Page 1

INSTRUCTION MANUAL

IM055

Model GB

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Page 2

SUBJECT PAGE

Safety Instructions ........................................................................................................................................................ 3

Engineering Data .......................................................................................................................................................... 3

Piping ........................................................................................................................................................................... 3

Wiring and Grounding ................................................................................................................................................. 3

Rotation ....................................................................................................................................................................... 3

Operation ..................................................................................................................................................................... 4

Maintenance................................................................................................................................................................. 4

Disassembly .................................................................................................................................................................. 4

Reassembly ................................................................................................................................................................... 4

Troubleshooting ........................................................................................................................................................... 5

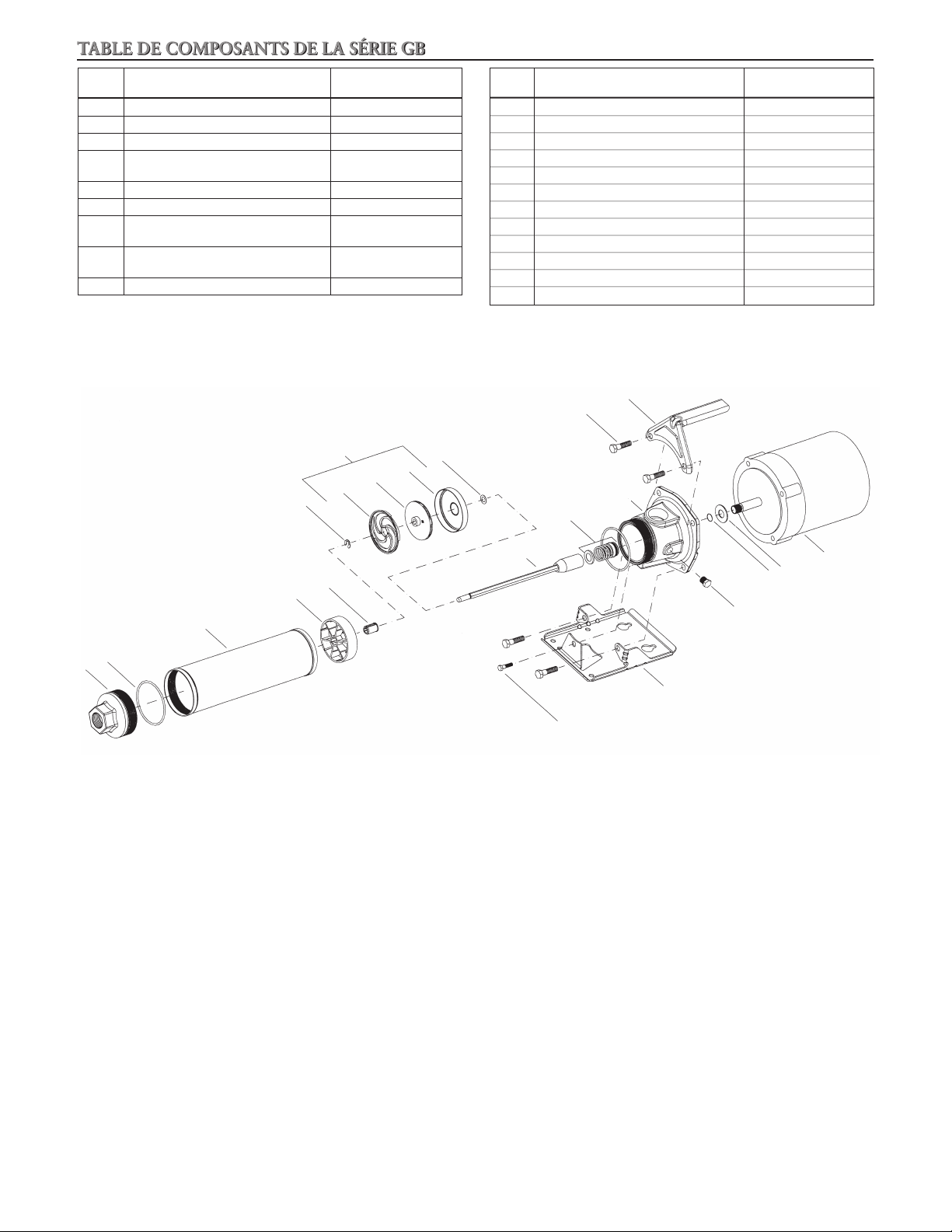

GB Components Parts Table ......................................................................................................................................... 6

Limited Warranty ......................................................................................................................................................... 7

Declaration of Conformity ......................................................................................................................................... 21

Pump Model Number:

Pump Serial Number:

Dealer:

Dealer Phone No.:

Date of Purchase:

Date of Installation:

Current Readings at Startup:

1 Ø 3 Ø L1-2 L2-3 L3-1

Amps: Amps:

Volts: Volts:

2

Page 3

SAFETY INSTRUCTIONS

DANGER

WARNING

CAUTION

WARNING

Hazardous fluids

can cause fire,

burns or death.

WARNING

WARNING

Hazardous voltage

can shock, burn or

cause death.

TO AVOID SERIOUS OR FATAL PERSONAL

INJURY OR MAJOR PROPERTY DAMAGE, READ

AND FOLLOW ALL SAFETY INSTRUCTIONS IN

MANUAL AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump

or in the manual, look for one of the following signal words and be alert to the

potential for personal injury or property

damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause personal injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

UNIT NOT DESIGNED FOR USE

WITH HAZARDOUS LIQUIDS OR

FLAMMABLE GASES. THESE

FLUIDS MAY BE PRESENT IN

CONTAINMENT AREAS.

DESCRIPTION and SPECIFICATIONS:

The GB Series pump is a portable horizontal multi-stage

pump designed for residential and agricultural washdown, misting and general boosting services.

The 304 stainless steel version of the GB is used for

HVAC, general commercial, reverse osmosis and filtration applications.

ENGINEERING DATA

PIPING

• Piping should be no smaller than the pump discharge

and/or suction connections. Piping should be kept as

short as possible, avoiding unnecessary fittings to minimize friction losses.

• All piping MUST be independently supported and

MUST NOT place any piping loads on the pump.

• All joints MUST be airtight. Use 3 – 4 wraps of

Teflon™ tape to seal threaded connections.

WIRING AND GROUNDING

Install ground and wire according

to local and National Electrical

Code requirements.

Install an all leg disconnect switch

near the pump.

Disconnect and lockout electrical

supply before installing or servicing pump.

Electrical supply MUST match pump’s name plate

specifications. Incorrect voltage can cause fire and/

or damage to the motor and voids warranty.

Motors not protected MUST be provided with

contactors and thermal overloads on single phase

motors, or starters with heaters on three phase motors. See motor nameplate.

• Use only stranded copper wire to motor and ground.

The ground wire MUST be at least as large as the wire

to the motor. Wires should be color coded for ease of

maintenance.

Pumps with open spray application must

be plugged into electrical service which is

protected by a Ground Fault Service Interrupter. Failure

to do so may result in serious personal injury or death

and property damage.

• Follow motor manufacturer’s wiring diagram on the

motor nameplate or terminal cover carefully.

WARNING

Hazardous

voltage

FAILURE TO PERMANENTLY

GROUND THE PUMP, MOTOR AND

CONTROLS BEFORE CONNECTING

TO ELECTRICAL POWER CAN CAUSE

SHOCK, BURNS OR DEATH.

• Maximum Liquid Temperatures: 160°F (72°C).

• Maximum Suction Pressure 75 psi.

• Pipe connections are 1" NPT suction and discharge.

¾" Hose Adapters are available.

• Capacities to 33 GPM.

• Heads to 600 Feet (260) psi.

• Rotation: Right hand, ie; clockwise when viewed from

motor end.

ROTATION

NOTICE: INCORRECT ROTATION MAY CAUSE

DAMAGE TO PUMP AND VOIDS THE

WARRANTY.

• Correct rotation is right-hand, CLOCKWISE when

viewed from the motor end.

• To reverse three phase motor rotation interchange any

two power supply leads.

3

Page 4

OPERATION

CAUTION

WARNING

Hazardous

voltage

SPLASHING OR IMMERSING OPEN

DRIP PROOF MOTORS IN FLUIDS

CAN SHORT OUT MOTOR AND

CAUSE FIRE, SHOCK, BURNS OR

DEATH.

• To REMOVE pump from service drain all pumpage

from pump and piping.

• To RETURN pump to service replace all plugs and pip-

ing using Teflon™ tape or equivalent on male threads.

• Refer to “OPERATION” section of manual.

NOTICE: PUMP MUST BE FULLY PRIMED BEFORE

OPERATION. DO NOT RUN PUMP DRY.

• After stabilizing the system at normal operating condi-

tions, check the piping. If necessary, adjust the pipe

supports.

Do not run pump dry; damage to me-

chanical seal will result. Do not run against

closed nozzle for prolonged periods or damage to pump

and piping will result.

HANDLE ASSEMBLY

Remove two top bolts from motor adapter. Insert them

through handle back into the motor adapter and tighten

securely.

NOZZLING

It is important to choose the right nozzle for proper

pump performance. The faucet supplying the water to

the pump should be checked to see what rate of flow it

will furnish. If the one min. flow with the faucet open is:

7 gals. — Use 6 gpm nozzle V2005

(which is included with each AM2)

6 gals. — Use 5 gpm nozzle V1502

5 gals. — Use 4 gpm nozzle SN0045 AM 7 Kit

4 gals. — Use 3 gpm nozzle V10152

By using this method of choosing nozzles we can keep a

positive pressure at the pump intake. This will keep the

pump from “robbing” water from other faucets.

DAIRY FARM USE

We recommend that all WaterGuns

®

used on farms

producing Grade “A’’ milk be equipped with a Vacuum

Breaker, installed according to instructions supplied with

Vacuum Breaker. This prevents sub-atmospheric pressure in the supply line even if the water supply should

diminish. We suggest the WaterGun be hung on a wall at

least 18" off the floor and that a hose rack be provided to

store the discharge hose off the floor.

MAINTENANCE

WARNING

Hazardous

voltage

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING ANY

MAINTENANCE CAN CAUSE SHOCK,

BURNS OR DEATH.

• Motors have permanently lubricated bearings. No

lubrication is possible or necessary. Follow the motor

manufacturer’s recommendations for maintenance.

DISASSEMBLY

• Place wrenches on adapter (13) and discharge head (1),

and unscrew discharge head and casing (3).

NOTE: CASING HAS A LEFT HAND THREAD

ON BOTH ENDS AND IS SEALED WITH

O-RINGS (2).

• Remove klip ring (6) from end of shaft (11). The

stages, each comprising a bowl (9), impeller (8) and

diffuser (7) may now be removed. If pump has been

clogged by foreign matter, but otherwise undamaged,

further dismantling may be unnecessary. If shaft assembly (11), shaft seal (12) or motor are to be replaced,

proceed as follows:

• Remove plug (18) from rear of motor and hold

motor shaft with screwdriver. Unscrew pump shaft

coupling assembly (11) from motor shaft. Remove

four motor mounting bolts (14), separate the motor

from frame by withdrawing it straight back.

• Motor may have to be pried with two screwdrivers

if the shaft seal sticks. The shaft seal stationary seat

may be pushed out of adapter from the motor side.

There is a rubber coupling o-ring (19) between motor

shaft and coupling which will usually remain on the

motor shaft as the seal is pulled over it.

REASSEMBLY

Check that the rubber deflector (20) and the coupling

o-ring (19) are on the motor shaft. If they are worn or

damaged, replace. Install stationary seal seat in frame

(13) and mount frame (13) and handle (15) to motor.

Install seal rotating element, making sure faces are clean

and that the last rubber member goes over the coupling

o-ring and onto the motor shaft. Screw the pump shaft

and coupling assembly (11) on until it seats up against

the motor shaft. With a straight edge across the face of

the frame check the location of the outboard end of the

coupling. Due to variations in motor shaft length, etc., it

will be from .030" short to flush. Add .010" shims 7K155

until they are flush or higher, i.e., the last shim interferes

with the straight edge. Put the required stages on checking each stage for additional shim requirements by putting the straight edge across the bowl and checking the

location of the impeller hub. After all the stages are on

the shaft replace klip ring (6).

Check o-ring on both frame and discharge head and

replace if damaged. Install casing (3) and bearing spider

(4). Thread on discharge head (1) (Notice: left hand

threads) and tighten.

4

Page 5

With screwdriver in the slotted end of the pump shaft,

WARNING

Hazardous voltage

can shock, burn or

cause death.

turn the unit over (clockwise) before replacing plug (18).

It should turn with no resistance except that of the shaft

seal.

TROUBLESHOOTING

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING ANY

MAINTENANCE CAN CAUSE

SHOCK, BURNS OR DEATH.

SYMPTOM

MOTOR NOT RUNNING

See Probable Causes 1 thru 5

LITTLE OR NO LIQUID DELIVERED

See Probable Causes 6 thru 12

EXCESSIVE POWER CONSUMPTION

See Probable Causes 3, 12, 13 & 14

PROBABLE CAUSES

1. Motor thermal protector tripped

2. Open circuit breaker or blown fuse

3. Impeller binding

4. Motor improperly wired

5. Defective motor

6. Pump is not primed, air or gases in pumpage

7. Discharge, suction plugged or valve closed

8. Incorrect rotation (3 phase only)

9. Low voltage or phase loss

10. Impeller worn or plugged with debris

11. System head too high

12. Incorrect impeller diameter

13. Discharge head too low — excessive flow rate

14. Fluid viscosity and/or specific gravity too high

15. Worn bearing

16. Pump, motor or piping loose

EXCESSIVE NOISE & VIBRATION

See Probable Causes 3, 6, 7, 10, 13, 15 & 16

5

Page 6

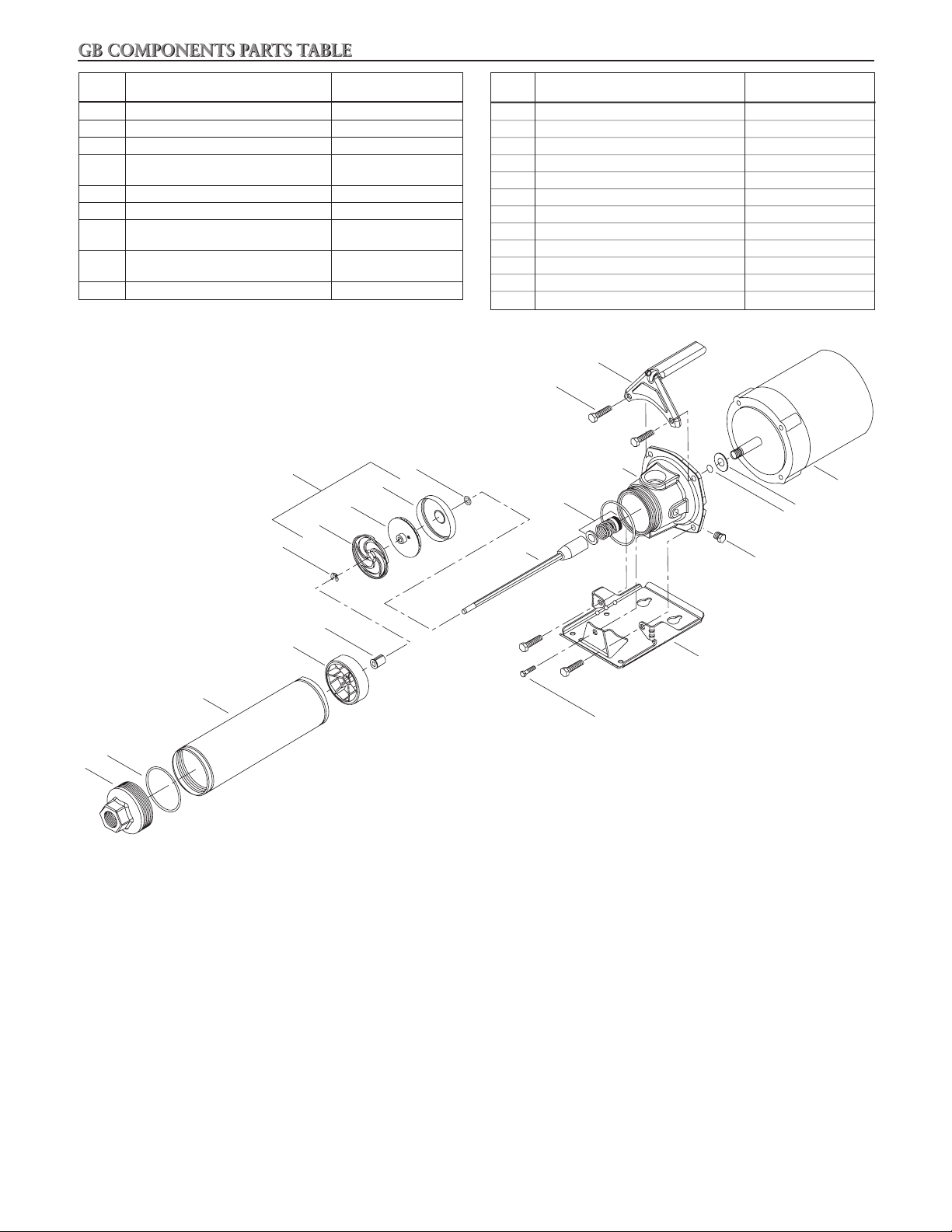

GB COMPONENTS PARTS TABLE

Item

No.

1 Discharge Head Cast Iron

2 O-ring, Casing BUNA

3 Casing 304SS

Polycarbonate

5 Bearing Urethane

6 Klip Ring 301SS

Polycarbonate

Polycarbonate

9 Bowl 304SS

Description Materials

4 Bearing Spider

7 Diffuser

8 Impeller

Glass Filled

Glass Filled

STAGING

7

6

Glass Filled

9

8

Item

No.

10 Shim 304SS

11 Shaft/Coupling Assembly 304SS

12 Mechanical Seal Varies

13 Motor Adapter Cast Iron

14 Screw, Motor Adapter to Motor Steel

15 Handle – optional Steel

16 Screw, Base to Motor Adapter Steel

17 Base Steel

18 Pipe Plug Steel

19 O-ring, Motor Shaft BUNA

20 Deflector BUNA

21 Motor Motor Shaft 300SS

10

Description Materials

15

14

13

12

11

21

20

19

18

5

4

17

3

16

2

1

6

Page 7

GOULDS WATER TECHNOLOGY LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Water Technology.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall exist for a

period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Water Technology distributor from whom the pump was purchased and furnish complete

details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Water Technology Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Water Technology and the dealer in

purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited liability

company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (800) 453-6777

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

© 2012 Xylem Inc. IM055 Revision Number 3 July 2012

7

Page 8

MANUAL DE INSTRUCCIÓN

IM055

Modelo GB

INSTRUCCIONES DE INSTALACIÓN, FUNCIONAMIENTO Y MANTENIMIENTO

8

Page 9

TEMA PÁGINA

Instrucciones de Seguridad ......................................................................................................................................... 10

Datos de Ingeniería .................................................................................................................................................... 10

Tubería ....................................................................................................................................................................... 10

Cableado y Puesta a Tierra ......................................................................................................................................... 10

Rotación ..................................................................................................................................................................... 11

Operación .................................................................................................................................................................. 11

Mantenimiento ........................................................................................................................................................... 11

Desmontaje ................................................................................................................................................................ 11

Reensamblaje .............................................................................................................................................................. 12

Identificación y Resolución de Problemas ................................................................................................................... 12

Componentes de las bombas LB ................................................................................................................................. 13

Garantía Limitada ...................................................................................................................................................... 14

Declaración de Conformidad ...................................................................................................................................... 21

Número de modelo de la bomba:

Número de serie de la bomba:

Representante:

Número telefónico del representante:

Fecha de compra:

Fecha de Instalación:

Lecturas actuales de la puesta en servicio:

1 Ø 3 Ø L1-2 L2-3 L3-1

Amps: Amps:

Voltios: Voltios:

9

Page 10

INSTRUCCIONES DE SEGURIDAD

ADVERTENCIA

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

ADVERTENCIA

PARA EVITAR LESIONES PERSONALES GRAVES O

FATALES, Y DAÑOS SIGNIFICATIVOS A LA PROPIEDAD, LEA Y SIGA TODAS LAS INSTRUCCIONES

DE SEGURIDAD QUE SE ENCUENTRAN EN ESTE

MANUAL O EN LA BOMBA.

ESTE MANUAL TIENE LA FUNCIÓN DE ASISTIRLO

EN LA INSTALACIÓN Y OPERACIÓN DE ESTA UNIDAD Y DEBE CONSERVARSE CON LA BOMBA.

Éste es un SÍMBOLO DE ALERTA DE

SEGURIDAD. Cuando vea este símbolo

sobre la bomba o en el manual, localice

una de las siguientes palabras de señalización y esté alerta ante posibles lesiones personales o daños a la propiedad.

PELIGRO

ADVERTENCIA

PRECAUCIÓN

AVISO: INDICA QUE EXISTEN INSTRUCCIONES

EXAMINE COMPLETAMENTE TODAS LAS INSTRUCCIONES Y ADVERTENCIAS ANTES DE REALIZAR CUALQUIER TRABAJO EN ESTA BOMBA.

CONSERVE TODAS LAS CALCOMANÍAS.

Advierte sobre los peligros que PROVOCARÁN lesiones graves, muerte o daños

significativos a la propiedad.

Advierte sobre los peligros que

PUEDEN PROVOCAR lesiones graves,

muerte o daños significativos a la propiedad.

Advierte sobre los peligros que PRO-

VOCARÁN o PUEDEN PROVOCAR

lesiones o daños a la propiedad.

ESPECIALES MUY IMPORTANTES QUE

DEBEN RESPETARSE.

ESTA UNIDAD NO SE ENCUENTRA

DISEÑADA PARA SER USADA CON

LÍQUIDOS O GASES INFLAMABLES.

ESTOS FLUIDOS PUEDEN ESTAR

PRESENTES EN ÁREAS CONTAMINADAS.

• Carga hasta 600 pies (260 psi)

• Rotación: Hacia la derecha, es decir, en el sentido de

las agujas del reloj cuando se observa desde el extremo

del motor.

TUBERÍA

• La tubería no debe ser menor que las conexiones de

descarga o succión de la bomba. Se debe mantener tan

corta como sea posible, evitando el uso de conexiones

innecesarias para minimizar las pérdidas por fricción.

• Toda la tubería DEBE estar soportada en forma in-

dependiente y NO DEBE existir ninguna carga de la

tubería sobre la bomba.

• Todas las juntas DEBEN ser herméticas. Utilizar 3 ó 4

vueltas de cinta de Teflon™ para sellar las conexiones

roscadas.

CABLEADO Y PUESTA A TIERRA

Instalar el cableado y la puesta

a tierra de acuerdo a los requisitos locales y al Código Eléctrico

Nacional.

Instalar un interruptor de desconexión de todos los circuitos cerca

de la bomba.

Desconectar y bloquear el suministro eléctrico antes de instalar

la bomba o realizar tareas de

mantenimiento.

El suministro eléctrico DEBE ser el que se especifica en la placa nominal de la bomba. Un voltaje

incorrecto puede provocar un incendio y/o dañar el

motor y anular la garantía.

DESCRIPCIÓN Y ESPECIFICACIONES

Las bombas de la Serie GB son bombas portátiles horizontales de etapas múltiples diseñadas para lavados residenciales y agrícolas, aplicaciones de rociado y servicios

de refuerzo en general.

La versión en acero inoxidable 304 se utiliza en la industria de la calefacción y el acondicionamiento de aire, de

filtración y ósmosis inversa y en aplicaciones comerciales

en general.

DATOS DE INGENIERÍA

• Temperatura máxima del líquido: 160°F (72°C)

• Presión máxima de succión: 75 psi

• Las conexiones para la tubería son NPT de 1 pulgada

• Capacidad hasta 33 GPM

10

en la succión y la descarga. Se encuentran disponibles

adaptadores para mangueras de ¾ de pulgada.

Los motores sin protección DEBEN equiparse

con contactores y protectores contra sobrecargas

térmicas si son monofásicos, o con arrancadores

con calentadores si son trifásicos. Consulte la placa

nominal del motor.

• Use únicamente cable trenzado de cobre para la conexión al motor y a tierra. El cable a tierra DEBE ser

por lo menos del mismo tamaño que el cable al motor.

Los cables deben estar codificados con colores para

facilitar el mantenimiento.

Las bombas en aplicaciones de rociado

abierto deben enchufarse en una fuente

de suministro eléctrico protegida por un interruptor de

servicio por falla a tierra. De no hacerlo, podrían ocasionarse lesiones personales graves o fatales y daños materiales.

• Siga cuidadosamente el diagrama de cableado indicado

por el fabricante del motor en la placa nominal o en la

tapa de la terminal.

Page 11

SI LA BOMBA, EL MOTOR Y LOS

Tensión

p

eligrosa

ADVERTENCIA

PRECAUCIÓN

Tensión

p

eligrosa

ADVERTENCIA

Tensión

p

eligrosa

ADVERTENCIA

CONTROLES NO SE CONECTAN A

TIERRA EN FORMA PERMANENTE

ANTES DE CONECTAR LA ALIMENTACIÓN ELÉCTRICA, SE PUEDEN

PRODUCIR SACUDIDAS ELÉCTRICAS, QUEMADURAS Y HASTA LA

MUERTE.

ROTACIÓN

AVISO: LA ROTACIÓN INCORRECTA PUEDE DA-

ÑAR LA BOMBA Y ANULA LA GARANTÍA.

• La rotación correcta es hacia la derecha, en el SENTIDO DE LAS AGUJAS DEL RELOJ cuando se mira

desde el extremo del motor.

Utilizando este método para seleccionar las toberas es

posible mantener una presión positiva en la admisión

de la bomba. Esto evitará que la bomba “robe” agua de

otros grifos.

USO EN GRANJAS LECHERAS

Recomendamos que todas las pistolas WaterGuns® que se

utilizan en granjas que producen leche grado “A” se equipen con un igualador de presión instalado de acuerdo a

las instrucciones que acompañan a este dispositivo. Esto

evitará la presión subatmosférica en la línea de suministro

aún cuando el suministro de agua disminuya. Sugerimos

colgar la pistola WaterGun de la pared, a por lo menos

18 pulgadas del suelo, y contar con un soporte para

mangueras de forma de poder guardar la manguera de

descarga sin que esté en contacto con el piso.

• Para invertir la rotación de un motor trifásico, intercambie dos conductores eléctricos cualesquiera.

OPERACIÓN

SI SE SALPICA O SUMERGE EN

FLUIDOS UN MOTOR ABIERTO A

PRUEBA DE FILTRACIONES PUEDE

OCURRIR UN CORTOCIRCUITO Y

PROVOCARSE UN INCENDIO, SACUDIDAS ELÉCTRICAS, QUEMADURAS,

O INCLUSO LA MUERTE.

AVISO: LA BOMBA DEBE ESTAR TOTALMENTE

CERRADA ANTES DE INICIAR LA OPERACIÓN. NO OPERAR LA BOMBA EN SECO.

• Luego de estabilizar el sistema en las condiciones

normales de operación, controlar la tubería. Si fuera

necesario, ajustar los soportes de la tubería.

No operar la bomba en seco, se dañará el

sello mecánico. No operar contra una

tobera cerrada por períodos de tiempo prolongados pues

se dañarán la bomba y la tubería.

ENSAMBLE DE LA MANIJA

Retirar los dos pernos superiores del adaptador del motor. Insertarlos a través de la parte posterior de la manija

en el adaptador del motor y ajustarlos seguramente.

MANTENIMIENTO

SI NO SE DESCONECTA Y BLOQUEA

EL SUMINISTRO ELÉCTRICO ANTES

DE INTENTAR TAREAS DE MANTENIMIENTO, SE PUEDEN PRODUCIR

SACUDIDAS ELÉCTRICAS, QUEMADURAS O INCLUSO LA MUERTE.

• Los motores tienen cojinetes lubricados en forma

permanente. No es posible, ni necesario, lubricarlos.

Siga las recomendaciones del fabricante para el mantenimiento.

• Para RETIRAR la bomba de servicio, desagote todo el

líquido bombeado de la bomba y la tubería.

• Para VOLVER A PONER la bomba en servicio,

reemplace todos los tapones y tubería utilizando cinta

de Teflon™ o equivalente en las roscas macho.

• Consulte la sección “OPERACIÓN” de este manual.

DESMONTAJE

• Coloque las llaves para tuercas en el adaptador (13)

y el cabezal de descarga (1) y destornille el cabezal de

descarga y la cubierta.

NOTA: LA CARCASA TIENE ROSCA IZQUIERDA EN

AMBOS EXTREMOS Y ESTÁ SELLADA CON

ANILLOS EN O (2).

TOBERAS

Es importante seleccionar la tobera apropiada para el

correcto desempeño de la bomba. Se debe examinar el

grifo que sirve de agua a la bomba para determinar la

velocidad del flujo que proveerá. Si el flujo de un minuto

con el grifo abierto es:

7 galones — Usar la tobera V2005 de 6 gpm

(que se incluye con cada AM2)

6 galones — Usar la tobera V1502 de 5 gpm

5 galones — Usar la tobera SN0045 de 4 gpm

4 galones — Usar la tobera V10152 de 3 gpm

AM

7 Kit

• Retire el anillo de sujeción (6) del extremo del eje (11).

Ahora puede retirar las etapas, consistentes cada una en

un recipiente (9), un impulsor (8) y un difusor (7). Si

la bomba se ha atascado con materia extraña pero no

presenta otros daños, tal vez no sea necesario proseguir

con el desmontaje. Si fuera necesario reemplazar el

conjunto del eje (11), el sello del eje (12) o el motor,

prosiga de acuerdo a las siguientes indicaciones:

• Retire el tapón (18) de la parte posterior del motor y sostenga el eje del motor con un destornillador. Destornille el conjunto del acoplamiento del

eje de la bomba (11) del eje del motor. Retire los

cuatro pernos de montaje del motor (14) y separe

11

Page 12

el motor del marco retirándolo directamente hacia

ADVERTENCIA

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

atrás.

• Puede ser necesario palanquear el motor con dos

destornilladores si el sello del eje se pega. El asiento estacionario del sello del eje puede empujarse

fuera del adaptador desde el lado del motor. Hay

un anillo en O de goma en el acoplamiento (19),

entre el eje del motor y el acoplamiento, que generalmente permanece en el eje del motor mientras

el sello se jala por encima de él.

IDENTIFICACIÓN Y RESOLUCIÓN

DE PROBLEMAS

SI NO SE DESCONECTA Y BLOQUEA

EL SUMINISTRO ELÉCTRICO ANTES

DE INTENTAR TAREAS DE MANTENIMIENTO, SE PUEDEN PRODUCIR

SACUDIDAS ELÉCTRICAS, QUEMADURAS O INCLUSO LA MUERTE.

REENSAMBLAJE

Verifique que el deflector de goma (20) y el anillo en O

del acoplamiento (19) estén sobre el eje del motor. Si

están gastados o dañados, reemplácelos. Instale el asiento

del sello estacionario en el bastidor (13) y monte el bastidor (13) y la manija (15) en el motor. Instale el elemento

rotativo del sello, asegurándose de que las caras estén

limpias y que el último miembro de goma pase sobre el

anillo en O del acoplamiento hasta el eje del motor. Enrosque el conjunto del eje de la bomba y el acoplamiento

(11) hasta que se asiente sobre el eje del motor. Con una

regla atravesada sobre la cara del bastidor, verifique la

ubicación del extremo exterior del acoplamiento. Debido

a variaciones en la longitud del eje del motor, etc., el extremo se encontrará entre 0,030 pulgadas corto o a nivel.

Agregue cuñas 7K155 de 0,010 pulgadas hasta que estén

a nivel o sobresalgan, es decir, hasta que la última cuña

interfiera con la regla. Coloque las etapas requeridas,

controlando cada etapa con la regla atravesada sobre el

recipiente y verificando la ubicación del cubo del impulsor para determinar si es necesario agregar cuñas. Una

vez que todas las etapas estén sobre el eje, reemplace el

anillo de sujeción (6).

Inspeccione el anillo en O en el bastidor y el cabezal de

descarga y reemplácelos si estuvieran dañados. Instale

la carcasa (3) y la cruceta del cojinete (4). Enrosque el

cabezal de descarga (1) (atención: roscas hacia la izquierda) y ajuste.

Con un destornillador en el extremo ranurado del eje de

la bomba, dé vuelta la unidad (en el sentido de las agujas

del reloj) antes de reemplazar el tapón (18). Debe girar

sin ninguna otra resistencia que la del sello del eje.

SÍNTOMA

EL MOTOR NO FUNCIONA

Lea las causas N° 1 a 5 en la lista de causas probables

SE ENTREGA POCO O NADA DE LÍQUIDO

Lea las causas N° 6 a 12 en la lista de causas probables

CONSUMO EXCESIVO DE ELECTRICIDAD

Lea las causas N° 3, 12, 13 y 14 en la lista de causas

probables

RUIDO O VIBRACIÓN EXCESIVOS

Lea las causas N° 3, 6, 7, 10, 13, 15 y 16 en la lista de

causas probables

CAUSAS PROBABLES

1. Se disparó el protector térmico del motor

2. Interruptor de circuito abierto o fusible quemado

3. Agarrotamiento del impulsor

4. El cableado del motor es incorrecto

5. El motor es defectuoso

6. La bomba no está cebada, hay aire o gases en el agua

bombeada.

7. Descarga o succión bloqueadas o válvula cerrada

8. Rotación incorrecta (motor trifásico solamente)

9. Baja tensión o pérdida de fase

10. Impulsor gastado o taponado con residuos

11. Carga del sistema muy alta

12. Diámetro incorrecto del impulsor

13. Carga de descarga muy baja — velocidad excesiva de

flujo

14. Viscosidad y/o gravedad específica del fluido muy

altas

15. Cojinete gastado

16. Bomba, motor o tubería flojos

12

Page 13

COMPONENTES DE LAS BOMBAS GB

Ítem

No.

1 Cabezal de descarga Hierro fundido

2 Anillo en O, carcasa BUNA

3 Carcasa Acero inox. 304

relleno de vidrio

5 Cojinete Uretano

6 Anillo de retención Acero inox. 301

relleno de vidrio

relleno de vidrio

9 Recipiente Acero inox. 304

Descripción Materiales

4 Cruceta del cojinete

7 Difusor

8 Impulsor

Policarbonato

Policarbonato

ETAPAS

6

Policarbonato

8

7

Ítem

No.

10 Cuña Acero inox. 304

11 Ensamble eje/acoplamiento Acero inox. 304

12 Sello mecánico Varía

13 Adaptador del motor Hierro fundido

14 Tornillo, adaptador del motor al motor Acero

15 Manija – optativa Acero

16 Tornillo, base al adaptador del motor Acero

17 Base Acero

18 Tapón de tubería Acero

19 Anillo en O, eje del motor BUNA

20 Deflector BUNA

Acero inox. 300

10

9

Descripción Materiales

21 Motor

Eje del motor

15

14

13

12

11

5

4

3

2

1

17

16

19

18

21

20

13

Page 14

GARANTÍA LIMITADA DE GOULDS WATER TECHNOLOGY

Esta garantía es aplicable a todas las bombas para sistemas de agua fabricadas por Goulds Water Technology.

Toda parte o partes que resulten defectuosas dentro del período de garantía serán reemplazadas sin cargo para el comerciante durante dicho período de garantía. Tal período de

garantía se extiende por doce (12) meses a partir de la fecha de instalación, o dieciocho (18) meses a partir de la fecha de fabricación, cualquiera se cumpla primero.

Todo comerciante que considere que existe lugar a un reclamo de garantía deberá ponerse en contacto con el distribuidor autorizado de Goulds Water Technology del

cual adquiriera la bomba, y ofrecer información detallada con respecto al reclamo. El distribuidor está autorizado a liquidar todos los reclamos por garantía a través del

Departamento de Servicios a Clientes de Goulds Water Technology.

La presente garantía excluye:

(a) La mano de obra, el transporte y los costos relacionados en los que incurra el comerciante;

(b) los costos de reinstalación del equipo reparado;

(c) los costos de reinstalación del equipo reemplazado;

(d) daños emergentes de cualquier naturaleza; y

(e) el reembolso de cualquier pérdida causada por la interrupción del servicio.

A los fines de esta garantía, los términos “Distribuidor”, “Comerciante” y “Cliente” se definen como sigue:

(1) “Distribuidor” es aquel individuo, sociedad, corporación, asociación u otra entidad jurídica que opera entre Goulds Water Technology y el comerciante para la compra,

consignación o contratos de venta de las bombas en cuestión.

(2) “Comerciante” es todo individuo, sociedad, corporación, asociación u otra entidad jurídica que realiza negocios de venta o alquiler-venta (leasing) de bombas a clientes.

(3) “Cliente” es toda entidad que compra o que adquiere bajo la modalidad de leasing las bombas en cuestión de un comerciante. El término “cliente” puede significar un

individuo, una sociedad, una corporación, una sociedad de responsabilidad limitada, una asociación o cualquier otra entidad jurídica con actividades en cualquier tipo de

negocios.

LA PRESENTE GARANTÍA SE EXTIENDE AL COMERCIANTE ÚNICAMENTE

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Teléfono: (800) 453-6777

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds es una marca registrada de Goulds Pumps, Inc. y se utiliza bajo licencia.

© 2012 Xylem Inc. IM055 Revisión Número 3 Julio 2012

Page 15

MANUEL D'UTILISATION

IM055

Modèle GB

DIRECTIVES D’INSTALLATION, D’UTILISATION ET D’ENTRETIEN

Page 16

SUJET PAGE

Consignes de Sécurité ................................................................................................................................................. 17

Données Techniques ................................................................................................................................................... 17

Tuyauterie .................................................................................................................................................................. 17

Câblage et Mise à la Terre .......................................................................................................................................... 17

Rotation ..................................................................................................................................................................... 18

Utilisation ................................................................................................................................................................... 18

Entretien .................................................................................................................................................................... 18

Démontage ................................................................................................................................................................. 18

Remontage ................................................................................................................................................................. 19

Diagnostic des Anomalies ........................................................................................................................................... 19

Table de Composants du Modèle GB .......................................................................................................................... 20

Déclaration de Conformité ......................................................................................................................................... 21

Garantie Limitée......................................................................................................................................................... 24

Informations pour le propriétaire

Numéro de modèle de la pompe :

Numéro de série de la pompe :

Détaillant :

Nº de téléphone du détaillant :

Date d’achat :

Date d’installation :

Courant mesuré au démarrage :

1 Ø 3 Ø L1-2 L2-3 L3-1

A : A :

V : V :

16

Page 17

CONSIGNES DE SÉCURITÉ

DANGER

AVERTISSEMENT

AVERTISSEMENT

Les fluides dangereux

peuvent causer un

incendie, des brûlures

ou la mort.

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures

ou la mort.

AVERTISSEMENT

Tension

dangereuse

AVERTISSEMENT

AFIN DE PRÉVENIR LES BLESSURES GRAVES OU

MORTELLES ET LES DOMMAGES MATÉRIELS

IMPORTANTS, LIRE ET SUIVRE TOUTES LES

CONSIGNES DE SÉCURITÉ FIGURANT DANS LE

MANUEL ET SUR LA POMPE.

LE PRÉSENT MANUEL A POUR BUT DE FACILITER

L’INSTALLATION ET L’UTILISATION DE LA POMPE ET DOIT RESTER PRÈS DE CELLE-CI.

Le symbole ci-contre est un SYMBOLE

DE SÉCURITÉ employé pour signaler

les mots-indicateurs dont on trouvera la

description ci-dessous. Sa présence sert à

attirer l’attention afin d’éviter les blessures

et les dommages matériels.

Prévient des risques qui VONT causer

des blessures graves, la mort ou des

dommages matériels importants.

Prévient des risques qui PEUVENT

causer des blessures graves, la mort ou

des dommages matériels importants.

ATTENTION

AVIS : SERT À ÉNONCER LES DIRECTIVES

SPÉCIALES DE GRANDE IMPORTANCE

QUE L’ON DOIT SUIVRE.

LIRE SOIGNEUSEMENT CHAQUE DIRECTIVE ET

AVERTISSEMENT AVANT D’EFFECTUER TOUT

TRAVAIL SUR LA POMPE.

N’ENLEVER AUCUN AUTOCOLLANT DE SÉCURITÉ.

Prévient des risques qui PEUVENT causer

des blessures ou des dommages matériels.

APPAREIL NON CONÇU POUR LES

LIQUIDES DANGEREUX NI POUR

LES GAZ INFLAMMABLES. CES

FLUIDES POURRAIENT ÊTRE PRÉSENTS DANS LES INSTALLATIONS

DE CONFINEMENT (PUITS COLLECTEURS).

TUYAUTERIE

• An de réduire les pertes de charge au minimum, on

devrait maintenir la tuyauterie aussi courte que possible, ne pas employer un calibre de tuyau inférieur

à celui des raccords d’aspiration et de refoulement

ni utiliser d’accessoires ou de raccords de tuyauterie

superflus.

• Tous les tuyaux DOIVENT posséder leurs propres

supports et N’appliquer AUCUNE contrainte sur la

pompe.

• Chaque joint DOIT être étanche. Enrouler les raccords

filetés de 3 ou 4 couches de ruban de téflonMC pour les

étancher.

CÂBLAGE ET MISE À LA TERRE

Poser le fil de terre et les autres

fils suivant les prescriptions du

code provincial ou national de

l’électricité.

Poser un sectionneur tout conducteur près de la pompe.

Verrouiller la source d’alimentation électrique en position ouverte

avant de procéder à l’installation

ou à l’entretien de la pompe.

L’alimentation électrique DOIT être conforme aux

spécifications de la plaque signalétique. Une tension inappropriée peut causer un incendie ou des

dommages au moteur et annule la garantie.

Les moteurs monophasés non protégés DOIVENT

être munis de contacteurs et de dispositifs de

protection contre les surcharges thermiques, et les

moteurs triphasés, de démarreurs à dispositif de

protection contre la surcharge. Consulter la plaque

signalétique du moteur.

DESCRIPTION et CARACTÉRISTIQUES

La pompe de la série GB est une pompe multi-étagée,

horizontale, portative, conçue pour l’augmentation de

pression générale, la nébulisation et le lavage au jet à des

fins domestiques et agricoles.

Sa version en inox 304 est utilisée pour les systèmes commerciaux ordinaires, de CVCA (chauffage, ventilation et

conditionnement d’air), de séparation par osmose inverse

et de filtrage.

DONNÉES TECHNIQUES

• Température maximale du liquide : 72 °C (160 °F).

• Pression d’aspiration maximale : 75 lb/po2.

• Raccords d’aspiration et de refoulement : 1 po NPT ;

• Débit de refoulement maximal : 33 gal US/min.

• Hauteur de charge maximale : 600 pi (à 260 lb/po2).

• Rotation : sens horaire (vers la droite, vu de l’extrémité

adaptateurs pour tuyaux flexibles de ¾ po offerts.

du moteur).

• N’utiliser que du l torsadé en cuivre pour la mise

à la terre et l’alimentation du moteur. Le calibre du

fil de terre DOIT être au moins égal à celui des fils

d’alimentation, et les fils devraient tous être chromocodés pour faciliter l’entretien.

On doit brancher les pompes servant à

la nébulisation ou au lavage au jet sur

une prise munie d’un disjoncteur de fuite à la terre pour

prévenir les blessures graves ou mortelles ainsi que les

dommages matériels.

• Suivre soigneusement le schéma de câblage sur la

plaque signalétique ou le cache-bornes du moteur.

OMETTRE LA MISE À LA TERRE PERMANENTE DE LA POMPE, DU MOTEUR OU DES COMMANDES AVANT

LE BRANCHEMENT À LA SOURCE

DE COURANT PEUT CAUSER UNE

COMMOTION ÉLECTRIQUE, DES

BRÛLURES OU LA MORT.

17

Page 18

ROTATION

AVERTISSEMENT

Tension

dangereuse

ATTENTION

AVERTISSEMENT

Tension

dangereuse

AVIS : LA ROTATION DANS LE MAUVAIS SENS

PEUT ENDOMMAGER LA POMPE ET ANNULE LA GARANTIE.

• La rotation appropriée est en sens HORAIRE (vers la

droite), vue de l’extrémité du moteur.

• Pour inverser la rotation des moteurs triphasés, en

intervertir deux des conducteurs.

UTILISATION

USAGE AGRICOLE JOURNALIER

Il est recommandé que tous les appareils WaterGunMD

utilisés sur les fermes produisant du lait de catégorie A

soient munis d’un casse-vide installé conformément aux

directives fournies avec le casse-vide. On évitera ainsi

la création d’une pression négative dans les conduites

d’alimentation, même si l’alimentation en eau diminuait. Il est suggéré d’accrocher le WaterGun au mur, à au

moins 18 po du plancher, et d’employer un support pour

ranger le tuyau de refoulement flexible de manière à que

le tuyau ne touche pas au plancher.

ARROSER UN MOTEUR ABRITÉ OU

LE PLONGER DANS UN LIQUIDE

PEUT CAUSER UN COURT-CIRCUIT,

UNE COMMOTION ÉLECTRIQUE,

DES BRÛLURES OU LA MORT.

AVIS : ON DOIT REMPLIR LA POMPE ENTIÈRE-

MENT POUR L’AMORCER AVANT DE

L’UTILISER. NE PAS FAIRE FONCTIONNER

LA POMPE À SEC.

• Faire fonctionner la pompe dans des conditions de

service normales, attendre que le système se stabilise,

vérifier la tuyauterie et régler les supports de celle-ci au

besoin.

Ne pas utiliser la pompe à sec pour ne pas

endommager la garniture (joint) mécanique. Ne pas la faire tourner longtemps lorsque l’ajutage

(sortie) est fermé, car cela endommagera la pompe et la

tuyauterie.

POSE DE LA POIGNÉE

Enlever les deux vis de fixation supérieures de

l’adaptateur de moteur, placer les deux trous de boulon

de la poignée en face de ceux de l’adaptateur, reposer les

vis et les serrer à fond.

ENTRETIEN

OMETTRE LE VERROUILLAGE DE

LA SOURCE D’ALIMENTATION

ÉLECTRIQUE EN POSITION OUVERTE PEUT CAUSER UNE COMMOTION ÉLECTRIQUE, DES BRÛLURES

OU LA MORT.

• Les moteurs sont dotés de roulements à billes lubriés

à vie. Aucune lubrification n’est donc nécessaire ni

possible. Suivre les recommandations du fabricant du

moteur.

• Pour mettre une pompe HORS service, vidanger la

pompe et tous les tuyaux.

• Pour remettre une pompe EN service, reposer tous les

bouchons de vidange après avoir recouvert les filets

extérieurs de ruban de téflonMC ou l’équivalent.

• Voir la section « UTILISATION » ci-dessus.

DÉMONTAGE

• À l’aide de deux clés – l’une sur l’adaptateur (13) et

l’autre sur la tête de refoulement (1) –, dévisser cette

dernière et le corps de pompe (3).

AJUTAGE

Il importe de choisir l’ajutage approprié pour optimiser

les performances de la pompe. On devrait vérifier le débit

du robinet d’alimentation de la pompe. Si le débit en gal

US/min est :

De 7, employer un ajutage V2005 (6 gal US/min),

inclus avec les AM2.

De 6, utiliser un ajutage V1502

(5 gal US/min).

De 5, utiliser un ajutage SN0045

(4 gal US/min).

Nécessaire

AM 7

De 4, employer un ajutage V10152

(3 gal US/min).

Cette méthode de sélection des ajutages permet de

maintenir une pression positive à l’entrée de la pompe et

d’empêcher cette dernière de « couper » l’alimentation en

eau des autres sorties (robinets).

18

NOTA : LE CORPS DE POMPE EST FILETÉ À

GAUCHE À CHAQUE EXTRÉMITÉ, ET

SON ÉTANCHÉITÉ EST ASSURÉE PAR DES

JOINTS TORIQUES (2).

• Enlever l’agrafe de retenue (6) de l’extrémité de l’arbre

(11). On peut maintenant démonter chaque étage, formé d’un corps d’étage (9), d’une roue (8) et d’un diffuseur (7). Si la pompe est engorgée sans pour autant

être endommagée, un démontage plus poussé peut être

inutile. Si l’on doit remplacer l’arbre (11), la garniture

mécanique (12) ou le moteur, procéder comme suit :

• Enlever le bouchon (18) situé à l’arrière du moteur et

bloquer l’arbre de moteur avec un tournevis. Dévisser l’ensemble accouplement-arbre de pompe (11).

Enlever les quatre vis de fixation (14) de l’adaptateur

de moteur. Séparer le moteur de l’adaptateur en le

tirant en ligne droite.

• Si la garniture mécanique est grippée sur l’arbre, on

peut employer deux tournevis en guise de leviers

pour retirer le moteur. On peut pousser l’élément

Page 19

fixe de la garniture hors de l’adaptateur en se plaçant

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures

ou la mort.

du côté moteur. Un joint torique en caoutchouc est

monté entre l’arbre de moteur et l’accouplement et

reste habituellement sur l’arbre lorsque la garniture

est retirée.

REMONTAGE

Vérifier si le déflecteur (20) en caoutchouc et le joint

torique (19) de l’accouplement sont montés sur l’arbre

de moteur. S’ils sont usés ou endommagés, les remplacer.

Poser l’élément fixe de la garniture mécanique dans

l’adaptateur (13), puis fixer l’adaptateur et la poignée

(15) au moteur. Mettre l’élément mobile de la garniture

en place tout en s’assurant que ses surfaces sont propres

et que son dernier élément en caoutchouc glisse par-dessus le joint torique de l’accouplement, puis sur l’arbre de

moteur. Visser l’ensemble accouplement-arbre de pompe

(11) à fond sur l’arbre de moteur. Avec une règle rectifiée placée en travers des bords de l’adaptateur, vérifier

la position de l’extrémité extérieure de l’accouplement.

En raison de variations dans la longueur de l’arbre de

moteur, notamment, l’extrémité peut affleurer ou être

jusqu’à 0,030 po trop à l’intérieur. En pareil cas, poser

des cales 7K155 de 0,010 po contre l’extrémité extérieure de l’accouplement jusqu’à ce qu’elles affleurent ou

dépassent la règle (la dernière cale touche alors la règle).

Remettre les étages requis en place tout en vérifiant, avec

une règle rectifiée placée en travers des bords de chaque

corps d’étage (cuvette), si le moyeu de roue de chaque

étage est bien placé ou s’il est nécessaire d’ajouter des

cales. Une fois les étages correctement en place, reposer

l’agrafe de retenue (6).

Vérifier le joint torique du corps de pompe et celui de la

tête de refoulement et les remplacer s’ils sont endommagés. Poser le corps de pompe (3) et la bague d’espacement

(4) du coussinet. Visser la tête de refoulement en place

(filetage à gauche) et à fond.

Avec un tournevis inséré par l’orifice du bouchon (18)

dans la fente située à l’extrémité de l’arbre de pompe,

faire tourner l’arbre dans le sens horaire : il devrait

tourner sans autre résistance que celle de la garniture

mécanique de l’arbre. Remettre le bouchon en place.

DIAGNOSTIC DES ANOMALIES

OMETTRE LE VERROUILLAGE DE

LA SOURCE D’ALIMENTATION

ÉLECTRIQUE EN POSITION OUVERTE PEUT CAUSER UNE COMMOTION ÉLECTRIQUE, DES BRÛLURES

OU LA MORT.

ANOMALIE

NON-FONCTIONNEMENT DU MOTEUR

(V. causes probables 1 à 5)

DÉBIT DE REFOULEMENT FAIBLE OU NUL

(V. causes probables 6 à 12)

CONSOMMATION D’ÉNERGIE EXCESSIVE

(V. causes probables 3, 12, 13 et 14)

VIBRATION ET BRUIT EXCESSIFS

(V. causes probables 3, 6, 7, 10, 13, 15 et 16)

CAUSES PROBABLES

1. Protecteur thermique du moteur déclenché

2. Disjoncteur ouvert ou fusible sauté

3. Roue grippée

4. Moteur mal connecté

5. Moteur défectueux

6. Pompe non amorcée, air ou gaz présent dans le

liquide pompé

7. Tuyau d’aspiration ou de refoulement obstrué ou

robinet fermé

8. Mauvais sens de rotation (moteurs triphasés

seulement)

9. Basse tension électrique ou perte de phase

10. Roue usée ou engorgée

11. Hauteur de charge trop élevée du système

12. Diamètre de roue inapproprié

13. Hauteur de refoulement trop faible - débit excessif

14. Viscosité ou densité trop élevée du liquide

15. Roulements usés

16. Pompe, moteur ou tuyauterie mal assujettis

19

Page 20

TABLE DE COMPOSANTS DE LA SÉRIE GB

No

d’article

1 Tête de refoulement Fonte

2 Joint torique (corps de pompe) Buna

3 Corps de pompe Inox 304

de fibre de verre

5 Coussinet Uréthane

6 Agrafe de retenue Inox 301

de fibre de verre

de fibre de verre

9 Corps d’étage (cuvette) Inox 304

Description Matériaux

4 Bague d’espacement (coussinet)

7 Diffuseur

8 Roue

Polycarbonate chargé

Polycarbonate chargé

Polycarbonate chargé

No

d’article

10 Cale Inox 304

11 Ensemble accouplement-arbre de pompe Inox 304

12 Garniture mécanique Varient

13 Adaptateur de moteur Fonte

14 Vis (adaptateur de moteur, moteur) Acier

15 Poignée (en option) Acier

16 Vis (plaque-support, adaptateur) Acier

17 Plaque-support Acier

18 Bouchon (conduite) Acier

19 Joint torique (arbre de moteur) Buna

20 Déflecteur Buna

21 Moteur Arbre en inox 300

Description Matériaux

14

ÉTAGE

8

7

6

5

4

3

2

1

10

9

12

11

16

15

13

21

20

19

18

17

20

Page 21

Declaration of Conformity

Declaration of Conformity

We at,

Goulds Water Technology/Xylem Inc.

1 Goulds Drive

Auburn, NY 13021

Declare that the following products: NPE, MCS, MCC, 3656, 3656 SP, GB, e-SV, SVI, NPO, Prime Line

SP, HB, HMS, LC, NPV, LB, LBS comply with Machine Directive 06/42/EC. This equipment is intended

to be incorporated with machinery covered by this directive, but must not be put into service until the

machinery into which it is to be incorporated has been declared in conformity with the actual provisions

of the directive.

Declaración de Conformidad

Declaración de Conformidad

Nosotros en

Goulds Water Technology/Xylem Inc.

1 Goulds Drive

Auburn, NY 13021

Declaramos que los siguientes productos: NPE, MCS, MCC, 3656, 3656 SP, GB, e-SV, SVI, NPO, Prime

Line SP, HB, HMS, LC, NPV, LB, LBS cumplen con las Directivas para Maquinarias 06/42/EC. Este

equipo ha sido diseñado para ser incorporado a la maquinaria cubierta por esta directiva pero no debe

ponerse en funcionamiento hasta que se declare que la maquinaria en la que será incorporado cumple

con las disposiciones reales de la directiva.

Déclaration de Conformité

Déclaration de Conformité

Nous, à

Goulds Water Technology/Xylem Inc.

1 Goulds Drive

Auburn, NY, U.S.A. 13021,

déclarons que les produits NPE, MCS, MCC, 3656, 3656 SP, GB, e-SV, SVI, NPO, Prime Line SP, HB,

HMS, LC, NPV, LB et LBS sont conformes à la directive 06/42/EC (législation relative aux machines). Ils

sont destinés à être intégrés dans la machinerie faisant l’objet de ladite directive, mais ne doivent pas être

mis en service tant que la machinerie en question ne sera pas déclarée conforme aux stipulations de la

directive.

21

Page 22

NOTES/NOTAS

22

Page 23

NOTES/NOTAS

23

Page 24

GARANTIE LIMITÉE DE GOULDS WATER TECHNOLOGY

La présente garantie s’applique à chaque pompe de système d’alimentation en eau fabriquée par Goulds Water Technology.

Toute pièce se révélant défectueuse durant la période de garantie sera remplacée sans frais pour le détaillant durant ladite période, qui dure douze (12) mois à compter de la

date d’installation ou dix-huit (18) mois à partir de la date de fabrication, soit la période qui expirera la première.

Le détaillant qui, aux termes de cette garantie, désire effectuer une demande de règlement doit s’adresser au distributeur Goulds Water Technology agréé chez lequel la pompe

a été achetée et fournir tous les détails à l’appui de sa demande. Le distributeur est autorisé à régler toute demande par le biais du service à la clientèle de Goulds Water

Technology.

La garantie ne couvre pas :

a) les frais de main-d’oeuvre ou de transport ni les frais connexes encourus par le détaillant ;

b) les frais de réinstallation de l’équipement réparé ;

c) les frais de réinstallation de l’équipement de remplacement ;

d) les dommages indirects de quelque nature que ce soit ;

e) ni les pertes découlant de la panne.

Aux fins de la présente garantie, les termes ci-dessous sont définis comme suit :

1) «Distributeur» signifie une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique servant d’intermédiaire entre Goulds

Water Technology et le détaillant pour les achats, les consignations ou les contrats de vente des pompes en question.

2) «Détaillant» veut dire une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique dont les activités commerciales sont la

vente ou la location de pompes à des clients.

3) «Client» signifie une entité qui achète ou loue les pompes en question chez un détaillant. Un «client» peut être une personne, une société de personnes, une société de

capitaux, une société à responsabilité limitée, une association ou autre entité juridique se livrant à quelque activité que ce soit.

CETTE GARANTIE SE RAPPORTE AU DÉTAILLANT SEULEMENT.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Téléphone: (800) 453-6777

Télécopie: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds est une marque déposée de Goulds Pumps, Inc. et est utilisé sous le permis.

© 2012, Xylem Inc. IM055 Révision numéro 3 Juillet 2012

Loading...

Loading...