Page 1

OPERATING MANUAL

ba75953e03 05/2017

NiCaVis 705 IQ

OPTICAL SENSOR FOR NITRATE AND CARBON SUM PARAMETERS

Page 2

2 ba75953e03 05/2017

NiCaVis 705 IQ

Copyright © 2017 Xylem Analytics Germany GmbH

Printed in Germany.

Page 3

NiCaVis 705 IQ Contents

3

ba75953e03 05/2017

Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 How to use this component operating manual . . . . . . . . . . . . . 5

1.2 Field of application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Measuring principle of the sensor NiCaVis 705 IQ . . . . . . . . . . 6

1.4 Structure of the sensor NiCaVis 705 IQ . . . . . . . . . . . . . . . . . . 7

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.1 Safety information in the operating manual . . . . . . . . . 8

2.1.2 Safety signs on the product . . . . . . . . . . . . . . . . . . . . . 8

2.1.3 Further documents providing safety information . . . 8

2.2 Safe operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.2 Requirements for safe operation . . . . . . . . . . . . . . . . . 9

2.2.3 Unauthorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 IQ SENSOR NET system requirements . . . . . . . . . . . . . . . . . . . 10

3.2 Scope of delivery of the NiCaVis 705 IQ . . . . . . . . . . . . . . . . . 10

3.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3.1 Mounting the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3.2 Mounting the shock protectors . . . . . . . . . . . . . . . . . . 13

3.3.3 Connecting the sensor to the IQ S

ENSOR NET . . . . . . 14

3.4 Initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4.2 Sensor structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4.3 Settings for the main sensor . . . . . . . . . . . . . . . . . . . . 18

3.4.4 Settings for virtual sensors . . . . . . . . . . . . . . . . . . . . . 21

4 Measurement / Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 Determination of measured values . . . . . . . . . . . . . . . . . . . . . 23

4.2 Measurement operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3.2 User calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.3 Sensor check/

Zero adjustment

. . . . . . . . . . . . . . . . . . 31

Page 4

NiCaVis 705 IQ

4

ba75953e03 05/2017

5 Maintenance and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

5.2 Sensor cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2.1 Cleaning agents and accessories . . . . . . . . . . . . . . . . 37

5.2.2 General steps to be taken . . . . . . . . . . . . . . . . . . . . . . 38

5.2.3 Basic cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

5.2.4 Cleaning the measuring gap . . . . . . . . . . . . . . . . . . . . 40

6 Spare parts, maintenance equipment, accessories . . . . . . . . 41

7 What to do if... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.1 Measurement characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.2 Application characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.3 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.4 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9 Indexes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.1 Explanation of the messages . . . . . . . . . . . . . . . . . . . . . . . . . .50

9.1.1 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.1.2 Informative messages . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.2 Status info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

10 Appendix: Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Page 5

NiCaVis 705 IQ Overview

5

ba75953e03 05/2017

1 Overview

1.1 How to use this component operating manual

Structure of the

IQ SENSOR NET

operating manual

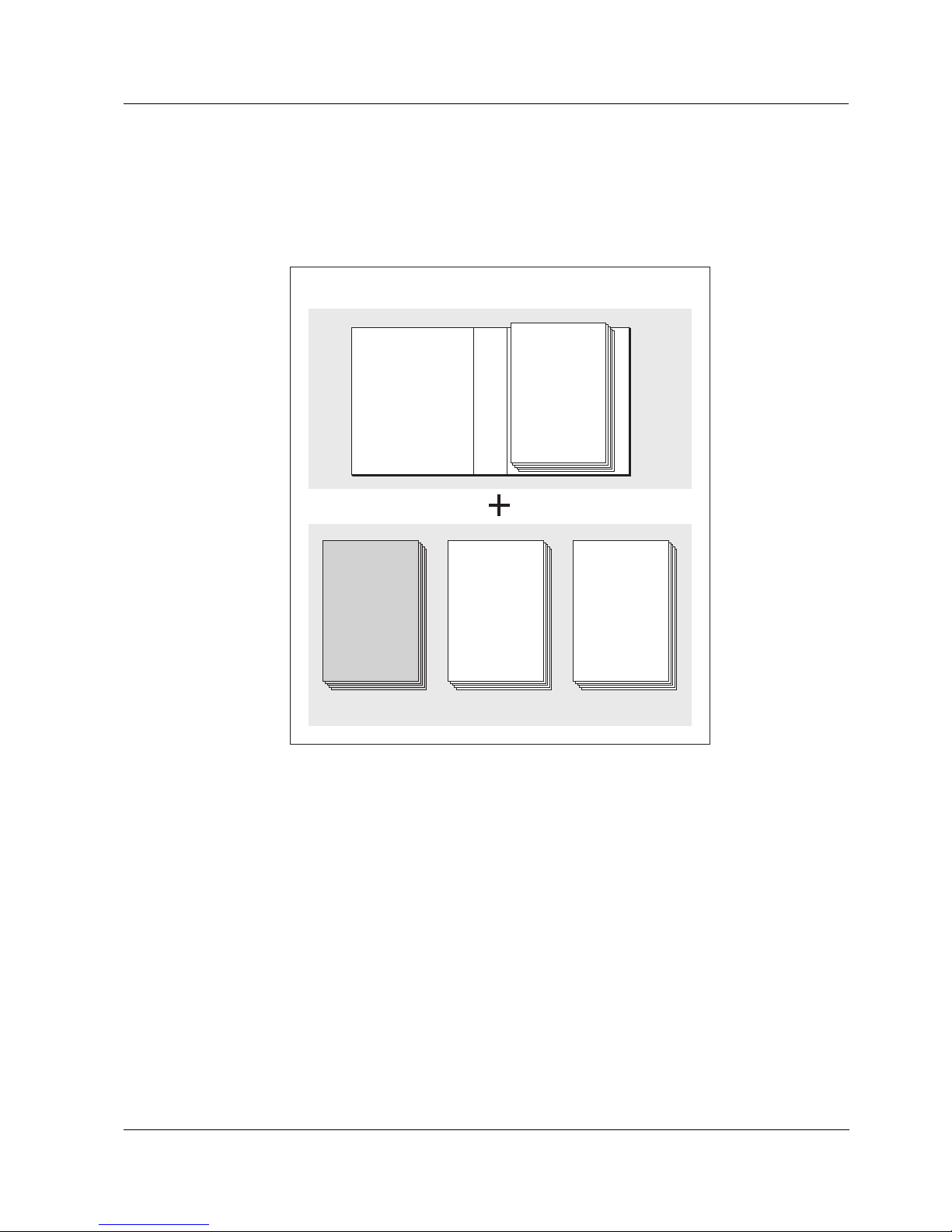

Fig. 1-1 Structure of the

IQ SENSOR NET operating manual

The IQ SENSOR NET operating manual has a modular structure like the IQ SENSOR NET

itself. It consists of a system operating manual and the operating manuals of all

the components used.

Please file this component operating manual into the ring binder of the system

operating manual.

IQ Sensor Net Operating Manual

System

Operating

Manual

(Ring Binder)

IQ Sensor

Operating

Manual

MIQ Module

Operating

Manual

MIQ Terminal

Operating

Manual

Component Operating Manuals

Page 6

Overview NiCaVis 705 IQ

6

ba75953e03 05/2017

1.2 Field of application

The NiCaVis 705 IQ is an online sensor for the on-site determination of nitrate

and carbon sum parameters in waste water treatment plants.

The range of application comprises control, feedback control and monitoring.

Measuring location

Ultrasound cleaning

system

The ultrasound cleaning system ensures low maintenance and long-term reliable measurement operation.

The ultrasound source integrated in the sensor excites the measurement

windows to produce vibrations in the ultrasound range. The

movement of the surface as a result of this prevents the growth of

pollution in almost all cases and, thus, ensures reliable measured

values during continuous operation.

Compressed air

cleaning (option)

The sensor is designed to be equipped with an additional compressed air-driven

cleaning system, which supports the ultrasound cleaning system as necessary.

1.3 Measuring principle of the sensor NiCaVis 705 IQ

The sensor operates according to the measuring principle of UV-VIS- spectrometry.

Any substance present in a measuring solution attenuates a light beam that

penetrates the measuring solution. The attenuation (absorbance) of the light

beam is measured for individual wavelengths.The wavelength dependent distribution produces the absorbance spectrum.

The wavelength range where an absorbance occurs is characteristic of the

substance.The extent of the absorbance depends on the amount of the

substance.

The influence of typical interference matrix variants occurring at municipal waste

water treatment plants can be eliminated by including the entire absorbance

spectrum.

With this measuring principle, measuring does not take place continuously but

at intervals.

NiCaVis 705 IQ Outlet

Page 7

NiCaVis 705 IQ Overview

7

ba75953e03 05/2017

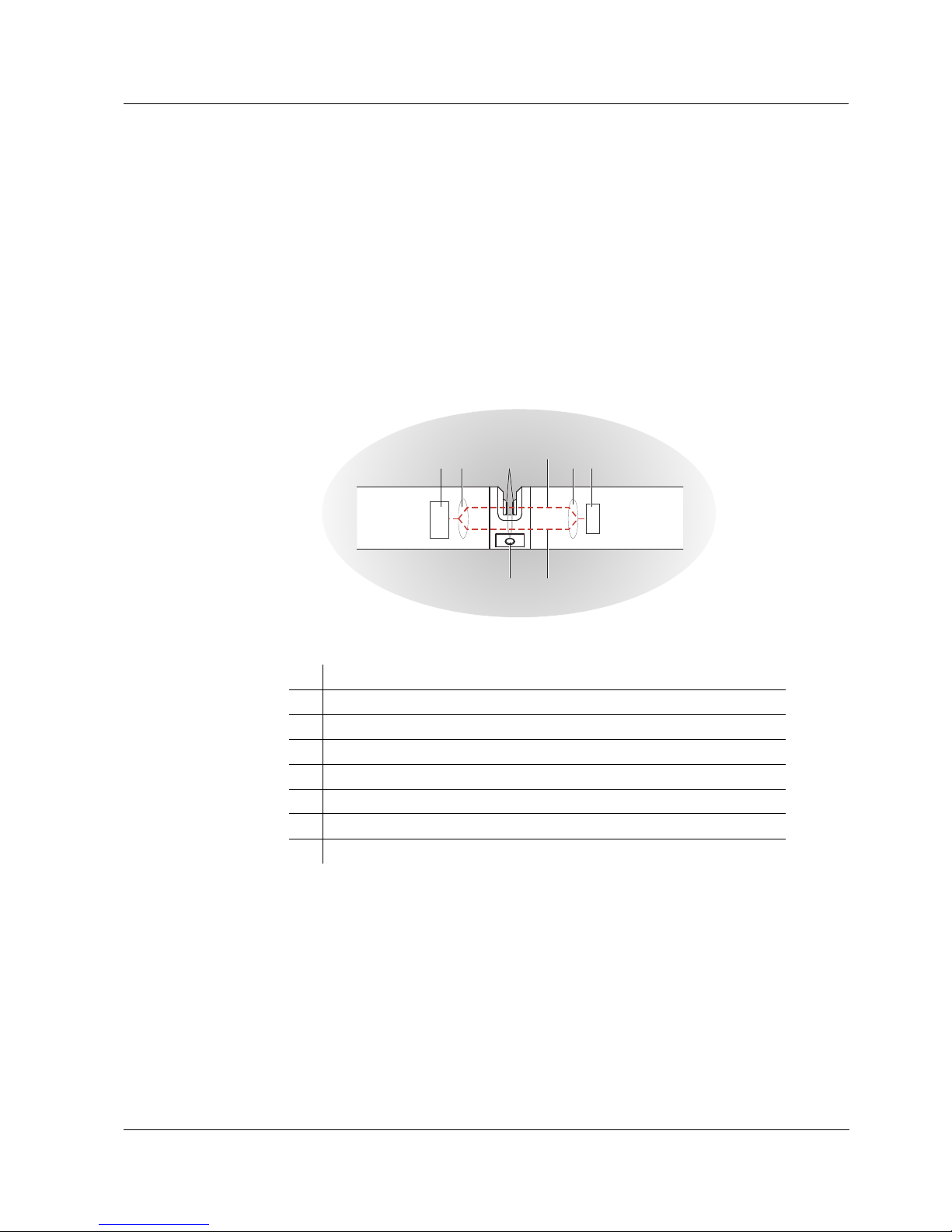

1.4 Structure of the sensor NiCaVis 705 IQ

The sensor has a light source (1), a measuring gap (3) to enable the contact of

light with the measuring solution, and a detector (5) to measure the attenuated

light beam.

The sender of the optical system (2) directs a light beam, the measuring beam

(6), through the measuring solution and a second light beam, the reference

beam (8), over a distance without measuring solution. The test sample is

between both measurement windows (3) in the measuring gap.

The receiver of the optical system (4) directs the measuring beam and reference

beam to the detector. In the detector, the light is received by fixed photo diodes.

Fig. 1-2 Structure of the sensor

1 Light source

2 Sender of the optical system

3 Measuring gap between the measurement windows

4 Receiver of the optical system

5 Detector

6 Measuring beam

7 Reference beam

8 Connection for the optional compressed air cleaning system

7

6

34

8

21 5

Page 8

Safety NiCaVis 705 IQ

8

ba75953e03 05/2017

2 Safety

2.1 Safety information

2.1.1 Safety information in the operating manual

This operating manual provides important information on the safe operation of

the product. Read this operating manual thoroughly and make yourself familiar

with the product before putting it into operation or working with it. The operating

manual must be kept in the vicinity of the sensor so you can always find the information you need.

Important safety instructions are highlighted in this operating manual. They are

indicated by the warning symbol (triangle) in the left column. The signal word

(e.g. "CAUTION") indicates the level of danger:

NOTE

indicates a situation where goods might be damaged if the actions mentioned

are not taken.

2.1.2 Safety signs on the product

Note all labels, information signs and safety symbols on the product. A warning

symbol (triangle) without text refers to safety information in this operating

manual.

2.1.3 Further documents providing safety information

The following documents provide additional information, which you should

observe for your safety when working with the measuring system:

Operating manuals of other components of the IQ S

ENSOR NET system

(power packs, controller, accessories)

Safety datasheets of calibration and maintenance equipment (e.g. cleaning

solutions).

WARNING

indicates a possibly dangerous situation that can lead to serious (irreversible) injury or death if the safety instruction is not

followed.

CAUTION

indicates a possibly dangerous situation that can lead to slight

(reversible) injury if the safety instruction is not followed.

Page 9

NiCaVis 705 IQ Safety

9

ba75953e03 05/2017

2.2 Safe operation

2.2.1 Authorized use

The authorized use of the NiCaVis 705 IQ consists of its use as a sensor in the

IQ S

ENSOR NET. Only the operation and running of the sensor according to the

instructions and technical specifications given in this operating manual is authorized (see chapter 8 T

ECHNICAL DATA). Any other use is considered unauthor-

ized.

2.2.2 Requirements for safe operation

Note the following points for safe operation:

The product may only be operated according to the authorized use specified

above.

The product may only be supplied with power by the energy sources men-

tioned in this operating manual.

The product may only be operated under the environmental conditions men-

tioned in this operating manual.

The product may not be opened.

2.2.3 Unauthorized use

The product must not be put into operation if:

it is visibly damaged (e.g. after being transported)

it was stored under adverse conditions for a lengthy period of time (storing

conditions, see chapter 8 T

ECHNICAL DATA).

Page 10

Commissioning NiCaVis 705 IQ

10

ba75953e03 05/2017

3 Commissioning

3.1 IQ SENSOR NET system requirements

Software versions of

the controller and

terminal

components

The operation of the NiCaVis 705 IQ requires the following software versions in

the IQ S

ENSOR NET:

For cleaning with

compressed air via

a relay

3.2 Scope of delivery of the NiCaVis 705 IQ

The following parts are included in the scope of delivery:

SensorNiCaVis 705 IQ

Sensor sleeve

Shock protectors

Operating manual

DIQ/S 28X Controller software: Version 3.72 or higher

DIQ/S 182 Controller software: Version 3.45 or higher

MIQ/MC3 Controller software: Version 3.72 or higher

MIQ/MC2 Controller software: Version 3.72 or higher

MIQ TC 2020 XT Controller software: Version 3.72 or higher

DIQ/S 28X Controller software: Version 3.72 or higher

DIQ/S 182 Software version: Version 3.45 or higher

MIQ/CR3 Software version: Version 2.90 or higher

MIQ/R6 Software version: Version 2.90 or higher

MIQ/CHV PLUS Software version: Version 2.90 or higher

Page 11

NiCaVis 705 IQ Commissioning

11

ba75953e03 05/2017

3.3 Installation

3.3.1 Mounting the sensor

NOTE

The sensor is an optical precision instrument that should be protected against

shocks. Make sure that the distances to the wall, bottom and other installation

surroundings are sufficient. If necessary, protect the sensor from hitting with the

protective ring provided. Mount any fixing elements only on the stable metal

shaft.

NOTE

Always make sure the surface of the enclosure is not damaged by sharp-edged

objects. The enclosure of the sensor may not touch any metallic objects in order

to prevent contact corrosion.

NOTE

Do not suspend the sensor on the sensor connection cable. Risk of cable break

and water penetration at the cable gland.

A wide range of mounting accessories is available for the installation of the

NiCaVis 705 IQ (see chapter 6 S

PARE PARTS, MAINTENANCE EQUIPMENT, ACCES-

SORIES). Thus, all prevalent ways of mounting are possible.

Generally, observe the following general rules

when mounting the sensor at the

measuring location:

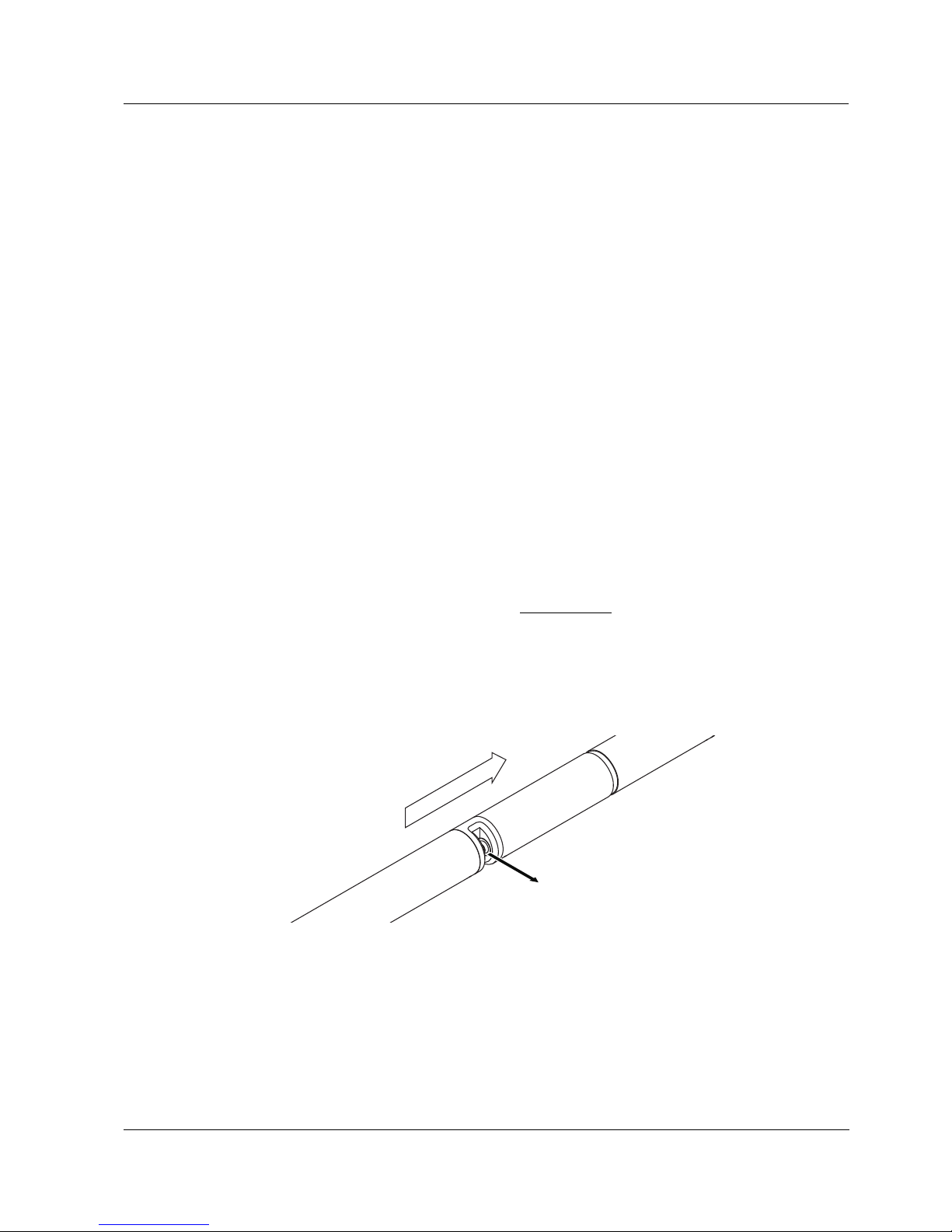

Horizontal

installation

When mounting the sensor horizontally, the measuring gap opening should be

on the side. Thus, any air bubbles can escape upward after cleaning and no sediment can collect in the measuring gap. The sensor should be aligned in parallel

with the flow direction.

Fig. 3-1 Horizontal installation

Measuring gap opening

Flow direction

Page 12

Commissioning NiCaVis 705 IQ

12

ba75953e03 05/2017

Vertical installation For vertical installation, mount the sensor in a position that allows interfering ele-

ments in the measuring gap to escape with the current. In the case of vertical

installation, the minimum flow rate is 0.2 m/s so the measuring gap is kept clean

optimally.

Fig. 3-2 Vertical installation

Protection against

shocks

When installing the sensor, always make sure it cannot knock against a wall or

another obstacle. Make sure the safety margins are sufficient (e. g. with suspended mounting).

Mount the enclosed shock protectors (see section 3.3.2). Their soft rubber compound absorbs hard impacts.

Fig. 3-3 Sensor with mounted shock protectors

Flow direction

Measuring gap opening

Page 13

NiCaVis 705 IQ Commissioning

13

ba75953e03 05/2017

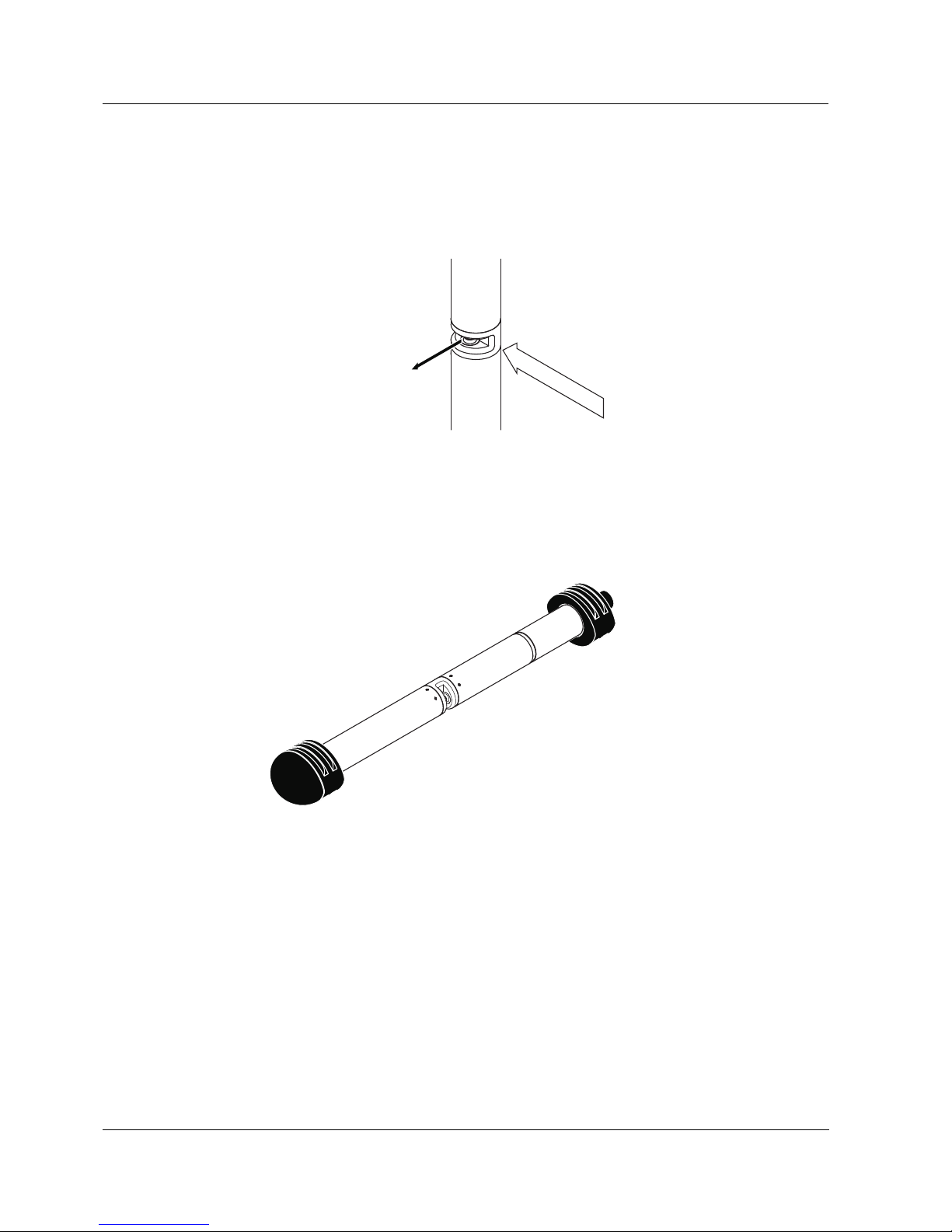

3.3.2 Mounting the shock protectors

The shock protectors consist of two rings, a cap and four cable ties. To mount

the shock protectors, proceed as follows:

Fig. 3-4 Mounting the shock protectors

1. Plug the cap (pos. 2 in Fig. 3-4) on one of the two rings (pos.1).

2. Put the assembled unit on the sensor end and fix it with 2 cable

ties (pos. 3) as shown in Fig. 3-4.

3. Put the second ring on the cable end of the sensor and fix it

with the remaining two cable ties in the same way.

1

3

2

Sensor with mounted

shock protectors

Page 14

Commissioning NiCaVis 705 IQ

14

ba75953e03 05/2017

3.3.3 Connecting the sensor to the IQ SENSOR NET

Connection cable A sensor connection cable of the SACIQ or SACIQ SW type is required to

connect the sensor. The cable is available in different lengths. Compared to the

standard model SACIQ, the SACIQ SW sensor connection cable is optimized

regarding its corrosion resistance in seawater and brackish water and adapted

for use in conjunction with the NiCaVis 705 IQ. Information on this and other

IQ S

ENSOR NET accessories is given in the WTW catalog and on the Internet.

Are the plug

connections dry?

Before connecting the sensor and sensor connection cable, please make sure

the plug connections are dry. If moisture gets into the plug connections, first dry

the plug connections (dab them dry or blow them dry using compressed air).

NOTE

Do not suspend the sensor on the sensor connection cable but use the suitable

mounting equipment. Information on this and other IQ S

ENSORNET

accessories

is given in the WTW

catalog and on the Internet.

How to connect the SACIQ (SW) sensor connection cable to the terminal strip of an MIQ module is described in chapter 3 I

NSTALLATION

of the IQ S

ENSOR NET system operating manual.

Page 15

NiCaVis 705 IQ Commissioning

15

ba75953e03 05/2017

Connecting the

sensor to the sensor

connection cable

Fig. 3-5 Connect the sensor

1. Take the protective caps off the plug connections of the sensor and the

SACIQ (SW) sensor connection cable and keep them safe.

2. Plug the socket of the SACIQ (SW) sensor connection cable onto the

plug head connector of the sensor. At the same time, rotate the socket

so that the pin in the plug head connector (1) clicks into one of the two

holes in the socket.

3. Then screw the coupling ring (2) of the sensor connection cable onto

the sensor up to the stop.

SACIQ (SW)

1

2

Page 16

Commissioning NiCaVis 705 IQ

16

ba75953e03 05/2017

3.4 Initial commissioning

3.4.1 General information

Measuring location The sensor is prepared for operation in the outlet of the waste water treatment

plant and calibrated in the factory.

The sensor is immediately ready to measure.

Use calibration after

initial ommissioning

On the basis of a reference measurement ("laboratory value"), check whether

the default settings deliver sufficiently accurate measured values or whether you

want to carry out a user calibration (see section 4.3 C

ALIBRATION).

CAUTION

Never look into the measuring window or put objects into the

measuring window during operation! The emitted UV radiation

can damage the eyes!

In the case of authorized use, inadvertent eye contact with the

light beam is not possible.

How to adjust the settings is described in the following section (section 3.4.3).

Page 17

NiCaVis 705 IQ Commissioning

17

ba75953e03 05/2017

3.4.2 Sensor structure

The physical sensor is the sensor with the instrument or model designation,

NiCaVis 705 IQ. The physical sensor processes the measurement signal

(absorbance spectrum) and supplies up to 5 measurement results to the

IQ S

ENSOR NET. The measurement results are administrated like 5 sensors that

differ in hierarchy as follows:

Main sensor The sensor for nitrate measurement is the main sensor.

It registers on the system under the designation, NiCaVis 705 IQ and the series

number of the physical sensor.

Virtual sensors All other sensors for carbon measurement are virtual sensors.

You register on the system under the designation, NiCaVis 705 IQ and the

series number of the physical sensor.

Sensor overlapping

settings and

functions

Some settings and functions are sensor overlapping. Sensor overlapping settings are generally edited in the setting menu of the main sensor.

These are the most important sensor overlapping settings and functions:

Measuring location

Times of the measuring cycle

(

Meas. interval, Cleaning duration Air, Adjustment phase

etc.)

Signal smoothing

Page 18

Commissioning NiCaVis 705 IQ

18

ba75953e03 05/2017

3.4.3 Settings for the main sensor

Measuring cycle A measuring cycle consists of the cleaning procedure, the adjustment time for

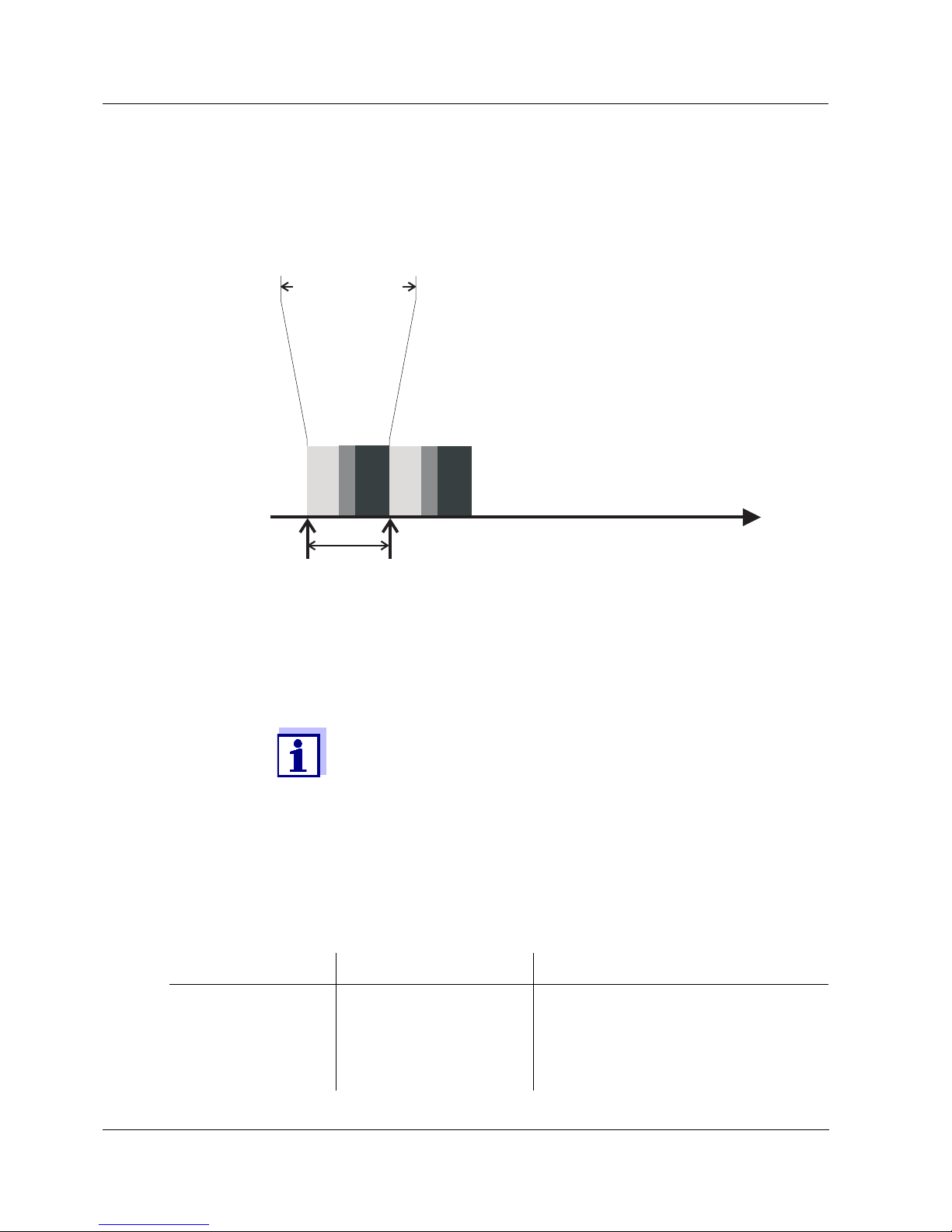

the measuring system and the determination of the measured value. The following graphic demonstrates the relevant settings:

Fig. 3-6 Measuring cycle of the sensor

Carrying out

settings

Using <S>, switch from the measured value display to the main menu of the

settings. Then navigate to the setting menu (setting table) of the sensor. The

procedure is described in detail in your IQ S

ENSOR NET system operating

manual.

Default values are marked in bold.

Time

Adjustment time

Measurement

Measuring

cycle

Measuring interval

Cleaning

A change of the following settings will take some time (up to a few

minutes) until it can be seen in the measured value display:

Measuring mode

Measuring location

Number of N-sensors

Number of C-sensors

Further changes can only be made when the last changes are visible in the measured value display.

Menu item Settings Explanations

Measuring mode

NO3-N

NO3

The measured parameter is displayed

in the selected citation form.

When changing the

Measuring mode

setting, always check the

Measuring

location

setting.

Page 19

NiCaVis 705 IQ Commissioning

19

ba75953e03 05/2017

Measuring location Outlet

(permanently set)

Measurement location or application of

the sensor.

The possible measurement loca-

tions are displayed depending on the

currently set measuring mode.

The sample matrix on which the cal-

culation of the measured value is

based changes with the location of

the sensor.

Measuring range

- Display of the measuring range

(see chapter 8 T

ECHNICAL DATA).

Cal - # raw value 1

Value pairs of the user calibration (see section 4.3.2).

Note

: Leave those values unchanged during the initial commission-

ing.

Cal - ref. value 1

Cal - # raw value 2

Cal - ref. value 2

Number of C-sensors

1 ... 4 Apart from the main sensor, up to 4

more sensors can be displayed.

The settings for the additional sensors

are done in the menus for the respective sensors.

Zero adjustment Factory

User

Setting of which zero adjustment is

used in the sensor.

Factory zero adjustment or

Zero adjustment carried out last

Signal smoothing

On

Off

Switching on/off the signal smoothing.

For details, see

Response time t90

.

Menu item Settings Explanations

Page 20

Commissioning NiCaVis 705 IQ

20

ba75953e03 05/2017

Response time t90

3 ... 60 min Response time of the signal smoothing.

Depending on the sample matrix, measured values can vary more or less

strongly (e.g. due to foreign bodies or

air bubbles).

The signal filter (here, the

Response

time t90

) reduces the limits of variation

of the measured values.

The

Response time t90

specifies the

time after which 90 % of a signal

change are displayed.

This menu item is only available with:

Signal smoothing

=

On

The specified time is used as a guide

value for low (10 min) to high (60 min)

signal smoothing and can deviate from

the value that was set.

Cleaning mode

On

Off

Switching on/off the automatic, timecontrolled cleaning function.

Cleaning type

Ultrasound

Air

Ultrasound+air

Cleaning methods / adjustment time

This menu item is only available with:

Cleaning mode

=

On

The duration of the cleaning procedure

with a ir is set in the m e nu item

Cleaning

duration Air

.

Cleaning duration Air

0,5 ...10 ... 300 s This menu item is only available with:

Cleaning type

=

Air

and

Cleaning type

=

Ultrasound+air

For this setting to come into effect, the

setting

Settings of outputs and links

/

Relay function

/

Sensor controlled

/

Puls duration /Automatic

has to be

selected for the linked relay.

Please note the software requirements

for the components with relay outputs,

MIQ/CR3, MIQ/R6, MIQ/CHVPlus,

DIQ/S 182, DIQ/S 28X (see section

3.1).

Save and quit

- The system confirms the saving of the

settings and the display switches to the

next higher level.

Menu item Settings Explanations

Page 21

NiCaVis 705 IQ Commissioning

21

ba75953e03 05/2017

3.4.4 Settings for virtual sensors

Carrying out

settings

Using <S>, switch from the measured value display to the main menu of the

settings. Then navigate to the setting menu (setting table) of the sensor. The

procedure is described in detail in your IQ S

ENSOR NET system operating

manual.

Default values are marked in bold.

Quit

- The display switches to the next higher

level without storing the new settings.

Menu item Settings Explanations

Menu item Settings Explanations

Measuring mode

(NitraVis 705 IQ)

NO3-N

NO3

The measured parameter is displayed

in the selected citation form.

Measuring mode

(CarboVis 705 IQ)

COD spectr., total

COD spectr., dissolv

TOC spectr., correl.

BOD spectr., correl.

DOC spectr., correl.

SAC 254, total

SAC 254, dissolved

UVT 254, total

*

UVT 254, dissolved

*

The measured parameter is displayed

in the selected citation form.

Measuring location Outlet

(permanently set)

Measurement location or application of

the sensor.

The setting is done in the setting menu

of the relevant main sensor.

Measuring range

- Display of the measuring range

(see chapter 8 T

ECHNICAL DATA).

Cal - # raw value 1

Value pairs of the user calibration (see section 4.3.2).

Note:

Leave those values unchanged during the initial commission-

ing.

Cal - ref. value 1

Cal - # raw value 2

Cal - ref. value 2

Page 22

Commissioning NiCaVis 705 IQ

22

ba75953e03 05/2017

Main sensor

Information that there are further sensor overlapping settings in the setting

menu of the relevant main sensor

(

Meas. interval, Cleaning duration Air

,

Signal smoothing

etc.).

Save and quit

- The system confirms the saving of the

settings and the display switches to the

next higher level.

Quit

- The display switches to the next higher

level without storing the new settings.

* The UVT-254 value is standardized to 10 mm gap width.

Menu item Settings Explanations

Page 23

NiCaVis 705 IQ Measurement / Operation

23

ba75953e03 05/2017

4 Measurement / Operation

4.1 Determination of measured values

Fig. 4-1 Determination of measured values

During a measurement, the absorbance spectrum of the test sample is recorded

and set against the stored absorbance spectrum of a zero adjustment (measurement in ultrapure water). The algorithm for the calculation depends on the

selected application and/or the measuring location. The resulting raw value can

be adjusted to an independent reference measurement with the aid of a socalled user calibration.

Absorbance spectrum

of zero adjustment

Absorbance spectrum

of measurement

Physical sensor, series number xxx

Main

sensor

software

Virtual

sensor

software

Main sensor meas. mode

(algorithm)

User calibration data

of main sensor

Main sensor raw value

Meas. value of main sensor

Virtual sensor raw value

Meas. value of virtual sensor

Virtual sensor meas. mode

(algorithm)

User calibration data

of virtual sensor

IQ Sensor Net

Page 24

Measurement / Operation NiCaVis 705 IQ

24

ba75953e03 05/2017

4.2 Measurement operation

Measured value

display

Fig. 4-2

Factors affecting the

measured values

The following factors can adversely affect the measurement quality:

The measuring gap is not sufficiently filled and flowed through by the test

sample

Foreign bodies and air bubbles are in the measuring gap

Extraordinary changes (interferences) of the sample matrix

Contaminated measurement windows due to difficult sample matrix

Damaged measuring windows

Lacking quality of the zero adjustment, e. g. due to contaminated ultrapure

water

The user calibration is not representative (or erroneous)

4.3 Calibration

4.3.1 Overview

In the delivery condition, the sensor is precalibrated and ready to measure (see

section 3.4.1).

There are two types of calibration that are included into the calculation of the

CAUTION

Never look into the measuring window or put objects into the

measuring window during operation! The emitted UV radiation

can damage the eyes!

In the case of authorized use, inadvertent eye contact with the

light beam is not possible.

Raw value,

identifiable by #

Measured value

Page 25

NiCaVis 705 IQ Measurement / Operation

25

ba75953e03 05/2017

measured value at different points (see section 4.1):

User calibration (see section 4.3.2)

Sensor check/

Zero adjustment

(see section 4.3.3).

An overview diagram of the calibration procedures can be found on page 4 - 32.

User calibration With a user calibration you compensate for the influence of the test sample. The

user calibration requires a successful

Sensor check (H2O dest.)

and a valid

Zero adjustment

.

We recommend to check the current user calibration against independent

comparison measurements if you suspect a basic change of the characteristics

of the test sample. If the comparison measurements show clear deviations,

these can be compensated by a user calibration.

Recalibration after a

change of the

measuring location

Sensor check (H2O

dest.)

The characteristics of a sensor and thus the measured values provided by it

change in the course of time.

The reasons for this can be the aging of the sensor, or contamination or

mechanical damage of the sensor. Contamination or mechanical damage in the

area of the measuring chamber or on the measurement windows affect the

measured values.

A

Sensor check (H2O dest.)

determines the condition of the sensor. By checking

the sensor with the aid of the

Sensor check (H2O dest.)

you can rapidly see any

changes of the sensor and whether it needs to be cleaned or if any other actions

have to be taken.

A

Sensor check (H2O dest.)

should be carried out twice per year at regular inter-

vals. An extraordinary

Sensor check (H2O dest.)

should be carried out if you

suspect that the sensor has been damaged such as by mechanical shock, or if

the measured values do not seem plausible.

Each time after the application or measurement location was

changed, we recommend to carry out a

Zero adjustment

(and, if the

Sensor check (H2O dest.)

was not successful, also a

Zero adjust

-

ment

with user calibration if necessary) (With a change of the

Measuring location

setting).

The data of the user calibration are stored in the IQ S

ENSOR NET

controller and thus assigned to the measuring location (not to the

sensor). The calibration data of the

Zero adjustment

are stored in

the sensor.

In spectroscopy, even very small contamination that is not visible to

the eye can considerably affect the measured value.

The proper and thorough cleaning of the sensor is the basis for reliable measurement data.

Page 26

Measurement / Operation NiCaVis 705 IQ

26

ba75953e03 05/2017

Zero adjustment

While the

Sensor check (H2O dest.)

just determines the current state of the

sensor, a

Zero adjustment

can be used to compensate for changes of the

sensor. A zero adjustment can be required if, for example, the

Sensor check

(H2O dest.)

is not successful even after the sensor was thoroughly cleaned.

If the

Zero adjustment

is not successful, the sensor is blocked for measurement.

A successful

Zero adjustment

is required for the determination of measured val-

ues.

Sensor check

(standard)

Use the

Sensor check (standard)

to check the sensor with a standard solution

(see chapter 6 S

PARE PARTS, MAINTENANCE EQUIPMENT, ACCESSORIES). During

the check, the recorded spectrum is compared to a reference spectrum of the

standard solution stored in the sensor.

The sensor should always be very thoroughly cleaned prior to a zero

adjustment.

Page 27

NiCaVis 705 IQ Measurement / Operation

27

ba75953e03 05/2017

4.3.2 User calibration

Calibration points

and value pairs

The adjustment is carried out at one or two points within the measuring range.

A value pair is determined at each point. Each value pair consists of the raw

value of the NiCaVis 705 IQ sensor and the corresponding reference value.

Each value pair has to be determined at the same time and place as the test

sample as possible. At the time of the calibration, the test sample should be in

a condition that is typical of the application.

Selection of

calibration points

If the required accuracy is low, the default setting of the first value pair can be

adopted unchanged. The first value pair is equivalent to the zero point in this

case. The second value pair should be close to the working point of the application. This method results in a single-point calibration.

If the application has to cover a wide value range with high measuring accuracy,

both value pairs should be used for calibration. When doing so, the calibration

value pairs should be determined and input at the limits of the application range

as possible.

You obtain samples of different concentrations e. g. by taking two samples

during clearly different conditions of the plant (dry period and rain period).

Storage location of

user calibration data

The calibration data of the user calibration are stored in the IQ S

ENSOR NET

controller. They are loaded into the sensor during operation and automatically

assigned to the replacement sensor if the sensor is exchanged.

The measurement results will be ever more accurate the closer the

composition of the test sample corresponds to the status at the time

of the calibration. If there is a fundamental change of the characteristics of the sample, a new calibration may be necessary.

Page 28

Measurement / Operation NiCaVis 705 IQ

28

ba75953e03 05/2017

Performing a user

calibration

Proceed as follows if you want to perform a user calibration:

1. Bring the sensor into the measuring position.

2. Switch to the measured value display with <M>.

3. Use <> to select the NiCaVis 705 IQ sensor.

4. Call up calibration with <C>. The

Maintenance condition:

Linked outputs are frozen.

window appears.

By activating the maintenance condition, linked outputs remain in

their present state. The cleaning and the determination of measured

values are switched off. The measured value display shows a flashing, invalid measured value ("----").

5. Confirm the maintenance condition with <OK>.

6. Select the menu item,

Single measurement

.

The measurement is started. After measuring, read the raw value (without dimension) and note it down. In the case of fluctuating values, carry

out several measurements and average the individual raw values.

7. Take a sample at the same time as the measurement and as close to

the sensor as possible.

8. Determine the reference value and note it down as a value pair together

with the raw value.

9. For a two-point calibration:

Determine the second value pair (step 6 to step 8).

At least one value pair and a maximum of two value pairs can be

entered for a valid calibration. The values must be in ascending

order. If they are not in ascending order, a calibration error will occur.

10. NiCaVis 705 IQ Switch off the maintenance condition (use <>

to select the sensor, press <OK> and make the setting in the

Anzeige/

Optionen

menu).

11. Switch to the measured value display with <M>. The measured value

stops flashing.

12. Sort the values pairs in ascending order.

13. In the

Settings of sensors and diff. sensors

menu, enter the value pair

or pairs (see the following table).

Page 29

NiCaVis 705 IQ Measurement / Operation

29

ba75953e03 05/2017

Default values are marked in bold.

Calibration

evaluation

The entered calibration data are checked for plausibility by the system. The

check can have the following results:

The entry of calibration values outside the measuring range leads

to a calibration error.

Menu item Settings Explanations

Cal - # raw value 1

CarboVis:

-10000,00 ... 0,00 ... 20000,00

NitraVis

:

-10000,00 ... 0,00 ... 5000,00

Raw value of the first value pair

(lower concentration).

For single-point calibration, enter 0.

Cal - ref. value 1

CarboVis:

0,00 ... 20000,00

NitraVis

:

0,00 ... 5000,00

Reference value of the first value pair

(lower concentration).

For single-point calibration, enter 0.

Cal - # raw value 2

CarboVis:

-10000,00 ... 0,00 ... 20000,00

NitraVis

:

-10000,00 ... 0,00 ... 5000,00

Raw value of the second value pair

(higher concentration) or raw value of the

single-point calibration.

Cal - ref. value 2

CarboVis:

0,00 ... 20000,00

NitraVis

:

0,00 ... 5000,00

Reference value of the second value pair

(higher concentration) or reference value

of the single-point calibration.

Display Meaning/actions

Measured

value display

Successful new valid calibration value pairs were entered for

the sensor.

"----" Calibration value pairs not accepted. Sensor is blocked for

measurement. A log book message is generated.

Causes:

Ascending order not observed.

At least one value is outside the measuring range.

Page 30

Measurement / Operation NiCaVis 705 IQ

30

ba75953e03 05/2017

Information on the contents and structure of the log book and how

you can call it up is given in the L

OG BOOK chapter of the

IQ S

ENSOR NET system operating manual.

The user calibration is not recorded in the calibration history. You

can, however, view the current value pairs in the

Settings of sen

-

sors and diff. sensors

menu at any time.

Page 31

NiCaVis 705 IQ Measurement / Operation

31

ba75953e03 05/2017

4.3.3 Sensor check/

Zero adjustment

NOTE

The sensor check or Zero adjustment must be carried out under absolutely

clean conditions. If you do not work carefully enough the Zero adjustment can

deteriorate the measuring quality.

Ultrapure water

(H2O dist.)

As ultrapure water exclusively use distilled or deionized water that is suitable for

analysis purposes.

Storage location of

the

Zero adjustment

data

The data of the sensor checks are not stored.

The data of the user zero adjustment are stored in the sensor.

Outlet A successful

Sensor check (H2O dest.)

is the prerequisite for a valid user cali-

bration. After each

Sensor check (H2O dest.)

the sensor is evaluated.

A changed sensor evaluation proves that the cleaning was effective.

The steps of the sensor check or

Zero adjustment

are identical except for the

used check solutions (ultrapure water or standard solution) and are described

together below. The sensor check and

Zero adjustment

are carried out with the

aid of the sensor sleeve.

Page 32

Measurement / Operation NiCaVis 705 IQ

32

ba75953e03 05/2017

Flowchart

Fig. 4-3

Overview of

Sensortest/Zero adjustment and user calibration.

After cleaning several times

without significant change of

the sensor assesssment:

Carry out zero adjustment

Main sensor:

Check user calibration

Virtual sensor:

Check user calibration

Sensor OK

Operating error or defective sensor

(Sensor blocked for measurement)

Sensor check

(Standard)

OK Error

-40 ... +40 < -40 or

> +40

Operating error or defective sensor

Zero adjustment

Error

OK

After several zero adjustments:

Reset to:

Factory zero adjustment or

last valid user zero adjustment

After several sensor checks:

Cleaning the sensor

Sensor check

(H2O dist.)

Assessment number

Rinse the measuring chamber

with ultrapure water several times

Clean the measurement windows

Carry out a sensor check (H2O)

TEST: MEASUREMENT WINDOWS

TEST: ELECTRONICS AND OPTICS

Page 33

NiCaVis 705 IQ Measurement / Operation

33

ba75953e03 05/2017

Preparing the

sensor check or

Zero adjustment

Prepare the sensor check or

Zero adjustment

as follows:

1. Switch to the measured value display with <M>.

2. Use <> to select the NiCaVis 705 IQ sensor.

3. Call up calibration with <C>. The

Maintenance condition:

Linked outputs are frozen.

window appears.

By activating the maintenance condition, linked outputs remain in

their present state. The cleaning and the determination of measured

values are switched off. The measured value display shows a flashing, invalid measured value ("----").

4. Confirm the maintenance condition with <OK>.

5. Take the sensor out of the test sample.

6. Remove the blind plug or unscrew the compressed air connection from

the sensor.

7. Thoroughly clean the sensor enclosure, sensor sleeve and the compressed air channels (see section 5.1 M

AINTENANCE).

To finish the cleaning procedure, thoroughly rinse the entire sensor with

ultrapure water.

8. Mount the cleaned sensor sleeve:

Loosen both coupling rings on the sensor sleeve.

Put the sensor sleeve on the sensor and align it:

– The measuring gap is in the center of the sensor sleeve

– The filling opening of the sensor sleeve and the measuring gap

opening of the sensor are offset by 90°.

Tighten both coupling rings on the sensor sleeve by hand.

Page 34

Measurement / Operation NiCaVis 705 IQ

34

ba75953e03 05/2017

Fig. 4-4 Putting the sensor sleeve on the sensor

Carrying out the

sensor check or

Zero adjustment

9. Put the sensor in a horizontal position on a firm and vibration-free surface. Turn the filling opening of the sensor sleeve upward (Fig. 4-4).

10. Rinse the measuring chamber with ultrapure water at least 3 times.

11. For

Sensor check (H2O dest.)

or

Zero adjustment

:

Fill the measuring chamber with ultrapure water.

or

For

Sensor check (standard)

:

Fill the measuring chamber with standard solution (see section 6).

12. If there are any air bubbles on the measuring windows remove them by

gently knocking on the sensor sleeve with a bar.

Carry out the intended sensor check or

Zero adjustment

directly

after filling the sensor sleeve. If you wait longer, the result of the

Sensor check/

Zero adjustment

will be affected.

Measuring

chamber

Sensor

sleeve

13. Select the required option with <> and <OK>:

Sensor check (H2O dest.)

Zero adjustment

Sensor check (standard)

14. Confirm with <OK>.

A multipart checklist appears. Use it to check once more whether all

preparations have been completed.

Page 35

NiCaVis 705 IQ Measurement / Operation

35

ba75953e03 05/2017

Result

after

Sensor

check (H2O dest.)

If the rating number is not in the zero range:

Repeat the cleaning procedure and the

Sensor check (H2O dest.)

until the rating

number no longer changes significantly.

If the rating number is still outside the zero range, a new zero adjustment is necessary.

Result

after

Zero

adjustment

If the result is erroneous, clean the sensor and all equipment once again. Then

carry out a new

Zero adjustment

and when doing so make sure the conditions

are absolutely clean.

15. Confirm each checklist with <OK> until the

Start measurement

display

appears.

Up to this point, you can break off the calibration procedure at any

time with the <ESC> key. The system continues to work with the old

calibration data. The maintenance condition, however, has to be

switched off again in any case.

After starting the calibration with the <OK> key (step 16.) you can no

longer cancel the calibration procedure.

16. Confirm with <OK>.

The measurement is started. After the end of the measurement the

result appears. With the

Zero adjustment

, the result is entered in the

calibration history at the same time.

Rating number Meaning

Zero range

(-40 ... +40)

Sensor check (H2O dest.)

successful (OK)

(0 = no deviation)

Positive number

(+40 ... +1000)

Measured values were too low.

Possible cause:

The measurement windows are contaminated.

Negative number

(-40 ...-1000)

Measured values were too high.

Possible cause:

During the last zero adjustment, the measurement

windows were contaminated more than during the

current sensor check.

Result

Meaning Sensor released for

measurement

OK Zero adjustment

successful. yes

Error Zero adjustment

not success-

ful.

No ("----")

Page 36

Measurement / Operation NiCaVis 705 IQ

36

ba75953e03 05/2017

Result

after

Sensor

check (standard)

Completing the

sensor check or

Zero adjustment

After a successful sensor check or

Zero adjustment

, return to measurement as

follows:

If no valid zero adjustment is possible under the current conditions,

you can restore the readiness for measurement by measuring with

an older valid zero adjustment.

To do so, select the

Zero adjustment

setting in the sensor settings

Factory

(factory zero adjustment) or

User

(last valid user zero

adjustment).

Then check the measurement results with a

Sensor check (stan

-

dard)

. Suitable standards (check equipment) for your sensor are

available as accessories (see chapter 6).

Result

Meaning

OK Sensor check (standard)

successful.

Error Sensor check (standard)

not successful.

Possible cause

: wrong or expired standard

17. Confirm the calibration result with <OK>.

18. Confirm the message,

"After successful cal ..."

with <OK>.

The display returns to the measured value display. The measured val ue

flashes because the sensor is still in the maintenance condition.

19. Pour away the ultrapure water or standard solution and remove the

sensor sleeve.

20. Screw in the blind plug or compressed air connector and install the sensor at the measuring site.

21. After the

Sensor check (standard)

:

Thoroughly rinse the sensor and sensor sleeve with ultrapure water.

22. NiCaVis 705 IQ Switch off the maintenance condition (use <>

to select the sensor, press <OK> and make the setting in the

Display/

Options

menu).

23. Switch to the measured value display with <M>. The measured value

stops flashing.

Store the sensor sleeve in a clean environment, e. g. in a plastic

bag, until the next sensor check or

Zero adjustment

.

Page 37

NiCaVis 705 IQ Maintenance and cleaning

37

ba75953e03 05/2017

5 Maintenance and cleaning

5.1 Maintenance

The UV-VIS- NiCaVis 705 IQ sensor operates maintenance-free.

5.2 Sensor cleaning

5.2.1 Cleaning agents and accessories

Cleaning agents To clean the sensor, use the following cleaning agents only:

* For the final cleaning prior to a

Sensor check

or

Zero adjustment

, only use

cleaning agents with purity grade "for analysis". Finally, thoroughly rinse the

sensor with ultrapure water.

Accessories Sponge

Plastic-bristled brushes of different sizes.

Interdental brushes are suitable for the cleaning of the compressed air channels.

Flocked cleaning cards (see accessories)

Lens tissues

Wash bottle

NOTE

Never use any pressure washer, steam blaster, abrasives or metal brushes to

clean the sensor. Risk of damaging the sensor.

Contamination Cleaning agents

Water-soluble substances – Primary cleaning: Tapwater, warm if

possible

(30 - 50 °C)

– Precision cleaning: Household wash-

ing-up liquid + ultrapure water.

Lime deposits 5 % hydrochloric acid *

Grease deposits Mixture of isopropanol and water (approx.

70 % isopropanol) *

Page 38

Maintenance and cleaning NiCaVis 705 IQ

38

ba75953e03 05/2017

5.2.2 General steps to be taken

Depending on the application site and the level of contamination of the sensor

as well as the coming job, the cleaning procedure includes the following parts:

Every cleaning procedure starts with a basic cleaning. It removes tough

grime such as incrustation of fouling matter, algae and biological deposits. If

the sensor surface might be contaminated with pathogenic germs it should

also be disinfected.

Cleaning the measuring gap: Removal of lime deposits.

Cleaning the measuring gap: Removal of grease deposits.

Example 1 A heavily contaminated sensor, for which a

Sensor check

or

Zero adjustment

should be carried out, must run through all cleaning steps properly. During the

cleaning process always keep all surfaces moist to prevent already dissolved

contamination and detergents from drying ("working wet-on-wet"). Finally, thoroughly rinse off all remaining cleaning agents with ultrapure water.

Example 2 If the sensor from example 1 should be cleaned on site during a routine visual

inspection and should then continue measuring, a basic cleaning might possibly

be sufficient.

The quoted examples and the following descriptions are intended to

give a general guideline. Due to the sensor's wide range of application, the type and level of contamination can considerably vary.

Therefore, the cleaning procedure has to be individually composed.

If necessary, individual cleaning steps have to be changed or

repeated several times until the result meets the requirements.

Page 39

NiCaVis 705 IQ Maintenance and cleaning

39

ba75953e03 05/2017

5.2.3 Basic cleaning

Steps of the basic

cleaning

After completing the cleaning procedure, screw in the blind plug or compressed

air connection.

1. Take the sensor out of the test sample and remove any solid matter

deposits and incrustation of fouling matter manually with a brush or

sponge.

2. Wash the sensor down with warm tapwater (30 - 50 °C).

Note:

Do not use a pressure washer or steam blaster.

3. If the sensor might be contaminated with pathogenic germs it should be

disinfected with a surface disinfectant. This also applies to the cable and

mounting parts.

Note:

Follow the instruction manual of the disinfectant (reaction time!).

4. Remove the blind plug or unscrew the compressed air connection from

the sensor.

5. Clean the sensor with soapy water. When doing so, clean the area of

the measuring gap and the compressed air channels very thoroughly.

The compressed air channels can be cleaned with the aid of interdental

brushes and rinsed with soapy water from a wash bottle.

6. Soak the flocked cleaning cards with soapy water and use them to clean

the measuring gap as shown in the following figure. Cut suitable strips

off the cleaning card to clean the bottom of the measuring gap.

Then rinse the sensor with running warm tapwater and finally with a lot

of ultrapure water.

7. Finally wipe the measurement window with a lens tissue.

Page 40

Maintenance and cleaning NiCaVis 705 IQ

40

ba75953e03 05/2017

5.2.4 Cleaning the measuring gap

To remove lime or grease deposits, use the flocked cleaning cards together with

the following detergents:

Proceeding Start by removing any lime deposits.

Soak a flocked cleaning card with the relevant detergent and use it to clean

the measuring windows according to step 6. in section 5.2.3 B

ASIC CLEANING.

If necessary, leave the cleaning card in the measuring gap for a few minutes

so the detergent can take effect.

Thoroughly rinse with ultrapure water the measuring gap and the surrounding

areas moistened with detergent.

Then wipe the measurement window with a lens tissue. The surface of the

measurement windows must be free of streaks.

Protect the cleaned sensor against new contamination.

Contamination Cleaning agents

Lime deposits Hydrochloric acid 5 % for analysis

Grease deposits Mixture of isopropanol and water (approx. 70 % iso-

propanol), made of 7 volume parts isopropanol for

analysis and 3 volume parts ultrapure water

Page 41

NiCaVis 705 IQ Spare parts, maintenance equipment, accessories

41

ba75953e03 05/2017

6 Spare parts, maintenance equipment,

accessories

General

accessories,

replacement parts

Test equipment

Components for the

optional

compressed air

cleaning system

Description Model Order no.

Calibration sleeve VIS/CV 481 074

20 flocked cleaning cards for cleaning the

measuring gap

VIS/CT 481 071

Cleaning set:

– 20 flocked cleaning cards

– Cleaning solutions

VIS C/SET 481 079

Description Model Order no.

Standard 1

with low concentration

for 5 mm UVVIS/SAC/NOx sensors

ST-1 481 077

Standard 2

with high concentration

for 1 mm UVVIS/SAC/NOx sensors

ST-2 481 078

Description Model Order no.

Compressed air cleaning set with 15 m

compressed-air hose, to be connected to a

valve module or Cleaning Air Box

SET/AP 481 075

Active valve module (does not require a

free relay output in the IQ S

ENSOR NET

system)

MIQ/CHV PLUS 480 018

Valve module for the IQ S

ENSOR NET sys-

tem 182 (external relay and compressed

air supply)

DIQ/CHV 472 007

Air compressor to be triggered by relay,

power supply 115 V AC

Cleaning Air Box

- 115 VAC

480 017

Air compressor to be triggered by relay,

power supply 230 V AC

Cleaning Air Box

- 230 VAC

480 019

Page 42

Spare parts, maintenance equipment, accessories NiCaVis 705 IQ

42

ba75953e03 05/2017

Mounting

accessories

Description Model Order no.

Mounting set for horizontal installation with

EH/F 170 swing mounting assembly

VIS Set/EH 481 073

Set for the mounting of UVVIS/SAC/NOx

sensors to the S 200 electrode floater

VIS Set/F 481 080

Flow-through armature VIS FT-1 480 080

Information on other IQ SENSOR NET accessories is given in the

WTW catalog and on the Internet.

Page 43

NiCaVis 705 IQ What to do if...

43

ba75953e03 05/2017

7 What to do if...

"----" display

(invalid measured

value)

Implausible

measured values

Cause Remedy

– User calibration values entered

incorrectly

– *

Sensor check (H2O dest.)

or

*

Zero adjustment

or

*

Sensor check (standard)

defective

– Correct the entry and enter once

again (section 4.3.2)

– Repeat

*

Sensor check (H2O dest.)

or

*

Zero adjustment

or

*

Sensor check (standard)

.

Check conditions, especially cleanliness (section 4.3.3)

–

Zero adjustment

still erroneous

after several trials

–Contact service

– Unknown – See log book

Cause Remedy

– Erroneous user calibration – Repeat user calibration. Make sure

the samples for comparison are representative.

– Substantial change of test sample

(sample matrix)

– Carry out new user calibration

– Measurement windows dirty – Clean the measurement windows

– Sensor setting wrong – Check and, if necessary, correct the

Measuring mode, Measuring loca

-

tion

sensor settings

– Carry out new user calibration

– Optical system maladjusted, e. g.

due to inadmissible mechanical

shock

– Carry out

*

Sensor check (H2O dest.)

or

*

Zero adjustment

or

*

Sensor check (standard)

Page 44

What to do if... NiCaVis 705 IQ

44

ba75953e03 05/2017

Drifting measured

values

Display of

OFL

Measured values

fluctuating heavily

Measured values

too low or too high

Cause Remedy

– Cleaning efficiency too low - mea-

surement windows becoming

more and more contaminated

– Clean the measurement windows

(section 5.2.4)

– Use other cleaning method

– Select different measurement loca-

tion

– Set longer cleaning duration

– Set more frequent cleaning proce-

dures

– Install optional compressed air

cleaning device

– Failure of the optional com-

pressed air cleaning system

– Clean the measurement windows

(section 5.2.4)

– Check all components of the com-

pressed air cleaning system (compressor, compressed air line,

sensor, rinsing openings)

– Substantial change of test sample

(sample matrix)

– Carry out new user calibration

Cause Remedy

– Measuring range exceeded – Check process

– Foreign matter in the measuring

gap

– Clean the measuring gap (section

5.2.3)

– Erroneous user calibration – Repeat user calibration. Make sure

the samples for comparison are representative.

Cause Remedy

– Gas bubbles in front of the mea-

surement windows

– Check the position within the pro-

cess and the installation position

Cause Remedy

– Gas bubbles in front of the mea-

surement windows

– Check the installation position of the

sensor

Page 45

NiCaVis 705 IQ What to do if...

45

ba75953e03 05/2017

Display of

ERROR

– Measurement windows dirty – Clean the measurement windows

Cause Remedy

Cause Remedy

– Sensor not correctly connected – Check the assignment of the termi-

nal connections

– Load at a power supply module

too high

– Install another power supply module

in the vicinity of the sensor

–IQS

ENSOR NET cable towards the

NiCaVis 705 IQ too long (voltage

drop too great)

– Install another power supply module

in the vicinity of the sensor

– Electrical connection between

power supply module and

NiCaVis 705 IQ is interrupted

– Check the cable connection step-

by-step starting with the power supply module, and replace any defective cable sections.

– Check the contacts on the MIQ

modules (stack mounting). Clean

any dirty contacts. Carefully bend

back contact springs that have been

pressed flat or bent (pay attention to

sufficient spring tension)

Page 46

Technical data NiCaVis 705 IQ

46

ba75953e03 05/2017

8 Technical data

8.1 Measurement characteristics

Measuring principle Spectrophotometric Absorption measurement; integrated microprocessor elec-

tronics, shielded 2-wire connection for power and data transmission.

Light source

Detector

Wavelengths range 200 - 720 nm

Measuring gap

(optical layer

thickness)

Nitrate

measurement,

5 mm gap width

Carbon

measurement,

5 mm gap width

Lamp type Xenon flashlamp

Photo diodes 256

NiCaVis 705 IQ 5 mm

Measuring location Measuring mode Measuring range Resolution

NO3

0.0 ... 250.0 mg/L 0.1 mg/L

NO3-N

0.00 ... 50.00 mg/L 0.01 mg/L

Measuring location Measuring mode Measuring range Resolution

Outlet COD spectr., total

0.0 ... 800.0 mg/L 0.1 mg/L

COD spectr., dissolv

0.0 ... 800.0 mg/L 0.1 mg/L

TOC spectr., correl.

0.0 ... 500.0 mg/L 0.1 mg/L

DOC spectr., correl.

0.0 ... 500.0 mg/L 0.1 mg/L

BOD spectr., correl.

0.0 ... 500.0 mg/L 0.1 mg/L

SAC 254, total

0.0 ... 600.0 1/m 0.1 1/m

SAC 254, dissolved

0.0 ... 600.0 1/m 0.1 1/m

UVT 254, total

*

* The UVT-254 value is standardized to 10 mm gap width.

0.0 ... 100.0 % 0.1 %

UVT 254, dissolved

* 0.0 ... 100.0 % 0.1 %

Page 47

NiCaVis 705 IQ Technical data

47

ba75953e03 05/2017

8.2 Application characteristics

Suitability and areas

of application

Measuring medium

Pressure resistance Sensor with connected SACIQ (SW) sensor connection cable:

The sensor meets all requirements according to article 3(3) of 97/23/EC ("pressure equipment directive").

Type of protection Sensor with connected SACIQ (SW) sensor connection cable:

IP X8, 1 bar (10

5

Pa)

Immersion depth

Operating position Any

The quoted measuring ranges are nominal measuring ranges that

are theoretically possible. In practice, real measuring ranges exist

that are given by the limits of photometric determination. The limits

are significantly influenced by the light scattering due to solids and

the absorption of accompanying substances (sample matrix).

Therefore, no fixed measuring range can be determined beforehand.

Municipal wastewater with a low proportion of industrial wastewater

pH value 4 - 12

Flow rate < 3 m/s

Temperature 0 °C ... + 45 °C

(32 °F ... + 113 °F)

Max. admissible overpressure 105 Pa (1 bar)

min The measuring gap must be

filled with test sample.

max 10 m depth

Page 48

Technical data NiCaVis 705 IQ

48

ba75953e03 05/2017

8.3 General data

Dimensions

(in mm)

Weight

Connection

technique

Connection via SACIQ (SW) sensor connection cable

Materials

Storage

temperature

Ø 96

891

Ø 60

Ø 96

891

120

Socket SACIQ...

With shock protection:

774

865

381

Approx. 3.8 kg (without shock protectors and without sensor connection cable)

Approx. 4.8 kg (with shock protectors but without sensor connection

cable)

Sensor shaft Titan Grade 2

Center piece PEEK

End cap PEEK

Measurement window Sapphire

Plug head connector housing POM

Plug, 3-pole ETFE (blue) Tefzel

®

Protection ring POM

- 10 °C ... + 50 °C (14 ... 122 °F)

Page 49

NiCaVis 705 IQ Technical data

49

ba75953e03 05/2017

Meter safety

Test certificates

8.4 Electrical data

Applicable norms – EN 61010-1

– UL 61010-1

– CAN/CSA C22.2#61010-1

– IEC 62471

cETLus, CE

2001759

Conforms to ANSI/UL 61010-1

Certified to CAN/CSA C22.2#61010-1"

Nominal voltage Max. 24VDC

via the IQ S

ENSOR NET (for more details,

see chapter T

ECHNICAL DATA of the

IQ S

ENSOR NET system operating manual)

Power consumption

8W

(maximum power consumption)

3.5 W

(medium power consumption)

If the system is supplied with power via a

MIQ/WL PS o DIQ/S 28X, only the

medium power consumption has to be

taken into account.

Protective class III

Page 50

Indexes NiCaVis 705 IQ

50

ba75953e03 05/2017

9 Indexes

9.1 Explanation of the messages

This chapter contains a list of all the message codes and related message texts

that can occur in the log book of the IQ S

ENSOR NET system for the

NiCaVis 705 IQ sensor.

Some error messages contain an internal error code, starting with "#".

Information on the contents and structure of the log book and the

structure of the message code is given in the L

OG BOOK chapter of

the IQ S

ENSOR NET system operating manual.

The last three digits of the message code form the component code.

It identifies the component (active component) that caused the message:

Module code Component

3A2 NitraVis 705 IQ

3AW CarboVis 705 IQ - virtual

3AX CarboVis 705 IQ - virtual

3AY CarboVis 705 IQ - virtual

3AZ CarboVis 705 IQ - virtual

541 BasicVis IQ

Page 51

NiCaVis 705 IQ Indexes

51

ba75953e03 05/2017

9.1.1 Error messages

Message code Message text

EA2541

Sensor temperature too high!

* Check process and application

EA3541

Sensor temperature too low!

* Check process and application

EAF541

Optical measuring range exceeded

* Check process (TSS or measured value too high)

* Select measuring location free of air bubbles

* Remove foreign matter from measuring gap

* Clean sensor

* Optimize cleaning settings

* Switch on signal smoothing, increase response time

EAI541

Zero adjustment erroneous

* Clean the sensor and sensor sleeve repeatedly

* Position the sensor sleeve according to operating manual

* Rinse the measuring chamber with ultrapure water several times

* Fill the measuring chamber with ultrapure water

* Repeat the zero adjustment

EAM3Ax

Meas. range exceeded or undercut

* Check process

EC33Ax

User calibration erroneous,

Check raw value / reference value pairs:

* Set all values within the measuring range

(see operating manual)

* Enter value pairs in ascending order

EI1541

Operational voltage too low

* Check installation and cable lengths, Follow installation instructions

* Power supply module(s) overloaded, add power supply module(s)

* Check terminal and module connections

* Defective components, replace components

EI2541

Operational voltage too low, no operation possible

* Check installation and cable lengths, Follow installation instructions

* Power supply module(s) overloaded, add power supply module(s)

* Check terminal and module connections

* Defective components,

replace components

ES2541

Humidity to high in sensor

* Contact service

ES3541

Failure optical measurement: deviation in reference channel too high

* Execute zero ajustment

Page 52

Indexes NiCaVis 705 IQ

52

ba75953e03 05/2017

ES4541

Overflow optical measurement

* Execute zero ajustment

ES5541

Failure optical measurement: hardware

* Contact service

ES6541

Failure optical measurement: software

* Contact service

ES7541

Failure optical measurement: software BIOS

* Contact service

Message code Message text

Page 53

NiCaVis 705 IQ Indexes

53

ba75953e03 05/2017

9.1.2 Informative messages

Message code Message text

IA23Ax

Calculation of negative concentrations

* Perform user calibration or check user calibration

IAC541

Zero adjustment was successfully carried out

* Carry out sensor check

* If required, carry out new user calibration

IC3541

Factory calibration has been activated. Make sure the sensor operates

correctly.

IC4541

The last valid user zero adjustment was activated. Make sure the sen

-

sor operates correctly.

IC5541

Invalid user zero adjustment was replaced by last valid user calibration.

Caution! Wrong measured values possible. Carry out a new successful

zero adjustment to make sure the sensor operates correctly.

IC6541

The invalid user zero adjustment was replaced by the factory zero

adjustment. Caution! Wrong measured values possible. Check

whether the sensor operates correctly or carry out a new successful

user zero adjustment.

Page 54

Indexes NiCaVis 705 IQ

54

ba75953e03 05/2017

9.2 Status info

The status info is a coded piece of information on the current status of a sensor.

Each sensor sends this status info to the controller. The status info of sensors

consists of 32 bits, each of which can have the value 0 or 1.

Status info,

general structure

The bits 0 - 15 are reserved for general information.

The bits 16 - 21 are reserved for internal service information.

You obtain the status info:

via a manual query in the

Einstellungen/Settings/Service/List of all compo

-

nents

menu (see system operating manual)

by an automated query

– from a superordinate process control (e. g. when connected to the Profi-

bus)

– of the IQ Data Server (see operating manual of the IQ S

ENSOR NET soft-

ware pack)

Status-Info

NiCaVis 705 IQ

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 (general)

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 (internal)

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

The evaluation of the status info, e.g. in the case of an automated

query, has to be made individually for each bit.

Status bit Explanation

Bit 0

Component hardware defective

Bit 1

Component hardware defective

xxx

Bit 2

Optical measuring range exceeded

Bit 3-31 -

Page 55

NiCaVis 705 IQ Appendix: Glossary

55

ba75953e03 05/2017

10 Appendix: Glossary

Absorbance (Absorption)

Attenuation of the light beam when it penetrates the sample.

Adjusting To manipulate a measuring system so that the relevant value (e.g. the

displayed value) differs as little as possible from the correct value or

a value that is regarded as correct, or that the difference remains

within the tolerance.

BSB, BOD Abbreviation for the "Biochemical Oxygen Demand". The biochemical

oxygen demand of the amount of oxygen required by microorganisms

in order to aerobically decompose organic substances in an aqueous

solution.

Calibration Comparing the value from a measuring system (e. g. the displayed

value) to the correct value or a value that is regarded as correct.

Often, this expression is also used when the measuring system is

adjusted at the same time (see adjusting).

Calibration value pair Value pair consisting of the raw value measured by the

NiCaVis 705 IQ sensor, and a reference value measured e.g. by a

laboratory determination. The calibration value pairs are the result of

the user calibration.

Concentration Mass or amount of a dissolved substance per volume, e. g. in g/L or

mol/L.

CSB, COD Abbreviation for the "Chemical Oxygen Demand". The chemical oxy-

gen demand is the equivalent amount of oxygen that is required for

the complete oxidation of the organic (major part) and anorganic

(minor part) substances in an aqueous solution.

DOC Abbreviation for dissolved organic carbon. Concentration of

dissolved, organically bound carbon in water.

Measured parameter The measured parameter is the physical dimension determined by

measuring, e.g. pH, conductivity or D.O. concentration.

Measured parameter

(correlated)

With the measuring method used, a correlated measured parameter

is not determined directly. A correlated measured parameter can,

however, be derived from a determinable measured parameter. The

precondition for this is that there is a reproducible interrelationship

(correlation) between the determinable and correlated measured

parameter.

Measured value The measured value is the special value of a measured parameter to

be determined. It is given as a combination of the numerical value and

unit (e. g. 3 m; 0.5 s; 5.2 A; 373.15 K).

The measured value is determined from the raw value taking into

account the data from a user calibration. The measured value is

displayed together with the raw value in the measured value display.

Page 56

Appendix: Glossary NiCaVis 705 IQ

56

ba75953e03 05/2017

Measuring gap The measuring gap is between the two measurement windows. In the

measuring gap, the light beam penetrates the test sample.

Measuring system The measuring system comprises all the devices used for measuring,

e. g. measuring instrument and sensor. In addition, there is the cable

and possibly an amplifier, terminal box and armature.

NO2-N The proportion of nitrogen coming from nitrite.

NO3-N The proportion of nitrogen coming from nitrate.

Raw value The raw value is determined from the spectrum while taking into

account the data from the zero adjustment. The raw value is displayed

on the right side of the measured value in the measured value display.

Reference sample Random sample of the test sample for comparative chemical-analyt-

ical laboratory analyses intended for user calibration.

Resolution Smallest difference between two measured values that can be

displayed by a meter.

Sample matrix Composition of the test sample of different individual substances.

Test sample Designation of the test sample ready to be measured.

Ultrapure water (H2O

dist.)

Ultrapure water is distilled or deionized water suitable for analysis

purposes.

Zero adjustment Measuring and saving the absorbance spectrum of ultrapure water.

Defines the zero points in the spectrum for all wavelengths. The light

beam is not alleviated at the zero point. The zero point influences the

calculation of the raw value.

TOC Abbreviation for total organic carbon. Total amount of organically

bound carbon in water.

UVT (dissolved) Transmission measurement after turbidity correction

(reference measurement at 550 nm).

UVT (total) Transmission measurement at a certain wavelength.

The UVT-254 value is standardized to 10 mm gap width.

Page 57

Page 58

What can Xylem do for you?

We're a global team unified in a common purpose: creating innovative solutions to

meet our world's water needs. Developing new technologies that will improve the way