Page 1

Global Water

800-876-1172 • globalw.com

PL200-H Hydrant Pressure Logger

01-690

Publication Number 38920512

Global Water

Instrumentation, Inc.

151 Graham Road

P.O. Box 9010

College Station, TX 77842-9010

T: 800-876-1172

Int’l: (979) 690-5560, Fax: (979) 690-0440

E-mail : globalw@globalw.com

- 1 -

Page 2

Global Water

800-876-1172 • globalw.com

Congratulations on your purchase of a Global Water PL200-H-1 Fire

Hydrant Pressure Data Logger. This instrument has been quality tested

and approved for providing accurate and reliable measurements. We are

confident that you will find the logger to be a valuable asset to your

applications. Should you requi re assistance, our technical staff will be

happy to help.

Table of Contents

I. Checklist ▫ ▫ ▫ ▫ ▫ 3

II. Inspection ▫ ▫ ▫ ▫ 3

III. Warranty ▫ ▫ ▫ ▫ ▫ 3

IV. Specification ▫

▫ ▫ ▫ ▫ 4

V. System Requirements ▫ ▫ ▫ 5

VI. Accessing the USB Port ▫ ▫ ▫ 5

VII. Software Installation ▫ ▫ ▫ ▫ 5

VIII. Connecting to the Software ▫ ▫ 9

IX. Main Screen ▫ ▫ ▫ ▫ ▫ 10

X. On-Line Help Files ▫ ▫ ▫ ▫ 14

XI. Get History ▫ ▫ ▫ ▫ ▫ 15

XII. Setup Menus ▫ ▫ ▫ ▫ ▫ 16

XIII. General Setup ▫ ▫ ▫ ▫ ▫ 17

XIV. Analog Setup ▫ ▫ ▫ ▫ ▫ 21

XV. Programming ▫ ▫ ▫ ▫ ▫ 24

XVI. Installing the data Logger ▫ ▫ ▫ 25

XVII. Battery Replacement ▫ ▫ ▫ 25

XVIII. Battery Life ▫ ▫ ▫ ▫ ▫ 26

XIX. Troubleshooting ▫ ▫ ▫ ▫ 27

XX. Customer Support ▫ ▫ ▫ ▫ 28

Copyright Global Water I nstrumentation, Inc. 2012

- 2 -

Page 3

I. Checklist:

a. PL200-H-1 USB Fire Hydrant Dat a Logger

b. PL200-H-1 Data Logger Manual

c. USB Cable, Type A to B

d. Global Logger II Interface Software on CDROM

II. Inspection:

a. Your Data Logger was carefully inspected and certified by our Quality

Assurance Team before shipping. If any dam age has occur r ed dur ing

shipping; please notify Global W ater Instrumentation, Inc. and file a

claim with the carrier involved.

III. Warranty:

a. Global Water Instrumentation, Inc. warrants that its products are

b. The warranty begins on the date of your invoice.

Global Water

800-876-1172 • globalw.com

free from defects in material and workmanship under nor m al us e

and service for a period of one year from dat e of shipm ent from

factory. Global Water’s obligations under this warranty are

limited to, at Global Water’s option: ( I) replacing or (II) repairing;

any products determined to be defective. In no case shall Global

Water’s liability exceed the products original purchase price.

This warranty does not apply to any equipment that has been

repaired or altered, except by Global Water Instrumentation, Inc.,

or which has been subject to misuse, negligence or accident. It

is expressly agreed that this warr anty will be in lieu of all

warranties of fitness and in lieu of the war r anty of

merchantability.

- 3 -

Page 4

Global Water

800-876-1172 • globalw.com

IV. Specification:

Power Supply: One 3.6 Volt, 2.4Ahr, AA Size Lithium Battery

Global Water Part number 01-678

or from mouser.com, part number 667-TL5903S

Operating Temperature Industrial, -40ºC to +85ºC

Pressure Sensor: 0-200 psi gauge type sensor

300 psi over-pressure

Accuracy, +/- 1%, full scale

Battery voltage monitor

Analog Resolution: 12-Bit, 4096 Steps

Sensor Warm-up Time: 0 Seconds (50mS Actual)

Sample Modes: Fixed Interval: Programmable from 1 Sec. to >1 Year

High Speed: 10 Samples per second

Logarithmic Sample Rate (Approxim ation)

Exception (Log only on deviation from prev i ous r eading)

Storage Capacity: 81,759 Recordings of water pressure and bat tery

voltage with date/time stamp

Communication Ports: USB Type B

Selectable Baud Rates: Auto detect or fixed r ates at

9600, 19200, 28800, 38400, 57600, 115200

57.6K Baud is recommended

Thread Size: PL200-H-1: 2.5” BSP Male

PL200-H-2: 2.5” NHT Female

Spanner Wrench: Optional, 95-100mm

Part Number 01-827

Optional Adaptors: 2.5” BSP Female to 2.5” NHT Female

Part Number 01-826

Call for other available adaptors

- 4 -

Page 5

Global Water

800-876-1172 • globalw.com

V. System Requirements:

Desktop or Lapto p c o m put e r wit h:

1) W indows 98, ME, 2000, XP Vista or Windows 7 Operating Syst ems

2) CDROM Dr ive

3) USB Port

Note that the software described here is f or r unning on des k top and laptop

computers only. Software for many popular Handheld P DA dev ic es is als o

provided by Global Water. Special cables m ay be required.

VI. Accessing the USB Port

Remove the thumbscrew from

the center of the cover and lift off,

the USB port is located inside.

VII. Software Installation:

Global Logger Installation: This software is

for use on Windows based desktop and laptop

computers only. Insert t he s oftware installation CD and run the Setup program.

This will install the Global Logger application in the Program Files folder and

automatically put the Global Logger I I icon on the desktop.

USB Driver Installation: With the inst allation CD in the CDROM drive and DC

power applied to the logger, plug the USB c able into the data logger to open the

ADD New Hardware Wizard. The menus that follow will look dif ferent for different

operation systems but the procedure is the sam e. Do not allow the H a r dwa r e

Wizard to automatically search for the driver. Instead, specify the location

(CDROM). If a generic driver gets, or has been previously ins talled, it must be

uninstalled before proceeding by using the Add or R em ov e P r ogr am s section of the

Control Panel. Instead, click the S ear c h Ext er nal Media box or S pec ify a Location

box and install the driver from the CDROM. Running the Setup progr am that installs

the Global Logger software also installs a folder with the driver in it. This location

can also be specified if the CDROM is not available; alt hough, it is recommended

that the driver be installed at the same tim e the Global Logger is installed.

- 5 -

Page 6

Global Water

800-876-1172 • globalw.com

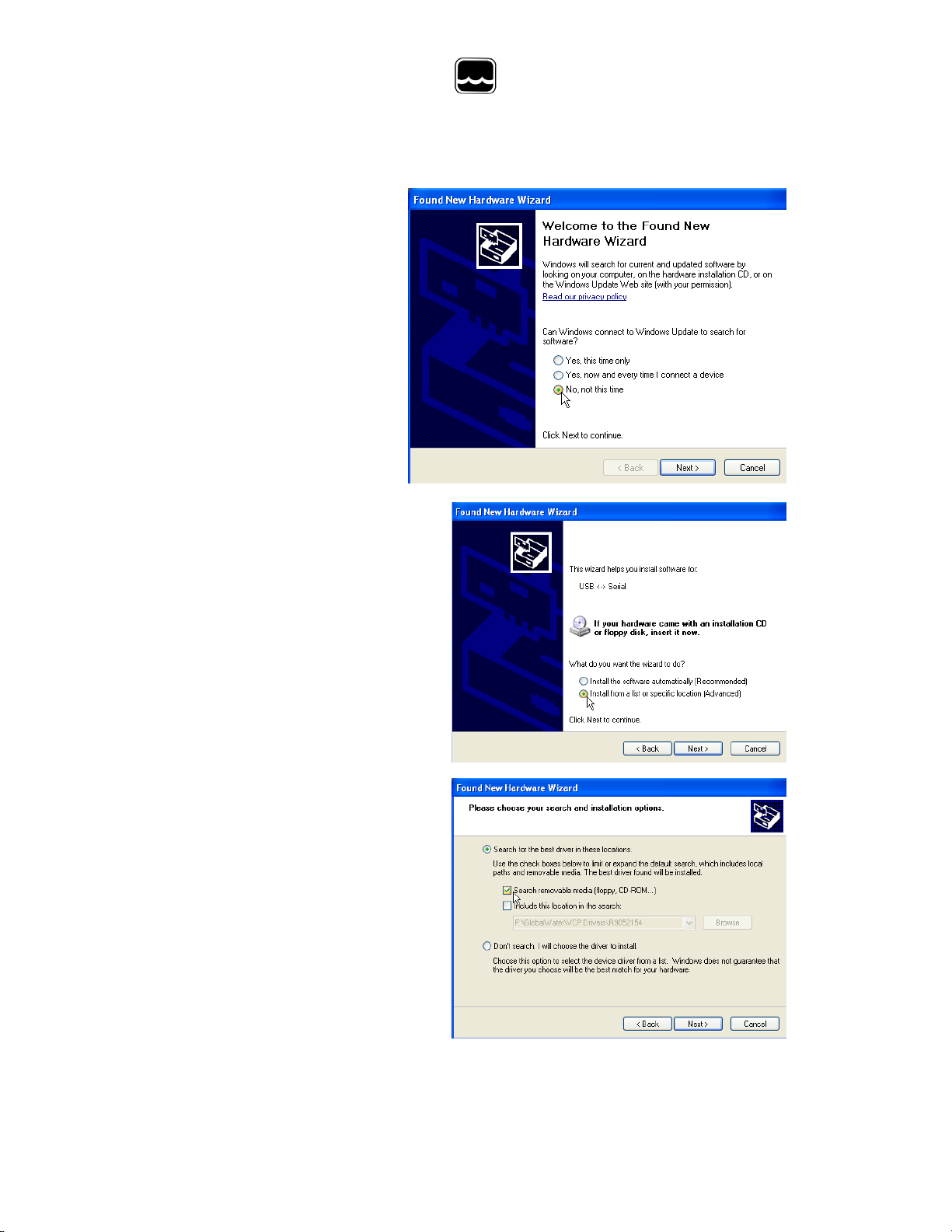

The following menus apply to the Windows X P operating s y s tem.

1) Do not let Windows search

for software. Click “No, not

at this time” when asked if

Windows Update can search

for software.

Click Next.

2) Do not let Windows automatically

install the software. Click “Inst all

from a specific location”.

Click Next.

3) Specify the location of the driver.

Make sure the Global Logger CDROM

is in the CD drive and click “Search

removable media” only.

Click Next.

- 6 -

Page 7

Global Water

800-876-1172 • globalw.com

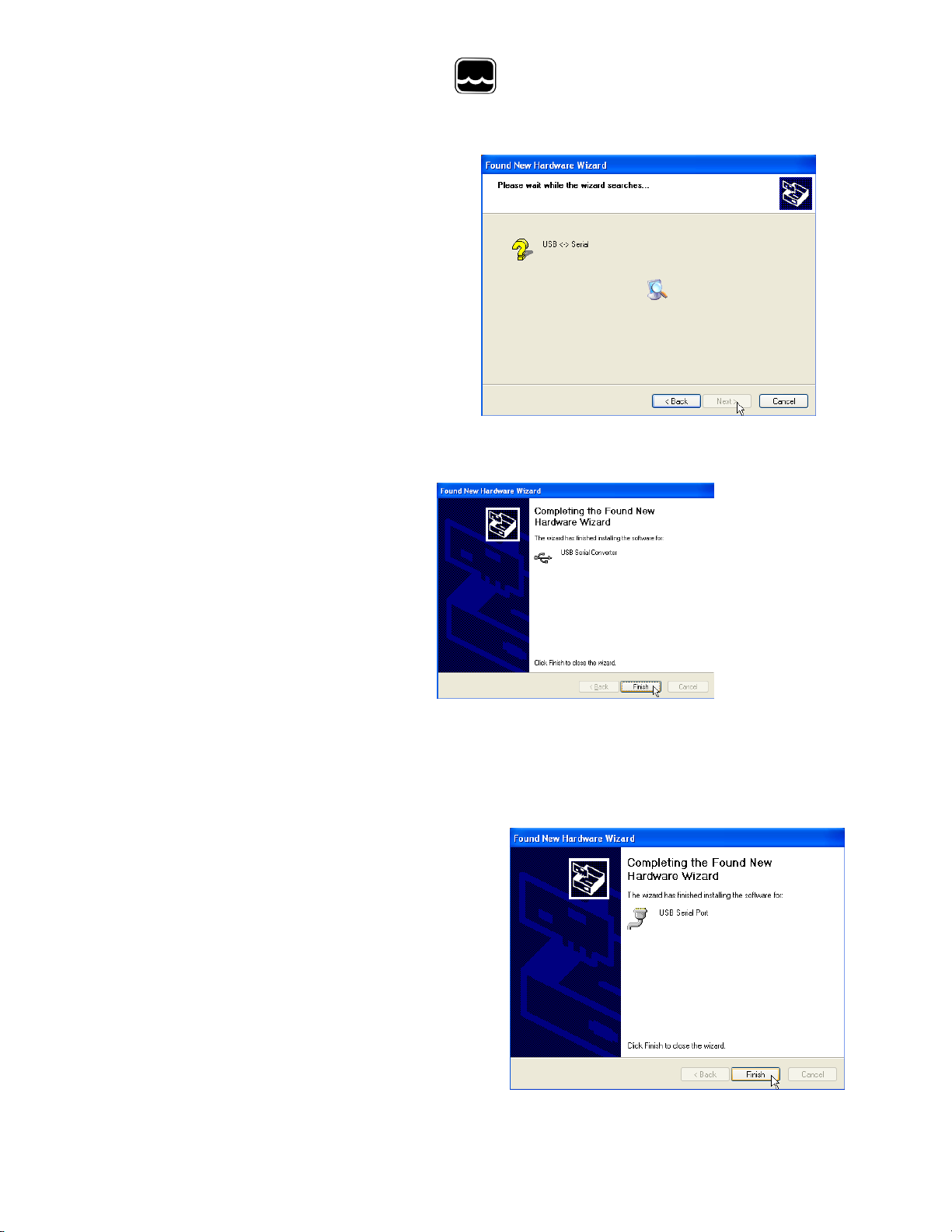

4) The Hardware Wizard searches

for the driver.

If Windows advises that the software

is not certified, click:

“Continue Anyway”.

This only means that Microsoft has not

licensed the software. Second party

software is allowed and no harm will

come to your computer.

5) The first half of the installation is

complete. The Hardware Wizard

must make two passes.

Click Finish.

6) Two drivers might be required so the Hardwar e Wizard may repeat the same

process again. As before; a: do not let the Windows Update do a s ear c h, b: tell

Windows to search from a specific loc ation instead of automatically inst alling

software, c: tell Windows to searc h from removable media (C DROM).

7) The installation is complete.

Click Finish.

- 7 -

Page 8

Global Water

800-876-1172 • globalw.com

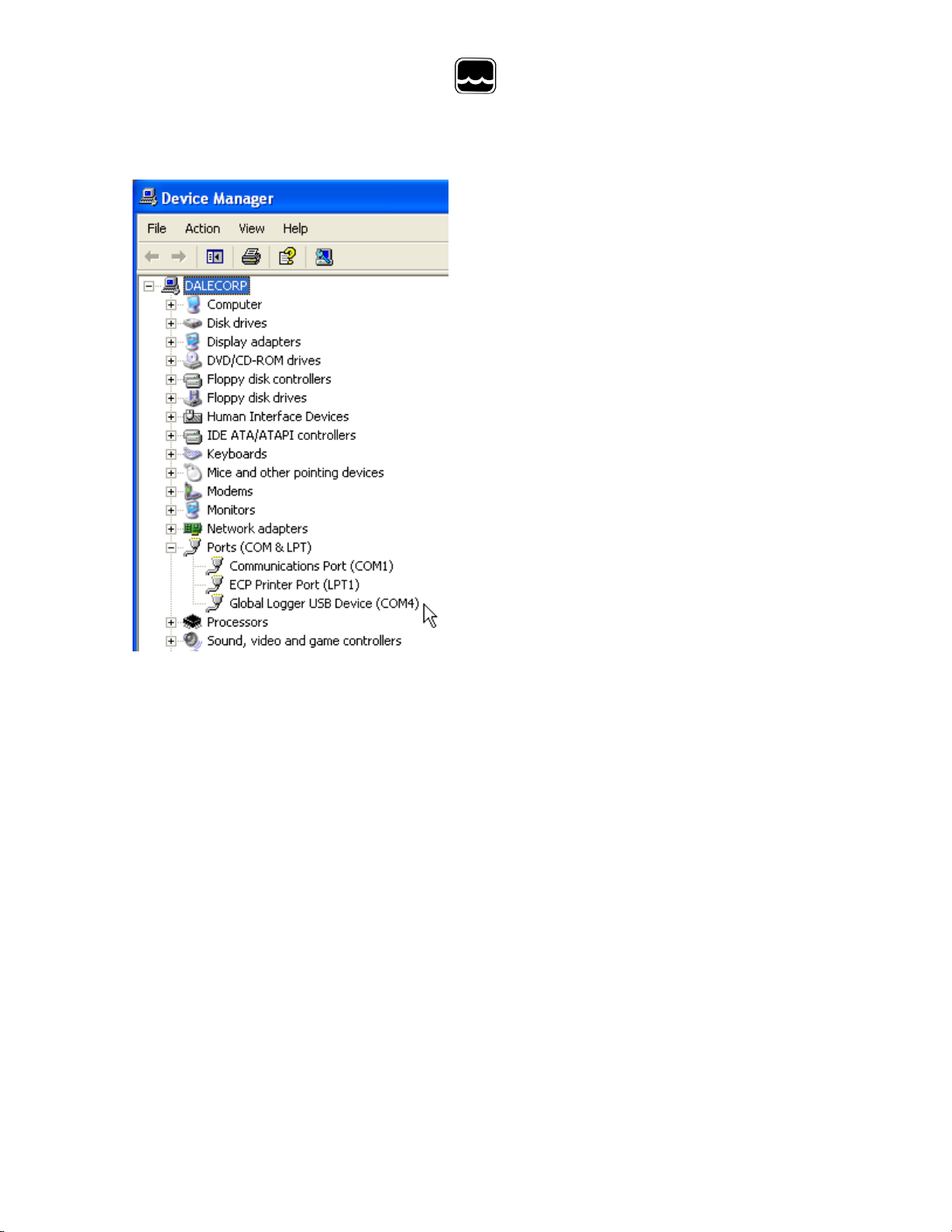

8) To confirm the installation, look in the

Device Manager and find the USB Ser ial

Port. The COM setting following that will

show the virtual COM port that has been

automatically assigned to the driver . As

you will see in the following sections, this

COM port will be automatically detect ed

by the Global Logger software so it is not

necessary to note which port is being

used by the driver.

- 8 -

Page 9

Global Water

800-876-1172 • globalw.com

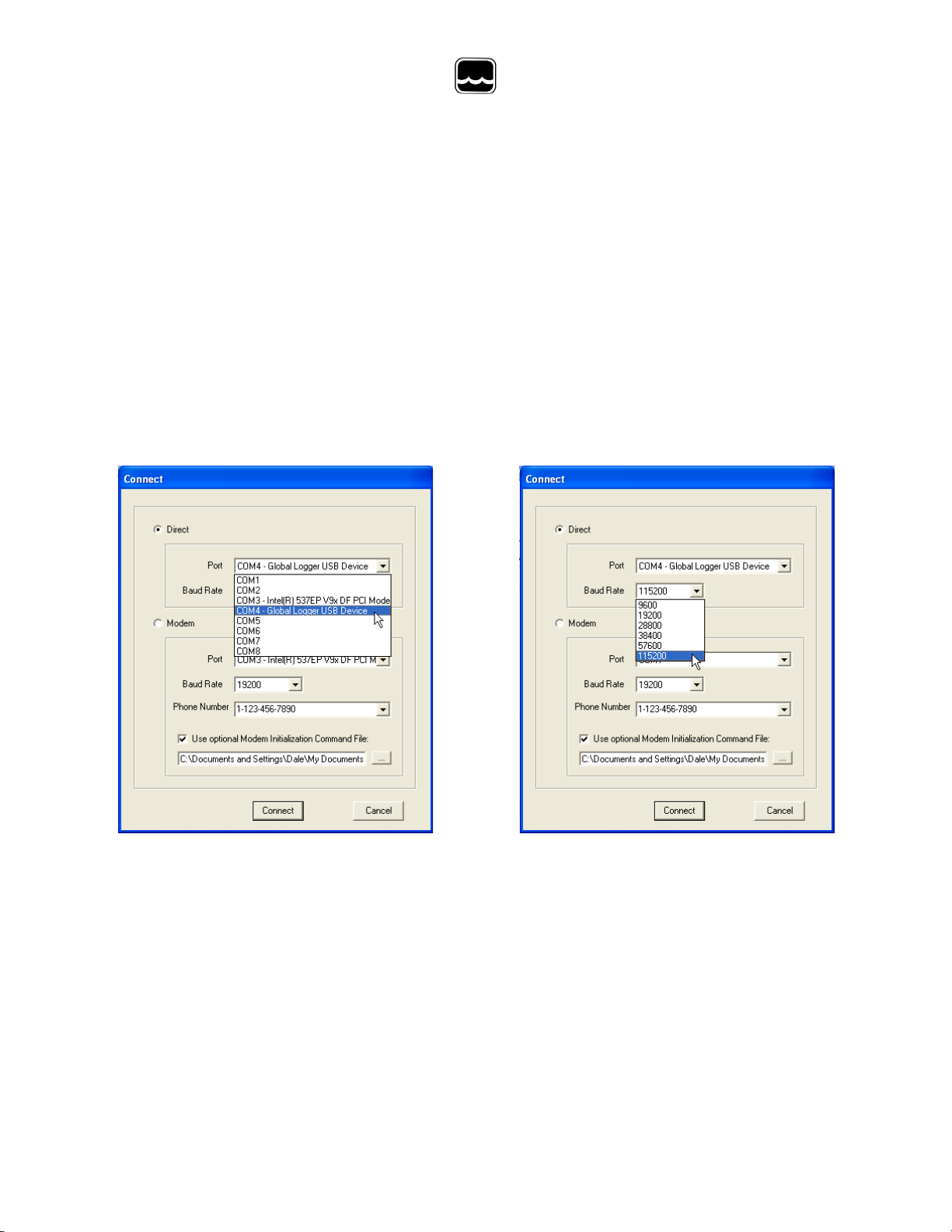

VIII. Connecting to the Softwa re:

Important: This data logger supports an Auto Baud Rate Mode which automatically

detects the communication speed. Howev er ; this communication software also

supports loggers which may be programmed in a Fixed B aud Rate Mode. This is

useful in telemetry applications, par ticularly when using Global Water data loggers

with our Global Access radio modem soft war e. The upcoming discussion assumes

that the logger is programmed in auto det ec t mode. If you cannot connect to the

logger and suspect that the logger may be using a fix ed r ate mode; try each

connection speed separately, es pec ially 38400 which is required when using the

Global Access software. Direct connection is made through the USB port.

To connect to the logger, click the “Direct” option and from the “Port” menu, select

the USB serial port at the COM port the driver was assigned, which is automatically

shown in the list as “Global Logger USB Device”.

Next, select the desired baud rate fr om the “Baud Rat e” menu. Generally, the

recommended rate of 57.6K baud is used although; long cables or other factors may

require a slower setting. Click “Connect” to make the connection. If a connection is

not made, an error message will appear. Chec k the battery, communication cable,

driver installation and COM port settings.

- 9 -

Page 10

Global Water

800-876-1172 • globalw.com

IX. Main Screen:

The main screen is where the status and option menus ar e ac c es s ed. The data

logger will continue to log at normal inter v als w hile connect ed to the Global Logger

software. While connected, the logger w ill dr aw an addition current from the power

supply of 5-10mA so it is advised that, if you plan to not access the logger for

extended periods of time, you disconnec t to increase battery life. Interface cables

may remain connected. To disconnect, click on the “Disconnec t” button. This label

on this button will change to “Connect” and click ing on it will return you to the

connection screen as previously discuss ed.

Tool Bar: The tool bar at the top of the screen has 3 options; File, Action and Help.

In this screen, the File option is used to ex it the program only. Action allows a menu

driven interface to the various functions and displays the hot-keys, which can be

used for fast access. In the Help menu; Help allows y ou to view the on-line help files

(see section X), Selecting A bout shows contact information and revision information

for the Global Logger software and Firm war e Version dis play s the data logger’s

revision number.

- 10 -

Page 11

Global Water

800-876-1172 • globalw.com

COM Status: This reads “Connected” in green or “Not Connected” in red,

depending on the current connection st atus.

Logger Name: The logger name is a us er defined name associated with a particular

logger to identify one from another. It is progr am m ed in the Setup menu as

described later and is limited to 32 c har ac ters.

Logger Time: The time and date displayed is that of the real-time clock in the

logger. It is only updated upon initial connection and certain functions that caus e

data to be read from the logger. These include Sample Continuously, Get Sample,

Sync Time and Setup whose functions are to be described lat er .

Interval: This field displays the logging mode. “Fast” indicates high-speed mode

and “Logarithmic” is shown in logarithmic m ode. If the logger is in the normal fixed

interval sampling mode, the time between samples will be displayed. These modes

are to be described later.

Warmup: This displays the sensor warm -up tim e, generally 3 seconds.

Records: This field indicates the number of data recordings in memory.

Logging State: This shows whether the data logger is currently logging or waiting to

be started or stopped by the alarm timers. These features are described in detail

later.

- 11 -

Page 12

Global Water

800-876-1172 • globalw.com

Sample Continuously: Clicking this check box causes the Global Logger software

to take and display a real-time reading once per s ec ond until stopped by clicking it

again, as well as update the rest of the fields on the s c r een. These data readings

are not stored in the historical record and do not affect the normal recording of the

logger. The initial reading has a sensor warm-up time of 50mS and the sensor is left

powered up until this feature is turned off.

Get Sample: Clicking this button causes the Global Logger software to take and

display a single reading as well as update t he rest of the fields on the screen. This

data reading is not stored in the historical rec or d and does not affect the normal

recording of the logger.

Get History: This button starts the download of all the historical data stored in the

logger memory. Oldest data is collected fir s t and Clicking “Stop” halts the process.

This function is described in detail later.

Clear History: This resets the number of r ec ordings in memory to zero. The user is

warned first and must confirm the act ion before the memory is cleared.

Sync Time: This button causes the data logger ’s internal clock to be set to the

system time of the computer it is connected to. The user is warned first and must

confirm the action before the tim e is set.

Setup: Clicking this button enters the setup screen where the user can change and

program all parameters into the data logger. This function is described in detail later .

Bar Graphs: The bar graphs show a vis ual r epr es entation of the most recent data

reading taken by using the Sample Continuousl y or Get Sample functions. The

upper and lower limits of the display are defined by the user as discussed in detail

later.

- 12 -

Page 13

Global Water

800-876-1172 • globalw.com

Numerical Reading: The numerical reading at the bottom of the bar graph shows

the actual data reading and is updated at the s am e time as the bar graph.

Successive numerical readings taken by us ing S am ple C ontinuously or Get Sample

are shown in a list below the bar, up to 5.

Alarm 1: This field shows the time that the logger is s et to start logging. The start

alarm is a 24-hour timer which will initiate logging, when enabled, at the next

occurrence of that time.

Alarm 2: This field shows the time that the logger is s et to stop logging. The stop

alarm is a 24-hour timer which will halt logging, when enabled, at the next

occurrence of that time after the logger has st arted r ec or ding. If the Alarm 1 timer is

set to initiate logging, the Alarm 2 tim er will halt logging at the next occurrence of the

Alarm 2 time after the logger has been started by A lar m 1. If the Alarm 1 timer is not

enabled, the Alarm 2 timer will halt the logger on t he nex t occurrence of that time.

Note: The alarm start and stop cycle is a one time occurrence. Once stop ped

by the Alarm 2 timer, the logger will not resume logging again until the logger

is reprogrammed. Reprogramming the logger with the timers enabled will

restart the alarm cycle. Reprogramming t he logger with the timers disabled

will return the logger to a normal logging state

Use care when programming the alarm times. If l ef t enabled, changing and

reprogramming any of the setup parameters wi ll rest art t he alarm timers and

could cause the logger to stop recording.

Using the Alarm 2 Stop Timer can significantly in crease battery life, especially

when using fast sampling speeds. See section XVIII for more information on

battery life.

- 13 -

Page 14

Global Water

800-876-1172 • globalw.com

X. On-Line Help Files:

Clicking on Help displays the on-line help files whic h c ontain all of the information

contained in this manual. There ar e 3 ways to access t he information. The first tab

is Contents which accesses the table of contents for the manual. Clicking on any of

the topics opens up the

body of text on that

subject. Within each

body of text is a

discussion of that

subject and links to

related topics

underlined in blue.

Clicking on the link

will bring up a new

window with specific

information on that

topic. In this case,

Sensor Warm-up time

in the General Setup

menu.

Click the Index tab to find a listing of topics. Type letters into the keyword field and

the program automatically sorts the topics alphabetically. To find relevant topics

based on a keyword, click the Search tab. Type in a keywor d and c lic k Lis t Topics.

When the desired topic is found, double-click on it or c lic k D is play at t he bott om of

the screen to show information on that s ubjec t.

- 14 -

Page 15

Global Water

800-876-1172 • globalw.com

XI. Get History:

Clicking the Get History button begins the downloading of the historical data into an

information screen. This screen allows the viewing of the recorded data and also

provides a path to export the data to an Excel compat ible file (.CSV file). Note that

the logger continues to log as data is download ed. Thus, more data points may be

downloaded than originally indicated.

At the top of the screen is shown the name assigned to t he logger and the number of

recordings that have been retrieved. A t t he bottom of the screen are three buttons,

Pack, Save to File and OK.

Pack: The Pack function removes recordings that are identical to the previous ones.

All the channels must be the same as the row above for it to be rem ov ed. If ev en a

single channel has data that differs from the previous sample, the row will not be

removed. This function works best when a single c hannel is being r ec orded and

allows only the data showing changing conditions to be viewed.

- 15 -

Page 16

Global Water

800-876-1172 • globalw.com

Save to File: Clicking this button

allows the data to be exported to an

Excel compatible .CSV file.

Specify the path and the file name

and click the Save button

Options: This opens a menu which

Allows you to select if you want the

Time and date in the time stamp to

Be in one column or two in the saved

.CSV file. Click Close to return.

OK: Clicking the OK button

returns you to the main screen.

XII. Setup Menus:

Clicking the Setup button enters the setup menu which is composed of three

sections, Analog, Digital and Gener al; with the digital screen not being supported by

the PL200H logger. The first screen to appear is General S etup. At the top of the

setup screen is a toolbar with three options, File, Action and Help.

File: The File option allows you to exit the setup screen but most importantly, it

allows all of the configuration information for the logger to be saved to a file or

restored from a file. Select “Load Setup File” to r es tore a configuration from a file

that has been previously saved or “Save Setup File” to sav e the current setup and

calibration information. The last 4 files are shown for convenience. Setup files have

a .SET extension. It is advised that after y ou calibrate and conf igur e the logger, you

save the configuration to a file as a backup precaution before exiting the setup

menu.

- 16 -

Page 17

Global Water

800-876-1172 • globalw.com

Action: The Action menu has two options, “Program Settings” and “Initialize to

Default Values”. Program sett ings w ill r epr ogr am the data logger with all the setup

and calibration information and works the same as the Program Settings Butt on at

the bottom of the screen. Initialize

will restore all of the analog, digital

and general setup information fields

to default values. Only the setup

menus are changed, the data logger

must still be programmed with the

new default values. A warning message will appear before this action is taken.

Help: The Help menu provides access to the on-line help files and Global Water

contact information as described previous ly .

XIII. General Setup:

In the General Setup menu, the logger name, sensor war m -up time, logging mode,

logging interval and alarm times ar e entered.

- 17 -

Page 18

Global Water

800-876-1172 • globalw.com

Name: The logger is a user definable name to identify the logger. Up to 32

characters are allowed however, a cont inuous s tring of characters of more than 16

with no spaces may not be displayed correctly . Click on the field to enter

information.

Sensor Warm-up Time: To conserve battery life, the

sensor does not normally have power applied to it.

Before taking a reading, the logger powers up the

sensor for the sensor warm-up time, and then rem ov es

power from them again. A warm-up time of 0 seconds

is recommended. Click on the field to enter or select

the time in seconds from the pull-down menu.

Baud Rate: Leave this set t o A uto Baud Rate.

Only change this to a fixed baud rate if planning t o

use this logger in a telemetry application, such as

using Global Water’s Global Access radio m odem

software. Once programmed in a fixed rat e mode,

you must set the baud rate in the opening connect ion menu of the Global Logger II

software to this speed, or the logger will not communicate.

Sample Periodically: Sam pling at regular intervals is the most common recording

mode. Click the Sample Periodically option, s elect the units from the pull-down

menu and click the numerical field to enter the number of those units up to 65,535.

Fast Sampling Mode : In Fast mode, the sample rate is fixed at 10 times per

second. The time stamp will not read fractions of a second so there will be 10

samples per time stamp. Click the Fast m ode option t o s elec t this feature.

- 18 -

Page 19

Global Water

800-876-1172 • globalw.com

Logarithmic Timing: Typically used in groundwater pump studies, this mode

speeds up the sample rate over time. Click the “Logarithmic” option to select this

mode. This is a logarithmic approximation that steps up the sample rate:

a. 10 times per second f or 20 seconds , 200 samples

b. 1 second interval for 100 s ec onds , 100 samples

c. 10 second interval for 10 minutes, 60 s am ples

d. 1 minute interval f or 60 minutes , 60 samples

e. 10 minute interval f or 10 hours, 60 s am ples

f. 1 hour interval for 48 hours, 48 samples

g. 1 day interval until memory s full

Log Upon Deviation: Clicking the “Log only if Channel 1 change exceeds +/-“ box

causes the logger to record the current r eading in m emory only if it exceeds the

previously reading by the preset am ount entered in the numeric field. This logging

exception applies to channel 1 only and the deviation is measured in Raw Data units

where the approximate raw data range is f r om 0-65535, cor responding to 0-20mA.

To find the actual number of raw data unit s per engineering unit, use the calibration

numbers in the Analog Setup screen for c hannel 1 as follows : Raw Data Units per

Engineering Unit = (High Raw – Low Raw) / (High EU – Low EU) . For example: The

PL500G has a High EU of 100, a Low EU of zero, a High Raw of 34874 and a Low

Raw of 7846. (34874-7846) / (100-0) = 270.3 raw data unit s per ps i. Thus, if you

want to log only when a reading exceeds the previous on by 10 ps i, set the deviation

to 2703. Click the numeric field to enter the desired range.

Wrap records: If the “Wrap records at End of Storage” box is chec k ed,

once the memory is full, the oldest data points will be replaced with the newest.

Thus, the memory block represents only the newest. If this feature is not checked,

the logger will halt recording once the memory is full.

- 19 -

Page 20

Global Water

800-876-1172 • globalw.com

Sample-On-Demand: This feature is not supported by the PL200H data logger.

Alarm Times: Check the box

associated with each alarm to

enable that feature and enter

the desired start or stop time.

The logger will start at the next

occurrence of the Alarm 1 time and stop at the next occurrence of the Alarm 2 time

after the Alarm 1 timer has expired. Either or both alarm s c an be enabled.

Important:

These timers are a one time event; the logger wi ll no t restart on th e next

occurrence of the Start timer unless th e logger i s reprogrammed with these

settings.

Use care when programming the alarm times. If l ef t enabled, changing and

reprogramming any of the setup parameters will restart the alarm timers and

could cause the logger to stop recording and the loss of important data.

Using the Alarm 2 Stop Timer can significantly increase battery life, especially

when using short sample intervals. See section XVIII for more information on

battery life.

- 20 -

Page 21

Global Water

800-876-1172 • globalw.com

Analog Setup:

The Analog Setup screen sets the engineering units and c alibr ation numbers for

each of the analog channels, the endpoints of the bar graphs in the main screen and

which of the analog channels are enabled. These channels ar e c alibr ated in the

same way so a single channel will be discussed.

information stored in the data logger’s memory is just the sensors output level before it is

adjusted by the following calibration parameters. These parameters are used to adjust the

stored data for display and storage purposes only, at the time the data is downloade d. If

they are changed, the same stored data can be downloaded again and the data will be

scaled differently according to the new settings.

It is important to note here that the

The PL200H Logger comes factory calibrat ed but you may want to re-calibrate on

occasion. The pressure sensor is designed to m eas ur e ov er the range of 0-200 psi

but it can be calibrated at lower pressures. The screen above s how s c hannel one

calibrated at 100 psi but set to display up to 200 ps i on the main screen.

- 21 -

Page 22

Global Water

800-876-1172 • globalw.com

Enable: If the “Enable” box at the top of a column is checked,

data for that channel will be shown in the hist or ic al r ec or d and

be available for export to Excel. The dat a

for all the analog channels is always being

recorded whether the channel is enabled

or not.

Units: This field shows the units that will

appear at the top of the data column for

that channel in the historical record as well

as the display of data in the main screen.

Click on the field to enter the unit or select

from a predefined list. Note that psi is not included in t his lis t.

High EU: The High EU field is the engineering unit where the

highest output from the sensor is achieved during the calibration process, in this

case a pressure of 100 psi.

Low EU: The Low EU field is the engineering unit where the lowest output from the

sensor is achieved during the calibrat ion pr oc ess, in this case a pressure of zero.

High Raw: This is the raw data value as measured by the data logger that

corresponds to the High EU value and is automatic ally s et by the calibration process.

In this case, the raw data value returned by t he logger at a pr es s ur e of 100 psi.

Low Raw: This is the raw data value as measured by the logger that corresponds to

the Low EU value and is automatically set by the calibrat ion pr oc es s . In this case,

the raw data value returned by zero pressure.

Disp High: This field sets the upper limit of the bar graph displayed in the main

screen and provides a way of scaling the graph beyond the upper limit used to

calibrate the logger. In this example, the upper calibration point was a pressure of

100 psi but the maximum range of the sensor is 200 psi.

Disp Low: This field sets the lower limit of the bar graph displayed in the main

screen and provides a way of scaling the graph beyond the lower limit used to

calibrate the logger. In this example, the lower calibration point was at zero psi.

- 22 -

Page 23

Global Water

800-876-1172 • globalw.com

Decimal Places: From the pull-down menu, select the

number of decimal places to the right of the decim al

point that should appear in the histor ic al data and in the

numerical data field at the bottom of the bar gr aph.

Calibrate: The “Calibra te” button provides a simple 4-step process for calibrating

the logger to a particular sensor. Click t he C alibr ate button and follow the menu

instructions.

Click on the High EU field and enter the

high engineering unit that will be used t o

calibrate the logger, not the highest r eading

the sensor can output. In this example, a

pressure of 100 psi is used to calibrate

the logger, even though the sensor c an

measure up to 200 psi.

Click Next.

Place the sensor in the condition that will

cause it to output the level corresponding

to the high EU entered in the previous menu.

Wait for the data reading to stabilize.

Click Next.

Click on the Low EU field and enter the

low engineering unit that will be used

to calibrate the logger, not necessarily

the lowest reading the sensor can output .

In this example, the value is zero psi.

Click Next.

Place the sensor in the condition that will

cause it to output the level corresponding

to the low EU entered in the previous menu.

Wait for the data reading to stabilize.

Click Next to complete the calibration.

- 23 -

Page 24

Global Water

800-876-1172 • globalw.com

XIV. Programming

Program Settings: The Program S ett ings button at the bottom of the setup menus

will cause all the setup and calibration inform ation to be programmed into the dat a

logger. A warning will

appear requiring the

use to confirm the

action. Click Yes to

program the logger

and No to cancel the

operation.

Back to Main Window: The Back to Main Menu button exits bac k to t he main

screen. If no settings have

changed, Exit will occur

immediately. If settings have

changed but not saved yet,

a message will appear that

asks the user if they would

like to save them now. If the

settings have changed but

not yet programmed into the

logger, another message will

be shown asking if the logger should be reprogram med. These layers of

protection are designed to prevent the user from unintentionally changing

settings or forgetting to save the configuration file. Should the settings

accidentally be changed, a saved configuration file can be loaded and used to

restore the original settings.

- 24 -

Page 25

+

Global Water

800-876-1172 • globalw.com

XV. Installing t he Data logger

The data logger is an electronic device and sensi t ive to excessive mechanical

abuse. Do not drop the logger or otherwise subject it to mechanical shock.

The assembly can be heavy and could do significant damage to the logger

housing if handle d im pr ope r ly.

Do not hammer the prongs to tighten the

logger onto the hydr ant, only use a spanner

wrench of appropriate size and turn the logger

carefully as it is tighten or is removed.

Do not twist the logger housing.

Picture shows optional 2.5”NHT adaptor

XVI. Battery Replacement:

Except for the battery, there are no user-servic eable par ts inside the PL200H Data

Logger. Global Water recommends check ing the batteries every 6 to12 months, or

when the battery voltage monitor shows a low voltage c ondition of 3.4 volts or less.

To change the battery; turn the thumbs c r ew in the center of the top cover counterclockwise and remove it. Remove the 3 scr ews holding down t he c r os s bar .

Replace the battery with a 3.6 volt AA size lithiu m battery only, AA size

batteries commonly used in consumer el ectro nics only produce 1.5 volts and

will not operate the data logger. Be careful to observe t he polarity, align the

battery as shown. The high capacity batter y described in the specifications section

is recommended. Replace the crossbar , making sure that the cutout on one side is

properly aligned with the USB port .

- 25 -

Page 26

Global Water

800-876-1172 • globalw.com

XVII. Battery Life

The 3.6 volt lithium battery may last 2-3 years, depending on use; however, higher

sample rates can reduce battery life significantly. It is impossible to accurat ely

predict the battery life for all types of usage and conditions, such as sample rate and

ambient temperature; however a general assumption is that a new battery will last

about 1-2 years based on continuous use at sample r ates of 1 minute or greater, and

normal ambient temperatures of at least 32ºF.

One of the best features of the PL300H Hydrant Logger is the 10 times per second

sample rate. This feature allows you to capt ure detailed data from pressure waves

cased by water hammer and other affects, but it also consumes the most power.

Under normal conditions, this feat ur e w ill deplete the battery in about one week if left

turned on.

You can increase the battery life significantly when using the high sample rate

mode by utilizing the alarm start and stop timers, as des c ribed on page 13. In

high speed mode, the memory will hold 81,759 data points or 2 hours and 16

minutes of data; which usually makes it im pr ac tical to keep the logger running any

longer than that. Use the alarm start and stop timers to record data and fill memory

only when data needs to be collected. How the memory w r ap-ar ound feat ur e

described on page 19 is set determines whether the first 81,759 accumulated data

points are stored or the most recent ones . Wit h wrap-around t ur ned off, the logger

will continue to take readings and consume po w er , the data is just not stored in

memory once it is full. Thus, turning m em or y wrap-around off will not save power.

- 26 -

Page 27

XVIII. Troubleshooting:

Issue: Logger is reading incorrect ly .

a. Verify the battery has enough voltage. To operate properly, the logger

must have about 3.3volts or more. If the batt er y voltage monitor is

reading less than 3.3 volts or seems incorrec t, check the batteries with

a voltmeter or replace them. Batter y v oltages less than 3.4 volts

indicate that the batteries need replacing soon.

b. Check the logger and sensor c alibr ation numbers in the Setup Menu.

Recalibrate the logger if necessar y . As a precaution, save the setup

file first as described in section XII.

Issue: Cannot communicate with t he logger .

a. Verify that a fres h batt ery is ins talled.

b. Check the communication cable.

c. Use the Device Manager to confirm that the dr iver is loaded and the

correct virtual COM port is select ed in the connection menu of the

Global Logger software. Check the D ev ic e Manager in your oper ating

system and confirm that the USB COM port is not being used by

another device.

d. Try reducing the baud rate in the connection screen of the Global

Logger software. Try each baud rate sett ing in case t he logger has

been programmed in Fixed Baud Rate mode.

Issue: Logger is not recording.

a. Check if the A lar m 2 Stop Tim er is s et. The status of the logger can

be seen in the top right corner of the Global Logger II m ain s creen. If it

says Stopped by Alarm 2, you must reprogram the logger.

b. Check the Memory Wr ap-Around f eature. If this setting is off and the

logger’s memory is full, no further logging will occur until the feature is

turned on or the memory is erased.

c. Check the battery for proper voltage.

Global Water

800-876-1172 • globalw.com

- 27 -

Page 28

XIX. Technical Support:

Call Global Water for tech support: 800-876-1172 or (979) 690-5560

(many problems can be solved over the phone). Fax: (979) 690-0440 or

Email:

globalw@globalw.com.

When calling for tech support, have the following information ready:

1. Model #.

2. Unit serial number.

3. P.O.# the equipment was purchas ed on.

4. Our sales number or the invoic e num ber .

5. Repair instructions and/or specific problems relating to the

product.

Be prepared to describe the problem you are experiencing including

specific details of the application, installation, and any additional pertinent

information.

In the event that the equipment needs to be returned t o the factory for any

reason, please call to obtain a RMA# (Ret ur n Material Authorization). Do

not return items without a RMA# displayed on the outside of the package.

Include a written statement describing the problems.

Global Water

800-876-1172 • globalw.com

Send the package with shipping prepaid to our factory address. Insure

your shipment; Global Water’s warr anty does not cover damage incurred

during transit.

- 28 -

Loading...

Loading...