 Measuring the conductivity . . . . . . . . . . . . . . . . . . . . . . 139

10.2.1 Preparatory activities . . . . . . . . . . . . . . . . . . . . 139

10.2.2 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

10.2.3 Measurement settings . . . . . . . . . . . . . . . . . . . 142

10.2.4 Determining/setting the

temperature compensation . . . . . . . . . . . . . 144

10.2.5 Selecting the nonlinear

temperature compensation TC nLF . . . . . . . . . 147

10.2.6 Selecting the linear

temperature compensation TC Lin... . . . . . . . . 147

10.2.7 Selecting and adjusting the nonlinear

temperature compensation TC nLin1 . . . . . 148

10.2.8 Selecting and determining the nonlinear

temperature compensation TC nLin2 . . . . . 150

10.2.9 Selecting and determining the nonlinear

temperature compensation TC nLin3 . . . . . 152

7

Page 8

Contents ProLab 4000

10.2.10 Selecting and determining the nonlinear

temperature compensation TC nLin4 . . . . . 154

10.2.11 Switching off the temperature compensation

(TC off) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

10.3 Determining the cell constant (calibration in control

standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

10.3.1 Determining the cell constant (calibration) . . . . 159

10.3.2 Calibration settings and calibration data. . . . . . 160

11 Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

11.1 Measurement data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

11.1.1 Creating and selecting a file for manually

stored measurement datasets . . . . . . . . . . . . . 162

11.1.2 Storing measurement datasets manually . . . . . 163

11.1.3 Automatically storing measurement datasets . . 164

11.1.4 Displaying and filtering stored measurement

datasets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

11.1.5 Erasing measurement datasets . . . . . . . . . . . . 167

11.2 Calibration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

11.2.1 Displaying stored calibration data. . . . . . . . . . . 168

11.2.2 Managing the calibration data. . . . . . . . . . . . . . 169

11.3 Recorder data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

11.4 Configuration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

12 Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

12.1 Recording the measured value curve . . . . . . . . . . . . . . 172

12.2 Recording the curve of the measured

temperature value . . . . . . . . . . . . . . . . . . . . . . . . 173

12.3 Storing recorder data . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

12.4 Displaying stored recorder data. . . . . . . . . . . . . . . . . . . 175

12.5 Settings for the recorder . . . . . . . . . . . . . . . . . . . . . . . . 176

12.5.1 Defining the recording interval . . . . . . . . . . . . . 177

12.5.2 Specifying the axes of the system

of coordinates . . . . . . . . . . . . . . . . . . . . . 177

12.5.3 Defining and activating limit values. . . . . . . . . . 179

12.5.4 Defining the colors for the

recorder representation . . . . . . . . . . . . . . . . 180

12.6 Changing the displayed axis intercept. . . . . . . . . . . . . . 181

12.7 Displaying exact measurement data at a point (cursor) 183

12.8 Deleting stored recorder data . . . . . . . . . . . . . . . . . . . . 183

13 Transmitting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

13.1 Printing current measurement data . . . . . . . . . . . . . . . . 185

13.2 Transmitting data (to a PC or printer) . . . . . . . . . . . . . . 185

13.2.1 RS232 interface . . . . . . . . . . . . . . . . . . . . . . . . 185

13.2.2 USB-B interface (USB Device) . . . . . . . . . . . . . 186

13.2.3 USB-A interface (USB Host). . . . . . . . . . . . . . . 187

13.2.4 Options for data transmission . . . . . . . . . . . . . . 187

8

ba75646e03 12/2012

Page 9

ProLab 4000 Contents

13.3 Data backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

13.3.1 Data backup by the administrator . . . . . . . . . . 188

13.3.2 Viewing backed up data. . . . . . . . . . . . . . . . . . 189

14 Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

14.1 Viewing a configuration . . . . . . . . . . . . . . . . . . . . . . . . . 191

14.2 Creating a new configuration . . . . . . . . . . . . . . . . . . . . 192

14.3 Loading a configuration. . . . . . . . . . . . . . . . . . . . . . . . . 193

14.4 Deleting a configuration . . . . . . . . . . . . . . . . . . . . . . . . 194

15 Maintenance, cleaning, disposal. . . . . . . . . . . . . . . . 195

15.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

15.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

15.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

16 What to do if... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

16.1 pH and ORP measurement. . . . . . . . . . . . . . . . . . . . . . 197

16.2 Ion selective measurement . . . . . . . . . . . . . . . . . . . . . . 199

16.3 Conductivity measurement . . . . . . . . . . . . . . . . . . . . . . 200

16.4 General errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

17 Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

17.1 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

17.2 Measuring ranges, resolution, accuracy . . . . . . . . . . . . 206

17.2.1 Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . 206

17.2.2 pH/ORP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

17.2.3 ISE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

17.2.4 Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

18 Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

A.19 Firmware update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

A.20 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

A.20.1 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

A.20.2 pH sensor menu. . . . . . . . . . . . . . . . . . . . . . . . 223

A.20.3 U sensor menu . . . . . . . . . . . . . . . . . . . . . . . . . 224

A.20.4 dU sensor menu. . . . . . . . . . . . . . . . . . . . . . . . 224

A.20.5 ISE sensor menu . . . . . . . . . . . . . . . . . . . . . . . 225

A.20.6 Cond sensor menu. . . . . . . . . . . . . . . . . . . . . . 226

ba75646e03 12/2012

9

Page 10

Contents ProLab 4000

10

ba75646e03 12/2012

Page 11

ProLab 4000 Overview

1

2

4

3

1Overview

1.1 General features

The ProLab 4000 precision meter enables you to

perform pH, ORP, conductivity and ion-selective measurements rapidly

and reliably.

Das ProLab 4000 provides the maximum degree of ease of use, reliability and, above all, measuring certainty for all applications.

The proven calibration procedures, and

stability control function (SC) and the sensor recognition function support your work with the meter.

In addition, the ProLab 4000 provides an electronic access control.

Documented measurement data is thus automatically assigned to a

user.

ba75646e03 12/2012

1 Keypad

2 Display

3 Reader field for electronic access con-

trol

4 Jack field

11

Page 12

Overview ProLab 4000

123

456

789

0

.

ABC DEF

GHI JKL MNO

PQRS TUV WXYZ

_

SCMODE

DEL

STO

ESC

PRINT

CAL

RCL

OK

MODE

CAL

SC

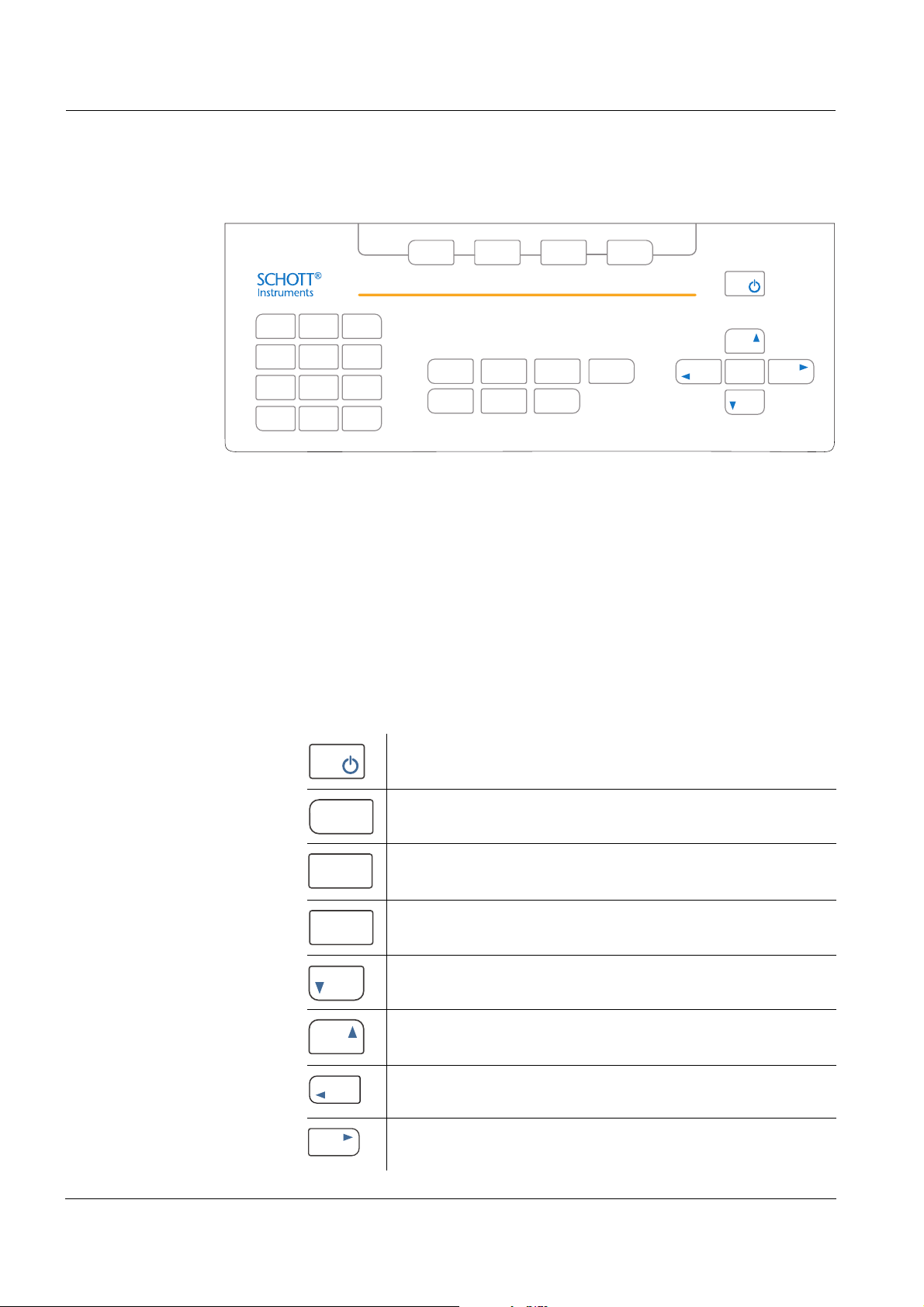

1.2 Keypad

Keys with dedicated

functions

Keys with changing

functions

(softkeys)

Key functions

Keys with dedicated functions are labeled on the meter.

In this operating manual, they are identified by the key labeling, bold letters and angle brackets <..> .

Keys with changing functions are not labeled; the currently assigned

function is shown on the display instead. In this operating manual,

these keys are identified by the displayed softkey function, bold letters

and angle brackets [..] .

The key symbol (e.g. <OK> or [OK]) generally means you should press

a key in this operating manual.

<On/Off> Switch the meter on/off

<MODE> Select measured parameter

<CAL> Call up calibration procedure

<SC> Switch on or off the stability control func-

tion manually.

<> Reduce values, Scroll

Move in the menu

12

<> Increase values, Scroll

Move in the menu

<> Reduce values, Scroll

Move in the menu

<> Increase values, Scroll

Move in the menu

ba75646e03 12/2012

Page 13

ProLab 4000 Overview

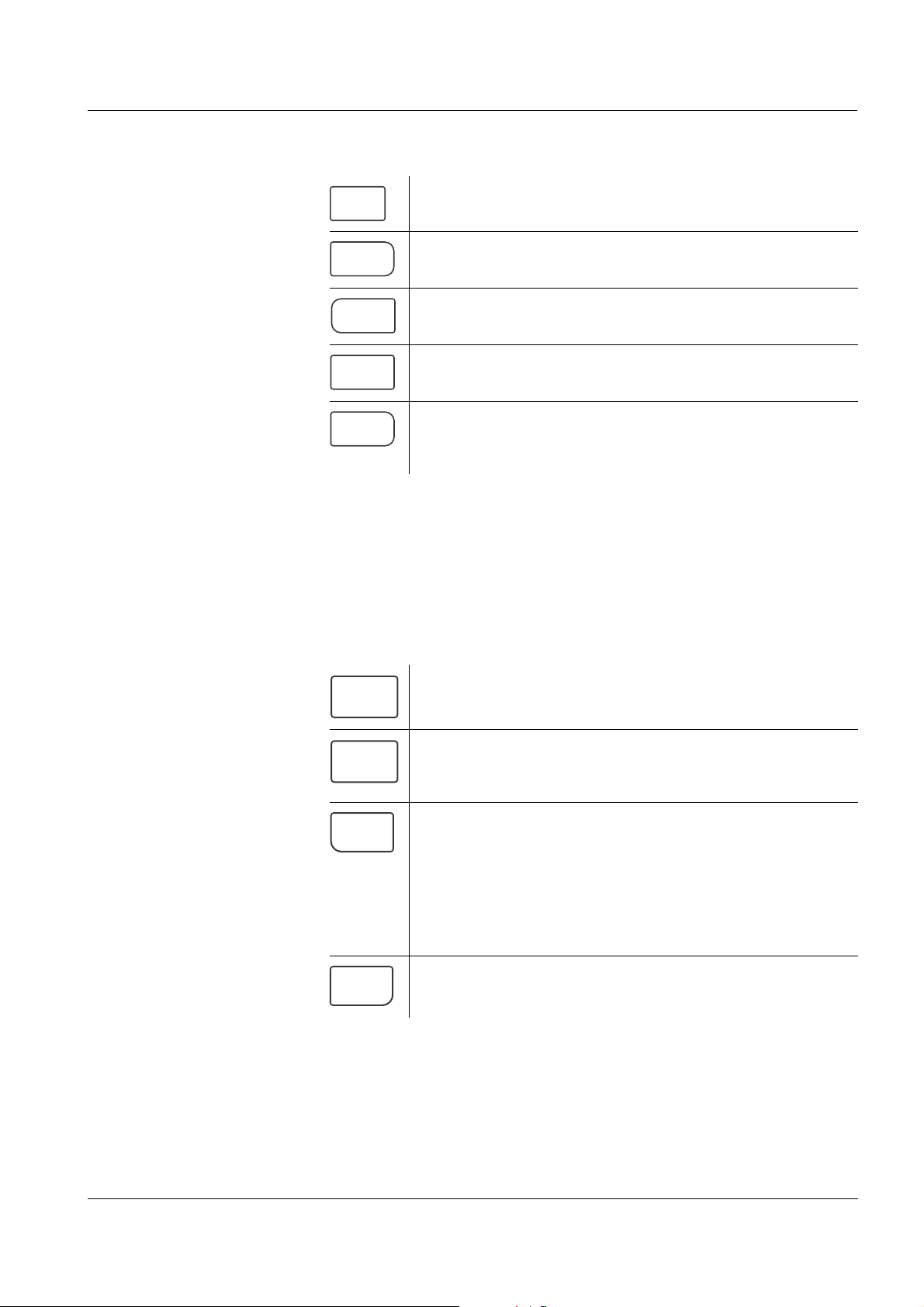

OK

ESC

STO

RCL

PRINT

7

PQRS

7

PQRS

.

_

LDE

<OK> Confirm entries

<ESC> Return to higher menu level /

Cancel inputs

<STO> Store a measured value

<RCL> Open the menu for stored measured val-

ues

<PRINT> Print or output data to an interface (serial

RS232, USB-A (USB Host) or USB-B USB

Device))

Alphanumeric keypad The keys of the alphanumeric keypad are used to enter numerals

(<0...9>), letters (<A...Z>) and characters (<- .>). The keys of the alpha-

numeric keypad only have a function if the ProLab 4000 is waiting for a

character to be entered, e.g. in input fields for the ID during manual

storage.

<0...9> Press the key once.

The numeral is displayed in the input field

<A...Z> Press the key several times if necessary

until the required letter is displayed in the

input field

<- .> Depending on the input field, the keys is

automatically interpreted as a minus sign

or decimal point.

Numeral input field:

Cursor is in front of the first digit: Minus.

Cursor is behind a numeral: Decimal point

<DEL> Deletes the character left of the cursor

ba75646e03 12/2012

13

Page 14

Overview ProLab 4000

1

2

3

10

9

8

7

6

5

11

4

1.3 Display

The graphic color display can display three measured parameters and

the current temperature value for each measured parameter at the

same time.The illumination enables to read the display even in the

darkness.

Elements:

1 Menu line (main menu)

2 Sensor window (title bar)

3 Menu line (sensor menu)

4 Status line

5 Info line with date and time, info or action text

6 Key assignment with changing functions (softkeys)

7 Temperature display

8 Measured value (with unit)

9 Measured parameter

10 ID sensor symbol

11 CalClock

14

ba75646e03 12/2012

Page 15

ProLab 4000 Overview

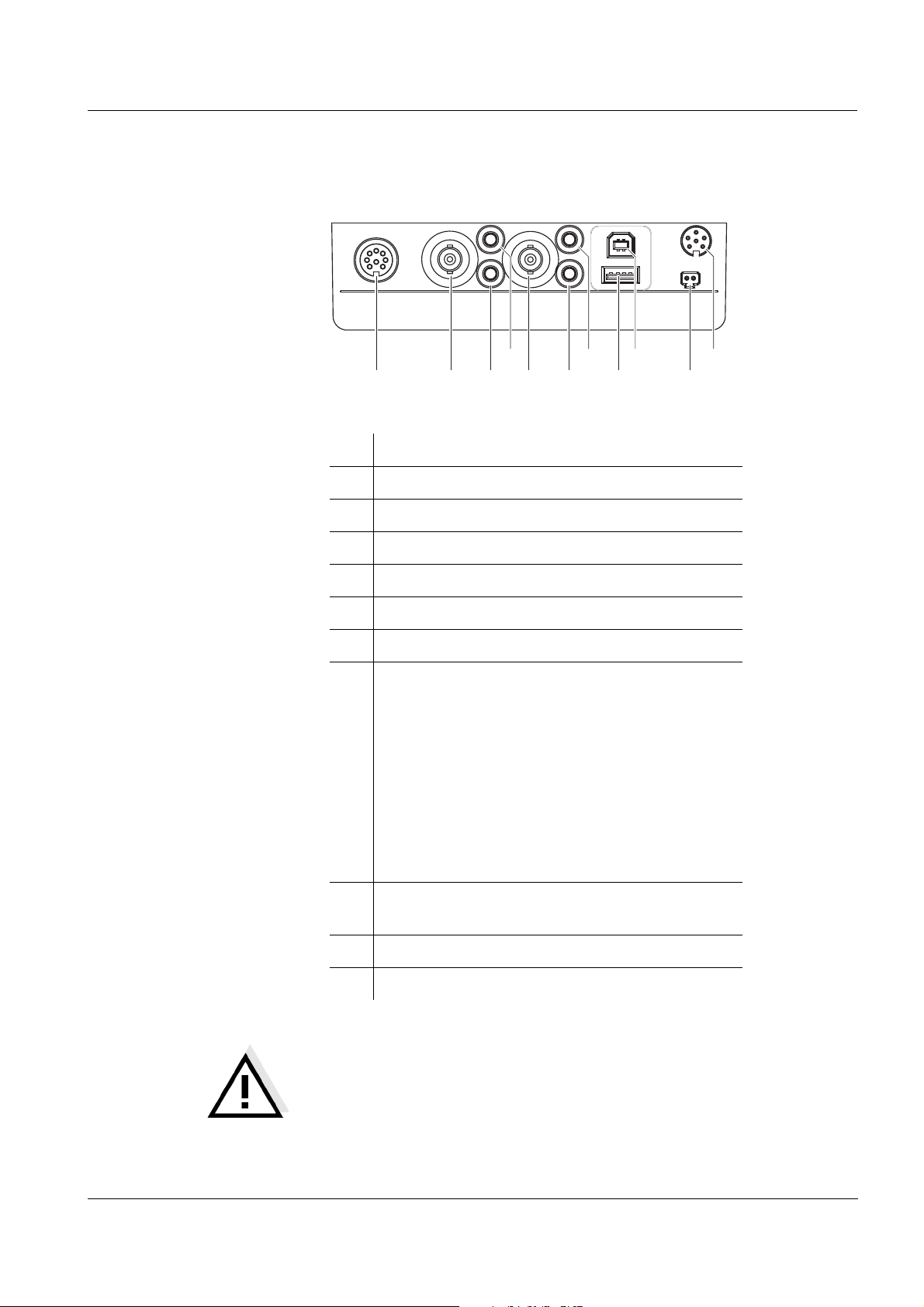

pH/U/ISE

Probe 2

Cond

Probe

TP 2

Ref 2

TP 1

Ref 1

pH/U/ISE

Probe 1

USB Device

USB Host

RS232

9V/DC

input

1 2

3

4

10

11

6

7

5

9

8

1.4 Socket field

Connections:

1 Conductivity measuring cell (Cond Probe)

2 pH/ISE/ORP electrode (pH/U/ISE Probe 2)

3 Reference electrode (Ref 2)

4 Temperature sensor (TP 2)

5 pH/ISE/ORP electrode (pH/U/ISE Probe 1)

6 Reference electrode (Ref 1)

7 Temperature sensor (TP 1)

8 USB Host interface, e.g. for

– the USB mouse,

– a USB printer,

– a USB hub,

– a USB keyboard,

– a USB storage,

– a USB card reader or

– other USB devices

9 USB interface (USB Device),

e.g. for a PC.

10 Power pack (9V/DC input)

11 RS232 interface (RS232)

ba75646e03 12/2012

CAUTION

Only connect sensors to the meter that cannot return any voltages or currents that are not allowed (> SELV and > current circuit

with current limiting).

Almost all sensors - in particular SI Analytics sensors - fulfill

these conditions.

15

Page 16

Overview ProLab 4000

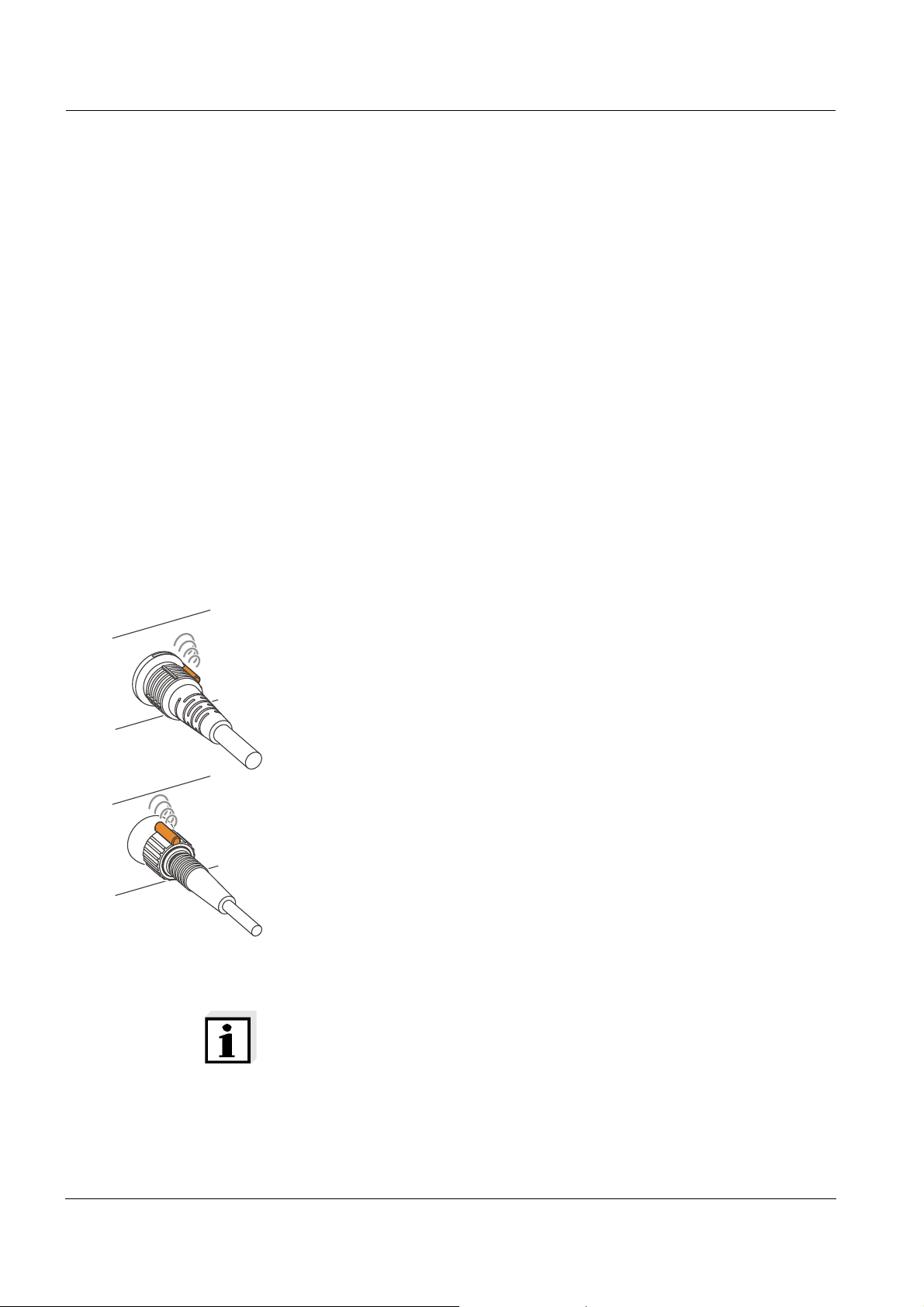

DIN

BNC

1.5 Automatic sensor recognition

The automatic sensor recognition function enables

to operate a sensor with different meters without recalibrating

to operate different sensors with one meter without recalibrating

to assign measurement data to a sensor

– measurement datasets are always downloaded to the interface

with the sensor type and sensor series number.

– measurement datasets are always stored together with the sen-

sor type and sensor series number.

to assign calibration data to a sensor

– calibration data is always downloaded to the interface with the

sensor type and sensor series number.

the automatic activation of the cell constants for conductivity sen-

sors

to hide menus that are not relevant for this sensor

To be able to use the automatic sensor recognition function a meter is

required that supports the automatic sensor recognition (e.g.

ProLab 4000), and a sensor (ID sensor) that is suitable for sensor recognition.

In every ID sensor, sensor data is stored that clearly identifies the sensor.

The sensor data is sent to the meter automatically via radio communication and used for sensor identification there.

16

Note

With the ProLab 4000 you can also operate non ID sensors. Then,

however, you cannot use the advantages of the sensor recognition

function.

ba75646e03 12/2012

Page 17

ProLab 4000 Overview

ID sensor

symbol

1.5.1 ID sensors

SI Analytics GmbH ID sensors support the automatic sensor recognition function. Their sensor designation has the addition "ID", e.g. BlueLine A 161 1M-BNC-ID electrode.

Note

Information on available ID sensors is given on the Internet or directly

by SI Analytics.

ID sensors connected to the ProLab 4000 meter can be recognized by

the ID sensor symbol on the display.

ba75646e03 12/2012

17

Page 18

Overview ProLab 4000

1.5.2 Sensor data from ID sensors

ID sensors transmit the following sensor data to the meter:

SENSOR ID

– Sensor type

– Sensor series number

Calibration data

– Calibration date

– User (having carried out the last calibration procedure)

– Calibration characteristics

– Calibration interval

– Selected buffer set (pH electrodes only)

– Last cell constant (conductivity measuring cell only)

Measurement settings (conductivity measuring cells only)

– Specified reference temperature

– Adjusted temperature coefficient

– Adjusted TDS factor

The calibration data is updated in the ID sensor after each calibration

procedure. A message is displayed while data is updated in the sensor.

Note

While data is updated in the sensor, the sensor must not be disconnected because otherwise the calibration data will not be completely

transmitted. The sensor will then have no valid calibration.

Note

If non-ID sensors are used, the calibration data from the meter is used

and also stored in the meter.

18

ba75646e03 12/2012

Page 19

ProLab 4000 Overview

Reader field for

the electronic

key

1.6 Electronic access control

The ProLab 4000 always documents measurement and calibration

data together with a user name.

Thus all measurement data is assigned to the user, in compliance with

GLP.

The user name is easily and safely transmitted to the ProLab 4000 via

an electronic key. Each electronic key in the form of a keyring pendant

contains a key number and a user name. The key number and user

name are read by the meter via a contactless radio data connection.

The meter checks the access authorization for the user name. Measurements with an electronic key are only possible if the key number

and user name is registered in the meter. The measuring data is then

documented along with the registered user name.

ba75646e03 12/2012

If the user name of an electronic key is not registered in the meter,

access to the meter with this electronic key is denied.

If access to the meter is anonymous (no password, no electronic key

required), all data are documented with the user name, Anonymous.

By labeling the measurement data with Anonymous, this data can be

excluded from the GLP-compliant documentation.

19

Page 20

Overview ProLab 4000

20

ba75646e03 12/2012

Page 21

ProLab 4000 Safety

2 Safety

This operating manual contains basic instructions that you must follow

during the commissioning, operation and maintenance of the meter.

Consequently, all responsible personnel must read this operating manual before working with the measuring system. The operating manual

must always be available within the vicinity of the meter.

Target group The meter was developed for work in the laboratory.

Thus, we assume that, as a result of their professional training and

experience, the operators will know the necessary safety precautions

to take when handling chemicals.

Safety instructions The individual chapters of this operating manual use the following

safety instruction to indicate various types of danger:

CAUTION

indicates instructions that must be followed precisely in order to

avoid the possibility of slight injuries or damage to the meter or

the environment.

Further notes

Note

indicates notes that draw your attention to special features.

Note

indicates cross-references to other documents, e.g. operating manuals.

2.1 Authorized use

This meter is authorized exclusively for measurements of the pH, ORP,

conductivity and ion-selective measurements in the laboratory.

The technical specifications as given in chapter 17 T

(page 203) must be observed. Only the operation and running of the

meter according to the instructions given in this operating manual is

authorized. Any other use is considered unauthorized.

ECHNICAL DATA

ba75646e03 12/2012

21

Page 22

Safety ProLab 4000

2.2 General safety instructions

This instrument is built and inspected according to the relevant guidelines and norms for electronic measuring instruments (see page 203).

It left the factory in a safe and secure technical condition.

Function and

operational safety

The smooth functioning and operational safety of the meter can only be

guaranteed if the generally applicable safety measures and the specific

safety instructions in this operating manual are followed during operation.

The smooth functioning and operational safety of the meter can only be

guaranteed under the environmental conditions that are specified in

chapter 17 T

ECHNICAL DATA (page 203).

If the instrument was transported from a cold environment to a warm

environment, the formation of condensate can lead to the faulty functioning of the instrument. In this event, wait until the temperature of the

meter reaches room temperature before putting the meter back into

operation.

Safe operation If safe operation is no longer possible, the meter must be taken out of

service and secured against inadvertent operation!

Safe operation is no longer possible if the meter:

has been damaged in transport

has been stored under adverse conditions for a lengthy period of

time

Obligations of the

purchaser

is visibly damaged

no longer operates as described in this manual.

If you are in any doubt, please contact the supplier of the meter.

The purchaser of this meter must ensure that the following laws and

guidelines are observed when using dangerous substances:

EEC directives for protective labor legislation

National protective labor legislation

Safety regulations

Safety datasheets of the chemical manufacturers.

22

ba75646e03 12/2012

Page 23

ProLab 4000 Commissioning

3 Commissioning

3.1 Scope of delivery

ProLab 4000 laboratory meter

Power pack

4 batteries 1.5 V Micro type AAA

1 electronic administrator key (as keyring pendant)

1 electronic user key (as keyring pendant)

Cover

USB cable (Z875)

USB mouse

CD-ROM with USB driver for the PC

Operating manual

ba75646e03 12/2012

23

Page 24

Commissioning ProLab 4000

3.2 Initial commissioning

Perform the following activities:

Insert the batteries (see page 195)

Connect the power pack (see page 24).

Switch on ProLab 4000 (see page 25).

Connect the USB mouse (see page 26)

Setting the language (see page 58)

Set the date and time (see page 59)

Set up the access authorization for user keys (see page 53)

Connect the sensor (see page 27).

3.3 Connecting the power pack

The power pack supplies the meter with low voltage (9 V DC).

The batteries are only used to buffer the system time if the power supply is interrupted.

CAUTION

The line voltage at the operating site must lie within the input

voltage range of the original power pack (see page 203).

CAUTION

Use original power packs only (see page 203).

1 Insert the plug into the socket of the meter.

2 Connect the original power pack to an easily accessible power

outlet.

The self-test, meter designation, software version and subsequently the Standby display appear.

24

ba75646e03 12/2012

Page 25

ProLab 4000 Commissioning

3.4 Switching on the ProLab 4000

The ProLab 4000 indicates the Standby display.

1 Switch the meter on with <OK>.

2 The meter switches itself on. The Login dialog box is displayed.

Note

The default password for the administrator is "00001".

For your safety, change it as soon as possible (see page 49).

ba75646e03 12/2012

25

Page 26

Commissioning ProLab 4000

3.5 Connecting the USB mouse

You can connect the USB mouse included in the scope of delivery to

the USB-A USB Host interface of the ProLab 4000. Thus the

ProLab 4000 can be operated like a PC.

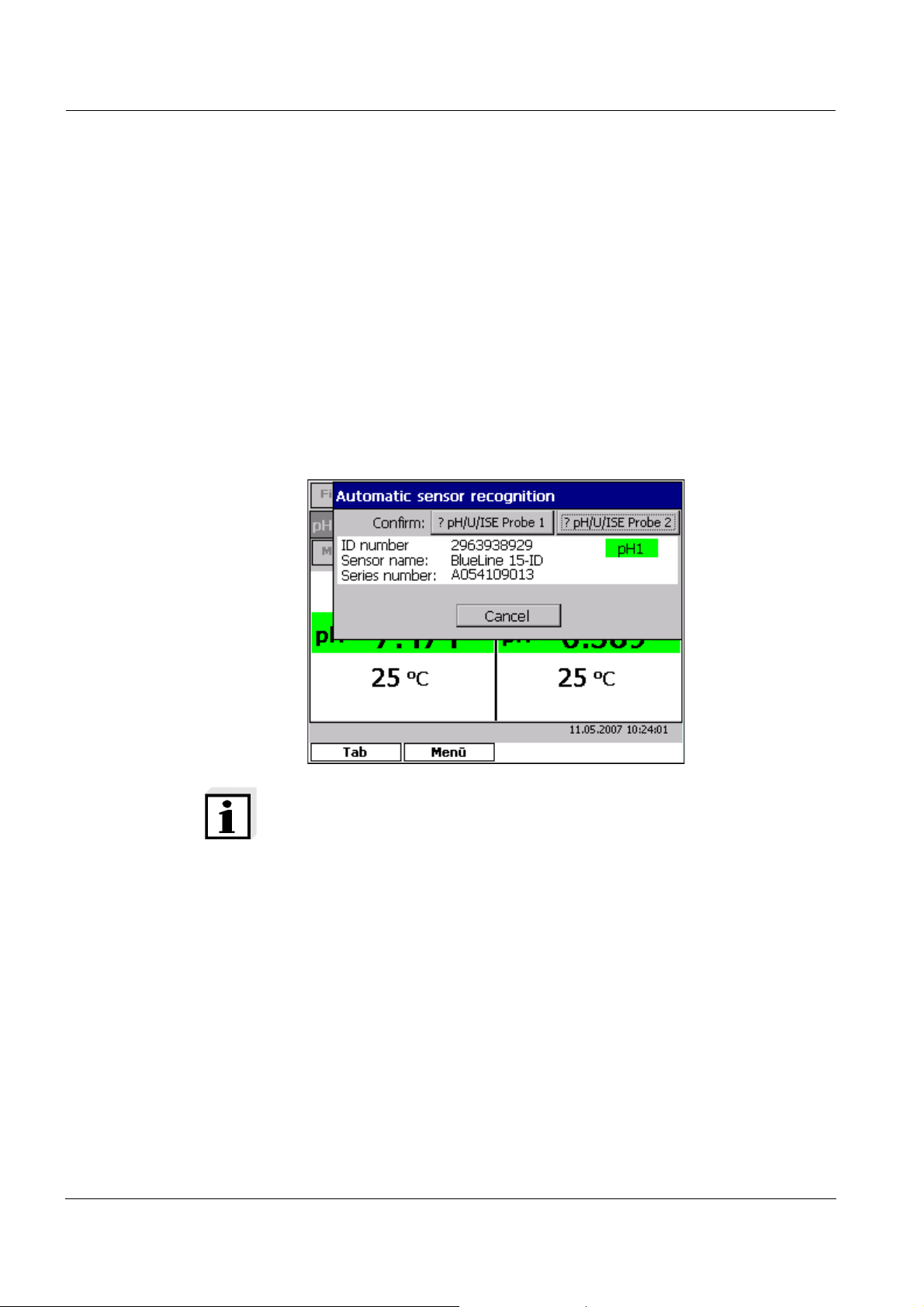

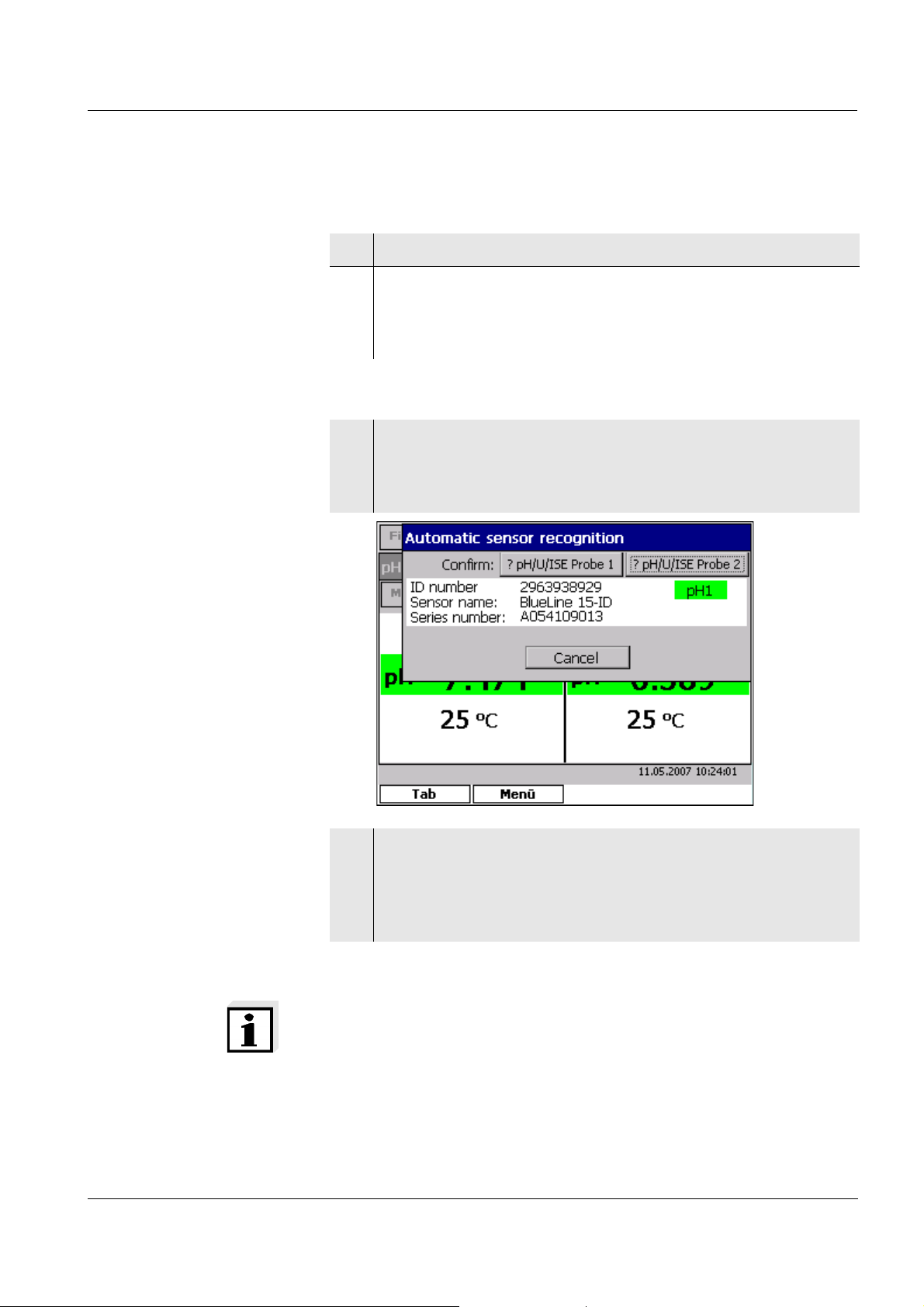

3.6 Connecting sensors

If an ID sensor is connected, the ProLab 4000 recognizes the sensor

type, sensor name and series number of the sensor.

If the ID sensor cannot be automatically assigned to a channel, the

Automatic sensor recognition window prompts the manual assignment.

26

Note

wrong assignment of ID sensors to channels can be corrected by

reassigning the sensors, e.g. after

Switching off, then on the meter

Disconnecting, then reconnecting all ID sensors.

ba75646e03 12/2012

Page 27

ProLab 4000 Commissioning

3.6.1 Connecting an ID sensor

ID sensor with

temperature sensor

ID sensor without

temperature sensor

1 Connect the temperature sensor of the ID sensor to the socket.

2 Connect the ID sensor to the socket of the meter.

The sensor is automatically assigned.

The channel to which is was assigned shows the measurement

data of the sensor.

1 Connect the ID sensor to the socket of the meter.

As soon as the meter has recognized the ID sensor, the Auto-

matic sensor recognition window appears with the sensor

name and series number.

ba75646e03 12/2012

2 Assign the sensor that was recognized to a channel with pH/U/

ISE Probe 1 or pH/U/ISE Probe 2.

As soon as a sensor was assigned to a channel, the assignment is completed and the Automatic sensor recognition is

closed again.

Note

The manual assignment of a sensor to a channel is stored in the

meter. The next time the meter is switched on while ID sensors are

connected, the last assignment of the sensor is displayed and can be

confirmed with <OK>.

27

Page 28

Commissioning ProLab 4000

3.6.2 Connecting a non ID sensor

1 Connect the sensor and if necessary, temperature sensor to a

socket.

The relevant channel shows the measurement data of the sensor.

2 Prior to measuring:

Calibrate the sensor.

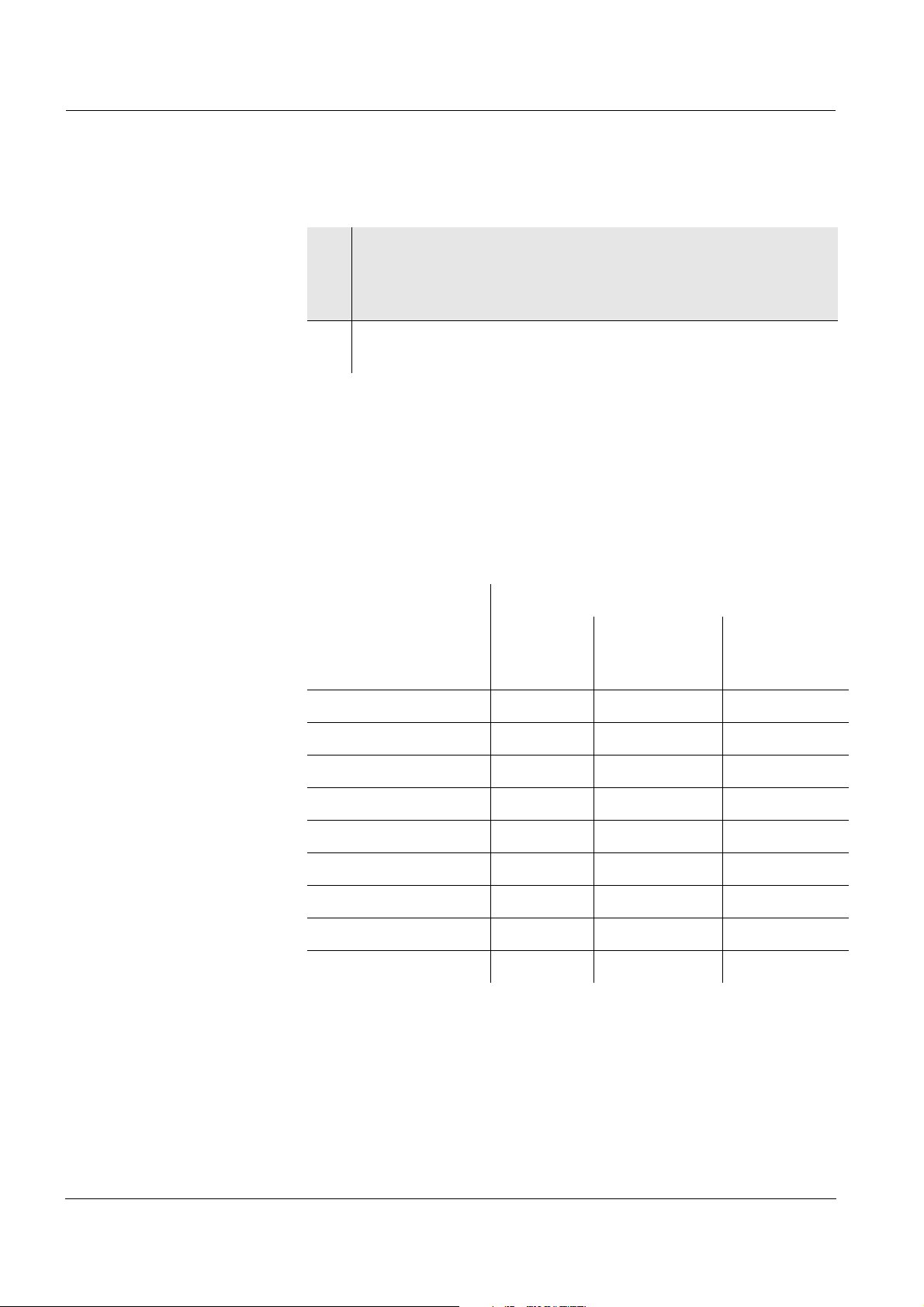

3.7 Connecting optional accessories

The ProLab 4000 has several interfaces to connect accessories to. To

connect a device, find the suitable interface in the following table.

More information on how to operate an interface is provided with the

description of the interface.

Interface

Accessory RS232

(see

page 29)

USB-B

(USB Device)

(see page 31)

USB-A

(USB Host)

(see page 32)

PC x x

Printer x x

Burette X

USB mouse x

USB memory x

USB card reader x

USB keyboard x

USB barcode reader x

USB hub x

28

ba75646e03 12/2012

Page 29

ProLab 4000 Commissioning

3.7.1 RS232 interface (serial port)

PC, printer and burettes can be connected via the RS232 interface.

Data that is transmitted to the interface with <PRINT> can be printed

out with a printer or received with a terminal program if a PC is connected.

Note

If the burette control is active, data output to the RS232 interface

(printer) is deactivated.

On the meter, the following transmission data are permanently set for

the RS232 interface:

– Baud rate: 4800

– Data bits: 8

– Stop bits: 1

– Parity: none

The transmission data must agree with the transmission data for the

interface adjusted on the burette.

Check the transmission data adjusted on the burette, and change

them if necessary (see operating manual of your burette).

Operation with RS232 Connect the interface of the ProLab 4000 to the devices using the Z390

(PC) or Z893 (external USB printer Z890) cable.

Set up the following transmission data on the PC/printer:

Baud rate selectable between: 1200 ... 115200

The baud rate must agree with the baud rate set on

the PC/printer.

Handshake RTS/CTS

PC only:

Parity none

Data bits 8

Stop bits 1

ba75646e03 12/2012

Note

Pin assignment of the socket: See page 203.

29

Page 30

Commissioning ProLab 4000

30

ba75646e03 12/2012

Page 31

ProLab 4000 Commissioning

3.7.2 USB-B interface (USB Device)

You can connect a PC to the meter via the USB-B interface(USB

Device).

Data that is transmitted to the interface with <PRINT> can be printed

out with a printer or received with a terminal program if a PC is connected.

The USB driver of the enclosed CD-ROM must be installed for the interface to be available for the PC.

Installation of the USB

driver on the PC

Operation at USB-B

(USB Device)

System requirements of the PC for installation of the USB driver:

PC with Pentium processor or higher with at least one free USB con-

nection and CD-ROM drive

Windows 2000, XP.

1 Insert the supplied installation CD in the CD drive of your PC.

2 Connect the meter to the USB input of the PC via the USB

cable.

Windows automatically installs the driver for the meter. Follow

the Windows installation instructions as necessary.

The meter is listed as a virtual COM interface among the connections in the Windows instrument manager.

Connect the interface on the ProLab 4000 to the PC using a cable with

a USB-A and a USB-B plug.

Set up the following transmission data on the PC/printer:

Baud rate selectable between: 1200 ... 115200

The baud rate must agree with the baud rate set on

the PC/printer.

ba75646e03 12/2012

Handshake RTS/CTS

PC only:

Parity none

Data bits 8

Stop bits 1

31

Page 32

Commissioning ProLab 4000

3.7.3 USB-A interface (USB Host)

You can connect the following devices to the USB-A interface (USB

Host) at the ProLab 4000:

Accessory Use

USB mouse Simple operation of the ProLab 4000 like a

PC

USB printer Simple output of data to the printer with the

<PRINT> key

USB memory Simple data backup on an external USB

medium

USB card reader Simple data backup on an external memory

card

USB keyboard Input of text with the keyboard

Operation at USB-A

(USB Host)

USB barcode reader Input of data such as sample designations

using a barcode.

Data input using the barcode reader is

always possible whenever it is possible to

input data via the keyboard.

USB hub (USB 2.0) Multiplication of the number of USB-A inter-

faces USB Hostfor simultaneous operation

of several USB devices

Connect the interface on the ProLab 4000 to the external device using

a cable with a USB-A and a USB-B plug.

The device is automatically recognized and is immediately operable.

32

ba75646e03 12/2012

Page 33

ProLab 4000 Operating principles

4 Operating principles

This section contains basic information on the operation of the

ProLab 4000.

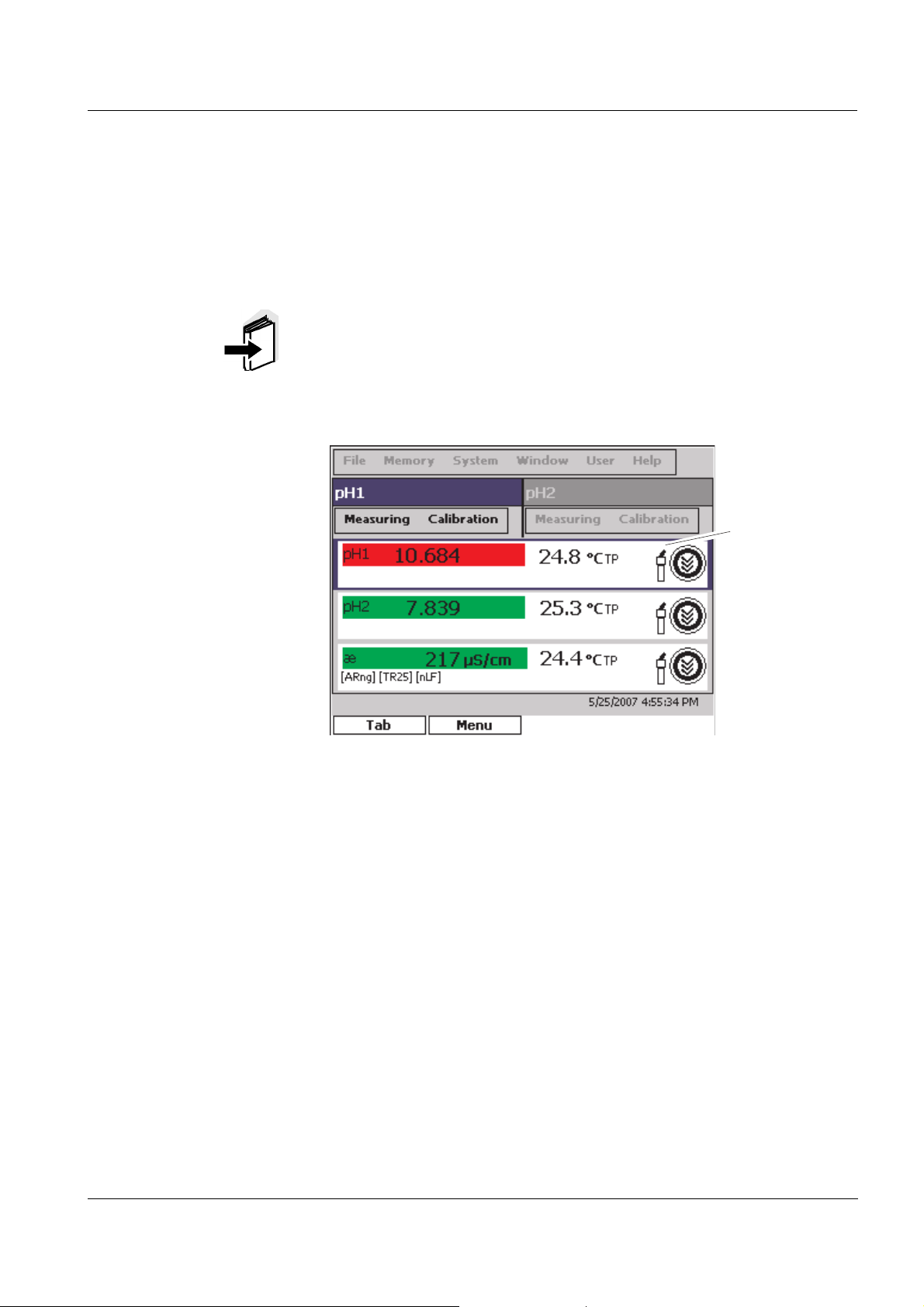

4.1 Operating and display elements

Mouse The ProLab 4000 is designed for mouse operation. With a mouse click

you can carry out all functions except for the entry of characters and

numerals. This means the ProLab 4000 can be operated as easily as a

software on the PC.

Keys Frequently required functions such as Store (<STO>), Calibrate

(<CAL>) or Print (<PRINT>) are directly available using keys. In this

operating manual, keys with dedicated functions are identified by the

key labeling, bold letters and angle brackets, e.g. <OK>.

Note

When the meter is operated with the mouse, all key functions are

available in a context menu (right mouse button).

Window The screen shows display windows and dialog boxes like a PC soft-

ware. Only one window is active at a time. The active window has a colored title bar. Windows that are not active have a grayed out title bar.

In the measured value display, for each channel there is a window with

special menus for the displayed measured parameter.

Windows contain further operating elements such as buttons, register

cards, selection lists, option fields and input fields.

When operating the meter without the mouse, use the [Tab] softkey to

activate the open window while scrolling, e.g. individual channels or the

main menu.

Buttons Functions in dialog boxes are executed using buttons. In this operating

manual, buttons are identified by angle brackets. Example: [Continue]

or [OK].

When operating without the mouse the buttons have to be selected

first. Then the respective function can be executed with <OK>. The

[Cancel] button can always be operated with the <ESC> key directly.

ba75646e03 12/2012

33

Page 34

Operating principles ProLab 4000

1

2

3

6

12

5

Main menu

Sensor menu

Display Depending on the operating situation, the color display shows mea-

surement data, calibration steps, setting dialogs or stored data.

Main menu (1)

1 Main menu

2 Channel

3 Menu for a measured parameter

5 Info line

6 Softkey assignment

12 Softkeys

34

ba75646e03 12/2012

Page 35

ProLab 4000 Operating principles

In the main menu, there are sensor independent functions and settings:

Manage configurations (File ) (see page 190)

Store current measurement data, and display and edit stored mea-

surement and calibration data (Memory) (see page 161)

System settings such as language, date, time, color assignment,

interface settings and general measurement settings (System) (see

page 56)

Select the measurement data to be displayed (Window)

Manage user data (User ) (see page 171)

ba75646e03 12/2012

35

Page 36

Operating principles ProLab 4000

Channel (2) In the measured value display, for each connected sensor you can see

a channel with special menus for the displayed measured parameter

(Measuring, Calibration).

Menu for a measured

parameter (3)

Info line (4) The info line shows the date and time, information or instructions on the

Softkey assignment and

softkeys (5+6)

Menus for a measured parameter comprise sensor dependent functions and settings:

Calibration settings and calibration data (Calibration) (see section

C

ALIBRATION in the chapter for the respective sensor)

Temperature settings such as usage of the temperature sensor of

another sensor, manual temperature setting (Measuring)

The measured value display with recorder (see page 172)

Resetting the sensor settings

Special measurement settings (Measuring)

A detailed description of the functions is given with the description of

the measured parameter.

current situation.

Softkeys provide additional, situation-related functions. In this operating manual, softkeys are indicated by the currently displayed function,

bold letters and angle brackets, e.g. [Tab].

The current functions are displayed in the four fields in the lower display

(empty field = no function).

36

ba75646e03 12/2012

Page 37

ProLab 4000 Operating principles

4.2 File system

Files With the ProLab 4000 you can store data in files just like using a PC.

Different data is stored in an extra file, such as

manually stored measured values

automatically stored measured values

recorder data

A complete overview of the data that can be stored and the corresponding file formats is given in chapter 11 M

File system The ProLab 4000 creates an individual directory with the user name for

each registered user.

In his/her directory, each user can:

Create folders

Store data

EMORY (see page 161).

Delete files

View stored files

File dialogs such as Save as always suggest the directory of the registered user.

Note

If an external USB memory is connected, the external memory

appears as a folder in the directory of the user.

Only the administrator can move to a higher directory and in other user

folders.

ba75646e03 12/2012

37

Page 38

Operating principles ProLab 4000

7

PQRS

4.3 Entry of numerals, letters and characters

Numerals, letters, punctuation marks and special characters are

entered on the alphanumeric keypad on the meter or an external keyboard.

Entering characters is required in operating situations such as the following:

Entry of the date and time

Entry of an ID, e. g. if you want to store measurement data

Entry of the user name and password

User management

Character set The following characters are available:

Numerals 0 ... 9

Letters A ... Z

Punctuation marks . -

Operating principle Characters can be entered as long as an input field is displayed.

The keys of the alphanumeric are assigned to the characters that are

printed on them. Example: With the <PQRS 7> key you can enter the

following characters: 7, P, Q, R, S.

The required character is selected by pressing the key several times

(similar to a cell phone). The numeral appears on the first pressing if

the key is assigned to several characters. One keypressing is sufficient

to enter a numeral.

The key for punctuation marks (<- .>) is assigned to a decimal point of

minus sign, depending on the context. If a number is in front of the

punctuation mark, a decimal point is automatically displayed, in all

other cases a minus (-).

A character is taken over in the input field if

the character is highlighted longer than one second,

the character is confirmed with <OK>,

another alphanumeric key is pressed.

Operating example:

Entering an ID

The input field for an ID appears if you press the <STO> key to store

measurement data. A dialog with input fields for the ID and comment

opens up. In the following example, a measurement dataset with the ID

"Test" should be stored.

1 Press <TUV 8> several times until "T" appears in the input line.

After approx. 1 second the character is taken over.

38

ba75646e03 12/2012

Page 39

ProLab 4000 Operating principles

2 Complete and confirm the ID with <A...9>.

Mouse operation:

With the mouse, you have in all entry fields the additional option of

showing a keyboard with the right mouse button. You can then enter

letters or numerals with the mouse.

Correcting wrong

entries

Move the cursor behind the character to be deleted with <><>.

Then delete the character in front of the cursor with <DEL>.

ba75646e03 12/2012

39

Page 40

Operating principles ProLab 4000

4.4 Navigation

The dialog with the meter takes place through menus and dialog boxes

as usual with any PC software. In each dialog box there are operating

elements such as register cards, selection lists, buttons or input fields.

Note

The ProLab 4000 is designed to be operated with a mouse. A suitable

mouse is included in the scope of delivery.

General operating

principles

If you wish to operate the meter without using a mouse, find some general operating principles listed below.

Key / softkey

[Tab] Select main

[Menu] Open main

Measured

value display

menu or

channel

Menu Dialog box

- Select an element

such as a register

card or button

--

menu or

selected

channel

<><>

and

<><>

<OK> - Execute a menu

- Select a menu

item

item, e.g. start an

action or open a

Select a subelement in a dialog

box

Execute the function of the

selected button

dialog box.

<ESC> - Close the menu Cancel current

action without

change

40

ba75646e03 12/2012

Page 41

ProLab 4000 Operating principles

Menu / chan-

nel, not high-

Channel,

highlighted

4.4.1 Navigation in the measured value display

The display shows, for example, the measurement data of all activated

channels, the main menu, the sensor menu and the softkey functions.

Using [Tab], activate channels or the main menu

Using [Menu], open the menu line.

Using <MODE>, change the measured parameter for the selected

channel (e. g. pH ><− mV).

Using the functions keys on the meter such as Calibrate (<CAL>),

Store (<STO>), Print (<PRINT>), Display stored measurement data

(<RCL>), Manual stability control (<SC>) etc. you can execute further functions.

Operating example:

Highlighting a channel

A channel is an indication on the display that corresponds to a physical

connection at the meter. The number of the channel is displayed with

the selected measured parameter, e.g. pH1, pH2.

1 In the measured value display, highlight the main menu or a

channel with [Tab].

The highlighting moves on with each keypressing.

ba75646e03 12/2012

Mouse operation:

1 Select a channel or menu name with a mouse click.

41

Page 42

Operating principles ProLab 4000

4.4.2 Navigation in menus

A menu item contains submenus, executes a function or opens a dialog

box.

The selection is made with the <><> and <><> keys or the

mouse.

The current selection is highlighted.

Menus

Submenus are marked by an arrow to the right (). Menus are

opened with <OK>.

Functions

Functions are indicated by the name of the function. They are immediately carried out by confirming with <OK>.

Dialog boxes

Settings are marked by dots (...).

The relevant setting window is opened with <OK>.

Operating example:

Navigation in the menu

Menus are available for general settings and functions and for each

individual measured parameter.

1 In the measured value display, highlight the main menu or a

channel with [Tab].

A highlighted channel is marked by a frame.

2 Open the menu with the current selection with [Menu].

3 Highlight a menu item with <><> and <><>.

The highlighted menu item is displayed inverse.

4 Confirm the highlighted menu item with <OK>.

42

ba75646e03 12/2012

Page 43

ProLab 4000 Operating principles

5 Highlight a menu item with <><> and <><>.

The highlighted menu item is displayed inverse.

6 Confirm the highlighted menu item with <OK>.

When a function is executed the main menu is closed and the

function executed, or a dialog box opens up.

Mouse operation:

1 Select a menu name with a mouse click.

The menu pops up.

2 Select a menu item and confirm with a mouse click.

When a function is executed the main menu is closed and the

function executed, or a dialog box opens up.

ba75646e03 12/2012

43

Page 44

Operating principles ProLab 4000

4.4.3 Navigation in dialog boxes

Dialog boxes contain further subelements such as register cards,

selection lists and buttons. The elements are selected with the [Tab]

softkey. Within a list or register card, they are selected with the

<><> or <><> keys.

Operating example:

Navigation and settings

in dialog boxes

1 Using [Tab], highlight individual elements in a dialog box.

Highlighted elements such as register cards, option fields or

buttons are marked by a dotted frame.

Highlighted lists are displayed inverse.

2 If an element such as a register card or list that allows a further

selection is highlighted:

Highlight a different selection in element with <><> or

<><>.

3 If an element such as a button that executes a function is high-

lighted:

Use <OK> to execute the function.

Mouse operation:

1 Select an element with a mouse click.

The relevant function is executed.

44

ba75646e03 12/2012

Page 45

ProLab 4000 Operating principles

4.4.4 Navigation in the file selection dialog box

The file selection dialog is opened if a file is to be created, stored,

selected or deleted.

All files are stored in the folder of the user. Each user can create or

delete subfolders in his/her folder.

The file dialog box contains further subelements such as

symbol buttons,

a list with files and subfolders,

an input field for the file name and

buttons.

The elements are selected with the [Tab] softkey. Within a list or register card, they are selected with the <><> or <><> keys.

The functions of the symbol buttons available with the keypad using the

[Menu] softkey. A context menu opens up that contains all key functions.

ba75646e03 12/2012

Note

Functions in file dialog boxes that are activated with symbol buttons

can be activated via the contest menu with [Menu] if you operate without the mouse. Examples:

: move one folder up

: create new folder

: display/hide header

45

Page 46

Operating principles ProLab 4000

Operating example:

Navigation and settings

in file selection dialogs

1 Highlight an element in a file dialog box with [Tab]. Highlighted

elements such as buttons are marked by a dotted frame.

Highlighted input fields are displayed inverse.

2 If an element such as the file list in the current folder allows a

further selection:

Highlight a different selection in element with <><> or

<><>.

3 If an element such as the input field for the file name allows an

entry:

Enter a name with <A...9>.

4 If an element such as a button that executes a function is high-

lighted:

Use <OK> to execute the function.

Mouse operation:

1 Select an element with a mouse click.

The assigned function is executed.

2 If an element such as the input field for the file name allows an

entry:

Enter a name with <A...9>.

46

ba75646e03 12/2012

Page 47

ProLab 4000 Access to the meter

5 Access to the meter

5.1 Switch the meter on and off

Switching on

Switching off

Login with password

1 Switch the meter on with <On/Off>.

The self-test, meter designation, software version and subsequently the Login dialog box appear.

1 Switch off the meter with <On/Off>.

5.2 Login as a user

After switching on, the Login dialog box pops up. Depending on the

adjusted type of access control, the dialog box contains:

a list to select a user name and a field to enter a password or

the prompt, Place the electronic key on the reader field.

In the delivery condition, access is possible with password.

ba75646e03 12/2012

1 Select an item in the User name list.

2 Enter the correct password for the user name and confirm with

<OK>.

The login has taken place.

47

Page 48

Access to the meter ProLab 4000

Note

The default password for the administrator is "00001".

For your safety, change it as soon as possible (see page 49). No

password entry is required for anonymous access.

Login with electronic

key

Login with electronic

key and password

The Login dialog box displays the instruction:

Place the electronic key on the reader field.

1 Place the electronic key on the read field and leave it there for

approx. 2 seconds until the key has been recognized.

The user name and key number is displayed. The login has

taken place.

The Login dialog box displays the instruction:

Place the electronic key on the reader field.

1 Place the electronic key on the read field and leave it there for

approx. 2 seconds until the key has been recognized.

The user name and key number is displayed.

2 Enter the correct password and confirm with <OK>.

The login has taken place.

Note

Depending on user rights, individual functions and settings may be

grayed out and thus locked.

More information on user rights: See page 51.

48

ba75646e03 12/2012

Page 49

ProLab 4000 Access to the meter

5.3 Password for login

If the used of a password for login to the meter was set by the administrator, each user has to enter his or her password during the login.

The ProLab 4000 is delivered with the password "00001" for the user

name, Administrator . Change this password as soon as possible.

5.3.1 Changing the password

All users can change their own password.

A valid password consists of at least 5 characters.

1 Open the User / Change password... menu.

The Change password window opens.

The old password is in the Old password field.

2 Enter the new password in the New password field.

3 Enter the new password once again in the Confirm password

field.

4 Confirm the new password with [OK].

The password is changed.

The Change password window is closed.

5.3.2 Assigning a password

During the first login with the new user name the Change password

window appears. Here the password is set by the user. A valid password consists of at least 5 characters.

5.3.3 Forgotten the password?

If the access control requires the entry of a password, access to the

meter is not possible without the password.

Users The administrator can delete the password for user profiles (see

page 53).

ba75646e03 12/2012

49

Page 50

Access to the meter ProLab 4000

5.4 Lock

During operation (e.g. if the automatic storing function is active), the

activated lock prevents the inadvertent use of the meter with the name

of the registered user.

The lock can only can only be released with the currently registered

electronic key or the administrator key.

Note

The lock can only be activated in the measuring mode of operation.

With anonymous access, the Activate lock function is not available.

Activating the lock

Releasing the lock

1 Activate the lock in the System / Activate lock menu.

The meter is locked against inadvertent use.

1 Press any key.

The login window pops up.

2 Log in with the password, electronic key or electronic key and

password.

The lock is released.

50

ba75646e03 12/2012

Page 51

ProLab 4000 Access to the meter

5.5 Access control and user rights

You as the administrator define the type of access (assess control) to

the ProLab 4000. In addition, you define the rights to carry out functions

and measurements for the users (user rights).

When the meter is delivered, only the enclosed electronic administrator

key has an access authorization for the meter.

The administrator can set up access authorizations for electronic user

keys (see below).

Anonymous access without password and electronic key (user name,

Anonymous) is always possible. Measurement and calibration data is

identified by the user name, Anonymous.

After the login as administrator, the user management functions are

available in the Access control and Administration register cards of the

User / Administration... menu.

Access control In the Access control register card you define the general access set-

tings that will apply to all users.

User rights Each user is given user rights with the ProLab 4000. The user rights are

limited by the user type and configuration:

User type User rights

Administrator Calibrate and measure

Create file for manual storage

Create user configuration

Define type of access to the meter

User administration

Delete all files

Users

without configuration

Calibrate and measure

Create file for manual storage

Create user configuration

Delete files in their own folder

with configuration Calibrate and measure

(limited by settings in configuration file)

ba75646e03 12/2012

51

Page 52

Access to the meter ProLab 4000

User type User rights

Anonymous Calibrate and measure

Create file for manual storage

Create user configuration

Delete files in the folder, Anonymous

Note

Only one user can be the administrator. The administrator is adjusted

in the delivery condition. The administrator can only create users of

the type, user.

5.5.1 Access control

The administrator defines the type of access to the meter.

The setting applies to all users and the administrator.

Type of access Description

Access with password The meter can only be unlocked by enter-

ing the password for a certain user.

Access with electronic

key

Access with el. key and

password

Access with electronic key only. No additional password is required here.

To be able to work with the meter, a password has to be entered in addition to

access with the electronic key.

1 Open the User menu with Administration....

The User administration dialog box pops up.

The General register card is open.

2 Select the type of access and confirm with [OK].

The new setting is active when the ProLab 4000 is switched on

the next time.

52

ba75646e03 12/2012

Page 53

ProLab 4000 Access to the meter

5.5.2 User management and assigning user rights

The ProLab 4000 has basic user management functions. The administrator can

add new users

delete users

delete the password assigned to a user

store a configuration file for users.

The configuration file contains measurement settings that cannot be

changed by the user. Besides, the administrator considerably

restricts the rights of the user.

The user cannot

– change or reset any defined measurement settings

– delete any files

– create or change any configuration

– backup any data

hide the anonymous access or any user. If a user or anonymous

access is hidden, it is no longer available in the login dialog and cannot be selected.

The administrator also defines the user rights for any new user (see

page 51).

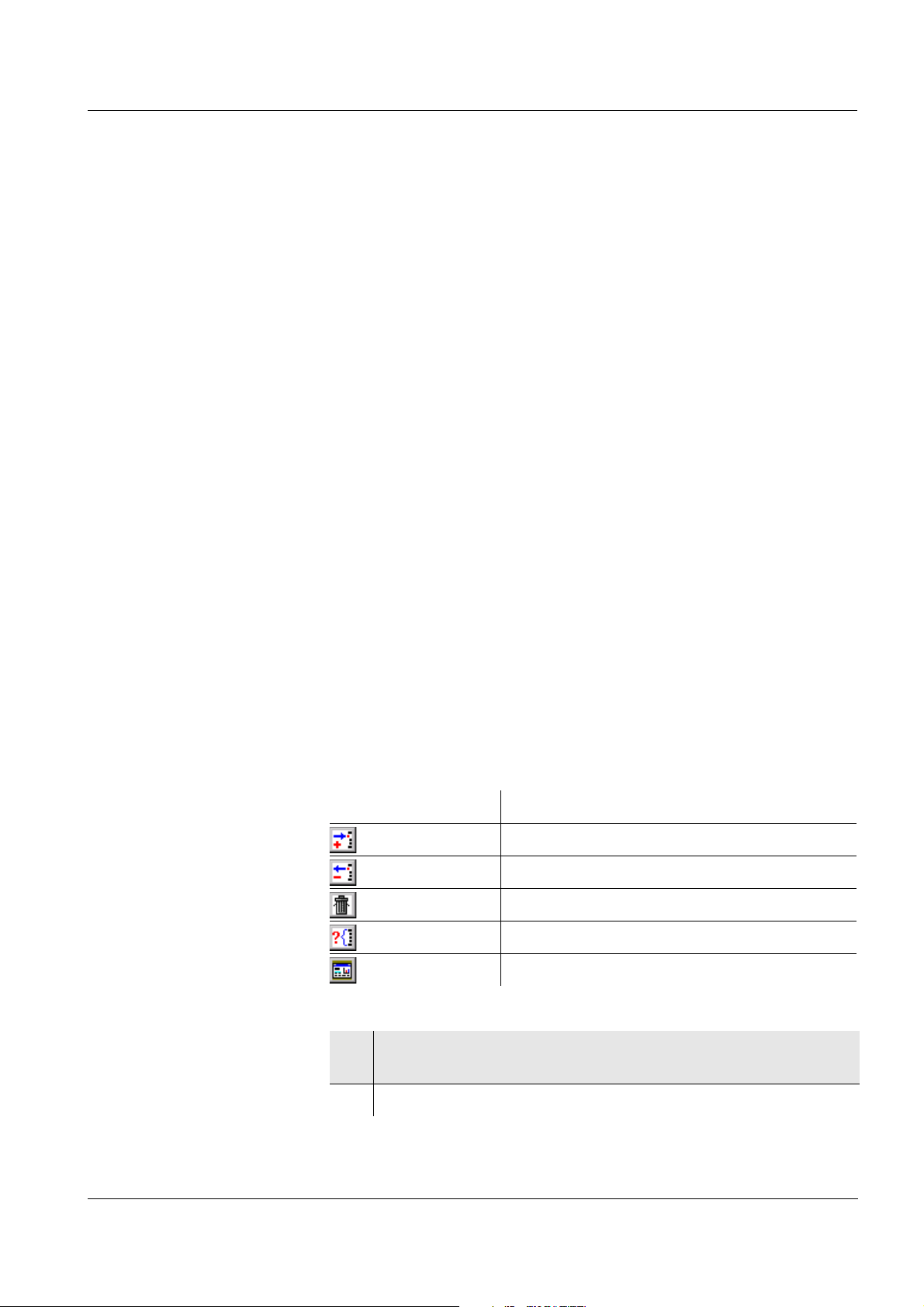

The symbol buttons are used for user management with the mouse.

The relevant functions are available as a context menu with the [Menu]

softkey when operating with the meter keypad.

Symbol button Function (designation in context menu)

Add user

Delete user

Delete old password

Hide user/visible

Add configuration...

ba75646e03 12/2012

1 Open the User menu with Administration....

The User administration dialog box pops up.

2 Open the Administration register card.

53

Page 54

Access to the meter ProLab 4000

Adding a new user

Assigning a

configuration to a user

1 Enter a new user name in the New user field.

or

Place an electronic user key on the reader field.

The key number and a user name already stored in the key are

displayed.

If necessary, enter a new user name in the New user field.

2 In the context menu, select the menu item, Add user.

The new user is included in the list of registered users.

On access with the electronic key, the user name is at the

same time stored in the electronic key.

3 Remove the electronic key from the reader field.

4 Highlight a user in the list of users.

5 In the context menu, select the menu item, Add configuration....

The Open file dialog box pops up.

6 Select a configuration file and confirm with [OK].

The configuration file is permanently assigned to the user and

is also displayed in the list of users.

Erasing a registered

54

user

7 Highlight a user in the list of users.

8 In the context menu, select the menu item, Delete user.

A safety query appears. After confirming the safety query the

access authorization for the currently highlighted user is

deleted.

ba75646e03 12/2012

Page 55

ProLab 4000 Access to the meter

Erasing the password

for a registered user

Hiding / displaying a

user

Exiting the user

management

9 Highlight a user in the list of users.

10 In the context menu, select the menu item, Delete old pass-

word.

A safety query appears. After confirming the safety query the

password for the currently highlighted user is deleted.

11 Highlight a user in the list of users.

12 In the context menu, select the menu item, Hide user/visible.

If the user is hidden, the [Hidden] labeling is displayed in the list

of users.

13 Confirm the settings with [OK].

The user settings are active.

5.6 Lost your electronic key?

Without an electronic key with access authorization, anonymous

access is possible only.

Electronic user key Keys for additional users can be obtained from SI Analytics GmbH.

The access authorization for new keys is set up by the administrator

(see page 53).

Electronic administrator

key

If the electronic administrator key is lost, the access authorization for a

new electronic administrator key can be set up in the factory only.

The addresses and telephone numbers of SI Analytics GmbH are given

on the cover of this operating manual.

ba75646e03 12/2012

55

Page 56

System functions ProLab 4000

6 System functions

System functions are all functions that are independent of the probe.

6.1 Overview: System settings

The following sensor-independent meter features can be adjusted in

the System menu and its submenus:

Menu item Setting Description

System

– Data output...

– USB printer ()

– USB interface /Baud () / 1200 ... 115200 Baud rate of the data interface

– Serial interface /Baud () / 1200 ... 115200 Baud rate of the data interface

– Output format – ASCII

– CSV

– Autom. printout... Printout interval Automatic output of the measure-

– Reset - Resets the system settings to the

– Measuring

– Autom. stability control () You can activate or switch off the

Output format for data transmission

For details, see page 187

ment data to the interfaces at the

specified interval.

default values.

For details, see page 66

automatic stability control function (see page 63).

56

– Temperature unit – Celsius

– Fahrenheit

– Connect Ref1/Ref2 () Use reference electrode of the

All temperatures are displayed

with the selected unit.

other pH/ISE input

ba75646e03 12/2012

Page 57

ProLab 4000 System functions

Menu item Setting Description

System

– Signal On () Switches on or off the acoustic

signal. The signal sounds e.g.

when a stable measured value

has been recognized (stability

control)

– Country and language...

– Country List with over 100

countries

With this setting you can select

the country-specific notation for

the date, time and numbers.

The setting applies to all data

that is stored or output to an

interface.

– Language – Deutsch

Select the menu language

– English

– Francais

– Espagñol

– Date and time...

– Date Setting the date

– Time Setting the time

– Color code... – SC stable

– SC not stable

– Instruction display

– Information dis-

play

Settings in the Color code group

field change the background

color for display indications with

certain states (stability criterion

for stable measured values met /

not met) and for indications in the

info line.

– Activate lock () After a user login with the elec-

ba75646e03 12/2012

tronic key, the key lock can be

activated here. The meter is

locked against operational

actions until the electronic key is

applied again.

57

Page 58

System functions ProLab 4000

6.2 Selecting the language

Menus can be displayed in different languages. The language is

selected in the System main menu.

1 Open the System / Country and language... menu.

The Country and language window opens.

2 Select a language in the Language list.

The active language is highlighted.

3 Confirm the selection with [OK] .

The language is changed.

6.3 Selecting the country

With this setting you can select the country-specific notation for the

date, time and numbers. This data is stored and output to an interface

in the country-specific notation.

1 Open the System / Country and language... menu.

The Country and language window opens.

2 Select a country in the Country list.

The active country is highlighted.

3 Confirm the selection with [OK] .

The country is changed.

58

ba75646e03 12/2012

Page 59

ProLab 4000 System functions

6.4 Setting the date and time

The data and time are displayed in the local format, according to the

Country setting (see above). The date and time are set in the menu,

System / Date and time....

1 Open the System / Date and time... menu.

The Date and time window opens.

2 Select the time zone in the Time zone field.

3 If necessary, mark the Automatic daylight saving time field.

4 Select the date.

5 Enter the time.

6 Confirm the entries with [OK] .

The date and time are taken over.

ba75646e03 12/2012

59

Page 60

System functions ProLab 4000

6.5 Selecting the channels for measured value display

In the Window / Channels... you can define which channels are visible

in the measured value display.

Depending on the number of activated measurement data one, two or

three sensor data are displayed at the same time.

Menu item Description

pH/U/ISE Probe 1 Display or hide the sensor data of the pH/U/ISE

1 channel.

pH/U/ISE Probe 2 Display or hide the sensor data of the pH/U/ISE

2 channel.

Cond Probe Display or hide the Cond sensor window.

6.6 Interfaces for data download

The meter has three interfaces to which data can be downloaded:

RS232: serial printer or PC

USB-B (USB Device): PC

USB-A (USB Host): USB printer

You can specify to which interfaces data will be downloaded at the

same time.

1 Open the System / Data output... menu.

The Data output window opens.

60

ba75646e03 12/2012

Page 61

ProLab 4000 System functions

2 Mark the option fields, USB printer, Serial interface and USB

interface.

The interfaces are selected for data download.

3 If data should be downloaded to the Serial interface or USB

interface interfaces:

Set the baud rate in the respective Baud list field.

The interface is ready for data download.

6.7 Temperature

The temperature affects the measurement results. You can select the

unit of the temperature display. The temperature is determined automatically with an external temperature sensor or one that is integrated

in the sensor. It is also possible to enter temperature values manually.

6.7.1 Temperature unit

Measured temperature values can be displayed in the unit, °C (degrees

Celsius) or °F (degrees Fahrenheit).

1 Open the System / Measuring / Temperature unit menu and

select the unit, Celsius or Fahrenheit.

The selected temperature unit is active.

ba75646e03 12/2012

61

Page 62

System functions ProLab 4000

6.7.2 Temperature measurement

For reproducible measurements it is essential to determine the corresponding temperature value.

The measuring system receives the temperature value from:

a temperature sensor integrated in the sensor,

a temperature sensor integrated in another sensor,

an external temperature sensor NTC30 or Pt1000, or

manual input of the temperature value.

On the display, the used temperature sensor is labeled with TP,

pH1 TP, pH2 TP or Cond TP

.

Using an integrated

temperature sensor

Using the temperature

sensor of another

sensor

Sensors with an integrated temperature sensor always measure the

measured parameter and temperature simultaneously. If the integrated

temperature sensor is recognized, the measured temperature value

and the TP status indicator appear on the display.

If no temperature sensor is available for a pH/ISE channel, you can

measure the temperature with the integrated temperature sensor of

another sensor.

To do so proceed as follows:

1 Immerse two electrodes in the measuring sample.

2 Highlight a channel in the measured value display.

3 In the sensor menu, select the Alternative TP menu item, e.g.

Measuring / Alternative TP.

The temperature measurement is active.

For checking purposes, the used temperature sensor is

indicated on the display.

Using an external

temperature sensor

62

If you want to measure the temperature using an external temperature

probe, proceed as follows:

1 Connect a temperature sensor to the measuring module.

2 Immerse the temperature sensor in the test sample.

The measured temperature value is shown on the display.

ba75646e03 12/2012

Page 63

ProLab 4000 System functions

SC stable

SC not stable

6.8 Automatic stability control

The Autom. stability control function continuously checks the stability of

the measurement signal. The stability has a considerable impact on the

reproducibility of measured values.

You can activate or switch off the Autom. stability control function

(menu, Autom. stability controlSystem).

The Autom. stability control function is carried out:

as soon as the measured value is outside the allowed stability range

when you switch over between the measured parameters with

<MODE>.

The stability of the measured value is indicated by the background

color of the measured value. In the delivery condition, the SC stable /