Page 1

Global Water

800-876-1172 • globalw.com

02-056

Publication Number 38580512

Global Water

Instrumentation, Inc.

151 Graham Road

P.O. Box 9010

College Station, TX 77842-9010

T: 800-876-1172

Int’l: (979) 690-5560, F: (979) 690-0440

E-mail : globalw@globalw.com

FC220 Flow Monitor

- 1 -

Page 2

Global Water

800-876-1172 • globalw.com

Congratulations on your purchase of the Global Water FC220 Flow

Monitor. This instrument has been quality tested and approved for

providing accurate and reliable measurements. We are confident that you

will find the monitor to be a valuable asset for your applicati on. Should you

require assistance, our technical staff will be happy to help.

Table of Contents

I. FC220 Flow Monitor Description • • • Page 3

II. FC220 Specifications • • • • 5

III. Flow Calculation Modes • • • • • 6

IV. Switch Settings • • • • • 8

V. Sensor Input • • • • • 9

VI. 4-20mA Output • • • • • 9

VII. Relay Operation • • • • • • 9

VIII. Power Saving Mode • • • • • 10

IX. Scientific Notation • • • • • 10

X. Totalizer • • • • • • 10

XI. Programming Setup Parameters • • • • 11

XII. Data Logger Option • • • • • 17

XIII. Maintenance and Troubleshooting • • • 18

XIV. Appendix A: Terminal Strip Diagram • • • 21

XV. Appendix B: Flume and Weir Equation Parameters • 22

* Copyright Global Water Instrumentatio n, Inc. 2012

- 2 -

Page 3

Global Water

800-876-1172 • globalw.com

I. FC220 Flow Monitor Description

The Global Water FC220 F low Monitor is a reliable and accurate instrument for

measuring and totalizing water flow in a wide variety of applications. Wate r level is

measured using Global W ater’s popular WL400 level sensor, WL700 ultrasonic

sensor, or almost any other 4-20mA, 0-5V or 0-1V water level sens or. Flow is then

calculated by the microprocessor using a variety of different techniques. The backlit

LCD display shows real-time flow, water level or total flow in user selectable units;

and the 8-button keypad easily guides the user thr ough the versa tile setup menus.

The FC220 supports several different types of flow calc ulation modes. Over 40

preprogrammed flume and weir equations are included. For monitoring in round pipes

and open rectangular channels; the Manning’s Equation mode allows the user to enter

their own parameters for material type, slope and pipe or chann el dimensions.

Standard flow equations c an also be defined; which c an calculate flow for almost all

flumes and w eirs. Another mode lets the user enter parameters for a b est fit 3

polynomial that is usefu l for calculating flow based on empirical data and lookup

tables. In addition, a factory programmable lookup table can be permanently stored in

the processor s m em ory for monitoring i n applications where a single equation can’t

accurately predict flo w, such as strea mbeds and open channels with complicated

geometry . A 16-character name can be programmed in to the FC220 by the user to

identify the ins tal la ti on si te or show other information about the configuration.

Water flow i s displayed w ith up to 7 digits which allows for the display of flow i n the

largest app lications. The totalizer records flow volume up to 9 digits with floating

point and sc ientific (engineering) notation supported in non-volatile memory, and is

password protected from reset. The maximum recordable total vol ume is more tha n

one trillion cubic feet. Available volume units are cubic feet, gallons, milli on gallons,

cubic meter s and liters; time units incl ude seconds, minutes, hou rs and days. T his

allows for the display of flow in 20 different user de fined units. Water level is

calibrated and displayed in feet, inc hes, meters or centimeters; and a level of fset

function allows the mea sured level to be adjusted to compensate f or variation s in

sensor installation. The engineering u nits for all display modes and setup parameters

are independently programmable, which allows f or the greate st possible versatility.

rd

order

- 3 -

Page 4

Global Water

800-876-1172 • globalw.com

Four indepe ndent relay outputs are provided for triggering external devices like water

samplers and monitoring devices. These relays can be separately programmed to

trigger bas ed on volume per pulse, and threshold se ttings can be used to limit

triggering to flows above preset levels. There is also an acc urate and scalable 4-20mA

output provided for monitoring flow using data loggers and PL C devices. An internal

USB data logger is available as a factory option tha t allows the historical flow data to

be recorde d, as well as the exact time of each relay trigger event. Free software is

provided for programming the data lo gger, downloading flow and relay data, and

exporting to spreadsheets. Programmable power sa ving features allow the supply

current to be reduced, which is import ant in remote monitoring ap plic a ti ons.

A 16 characte r by 2 line LCD display can s how either the current flow ra te, the water

level, or the volume in the totalizer. The 8-button keypad allows the selection of the

display modes, and the pr ogramming of the setup para meters. The DISPLAY button

toggles the LCD display between the flow rate, the water level, and the totalizer. This

button also allows the quick exit from the setup menus when in any setup mode.

Holding the MENU button down for two seconds enters the setup menu. In setup

mode, the MENU button moves from one menu selection to another. The BACK

button moves the user backward through the vario us setup options. The SAVE bu tton

will save a se tup param eter to memory. The UP, DOWN, LEFT and RIGHT arrow

buttons are used to select a nd change setup parameters.

Note:

The FC220 fl ow monitor re quires a level sensor to ope rate. Two and three wire level

sensors with 4-20mA, 0-5 volt and 0-1 volt outputs are sup ported. A sen sor is not

supplied with the FC220, contact Global Water for more information on available

sensors.

- 4 -

Page 5

Global Water

800-876-1172 • globalw.com

II. FC220 Specif ications:

Power Requirements: 12VDC or 18-24VDC Input, +/-10%

Supply Current: 13mA + Sensor Current + Backlight + 4-20mA Output

150mA M aximum Total Cur rent

Backlight C urrent: 23mA when on

Internal Fuse: 315mA

Power Adap tor: 18VDC Universal Power Supply, 90-220VAC Input

Equation Fo rmats: Manning’s Equation for Round Pipes

Manning’s Equation for Rectangular Channels

Standard Flow Equation : Q=A*(B+Ch)^ D

3

rd

Order Polynomial: Q=A+Bh+Ch^2+Dh^3

Stored Flumes: H Type: 0.5, 0.75, 1.0, 1.5, 2.0

HS Type: 0.4, 0.6

Parshall : 1”, 2”, 3”, 6” , 9”, 12”, 24”, 36”, 48”, 60”, 72”

Palmer-Bowlus: 4”, 6”, 8”, 10”, 12”, 15”, 18”, 24”, 30”, 36”

Trapezoi da l: 60º

Stored Weirs: Rectangular: 1’, 2’ 3,

V-Notch: 22.5º, 30º, 45º, 60º, 90º, 120º

Cipollet ti: 1’, 1.5’, 2’, 3’, 4’

Lookup Table: One, Factory Programmable Only

Output Relays: 4 Independent SPDT Relays, Pulse On Time = 1 Second

Contact Rating: 8A @ 250VAC, 5A @ 30VDC Resistive

Level Sensor Input: 2-Wire or 3-wire, 4-20mA, 0-5VDC, 0-1VDC

Output: 4-20mA Scalable

Display/Keypad: 16 Character x 2 Line Backlit LCD, 8-Button Tactile Keypad

Flow Capacity: 7 Digit Maximum, Auto-Floating point

Totalizer Capacity: 9 Digit Maximum

Auto-Floating Point, Engineering notation su ppor ted

Max Volume = 1.0995E12 Cubic Feet (1.0995 x 10^ 12 Ft³)

Level Capacity: 5 Digit Maximum

Display Resolution: 3 Decimal Pla ces Maximum, Auto-Adjusting

Accuracy: Sensor Accuracy + Equation/Table Error + 0.1% + 1 Digit

Level Units: Feet, Inches, Meters, Centimeters

Volume Units: Cubic Feet, Gallons, Million Gallons, Cubic Meters, Liters

Time Units: Seconds, Minutes, hours, Days

Flow Units: 20 Combinations of Volume and Time Units Above

Dimensions: 7.1”W x 5.1”H x 1.4D (180mm x 130mm x 35mm)

Weight: 1 lb

- 5 -

Page 6

Global Water

800-876-1172 • globalw.com

III. Flow Calculation Modes

The FC220 de termines flow from water level in several different ways. Standard flow

equations, Manning’s Equation, polynomials or a lookup table can all be used. The

following equation formats calculate flow in cubic feet per second based on the

measured wa ter level in feet. A conversion is made by the microprocessor so that the

display and 4-20mA output work in the user defined flow units.

Flow Equation:

There are standard flow equati on parameters for over 40 flumes and weirs stored in the

FC220. The user also has the ability to enter their ow n parameters for the flow

equation in the form of:

Q = A * (B+Ch)^D

Where:

Q = Flow in Cubic Feet Per Second

A - D = User Programmable C oefficients. If B is not used, enter zero

h = Water Level in Feet

If this mode is selected, the user is prompted to enter the four param eter s in the

equation, A, B, C and D.

Manning’s Equation:

The Manning’s Equation is a widely accepted way of ca lculating the flow in any

gravity feed partially full channel of known geometry. Two applications are

supported, round pipes and rectangular channels. T he equation is in the form of :

Q = ( 1.486 / n ) * WA * ( WA / WP ) ^ 0.6667 * ( Slope ) ^ 0.5

Where:

Q = Flow in cubic feet per second

n = Roughness Factor

WA = Wetted Area in Feet², cross sectional area of the w ater at any given depth

WP = Wetted Pe rimeter in ft, length of bottom and side s tha t is we t at any given de pt h

Slope = Slope of channel or pipe, drop in elevation divided by length of drop.

- 6 -

Page 7

Global Water

800-876-1172 • globalw.com

In these modes the user is either prom pted to enter the pipe diameter or rectangular

channel width, in use r programmable units. The WA and WP are automatically

calculated ba se d on the diameter or width, and the measured water level.

The roughness factor is determined by the construction material, typical values are:

0.010 Plastic, othe r smooth surf aces

0.012 Smooth unpainted steel

0.013 Painted steel, coated cas t iron

0.013 Clay drainage tile, sm ooth asphalt

0.013 Finished conc rete

0.014 Vitrified clay sewer tile

0.014 Uncoated cast iron

0.017 Unfinished concrete

0.024 Corrugated metal storm drain

Polynomial:

A best fit 3

rd

order poly nomial can also be used to calculate flow. This is useful when

you need to find an equatio n that best fits measured data or a lookup table. The

equation is in the for m of:

Q = A + Bh + Ch² + Dh³

Where:

Q = Flow in cubic feet per second

A - D = User defined coefficients

h = Water level in feet

When selec ting this mode, the user is prompted to enter the values for A, B, C and D.

Look-Up Table:

For applications where a single equation does no t properly calculate flow, a single

look-up table can be programmed into the FC220. This is a factory programmable

option only. Data for this table must be provided to G lobal Water in two columns and

no more than 200 lines. The firs t column is water level in fee t and the second column

is the flow in cubic feet per second at that water level. Liner interpolation is

automatically done when a measured water level is between two data points.

- 7 -

Page 8

Global Water

800-876-1172 • globalw.com

IV. Switch Settings

Inside the FC220 is a bank of 8 switches which are used to select the s ensor type and

power input. Select the switches as follows:

Select only one of SW1 and SW2, leave the other swi tch off

SW1: ON, Sensor power is 12 volts

SW2: ON, Sensor power is 18-24 volts depending on the voltage input to the

FC220. Note this feature is not available when running from a 12 volt batte ry

SW3: ON, Sensor power is continuous

SW3: OFF, S ensor power is switched on and off by the microprocess or in power

saving mode. If not using power saving mode, set SW3 to ON.

SW4: ON, Sensor type is 4-20mA

SW4: OFF, S ensor type is 0-5 VDC or 0-1 VDC

SW5: ON, Sensor type is 4-20m A or 0-5 VDC

SW5: OFF, S ensor type is 0-1 VDC

SW6: This switch is unused

Select only one of SW7 and SW8, leave the other switch off

SW7: ON, Power input to the FC220 is 18-24 VDC

SW8: ON, Power input to the FC220 is 12 VDC

- 8 -

Page 9

Global Water

800-876-1172 • globalw.com

V. Sensor Input

The FC220 acc epts any water level sensor with a 4-20mA, 0-5VDC or 0-1VDC output.

Available power for the sensor depends on the power input to the F C220. When

powering the FC2 2 0 from 12 volts, the sensor p ow er is also 12 volts. I f you are

running from a power supply of 18-24 volt s, the sensor power can be se lected from

either a regulat ed 12 vo lt s upply, or directly from the 18-24 volt input. The power can

also be conne cted continuously or it can be set to be tur ned on and off by the FC220

when using powe r saving mode . In this mode the sensor is turned on at user defined

intervals f or a programmable warm-up time, then turned off again to conserve powe r.

VI. 4-20mA Output

A 4-20mA output is prov ide d tha t is pro p ort i ona l to wa ter fl ow . This allow s the water

flow history to be recorded by an external data logger or PLC, or by the internal data

logger opti on, or both. The output is scalable and allows the user to se lect the flow

rates that ar e proportional to the 4mA and 20mA output currents.

VII. Relay Operation

Four indepe ndently prog rammable relays are provided for triggering extern al devices.

These outputs are generally intended for triggering water sam plers when doing flow

proportion al sampling, or f or recording by an external data logger or PLC. The relays

are single pole double throw (SPDT) types with common, normally open and normally

closed conta cts available at the terminal block inside the FC220. The setup menu

allows the user to independently set the volume of water per output pulse, and set a

threshold level that inhibits the acc umulation of volume when the flow is below a user

defined flow rate. The relays are pulsed on for 1 second when the volume of water

since the last pulse equals the volume per pulse setting, and the flow rate is a bove the

threshold level. Example: The volume per pulse is se t to 100 gallons and the

threshold setting is 10 gallons per minute. As long a s the flow rate is 10 gallons per

minute (GPM) or more, the water volume is counted and one pulse will occur for

every 10 gallons. If the flow f alls below 10 GPM the counting of water volume will

stop until the flow rises above the thre shold setting again. If the flow is above 10

GPM long enough to accumulate 5 gallons, then falls below 10GPM, counting stops

but the accumulated 5 gallons is r etained. W hen the flow rate rises above 10GPM

again, only 5 more gallon s is needed to output a relay pulse.

- 9 -

Page 10

Global Water

800-876-1172 • globalw.com

VIII. Power Saving Mode

A power saving mode is provided that allows the operating current to be reduced in

remote monitoring applic ations. One wa y this is accomplished is to turn off the LCD

display backlight, this saves about 20mA of current. Three modes allow the user to

turn the backlight on all the time, off all the time, or turn it on for one minute only. In

this last mode, the backlight will come on for one minute when any of the b uttons on

the keypad are pressed, then turn off again. The wate r level sensor can also be turned

on and off periodically to r educe power consumption. The user can program a sample

rate of 0-60 minutes, and can se t the sensor warm-up time of 0-60 seconds. Example:

The sample rate is 30 minutes and the warm-up time is 3 seconds. The sensor will be

turned on for 3 seconds every 30 minutes then shut off again. Durin g the time the

sensor is off the flow display and 4-20mA output will in di cat e a flow ba se d on t he las t

level reading. The totalizer will continue to be incre mented, and the relays will

continue to oper a te, based on that last reading. A fter 30 minut es more, a new reading

will be taken and the di spla y and 4-20mA output updated aga in. Note that using the

4-20mA output will increase the current draw by a n amount equal to the output

current.

IX. Scientific Notation

Scientific no tat i on is generally used for displaying very large or very small numbers.

It represen ts a number as being multiplied by 10 raised to a power, such as 5.67* 10^2

being equal to 567 since 10^2 equals 100 (10^2 = 10²). Engineering notation is similar

but only uses 10 raised to a power that is a multiple of 3; like 10^3 (one t ho us an d),

10^6 (one million) or 10^9 (one billion) . This notatio n also replaces “*10^” with “E”

(Exponent) so that 5.67E2 is eq uivalent to 5.67*10^2 or 567. The notation E2 is also

equivalent to “shift the decimal point to the right two times”. This makes the di splay

of large numbers easier to read; 5.67E 3 is 5.67 thousand or 5670, 5.67E6 is 5.67

million, et c. In the same way, small numbers less that one can be shown as 10 raised

to a negative power, or “shift the decimal point that many time s to the lef t” ; suc h as

5.67E-3 = 0.0 0567 or 5.67 thousandths, 5.67E-6 = .0000 0567 or 5.67 millionths.

X. Totalizer

A 9-digit totalizer keeps track of the total volume of water that has ac cumulated since

the last time the totaliz er was reset. The totalizer display supports engineering notation

and can store volumes up to 1.1E 1 2 cub ic fe et ( 1. 1 x 10^ 12 or 1. 1 tril li o n) in any of the

- 10 -

Page 11

Global Water

800-876-1172 • globalw.com

5 selectable volume uni ts. The engine ering notation is automa tically switched on

when the totalizer volume exceeds the capacity of the 9-digit display.

The totalizer re se t funct i on is pa ssword protected, pre ve nt in g a user from entering the

reset menu. This menu also allows the user to change the password. The password is

4 digits in the range of 0000-9999. When s hipped from the factory the def ault

password is 123 4. It is recom mended that the password be changed bef ore ins tal l in g

the FC220. If the password is lost or forgotten, contact the Technical Support

department at Global Water.

XI. Programming Se tup Paramet ers

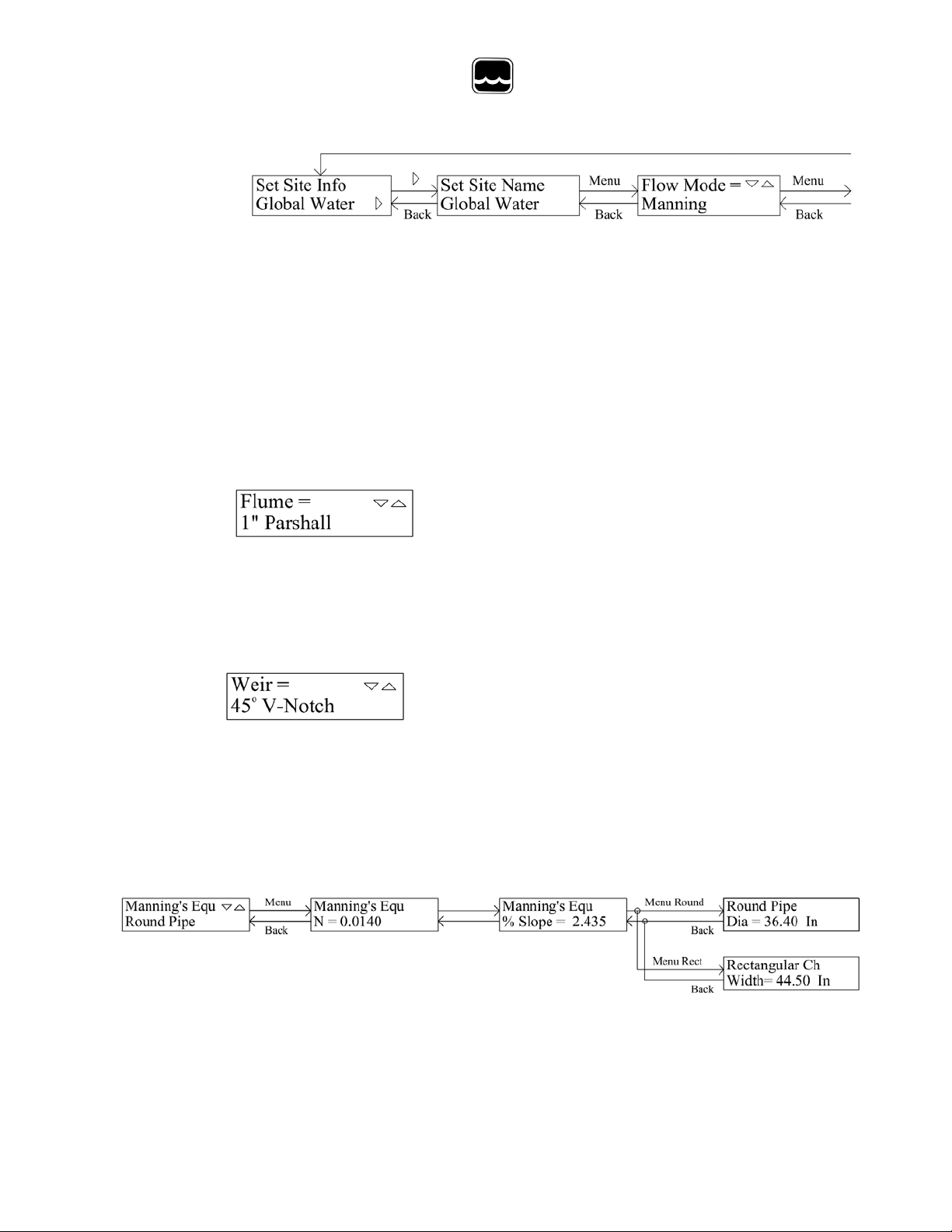

Press the MENU button for 2 second s to enter the s etup menu. Pressing the MENU

button again cycles through the differ ent setup options. Pressi ng the BACK button

moves backw ard to the previous display. Pressing the DISPLAY button from any

menu exits to the norma l display mode. Press the RIGHT arrow button to enter any of

the setup sub-m enus. These su b-menus are Set Leve l Unit, Set Volume Unit, Set Time

Unit, Calibrate Sensor, 4-20mA Output Calibration, Set Site Info, Power Saving, Relay

Settings, and Totalize r Reset. Note that while in the setup menus, flow calc ulations

and relay opera ti ons w ill s to p. A fter one minute of inactivity, the FC220 will

automatically return to the main dis play and operation mode.

The followi ng three menus set the level, volume and time units used for sh ow i ng da t a

on the main display. The level unit is used to display the water level. The volume

unit is used to display the totalizer, the total volume of flow since last reset. The

volume and time units are combined to form the flow units of Volume/Time. Other

setup parameters in these menus have independently programmable units. Cha ng i ng a

unit of measure in one me nu will not affect the settings in any other menu.

Set Level Unit:

This unit is used to display water leve l on the main display. The current se tt ing is

shown in the Set Level Units menu. Use the RIGHT arrow to change the level units.

Use UP and DOWN to select either Feet, Inches, Meter s or Centimeters. Press Save to

store the new setti n g.

- 11 -

Page 12

Global Water

800-876-1172 • globalw.com

Set Volume Unit:

This unit is used to d isplay the to talizer volume on the main display. The current

setting is shown in the Set Volume Unit menu. Use the RIGHT arrow to change the

volume units. Use Up and D OWN to select either Cubic Feet, Gallons, Million

Gallons, C ubic Meters, or L iters. Press SAVE to store.

Set Time Unit:

This unit, combined with the volume unit from the previous menu, is used to determine

the flow unit on the main d isplay. The c urrent time units are shown in the Set Tim e

Unit menu. Use the RIGHT arrow to change the time units. Use U p and DOWN to

select either Seconds, M inutes, Hours or Days. Press SAVE to store.

Example: If the volum e unit is set to cubic feet and th e time unit is se t to seconds, the

flow unit is autom atic a lly cub ic fe et per sec ond. There are 20 possible combinations

of volume a nd time units that determine the flow unit.

Calibrate Sensor:

To change or check the sensor calibra tion press the RIGHT arrow button. To skip the

calibration option press the MENU ke y to move to the next option or press BACK to

return to norm al disp l ay mode.

The low water level is set a t zero. Remove the level se nsor from the water and pres s

SAVE to store the raw data num be r for t he zero le vel sensor output. I n the case of an

ultrasonic sensor, place it at a distance from a target equivalent to the zero water level

point. Press MENU to move forward to the High Level option. Place the sensor at a

known depth as close to maximum range of the sensor as possible. Use the LEFT and

RIGHT arrows to select a digi t to modify, then use the UP and DOWN arr ows to scroll

through digits 0-9 and decimal point. Select just one decimal point if it is needed. In

this manner change the High Level numbers to match the depth of the sensor. Use the

- 12 -

Page 13

Global Water

800-876-1172 • globalw.com

RIGHT arrow to move to the level unit, the units will flash. Use UP and DOWN to

select the unit that corresponds to th e high level that was just set. Press SAVE to store

these setting s. Press MENU to move forward. Press the SAV E button to store the raw

data value for the high level sensor output. Press MENU to move to the level offset

option. The level offset is added to (or subtracted from) the measured water level to

correct for e rrors in installation. For example, if a sensor is installed horiz ontally in

the bottom of a pipe you can a dd the radius of the sensor housing to m ake up for the

fact that the sensor out put will not change until the water level reaches the center. The

radius of the WL400 sensor is 0.41” and the radius of the FL400 sensor is 0.50”. Use

the arrows to set the leve l offset. Set the first character to either + or – to add or

subtract the offset respectively, select the remaining characters f rom 0-9 and decimal

point. Press SAVE to store the offset value.

4-20mA Output Calibration:

To scale and calib rate the 4-20mA output press the RIGHT arrow key. The 4mA Set

Point is the amount of flow that results in an output current of 4mA, generally zero.

Use the arrow buttons to change the setting. Use the RIGHT arrow to advance to the

volume unit until it flashes. Use UP and DOWN to select the volume unit. Use the

RIGHT arrow to advance to the time unit. Use UP and DOWN to select the time unit .

Press SAVE to store these settings and MENU to move forward. The 20mA Set Point

is the magnitude of flow that c auses a 20mA output current. Use the arrow buttons to

change the s et point valu e, the units are those selected in the previous me nu. Press

SAVE to store this setting. Any flow betwee n the se tw o set po i nts wi ll be scal ed to t he

corresponding output cur rent. The next three me nus are generally set at the factory

and should not need to be changed. The 4mA Output Cal menu allows the 4-20mA

output to be set to exactly 4mA. Connect a DC current meter between the 4-20mA

output and grou nd. Use the UP and DOWN arrows to raise and lower the r aw data

number (and output current) until the current meter reads exactly 4.000mA. Press

SAVE and MENU. The 20mA Output Cal menu sets the 20mA output in the same

way. Use UP and DOWN to adjust the output until the current meter read s exactly

20.000mA. The Calibrate Logger menu is used to recalibrate the FC220 data lo gger

option only and will be discussed in the section titled Data Logger Option and in the

Data Logger Option softwa re manual.

- 13 -

Page 14

Global Water

800-876-1172 • globalw.com

Set Site Info:

The Site Info menu is where the type of fl ow monitor ca lculation is defined. A 16

character site name or label can also be added for reference. The current site name is

shown in the Set Site Info menu. T o change site information press the RIGHT arrow

button. Change the site name in the first sub-menu. Use the LEFT and RIGHT arrows

to select a charac ter and th en scroll throug h available characters usin g UP and DOWN.

Press SAVE to store and MENU to move forward. The next menu sets the ty pe of

flow calculation; use UP and DOWN to choose one of: flume, weir, Manning’s

Equation (round pipe or rectangular channel), standa rd flow equation, best fit 3

rd

order

polynomial, or look-up table. Press SAV E to store the f low mode.

Flume:

If Flume is selected, the user is prompte d to select a flume type from a list of standard

flumes. See the specifications secti on for a list of available flumes. The flow equation

parameters a re shown in Appendix C. Use UP and DOWN to select the flume type

and press SAVE to store the change.

Weir:

If Weir is selected, the user is prompted to select a weir type from a list of standard

weirs. See the specifications section for a list of available weirs. The flow equation

parameters a re shown in Appendix C. Use UP and DOWN to select the we ir type and

press SAVE to store the change.

Manning’s Equation:

Use UP and DOWN to select either Round Pipe or

Rectangular Channel. Pr ess SAVE to store and MENU to

advance. To set the roughness ind ex n, use LEFT and RIGHT to select a digit and UP

and DOWN to change it. Press SAVE and MENU. In the same manner, enter the

slope in percent. Press SAVE and MENU. Enter the diameter of the round pipe or the

- 14 -

Page 15

Global Water

800-876-1172 • globalw.com

width of the rectangular channel. Use the RIGHT arrow to advance to the units until

they flash, use UP and DOWN to select the unit and press SAVE to store the settings.

Standard Flow Equation:

The water flow through most or all flumes and weirs can be described by the equation

shown above. Use the MENU, arrow buttons and SAVE to set the parameters A - D.

Not all flow equations req uire all 4 coefficients. If B is not used enter 0.000, if C is

not used enter 1.000 as shown above. A and D can also be set to 1.000.

rd

3

Order Polynomial:

A set of data points such as from a lookup table can be approximated by a polynomial.

The 3

rd

order polynomial show n above can give a very good approximation of flow in

many cases. The accuracy of the equat ion will vary depending on the accuracy and

number of the data point s. Errors can i ncrease toward the uppe r and low e r end s of the

curve. If the normal range of flow is kno wn, the equati on coefficients can be adjusted

to minimize errors within the measurement range. Near zero flow the approximation

can result in negative numbers. While these negative numbers are generally very

small, they must be ignored for the purposes of displaying flow and updating the

totalizer and 4-20mA output. Any negative number calculated by the p olynomial wi ll

be consider ed zero flow. U sin g the ar row bu tto ns, SAVE and MENU; set the

parameters A – D observing the +/- signs. The expon ent is one digit in the range of -9

to +9.

Look-Up Table:

A single lookup table can be selected i n cases where an application can’t be modeled

by an single equation. The lookup table and table name are factory programmable

only. A name of up to 16-characters, and lookup ta ble da ta must be supplied. For

more information contact the Technical Support department at Global Water.

- 15 -

Page 16

Global Water

800-876-1172 • globalw.com

Power Saving Mode:

The power sa ving mode allows the average power consumption to be reduced by

controllin g the time when the water level sensor and LCD backlight are turned on. To

set the power saving parameters, press the RIGHT arrow button. The LCD Backlight

has 3 settings, ON turns the backlight on all the time, OFF forces the backlight to be

off, and 1 Minute mode will turn the backlight on when any butt on on the keypad is

pressed, then it will turn off again after one minute of inactivity. Use the UP and

DOWN arrows and SAVE to set and save the s etting. The Sample Rate is the interval

between sens or rea d ing s (and how often the display and 4-20mA output will be

updated). Use LEFT and RIG HT to select a digit and use U P and DOWN to scroll

through 0-9, press SAVE to st ore the setti ng. The Sensor Warmup time is how long

the sensor will be powered on before a reading is take n. Set this para meter in the same

manner as the sample rate. In this e xample the backlight is in 1 minute mode. The

sensor will be turned on for 3 seconds every 60 minutes. T he di spla y and 4-20mA

output will remain on but will continue to indicate the flow that corr e spo n ds to the last

level measur ement. During the tim e the sensor is off , the totaliz er and relays will

continue to operate based on the last sensor reading.

Relay Settings:

To modify Relay Settings, press the RIG HT arrow button. Each relay is independe nt

of the others and must be programmed sep arately. Use the UP and DOWN arrows to

select which relay is to be changed, press MENU to move to the next sub-menu. The

Volume of Pulse setting is the am ount flow needed to generate a relay pulse. The relay

number selected is shown at the lower right. If a relay is not used, enter zero and no

pulses will be generate d. Use LEFT and RIGHT to select a digit, and UP and Down to

scroll through the numbers. Use the RIGHT arrow to move to the volume units, select

using UP and DOWN. Press SA VE to store the setting. The Minimum T hreshold

setting inhibits the counting of pulse volume unless the flow rate is above the threshold

level. The selected relay number is shown at the lowe r right. Set the threshold level,

volume unit and time unit in the same w ay , then press SAVE. In the above example,

relay 2 will be pulsed for every 100 cubic feet of water as long as the flow rate is over

10 cubic feet per second. Any water flow while the flow rate is below the 10 cubic

feet per second threshold will not be counted toward the 100 cubic foot pulse volume.

- 16 -

Page 17

Global Water

800-876-1172 • globalw.com

Totalizer Reset:

The Totalize r Reset me nu allows the totalizer to

be reset to ze ro. The rese t is password protected.

This menu also allows the password to be changed. When shipped from the factory

the password is set to 1234. Press the RIGHT arrow to e nter the password. Use the

LEFT and RIGHT arrows to select each digit, and use UP and DOWN to scroll

through the numbers. Pre ss MENU to m ove forward provided that the password was

entered cor rectly. If the password is lost or forgotten, contact t he Global Water

Technical Support department. If you want to reset the totalizer c oun ter to zer o, use

UP or DOWN to select YES, then SAVE. If you do not want to reset the counter,

select NO. Press Menu to move forward. I f you said YES you must confirm the reset,

use UP or DOWN to select yes, then SAVE and MENU. If you want to cha nge the

password, use UP or DOWN to select YES, then SAVE and MENU. Use the LEFT

and RIGHT a rrows to select each digit and use UP and DOWN to scroll through the

numbers. Press SAVE and MENU. Confirm the new password by e ntering it agai n in

the same manner as before.

XII. Data Logger Option

A factory option for the FC220 is an internal data logger which records a historical

record of wa ter flow, and r ecords the exact time of each relay pulse. C ha nne l o ne of

the data logger records f low and channel two records relay events. A special software

package allows the programming of the logger and the download of recorded flow and

relay data. This softwar e differs from other Global Water data logger software in the

way it proce sses the relay data. Softwar e such as Global Logger II will work with the

FC220 data logger option but some rela y information will not be seen. The data logger

is factory calibrated a nd should not need to be recalibrated again. Should you need to

recalibrate the logger, consult the Data Logger Option manual.

- 17 -

Page 18

Global Water

800-876-1172 • globalw.com

XIII. Maintenance and Troubleshooting

a. Global Water recomme nds verifying the sensor’s calibration e very 6

months.

b. The screen on the end of the sensor must be peri odically checked for

clogging from mud, sludge , and other debris. Wash the screen with clean

water and/ or scrub it gently with a toothbrush. Do not insert obj ects

through the screen, as this may cause damage to the sensor.

c. In battery ope rated systems it is recommended that the battery be replaced

every 3-4 years, more often in harsh enviro nments or when the battery is

allowed to be completely discharged.

Trou ble Shootin g

d. Verify that the power source is supplying correct vo lta ge to t he F C2 20

and to the sensor.

e. Make sure that the vent tube ha s not be e n kinked or sealed. The sensor

uses this tube to compensate for barometric pressure changes.

f. Check the sensor’s calibration.

g. Clean the sensor following the maintenance instructions.

Testing the sensor:

To check the level sensor calibration separate from the flow monitor, you

will need:

1 column of water (the closer the depth is to the maximum range of the

sensor the better the cali bration will be)

1 power supply

1 current meter

Connecting wires as necessary

Unplug the Flow Meter and disconnect the sensor. Connect the

sensor to the power supply and current meter in the following way.

Attach the black wire to the positive input of the current meter. Connect

the ground terminal of the power supply to the ground of the current

meter. Attach the red wire to the positive termina l of the power supply.

- 18 -

Page 19

Global Water

800-876-1172 • globalw.com

See Appendix A. Warning: Always connect the sensor with the power

turned off.

At zero feet (out of water ), the se ns or sh ou ld ou t put a ppr o xim a tely

4mA. This can be read directly on the current meter or, if using the

voltmeter method, the meter should read 0.5 volts across a 125 ohm

resistor. At the maximum water depth of t he sensor, the sensor should

output approximately 20mA or 2.50 volts across the 125 ohm resistor.

Issue: Wate r in the vent tube

a. If water gets into the vent tube the water level readings can show very

large errors and can be erratic. If water gets into the vent tube of the cable

place it nex t to a heater for 24 hours to dry the inside of the cable.

Other issues

a. Call Global Water for tec h support: 800-876-1172 or (979) 690-5560

(many problems can be solved over the phone). Fax: (979) 690-0440 or

Email:

globalw@globalw.com

.

When calling for tech support, please have the following information

ready;

1. Model #.

2. Unit serial number .

3. P.O.# the equipment was pur c ha sed o n.

4. Our sales number or the invoice number.

5. Repair instructio ns and/or specific problems relating to the

product.

Be prepared to describe the problem you are experiencing including

specific deta ils of the appl ica ti on, ins tallation, an d any addition al

pertinent inf ormation.

b. In the event that the equipment needs to be retur ned to the factory for any

reason, ple ase call to ob tain an RMA# (Return Material Authori zation).

Do not return items without an RMA# displayed on the outside of the

package.

Clean and decontaminate the FC220 if necessary.

Include a written statement describing the problems.

- 19 -

Page 20

Warranty

a. Global Water Instrumentation, Inc. warrants that its products are free

b. The warr anty begins on the date of your invoice.

Global Water

800-876-1172 • globalw.com

Send the package with shipping prepaid to our factory address. Insur e

your shipment, Global Water’s warranty does not cover damage incurred

during transi t.

from defects in material and workmanship under nor mal use and

service for a period of one year from date of shipm ent from factory.

Global Water’s obligations under this warranty are limited to, at

Global Water ’s option: (I) replacing or (II) repairing; any products

determined to be defective. In no case shall Global Water’s liab ility

exceed the prod uc ts or igi na l pur c has e pr ice . This warra nty does no t

apply to any equipment that has been re paired or altered, except by

Global Water Instrumentation, Inc., or which has been subject to

misuse, negligence or a ccident. It is e xpressly agreed that this

warranty will be in lieu of a ll warranties of fitness and in lieu of the

warranty of merchantability.

- 20 -

Page 21

Global Water

800-876-1172 • globalw.com

XIV. Appendix A: Ter m ina l S tr ip Diagram

POWER IN:

V+ 12VDC or 18-24VDC Input

V+ 12VDC or 18-24VDC Input

12VDC Input: SW7 OFF, SW8 ON

18-24VDC Input: SW7 ON, SW8 OFF

GND Power Supply and System Ground

GND Power Supply and System Ground

SENSOR IN:

V+ Sensor Power

12VDC Sensor Power: SW1 ON, SW2 OFF

18-24VDC Sensor Power: SW1 OFF, SW2 ON

(18VDC Power Input Only)

IN Sensor Input

Sensor Power Cont inuous: SW3 ON

Sensor Power Switched: SW3 OFF (Power Saving Mode)

4-20mA Sensors: SW4 ON, SW5 ON

0-5VDC Sensors: SW4 OFF, SW5 ON

0-1VDC Sensors: SW4 OFF, SW5 OFF

4-20mA:

OUT 4-20mA Output

GND Power Supply and System Ground, 4-20mA return P ath

RELAY 1-4:

- 21 -

Page 22

EQ Type:

1 = Flow

2 = Poly

Q=A*(B+Ch)^D

Q=A+Bh+Ch^2+Dh^3

Flumes

EQ Type A B C D

0.5 H Flume 1 1.600

0.000000

1

2.200

0.75 H Flume

1

1.770

0.000000

1

2.230

1.0 H Flume 1 1.950

0.000000

1

2.300

1.5 H Flume 1 2.120

0.000000

1

2.300

2.0 H Flume 1 2.370

0.000000

1

2.230

1" Parshall 1 0.338

0.000000

1

1.550

2" Parshall 1 0.676

0.000000

1

1.550

3" Parshall 1 0.992

0.000000

1

1.550

6" Parshall 1 2.060

0.000000

1

1.580

9" Parshall 1 3.070

0.000000

1

1.530

12" Parshall 1 3.950

0.000000

1

1.550

24" Parshall 1 8.000

0.000000

1

1.550

36" Parshall

1

12.000

0.000000

1

1.570

48" Parshall

1

16.000

0.000000

1

1.580

60" Parshall

1

20.000

0.000000

1

1.590

72" Parshall

1

24.000

0.000000

1

1.590

4" Palmer-Bowlus

1

1.730

0.005880

1

1.957

6" Palmer-Bowlus

1

2.071

0.005421

1

1.903

8" Palmer-Bowlus

1

2.537

0.014560

1

1.972

10" Palmer-Bowlus

1

2.843

0.016160

1

1.953

12" Palmer-Bowlus

1

3.142

0.017000

1

1.936

15" Palmer-Bowlus

1

3.574

0.016800

1

1.906

18" Palmer-Bowlus

1

3.988

0.018750

1

1.898

24" Palmer-Bowlus

1

4.574

0.040800

1

1.950

30" Palmer-Bowlus

1

5.022

0.062500

1

1.966

36" Palmer-Bowlus

1

5.462

0.080000

1

1.991

60º Trapezoidal

1

1.550

0.000000

1

2.580

0.4HS

2

-3.48332E-05

2.10389E-03

3.51517E-01

4.39885E-01

0.6HS

2

-7.52381E-05

8.29552E-03

4.01877E-01

3.79339E-01

Global Water

800-876-1172 • globalw.com

XV: Appendix B: Flume and Weir Equation Parameters

- 22 -

Page 23

Weirs

EQ Type A B C D

1.0' Rectangular

1

3.333

0.000000

1

1.500

2.0' Rectangular

1

6.667

0.000000

1

1.500

3.0' Rectangular

1

10.000

0.000000

1

1.500

22.5º V-Notch

1

0.505

0.000000

1

2.500

30º V-Notch 1 0.676

0.000000

1

2.500

45º V-Notch 1 1.028

0.000000

1

2.500

60º V-Notch 1 1.420

0.000000

1

2.440

90º V-Notch 1 2.490

0.000000

1

2.475

120º V-Notch

1

4.333

0.000000

1

2.500

0.5' Cipolletti

1

1.684

0.000000

1

1.500

1.0' Cipolletti

1

3.367

0.000000

1

1.500

1.5' Cipolletti

1

5.051

0.000000

1

1.500

2.0' Cipolletti

1

6.374

0.000000

1

1.500

3' Cipolletti 1 10.101

0.000000

1

1.500

4' Cipolletti 1 13.468

0.000000

1

1.500

Global Water

800-876-1172 • globalw.com

- 23 -

Loading...

Loading...