Page 1

Operating Manual

System OxiTop® Control

OxiTop® OC100

Controller

OxiTop®-C

Measuring Heads

OC Model

Page 2

2 BA31114e5 07/2006 BA31114e5 07/2006 3

Page 3

Safety Instructions

This instrument is built and checked according to IEC 1010, safety rules for

electronic measuring instruments and left the factory secure from a safety

engineering aspect.

The smooth functioning and operational safety of the equipment can only be

guaranteed by following the general safety precautions applicable and the special

safety instructions given in this operating manual.

– The trouble-free function and operational safety of the instrument can only be

guaranteed by following the climate conditions specified in the chapter

"Technical data" in this operating manual.

– If the system is transported from a cold environment to a warm environment, its

function can be impaired as a result of condensation forming. In this case, the

temperature of the equipment must be allowed to adapt to room temperature

before putting it into operation again.

– Adjustment of the equipment and maintenance or repair work must only be

performed by personnel authorized by WTW.

– If safe operation is no longer possible, the equipment must be taken out of

service and secured against inadvertent operation by labeling with warning

signs.

– The safety of the user can be affected by the instrument if, for example,

• the instrument is visibly damaged,

• the instrument no longer operates as prescribed,

• the instrument has been stored under adverse conditions for a lengthy

period of time,

• the instrument was exposed to adverse transport conditions.

– Basically, if you are in any doubt, please return the instrument for repair or

maintenance to the manufacturer of the equipment,

"Wissenschaftlich-Technische-Werkstätten GmbH".

Please read these safety instructions carefully before installing

the instrument!

Page 4

Contents

Safety Instructions .................................................................................................... 3

Contents.....................................................................................................................4

Introduction ...............................................................................................................6

The measuring principle ........................................................................................7

The OxiTop

Operating modes ...................................................................................................8

Litterature.........................................................................................................8

Operating Elements ..................................................................................................9

Controller keybord .................................................................................................9

General Operating Principles.................................................................................10

Switching On ...........................................................................................................11

Switching on the controller...................................................................................11

Switching on the measuring heads .....................................................................11

Operating Mode: Routine BOD...............................................................................12

Sample preparation .............................................................................................12

Start the measurement ........................................................................................12

Call up all data ....................................................................................................15

Sample management...........................................................................................17

Show sample ......................................................................................................19

Erase data of finished samples ...........................................................................20

Show measuring head list....................................................................................21

Call up data .........................................................................................................22

Call up data - Stop ...............................................................................................24

Evaluation............................................................................................................25

Curve display of samples that are too cold ....................................................26

Measured values outside the measurement ranges ......................................26

Printing.................................................................................................................27

Operating Mode: Standard BOD ............................................................................29

Sample preparation .............................................................................................29

Start the measurement ........................................................................................29

Call up all data ....................................................................................................32

Sample management...........................................................................................35

Show sample ......................................................................................................36

Erase data of finished samples ...........................................................................37

Show measuring head list....................................................................................38

Call up data .........................................................................................................39

Call up data - Stop ...............................................................................................42

Evaluation............................................................................................................44

Sample statistics..................................................................................................45

Excluding a curve ................................................................................................46

Cursor interrogation .............................................................................................48

Curves display for cold samples ....................................................................49

Measured values outside the measuring range .............................................50

Print .....................................................................................................................51

4 BA31114e5 07/2006 BA31114e5 07/2006 5

®

Control measuring system ...............................................................7

Page 5

Contents

GLP/Tools ................................................................................................................53

GLP/Tools main menu .........................................................................................53

Show free measuring heads ................................................................................54

Show settings ......................................................................................................55

Settings................................................................................................................56

Operating mode .............................................................................................56

Measuring time...............................................................................................57

Date/Time.......................................................................................................57

GLP ................................................................................................................58

GLP - calibrating interval (”Calinterval”) ...................................................59

Memory ..........................................................................................................60

AutoTemp.......................................................................................................61

Switch-off interval...........................................................................................63

Language .......................................................................................................64

Check...................................................................................................................65

Show measuring heads..................................................................................65

Measuring head info.......................................................................................66

Controller info.................................................................................................67

Cal test ...........................................................................................................68

Pneumatic test measuring head.....................................................................71

Maintenance ........................................................................................................72

Erase finished samples..................................................................................72

Reset/release measuring head ......................................................................74

RS232 Interface .......................................................................................................76

Cleaning ...................................................................................................................77

Cleaning the sample bottles ................................................................................77

Cleaning the controller and measuring heads .....................................................77

Power Supply...........................................................................................................78

OxiTop®-OC100 controller ...................................................................................78

®

OxiTop

Disposing of the batteries ....................................................................................83

What to do if ...? ......................................................................................................84

Display messages................................................................................................84

Requirements / Problems ....................................................................................90

Accessories and Spare Parts.................................................................................95

Technical Data .........................................................................................................96

Note:

This operating manual refers to software release 1.xx.

The right to implement minor changes is reserved.

-C measuring head.................................................................................82

Page 6

Introduction

The OxiTop® Control system provides a further development of the mercury-free,

measured value storing OxiTop

a multitude of new technological features that simplify the whole process of the BOD

determination for the user. Furthermore, the instrument is almost unlimited with

respect to its sample capacity and use. It can also be expanded flexibly to fulfill its

tasks. In addition to its application in the water economy, the OxiTop

”respirometric” measuring principle can also be used in other areas such as

• Evaluation of biological degradability, i.e. testing aerobic degradation

(e.g. test according to OECD 301F)

• Evaluation of respiration and toxicity in earth, sludge, waste and sediment (e.g.

extraction of earth contaminated according to recovery concepts)

• Evaluation of the respiration rate of cell cultures

• Microbiological growth and stress examinations

®

BOD measurement system. The instrument provides

®

Control with its

6 BA31114e5 07/2006 BA31114e5 07/2006 7

Page 7

Introduction

In addition, in conjunction with the enhanced OxiTop

accessories, the OxiTop

®

-C measuring heads can also be used to

®

Controller OC110 and relevant

• Measure anaerobic degradation processes (e.g. biogas evaluation)

The measuring principle

The sample bottles are filled according to the data visible in the display (BOD

measuring range with assigned water sample amount). The microorganisms draw

oxygen to degrade organic substances from the amount of air remaining in the closed

system. The carbon dioxide formed by this process is absorbed. Due to the reduction

in the amount of oxygen, the pressure in the bottle sinks. This change is detected and

stored by the measuring head. After the data transfer to the controller, it is used to

determine the BOD value.

Further information is given in the WTW BOD handbook.

The OxiTop® Control measuring system

The 6 or 12 position OxiTop

and consist of the OC100 OxiTop

inductive stirring system and various accessories.

The measured value determination and storage of the measurement data is

performed in the measuring head. This data is transmitted via ”infrared to the

controller” without the need for wires and then calculated to the BOD value. The user

can start his individual measuring program and printout the calculated data via the

TD100 IR printer or further process it via a PC program using the ”Routine BOD” and

”Standard BOD” operating modes described in detail in this operating manual. The

user interface appears in one of 5 selectable languages. An overview of the entire

sample management together with the status and function response is shown on the

display. With the aid of the display function, sample identification is no longer

required. Via the OxiTop

to 144 measuring positions.

An overview of the essential advantages

• DIN procedure • Modular extensions

• Mercury-free • Data storage

• Precise • Comfortable handling

• Automatic sample management

• Automatic measurement report

®

Control systems are configured for BOD determination

®

controller, the OxiTop®-C measuring heads, the

®

-C IS 6/12 expansion sets, the system can be extended up

• Wireless data transfer,

(even through glass or transparent

plastic)

Page 8

General Operating Principles

Operating modes

The OC100 controller has 2 standard operating modes that differ from one another as

described below:

”Routine BOD”

This mode provides the user-friendly ”quick introduction”. The samples are managed

as single samples. The setting functions are logically restricted.

”Standard BOD”

The main difference to the ”Routine BOD” mode is in the parallel sample process for

up to 12 measuring heads per whole sample with mean value formation and statistical

evaluation. The setting is made via the function ”GLP/Tools”. The extended setting

functions allow a multitude of further options (see chapter ”GLP/Tools”). The samples

plotted in the ”Standard BOD” mode are not displayed in the ”Routine BOD” mode.

A table of the settings in the delivery state is given in the chapter ”GLP/Tools”.

Literature

Further information on this subject can be obtained at no cost from WTW:

- BOD handbook

- Application reports

- Special printouts

8 BA31114e5 07/2006 BA31114e5 07/2006 9

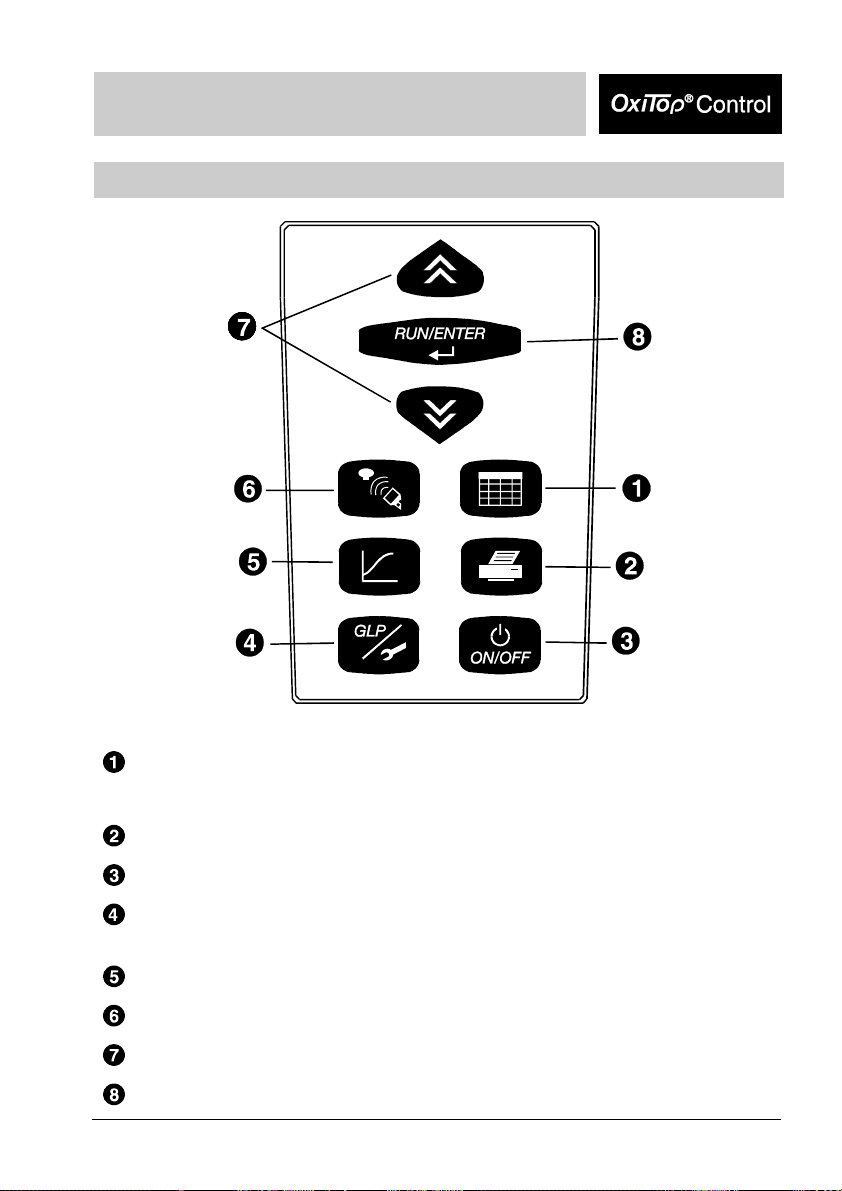

Page 9

Switching On

Controller keyboard

Sample management: List of samples, reading the data of individual

measuring heads or samples, displays of measuring

heads or samples

Printing of measurement data and settings

Switching on/off

GLP / Tools: Display free measuring heads, display or change settings,

perform checks or maintenance

Evaluation: Graphic and numerical display of measuring data

Communication with measuring heads: Start measuring, call up data

Select

Confirmation of entries

Page 10

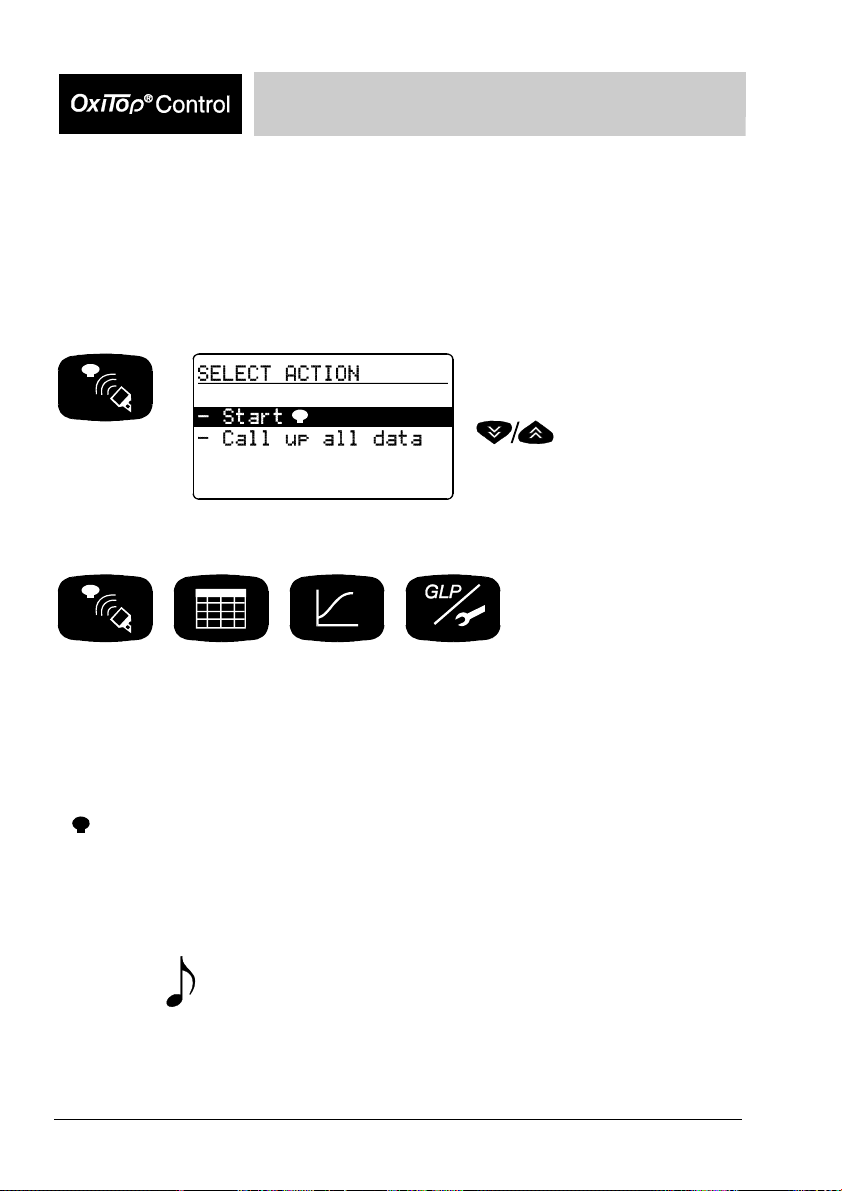

General Operating Principles

Representation of keys and displays:

Example: Pressing the ”Communication” button causes the mode to change to the

”Communication with the measuring heads” mode of operation:

Required

action: press

button.

The instrument displays:

Description of what the action

caused and possible further

request:

Starting communication with the

measuring heads.

Select a menu item using

.

Function keys:

These function keys are used to start or change a function.

Confirmed data and settings are preserved.

Display:

- In selection menus, the selected function or line appear in a lighter font on a

dark background

- :

Measuring head:

Each measuring head that receives a command from the controller, indicates this by

a short flashing signal.

Signal tone: This symbol means: A signal tone sounds.

Notes:

Instructions and additional information appear in italics.

Symbol for an OxiTop®-C measuring head

10 BA31114e5 07/2006 BA31114e5 07/2006 11

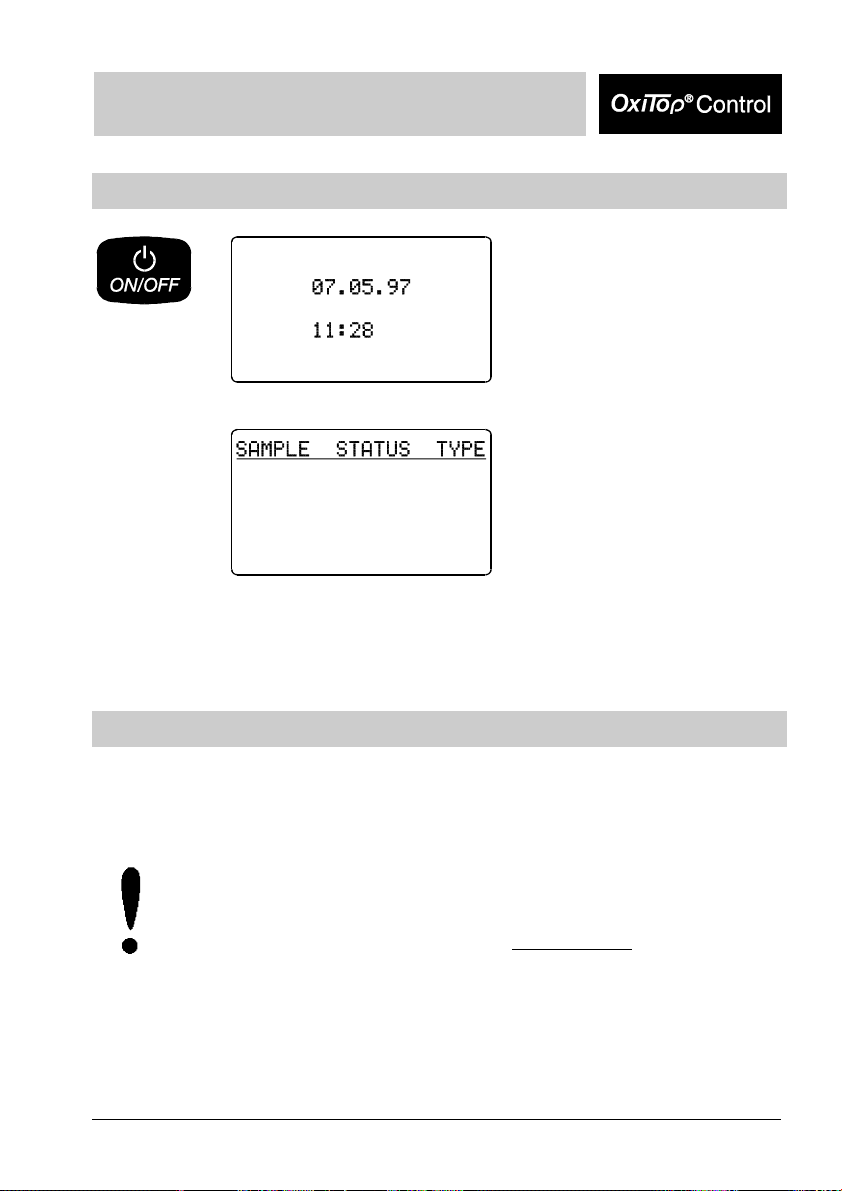

Page 11

Switching On

Switching on the controller

The current date and time appear

(important for the allocation of

sample numbers).

If the date/time is incorrect,

undertake corrections in

”GLP/Tools”.

The instrument is in the sample

management

(Routine mode,

in the delivery state).

Switching on the measuring heads

The measuring heads are immediately ready for operation. The controller switches

the measuring heads independently on and off during communication.

To avoid malfunctions:

In case of using two or more controllers please pay attention to the following:

Absolutely avoid starting measuring heads simultaneously

between controllers is less than 3 meters when doing this.

if the distance

Page 12

Operating Mode: Routine BOD

Operating mode: Routine BOD

Sample preparation

See WTW application reports

(contained within the scope of delivery of the accessories supplied).

Screw the OxiTop

and tightly close them.

Important note:

Never use joint grease or other lubricant for your OxiTop

heads. Some of these products contain solvents that can cause severe damage

to the plastic housing.

The sealing of the BOD bottles is also perfectly adequate without grease.

However, you should always wipe off heavy contamination and particles on the

sealing surfaces of the rubber sleeves and OxiTop

liability for damage due to the use of joint grease.

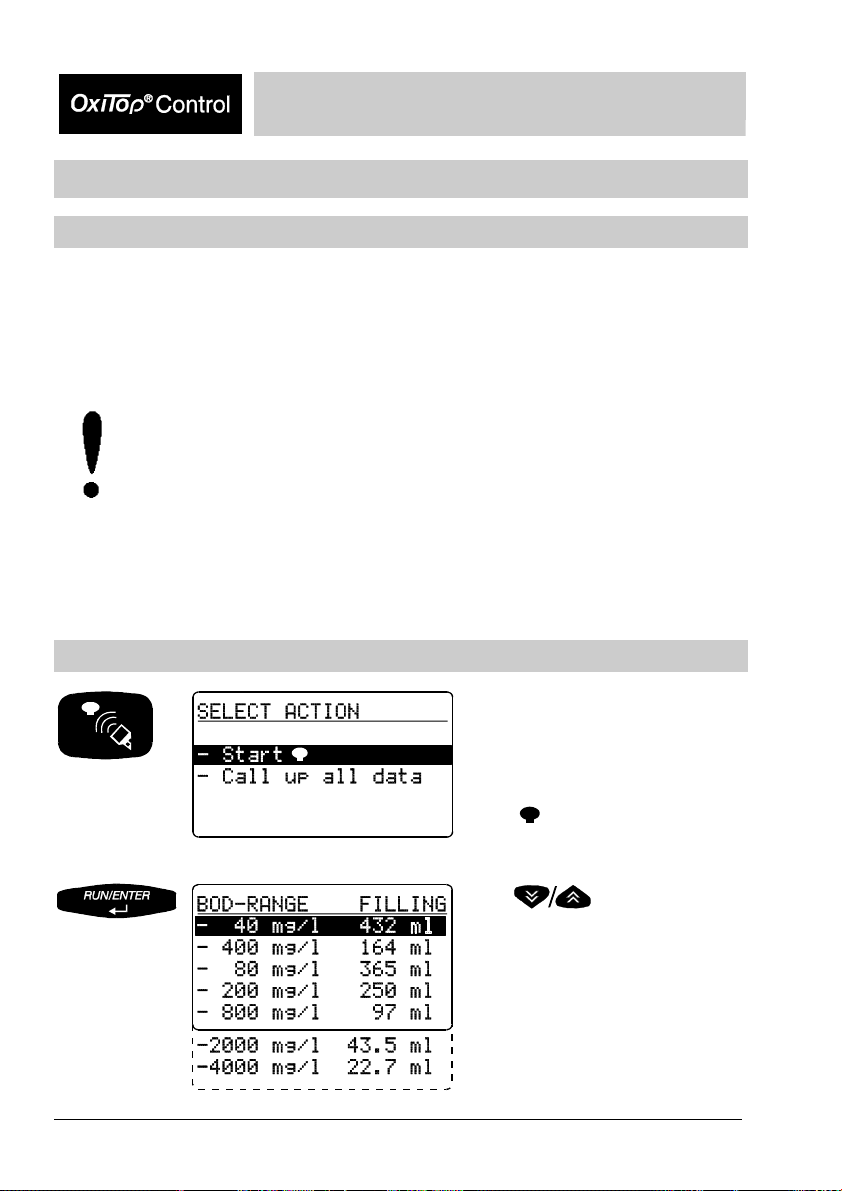

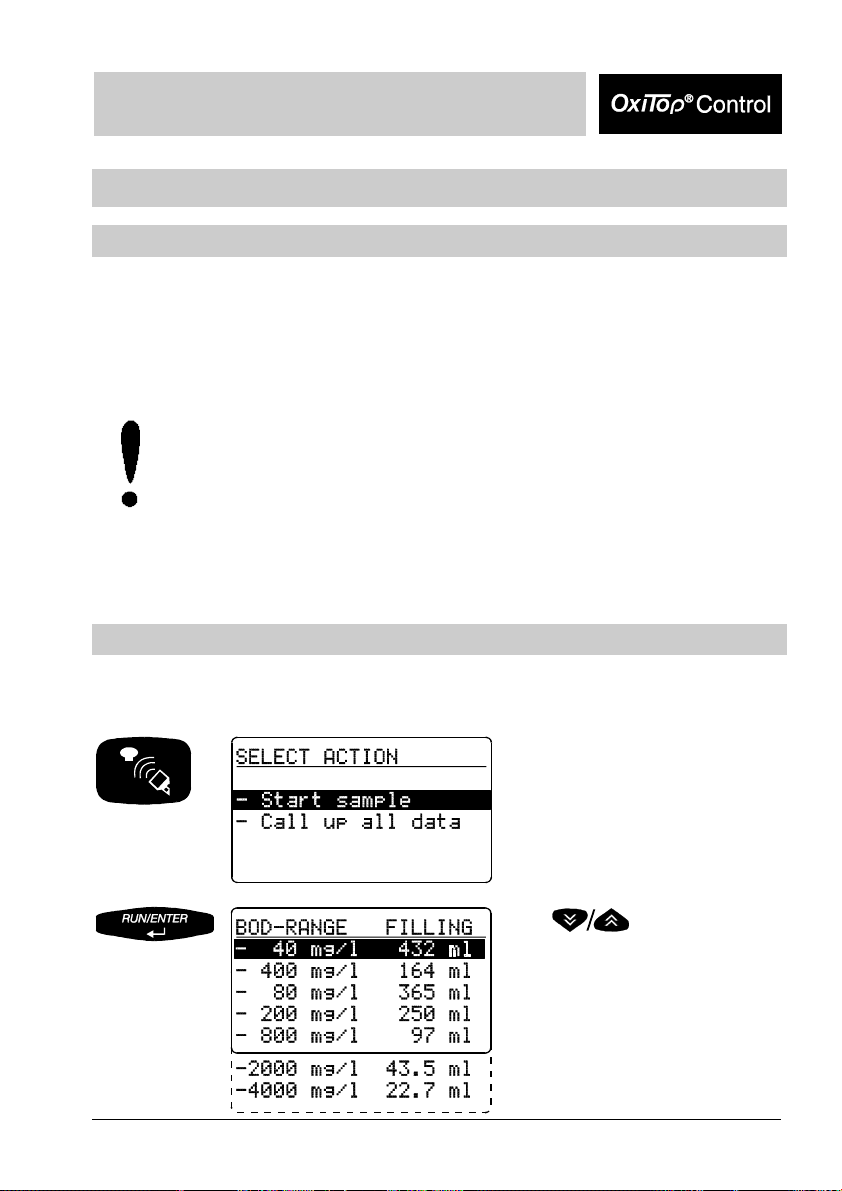

Start the measurement

-C measuring heads onto the sample bottles

-C. WTW accepts no

Entry into the mode

“Communication with the

measuring heads“.

Preselected:

Start

Use

to select the measurement range.

The filling volume required is given

in the right-hand column.

The controller stores the setting

(memory function: the last selected

measurement range is set).

(measuring head).

-C measuring

12 BA31114e5 07/2006 BA31114e5 07/2006 13

Page 13

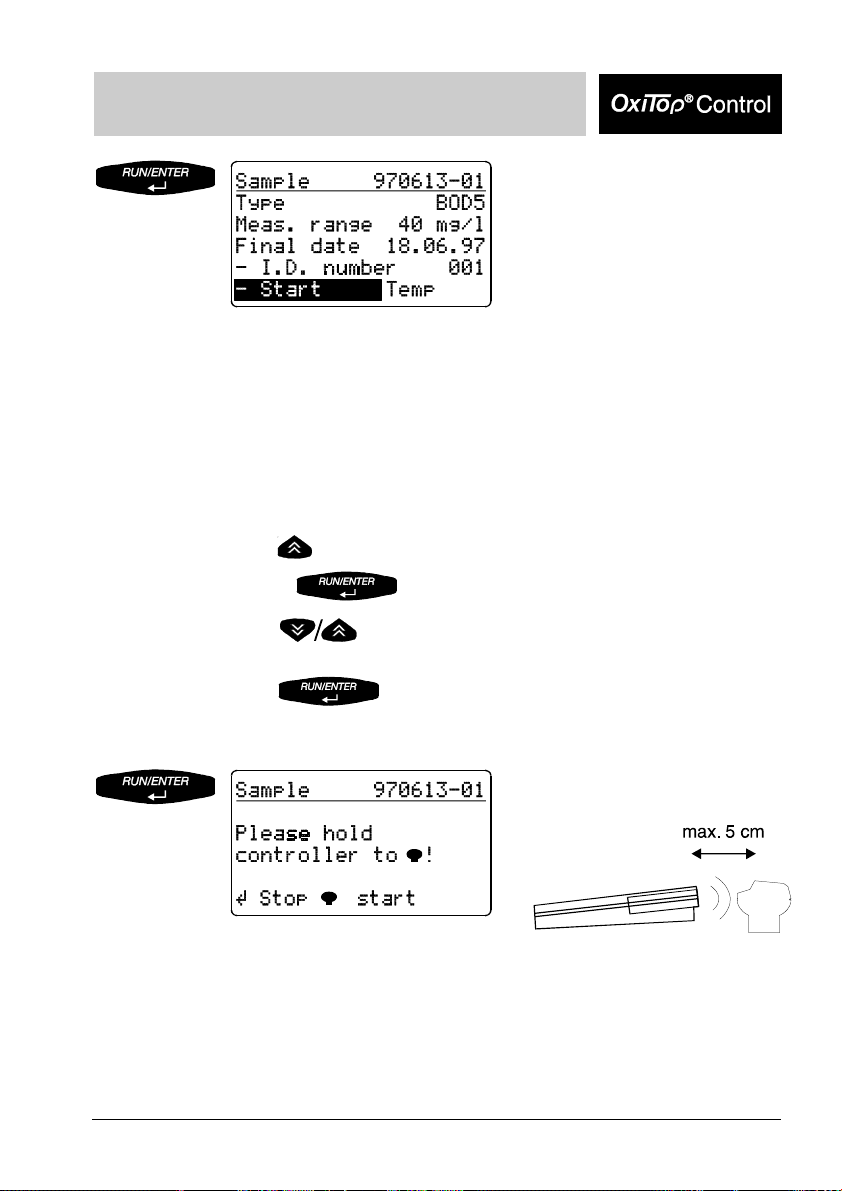

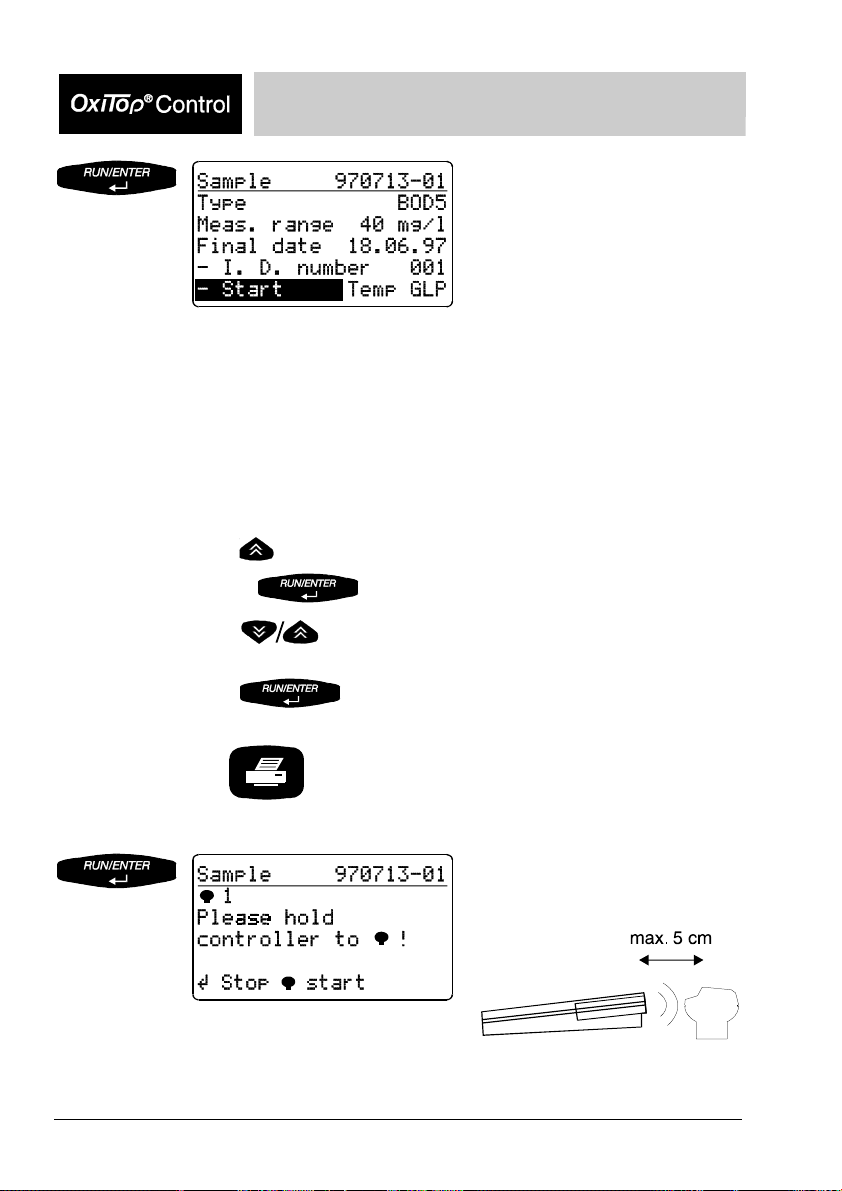

Operating Mode: Routine BOD

Confirm the selected

measurement range for the

sample. The automatically

allocated sample number is given

in the header line (YY/MM/DD and

sequential number).

Additional information:

Type of measurement, run time, measurement range, final date, Id

number.

“Temp“ display => the AutoTemp function (see the chapter “GLP/Tools”)

is set as a default in the routine mode.

Change the Id number of the additional identification of the sample

(e.g. extraction location) as follows:

- Use

- Press and

- Use

(setting range 001 ... 255).

- Use

to move the cursor to the Id number,

to set the Id number required

to confirm this.

Confirm the start of the

measurement. Contact selection:

The controller repeatedly sends the

start information in the scanner

mode until successful feedback is

received from the OxiTop®-C

measuring head.

Page 14

Operating Mode: Routine BOD

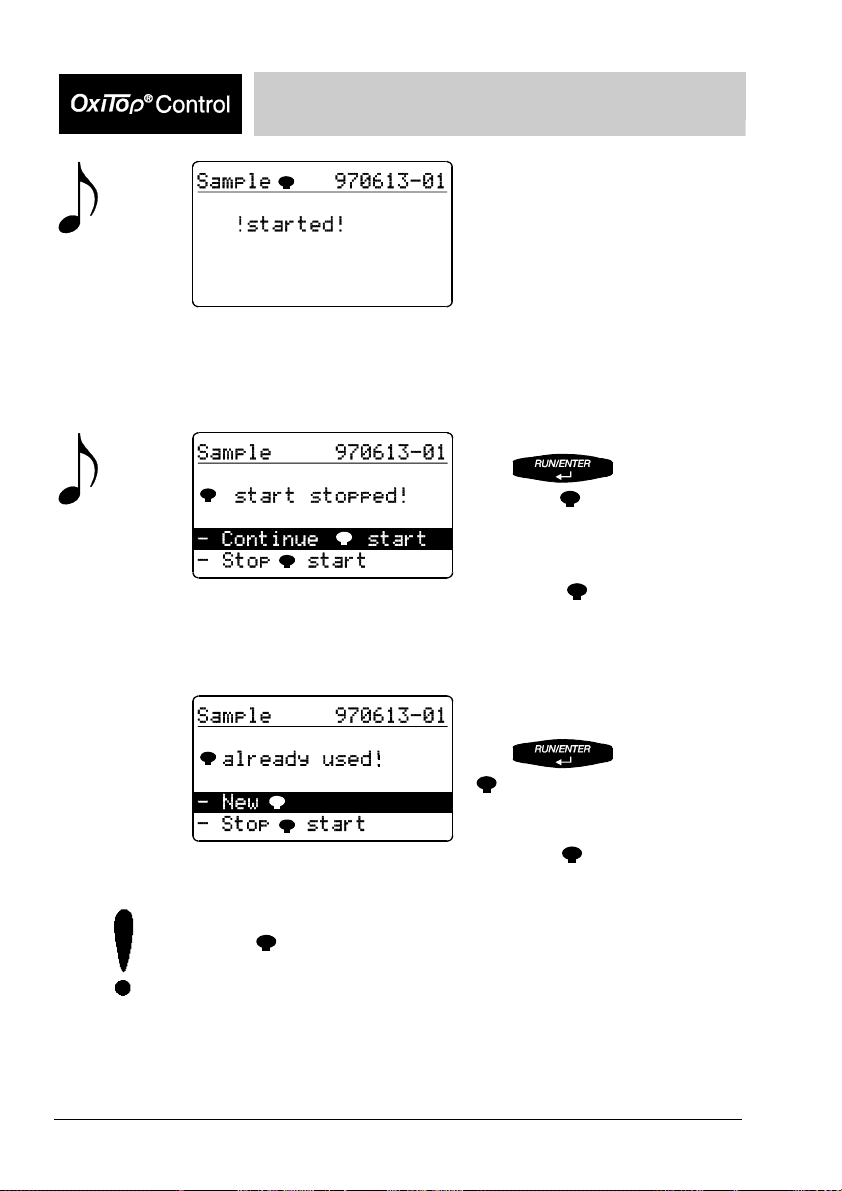

Displays “Started“. From this point in

time, the sample exists within the

If no sample starts (e.g. because the controller was not held to - or not

held close enough to - a measuring head):

sample management. Subsequently,

the controller returns automatically to

the input menu.

The sample start was stopped.

Use

If an attempt is made to start an already started sample:

“Continue

controller to the measuring head

(see above).

Use “Stop start“ if you want to

return to the entry menu.

to confirm

start“ and hold the

In the delivery state, the controller automatically makes space when

“Start

erases the oldest finished sample (if a finished sample is available). You

can change this setting in “manual erase” (see the chapter “GLP/Tools Settings”).

” is selected if the measured value memory is full. To do this, it

Display shows “Measuring head

already used!”

Use

” and hold the controller to the

measuring head (see above).

Use “Stop start“ if you want to

return to the entry menu.

to confirm “New

14 BA31114e5 07/2006 BA31114e5 07/2006 15

Page 15

Operating Mode: Routine BOD

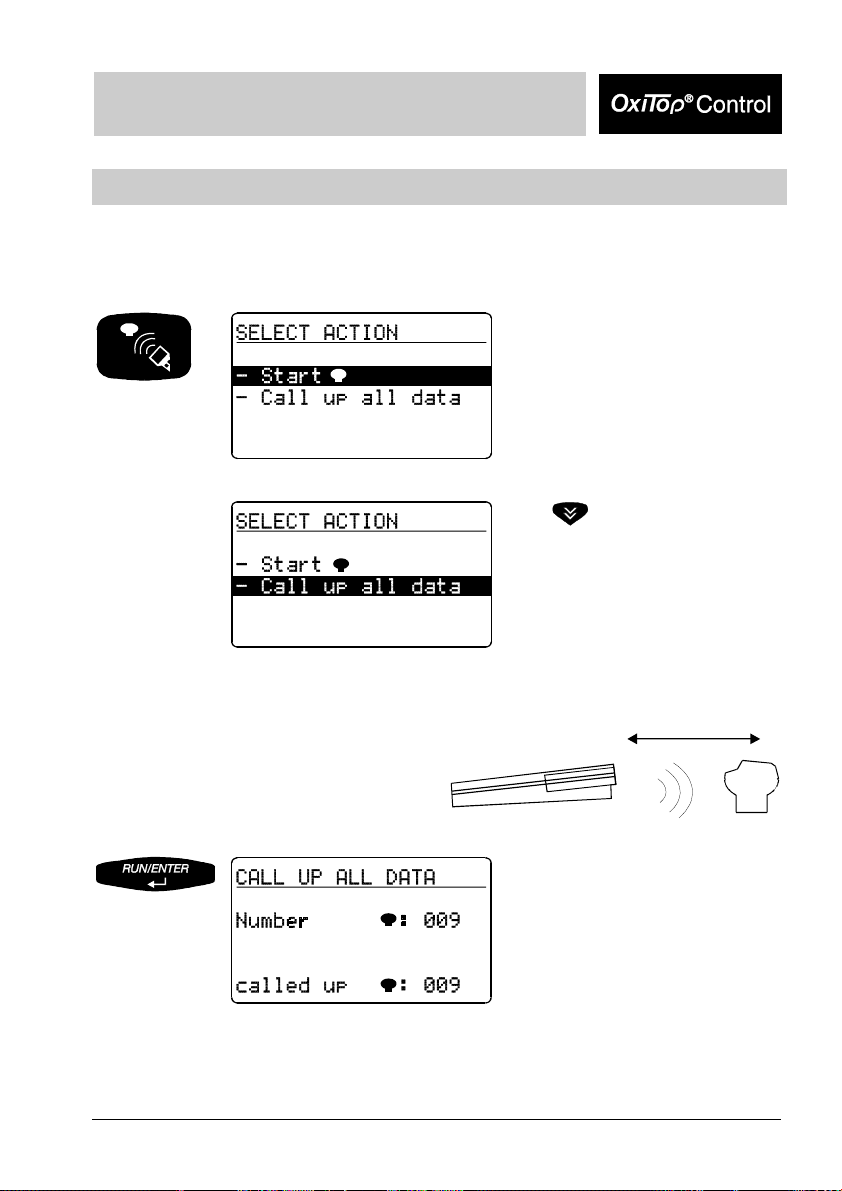

Call up all data

This function is used to call up the data of all measuring heads.

For the call up of the data of individual measuring heads: see the chapter on sample

management.

Entry menu “Communication with

the measuring heads“.

Point the controller at the measuring

heads:

Use

to select “Call up all data“.

40 cm to 100 cm

Queries the data of all active

measuring heads in the scanner

mode.

The controller stores the data

obtained and updates the list of

the sample management.

Duration of a pass: approx. 3

seconds for 12 measuring heads

in a stirring system.

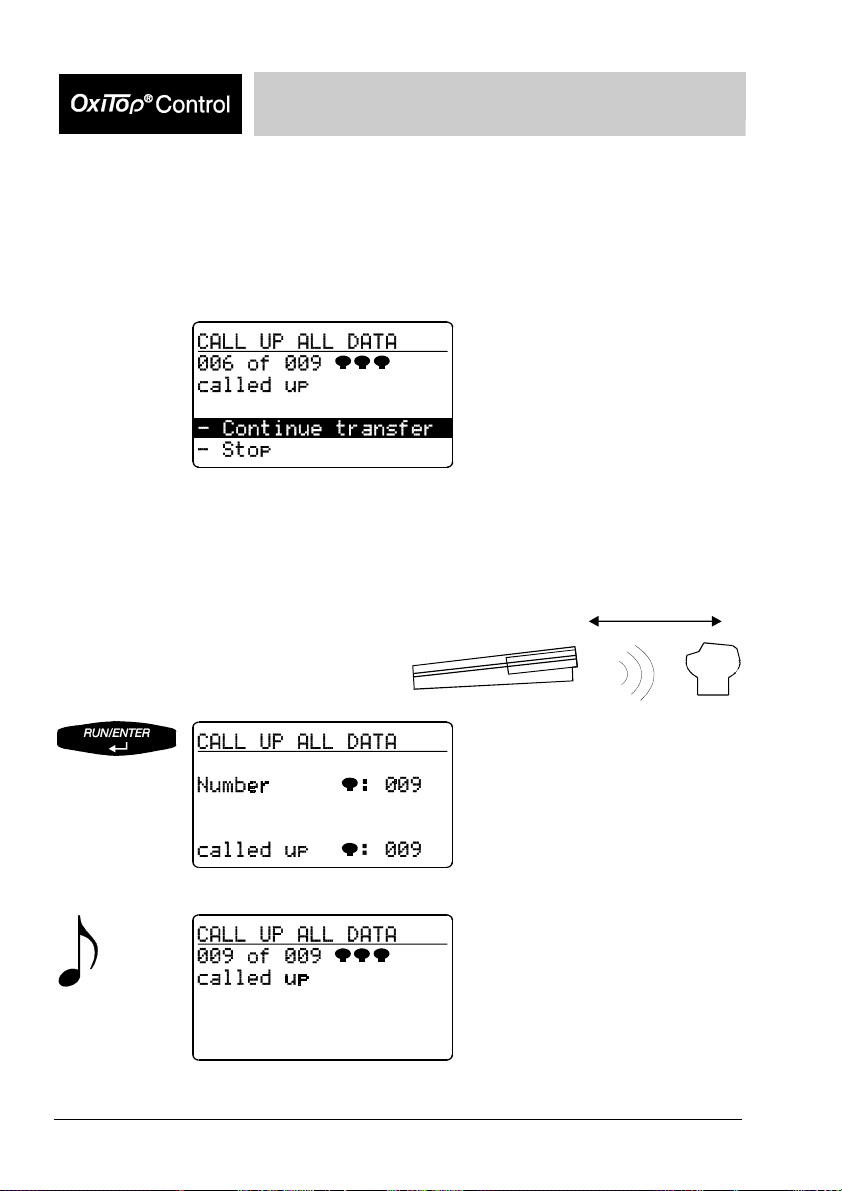

Page 16

Operating Mode: Routine BOD

If all the measuring heads do not respond in the 1st pass of the data query, the

controller searches for the missing measuring heads for approximately a further 7

seconds in the scanner mode. Without having to press another key, you can continue

the data queries at other locations (e.g. other stirring platforms or other thermal

cabinets). Approximately 7 seconds after the last call up was performed, the scanner

mode breaks off automatically and the following display appears:

Point the controller at the measuring

heads:

“Continue transfer“ (preselected):

A new pass is made only for

measuring heads that have not

yet responded.

Stop: The instrument returns to

the entry menu.

For information on searching for

missing measuring heads, see

the chapter “What to do if...“

40 cm to 100 cm

The call up of further measuring

heads takes place in the scanner

mode.

Message that the data of all

measuring heads has been

called up. The instrument

subsequently returns to the input

menu.

16 BA31114e5 07/2006 BA31114e5 07/2006 17

Page 17

Operating Mode: Routine BOD

Immediately after the data call up of the complete measurement data records of a

finished measuring head, this measuring head is set to the “free“ status. The

measuring head is now available for a new measurement. The sample allocated in

the sample management is “finished“ (see the chapter “Sample management”).

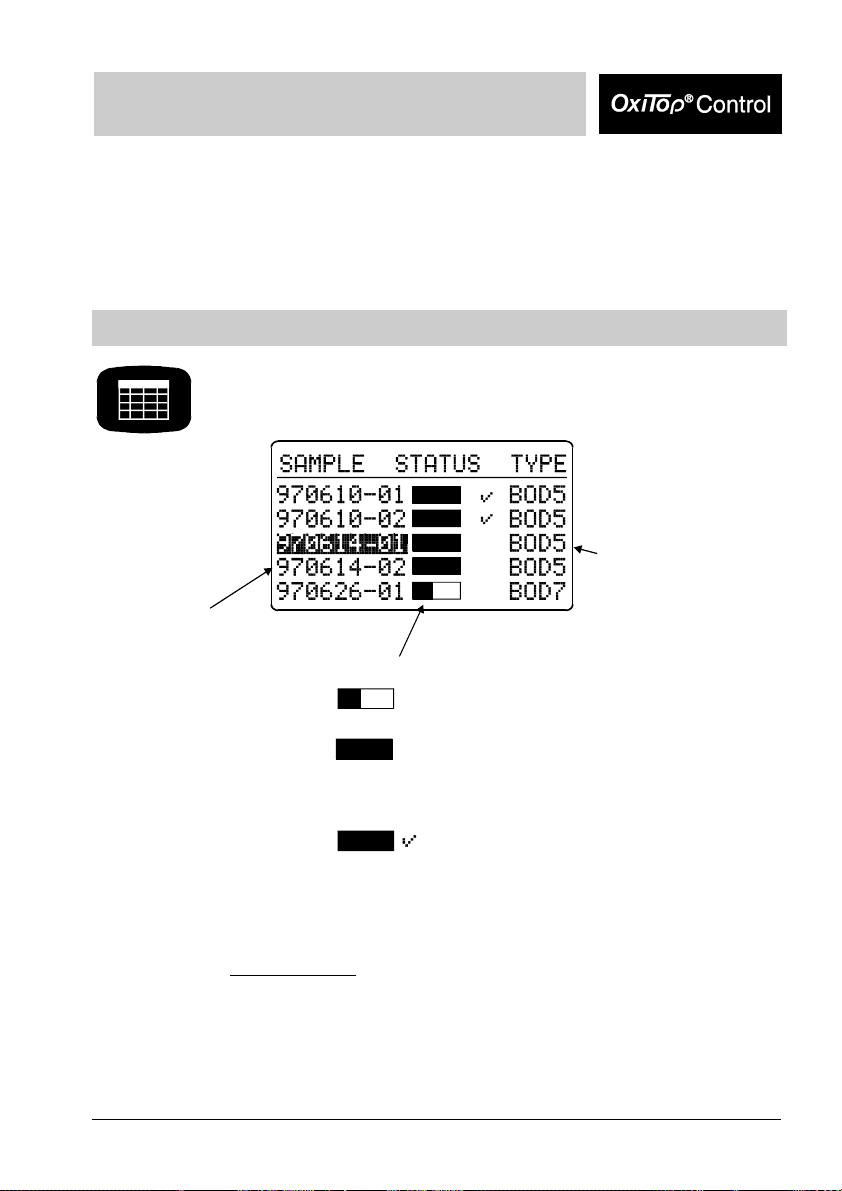

Sample management

Entry into the sample management.

A list of samples appears in the display (if samples are available):

BOD type and

run-duration

Sample number:

Date (YY/MM/DD)

and consecutive

number

Data of samples that have been started in the standard BOD operating mode, are not

listed in the routine BOD operating mode.

Reporting order:

- At the upper end of the list: finished samples (if available)

- Under this: running samples

Sorting of the samples: according to date and

sequential number 01 ... 99 from the oldest to the newest sample.

Temporal process of the sample:

Status bar partly filled:

The sample is not yet ready.

Status bar filled:

The ready and complete data set

of the sample can be called up from

the measuring head.

Status bar filled plus hook:

The sample is ready. The complete data

set is given in the controller for evaluation.

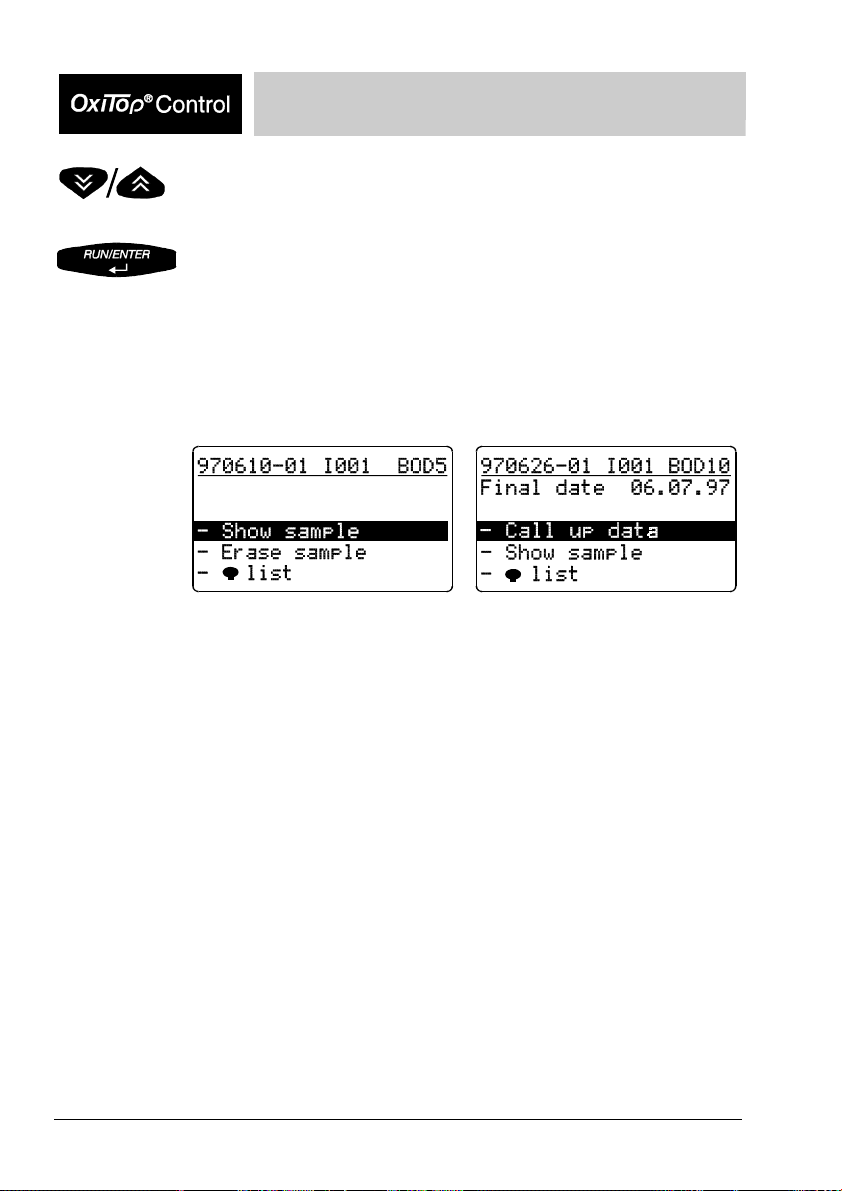

Page 18

Operating Mode: Routine BOD

Select a sample.

Depending on the sample selected, one of the two following menus

appears. The header line contains the:

- sample number

- Id number (e.g. I001)

- BOD type and run time

of the selected sample.

Finished sample

Current sample

18 BA31114e5 07/2006 BA31114e5 07/2006 19

Page 19

Operating Mode: Routine BOD

Show sample

This function is used to find the measuring heads. A sample labeling is not necessary.

Starting point: sample

management .

Point the controller at the measuring

heads:

Use

to select a sample.

Use

to select “Show sample“.

40 cm to 100 cm

The controller transmits the call

up of the selected sample. The

allocated measuring head flashes

for approx. 5 seconds.

After the message, the controller automatically returns to the

previous menu.

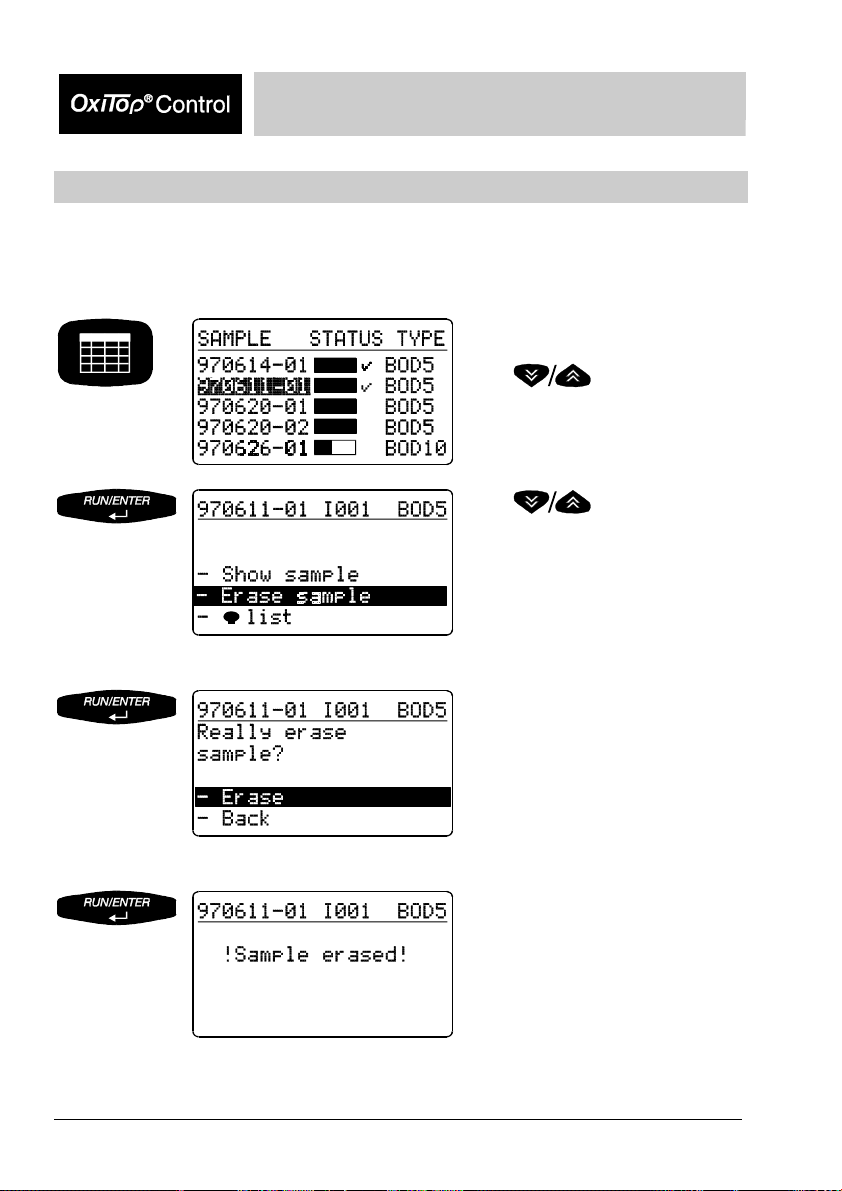

Page 20

Operating Mode: Routine BOD

Erase data of finished samples

This function erases the data of finished samples from the sample management of the

controller. You can only erase a sample if it is finished; in non-finished samples, the

menu item “Erase sample“ does not appear.

Starting point: sample

management .

Use

to select a finished sample.

Use

to select the “Erase sample“

submenu.

Safety query with possibility to

return.

The sample has been erased.

After the message, the controller automatically returns to the starting

menu, “Sample management“.

20 BA31114e5 07/2006 BA31114e5 07/2006 21

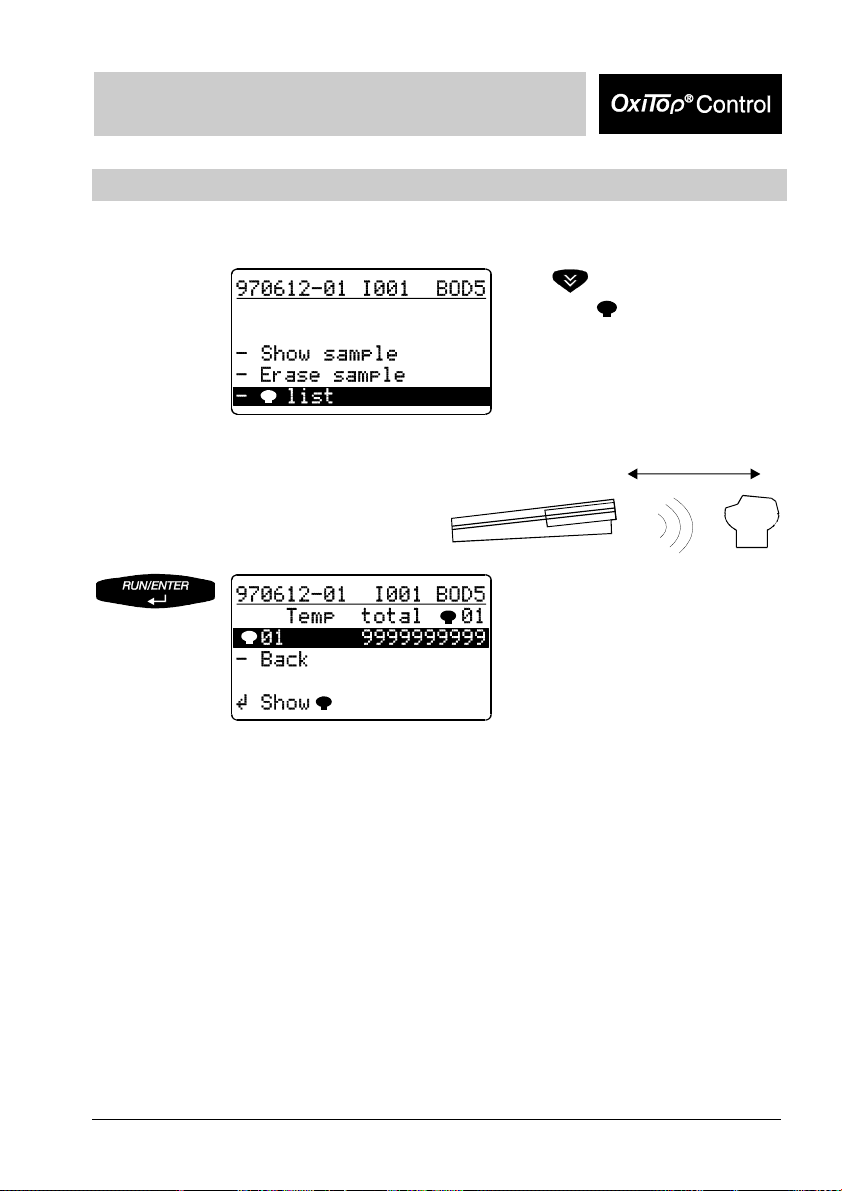

Page 21

Operating Mode: Routine BOD

Show measuring head list

This function is used to allocate a measuring head to the relevant sample.

Point the controller at the measuring

heads:

Use

to select “ list“.

“List“, i.e. a measuring head is

displayed together with the serial

number of the measuring head.

The controller transmits the call

up of the selected sample. The

allocated measuring head flashes

for approx. 5 seconds.

40 cm to 100 cm

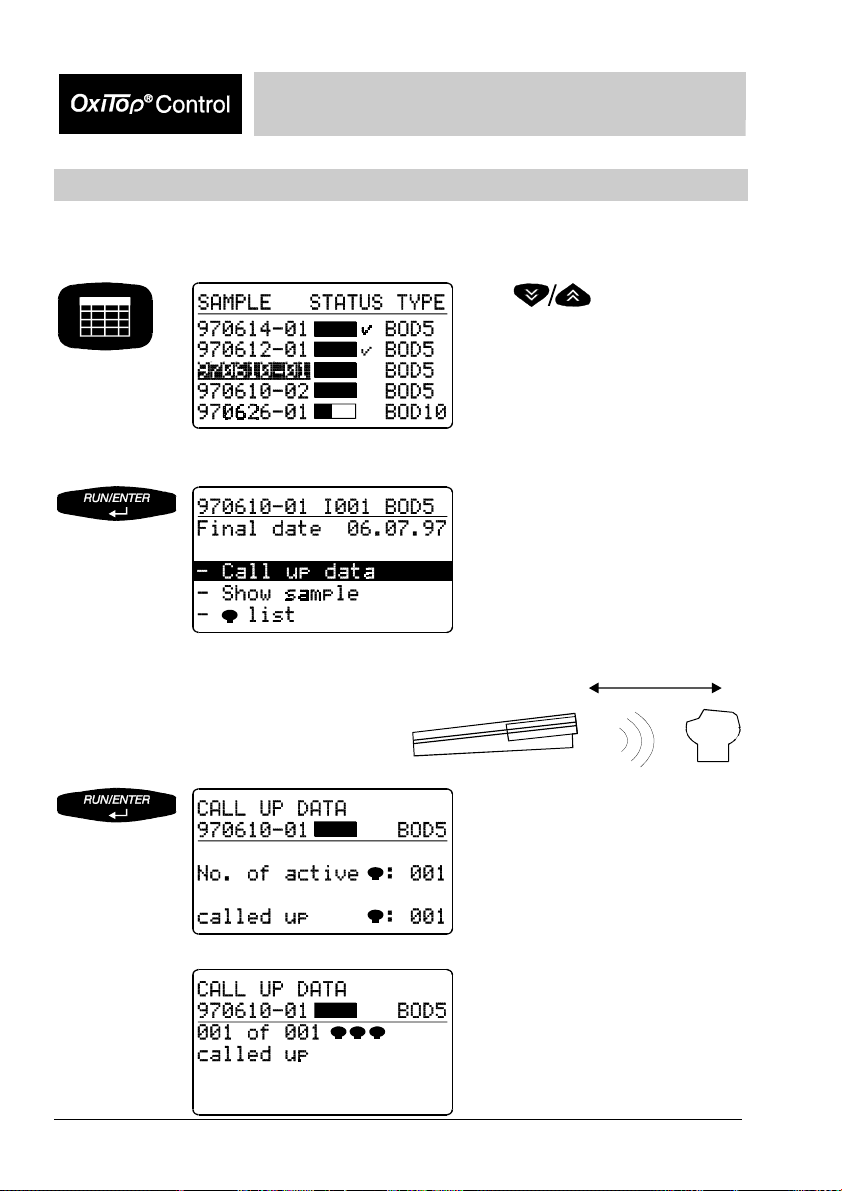

Page 22

Operating Mode: Routine BOD

Call up data

This function is used to call up the data of individual measuring heads. To call up the

data of all measuring heads, see the chapter “Call up all data“.

Use

to select a sample whose

- run time is not yet completed

(bar not yet full)

- data after complete

measurement that has not yet

been called up

(bar full, no tick)

Jumps to the submenu of the

selected sample.

Preselected: “Call up data“

Point the controller at the measuring

heads:

40 cm to 100 cm

Call up the measuring head

allocated to the sample in the

scanner mode:

The controller

- stores the data obtained

- updates the lists of the

sample management

The controller confirms the call

up performed.

22 BA31114e5 07/2006 BA31114e5 07/2006 23

Page 23

Operating Mode: Routine BOD

If the measuring head does not respond, the following display appears:

The controller then returns

automatically to the submenu.

The controller continues to search for the measuring head in the scanner mode.

Without pressing any further keys, the data call up can be continued at other

locations (e.g. other stirring platforms or other thermal cabinets). After approx. 7

seconds, the scanner mode automatically breaks off and the following display

appears:

Use to restart the

call up of the data (see above).

Return to the main menu,

“Sample management“.

Samples that were called up and

completed appear with a tick next

to them.

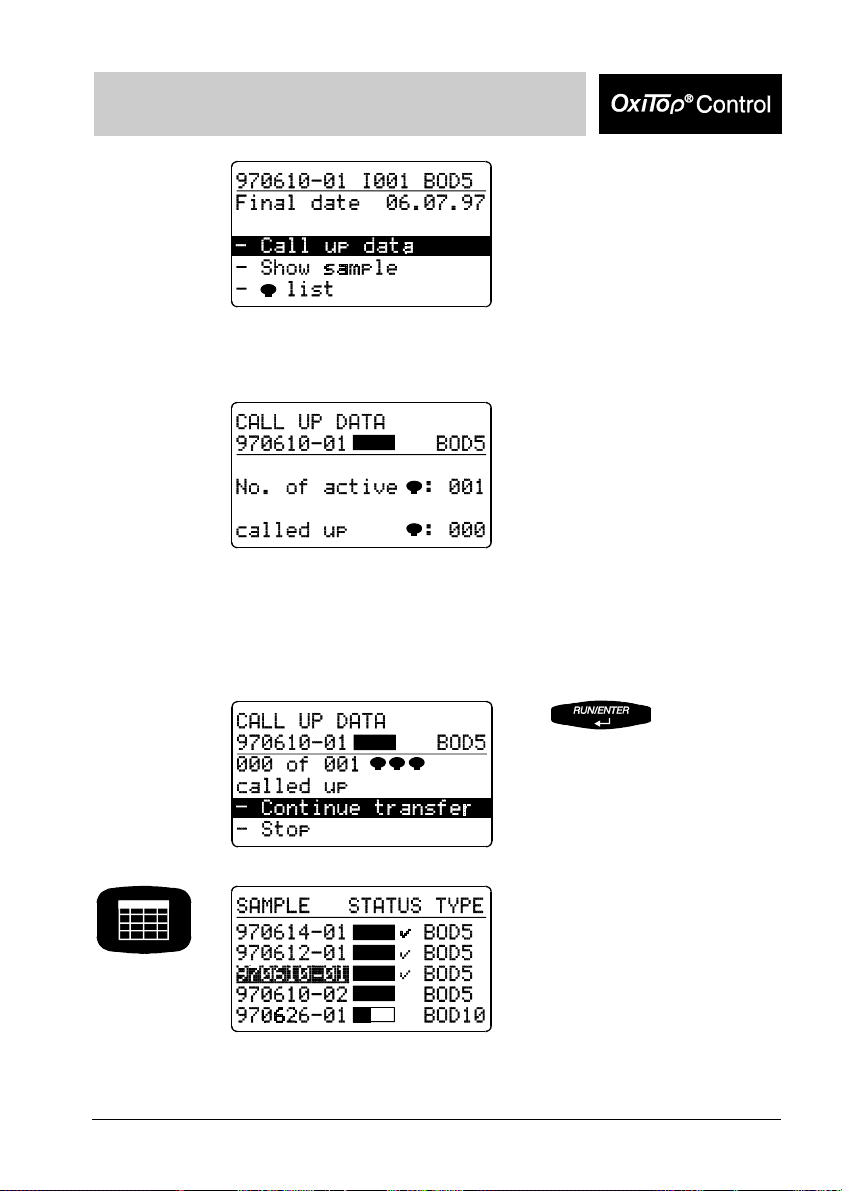

Page 24

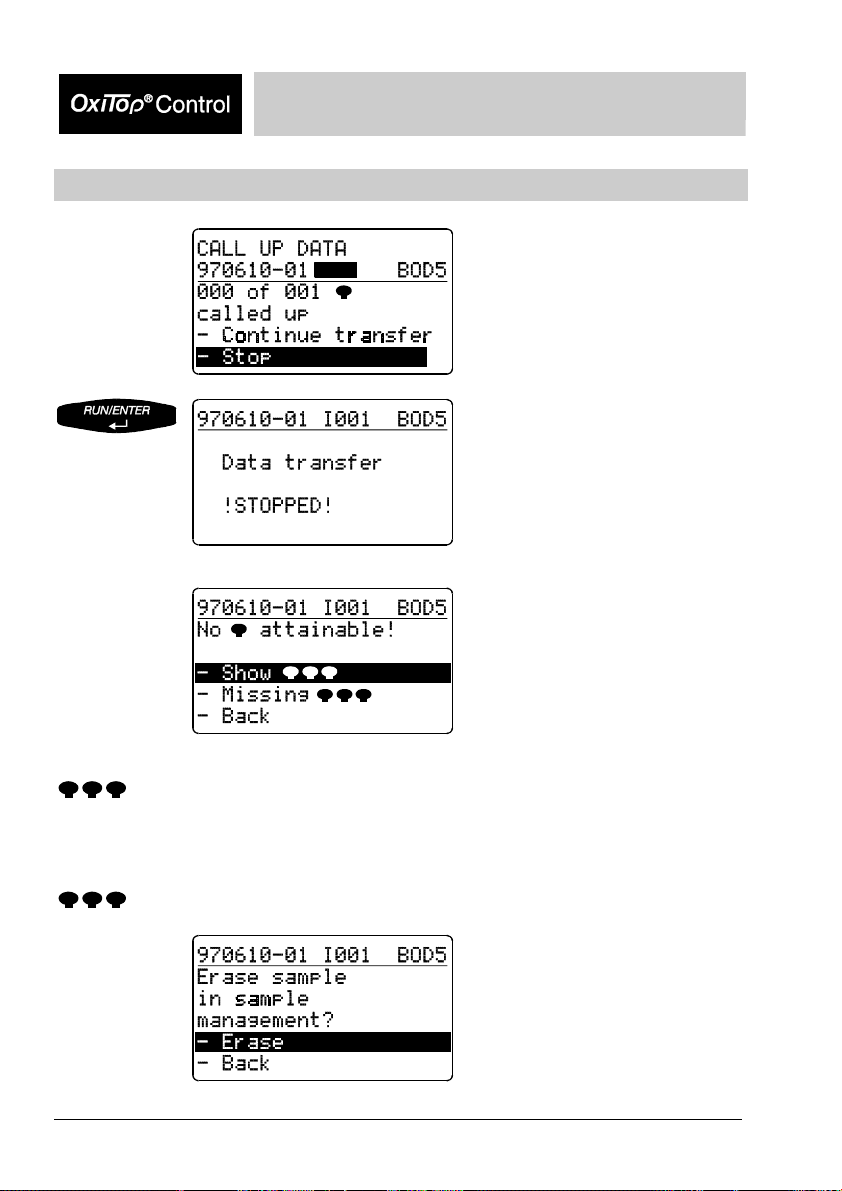

Call up data - Stop

Operating Mode: Routine BOD

If a measuring head is missing or

defective and the controller

cannot transfer the data as a

result, the menu item “Stop“ is

provided.

After confirmation, the display

message shown here appears.

Then:

“Show

“Missing

“:

“:

As in “Show sample“ but used selectively for missing measuring

heads (identification option if only the sender of the measuring head

is defective. Otherwise identify missing measuring heads using

“Show all“ (see the chapter “GLP/Tools”).

Using this you can remove the data of a missing or defective

measuring head from the sample management of the controller.

Erase:

Removes missing samples from

the data stock.

Return:

Jumps back to the previous

menu.

24 BA31114e5 07/2006 BA31114e5 07/2006 25

Page 25

Operating Mode: Routine BOD

Evaluation

Change to cursor prompt:

Starting point: sample

management.

Use

to select a sample.

Enters into the evaluation:

Display of the selected sample as

a curve together with measured

value data.

Pressing causes the

cursor (crosswire) to run through

the points of the curve. The

allocated run time and the

corresponding measured value

are each displayed.

Pressing

display of the curve together with the measured value data.

changes between the cursor prompt and

Page 26

Operating Mode: Routine BOD

Curve display of samples that are too cold

Display of a curve

In using samples that are too cold, the maximum AutoTemp time is not sufficient to

reach the temperature adaption of the sample: By warming the sample, excess

pressure can result.

Display: Negative values of the curve are truncated and the curve emerges from

the time axis but not from the origin.

Measured values outside the measurement ranges

In the following cases, the evaluation displayed is not the measured value but “undef.“

(undefined):

- The measurement curve exceeds the measurement range at some point of its path.

- The measurement curve undercuts the measurement range at its end point.

Sample displays:

The measured value exceeds the

measurement range (overflow).

26 BA31114e5 07/2006 BA31114e5 07/2006 27

Page 27

Operating Mode: Routine BOD

The measured value undercuts

the measurement range

(underflow).

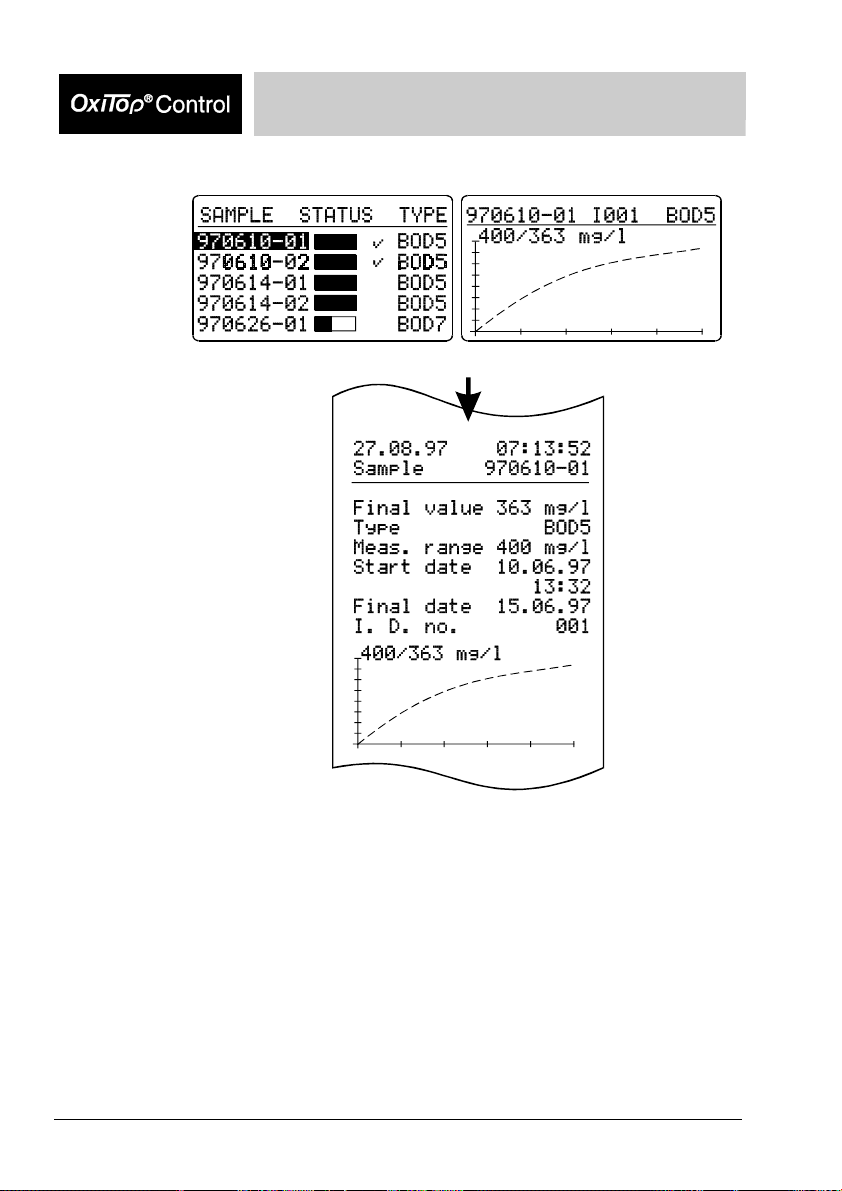

Printing

Point the controller at the printer:

Switch on the TD 100 IR printer.

The controller outputs the report data of the selected sample on the

IR interface.

Printout of:

- sample information

(start date and time, final date, type, measurement range,

identification number)

- curve + BOD final value

- report printouts: - current settings

- start information

-

- controller info

The measured value temporarily

leaves the measurement range.

10 cm to 100 cm

info

Page 28

Operating Mode: Routine BOD

From the sample management: From the evaluation:

28 BA31114e5 07/2006 BA31114e5 07/2006 29

Page 29

Operating Mode: Standard BOD

Operating mode: Standard BOD

Sample preparation

See WTW application reports

(contained within the scope of delivery of the accessories supplied).

Screw the OxiTop

and close them tightly.

Important note:

Never use joint grease or other lubricant for your OxiTop

heads. Some of these products contain solvents that can cause severe damage

to the plastic housing.

The sealing of the BOD bottles is also perfectly adequate without grease.

However, you should always wipe off heavy contamination and particles on the

sealing surfaces of the rubber sleeves and OxiTop

liability for damage due to the use of joint grease.

Start the measurement

To change to the operating mode BOD Standard refer to chapter GLP/Tools Settings - Operating mode.

-C measuring heads onto the sample bottles

-C measuring

-C. WTW accepts no

“Communication with the

measuring heads” mode.

Preselected: “Start sample”.

Use

to select the measurement range.

The filling volume required is

given in the right hand column.

The controller stores the setting

(memory function: the last

selected measurement range is

set).

Page 30

Operating Mode: Standard BOD

Additional information:

Type of measurement, run time, measurement range, final date, Id

number.

“Temp“ display => the AutoTemp function (see the chapter

“GLP/Tools”) is switched on.

Change the Id number for the additional identification of the sample

(e.g. extraction location) as follows:

- Use

- Press and

- Use

(setting range 001 ... 255).

- Use

to move the cursor to the Id number,

to set the Id number required

to confirm this.

Confirm the selected

measurement range for the

sample. The automatically

assigned sample number

(YY/MM/DD and sequential

number) is given in the header

line.

Use

possible (see the chapter “Standard BOD - Print”).

to print out the entire sample information

Confirm the start of

measurement.

Contact selection:

30 BA31114e5 07/2006 BA31114e5 07/2006 31

Page 31

Operating Mode: Standard BOD

The controller repeatedly sends the start information in the scanner

mode until successful feedback is received from the OxiTop®-C

measuring head. After the successful start message from the

measuring head:

Displays “!Started!”. From this

point in time, the sample exists

within the sample management.

Subsequently, the request to

start the next measuring head is

made automatically.

Start the next measuring head

2).

(

Contact selection:

The number of the measuring

head is automatically

incremented.

The controller continues to work with the stirring selection, i.e. you

can now start a sequence of measuring heads (parallel sample start)

without having to press any further keys by holding the controller to

the next measuring head to be started.

When all the measuring heads provided for this sample have been started:

Use

The controller returns to the input menu.

to selecct “Stop start”:

If no measuring head is started (e.g. because the controller was not held to - or not

close enough to - a measuring head):

Page 32

Operating Mode: Standard BOD

The start was stopped.

Use

If an attempt is made to start a measuring head that was already

started:

“Continue

controller to a measuring head

(see above).

Select “Stop start” to return to

entry level menu.

Displays “Measuring head

already used!”

Use

” and hold the controller to a

free measuring head (see

above).

to confirm

start” and hold the

to confirm “New

Select “Stop start” to return to

entry level menu.

In the delivery state, the controller automatically makes space when

“Start

it deletes the oldest finished sample (if a finished sample is

available). You can change this setting in “manual erase” (see the

chapter “GLP/Tools - Settings”).

” is selected if the measured value memory is full. To do this,

Call up all data

This function is used to call up the data of all measuring heads.

To call up the data of individual measuring heads: see the chapter “ Sample

management”.

Entry menu “Communication with

the measuring heads“.

32 BA31114e5 07/2006 BA31114e5 07/2006 33

Page 33

Operating Mode: Standard BOD

Use

to select “Call up all data”.

Point the controller at the measuring

heads:

40 cm to 100 cm

Queries the data of all active

measuring heads in the scanner

mode.

The controller stores the data

obtained and updates the list of

the sample management.

Duration of a pass: approx. 3

seconds for 12 measuring heads

in a stirring system.

If the measuring heads do not all respond in the 1st pass of the data query, the

controller searches for the missing measuring heads in the scanner mode for

approximately a further 7 seconds. Without having to press another key, you can

continue the data queries at other locations (e.g. other stirring platforms or other

thermal cabinets). Approximately 7 seconds after the last call up was performed, the

scanner mode breaks off automatically and the following display appears:

“Continue transfer“ (preselected):

A new pass is made only for

measuring heads that have not

yet responded.

Stop: The instrument returns to

the entry menu.

For information on searching for

missing measuring heads, see

Page 34

Operating Mode: Standard BOD

Point the controller at the measuring

heads:

the chapter “What to do if...“

40 cm to 100 cm

The call up of further measuring

heads is performed in the

scanner mode.

Message that all the data of all

the measuring heads has been

called up. The instrument then

returns to the input menu.

Immediately after the data transfer of the complete measurement data records of a

finished measuring head, this measuring head is given the “free” status. The

measuring head can be used for a new measurement. The relevant sample in the

sample management is marked as finished (see the chapter “Sample management”).

34 BA31114e5 07/2006 BA31114e5 07/2006 35

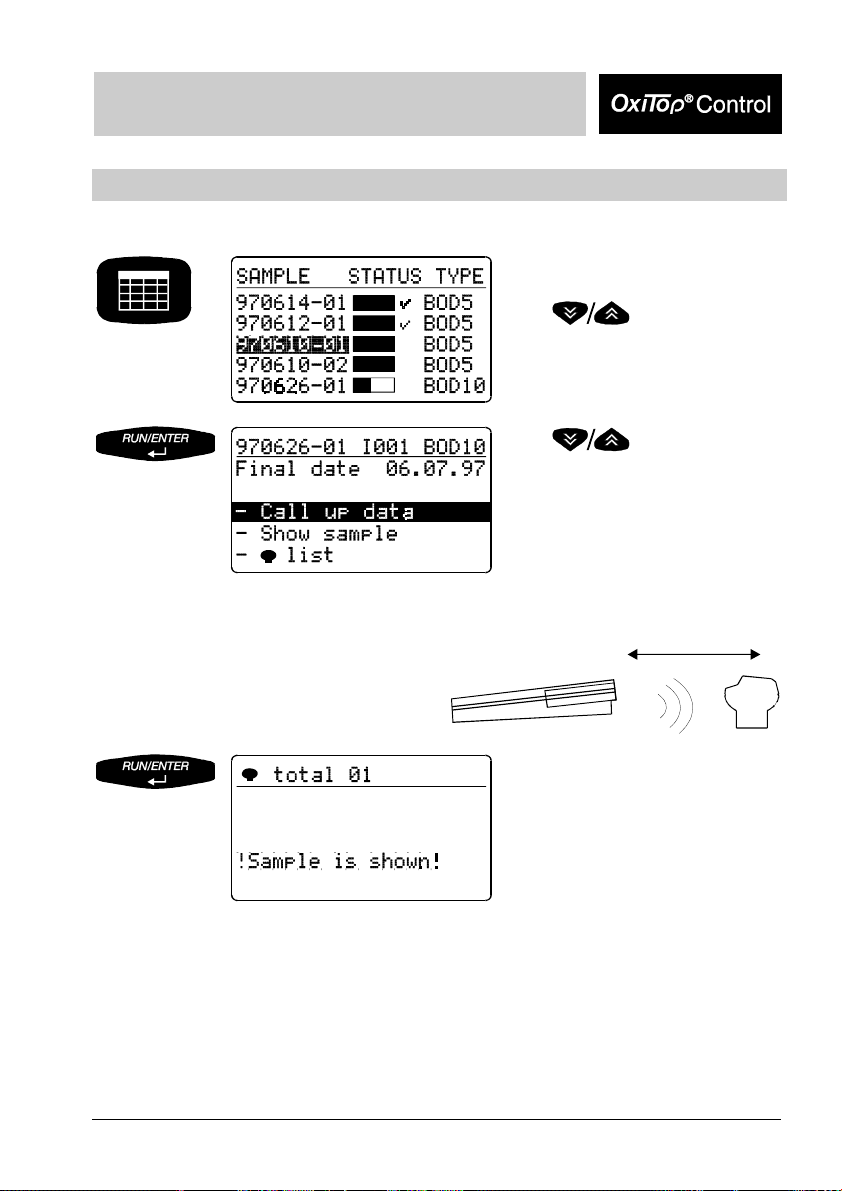

Page 35

Operating Mode: Standard BOD

Sample management

Entry into the sample management.

A list of samples appears in the display (if samples are available):

Data of samples that have been started in the standard BOD operating mode is not

listed in the routine BOD operating mode.

Reporting order:

- At the upper end of the list: finished samples (if available)

- Under this: current samples

Sorting of the samples: according to date and

sequential number 01 ... 99 from the oldest to the newest sample.

Select a sample.

Page 36

Operating Mode: Standard BOD

According to the sample selected, one of the two following menus

appears. The header line contains the:

- sample number

- Id number (e.g. I001)

- BOD type and run time

of the selected sample.

Finished sample

Current sample

Show sample

This function is used to find the measuring heads or samples. Sample labeling is not

necessary.

Starting point: sample

management .

Use

to select a sample.

36 BA31114e5 07/2006 BA31114e5 07/2006 37

Page 37

Operating Mode: Standard BOD

Point the controller at the measuring

heads:

40 cm to 100 cm

The controller transmits the call

up of the selected sample. The

allocated measuring head flashes

for approx. 5 seconds.

After the message, the controller automatically returns to the

previous menu.

Erase data of finished samples

This function erases the data of finished samples from the sample management of

the controller. You can only erase a sample if it is finished; in non-finished samples,

the menu item “Erase sample“ does not appear.

Starting point: sample

management .

Use

to select a finished sample.

Use

to select the “Erase sample“

submenu.

Page 38

Operating Mode: Standard BOD

Safety prompt with possibility to

return.

The sample has been erased.

After the message, the controller automatically returns to the starting

menu, “Sample management“.

Show measuring head list

This function is used to allocate individual measuring heads to the relevant sample in

the sample management and to find individual measuring heads.

Use

to select “Measuring head list”.

38 BA31114e5 07/2006 BA31114e5 07/2006 39

Page 39

Operating Mode: Standard BOD

Point the controller at the measuring

heads:

List of measuring heads of the

selected sample is displayed

together with the serial numbers

of the measuring heads.

40 cm to 100 cm

Use

confirm.

The controller again transmits the call up of the selected sample.

The measuring head flashes for approx. 5 seconds.

Use

to select the measuring head and use to

to return to the sample management.

Call up data

This function is used to call up the data of individual samples. To call up the data of

all samples, see the chapter “Call up all data“.

Use

to select a sample whose

- run time is not yet completed

(bar not yet full)

- data after complete

measurement that has not yet

been called up

(bar full, no tick)

Page 40

Operating Mode: Standard BOD

Point the controller at the measuring

heads:

Jumps to submenu of the

selected sample.

Preselected: “Call up data“

40 cm to 100 cm

Sequential call up of the

measuring heads allocated to the

sample (in this example: 7) in the

scanner mode:

The controller

- stores the data obtained

- updates the list of the

sample management

Duration of a pass:

approx. 3 seconds for 12

measuring heads in a stirring

system.

The controller confirms the call

up performed.

40 BA31114e5 07/2006 BA31114e5 07/2006 41

Page 41

Operating Mode: Standard BOD

The controller then returns

automatically to the submenu.

If the measuring heads do not all respond, the following display appears:

Renewed start of the data call up.

The controller continues to search for missing measuring heads in the scanner mode.

Without pressing any further keys, the data call up can be continued at other

locations (e.g. other stirring platforms or other thermal cabinets). Approximately 7

seconds after the last request was performed, the scanner mode automatically breaks

off and the following display appears:

Use to restart the

the data transfer (see above).

Immediately after the successful data transfer of a sample, the allocated measuring

heads are given the “free” status. The measuring heads can be used for a new

measurement.

Return to the main menu,

“Sample management“.

Transferred and completed

samples appear with a tick next

to them. (The complete

measurement data records of all

finished measuring heads of the

sample have been procured.)

Page 42

Call up data - Stop

Operating Mode: Standard BOD

If a measuring head is missing or

defective and the controller

cannot completely call up the

sample as a result, the menu

item “Stop“ is provided to stop

the data transfer.

After confirmation, the display

message shown here appears.

The sample is still running and

individual measuring heads of the

sample are not attainable.

Case 1

Three displays are then possible:

Case 2

The run time of the sample has

ended and the finished, complete

data of the attainable measuring

heads has been transferred.

42 BA31114e5 07/2006 BA31114e5 07/2006 43

Page 43

Operating Mode: Standard BOD

then

Case 3:

then

“Show

“Missing

”:

”:

Erase:

Removes missing measuring

heads from the data stock. The

completed sample is given the

“finished” status.

Back:

Jumps back to the previous

menu.

Abort using a function key: The

stopped sample is not declared

as “finished”.

No measuring head of a sample

is attainable.

Erase:

Removes a sample from the data

stock.

Back:

Jumps back to the previous

menu.

As in “Show sample“ but selectively for missing measuring heads

(Identification option if only the sender of the measuring head is

defective. Otherwise, see the chapter “What to do if...?”)

Only appears when the run time of the sample has expired. It is used

to set the sample to the “finished” status (ticked) if all the other

measuring heads are already “finished”: Erases the missing

measuring heads from the sample management.

Page 44

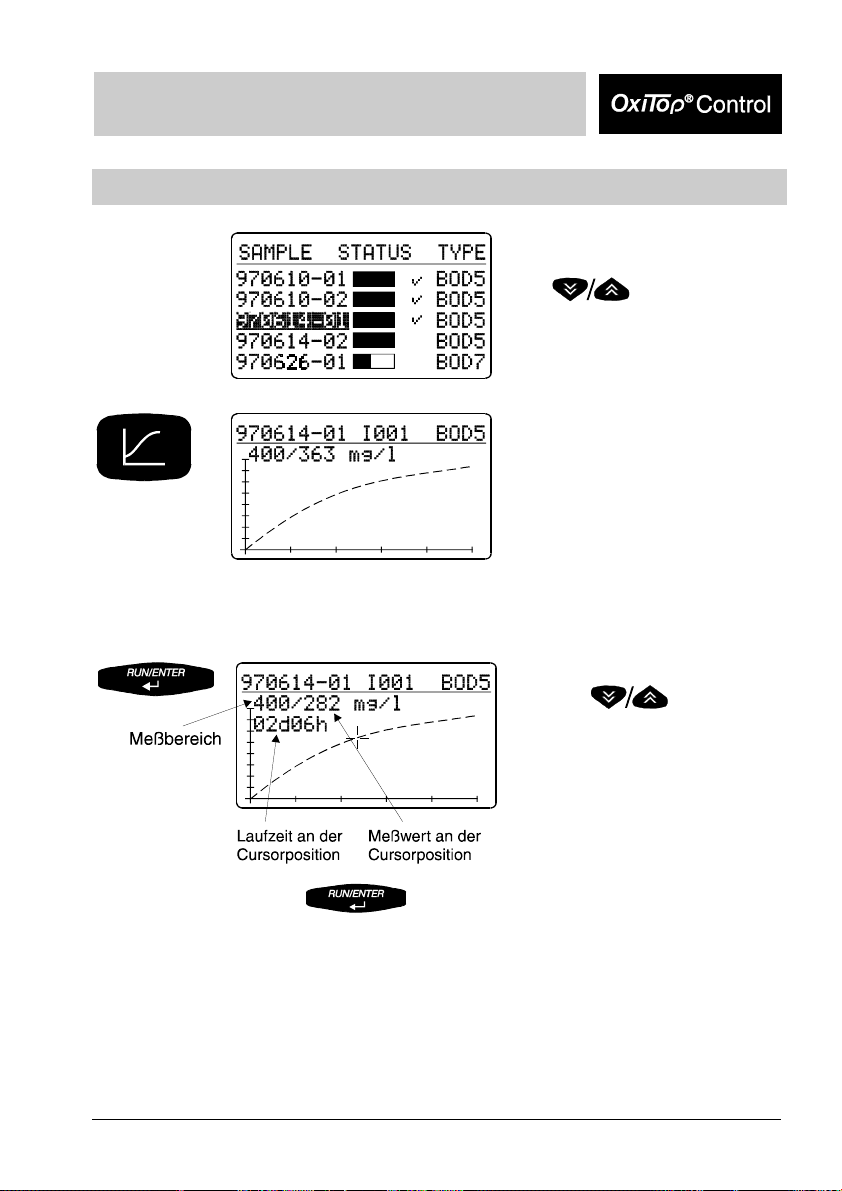

Evaluation

Operating Mode: Standard BOD

Starting point: Sample

management.

Use

sample.

to select the

Printout of the results with

curves.

Evaluation of the whole sample:

Display of all the curves together

with mean value data.

Check the display for outliers.

Printout of the results with curves

(according to printing format see the chapter “Print“)

Example: Whole sample with

outliers.

Scroll through the parallel

samples: Display of individual

curves (cyclical pass) with data of

the BOD final value.

Printout of a single result with a

single curve.

44 BA31114e5 07/2006 BA31114e5 07/2006 45

Page 45

Operating Mode: Standard BOD

Sample statistics

When jumping to the pull-down menu from “Show all curves“, the

menu item “Exclude curve“ disappears.

Results of the finished sample: Data of the current sample:

Starting point: display of a single

curve.

Changes to sample statistics.

The menu selection shown here

only appears if n (the number of

measuring heads) is at least 2.

If n = 1, see the chapter “Routine

BOD - Evaluation”.

- mean value

- SD: standard deviation

(from n = 3)

- n: number of measuring heads

- end date

- current mean value

- n: number of measuring heads

Printout of the results with curves

Printout of the data (current

mean value, n, sample

information) with curve paths to

date

Page 46

Operating Mode: Standard BOD

Excluding a curve

This function is used to temporarily exclude a single curve (e.g. an outlier) from the

evaluation and averaging of a whole sample.

The curve is only excluded temporarily! The data stock of the sample

management does not change. The excluded curve is present again when the call is

repeated.

The function “List of measuring heads“ (see the chapter “Sample management”) is

used to find leaky or defective single samples.

Display of the single curves:

Select curve.

:

Change to

“Exclude curve“.

“Exclude curve“

is preselected.

“Return“: Returns to the previous

menu.

46 BA31114e5 07/2006 BA31114e5 07/2006 47

Page 47

Operating Mode: Standard BOD

Message

“Curve excluded“.

Updated display

(curve excluded, mean value

newly calculated).

Printout of the updated results

with curves

(without the excluded curve).

Page 48

Operating Mode: Standard BOD

Cursor interrogation

Starting point:

Display of a single curve with

measured value data.

Use

to change to “Cursor query“.

Or from the display of all the single curves:

Use

to run through the curve values.

Use

current display.

Use to run through

the curve mean values.

to print out the

Use to print out the

current display.

Return to the previous menu using

Return to the display of all the single curves using

.

.

48 BA31114e5 07/2006 BA31114e5 07/2006 49

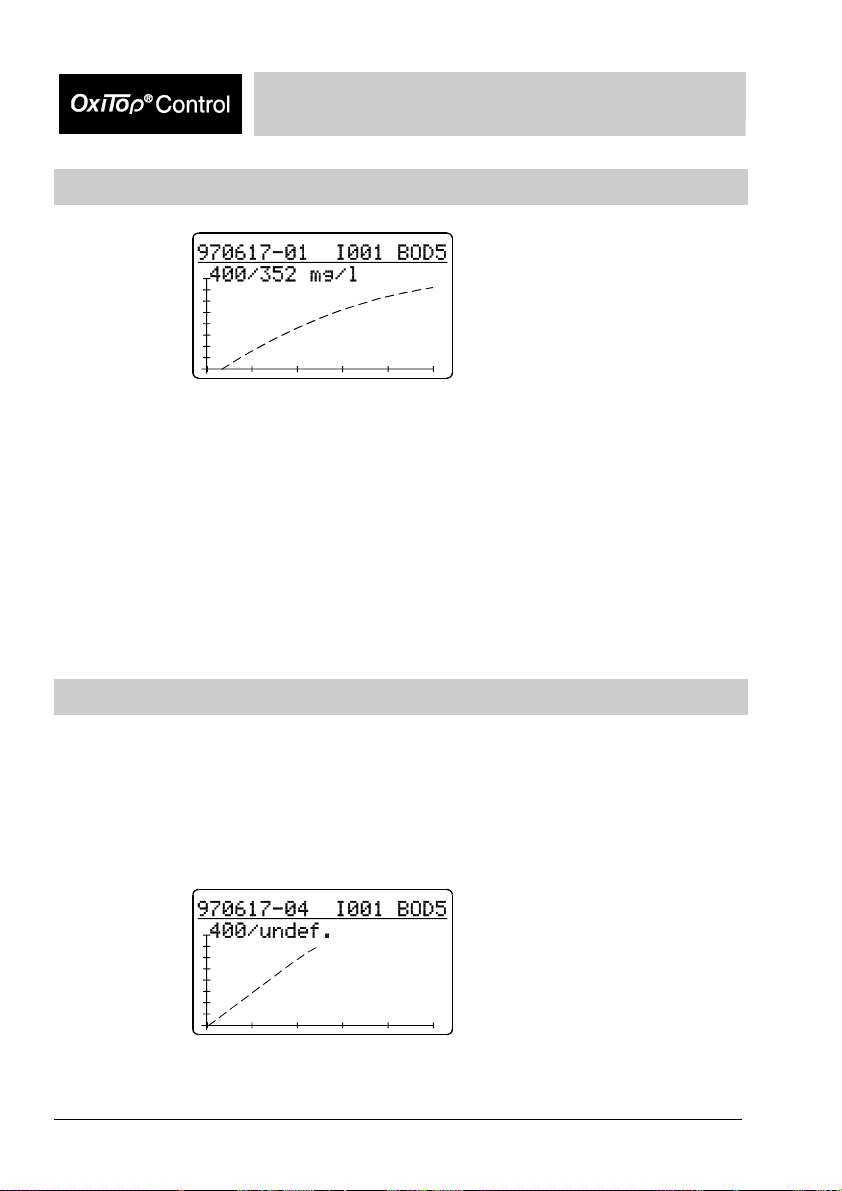

Page 49

Operating Mode: Standard BOD

Curves display for cold samples

Display of a single curve.

When using samples that are too cold, the maximum AutoTemp time is not sufficient

to reach the temperature balance of the sample: Warming the sample can cause

excess pressure.

Display: Negative values of the curve will be truncated and the curve arises

from the time axis but not the origin.

Display of all curves.

Page 50

Operating Mode: Standard BOD

Measured values outside the measuring range

In the following cases, “undef.“ (undefined) is displayed instead of the measured

value or mean value during evaluation:

- A measured curve exceeding the measuring range at any point of its path.

- A measured curve undercutting the measuring range at its end point.

After the exclusion of the defective curve (see chapter “Exclude curve“), the controller

displays the mean value again.

Sample displays:

A measured value exceeding the

measuring range (Overflow).

A measured value undercuts the

measuring range (Underflow).

A measured value temporarily

leaves the measuring range.

50 BA31114e5 07/2006 BA31114e5 07/2006 51

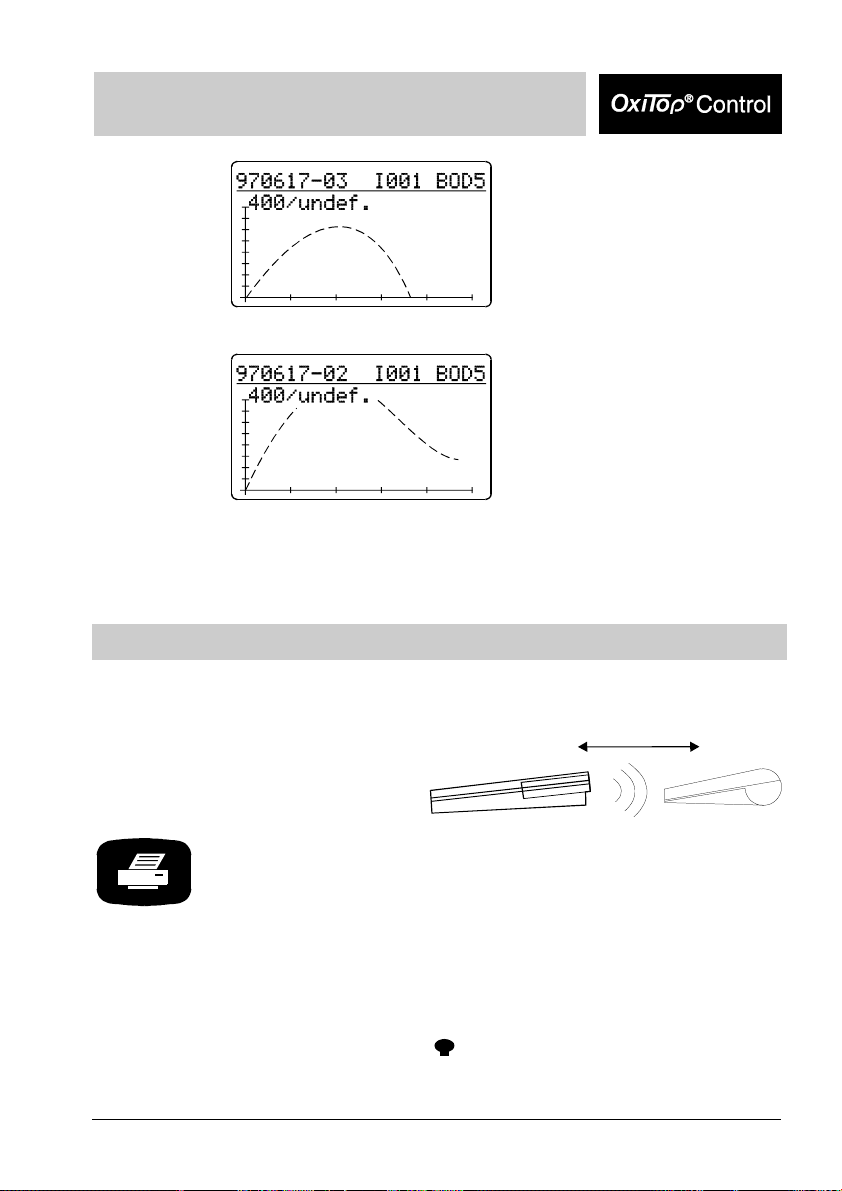

Page 51

Operating Mode: Standard BOD

Print

Point the controller at the printer:

Switch on the TD100 IR printer.

10 cm to 100 cm

The controller outputs the report data of the selected sample to

the IR interface.

Printout of

- sample statistics (mean value, SD, n)

- sample information (type, running time, measuring range, start

date and start time, end date, identification no.)

- curve + BOD final value

- with GLP On: additional information on the system status

and list of the series nos. of the measuring heads allocated to

the sample

- If AutoTemp is switched on: note “AutoTemp on“

- Report printouts: - current settings

- start information

-

- controller info

From the sample management: From the evaluation (display of

info

all the curves):

Page 52

Operating Mode: Standard BOD

Print from the evaluation:

If the controller is located

- in the display of all the curves with cursor display or

- in the display of single curves with or without cursor query,

the printout shows a copy of the relevant display.

52 BA31114e5 07/2006 BA31114e5 07/2006 53

Page 53

GLP / Tools

GLP/Tools main menu

Main menu:

Use

Submenus of the GLP/Configuration:

Show free

Show settings The current settings are displayed here.

Setup point Preset

Operating mode Routine BOD

Routine BOD: Standard BOD:

BOD type and measuring

time

Date Current Current

Time Current Current

GLP: ON or OFF Off (fixed setting) On

Calibrating interval --- 12 months

Erase memory auto

AutoTemp: ON or OFF

Switch-off interval 5 minutes (fixed setting) 5 minutes

Language German German

This function is used to identify free measuring heads without

requiring sample labeling. Free measuring heads can be used to

start new samples.

(The table shows the settings in the delivery state):

BOD5 (5 days) BOD5 (5 days)

(automatic erase)

On (fixed setting) On

to select a submenu

Use

to change to the submenu

auto

(automatic erase)

Page 54

GLP / Tools

Settings

Check Show

Here you can undertake or change the following settings:

Operating mode

Measuring time

Date/time

* GLP; calibrating interval

Memory

* AutoTemp

* Switch-off interval

Language

(finished/all)

info (with report printout)

Controller info (with report printout)

Cal test

Pneumatic test

Maintenance Erase finished samples (in the controller - sample management)

Reset/release

* only in the standard BOD operating mode

Show free

Main menu, “GLP/Tools“.

The “Show free

is preselected.

“ menu

Press .

Point the controller at the measuring

heads:

40 cm to 100 cm

All free measuring heads flash for approx.

5 seconds.

54 BA31114e5 07/2006 BA31114e5 07/2006 55

Page 55

GLP / Tools

Show settings

The following example illustrates the presettings in the Standard

BOD operating mode.

Main menu, “GLP/Tools“.

Use to select

the “Show settings“ menu.

“Show settings“ menu: A list

containing the current settings is

displayed.

Use

to scroll through the list where

the scrolling stops at the

beginning and end of the list

In the “Show settings“ submenu:

Print out the whole list of current settings (as in the display).

Page 56

Settings

Operating mode

GLP / Tools

Main menu, “GLP/Tools“.

Use

to select the “Settings“ menu.

“Settings“ submenu:

Use

to select “Operating mode“.

Use to acknowledge

it and to select

between the operating modes,

Routine BOD and Standard BOD.

Confirm using

.

Return to the “Settings“ main

menu:

, then .

56 BA31114e5 07/2006 BA31114e5 07/2006 57

Page 57

GLP / Tools

Measuring time

Set the type and measuring time of the BOD measurement here.

“Settings“ submenu:

Use

to select the “Measuring time“

submenu.

Use

to set the days (1 to 99) or

hours (0.5 to 23).

Confirm using

Display:

preset measuring time.

Default on delivery: 5 days.

.

Date/Time

Set the date and time in the controller here (important for sample number allocation).

“Settings“ submenu:

Use

to select the “Date/Time“

submenu.

Page 58

GLP / Tools

Set each of the number blocks

underlaid in black using

.

Confirm and continue with

The measuring time of samples already started is not affected by a change of date

and time.

Set the day, month, year, hours,

minutes, seconds consecutively.

.

GLP

The GLP (Good Laboratory Practice) set of rules presents particular requirements

concerning test resource monitoring for the measuring systems implemented

(quality assurance).

The following points must be fulfilled to comply with the requirements of GLP,:

1. Documentation of the calibration intervals.

2. Reporting of the calibrations:

Identification no. of the measuring head/controller

Date and signature of the operator.

3. Determination of the calibration frequency and instructions for the

performance:

The frequency depends on the operating conditions and the data of the test plan.

The OxiTop

This mode inhibits measuring if the calibrating interval is exceeded.

As a result of these restrictions, the GLP mode effects a standardization of the

calibrating and measuring conditions that are indispensable for working from the

aspect of quality assurance.

®

Control system supports these standards using an add-on GLP mode:

58 BA31114e5 07/2006 BA31114e5 07/2006 59

Page 59

GLP / Tools

Switch the GLP function on or off (only in the standard BOD operating mode):

“Settings“ submenu:

Use

to select the “GLP“ submenu.

“GLP“ submenu.

“GLP“ is preselected.

,

Press

then use to select

either GLP “On“ or “Off“

Confirm using

.

GLP - calibrating interval (“Calinterval”)

Set the time period (1 to 36 months) here. When it expires, the instrument registers

that the next test resource monitoring of the measuring heads is due. After the

calibrating interval expires, measuring is blocked until the calibration is performed or

the GLP setting is set to “Off“.

If the end of the calibrating interval set up lies within the measuring time of a

measurement to be started, this measurement cannot be started.

“GLP“ submenu.

Use to select the

subitem, “Calinterval“.

Page 60

GLP / Tools

Press ,

then set the time period for the

calibrating interval (1 - 36

months) using

Default: 12 months.

Confirm by

.

.

Memory

Here, you can set whether the controller should automatically erase the oldest

finished samples if the memory is full to create space for new measurement data

(setting “auto“).

With the “manual“ setting, the message “Lack of memory! Erase finished samples!“ is

displayed if the memory is full (See chapter “What to do if ...?).

“Settings“ menu:

Use

to select the “Memory“ submenu.

Erase memory is preset to

“automatic“.

To change it:

Press

use to select between

automatic and manual and

use to acknowledge

it.

Return to the “Settings“ menu:

then

,

and

.

60 BA31114e5 07/2006 BA31114e5 07/2006 61

Page 61

GLP / Tools

AutoTemp

The AutoTemp function controls the automatic start of the measurement after

checking the temperature adaption.

The pretemperature regulation to the precise incubator temperature is

recommended but not essential. Recommendation: e.g. regulate the temperature

of the sample for BOD5 measurements from 15 °C up to 20 °C.

You can tightly close the sample bottle with the measuring head immediately and

start the measurement. The AutoTemp function then automatically triggers the start of

the actual measuring after checking the temperature adaption. The measuring time of

the AutoTemp phase (adaption phase plus the test phase) is added to the sample

measuring time selected in the settings.

Pretemperature regulation of the sample

With the AutoTemp function switched on and, adhering to the recommendation

according to the table, the error quota that results from the temperature adaption of

the sample to the incubator temperature, T

selected measurement range final value.

Measuring time of the

measurement

Recommended sample temperature at the start of the

1 day T

2 days T

3 days T

4 days T

5 ... 99 days T

BOD5 15°C ... 20°C

, is smaller than 1% of the

Incubator

measurement

-0.5K ... T

Incubator

-1K ... T

Incubator

-2K ... T

Incubator

-3K ... T

Incubator

-5K ... T

Incubator

Incubator

Incubator

Incubator

Incubator

Incubator

AutoTemp function in detail

The AutoTemp function is made up of the adaption phase and the test phase.

Adaption phase

The phase without evaluation of the pressure process. The duration of the adaption

phase is defined for the various measuring times according to the table.

The adaption of the microbiology to the characteristics of the sample is made in this

phase and small temperature deviations, too high and too low temperatures of the

sample, can be compensated.

Test phase

The phase in which the further pressure process direction in the sample bottle is

checked. The test phase is defined for various measuring times according to the

table. In this phase, the continuing temperature deviation can be compensated if the

temperature of the sample is too low.

Page 62

GLP / Tools

Sequence of the test phase:

With a further drop in pressure (consumption) or constant pressure after the adaption

phase, the pressure value at the end of the adaption phase is the starting point of the

measurement.

On a further increase of pressure following the adaption phase (the sample is still too

cold), the turning point of the pressure process at which the pressure increase

changes into a pressure drop, is the starting point of the measurement.

If no starting point is found (according to the procedure given in points 1 and 2) after

the termination of the AutoTemp phase (time limit exceeded), the last measuring point

of the AutoTemp phase forms the starting point.

This means that the BOD curve in the graphical evaluation does not emerge from the

coordinate origin at the zero time point. A sample that was too cold was started.

BOD measuring

time

0.5 to 23 hours Since the measurement times are very short, the system

1, 2, 3, 4, 5 days 14, 28, 42, 56, 70 minutes Maximum of 28, 56, 84, 112,

6 to 99 days

in a 1 day pattern

Switch the AutoTemp function on or off (only in the standard BOD operating mode):

Adaption phase duration Test phase duration

always suppresses the AutoTemp phase here even if the

AutoTemp function is switched on in the settings.

70 minutes Maximum of 140 minutes

140 minutes

“Settings“ menu:

Use

to select “AutoTemp“ submenu.

62 BA31114e5 07/2006 BA31114e5 07/2006 63

Page 63

GLP / Tools

AutoTemp is preset to “On“.

To change:

Press

and use to select

between AutoTemp “On“ and

“Off“ and

use

Return to the “Settings“ menu:

then

,

to confirm it.

.

Switch-off interval

The time interval after the last time a key is pressed can be set here. After this time

interval expires, the controller switches itself off to save energy. (Settings of 5 to 15

minutes are possible, only in the standard BOD operating mode.)

“Settings“ menu:

Use

to select the “Switch-off interv.“

submenu.

The switch-off interval is preset to

5 minutes.

To change it:

Press

use to set the no. of

minutes required and

again to confirm it.

Return to the “Settings“ menu:

then

,

and

.

Page 64

GLP / Tools

Language

Select the language here in which the displays of the OxiTop® Controller appear. The

controller has the following 5 languages stored in it (default German): German English - French - Italian - Spanish.

“Settings” menu:

Use

to select the “Language“

submenu.

The default language is

“German“.

To change this:

Press

use to set the

language required and

again to confirm it.

From now on the displays appear

in the selected language.

Return to the “Settings“ menu:

then

,

and

.

“Settings“ menu.

Return to the main menu,

“GLP/Tools“:

then

or

using

,

.

64 BA31114e5 07/2006 BA31114e5 07/2006 65

Page 65

Check

Show

GLP / Tools

Main menu, “GLP/Tools“.

Use

to select the

“Check“ menu.

“Check“ menu.

“Show

“ preselected.

Point the controller at the measuring

heads:

All the measuring heads that are addressed flash for 5 seconds.

“Show “ submenu.

Use to select between

“Show free

“Show all

“ and

“.

40 cm to 100 cm

Page 66

info

GLP / Tools

“Check“ menu.

Use to select “

info“.

The measuring head flashes and

a display appears on the

controller giving the following

information:

- serial number of the measuring

head,

- battery status

(OK/LOBAT/EMPTY!!),

- the next calibration date

(only in the measuring mode,

Standard BOD and GLP “On“

- status of the measuring head

(free/used/defective).

If the measuring head is “used“,

use to scroll through the

display of further information:

- start date

- final date

- sample number

- type and

- range for the measurement

Return to the “Check“ menu

using

Repeat the procedure for each

measuring head.

.

66 BA31114e5 07/2006 BA31114e5 07/2006 67

Page 67

GLP / Tools

If the measuring head does not respond, the following display

appears after approximately 7 seconds:

Controller info

The query was stopped.

You can select between

- continue query (see above) and

- Stop (return to the

“Check“ menu

“Check“ menu.

Use to select

“Controller info“.

The display shows the following

information:

- number of measuring heads for

which there is still memory

capacity

- status of the supply batteries

- status of the data backup

batteries

(OK/LOBAT).

Use

specification of the

- software version

- Ser.no.

(can differ from the example

shown here)

Return to the “Check“ menu

using

to scroll to the

.

Page 68

GLP / Tools

Cal test

The Cal test is used to test the sealing of the system measuring head - rubber

sleeve - sample bottle and the operability of the systems OxiTop

In the standard BOD operating mode with the “GLP ON” setting, the controller

indicates when the next Cal test is due after each set up calibration interval (see the

chapter “GLP/Tools - GLP”),.

To perform the test, you need the WTW test resource, OxiTop

209 333.

Sample preparation: see operating manual, OxiTop

®

PM test resource.

®

Control.

®

PM, order number

“Check“ menu.

Use to select “Cal

test”.

For information on the further handling of the sample up to the “finished” status: See

the chapter “Start”.

The Cal sample appears together with the other samples in the sample management.

The BOD type is “CAL“:

The instrument automatically

allocates the sample number (in

the header line).

The filling volume (164 ml) and

the type together with the run

time of 5 days are preset.

68 BA31114e5 07/2006 BA31114e5 07/2006 69

Page 69

GLP / Tools

Evaluation of the Cal test

In the standard BOD operating mode and GLP “On“:

Starting point: sample

management.

Use

to select the test sample.

Enter the evaluation.

Display of the selected sample as

a curve with measurement value

data.

Compare measurement values

with batch test value

(according to operating manual,

®

OxiTop

Now you can set a new

calibration date for the measuring

head with the controller.

- “Show “ (to find the relevant

measuring head):

Function and messages as

described in the chapter

“Sample management“.

- “Set cal date“ (appears only if

the Cal test is finished and the

controller is in the standard

BOD operating mode, GLP is

switched on and the test is

finished).

- see below.

- “Stop“: Return to the curve

display.

Use

to select “Set cal date“.

PM).

Page 70

GLP / Tools

The controller sets a new test

date in the measuring head. The

controller calculates the new test

date from the current date + the

check interval set up (see the

chapter “GLP/Tools - Settings GLP - Check interval”).

The controller displays the setting

of the calibration date.

If the date was not set successfully (e.g. because the controller was

not held to - or not held close enough to - the measuring head):

Repeat the procedure using

,

then continue as described

above.

70 BA31114e5 07/2006 BA31114e5 07/2006 71

Page 71

GLP / Tools

Pneumatic test

The pneumatic test tests the measurement precision of the measuring head. It says

nothing about the long-term impermeability of the system.

To perform the pneumatic test, you require the testing agent, OxiTop

order number 209 334).

The user interface of the controller guides you through the test:

“Check“ menu.

Use

menu item “Pneumatic test

®

PT (WTW

to select the

“.

Set the plunger of the siringe on

the OxiTop

5 scale parts.

Tightly screw the measuring

head to be tested onto the

OxiTop PT tesing agent.

®

PT testing agent to

(Exceeding the time causes a

return to the “Check“ menu“).

Page 72

GLP / Tools

Maintenance

(Exceeding the time causes a

return to the “Check“ menu).

The controller display shows the

result of the pneumatic test.

Use to return to the

“Check“ menu.

Main menu, “GLP/Tools“.

Use

to select “Maintenance“ menu.

Erase finished samples

Here you can erase the data of finished samples that is already evaluated or no

longer required in order to free memory in the controller.

Menu item “Erase samples“ is

preset.

72 BA31114e5 07/2006 BA31114e5 07/2006 73

Page 73

GLP / Tools

A submenu appears with the

selection:

- From sample no. (preselected)

- All

- Back (from the “Maintenance”

submenu)

The controller displays the list of

finished samples.

The oldest finished sample is

marked.

With , you can mark further

samples.

With

marking again.

The controller asks again if you

really want to erase the marked

samples from the memory.

, you can remove the

After confirmation, the display

message shown here appears for

2 seconds and then the controller

returns to the menu “Erase

finished samples“.

Page 74

GLP / Tools

In the selection of erase “All“ samples, the following display appears:

The controller asks again if you

really want to erase the samples

from the memory.

Further: See above.

If no finished samples are available in the memory, the following

display appears:

Reset/release

This function can be used to release measuring heads again that were unintentionally

started.

Caution: After carrying out the “Reset/release“, the data of the measuring head

is erased!

Use to select the

Reset/release

menu item.

74 BA31114e5 07/2006 BA31114e5 07/2006 75

Page 75

GLP / Tools

The serial number of the

measuring head and the sample

number appear on the display.

Press

release the measuring head.

(If you do not want to release the

measuring head, select and

confirm it with “Return“.)

if you want to

Display message: The release/

reset has been performed.

Repeat the process for each of

the measuring heads to be

released.

Display message when the last measuring head of a sample has

been released:

Use

Reset/release

to return to the

menu.

Page 76

RS232 interface

RS232 Interface

The RS232 interface is used for communication with the computer (PC).

The RS232 interface is provided solely for the implementation of the WTW software,

“Achat OC“ (WTW software “ACHAT OC“ and RS232 interface cable AK 540/B

available from 1998).

Brief information about the software “Achat OC” (requires Microsoft Windows)

• Downloads the sample management of the controller to the PC

• Comfortably displays the sample management together with additional information

on the screen

• Enables the selection of samples in the PC and transfers the measurement data

of the selected samples from the controller to the PC

• Creates files from the measurement data for further processing with tabular

calculation programs

RS232 interface

76 BA31114e5 07/2006 BA31114e5 07/2006 77

Page 77

Cleaning

Cleaning the sample bottles

See the WTW application report.

Cleaning the controller and measuring heads

• Do not use any solvent (such as alcohol or acetone)!

Use a soft, damp cloth and dilute soapy solution for cleaning.

•

Page 78

Power Supply

The OxiTop®-OC100 and OxiTop®-C instruments are battery-powered.

To ensure reliable operation, both instruments have a 2-stage battery status monitor

1st level = warning level : Batteries LoBat !

2nd level = error level : Batteries empty !

OxiTop

Economy circuit (automatic switch off)

The instrument switches off automatically following the last key actuation after expiry

of the set switch-off interval.

Switch-off interval:

• Routine BOD operating mode: preset to a fixed period of 5 min.

• Standard BOD operating mode: delivery state of 5 min.,

settings of 5...15 min. possible

Supply batteries

Batteries: 3 pcs, alkaline (alkaline manganese), size: Mignon, AA, AM3, LR6

These batteries ensure the energy supply of the OxiTop

Run time: > 100 h (approx. 1000 start-ups in normal use)

Supply batteries status signals

are given on switching on the instrument by display messages and a signal tone

or can be called up under “GLP/Tools - Check - Controller info”.

Display message

Supply

Battery/ies LoBat !

Please change !

Supply

Battery/ies empty!

Please change !

®

-OC100 controller

Note / Meaning

The warning appears for approx. 3 seconds.

The instrument then continues to run normally.

The instrument can still be safely operated within the

specifications.

When the message first appears, there is still a

running reserve available.

Please obtain new batteries and replace the old ones

!

The message appears for approx. 3 seconds.

The instrument then switches itself off.

The instrument can no longer be used.

The supply batteries must be replaced by new ones.

®

OC100.

78 BA31114e5 07/2006 BA31114e5 07/2006 79

Page 79

Power Supply

Changing supply batteries:

• Switch off the OxiTop

• Loosen the 4 screws underneath the housing using a Phillips screwdriver (see

).

figure

• Place the controller on the lower case.

• Remove the upper case and put it down to the right next to the lower case with

the display downwards (see figure

• Remove the supply battery holder from the fixing in the lower case and turn it

around.

• Remove the empty supply batteries.

• Turn the supply battery holder around again and place it in the fixing in the lower

case.

• Set the upper case on top of the lower case, turn the controller and tighten the

housing screws using the screwdriver (see figure

• Switch on the controller. The battery change was successful if no error message

appears concerning the supply batteries.

• It is recommended to use only brand name batteries of the type specified as

“Alkaline“. Using other types of battery can affect reliable functioning.

• The supply batteries have no influence on data integrity.

• Insert new supply batteries - 3 pieces, alkaline (alkaline manganese),

size: Mignon, AA, AM3, LR6).

Ensure that they are the right way round!

(The poles are marked in the supply battery holder)

Always replace the complete set of batteries.

®

-OC100 controller.

).

).

Page 80

Power Supply

Data backup battery

1 x lithium battery, CR2430, e.g. WTW type Batt/OxiTop

order no. 209 012. This battery ensures that your measurement data and the

instrument settings in the OxiTop

years

Data backup battery - status messages

are given on switching on the instrument by display messages and a signal tone