Page 1

Installation,

Operation, and

Maintenance Manual

Flygt 3201

Page 2

Page 3

Table of Contents

Introduction and Safety.........................................................................................................................3

Safety.....................................................................................................................................................3

Safety message levels......................................................................................................................3

User health and safety......................................................................................................................4

Safety regulations for Ex-approved products in potentially explosive atmospheres..............6

Environmental safety........................................................................................................................7

Product warranty.................................................................................................................................7

Spare parts........................................................................................................................................8

Transportation and Storage..................................................................................................................9

Inspect the unit upon delivery...........................................................................................................9

Receive the unit.................................................................................................................................9

Unpack the unit.................................................................................................................................9

Lifting guidelines.................................................................................................................................9

Store the unit.....................................................................................................................................10

Product Description.............................................................................................................................11

Pump design......................................................................................................................................11

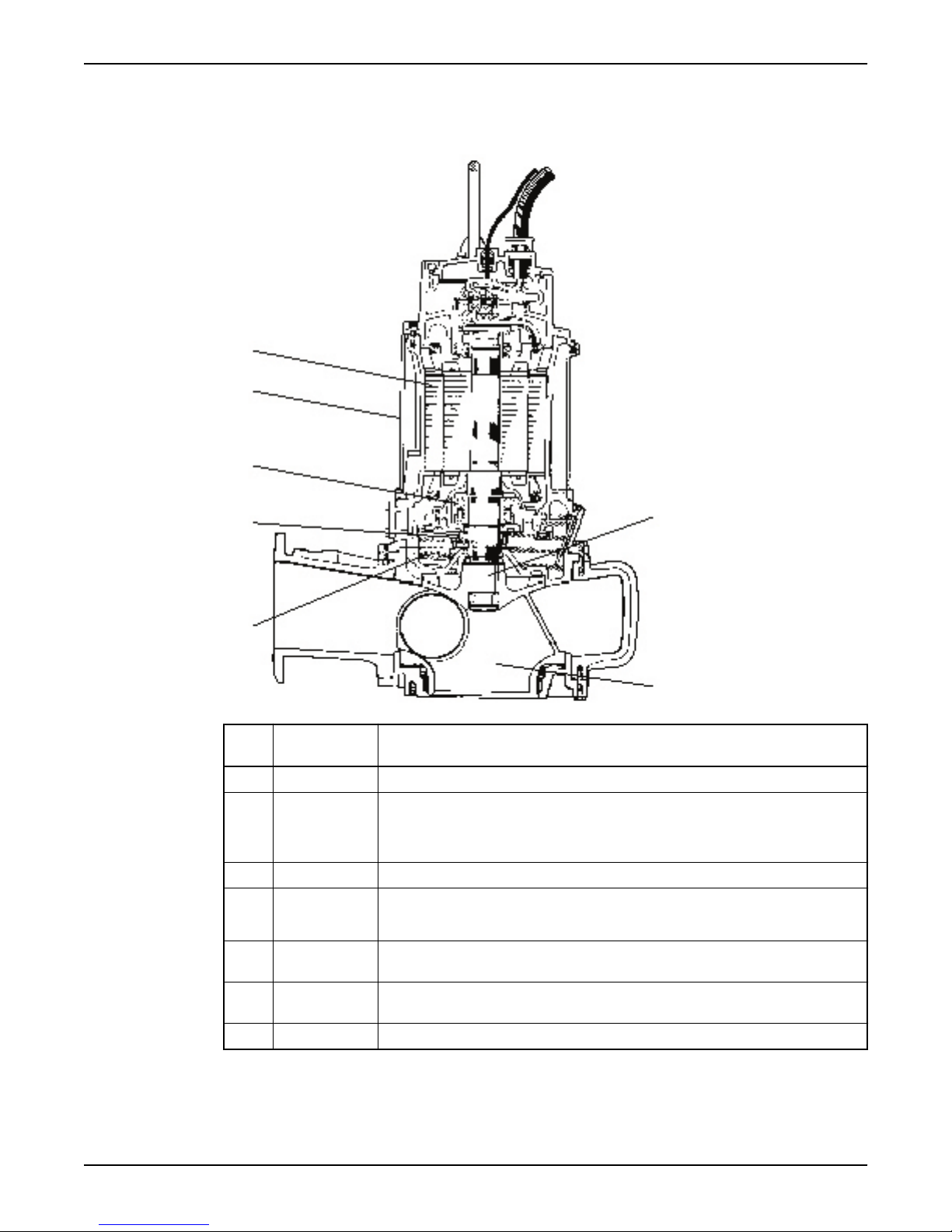

Parts....................................................................................................................................................12

Monitoring equipment.....................................................................................................................13

Optional sensors.............................................................................................................................13

The data plate....................................................................................................................................14

Approvals...........................................................................................................................................14

Product denomination......................................................................................................................15

Table of Contents

Installation.............................................................................................................................................17

Install the pump.................................................................................................................................17

Install with P-installation.................................................................................................................17

Install with S-installation.................................................................................................................18

Install with T/Z-installation.............................................................................................................19

Make the electrical connections......................................................................................................21

General precautions.......................................................................................................................21

Requirements..................................................................................................................................21

Cables..............................................................................................................................................21

Earthing (Grounding).....................................................................................................................22

Connect the motor cable to the pump........................................................................................22

Connect the motor cable to the starter and monitoring equipment.......................................23

Cable charts....................................................................................................................................24

Check the impeller rotation.............................................................................................................29

Operation..............................................................................................................................................31

Distance to wet areas........................................................................................................................31

Start the pump...................................................................................................................................31

Maintenance.........................................................................................................................................32

Maintenance guidelines...................................................................................................................32

Torque values....................................................................................................................................32

Change the oil...................................................................................................................................33

Replace the wear rings.....................................................................................................................34

Replace the wear ring in the pump housing, diffuser ring, or suction cover..........................34

Replace the impeller wear ring.....................................................................................................35

Replace the impeller.........................................................................................................................35

Flygt 3201 Installation, Operation, and Maintenance Manual 1

Page 4

Table of Contents

Remove the impeller and the wear protections ........................................................................36

Install the impeller and the wear protections.............................................................................36

Adjust the lower wear protection.................................................................................................37

Service the pump..............................................................................................................................37

Intermediate service.......................................................................................................................37

Major service...................................................................................................................................38

Service in case of alarm.................................................................................................................39

Troubleshooting...................................................................................................................................40

Introduction.......................................................................................................................................40

The pump does not start..................................................................................................................40

The pump does not stop when a level sensor is used.................................................................41

The pump starts-stops-starts in rapid sequence...........................................................................41

The pump runs but the motor protection trips.............................................................................42

The pump delivers too little or no water........................................................................................42

Technical reference.............................................................................................................................44

Application limits...............................................................................................................................44

Motor data..........................................................................................................................................44

2 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 5

Introduction and Safety

Safety

WARNING:

• The operator must be aware of safety precautions to prevent physical injury.

• Any pressure-containing device can explode, rupture, or discharge its contents if it is

over-pressurized. Take all necessary measures to avoid over-pressurization.

• Operating, installing, or maintaining the unit in any way that is not covered in this manual

could cause death, serious personal injury, or damage to the equipment. This includes

any modification to the equipment or use of parts not provided by Xylem. If there is a

question regarding the intended use of the equipment, please contact an Xylem

representative before proceeding.

• Do not change the service application without the approval of an authorized Xylem

representative.

• Never operate the pump without safety devices installed.

• Never operate the pump with the discharge valve closed.

NOTICE:

For information about how to transport and store the pump, see Transportation and

Storage in the Installation, Operation and Maintenance manual.

Introduction and Safety

Safety message levels

Definitions

Safety message level Indication

DANGER:

WARNING:

CAUTION:

Electrical Hazard:

A hazardous situation which, if not avoided, will result in

death or serious injury

A hazardous situation which, if not avoided, could result

in death or serious injury

A hazardous situation which, if not avoided, could result

in minor or moderate injury

The possibility of electrical risks if instructions are not

followed in a proper manner

Flygt 3201 Installation, Operation, and Maintenance Manual 3

Page 6

Introduction and Safety

Safety message level Indication

NOTICE:

User health and safety

General precautions

The product is designed for use in liquids that can be hazardous to health. Observe these

rules when working with the product:

• Make sure that all personnel who work with sewage systems are vaccinated against

diseases to which they may be exposed.

• Observe strict personal cleanliness.

Safety equipment

Use safety equipment according to the company regulations. Use this safety equipment

within the work area:

• Helmet

• Safety goggles (with side shields)

• Protective shoes

• Protective gloves

• Gas mask

• Hearing protection

• A potential situation which, if not avoided, could

result in an undesirable result or state

• A practice not related to personal injury

NOTICE:

The noise level of the product is lower than 70 dB. However, the noise level of 70 dB

may be exceeded in some installations and at certain operating points on the

performance curve. Make sure that you understand the noise level requirements in the

environment where the pump is installed. Failure to do so may result in hearing loss or

violation of local laws.

The work area

Observe these regulations and warnings in the work area:

• Always keep the work area clean.

• Pay attention to the risks presented by gas and vapors in the work area.

• Avoid all electrical dangers. Pay attention to the risks of electric shock or arc flash

hazards.

Product and product positioning requirements

Observe these requirements for the product and the product positioning:

• Vent the tank of a sewage station in accordance with local plumbing codes.

• Never operate a pump unless safety devices are installed.

Electrical connections regulations

Electrical connections must be made by certified electricians in compliance with all

international, national, state, and local regulations.

Observe these guidelines and warnings for electrical connections:

• Make sure that the product is isolated from the power supply and cannot be energized

by mistake. This guideline also applies to the control circuit.

• Make sure that the thermal contacts are connected to a protection circuit according to

the product approvals, and that they are in use.

4 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 7

Earthing (grounding)

Introduction and Safety

• Make sure that the cable and the cable entry have not been damaged during shipping.

• Use only the screened cable when using a variable-frequency drive (VFD). The

screened cable is necessary to fulfill European CE requirements. Contact your Xylem

representative and ask your VFD supplier for electrical limitations. See also VFD

recommendation in article no. 893472.

Observe the following regulations for earthing (grounding) connections.

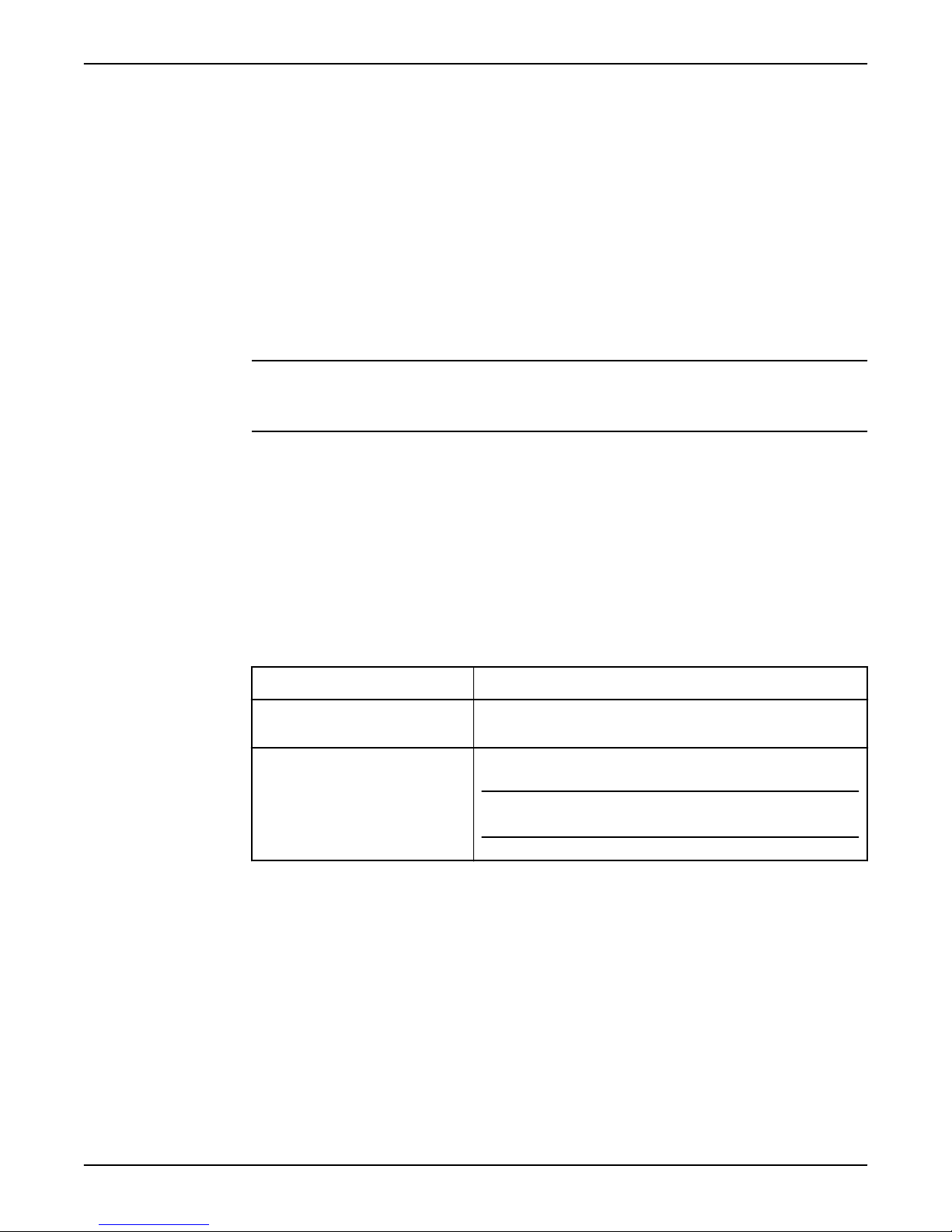

Earthing (grounding) regulation Comment

All electric equipment must be earthed (grounded). This rule applies to pumps and mixers as well as

monitoring equipment.

The earthing (grounding) conductors must be correctly

connected.

The earthing (grounding) conductors should always be

longer than the phase conductor/conductors.

Risk of electrical shock or burn. You must connect an

additional earth- (ground-) fault protection device to the

earthed (grounded) connectors if persons are likely to

come into physical contact with the pump or pumped

liquids.

Precautions before work

Observe these safety precautions before you work with the product or are in connection

with the product:

• Provide a suitable barrier around the work area, for example, a guard rail.

• Make sure that all safety guards are in place and secure.

• Allow all system and pump components to cool before you handle them.

• Make sure that you have a clear path of retreat.

• Make sure that the product cannot roll or fall over and injure people or damage

• Make sure that the lifting equipment is in good condition.

• Use a lifting harness, a safety line, and a breathing device as required.

• Make sure that the product is thoroughly clean.

• Make sure that there are no poisonous gases within the work area.

• Make sure that you have quick access to a first-aid kit.

• Disconnect and lock out power before servicing.

• Check the explosion risk before you weld or use electric hand tools.

Failure to follow this rule could result in a fatal accident.

If the motor cable is disconnected by mistake, the

earthing (grounding) conductor needs to be

disconnected last from its terminal. This rule applies to

both ends of the cable.

—

property.

Precautions during work

Observe these safety precautions when you work with the product or are in connection

with the product:

• Never work alone.

• Always wear protective clothing and hand protection.

• Stay clear of suspended loads.

• Always lift the product by its lifting device.

• Never lift the product by its motor cable or hose.

• Beware of the risk of a sudden start if the product is used with an automatic level

control.

• Beware of the starting jerk, which can be powerful.

• Rinse the components in water after you disassemble the pump.

Flygt 3201 Installation, Operation, and Maintenance Manual 5

Page 8

Introduction and Safety

• Do not open any vent or drain valve or remove any plugs while the system is

pressurized. Make sure that the pump is isolated from the system and that pressure is

relieved before you disassemble the pump, remove plugs, or disconnect piping.

• Always bear in mind the risk of drowning, electrical accidents, and burn injuries.

Clean chemicals from the eyes

1. Hold your eyelids apart forcibly with your fingers.

2. Rinse the eyes for at least 15 minutes.

Use an eyewash or running water.

3. Seek medical attention.

Clean chemicals from the body

1. Remove contaminated clothing.

2. Wash the skin with soap and water for at least one minute.

3. Seek medical attention, if required.

Safety regulations for Ex-approved products in potentially explosive atmospheres

General guidelines

ATEX compliance is only fulfilled when the pump is operated within its intended use, for

example within its intended hydraulic range. The conditions of the service must not be

changed without approval of an authorized Xylem representative. When installing or

maintaining ATEX-compliant pumps, follow these guidelines:

• Always install ATEX-approved equipment in compliance with the directive and

applicable standards (IEC/EN 60079–14).

• Always install FM-approved products according to ANSI/NFPA 70-2005.

WARNING:

Installation, Operation, and Maintenance manuals clearly identify accepted methods for

disassembling units. These methods must be adhered to. Trapped liquid can rapidly

expand and result in a violent explosion and injury. Never apply heat to impellers,

propellers, or their retaining devices to aid in their removal.

If there are any questions regarding these requirements, the intended use, or if the

equipment requires modification, contact an Xylem representative before you proceed.

Personnel requirements

Xylem disclaims all responsibility for work done by untrained and unauthorized personnel.

These are the personnel requirements for Ex-approved products in potentially explosive

atmospheres:

• All work on the product must be carried out by certified electricians and Xylem-

authorized mechanics. Special rules apply to installations in explosive atmospheres.

• All users must know about the risks of electric current and the chemical and physical

characteristics of the gas and/or vapor present in hazardous areas.

• The maintenance operation for Ex-approved products must be made in conformity to

the international or national standards (IEC/EN 60079-17).

Product and product handling requirements

These are the product and product handling requirements for Ex-approved products in

potentially explosive atmospheres:

• Only use the product in accordance with the approved motor data stated on the

nameplates.

• The Ex-approved product must never run dry during normal operation. Dry running

during service and inspection is only permitted outside the classified area.

6 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 9

• See the dimensional drawings of the product for the minimum permitted water level

according to the ATEX approval. Level-sensing equipment must be installed if the

product can be operated at less than the minimum submersion depth.

• Before you start working with the product, make sure that the product and the control

panel are isolated from the power supply and the control circuit, so they cannot be

energized.

• Do not open the product while it is energized or in an explosive gas atmosphere.

• Make sure that thermal contacts are connected to a protection circuit according to the

approval classification of the product.

• Intrinsically safe circuits are normally required for the automatic level-control system by

the level regulator if mounted in zone 0.

• The yield stress of fasteners must be in accordance with the approval drawing and the

product specification.

• Do not modify the equipment without approval from an authorized Xylem

representative.

• Only use parts that have been provided by an authorized Xylem representative.

Equipment for monitoring

For additional safety, use condition-monitoring devices. Condition-monitoring devices

include but are not limited to these devices:

• Level indicators

• Temperature detectors

Introduction and Safety

Environmental safety

The work area

Always keep the pump station clean to avoid and/or discover emissions.

Recycling guidelines

Always recycle according to these guidelines:

1. If the unit or parts are accepted by an authorized recycling company, then follow

local recycling laws and regulations.

2. If the unit or parts are not accepted by an authorized recycling company, then return

them to the nearest Xylem representative.

Waste and emissions regulations

Observe these safety regulations regarding waste and emissions:

• Dispose appropriately of all waste.

• Handle and dispose of the pumped fluid in compliance with applicable environmental

regulations.

• Clean up all spills in accordance with safety and environmental procedures.

• Report all environmental emissions to the appropriate authorities.

Reference for electrical installation

For electrical installation requirements, consult your local electric utility.

Product warranty

Coverage

Xylem undertakes to remedy faults in products from Xylem under these conditions:

• The faults are due to defects in design, materials, or workmanship.

• The faults are reported to an Xylem representative within the warranty period.

• The product is used only under the conditions described in this manual.

• The monitoring equipment incorporated in the product is correctly connected and in

use.

Flygt 3201 Installation, Operation, and Maintenance Manual 7

Page 10

Introduction and Safety

Limitations

Warranty claim

• All service and repair work is done by Xylem-authorized personnel.

• Genuine Xylem parts are used.

• Only Ex-approved spare parts and accessories authorized by Xylem are used in Exapproved products.

The warranty does not cover faults caused by these situations:

• Deficient maintenance

• Improper installation

• Modifications or changes to the product and installation made without consulting

Xylem

• Incorrectly executed repair work

• Normal wear and tear

Xylem assumes no liability for these situations:

• Bodily injuries

• Material damages

• Economic losses

Xylem products are high-quality products with expected reliable operation and long life.

However, should the need arise for a warranty claim, then contact your Xylem

representative.

Spare parts

Xylem guarantees that spare parts will be available for 15 years after the manufacture of

this product has been discontinued.

8 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 11

Transportation and Storage

Inspect the unit upon delivery

Receive the unit

1. Inspect the package for damaged or missing items upon delivery.

2. Note any damaged or missing items on the receipt and freight bill.

3. File a claim with the shipping company if anything is out of order.

Unpack the unit

1. Remove packing materials from the unit.

Dispose of all packing materials in accordance with local regulations.

2. Inspect the unit to determine if any parts have been damaged or are missing.

3. Contact your Xylem representative if anything is out of order.

Lifting guidelines

General

The following are general guidelines for lifting the unit:

• Always use lifting equipment when handling the unit.

• When you use a lifting eyebolt or shackle for lifting the unit, make sure that the eyebolt

or shackle is fastened firmly before lifting.

• The unit can be transported either horizontally or vertically.

Transportation and Storage

Precautions

WARNING:

• The unit might get stuck if it hangs at any angle when lifting or lowering along guide

bars. Make sure the unit hangs straight up and down from the lifting hook.

• Crush hazard. The unit and the components can be heavy. Use proper lifting methods

and wear steel-toed shoes at all times.

• Do not attach sling ropes to shaft ends.

• Stay clear of suspended loads.

• Always lift the unit by its lifting handle. Never lift the unit by the motor cable or by the

hose.

Flygt 3201 Installation, Operation, and Maintenance Manual 9

Page 12

Transportation and Storage

Lifting equipment

The lifting equipment must fulfill the following requirements:

• The minimum height between the lifting hook and the floor must be sufficient to lift the

• The lifting equipment must be able to hoist the unit straight up and down in the sump,

• The lifting equipment must be securely anchored and in good condition.

• The lifting equipment must support the entire assembly and must only be used by

• Two sets of lifting equipment must be used to lift the unit for repair work.

• The lifting equipment must be dimensioned to lift the unit with any remaining pumped

• The lifting equipment must not be oversized.

Store the unit

unit out of the sump. Contact Xylem for information.

preferably without the need for resetting the lifting hook.

authorized personnel.

media (liquid) in it.

NOTICE:

Oversized lifting equipment could cause damage if the unit should stick when being

lifted.

1. After raising the unit, allow it to run for a short time to discharge all remaining pumped

media (liquid).

The unit is frost-proof while operating or immersed in liquid, but the impeller and the

shaft seal may freeze if the unit is raised in a temperature below freezing.

2. Store the unit in a covered and dry location free from heat, dirt, and vibrations.

3. If the unit is stored more than 6 months, rotate the shaft every other month to prevent

the seals from sticking together.

4. Before operating the unit after storage:

If... Then…

the unit has been stored more than 6

months

the impeller is frozen thaw the impeller by immersing the unit in liquid.

inspect the unit with special attention to the seals and the cable entry.

NOTICE:

Never use a naked flame to thaw the unit.

10 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 13

Product Description

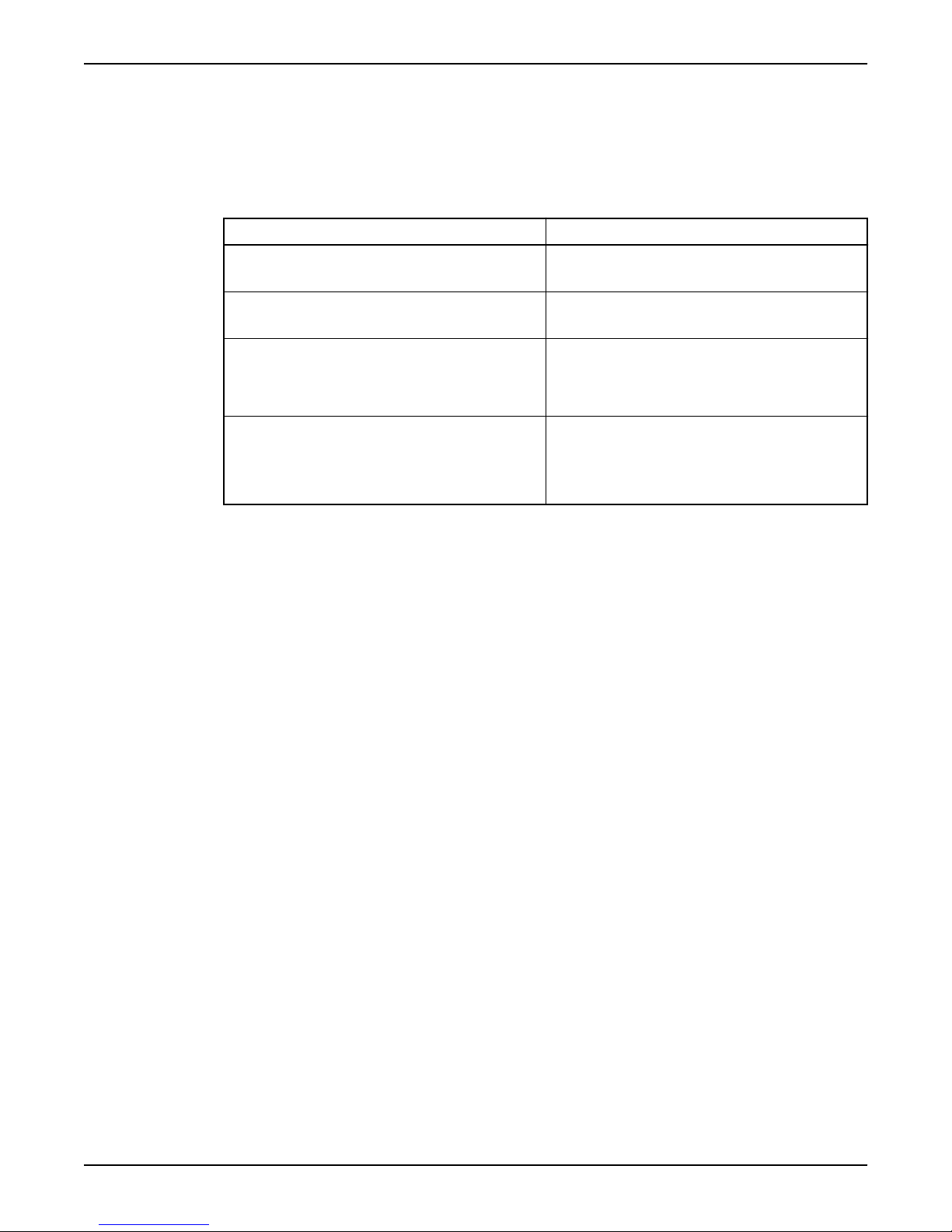

Pump design

The pump is submersible, and driven by an electric motor.

Intended use

WARNING:

Only use Ex- or MSHA-approved pumps in an explosive or flammable environment.

NOTICE:

Do NOT use the pump in highly corrosive liquids.

For information about pH, see Application limits (page 44).

Spare parts

• Modifications to the unit or installation should only be carried out after consulting with

Xylem.

• Original spare parts and accessories authorized by Xylem are essential for compliance.

The use of other parts can invalidate any claims for warranty or compensation. For

more information contact your Xylem representative.

Product Description

Flygt 3201 Installation, Operation, and Maintenance Manual 11

Page 14

1

5

2

4

6

7

3

Product Description

Parts

PositionPart Description

1 Impeller A wide range of impellers are available for different applications and capacities.

2 Mechanical seal The seals are made of:

12 Flygt 3201 Installation, Operation, and Maintenance Manual

3 Shaft Stainless steel or carbon steel shaft with an integrated rotor.

4 Bearing

5 Oil housing A housing with oil that lubricates and cools the seals, and acts as a buffer between the

6 Cooling The stator is cooled by either the surrounding media (liquid) or by forced circulation in a

7 Motor For information about the motor, see Motor data.

• Inner seal: corrosion-resistant cemented carbide WCCR/WCCR

• Outer seal: corrosion-resistant cemented carbide WCCR/WCCR

• The main bearing consists of a two-row angular-contact ball bearing.

• The support bearing consists of a single-row roller bearing.

pumped media (liquid) and the drive unit.

cooling jacket.

Page 15

Monitoring equipment

The following applies to the monitoring equipment of the pump:

• Normally the stator incorporates thermal contacts connected in series that activates the

alarm at overtemperature.

• The thermal contacts open at 125°C (257°F).

• Ex-approved pumps must have thermal contacts connected to the control panel.

• The sensors must be connected to either the MiniCAS II monitoring unit or an

equivalent unit.

• The monitoring equipment must be of a design that makes automatic restart

impossible.

• The label in the junction box shows if the pump is equipped with optional sensors.

Optional sensors

Product Description

Thermistor

FLS FLS is a miniature float switch for detection of liquid in the stator housing. Due

CLS CLS is a sensor for detection of water in the oil housing. The sensor initiates an

Two FLS sensors or one CLS and one FLS sensor can be used in the same pump,

connected in parallel.

Thermistors are optional sensors for measuring the temperature. They are

connected in series in the stator and activate the alarm at overtemperature.

The sensors are only optional for standard pumps.

NOTICE:

Thermistor must never be exposed to voltages higher than 2.5 V. If the

voltage exceeds this value, for example when the control circuit is tested, the

thermistors will be destroyed.

to its design it is best suited for pumps in a vertical position. The FLS sensor is

installed in the bottom of the stator housing.

alarm when the oil contains approximately 35% water. The sensor is installed

in the bearing housing/bearing holder with its sensing part in the oil housing.

NOTICE:

The CLS sensor body is made of glass. Handle with care.

Flygt 3201 Installation, Operation, and Maintenance Manual 13

Page 16

2

1312 14

22

21

20

17 18 1916159 10 11

8

7

6

5

4

3

1

23

24

Product Description

The data plate

The data plate is a metal label located on the main body of the pump. The data plate lists

key product specifications. Explosion-proof products also have an approval plate. Both are

described below.

Figure 1: The data plate

1. Curve code/Propeller code

2. Serial number, see Product denomination (page 15)

3. Product number

4. Country of origin

5. Additional information

6. Phase; type of current; frequency

7. Rated voltage

8. Thermal protection

9. Thermal class

10. Rated shaft power

11. International standard

12. Degree of protection

13. Rated current

14. Rated speed

15. Maximum submergence

16. Direction of rotation: L=left, R=right

17. Duty class

18. Duty factor

19. Product weight

20. Locked rotor code letter

21. Power factor

22. Maximum ambient temperature

23. Read installation manual

24. Notified body/only for EN-approved Ex-products

Approvals

This section describes the EN and FM approvals that explosion-proof products have. For

more information, please contact your Xylem representative. In addition to the data plate,

explosion-proof products also have either an EN or a FM approval plate.

EN

14 Flygt 3201 Installation, Operation, and Maintenance Manual

• European Norm

• ATEX Directive

• EN 50014, EN 50018, EN 1127-1

II 2 G EEx d IIB T4

•

Page 17

1 2 3

4

5

6 7

8

9 10

12

11

13

14

15

1. Approval

1

2

2. Approval authority + approval number

3. Approval for Class I

4. Approved drive unit

5. Stall time

6. Starting current/Rated current

7. Duty class

8. Duty factor

9. Input power

10. Rated speed

11. Controller

12. Additional information

13. Maximum ambient temperature

14. Serial number

15. ATEX marking

Figure 2: EN approval plate

Product Description

EN approval for cable entry:

• Certificate number: INERIS 02ATEX9008 U

•

II 2 G or IM2 EEx d IIC or EEx dI

FM

This illustration describes the approval plate for Factory Mutual (FM) and the information

contained in its fields.

1. Temperature class

2. Maximum ambient temperature

Figure 3: FM approval plate

Product denomination

Flygt 3201 Installation, Operation, and Maintenance Manual 15

Page 18

1

NP 3085

2 3

3085.183

1 2

NP

1

NP 3085.183 - 951 0163

2 3 4

Product Description

Sales denomination

Product code

Serial number

The sales denomination consists of the four-digit sales code and two letters that indicate

the hydraulic end and type of installation.

This is an example of a sales denomination, and an explanation of its parts.

1. Hydraulic part

2. Installation type

3. Sales code

The product code consists of nine characters divided into two parts.

This is an example of a product code, and an explanation of its parts.

1. Sales denomination

2. Version

The serial number is used for identification of an individual product, and is divided into

four parts.

This is an example of a serial number, and an explanation of its parts.

1. Product code

2. Production year

3. Production cycle

4. Running number

16 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 19

Installation

Install the pump

These requirements apply:

• Use the pump dimensional drawing in order to ensure proper installation.

• In S-, T-, and Z-installations the pump must be equipped with cooling jacket

• Provide a suitable barrier around the work area, for example, a guard rail.

• Check the explosion risk before you weld or use electric hand tools.

• Remove all debris from the inlet piping system before you install the pump.

WARNING:

• Before installing the pump, check that the cable and cable entry have not been

damaged during transportation.

• Note that special rules apply to installation in explosive atmospheres.

• Make sure that the pump cannot roll or fall over and injure people or damage property.

• Do not install CSA-approved products in locations that are classified as hazardous in the

national electric code, ANSI/NFPA 70-2005.

Installation

NOTICE:

• Do not run the pump dry.

• Never force piping to make a connection with a pump.

Install with P-installation

In the P-installation, the pump is installed on a stationary discharge connection, and

operates either completely or partially submerged in the pumped liquid. These

requirements and instructions only apply when the installation is made according to the

dimensional drawing.

Figure 4: P-installation

Flygt 3201 Installation, Operation, and Maintenance Manual 17

Page 20

Installation

These items are required:

• Guide bars

• Guide bar bracket for attaching the guide equipment to the access frame or to the

upper part of the sump

• Level regulators or other control equipment for start, stop, and alarm

• Cable holder for holding the cable and regulating the height of the level regulators

• Access frame (with covers) to which the upper guide bar bracket and cable holder can

be attached

• Discharge connection for connecting the pump to the discharge line

The discharge connection has a flange which fits the pump casing flange and a bracket

for attaching the guide equipment.

• Fasteners for the discharge connection

• Anchor bolts

1. Run a cable between the sump and the stator and monitoring equipment.

Make sure that the cable is neither sharply bent, nor pinched.

2. Install the access frame:

a) Place the access frame in position and align it horizontally.

b) Grout the frame in place.

3. Grout the anchor bolts in place.

Be careful when you align and position the discharge connection in relation to the

access frame.

4. Place the discharge connection in position, and tighten the nuts.

5. Install the guide bars:

a) Secure the guide bars in the bracket.

b) Check that the guide bars are placed vertically. Use a level or a plumb line.

6. Connect the discharge pipe to the discharge connection.

7. Prepare for the level regulator:

a) Bolt the cable holder to the access frame.

b) Thread the level regulator cable through the holes in the cable holder, and adjust

the height of the level regulators.

c) Protect bolts and nuts with a corrosion-preventive compound.

8. Lower the pump along the guide bars.

9. Secure the motor cable:

a) Fasten the permanent lifting device to the pump and to the access frame. For

example, you can use a stainless-steel lifting chain with shackles.

b) Fasten the cable to the cable holder.

Make sure that the cable cannot be sucked into the pump inlet or that it is neither

sharply bent, or pinched. Support straps are required for deep installations.

c) Connect the motor cable and the starter and monitoring equipment according to

the separate instructions.

Make sure that the impeller rotation is correct. For more information, see Check the

impeller rotation (page 29).

Clean all debris from the sump before starting the pump.

Install with S-installation

In the S-installation, the pump is transportable and intended to operate either completely

or partially submerged in the pumped liquid. The pump is equipped with a connection for

hose or pipe and stands on a base stand.

18 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 21

Installation

These requirements and instructions only apply when the installation is made according to

the dimensional drawing. For more detailed information about the different installation

types, see the Parts List document.

Figure 5: S-installation

1. Run the cable so that it has no sharp bends, is not pinched, and cannot be sucked into

the pump inlet.

2. Connect the discharge line.

3. Lower the pump into the sump.

4. Place the pump on the base and make sure it cannot fall over or sink.

Alternatively, the pump can be suspended with a lifting chain just above the sump

bottom. Make sure that the pump cannot rotate at startup or during operation.

5. Connect the motor cable and the starter and monitoring equipment according to the

separate instructions.

Make sure that the impeller rotation is correct. For more information, see Check the

impeller rotation (page 29).

Install with T/Z-installation

• In the T-installation, the pump is installed in a vertical position in a dry well next to the

wet sump. These requirements and instructions only apply when the installation is

made according to the dimensional drawing.

• In the Z-installation, the pump is installed in a horizontal position on a support stand in

a dry well next to the wet sump, and a bell-mouth is connected to the inlet pipe. These

requirements and instructions are for Z-installations that comply to the dimensional

drawing.

Flygt 3201 Installation, Operation, and Maintenance Manual 19

Page 22

Installation

Figure 7: Z-installation

Figure 6: T-installation

These items are required:

• Support stand and anchor bolts for anchoring the pump to a base

• Inlet elbow for connecting the suction line and discharge line

• Shut-off valves that allow you to remove the pump from service

• Air vent on the discharge side between the pump and the check valve

• Level regulators or other control equipment for start, stop, and alarm

NOTICE:

The risk of freezing is particularly high in T- or Z-installations.

1. Fasten the pump:

a) Use the anchor bolts to bolt the support stand to the concrete base.

b) Bolt the pump to the support stand and the suction connection.

2. Make sure that the pump is vertical for the T-installation or horizontal for the Z-

installation.

3. Connect the suction line and discharge line.

4. Connect the motor cable and the starter and monitoring equipment according to the

separate instructions.

Make sure that the impeller rotation is correct. For more information, see Check the

impeller rotation (page 29).

5. Make sure that the weight of the pump does not put strain on the piping.

20 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 23

Make the electrical connections

General precautions

Electrical Hazard:

• A certified electrician must supervise all electrical work. Comply with all local codes and

regulations.

• Before starting work on the pump, make sure that the pump and the control panel are

isolated from the power supply and cannot be energized. This applies to the control

circuit as well. If the pump is equipped with automatic level control, there is a risk of

sudden restart.

• Leakage into the electrical parts can cause damaged equipment or a blown fuse. Keep

the end of the motor cable above the liquid level.

• Make sure that all the conductors that are not used are insulated.

• There is a risk of electrical shock or explosion if the electrical connections are not

correctly carried out or if there is fault or damage on the product.

Requirements

These general requirements apply for electrical installation:

• The supply authority must be notified before installing the pump if it will be connected

to the public mains. When the pump is connected to the public power supply, it may

cause flickering of incandescent lamps when started.

• The mains voltage and frequency must agree with the specifications on the data plate.

If the pump can be connected to different voltages, the connected voltage is specified

by a yellow sticker close to the cable entry.

• The fuses, short-circuit, and circuit breakers must have the proper rating, and the

pump overload protection (motor protection breaker) must be connected and set to

the rated power according to the data plate. The starting current in direct-on-line

starting can be up to six times higher than the rated current.

• The fuse rating and the cables must be in accordance with the local rules and

regulations.

• If intermittent operation is prescribed, the pump must be provided with monitoring

equipment supporting such operation.

• The motor is convertible between different voltages, as stated on the data plate. This

conversion is done on the terminal board.

Installation

Cables

These are the requirements to follow when you install cables:

• The cables must be in good condition, not have any sharp bends, and not be pinched.

• The sheathing must not be damaged and must not have indentations or be embossed

(with markings, etc.) at the cable entry.

• The cable entry seal sleeve and washers must conform to the outside diameter of the

cable.

• The minimum bending radius must not be below the accepted value.

• If using a cable which has been used before, a short piece must be peeled off when

refitting it so that the cable entry seal sleeve does not close around the cable at the

same point again. If the outer sheath of the cable is damaged, then replace the cable

(contact an Xylem service shop).

Flygt 3201 Installation, Operation, and Maintenance Manual 21

Page 24

1

2

Installation

• The voltage drop in long cables must be taken into account. The drive unit’s rated

voltage is the voltage measured at the terminal board in the upper part of the pump.

• The screened cable must be used according to the European CE requirements if a

Variable Frequency Drive (VFD) is used. For more information, contact your Xylem

representative (VFD-supplier).

Earthing (Grounding)

Electrical Hazard:

• You must earth (ground) all electrical equipment. This applies to the pump equipment,

the driver, and any monitoring equipment. Test the earth (ground) lead to verify that it is

connected correctly.

• If the motor cable is jerked loose by mistake, the earth (ground) conductor should be the

last conductor to come loose from its terminal. Make sure that the earth (ground)

conductor is longer than the phase conductors. This applies to both ends of the motor

cable.

• Risk of electrical shock or burn. You must connect an additional earth- (ground-) fault

protection device to the earthed (grounded) connectors if persons are likely to come

into physical contact with the pump or pumped liquids.

Connect the motor cable to the pump

CAUTION:

Leakage into the electrical parts can cause damaged equipment or a blown fuse. Keep the

end of the motor cable above the liquid level.

1. Entrance cover

2. O-ring

For more information about the cable entry, see the Parts list.

1. Remove the entrance cover and the O-ring from the stator housing.

This provides access to the terminal board.

2. Check the data plate to see which connections are required for the power supply:

• Y

• D

• Y serial

• Y parallel

• Y/D

22 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 25

3. Arrange the connections on the terminal board in accordance with the required power

supply.

Links (jumper strips) are not used with the Y/D start.

4. Connect the motor conductors (U1, V1, W1, and earth (ground)) to the terminal board.

The earth (ground) conductor must be 50 mm ( 2.0 in.) longer than the phase

conductors in the junction box of the unit.

5. Make sure that the pump is correctly connected to earth (ground).

6. Make sure that any thermal contacts incorporated in the pump are properly connected

to the terminal board.

7. Install the entrance cover and the O-ring on the stator housing.

8. Fasten the screws on the entrance flange so that the cable insertion assembly bottoms

out.

Connect the motor cable to the starter and monitoring equipment

WARNING:

Do not install the starter equipment in an explosive zone or in the sump.

NOTICE:

• Either thermal contacts or thermistors are incorporated in the pump.

• Thermal contacts must never be exposed to voltages higher than 250 V, breaking

current maximum 4 A. It is recommended that they are connected to 24 V over

separate fuses to protect other automatic equipment.

Installation

1. If thermal contacts are included in the pump installation, connect the T1 and T2 control

conductors to the MiniCAS II monitoring equipment.

Do not connect the T1 and T2 leads to thermal contacts if the temperature of the

pumped liquid is above 40°C (104°F).

NOTICE:

Ex-approved products must always have the thermal contacts connected irrespective

of the ambient temperature.

2. If thermistors are included in the pump installation, and screened or auxiliary cable is

used, then connect T1(1) and T2(2) to thermistor relay or MAS 711, and T3(3) and T4

(4) to MiniCAS II or MAS 711.

3. Connect the mains leads (L1, L2, L3, and earth [ground]) to the starter equipment.

For the color codes of the leads, see Cable charts (page 24).

4. Check the functionality of the monitoring equipment:

a) Check that the signals and the tripping function work properly.

b) Check that the relays, lamps, fuses, and connections are intact.

Replace any defective equipment.

Flygt 3201 Installation, Operation, and Maintenance Manual 23

Page 26

1 2 3 4 5 6 7

1 2 L1 L2 L3 GC

U1 W2 V1 U2T16 T15 T2 T1 W1 V2

1

2

3

6

5

4

7

Installation

Cable charts

Connection locations

1. Control leads

2. Starter equipment

3. Mains leads

4. Motor cable

5. Terminal blocks on pump

6. Stator leads

7. Control cable

Colors and marking of the mains leads

Mains SUBCAB 7GX SUBCAB 4GX SUBCAB AWG

Color and marking of the control leads

Colors of the stator leads

L1 Black 1 Brown Red

L2 Black 2 Black Black

L3 Black 3 Grey White

Yellow/Green Yellow/Green Yellow/Green

Groundcheck (GC) - - Yellow

Control SUBCAB 7GX and SUBCAB 4GX SUBCAB AWG

T1 White T1 Orange

T2 White T2 Blue

Stator connection Lead color

U1 Red

U2 Green

U5 Red

V1 Brown

V2 Blue

24 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 27

Stator connection Lead color

U2W2 V2

V1U1 W1

T1

T2

L1 L2 L3 T1 T2

1 4 2 5 3 6

1 4 2 53 6

T1 T2

T1

T2

T1 T2

W2 U1 V1 U2 W1

V2

SUBCAB

®

SUBCAB

®

V5 Brown

W1 Yellow

W2 Black

W5 Yellow

SUBCAB 7GX, 6 stator leads, D connection

This table shows the connection diagrams for the SUBCAB 7GX (3-phase power cables),

with D connection.

D connection

Installation

SUBCAB 7GX, 6 stator leads, Y/D connection

This table shows the connection diagrams for the SUBCAB 7GX (3-phase power cables),

with Y/D connection.

Flygt 3201 Installation, Operation, and Maintenance Manual 25

Page 28

T1

W2U1

V1

U2

W1

V2

SUBCAB

®

T1 T 2

3~

T2

L1

1

3

4

2

6

5

1

2 3 4 5 6

L3L2 L1 L2L3

T1

T2

V1

U1

W1

V2

U2

W2

U2W2 V2

V1U1 W1

T1

T2

GC L2L1 L3

T1 T2

T1 T2

T1

T2

T1 T2

U1 V1 U2 V2

SUBCAB

®

SUBCAB

®

GC

L1 L2

L3

W1W2

U2

W2

V2

V1U1 W1

T1

T2

GC L2L1 L3

T1 T2

T1 T2

T1

T2

T1 T2

U1 V1 U2 V2

SUBCAB

®

SUBCAB

®

GC

L1 L2

L3

W1W2

Installation

Y/D connection

SUBCAB 4GX/SUBCAB AWG, 6 stator leads, Y and D connections

This table shows the connection diagrams for the SUBCAB 4GX/SUBCAB AWG (3-phase

power cables), with Y and D connections.

Y connection D connection

SUBCAB 4GX, 6 stator leads, Y/D connection

This table shows the connection diagrams for the SUBCAB 4GX (3-phase power cables),

with Y/D connection.

26 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 29

Y/D connection

V1W1 U1

U2V2 W2

T1

T2

L1 L2 L3 L1 L2

L3

1 2 43 5 6

11223

3

T1T1T2

T2

W1 V1

SUBCAB

®

SUBCAB

®

SUBCAB

®

U1 V2

U2

44556 T1 T2 T1 T2

6

W2

L1

L2L3

L3

V1

W1

T1

T2

U1

T1

W2

U1

V1 U2

W1

V2

SUBCAB

®

SUBCAB

®

GC L1 L2

T1 T2

3~

V2

W2

U2

GC

T2

T1

T2

GC

U5

V5

W5

Installation

SUBCAB 4GX/SUBCAB AWG, 9 stator leads, 230V

This table shows the connection diagrams for the SUBCAB 4GX/SUBCAB AWG (3-phase

power cable), with Y parallel connection (60 Hz only).

Y parallel connection

This table shows the connection diagram for the SUBCAB 4GX/SUBCAB AWG (3-phase

power cable), with Y serial connection (60 Hz only).

SUBCAB 4GX/SUBCAB AWG, 9 stator leads, 460V

Flygt 3201 Installation, Operation, and Maintenance Manual 27

Page 30

L1 L2L3

L3

V1

W1

T1

T2

U1

T1

W2

U1

V1

U2

W1

V2

SUBCAB

®

SUBCAB

®

GC L1 L2

T1 T 2

3~

V2

W2

U2

GC

T2

T1

T2

GC

U5

V5

W5

Installation

Y serial connection

Sensor-connection

FLS and Thermal contact Value

0 mA Overtemperature

7.8 mA OK

36 mA Leakage

The values have a 10 % tolerance

CLS and Thermal contact (only standard version) Value

0 mA Overtemperature

5.5mA OK

29mA Leakage (5 second delay)

The values have a 10 % tolerance

28 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 31

CLS, FLS, and Thermal contact (only standard version) Value

0 mA Overtemperature

13.3 mA OK

36-42mA Leakage (0/5 seconds delay)

The values have a 10 % tolerance

Two FLS, and Thermal contact (only standard version) Thermal contact

Installation

Check the impeller rotation

WARNING:

The starting jerk can be powerful.

1. Start the motor.

2. Stop the motor.

3. Check that the impeller rotates according to this illustration.

Flygt 3201 Installation, Operation, and Maintenance Manual 29

Page 32

Installation

The correct direction of impeller rotation is clockwise when you look at the pump from

above.

4. If the impeller rotates in the wrong direction, do one of these steps:

• If the motor has a 1-phase connection, contact the local Xylem shop.

• If the motor has a 3-phase connection, transpose two phase leads and do this

procedure again.

30 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 33

Operation

Distance to wet areas

Electrical Hazard:

Risk of electrical shock when pumping or mixing near a lake, jetties, beaches, ponds,

fountains, or similar. There must be a safety distance of at least 20 m (65 ft.) between the

person and the product if the person is in contact with the pumped or mixed liquid.

Start the pump

WARNING:

• If you need to work on the pump, make sure that it is isolated from the power supply and

cannot be energized.

• Make sure that the pump cannot roll or fall over and injure people or damage property.

• In some installations, the pump and the surrounding liquid may be hot. Bear in mind the

risk of burn injuries.

• Make sure nobody is close to the pump when it is started. The pump will jerk in the

opposite direction of the impeller rotation.

Operation

NOTICE:

Make sure that the rotation of the impeller is correct. For more information, see Check the

impeller rotation.

1. Check the oil level in the oil housing.

2. Remove the fuses or open the circuit breaker, and check that the impeller can be

rotated freely.

3. Conduct insulation test phase to ground. To pass, the value must exceed 5 megohms.

4. Check that the monitoring equipment works.

5. Start the pump.

Flygt 3201 Installation, Operation, and Maintenance Manual 31

Page 34

Maintenance

Maintenance

Maintenance guidelines

During maintenance and before reassembly, always remember to perform these tasks:

• Clean all parts thoroughly, particularly O-ring grooves.

• Change all O-rings, gaskets, and seal washers.

• Lubricate all springs, screws, and O-rings with grease.

During reassembly, always make sure that existing index markings are in line.

Torque values

Screw and nuts

Stainless steel, A2 and A4

Property

class

Torque,

Nm (ftlbs)

Carbon steel and alloyed steel

Torque,

Nm (ftlbs)

Screws with countersunk heads

70 +80 2.7 (2) 5.4 (4) 9.3 (6.9) 22 (16) 44 (32) 76 (56) 187 (138) 364 (268) 629 (464) 1240

8.8 2.9 (2.1) 5.7 (4.2) 9.8 (7.2) 24 (18) 47 (35) 81(60) 194 (143) 385 (285) 665 (490) 1310

10.9

12.9

M4 M5 M6 M8 M10 M12 M16 M20 M24 M30

4.0 (2.9) 8.1 (6) 14 (10.3) 33 (24.3) 65 (48) 114 (84) 277 (204) 541 (399) 935 (689) 1840

4.9 (3.6) 9.7 (7.2) 17 (12.5) 40 (30) 79 (58) 136 (100) 333 (245) 649 (480) 1120

(825)

(915)

(966)

(1357)

2210

(1630)

Stainless steel, A2 and A4

Property

class

1

Property class 70 is torque tightened as class 80.

32 Flygt 3201 Installation, Operation, and Maintenance Manual

M4 M5 M6 M8 M10 M12 M16 M20 M24

Page 35

Maintenance

Torque,

70 +8011.2 (0.9) 2.7 (2) 5.4 (4) 9.3 (6.9) 22 (16) 44 (32) 76 (56) 120 (88) 187 (138)

Nm (ft-lbs)

Carbon steel and alloyed steel

Torque,

Nm (ft-lbs)

8.8 2.3 (1.7) 4.6 (3.4) 7.8 (5.8) 19 (14) 38 (28) 65 (48) 158 (116) 308 (228) 532 (392)

10.9

12.9

3.2 (2.4) 6.5 (4.8) 11(8) 26 (19) 52 (38) 91 (67) 222 (164) 433 (320) 748 (552)

3.9 (2.9) 7.8 (5.8) 14 (10.3) 32 (23.6) 63 (46) 109 (80) 266 (196) 519 (383) 896 (661)

Change the oil

The following items are needed for this procedure:

• New oil plugs

• New O-rings

• Oil drainage pump 83 95 42 or equivalent

• Oil

Oil type Viscosity Amount

Medical white oil of paraffin type

that fulfills FDA 172.878 (a)

1. Unscrew the oil plug.

ISO VG32 7.5 liters (7.92 US quarts)

The plug is marked "oil out".

WARNING:

The oil housing may be pressurized. Hold a rag over the oil plug to

prevent oil from spraying out.

1. Inspection plug

2. Oil plug

2. Drain the pump.

Use the oil drainage pump. Make sure that the plastic tube goes all the way to the

bottom of the oil housing.

3. Fill the housing with new oil.

Flygt 3201 Installation, Operation, and Maintenance Manual 33

Page 36

Maintenance

Quantity: approximately 7.5 liters (7.92 US quarts)

4. Insert and tighten the new O-rings and plugs.

Tightening torque: Inspection plug 20 Nm (14.8 ft-lbs), Oil plug 30-60 Nm (22.1-44.3

ft-lbs)

Replace the wear rings

Before replacing any wear ring, do the action applicable for your pump model:

• Disconnect and remove the drive unit end from the pump housing.

When the clearance between the impeller wear ring (rotating) and pump housing wear

ring (stationary) exceeds 2mm (0.08in), one of the following wear rings must be replaced.

• the wear ring in the pump housing

• the impeller wear ring

Replace the wear ring in the pump housing, diffuser ring, or suction cover

Figure 8: The wear ring in the pump housing

1. Knock off the wear ring using a hammer and a chisel.

If necessary, saw grooves in the wear ring using a hacksaw.

2. Please, check the surface intended for the wear ring that it is clean, before you are

mounting a new wear ring.

3. Drive in the new wear ring.

Use a rubber mallet or a wooden block to prevent deformation.

The work will proceed more easily if the pump housing , diffuser ring, or suction cover

first is heated and/or the wear ring cooled.

34 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 37

4. Before assembling the pump housing or diffuser ring with the drive unit end, check the

following:

• Check the O-ring and fit it in place.

• Check the orientation of the pump housing or diffuser ring.

5. Install the drive unit on the pump housing.

Tightening torque, see Torque values (page 32).

Replace the impeller wear ring

Figure 9: The impeller wear ring

1. Lay the drive unit on its side.

2. Knock off the impeller wear ring from the impeller.

If necessary, saw grooves in the wear ring using a hacksaw.

3. Heat the new impeller wear ring and press it onto the impeller.

4. Before assembling the pump housing or diffuser ring with the drive unit end, check the

following:

• Check the O-ring and fit it in place.

• Check the orientation of the pump housing or diffuser ring.

5. Install the drive unit on the pump housing.

Tightening torque, see Torque values (page 32).

Maintenance

Replace the impeller

WARNING:

A worn impeller and/or pump housing can have very sharp edges. Wear protective gloves.

1. Wear protection

2. Lock nuts

1

2

3

4

Flygt 3201 Installation, Operation, and Maintenance Manual 35

Page 38

Maintenance

3. Sleeve screws

4. Cap nuts

Figure 10: HS 3201

Remove the impeller and the wear protections

For the HS-version, also remove the wear protections.

1. Disconnect and remove the drive unit end from the pump housing.

2. Lay the drive unit end on its side.

3. Remove the impeller screw or nut.

4. Depending the pumps model, do the following.

If the pump model is

Then...

a...

HS-version

1. Remove the washer.

2. Remove the impeller using a impeller puller for HS-versions.

3. Remove the upper wear protection.

4. Unscrew the four cap nuts and withdraw the lower wear protection from the

pump housing.

Other version Remove the impeller, impeller hub, or propeller using a impeller hub.

Install the impeller and the wear protections

For the HS-version, also install the wear protections.

1. Prepare the shaft:

a) Make sure that the end of the shaft is clean and free from burrs.

Polish off any flaws with a fine emery cloth.

b) Make sure that the key is seated in the keyway on the shaft.

c) Grease the end of the shaft.

2. Mount the impeller, impeller hub, or propeller

a) If the pump is a HS-version, fit the upper wear protection.

b) If the pump is another version, clean and oil all the sealing surfaces and O-rings.

c) Grease the impeller hub.

d) If the pumps is a LT-version, place the sleeve on the impeller screw.

e) If the pump is another version, place the washer with the gasket. Use the O-ring on

the impeller or propeller screw.

Not applicable for HS-, or LT-version.

f) Press the impeller, impeller hub, or propeller onto the shaft with the impeller or

propeller screw.

Heat the impeller, impeller hub, or propeller to about 100°C (212°F), to ease the

fitting.

36 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 39

Maintenance

3. Tighten the impeller or propeller screw.

Tightening torque, see Torque values (page 32).

4. Check that the impeller is firmly seated and can be easily rotated by hand.

5. Before assembling the pump housing and the drive unit end, check the following:

a) Check the O-ring and fit it in place.

b) Check the orientation of the pump housing.

6. Assemble the pump.

Tightening torque, see Torque values (page 32).

More extensive repairs require special tools and should be completed by an Xylem

authorized service technician.

Adjust the lower wear protection

For the HS version, the lower wear protection may need adjustment. The clearance

between the impeller and the wear protection should be minimal. The clearance is

adjusted with the sleeve screws.

1. Check that the impeller can easily be rotated by hand.

2. Tighten the sleeve screws evenly until the wear protection is flush against the impeller.

3. Back off the sleeve screws a quarter turn.

4. Tighten the lock nuts evenly all around.

5. Fit and tighten the cap nuts.

6. Check that the impeller can easily be rotated by hand.

For the pump to perform at maximum capacity, the impeller must be adjusted regularly.

More extensive repairs require special tools and should be carried out by an Xylem

authorized service technician.

Service the pump

Regular inspection and service of the pump ensures more reliable operation.

Type of service Inspection interval

Intermediate service Every 2 years /8000 hours

(For standard sewage applications with FLS in use and a

pumped liquid temperature of 40ºC (104ºF ) or less.)

Major service in an authorized service shop Every 20,000 hours

Intermediate service

Flygt 3201 Installation, Operation, and Maintenance Manual 37

(May vary considerably depending on operating

conditions.)

Page 40

Maintenance

Service of the... Action

Cable

1. If the outer jacket is damaged, replace the cable.

2. Check that the cables do not have any sharp bends and are not

pinched.

Connection to power Check that the connections are properly tightened.

Electrical cabinets Check that they are clean and dry.

Impeller

1. Check the impeller clearance.

2. Adjust the impeller, if necessary.

Stator housing Drain all liquid, if any.

Insulation

1. Check that the resistance between the earth (ground) and

phase lead is more than 5 megohms.

2. Conduct a phase-to-phase resistance check.

Junction box Check that it is clean and dry.

Level regulators Check the condition and functionality.

Lifting device Check that local safety regulations are followed.

Lifting handle

1. Check the screws.

2. Check the condition of the lifting handle.

3. Replace if necessary.

Major service

O-rings

1. Replace the oil plug O-rings

2. Replace the O-rings at the entrance or junction cover.

3. Grease the new O-rings.

Overload protection and other

Check the correct settings.

protections

Personnel safety devices Check the guard rails, covers, and other protections.

Rotation direction Check the impeller rotation.

Oil housing Fill with new oil, if necessary.

Terminal board Check that the connections are properly tightened.

Thermal contacts Check the resistance of the leakage sensor.

Normally closed circuit; interval 0–1 ohm.

Thermistor Check the resistance is between 20–250 ohms and the measured

voltage is maximum 2 V DC.

Voltage and amperage Check the running values.

For a major service, take this action, in addition to the tasks listed under intermediate

service.

Service of the... Action

Support and main bearing Replace the bearings with new bearings.

38 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 41

Service of the... Action

Mechanical seal Replace with new seal units.

Service in case of alarm

Alarm source Action

The thermistor/Thermal contact Check that the cooling jacket is not clogged. Clean if necessary.

The overload protection Check that the impeller can rotate freely.

Maintenance

Flygt 3201 Installation, Operation, and Maintenance Manual 39

Page 42

Troubleshooting

Troubleshooting

Introduction

Follow these guidelines when troubleshooting the pump:

• Disconnect and lock out the power supply except when conducting checks that

require voltage.

• Make sure that no one is near the pump when the power supply is reconnected.

• When troubleshooting electrical equipment, use the following:

• Universal instrument multimeter

• Test lamp (continuity tester)

• Wiring diagram

The pump does not start

WARNING:

Always disconnect and lock out power before servicing to prevent unexpected startup.

Failure to do so could result in death or serious injury.

Cause Remedy

An alarm signal has been triggered

on the control panel.

The pump does not start

automatically, but can be started

manually.

The installation is not receiving

voltage.

Check that:

• The impeller rotates freely.

• If the sensor indicator indicates an alarm.

• The overload protection is not tripped.

If the problem still persists:

Contact the local Xylem service shop.

Check that:

• The start level regulator is functioning. Clean or replace if necessary.

• The thermal contacts have not opened.

• All connections are intact.

• The relay and contactor coils are intact.

• The control switch (Man/Auto) makes contact in both positions.

Check that:

• The main power switch is on.

• There is control voltage to the start equipment.

• The fuses are intact.

• There is voltage in all phases of the supply line.

• All fuses have power and that they are securely fastened to the fuse

holders.

• The overload protection is not tripped.

• The motor cable is not damaged.

The impeller is stuck. Clean:

If the problem persists, refer to the Flygt Service Guide on the web or contact the local

Xylem service shop. Always state the serial number of your pump when you contact Xylem,

see Product Description (page 11).

40 Flygt 3201 Installation, Operation, and Maintenance Manual

• The impeller

• The sump in order to prevent the impeller from clogging again.

Page 43

The pump does not stop when a level sensor is used

WARNING:

Always disconnect and lock out power before servicing to prevent unexpected startup.

Failure to do so could result in death or serious injury.

Cause Remedy

Troubleshooting

The pump is unable to empty the

sump to the stop level.

There is a malfunction in the levelsensing equipment.

The stop level is set too low. Raise the stop level.

If the problem persists, refer to the Flygt Service Guide on the web or contact the local

Xylem service shop. Always state the serial number of your pump when you contact Xylem,

see Product Description (page 11).

Check that:

• There are no leaks from the piping and/or discharge connection.

• The impeller is not clogged.

• The non-return valve(s) are functioning properly.

• The pump has adequate capacity. For information:

Contact the local Xylem service shop.

• Clean the level regulators.

• Check the functioning of the level sensors.

• Check the contactor and the control circuit.

• Replace all defective items.

The pump starts-stops-starts in rapid sequence

Cause Remedy

The pump starts due to back-flow

which fills the sump to the start

level again.

Check that:

• The distance between the start and stop levels is not too small.

• The non-return valve(s) work(s) properly.

• The rinser is not too long without a non-return valve.

The self-holding function of the

contactor malfunctions.

If the problem persists, refer to the Flygt Service Guide on the web or contact the local

Xylem service shop. Always state the serial number of your pump when you contact Xylem,

see Product Description (page 11).

Flygt 3201 Installation, Operation, and Maintenance Manual 41

Check:

• The contactor connections.

• The voltage in the control circuit in relation to the rated voltages on the

coil.

• The functioning of the stop-level regulator.

• Whether the voltage drop in the line at the starting surge causes the

contactor's self-holding malfunction.

Page 44

Troubleshooting

The pump runs but the motor protection trips

WARNING:

Always disconnect and lock out power before servicing to prevent unexpected startup.

Failure to do so could result in death or serious injury.

Cause Remedy

The motor protection is set too low. Set the motor protection according to the data plate.

The impeller is difficult to rotate by

hand.

The drive unit is not receiving full

voltage on all three phases.

The phase currents vary, or they are

too high.

The insulation between the phases

and ground in the stator is

defective.

The density of the pumped fluid is

too high.

There is a malfunction in the

overload protection.

If the problem persists, refer to the Flygt Service Guide on the web or contact the local

Xylem service shop. Always state the serial number of your pump when you contact Xylem,

see Product Description (page 11).

• Clean the impeller.

• Clean out the sump.

• Check that the impeller is properly trimmed.

• Check the fuses. Replace fuses that have tripped.

• If the fuses are intact, notify a certified electrician.

Contact the local Xylem service shop.

1. Use an insulation tester. With a 1000 V DC megger, check that the

insulation between the phases and between any phase and ground is

> 5 megohms.

2. If the insulation is less:

Contact the local Xylem service shop.

Make sure that the maximum density is 1100 kg/m3 (9.2 lb/US gal)

• Change the impeller or to a more suitable pump.

• Contact the local Xylem service shop.

Replace the overload protection.

The pump delivers too little or no water

WARNING:

Always disconnect and lock out power before servicing to prevent unexpected startup.

Failure to do so could result in death or serious injury.

NOTICE:

Do NOT override the motor protection repeatedly if it has tripped. Doing so may result in

equipment damage.

42 Flygt 3201 Installation, Operation, and Maintenance Manual

Page 45

Cause Remedy

Troubleshooting

The impeller rotates in the wrong

direction.

• If it is a 3-phase pump, transpose two leads.

• If it is a 1-phase pump:

Contact the local Xylem service shop.

One or more of the valves are set in

the wrong positions.

• Reset the valves that are set in the wrong position.

• Replace the valves, if necessary.

• Check that all valves are correctly installed according to media flow.

• Check that all valves open correctly.

The impeller is difficult to rotate by

hand.

• Clean the impeller.

• Clean out the sump.

• Check that the impeller is properly trimmed.

The pipes are obstructed. Clean out the pipes to ensure a free flow.

The pipes and joints leak. Find the leaks and seal them.

There are signs of wear on the

Replace the worn parts.

impeller, pump, and casing.

The liquid level is too low.

• Check that the level sensor is set correctly.

• Depending on the installation type, add a means for priming the pump,

such as a foot valve.

If the problem persists, refer to the Flygt Service Guide on the web or contact the local

Xylem service shop. Always state the serial number of your pump when you contact Xylem,

see Product Description (page 11).

Flygt 3201 Installation, Operation, and Maintenance Manual 43

Page 46

Technical reference

Technical reference

Application limits

Data Description

Liquid temperature 40°C (104°F) maximum

If the pump is not equipped with cooling jacket, the pump can be operated at full

load only if at least half the stator housing is submerged.

Warm-liquid version: 90°C (195°F) maximum

At increased temperatures, the pump must be completely submerged when

operating at full load.

Ex-approved pumps: 40°C (104°F) maximum

Liquid density 1100 kg/m³ (9.2 lb per US gal) maximum

Motor data

pH of the pumped media

(liquid)

Depth of immersion 20 m (65 ft) maximum

Other For the specific weight, current, voltage, power ratings, and speed of the pump, see

Feature Description

Motor type Squirrel-cage induction motor

Frequency 50 or 60 Hz

Supply 1-phase or 3-phase

Starting method

Maximum starts per

hour

Code compliance IEC 60034-1

5.5–14 for cast iron pumps

3–14 for stainless steel pumps

the data plate of the pump.

• Direct on-line

• Star-delta

30 evenly spaced starts per hour

Rated output variation ±5%