Page 1

F-1000

INSTRUCTION

MANUAL

R

Blue-White

Industries, Ltd.

5300 Business Drive

Huntington Beach, CA 92649

USA

Phone: 714-893-8529 FAX: 714-894-9492

E mail: sales@blue-white.com or techsupport@blue-white.com

Website: www.blue-white.com

Page 2

F-1000

TABLE OF CONTENTS

SECTION HEADING PAGE

1 Introduction 2

2 Specifications 3

3 F-1000 Features 3

4 How to install the F-1000 4

4.1 Mounting location 4

4.2 Pipe Flow Stream Requirements 4

4.3 How to install Your F-1000 Saddle Fitting 6

4.3.1 Drill the Mounting Hole 7

4.3.2 Install the Saddle 7

4.3.3 Check the Saddle Alignment 7

4.3.4 Install the F-1000 Sensor 7

4.4 Installing the F-1000 Machined In-Line Fitting (PI) 8

Page 2

4.5 Installing the Molded In-Line Fitting (MI) 9

4.6 How to Install Molded PVC Tee Fitting 9

5 How to Operate the F-1000 10

6 F-1000 Flow Ranges 11

7 How to Maintain the F-1000 12

8 Troubleshooting 12

9 Replacement Parts List 13 - 15

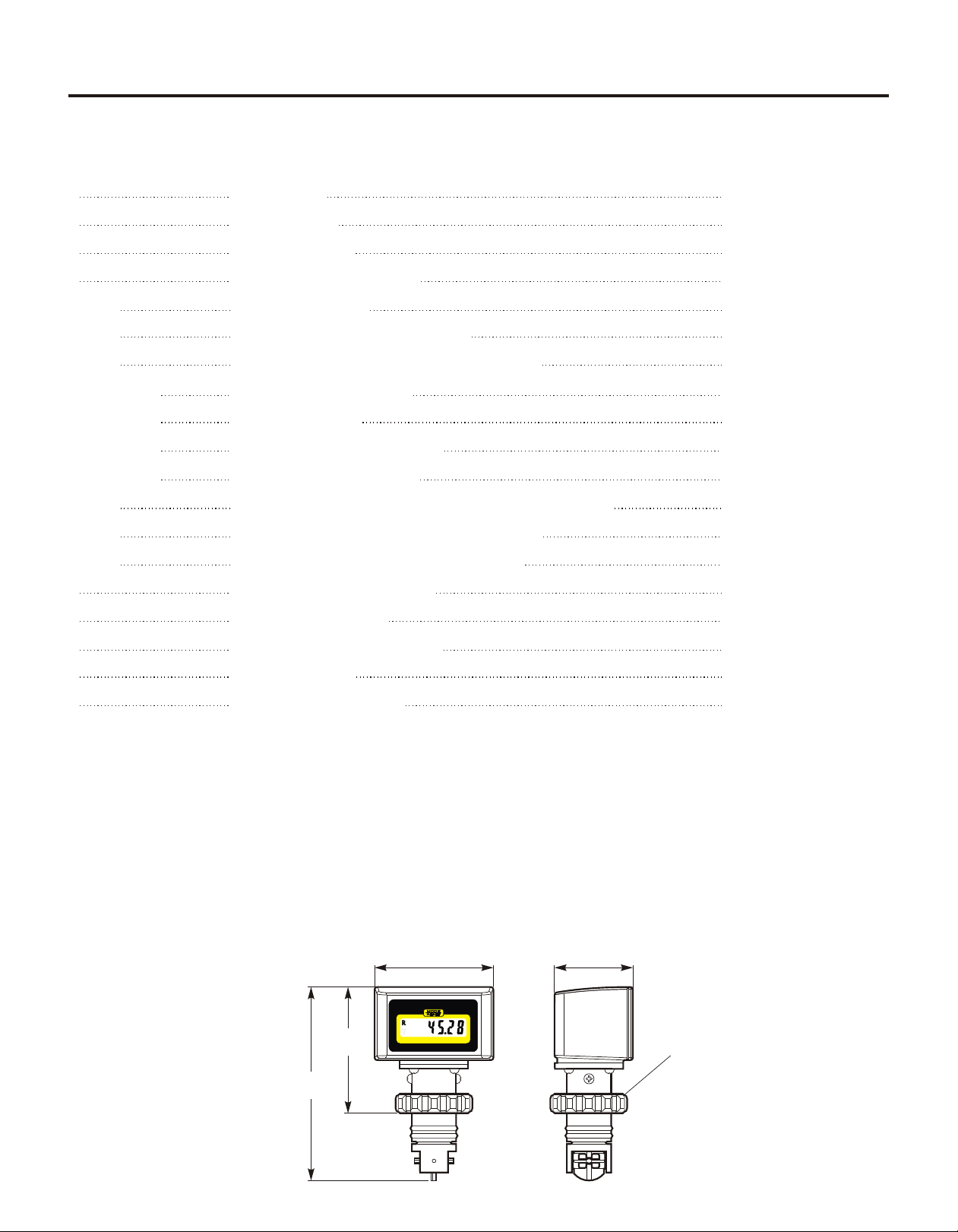

1.0 INTRODUCTION TO THE F-1000

Congratulations on purchasing the F-1000 electronic flow meter. The F-1000 is designed to measure the flow

of a fluid in a pipe. The meter is factory calibrated to any engineering units and displays the rate of flow or the

total of flow on a 6 digit LCD display. Two AAA batteries power the unit for up to one year. There are three

models are available:

F-1000-RB is a rate meter - designed to measure and display the rate of flow.

F-1000-TB is a totalizer meter - designed to measure and display the total flow.

F-1000-RT is a rate/totalizer meter - designed to measure and display both the rate of flow and the total flow.

3.03 in.

(77 mm)

®

BLUE-WHITE INDUSTRIES

2.00 in.

(50.8 mm)

(78.7 mm)

4.93 in.

(125.2 mm)

3.10 in.

GALLONS PER MINUTE

F-1000-RTRate - Totalizer

Union Nut

Fig. 1

Page 3

Page 3

2.0 SPECIFICATIONS

Maximum Working Pressure* 300 psig / 20.7 bar

Maximum Fluid Temperature* 200 F / 93.3 C -Saddle and sensor only

oo

200 F / 93.3 C -When mounted on polypropylene and PVDF inline units.

oo

140 F / 60 C -When mounted on molded PVC tee units or PVC pipe.

Ambient Temperature Range 32 to 110 F / 0 to 43 C

oo

oooo

Enclosure NEMA 4X (acceptable for outdoor use)

NOTE: Protect the LCD display from direct sunlight.

Accuracy +/-2% of full scale rate reading

Repeatability +/-1% of full scale rate reading

Power Requirements Two standard AAA alkaline batteries (included)

Battery Life Expectancy 1 year minimum

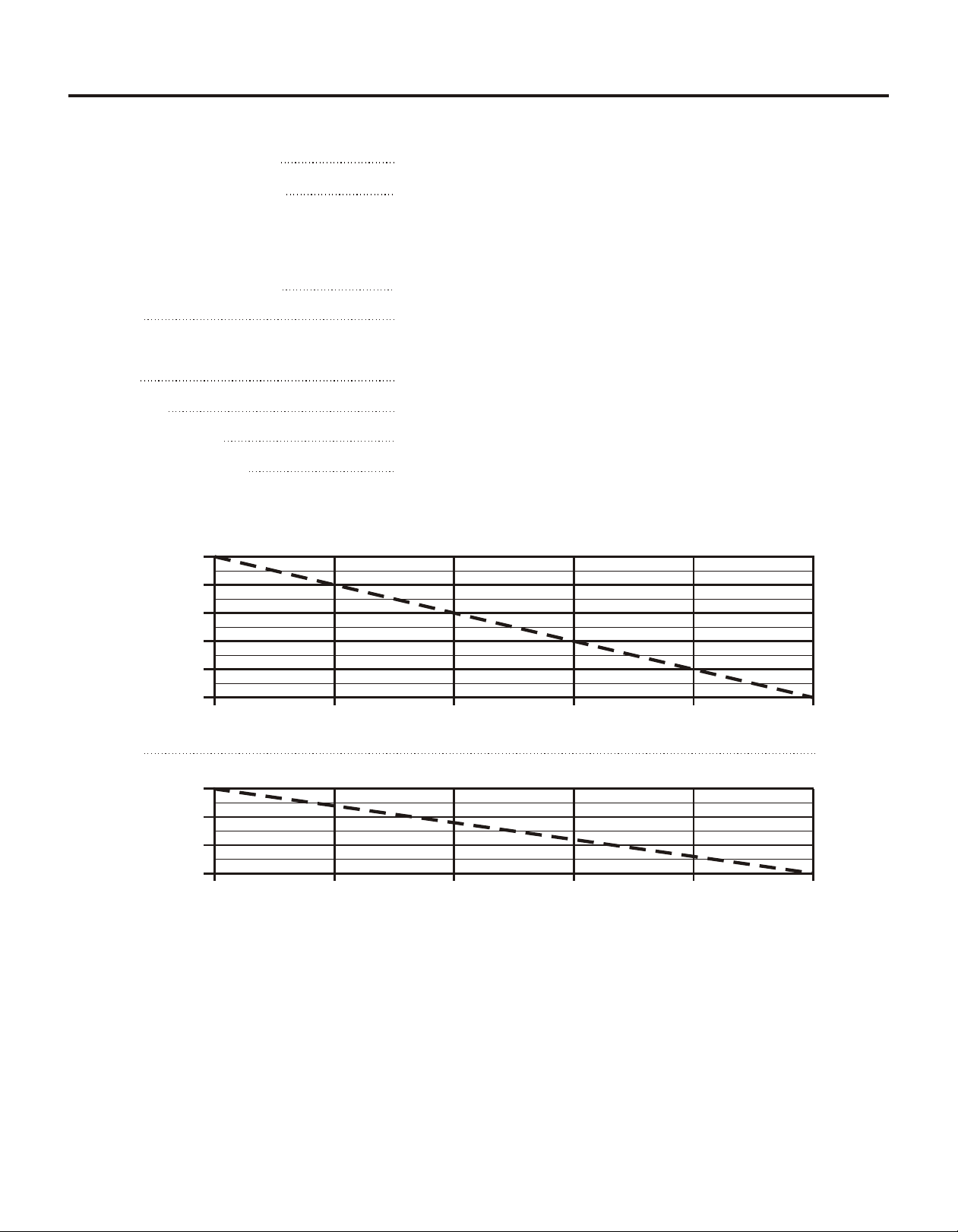

*Temperature vs. Pressure

Temperature

200°F (93.3°C)

When mounted on Polypropylene and PVDF inline units or PVDF Saddles

F-1000

175°F (79.4°C)

150°F (65.5°C)

125°F (51.6°C)

100°F (37.8°C)

70°F (21.1°C)

Temperature

140°F (60°C)

120°F (48.9°C)

100°F (37.8°C)

70°F (21.1°C)

0 (0) 60 (4.1) 120 (8.3) 180 (12.4) 240 (16.5) 300 (20.7)

PSIg (BAR)

When mounted on Molded PVC Tee or PVC pipe units

0 (0) 60 (4.1) 120 (8.3) 180 (12.4) 240 (16.5) 300 (20.7)

PSIg (BAR)

*Pressure and temperature limits are inversely proportional.

3. FEATURES

Fig. 2

!

Easy to read .35" high, six digit LCD display.

!

Installs quickly on existing pipe.

!

Factory calibrated -nothing to program. enclosure.

!!

Minimal maintenance required. High accuracy.

!!

No pressure drop. Large calibrated flow range.

!

Weather resistant enclosure.

!

Corrosion resistant PVDF sensor, ABS

Page 4

F-1000

Page 4

4.0 HOW TO INSTALL THE F-1000

4.1 MOUNTING LOCATION

Note: All diagrams are strictly for guideline purposes only. Always consult an expert before installing the

F-1000 on specialized systems.

Note: The F-1000 should be serviced by qualified persons only.

Although the F-1000 is designed to withstand outdoor conditions, a cool, dry location where the unit can be easily

serviced is recommended. The life of the LCD display will be severely reduced when installed in direct sunlight. Do

not install the meter so that the LCD is in direct sunlight.

!

The F-1000 can be mounted on horizontal or vertical runs of pipe (see figure 4, 5 and 6). Mounting at the twelve

o'clock position on horizontal pipe is recommended. Mounting anywhere around the diameter of vertical pipe is

acceptable, however, the pipe must be completely full of water at all times. Back pressure is essential on downward

flows.

!

The F-1000 accuracy is affected by disturbances such as pumps, elbows, tees, valves in the flow stream. Install the

meter in a straight run of pipe as far as possible from any disturbances. The distance required for accuracy will

depend on the type of disturbance.

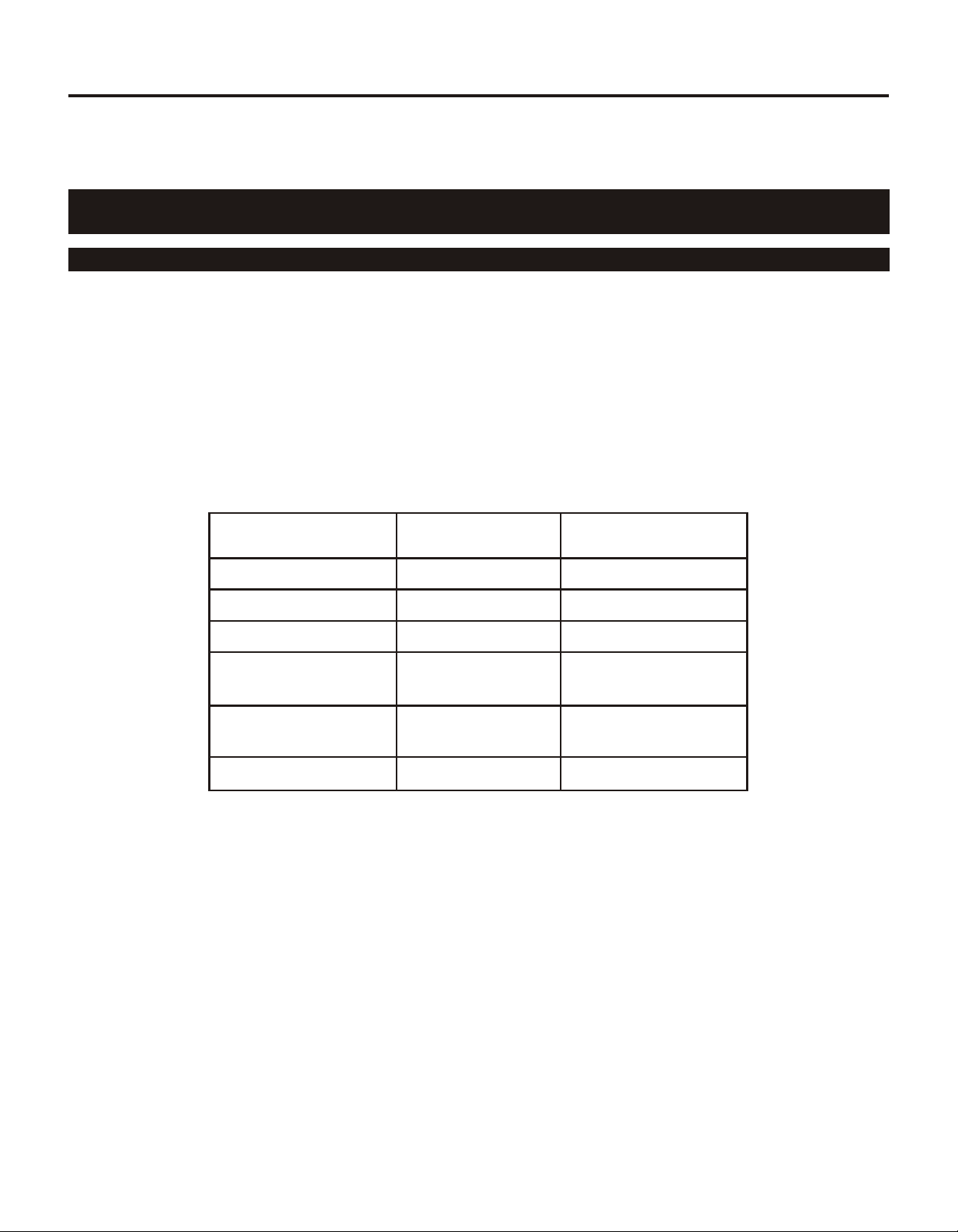

Type Of Disturbance Minimum Inlet Pipe Minimum Outlet

Length Pipe Length

Flange 10 X Pipe I.D. 5 X Pipe I.D

Reducer 15 X Pipe I.D. 5 X Pipe I.D.

o

90 Elbow

Two 90 Elbows -1

o

20 X Pipe I.D. 5 X Pipe I.D.

25 X Pipe I.D. 5 X Pipe I.D.

Direction

Two 90 Elbows -2

o

40 X Pipe I.D. 5 X Pipe I.D.

Directions

Pump Or Gate Valves

!

The pipe must be completely full at all times. Air bubbles or air pockets in the flow stream will adversely affect the

reading. A small amount of back pressure is recommended in horizontal runs of pipe.

!

The F-1000 is powered by two AAA batteries. Life expectancy is one year minimum.

50 X Pipe I.D. 5 X Pipe I.D.

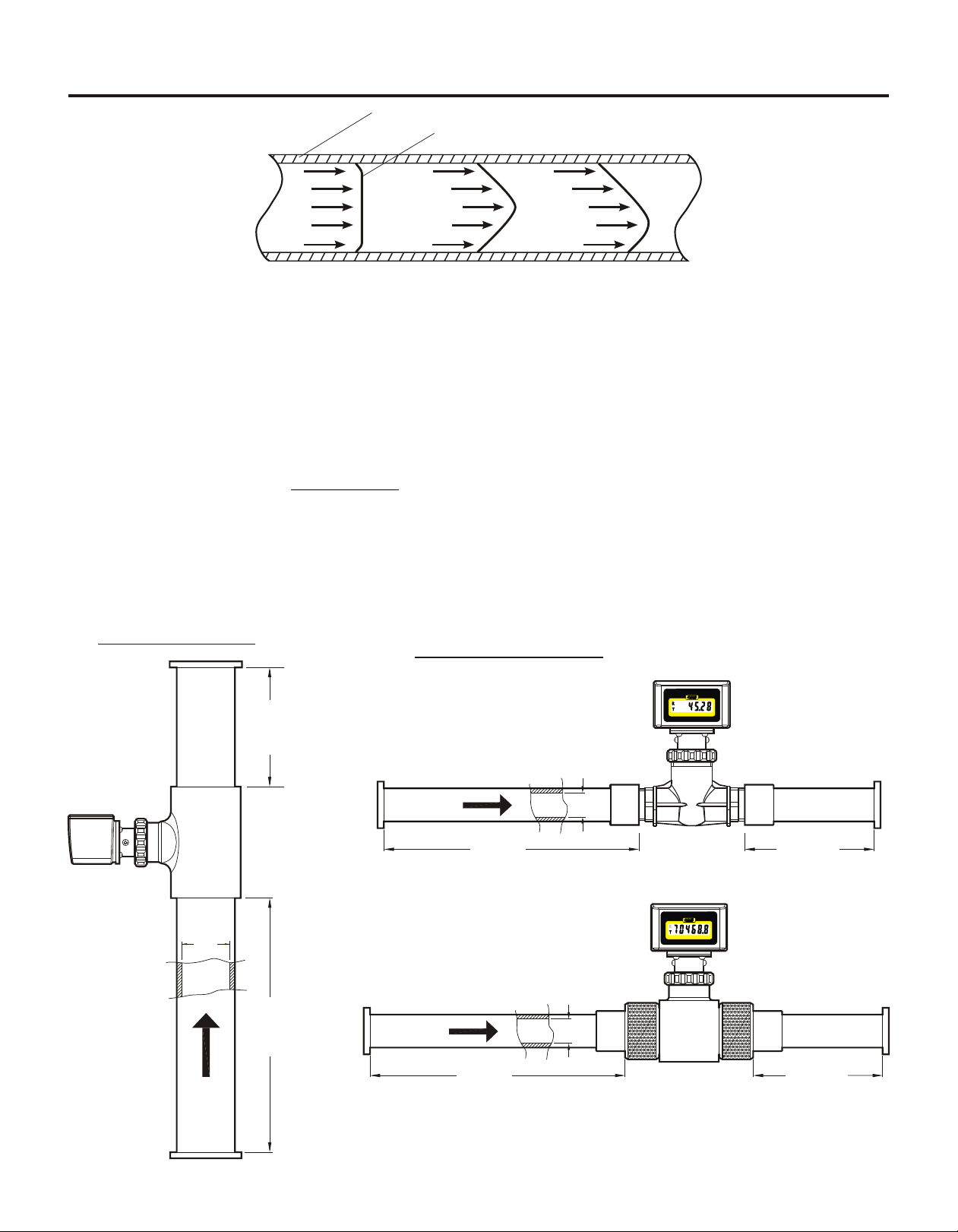

4.2 PIPE FLOW STREAM REQUIREMENTS

!

The F-1000 accuracy is based on steady, undisturbed flow with a fully developed turbulent flow profile. Pulsating,

swirling and other disruptions in the flow stream will effect the meter’s accuracy.

!

The F-1000 is factory calibrated to ± 2% of full scale rate reading. When measuring total flow, accumulated error over

time must be considered. Accuracy is based on laboratory testing of nominal pipe dimensions. Your actual accuracy

will vary based on your actual pipe I.D. And other installation factors.

!

There are two basic types of flow profiles; turbulent and laminar (see figure 3). Turbulent flow exists when the

speed of the fluid flowing in the pipe is nearly constant across the entire width of the pipe. This is typical of low

viscosity fluids; like water, flowing at high velocity. Laminar flow exists when the speed of the fluid flowing in the

center of the pipe is greater than the speed of the fluid at the outer edge near the pipe wall. This is typical of high

viscosity fluids flowing at low velocity. Because the F-1000 is measuring the fluid near the pipe wall only (especially

in larger pipe sizes), a constant flow velocity across the flow stream is required.

!

Page 5

Page 5

F-1000

Pipe Cross Section

Flow Velocity Profile

Fully Developed

Turbulent Flow

Laminar

Disturbed Flow

(due to swirling)

Fig. 3

To determine which type of flow exists in your installation, the following is required:

Flow rate of the fluid in GPM -Q

Specific gravity of the fluid -G

Pipe inside diameter in inches -D

Fluid viscocity in centepoise -V

Use the following equation to determine the REYNOLDS NUMBER:

REYNOLDS NUMBER = 3160 x Q x G

D x V

Flow conditions with a Reynolds Number greater than 4000 is fully developed turbulent flow. A Reynolds Number less

than 2000 is laminar flow. The F-1000 requires a Reynolds number greater than 4000 to maintain accuracy.

Vertical Mount

Horizontal Mount

®

Fig. 4

MINIMUM

OUTPUT

LENGTH

Fig. 5

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

F-1000-RTRate - Totalizer

I.D.

FLOW

MINIMUM

INPUT

LENGTH

FLOW

FLOW

MINIMUM

INPUT

LENGTH

Fig. 6

MINIMUM

INPUT

LENGTH

I.D.

I.D.

®

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

MINIMUM

OUTPUT

LENGTH

F-1000-RTRate - Totalizer

MINIMUM

OUTPUT

LENGTH

Page 6

F-1000

Page 6

4.3 HOW TO INSTALL YOUR F-1000 SADDLE FITTING

The F-1000 saddle is designed to mount on smooth schedule 40 IPS pipe, schedule 80 IPS pipe (ASTM-D-

1785) , PN10 metric pipe or PN16 metric pipe (DIN 8062). The outside of the pipe must be clean, smooth and

free of surface imperfections. The outside diameter must be as specified to ensure a leak free installation. The

inside diameter must be as specified to ensure meter accuracy.

®

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

F-1000-RTRate - Totalizer

H

PIPE O.D.

L

(Outside Diameter)

Fig. 7

I.P.S. Pipe Sizes (in inches)

(ASTM-D-1785)

Nominal Pipe

Size

1-1/2”

2”

3”

4”

6”

8”

10”

12”

Metric Pipe Sizes (in millimeters)

(DIN 8062)

Nominal Pipe

Size

50 mm

63 mm

90 mm

110 mm

160 mm

200 mm 81 200.0 180.8 200.0 170.2

250 mm 114 108 250.0 226.2 N/A N/A

315 mm 114 315.0 285.0 N/A N/A

Length

3-3/16”

3-3/16”

3-3/16”

3-3/16”

3-3/16”

3-3/16”

4-1/2”

4-1/2”

Length

81

81

81

81

81

Height

4-5/16”

4-5/16”

4-5/16”

4-5/16”

4-1/4”

4-1/4”

4-1/4”

4-1/4”

Height

110

110

110

110

108

108

108

Diameter

Diameter

Schedule 40 Schedule 80

Outside

1.900

2.375

3.500

4.500

6.625

8.625

10.750

12.750

Pn10 Pn16

Outside

50.0

63.0

90.0

110.0

160.0

Inside

Diameter

1.610

2.067

3.068

4.026

6.065

7.981

10.020

11.938

Inside

Diameter

45.2

57.0

81.4

99.4

144.6

Outside

Diameter

1.900

2.375

3.500

4.500

6.625

8.625

10.750

12.750

Outside

Diameter

50.0

63.0

90.0

110.0

160.0

Inside

Diameter

1.500

1.939

2.900

3.826

5.761

7.625

9.564

11.376

Inside

Diameter

42.6

53.6

76.6

93.6

136.2

Page 7

Page 7

F-1000

4.3.1 DRILL THE MOUNTING HOLE

!

Select an area on the pipe as outlined in section 4.1. Be sure the surface area of the pipe is clean and

smooth.

!

Drill a 1-1/8" diameter hole through the center of the pipe wall. On horizontal installations, drill the hole as

close to the 12 O'clock position as possible. A hole saw kit is available from the factory, order part number

20000-062.

!

Clean all burrs from inside and outside the hole. Use fine sandpaper (440 grit) if necessary.

4.3.2 INSTALL THE SADDLE

!

Insert the alignment tool through the top of the saddle. Proper alignment is critical! Slide the large O-ring

over the bottom of the alignment tool and into the groove on the underside of the saddle.

!

With the alignment tool and O-ring in place, position the saddle over the drilled hole. Insert the alignment

tool into the hole seating the saddle. Be sure the O-ring is properly seated in the O-ring groove.

!

Place the pipe clamps around the pipe and into the slots on the saddle. Tighten the clamps in an alternating

method.

®

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

Union Nut

Sensor Body

O-rings

F-1000-RTRate - Totalizer

Alignment

Tool

Fig. 8

Alignment

Tool

See Chart

on Page 4

FLOW

Hose Clamps

Saddle

See Chart

on Page 4

I.D.

.030

Drill Hole 1.125±Saddle O-ring

In. Diameter On Center

.000

Saddle

O-ring

Pipe

4.3.3 CHECK THE SADDLE ALIGNMENT

!

Pull the alignment tool out of the saddle. (If the tool is not easily removed, slightly loosen the clamps)

Inspect the hole. The saddle must be mounted directly over the hole. Adjust the saddle alignment until the

alignment tool slides freely in and out of the saddle.

!

Be certain the O-ring is properly seated and visible in the groove around the hole.

!

Tighten the clamps.

4.3.4 INSTALL THE F-1000 SENSOR

!

Be sure two O-rings are located on the sensor body. The O-rings have been lubricated at the factory with

silicone oil.

Center Line

!

Push the sensor assembly into the saddle with a twisting motion. The notch on the sensor body must fit into

the slot on the saddle. Be sure the sensor is fully inserted into the saddle.

!

HAND TIGHTEN the union nut.

Page 8

F-1000

Page 8

4.4 INSTALLING THE F-1000 MACHINED IN-LINE FITTING (PI)

F-1000 machined in-line fittings consist of a meter body, two pipe adapter fittings (inlet and outlet), and two

half union nuts. Pipe adapters are supplied with female American National Standard Taper Pipe Threads (NPT).

The adapters are secured to the meter body with half union nuts and sealed with Viton O-rings.

!

Select an area on the pipe as outlined in section 4.1.

!

Install the F-1000 as you would any other plastic pipe fitting. Because the F-1000 uses half union nut style

connections, the adapters can be installed on the piping system first and then secured to the meter body with

the unions.

!

The F-1000 can be mounted on horizontal or vertical runs of pipe. Mounting at the twelve o'clock position

on horizontal pipe is recommended. Mounting anywhere around the diameter of vertical pipe is acceptable,

however, the pipe must be completely full of water at all times. See figure 4, 5 and 6.

!

Be sure the inlet and outlet fittings are aligned properly. Improper alignment of the fittings will put stress on

the adapter connections and may cause leaking or fitting damage.

!

Do not over tighten the fittings.

!

Use Teflon® tape sealant only on the adapter threads. Do not use pipe dope or glue.

!

Be sure the inlet and outlet plumbing is properly secured. The F-1000 is not designed to support the weight

of related piping. Improperly supported pipes will put stress on the adapter connections and may cause

leaking or fitting damage.

Nominal Pipe Size

3/8”

1 /2”

3/4”

1.0”

1-1/2”

2.0”

®

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

F-1000-RTRate - Totalizer

Pipe Threads

Size

3/8” - F/NPT

1 /2” - F/NPT

3/4” - F/NPT

1.0” - F/NPT

1-1/2” - F/NPT

2.0” - F/NPT

Machined in-line body

O-ring

Machined adapter with FPT

Union nut

Overall Length

L

7.4” (188 mm)

7.4” (188 mm)

7.4” (188 mm)

7.4” (188 mm)

9.4” (239 mm)

11.4” (290 mm)

H

K

Pipe

Overall Height

H

6.3” (159 mm)

6.3” (159 mm)

6.3” (159 mm)

6.3” (159 mm)

6.6” (167 mm)

7.1” (180 mm)

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

Center Height

K

1.22 “ (31 mm)

1.22 “ (31 mm)

1.22 “ (31 mm)

1.22 “ (31 mm)

1.70” (43 mm)

2.00” (51 mm)

®

F-1000-RTRate - Totalizer

F/NPT - Female

Pipe Threads

D

L

W

Fig. 9

Adapter O.D.

D

1.60” (40.6 mm)

1.60” (40.6 mm)

1.60” (40.6 mm)

1.60” (40.6 mm)

2.50” (63.5 mm)

3.08” (78.2 mm)

Body Width

W

2.45” (62 mm)

2.45” (62 mm)

2.45” (62 mm)

2.45” (62 mm)

2.5” (63 mm)

3.0” (76 mm)

Page 9

Page 9

F-1000

4.5 INSTALLING THE MOLDED IN-LINE FITTING (MI)

All molded in-line (MI) fittings have male American National Standard Taper Pipe Threads (MPT).

!

Select an area on the pipe as outlined in section 4.1.

!

Install the F-1000 as you would any other plastic pipe fitting. Be sure the inlet and outlet fittings are aligned

properly. Improper alignment of the fittings will put stress on the adapter connections and may cause

leaking or fitting damage. Do not over tighten the fittings. Use Teflon® tape sealant only on the adapter

threads.

!

The F-1000 can be mounted on horizontal or vertical runs of pipe. Mounting at the twelve o'clock position

on horizontal pipe is recommended. Mounting anywhere around the diameter of vertical pipe is acceptable,

however, the pipe must be completely full of water at all times. See figure 4, 5 and 6.

!

Be sure the inlet and outlet plumbing is properly secured. The F-1000 is not designed to support the weight

of related piping. Improperly supported pipes will put stress on the adapter connections and may cause

leaking or fitting damage.

®

Nominal Pipe

Size

3/8”

3/8”

1/2”

1/2”

3/4”

3/4”

1.0”

1.0”

Body Description

3/8” MPT-low flow

3/8” MPT-std flow

1/2” MPT-low flow

1/2” MPT-std flow

3/4” MPT-low flow

3/4” MPT-std flow

1.0” MPT-low flow

1.0” MPT-std flow

Length

L

4.73”

4.73”

5.09”

5.09”

5.25”

5.25”

5.65”

5.65”

Height

H

5.29”

5.38”

5.29”

5.38”

5.38”

5.57”

5.57”

5.57”

H

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

F-1000-RTRate - Totalizer

Molded in-line body

with M P T

Pipe

4.6 HOW TO INSTALL MOLDED PVC

TEE FITTINGS (TE)

!

Select an area on the pipe as outlined in section 4.1.

!

Remove the F-1000 sensor from the tee fitting. Do not glue the

TEE while the sensor is installed.

!

Install the F-1000 tee fitting as you would any other plastic

pipe solvent weld (glue) fitting. Do not use too much glue.

Excessive glue may create a disturbance in the flow stream

which will effect the accuracy of the meter.

!

The F-1000 can be mounted on horizontal or vertical runs of

pipe. Mounting at the twelve o'clock position on horizontal

pipe is recommended. Mounting anywhere around the diameter of vertical pipe is acceptable, however, the pipe must be

completely full of water at all times. See figure 4, 5 and 6.

!

Install the F-1000 sensor. Be sure two O-rings are located on

the sensor body. The O-rings have been lubricated at the

factory with silicone oil. Push the sensor assembly into the

saddle with a twisting motion. The notch on the sensor body

must fit into the slot on the saddle. Be sure the sensor is fully

inserted into the saddle. HAND TIGHTEN the union nut.

L

Nominal Pipe

Size

1” 4” 6”

1-1/2” 4-1/2” 6-5/8”

2” 4-3/4” 7-1/8”

®

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

F-1000-RTRate - Totalizer

H

Tee Fitting

Fig. 10

LengthLHeight

H

Nominal

Pipe Size

L

Fig. 11

Page 10

F-1000

Page 10

5.0 HOW TO OPERATE THE F-1000

Note: The calibrated units of measure such as GPM, LPM, M3H, GALLONS, LITERS, CUBIC METERS, ect., And the decimal

point location are pre-programmed at the factory to standard flow ranges (see chart). Any unit of measure can be factory programmed.

Please contact the factory for details.

!

The meter is shipped from the factory with 2 AAA batteries installed.

!

When measuring continuous flow (i.e. 24 hours per day, 7 days per week), do not operate the meter in the upper 25% of the

calibrated flow range. The paddle speed in these high flow ranges is fast. Damage to the paddle may occur if the meter is

allowed to run continuously at the high flow rate, especially with corrosive or abrasive fluids.

!

Model F-1000-RB:The F-1000-RB is the basic rate meter. The meter will display the rate of flow from .01 through 999999 in

any engineering units. Some standard units of measure are GPM, GPH, GPD, LPM, LPH, LPD, M3H, etc.

!

Model F-1000-TB:The F-1000-TB is the basic totalizer meter. The meter will display the total flow amounts from .01 through

999999 in any engineering units. Some standard units of measure are GALLONS, LITERS, CUBIC METERS. Pressing and

holding the RESET button (located on the front panel) for at least 2.0 seconds resets the total to zero. This feature can be

disabled -- see Fig. 12 below.

!

Model F-1000-RT:The F-1000-RT is the rate and totalizer meter. The meter will display the flow rate amounts and the total flow

amounts from .01 through 999999 in any engineering units. Some standard units of measure are GALLONS PER MINUTE,

GALLONS PER HOUR, GALLONS PER DAY, LITERS PER MINUTE, LITERS PER HOUR, LITERS PER DAY, CUBIC

METERS PER HOUR, CUBIC METERS PER DAY. Pressing the RESET button (located on the front panel) toggles the display

between flow rate and total flow. Pressing and holding the RESET button for at least 2.0 seconds while the total flow value is

displayed will reset the total to zero. This feature can be disabled -- see Fig. 12 below.

F-1000-RB

F-1000-RBFlow Rate Meter

BLUE-WHITE INDUSTRIES

®

GPM

F-1000 Circuit Board

(Negative lead)

Header pins

(Tail membrane connector)

Black wire

Battery size: two AAA (1.5 V each)

+

Red wire

(Positive lead)

F-1000-TB F-1000-RT

BLUE-WHITE INDUSTRIES

Screw size: #4 x .50 Philip oval “A”

®

RESET

GALLONS

F-1000-TBFlow Totalizer

Terminal blocks

(AC Coil sensor input)

Mounting holes (x2)

21

Fig. 12

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

JUMPER CONFIGURATION

Jumper Not

Installed (open)

Total flow reset

to zero Enable

(Factory default)

Jumpers

(Front Panel Totalizer Reset

Enable/Disable)

®

MODE

RESET

F-1000-RTRate - Totalizer

Jumper

Installed

Total flow reset

to zero Disable

6.0 FLOW RANGES

! The F-1000 is factory calibrated to ± 2% of full scale rate reading. When measuring total flow, accumulated error

over time must be considered. Accuracy is based on laboratory testing of nominal pipe dimensions. Your actual

accuracy will vary based on your actual pipe I.D. And other installation factors.

! Due to increased wear on the paddle and axle, continuous operation at the upper 25% of the flow range is not

recommended.

Page 11

Page 11

F-1000

METRIC PIPES

(Meet DIN 8062)

SADDLES - Standard Flow [Min - Max]

Pipe Size

LPM 1

50 MM - PN 10 & PN 16

63 MM - PN 10 & PN 16

90 MM - PN 10 & PN 16

110 MM - PN 10 & PN 16

160 MM - PN 10 & PN 16

200 MM - PN 10 & PN 16

160 MM - PN 10

200 MM - PN 10

110 - 1100

230 - 2300

350 - 3500

720 - 7200

1150 - 11500

1700 - 17000

2700 - 27000

IPS PIPES

(Meet ASTM-D-1785)

MOLDED INLINE BODIES - Standard Flow Range #1 [Min - Max]

Pipe Size

3/8” INLINE

1 /2” INLINE

3/4” INLINE

1.0” INLINE

MOLDED INLINE BODIES - Low Flow Range #2 [Min - Max]

Pipe Size

3/8” INLINE

1 /2” INLINE

3/4” INLINE

1.0” INLINE

GPM 1

2.00 - 20.00

3.00 - 30.00

5.00 - 50.00

GPM 2

.500 - 5.000

.800 - 8.000

2.00 - 20.00

GPH 1

48.0 - 480.0.800 - 8.000

120 - 1200

180 - 1800

300 - 3000

GPH 2

20.0 - 200.0.400 - 4.000

30.00 - 300.0

48.0 - 480.0

120 - 1200

GPD 1

1100 - 11000

2800 - 28000

4320 - 43200

7200 - 72000

GPD 2

550 - 5500

700 - 7000

1100 - 11000

2800 - 28000

LPH 1

4200 - 4200070.0 - 700.0

6600 - 66000

13800 - 138000

21000 - 210000

43000 - 430000

70000 - 700000

100000 - 1000000

170000 - 1700000

LPM 1

7.00 - 70.00

11.0 - 110.0

20.0 - 200.0

LPM 2

2.00 - 20.00

3.00 - 30.00

7.00 - 70.00

M3H 1

4.20 - 42.00

6.60 - 66.00

13.8 - 138.0

21.0 - 210.0

43.0 - 430.0

70.0 - 700.0

100 - 1000

170 - 1700

LPH 1

180 - 18003.00 - 30.00

420 - 4200

660 - 6600

1200 - 12000

LPH 2

60.0 - 600.01.00 - 10.00

120 - 1200

180 - 1800

420 - 4200

M3H 1

0.180 - 1.800

0.420 - 4.200

0.660 - 6.600

1.20 - 12.00

M3H 2

0.060 - 0.600

0.120 - 1.200

0.180 - 1.800

0.420 - 4.200

MACHINED INLINE BODIES - Standard Flow Range #1 [ Min - Max]

Pipe Size

3/8” INLINE

1 /2” INLINE

3/4” INLINE

1.0” INLINE

1-1/2” INLINE

2.0” INLINE

GPM 1

2.00 - 20.00

4.00 - 40.00

6.00 - 60.00

15.0 - 150.0

30.0 - 300.0

GPH 1

48.0 - 480.0.800 - 8.000

120 - 1200

240 - 2400

360 - 3600

900 - 9000

1800 - 18000

GPD 1

1100 - 11000

2800 - 28000

5700 - 57000

8600 - 86000

21500 - 215000

43000 - 430000

LPM 1

7.00 - 70.00

15.0 - 150.0

25.0 - 250.0

60.0 - 600.0

100 - 1000

MACHINED INLINE BODIES - Low Flow Range #2 [Min - Max]

Pipe Size

3/8” INLINE

1 /2” INLINE

3/4” INLINE

1.0” INLINE

1-1/2” INLINE

2.0” INLINE

GPM 2

.500 - 5.000

.800 - 8.000

2.00 - 20.00

10.0 - 100.0

15.0 - 150.0

GPH 2

20.0 - 200.0.400 - 4.000

30.00 - 300.0

48.0 - 480.0

120 - 1200

600 - 6000

900 - 9000

GPD 2

550 - 5500

700 - 7000

1100 - 11000

2800 - 28000

14400 - 144000

21500 - 215000

LPM 2

2.00 - 20.00

3.00 - 30.00

7.00 - 70.00

40.0 - 400.0

60.0 - 600.0

MACHINED INLINE BODIES - Low Flow Ranges #3, 4, 5, and 6 [Min - Max]

Pipe Size

3/8” INLINE

1 /2” INLINE

3/4” INLINE

1.0” INLINE

1-1/2” INLINE

2.0” INLINE

GPM 3

-

-

-

6.00 - 60.00

10.0 - 100.0

LPM 3

-

-

-

-

25.0 - 250.0

40.0 - 400.0

GPM 4

--

-

-

-

2.00 - 20.00

6.00 - 60.00

LPM 4

-

-

-

-

7.00 - 70.00

25.0 - 250.0

GPM 5

-

-

-

-

1.00 - 10.00

4.00 - 40.00

SADDLES - Standard Flow [Min - Max]

Pipe Size

1-1/2” IPS

2.0” IPS

3.0” IPS

4.0” IPS

6.0” IPS

8.0” IPS

10.0” IPS

12.0” IPS

GPM 1

15.0 - 150.0

30.0 - 300.0

60.0 - 600.0

100 - 1000

250 - 2500

400 - 4000

600 - 6000

800 - 8000

GPH 1

900 - 9000

1800 - 18000

3600 - 36000

6000 - 60000

15000 - 150000

24000 - 240000

36000 - 360000

48000 - 480000

GPD 1

21500 - 215000

43000 - 430000

86500 - 865000

144000 - 999999

360000 - 999999

575000 - 999999

865000 - 999999

N/A

LPM 1

60.0 - 600.0

100 - 1000

250 - 2500

400 - 4000

900 - 9000

1500 - 15000

2200 - 22000

3000 - 30000

180 - 18003.00 - 30.00

420 - 4200

900 - 9000

1500 - 15000

3600 - 36000

6000 - 60000

60.0 - 600.01.00 - 10.00

120 - 1200

180 - 1800

420 - 4200

2400 - 24000

3600 - 36000

LPM 5

-

-

-

-

4.00 - 40.00

15.0 - 150.0

3600 - 36000

6000 - 60000

15000 - 150000

24000 - 240000

54000 - 540000

90000 - 900000

132000 - 999999

180000 - 999999

LPH 1

LPH 2

LPH 1

GPM 6

-

-

-

-

-

2.00 - 20.00

M3H 1

0.180 - 1.800

0.420 - 4.200

0.900 - 9.000

1.50 - 15.00

3.60 - 36.00

6.00 - 60.00

M3H 2

0.060 - 0.600

0.120 - 1.200

0.180 - 1.800

0.420 - 4.200

2.40 - 24.00

3.60 - 36.00

LPM 6

-

-

-

-

-

7.00 - 70.00

M3H 1

6.00 - 60.00

15.0 - 150.0

24.0 - 240.0

54.0 - 540.0

90.0 - 900.0

132 - 1320

180 - 1800

Page 12

F-1000

Page 12

7.0 HOW TO MAINTAIN THE F-1000

The F-1000 requires very little maintenance, however, some conditions will cause increased wear on the paddle and/or

possible damage to the unit. Damage caused by corrosive or abrasive fluids is not covered under warranty.

!

Periodically remove the sensor assembly from the pipe fitting and inspect the meter for signs of wear and obstructions. Clean the paddle of any foreign objects. Paddle and axle wear can be caused by chemical attack and/or

abrasive fluids. Replace the paddle and axle if worn. Various axle materials are available for corrosive fluids.

!

Although the meter is capable of operating at the high end of the flow range, the meter should not be allowed to

operate continuously at flow rates in the upper 1/4 or 25% of the calibrated flow range. The paddle and axle life is

directly related to the rate of flow and the fluid being measured. Corrosive and abrasive fluids moving at high flow

rates will cause increased wear requiring frequent inspection and maintenance. Ceramic, titanium or nickel axles are

available for corrosive and abrasive fluids.

!

Although the F-1000 is designed to withstand outdoor conditions, a cool, dry location where the unit can be easily

serviced is recommended. The life of the LCD display will be severely reduced when installed in direct sunlight.

Do not install the meter so that the LCD is in direct sunlight.

!

O-rings should be inspected periodically. Immediately replace the o-rings at any sign of wear, swelling, cracking or

discoloration.

!

The meter is designed to withstand minor condensation inside the enclosure. Prolonged excessive moisture inside the

enclosure, due to high humidity conditions, may damage the meter. Reduce the humidity or move the meter to a less

humid location.

!

Replace the two AAA batteries every 12 months. The program memory is “non-volitile” and will not erase when

replacing the batteries. Processing power will be maintained for about 45 seconds, preventing the lose of totalizing

data, while the batteries are being replaced. To replace the batteries, open the rear panel of the enclosure by removing

the two Phillips screws. After replacing the batteries, be sure the foam insert is in place and the panel gasket seal is in

good condition, before closing the rear panel.

!

Test the electronics by removing the sensor assembly from the pipe fitting and spinning the paddle by hand. While

spinning, the number “0” reading in the display window indicates that the battery is supplying power to the meter but

a signal is not being processed by the circuitry. In this case, the circuitry must be serviced by an authorized service

center.

8.0 TROUBLESHOOTING

Situation: Leaking

Cause: Improper installation .............................Solution: Page 6, section 4.3

Page 7, section 4.3.1 thru 4.3.4

Page 8, section 4.4, 4.5

Worn or damaged O-rings......................Solution: Page 12, section 7.3

Situation: Moisture inside enclosure

Cause: Condensation .........................................Solution: Page 12, section 7.4

Damaged panel gasket ...........................Solution: Page 12, section 7.5

Situation: Flow rate reading is inaccurate

Cause: Improper installation..............................Solution: Page 6, section 4.3

Improper velocity profile........................Solution: Page 4, section 4.1, 4.2

Improper alignment / installation...........Solution: Page 7, section 4.3.3

Worn paddle and/or axle.........................Solution: Page 12, section 7.1

Accumulated reading error......................Solution: Page 10, section 6.1

Situation: No display

Cause: Electronics damaged...............................Solution: Page 12, section 7.5

Dead batteries.........................................Solution: Page 12, section 7.6

Situation: Display shows zero flow

Cause: Saddle not aligned..................................Solution: Page 7, section 4.3.3

Electronics damaged...............................Solution: Page 12, section 7.6

Flow rate is out of range.........................Solution: Page 10, section 6.0

Paddle Removal

Step 1: Locate notch on

The sensor body.

Step 2: Push shaft out in

the arrow pointing

Direction.

w

rro

n

A

c

e tio

i

D r

Step 3: Replace the paddle,

then press shaft back

into place in the

Opposite direction.

Fig. 13

Page 13

Page 13

9.0 F-1000 PARTS LIST

F-1000

Item Part #

1 70000-783

2

3

4

5

6

7

8

9

90003-021

90007-589

71000-238

91001-051

90011-080

90012-198

90012-199

90012-200

90012-201

90012-202

90012-221

90012-222

76001-187

71000-386

71000-387

71000-388

Description

Paddle assembly PVDF

O-ring 022 Viton E60

Axle PVDF

Sensor body assembly F-1000 no paddle

Union nut

Screw #6 x .37 PH Pan B 18/8

Label F-1000-RB GPM

Label F-1000-RB GPH

Label F-1000-RB LPM

Label F-1000-RB LPH

Label F-1000-RB M3H

Label F-1000-TB overlay

Label F-1000-RT overlay

Housing F-1000

Kit circuit board F-1000-RB

Kit circuit board F-1000-RT

Kit circuit board F-1000-TB

3

Qty

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

10

11

12

13

14

15

16

90011-169

90013-215

90008-318

90006-590

90008-319

90002-203

90011-113

Screw #4 x .25 Phil Pan “A”

Foam pad 1.25 x 1.25 x 2.25

Battery each AAA

Gasket F-1000

Battery clip F-1000

Rear plate F-1000

Screw #4 x .50 Phil oval "A"

2

1

2

1

1

1

2

Page 14

F-1000

MACHINED IN-LINE BLOCK PARTS LIST

®

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

F-1000-RTRate - Totalizer

1

2

3

4

Page 14

Pipe

Replacement Part Numbers

Item

1

2

3

4

Part No .

76100-107

76100-109

76100-106

76100-108

76100-105

76100-107

76100-104

76100-106

76100-134

76100-135

76100-136

76100-137

76100-138

76100-128

76100-129

76100-130

76100-131

76100-132

76100-133

90003-079

90003-134

90003-118

76001-052

76001-053

76001-050

76001-051

76001-048

76001-049

76001-046

76001-047

76001-193

76001-195

76001-066

76001-196

76001-197

Body .38” .8-8 GPM PP

Body .38” .4-4 GPM PP

Body .50” 2-20 GPM PP

Body .50” .5-5 GPM PP

Body .75” 4-40 GPM PP

Body .75” .8-8 GPM PP

Body 1.0” 6-60 GPM PP

Body 1.0” 2-20 GPM PP

Body 1.5” 15-150 GPM PP

Body 1.5” 10-100 GPM PP

Body 1.5” 6-60 GPM PP

Body 1.5” 2-20 GPM PP

Body 1.5” 1-10 GPM PP

Body 2.0” 30-300 GPM PP

Body 2.0” 15-150 GPM PP

Body 2.0” 10-100 GPM PP

Body 2.0” 6-60 GPM PP

Body 2.0” 4-40 GPM PP

Body 2.0” 2-20 GPM PP

O-ring for .38” - 1.0” Viton

O-ring for 1.5” Viton

O-ring for 2.0” Viton

Adapter .38” .8-8 GPM PP

Adapter .38” .4-4 GPM PP

Adapter .50” 2-20 GPM PP

Adapter .50” .5-5 GPM PP

Adapter .75” 4-40 GPM PP

Adapter .75” .8-8 GPM PP

Adapter 1.0” 6-60 GPM PP

Adapter 1.0” 2-20 GPM PP

Union nut .38”-1.0” alum.

Union nut 1.5” alum.

Union nut 2.0” alum.

Description

Adapter 1.5” PP

Adapter 2.0” PP

Complete Kit Ordering Numbers

Machined In-Line Pipe Fittings - U.S. (IPS) F/NPT

Machined In-Line Pipe Fittings - U.S. (IPS) F/NPT

Kit No

Kit No

38P1

38P1

38P2

38P2

38K1

38K1

38K2

38K2

50P1

50P1

50P2

50P2

50K1

50K1

50K2

50K2

75P1

75P1

75P2

75P2

75K1

75K1

75K2

75K2

10P1

10P1

10P2

10P2

10K1

10K1

10K2

10K2

15P1

15P1

15P2

15P2

15P3

15P3

15P4

15P4

15P5

15P5

20P1

20P1

20P2

20P2

20P3

20P3

20P4

20P4

20P5

20P5

20P6

20P6

1/2” In-Line block, 2-20 GPM, PVDF

1/2” In-Line block, 2-20 GPM, PVDF

1/2” In-Line block, .5-5 GPM, PVDF

1/2” In-Line block, .5-5 GPM, PVDF

3/4” In-Line block, .8-8 GPM, PVDF

3/4” In-Line block, .8-8 GPM, PVDF

Description

Description

3/8” In-Line block, .8-8 GPM, PP

3/8” In-Line block, .8-8 GPM, PP

3/8” In-Line block, .4-4 GPM, PP

3/8” In-Line block, .4-4 GPM, PP

3/8” In-Line block, .8-8 GPM, PVDF

3/8” In-Line block, .8-8 GPM, PVDF

3/8” In-Line block, .4-4 GPM, PVDF

3/8” In-Line block, .4-4 GPM, PVDF

1/2” In-Line block, 2-20 GPM, PP

1/2” In-Line block, 2-20 GPM, PP

1/2” In-Line block, .5-5 GPM, PP

1/2” In-Line block, .5-5 GPM, PP

3/4” In-Line block, 4-40 GPM, PP

3/4” In-Line block, 4-40 GPM, PP

3/4” In-Line block, .8-8 GPM, PP

3/4” In-Line block, .8-8 GPM, PP

3/4” In-Line block, 4-40 GPM, PVDF

3/4” In-Line block, 4-40 GPM, PVDF

1” In-Line block, 6-60 GPM, PP

1” In-Line block, 6-60 GPM, PP

1” In-Line block, 2-20 GPM, PP

1” In-Line block, 2-20 GPM, PP

1” In-Line block, 6-60 GPM, PVDF

1” In-Line block, 6-60 GPM, PVDF

1” In-Line block, 2-20 GPM, PVDF

1” In-Line block, 2-20 GPM, PVDF

1.5” In-Line block, 15-150 GPM, PP

1.5” In-Line block, 15-150 GPM, PP

1.5” In-Line block, 10-100 GPM, PP

1.5” In-Line block, 10-100 GPM, PP

1.5” In-Line block, 6-60 GPM, PP

1.5” In-Line block, 6-60 GPM, PP

1.5” In-Line block, 2-20 GPM, PP

1.5” In-Line block, 2-20 GPM, PP

1.5” In-Line block, 1-10 GPM, PP

1.5” In-Line block, 1-10 GPM, PP

2.0” In-Line block, 30-300 GPM, PP

2.0” In-Line block, 30-300 GPM, PP

2.0” In-Line block, 15-150 GPM, PP

2.0” In-Line block, 15-150 GPM, PP

2.0” In-Line block, 10-100 GPM, PP

2.0” In-Line block, 10-100 GPM, PP

2.0” In-Line block, 6-60 GPM, PP

2.0” In-Line block, 6-60 GPM, PP

2.0” In-Line block, 4-40 GPM, PP

2.0” In-Line block, 4-40 GPM, PP

2.0” In-Line block, 2-20 GPM, PP

2.0” In-Line block, 2-20 GPM, PP

Complete kits include:

1) Body fitting

2) Pipe adapters

2) Adapter O-ring seals

2) Union nuts

1) Instruction manual

Page 15

Page 15

F-1000

MOLDED IN-LINE BODY PARTS LIST

®

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

F-1000-RTRate - Totalizer

Pipe Fitting

Complete Kit Ordering Numbers

Complete Kit Ordering Numbers

Machined In-Line Pipe Fittings - U.S. (IPS) F/NPT

Molded In-Line Pipe Fittings - U.S. (IPS) M/NPT

Kit No

Kit No

38M1

38M2

38F1

38F2

50M1

50M2

50F1

50F2

75M1

75M2

75F1

75F2

10M1

10M2

10F1

10F2

15M1

15M2

15M3

15F1

15F2

15F3

20M1

20M2

20M3

20M4

20F1

20F2

20F3

20F4

Description

Description

3/8” MPT .800 - 8.000 GPM - PP

3/8” MPT .400 - 4.000 GPM - PP

3/8” MPT .800 - 8.000 GPM - PVDF

3/8” MPT .400 - 4.000 GPM - PVDF

1/2” MPT 2.00 - 20.00 GPM - PP

1/2” MPT .500 - 5.000 GPM - PP

1/2” MPT 2.00 - 20.00 GPM - PVDF

1/2” MPT .500 - 5.000 GPM - PVDF

3/4” MPT 3.00 - 30.00 GPM - PP

3/4” MPT .800 - 8.000 GPM - PP

3/4” MPT 3.00 - 30.00 GPM - PVDF

3/4” MPT .800 - 8.000 GPM - PVDF

1” MPT 5.00 - 50.00 GPM - PP

1” MPT 2.00 - 20.00 GPM - PP

1” MPT 5.00 - 50.00 GPM - PVDF

1” MPT 2.00 - 20.00 GPM - PVDF

1-1/2” MPT 4.00 - 40.00 GPM - PP

1-1/2” MPT 6.00 - 60.00 GPM - PP

1-1/2” MPT 10.0 - 100.0 GPM - PP

1-1/2” MPT 4.00 - 40.00 GPM - PVDF

1-1/2” MPT 6.00 - 60.00 GPM - PVDF

1-1/2” MPT 10.0 - 100.0 GPM - PVDF

2” MPT 4.00 - 40.00 GPM - PP

2” MPT 6.00 - 60.00 GPM - PP

2” MPT 10.0 - 100.0 GPM - PP

2” MPT 20.0 - 200.0 GPM - PP

2” MPT 4.00 - 40.00 GPM - PVDF

2” MPT 6.00 - 60.00 GPM - PVDF

2” MPT 10.0 - 100.0 GPM - PVDF

2” MPT 20.0 - 200.0 GPM - PVDF

Complete kits include:

1) Molded inline body fitting

1) Instruction manual

MOLDED PVC TEE PARTS LIST

SADDLE PARTS LIST

4

Replacement Part Numbers

Part No .

Item

1

76000-830

91001-115

2

91001-114

91001-116

76100-087

76100-088

76100-089

76100-139

90008-010

3

90008-137

90008-015

90008-018

90008-019

90008-020

90008-348

90008-349

90003-108

4

90003-114

Complete Kit Ordering Numbers

Metric (DIN 8062) Pipe Saddle Fittings

Kit No

05K0

05K6

06K0

06K6

09K0

09K6

11A0

11A6

16A0

16A6

20A0

Description

50mm Metric pipe, Pn10, PVDF

50mm Metric pipe, Pn16, PVDF

63mm Metric pipe, Pn10, PVDF

63mm Metric pipe, Pn16, PVDF

90mm Metric pipe, Pn10, PVDF

90mm Metric pipe, Pn16, PVDF

110mm Metric pipe, Pn10, PVC

110mm Metric pipe, Pn16, PVC

160mm Metric pipe, Pn10, PVC

160mm Metric pipe, Pn16, PVC

200mm Metric pipe, Pn10, PVC

Complete kits include:

1) Saddle fitting

2) Pipe clamps

1) O-ring seal

1) Installation alignment tool

1) Instruction manual

Saddle, 1-1/2” pipe (50mm)

Hose-Clamp #28 for 1-1/2” pipe

Hose-Clamp #40 for 2” pipe

Hose-Clamp #52 for 3” pipe

Hose-Clamp #72 for 4” pipe

Hose-Clamp #116 for 6” pipe

Hose-Clamp #152 for 8” pipe

Hose-Clamp #188 for 10” pipe

Hose-Clamp #224 for 12” pipe

O-ring / Viton for 1-1/2”, 2”, 3”

O-ring / Viton for 4”, 6”, 8”, 10”, 12”

1

2

Description

Alignment tool

Saddle, 2” pipe (63mm)

Saddle, 3” pipe (90mm)

Saddle, 4” pipe (110mm)

Saddle, 6” pipe (160mm)

Saddle, 8” pipe (200mm)

Saddle, 10” & 12” pipe

®

®

U.S. (IPS) Pipe Saddle Fittings

Kit No

15K4

15K8

20K4

20K8

30K4

30K8

40A4

40A8

60A4

60A8

80A4

80A8

100A4

100A8

120A4

120A8

Description

1-1/2” IPS pipe, schedule 40, PVDF

1-1/2” IPS pipe, schedule 80, PVDF

2” IPS pipe, schedule 40, PVDF

2” IPS pipe, schedule 80, PVDF

3” IPS pipe, schedule 40, PVDF

3” IPS pipe, schedule 80, PVDF

4” IPS pipe, schedule 40, PVC

4” IPS pipe, schedule 80, PVC

6” IPS pipe, schedule 40, PVC

6” IPS pipe, schedule 80, PVC

8” IPS pipe, schedule 40, PVC

8” IPS pipe, schedule 80, PVC

10” IPS pipe, schedule 40, PVC

10” IPS pipe, schedule 80, PVC

12” IPS pipe, schedule 40, PVC

12” IPS pipe, schedule 80, PVC

3

®

BLUE-WHITE INDUSTRIES

GALLONS PER MINUTE

F-1000-RBFlow Rate Meter

F-1000-RTRate - Totalizer

1

Replacement Tee Part Numbers

Item Part No. Description

1 76000-978 1.0” TEE fitting - PVC

Nominal

Pipe Size

76000-975 1-1/2” TEE fitting - PVC

76000-976 2.0” TEE fitting - PVC

Page 16

Warranty

!

Blue-White flowmeters are warranted to be free from defects in material and workmanship for 12 months from date of factory

shipment. Warranty coverage is limited to repair or replacement of the defective flowmeter only.

!

This warranty does not cover damage to the flowmeter that results from misuse or alterations, nor damage that occurs as a result

of: meter misalignment, improper installation, over tightening, use of non-recommended chemicals, use of non-recommended pipe

dopes or adhesives, excessive heat or pressure or allowing the meter to support the weight of related piping.

!

Flowmeters are repaired at the factory only. Call or write the factory to receive a RA (return authorization) number. Carefully pack

the flowmeter to be returned, including a brief description of the problem, chemical used, and a description of the application.

Note: Write the RA number on the outside of the shipping carton.

!

Prepay all sipping costs. The factory does not accept C.O.D. Shipments. Damage that occurs during shipping is the responsibility

of the sender.

# 80000-335 Rev. 8/02/2004

Loading...

Loading...