Page 1

Manual

Expert™ 1400 / Expert™ 3400

Submersible Hydrostatic Level Transmitters

ll 2G

EEx ia llC T6

Manual Expert 1400/3400 GB 0704

As our products are continuously improved, we reserve the right to make

any change in the stated specifications and dimensions without prior notice.

MJK Automation A/S

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Page 2

Manual

Approvals

CE Certificate of conformity

This product complies with the requirements concerning electromagnetic compatibility (EMC) stipulated in Council

directive no. 89/336/EEC of 3rd May 1989, altered at directive no. 92/31/EEC, on the approximation of the laws of the

Member States relating to electromagnetic compatibility.

We declare that the product complies to the values stipulated in EN50014:1997, EN50020:2002,

EN61000-6-3/-4:2001 and EN61000-6-1/-2:1999.

Manual Expert 1400/3400 GB 0704

2

MJK Automation A/S

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Page 3

Manual

Introduction 4

Product identification

Safety instructions 4

Hazardous areas 4

Repair 4

Mechanical mounting 5

Model 1400 5

Model 3400 5

Model 3400 with thread top 5

Electrical mounting 6

Cable length vs. supply voltage 6

Designation of wires, cutting & stripping the cable 6

Explosion hazardous zone 7

Isolator 7

Zener barrier

Appendices 8

Mechanical dimensions 8

Demands for cables in explosive areas 8

Safety Instructions 9

Data Sheet for Expert™ 1400 Level Transmitter 12

Data Sheet for Expert™ 3400 Level Transmitter 13

4

7

Manual Expert 1400/3400 GB 0704

3

MJK Automation A/S

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Page 4

Manual

Introduction

Thank you for choosing ExpertTM Level Transmitter.

We have done everything possible to make a level

transmitter that can fulfil all your demands.

ExpertTM Level Transmitter is suitable for all kinds of level

measurements. It can control and supervise levels in wells

and tanks - including aggressive and polluted media.

The ExpertTM Level Transmitter is both easy to install and

put into service, but read this manual first - then you will

get the most benefits from the ExpertTM Level Transmitter

right from the beginning.

You can always contact your representative or the MJK

Service Hotline for advice and guidance. Also, take a

look at http://www.mjk.com

ExpertTM Level Transmitter is registered trademark of MJK.

Thank you for choosing MJK Automation A/S as your

supplier of hydrostatic level transmitter.

Product identification

It is very important for the overall measuring accuracy that

the pressure transmitter has the correct pressure range.

Check that the item(s) delivered corresponds to the

ordered item (s) by means of the information on the label

on the packing:

On the model 3400 transmitters, the pressure ranges together with the corresponding part numbers are printed

on a label on the transmitter housing.

For all versions the pressure range is indicated on the

label.

3400 transmitter

Safety instructions

1: Read this manual carefully.

2: Be aware of the environment on the installation site.

Wear necessary protective equipment and follow all current

safety regulations.

3: Do not operate the equipment outside the specified

electrical, thermal and mechanical parameters (see

datasheet). Install the device only in media for which the

wetted materials have sufficient durability. (See datasheet

for housing material)

Max. supply voltage is 30 VDC.

4: Do not connect or use any programming interface/

equipment while the transmitter is located in an explosion

hazardous environment.

On the model 1400 transmitters, the pressure ranges together with the corresponding part numbers are printed

on a label on the transmitter housing.

For all versions the pressure range is indicated on the

label.

1400 transmit ter

Manual Expert 1400/3400 GB 0704

Hazardous areas

1: All current local and national standards, regulations

regarding installation and use of Ex or hazardous zone

approved equipment, certifications and safety instructions

for Ex equipment that have been used together with the

installation of the Expert 1400 or 3400 level transmitter

must be strictly observed.

2: The use of an approved zener barrier or isolator is

mandatory when installing Expert™ Level Transmitter

1400 and 3400 in explosion hazardous areas.

Repair

1: Repair of EX approved equipment must only be made

by MJK or by a service representative approved by MJK.

4

MJK Automation A/S

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Page 5

Manual

Mechanical mounting

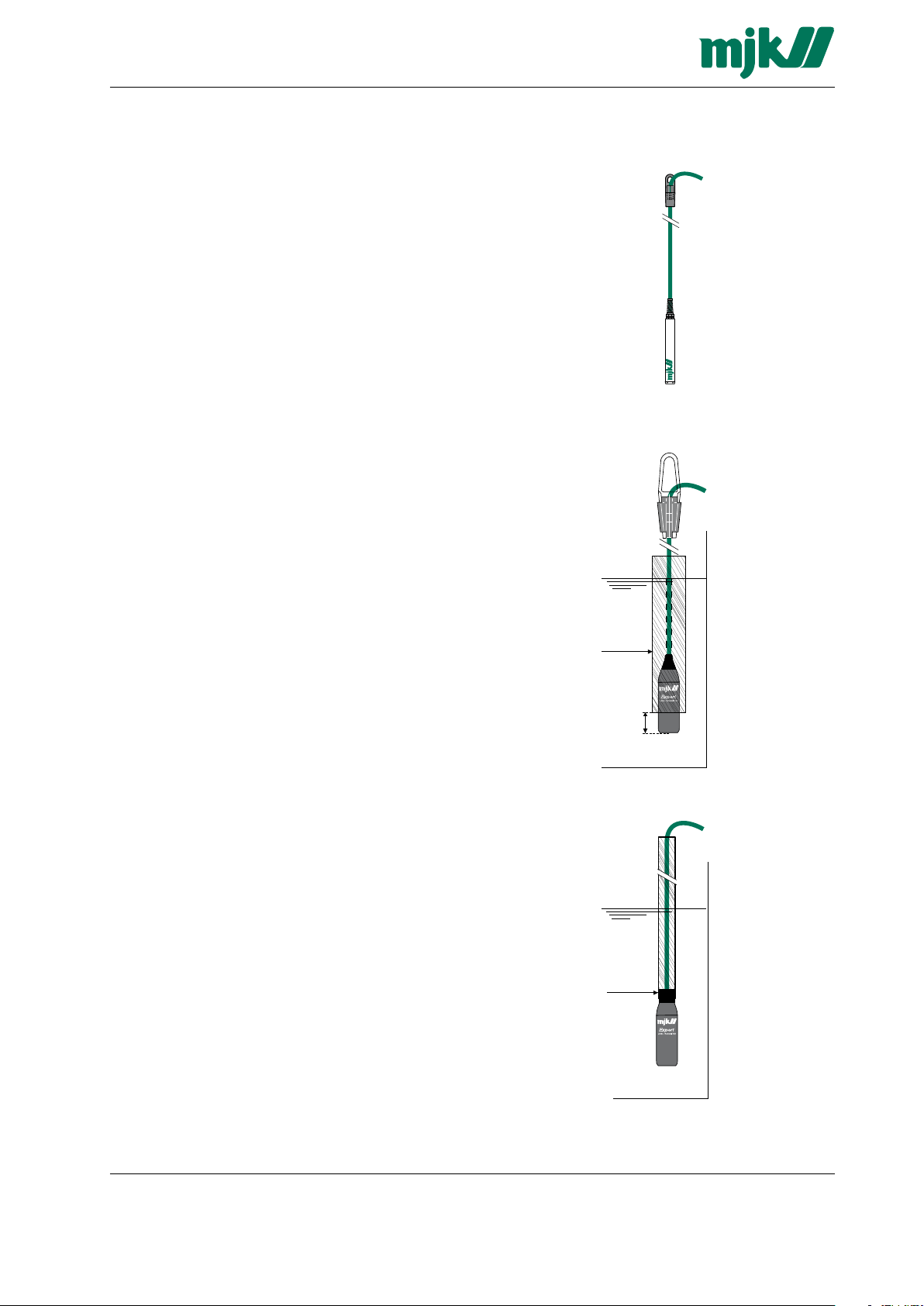

Model 1400

1: Mount a suitable hook over the desired measuring

location. Note the weight of the cable.

2: Remove the inner conical sleeve from the cable fitting

and pull the cable through the outer part. Open the inner

sleeve and fit it around the cable at the desired fixation

point and press the inner sleeve into place in the outer

part. Secure the cable fitting by pulling the

cable downwards.

3: Lower the pressure transmitter into the wellpipe.

Take care not to hit the bottom hard since it may damage

the transmitter!

Model 3400

1: Mount a suitable hook over the desired measuring

location. Note the weight of the cable.

2: Mount the cable fitting onto the cable. Open the fitting

by sliding the two plastic jaws upwards, place the cable

between the jaws and slide the jaws downwards until the

cable locks. Secure the cable fitting by pulling the

cable downwards.

3: Lower the pressure transmitter into the liquid.

Take care not to hit the bottom hard since it may damage

the transmitter!

4: If the transmitter is to be used in a wetwell or other

locations with turbulence or other disturbance, it is advisable to install a pipe (min. nominal diameter = 75 mm)

to protect the transmitter from bumping into the wall or

other components.

It is very important that minimum 25 mm of the pressure

transmitter is not being covered by the pipe!

Cable

bracket

Model 1400

Cable

bracket

Protective pipe.

Protective pipe.

Min. nominal

diamete r = 75mm

Model 3400

Min. 25-50 mm

Model 3400 with thread top

1: Mount the pressure transmitter onto a 1 in pipe

(1” ISO thread) and mount the pipe firmly at the desired

measuring location.

2: Lower the pressure transmitter into the liquid.

Take care not to hit the bottom hard since it may damage

the transmitter!

Manual Expert 1400/3400 GB 0704

1" ISO thread

Model 3400

5

MJK Automation A/S

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Page 6

Manual

Electrical mounting

Cable length vs. supply voltage

The cable can be lengthened with any type of cable

using connection box 202922. Although the measuring

signal is not sensitive to electrical noise, we recommend

the use of a screened cable.

Ensure that no moisture can enter the pressure compensation tube inside the cable.

The length of the cable is only limited by the total resistance (A) of the cable conductors + the input impedance

of the analog input on the MJK 704, MJK 713, PLC etc.

(typically 10 to 100 Ω) and the available supply voltage

(B) (typically 24 V DC).

Example:

The nominal resistance for 1 conductor in a transmitter

cable is 0,036 Ω /m. A standard 12 m cable will therefore

add 2 x 0,036 x 12 = 0,86 Ω to the loop resistance. If the

analog input has an impedance of 50 Ω., the total

resistance will be approx. 51 Ω.

Necessary supply voltage in relation to the total loop resistance.

(A) Total loop resistance [ Ω]

Designation of wires, cutting & stripping the cable

The factory delivered cable has the wires marked with

the numbers 1 - 2 - 3 as to the table to the right. If the

cable needs to be cutted and stripped, the shield should

be connected as the no. 3 wire.

Do NOT connect any of the colored programming wires

as it may damage the transmitter. The programming

wires should be cut off in different lengths to prevent

them from short circuit.

Take care not to block or squeeze the air pressure

compensation tube ➄.

Designations:

1: Positive (+) wire, red

2: Negative (-) wire, brown

3: Shield

(NOT signal ground!)

4: Moisture filter for compensation tube

5: Air pressure

compensation tube

6: Programming wires

➀

➁

➂

➃

➁

➀

➄

➃

➅

➂

(B) Supply voltage [ V DC]

According to the diagram above, approx. 12 V DC will

be sufficient.

Factory delive ry

Do not connect a programming unit to the transmitter

or make any attemt to program the tranmitter while the

transmitter is located in an explosion hazardous zone!

Cutted and

stripped

Manual Expert 1400/3400 GB 0704

6

MJK Automation A/S

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Page 7

Manual

Hazardous area Safe area

Isolator

202993

1 +

2 -

POWER SUPPLY 515

200100

24VDC

7

24VDC

+

6

230VAC

N

3

230VAC

L

1

Pasiv

mA input

AI

+

AI

-

230 VAC

KFD0-CS-Ex1.50P isolator

+

Wire 1

Red

Wire 2

Brown

shield

Wire 3

black

11 (+)

12 (-)

Safe areaHazardous area

POWER SUPPLY 515

200100

24VDC

-

7

24VDC

+

6

230VAC

N

3

230VAC

L

1

Pasiv

mA input

AI

-

AI

+

230 VAC

+

Wire 1

Red

Wire 2

Brown

shield

Wire 3

black

1

3

2

8

Zener barriere

202995

4

7

Z788 Zener Barrier

Explosion hazardous zone

The insulation between the intrinsic safe circuit and the enclosure withstands 500 VAC.

Isolator

The KFD0-CS-Ex1.50P isolator (MJK part no.: 202993) which supplies the pressure transmitter through a galvanic separator so neither current nor voltage exceeds the specified limits.

Zener barrier

The Z788 Zener Barrier ( MJK part no. 202995) has a safety fuse which will blow if the current exceeds the limit.

The voltage protection in the Zener barrier contains a number of zener diodes, which are connected from each signal

cable to ground.

Manual Expert 1400/3400 GB 0704

MJK Automation A/S

7

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Page 8

Manual

135

135

152 65

Appendices

Mechanical dimensions

MJK model 1400

Level transmitter

MJK model 3400

Level transmitter

Cable bracket

Cable bracket

Demands for cables in explosive areas

Using the the KFD0-CS-Ex1.50P isolator (MJK order

no.: 202993) the max cable length can be calculated.

The Cmax and Lmax for the isolator in explosion group

IIC are: Cmax : 2,41 μF, Lmax : 4 mH. The capacity of

MJK cable type 691005 or 691014 < 800 pF/m and

the inductance is < 1,5 μH/m and the capacity and the

inductance of the Expert Level Transmitter is Ci = 3,5 nF

Li = 7 μH. Cable length based on the capacity:

Max.cable length = (Cmax-Ci)/Ccable = 129 m

Cable length based of the inductance:

Max. cable length = (Lmax-Li)/Lcable = 2862 m

In this case the capacitance sets the limit of the cable

length to 129 m. If another approved isolator or another

cable is used the max. cable length must be recalculated.

Using The Z788 Zener Barrier (MJK Order no. 202995)

the max cable length can be calculated. The Cmax and

Lmax for the zener barrier in explosion group IIC are:

Cmax : 83 nF, Lmax : 3,05 mH. The capacity of MJK

cable type 691014 is < 800 pF/m and the inductance is

< 1,5 μH/m and the capacity and the inductance of the

Expert Level Transmitter is Ci = 3,5 nF Li = 7 μH.

Cable length based on the capacity:

Max. cable length = (Cmax-Ci)/Ccable = 99 m

Cable length based on the inductance:

Max. cable length = (Lmax-Li)/Lcable = 2,0 km

In this case the capacitance sets the limit of the cable

length to 99 m. If another Atex-approved isolator or

another cable is used the max. cable length must

be recalulated.

Manual Expert 1400/3400 GB 0704

8

MJK Automation A/S

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Page 9

Manual

Safety Instructions

for electrical apparatus for explosion-hazadous areas

Designation according to Directive 94/9/EC

- Equipment group II

- Equipment Category: sensor and housing category 2

- For explosive mixtures of air and combustible gases vapour or mists

Area of application:

For explosive mixtures of air and combustible gases, vapour or mists:

Equipment category Explosive gas-air mixtures (G)

Category 1 Zone 0, 1 or 2

0539

2GII

Category 2 Zone 1 or 2

Category 3 Zone 2

Designation of explosion protection: EEx ia IIC T6

- Electrical apparatus with explosion

- Protection to European standard

- Type of protection

- Apparatus group

- Temperature class

Marking of Expert transmitter type 1400/3400 for Ex environment

II 2 G EEx Ia IIC T6 means:

II: Equipment group: Surface industry

2: Category: Category 2 (Zone 1 and 2)

G: Explosive atmosphere: Gas

E: European Standards.

Ex: Equipment for explosive atmospheres.

Ia: Ex Protection principle: Intrinsically safety.

IIC: Gas groups: Acetylene & hydrogen.

T6: Temperature class: 85°C surface temperature

Manual Expert 1400/3400 GB 0704

9

MJK Automation A/S

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Page 10

Manual

Non hazardous area

Explosive hazardous area

Zone 1

+ Red

- Brown

Shield

Black

Type 3400 Type 1400

+ Red

- Brown

Shield

Black

Type of protection Electrical data Ambient temperatur

II 2G EEx ia IIC T6 IP 65

Ui: 30 V DC

Ii: 101 mA

Pi: 750 mW

Ci: 3,5 nF+800 pF/m*cable length

Li: 7 μH+1.5 μH/m*cable length

-20 °C < Ta < 40 °C

Using the KFD0-CS-Ex1.50P isolator (MJK order no.:

202993) the max. cable length is 129 m.

Using The Z788 Zener Barrier (MJK Order no. 202995)

the max. cable length is 99 m.

Alternatively other cable types with equivalent specifications may be used. If a cable is used with other electrical

specifications or other approved isolators and zener

barrier are used, the cable length must be recalculated.

Manual Expert 1400/3400 GB 0704

10

MJK Automation A/S

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Page 11

Manual

Please note the following installation instructions:

1. Follow the installation and safety instructions contained

in the Operation Instructions.

2. Install according to the manufacturer’s instructions

and other valid standards and guidelines.

3. Do not operate the sensor outside the specified electrical,

thermal and mechanical parameters.

4. Install the device only in media for which the wetted

materials have sufficient durability.

5. Expert transmitter type 1400/3400 hydrostatics level

transmitter may not be used in explosive areas without

use of correct Isolator or Zener Barrier.

6. The approved Expert Level Transmitter type

1400/3400 does not need to be separately connected

with, structural parts or piping which are connected to

the equipotential bonding system.

7. The ambient temperature range of the Expert Level

Transmitter type 1400/3400 (-20 °C< Ta<+40 °C.)

Be aware about the environment on the installation site.

Use necessary protection equipment and follow all

safety regulations.

Manual Expert 1400/3400 GB 0704

11

MJK Automation A/S

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Page 12

Manual

Dia. 24 mm

73 mm

152 mm 65 mm

Dia. 22 mm

Data Sheet for

Exper t™ 1400 Level

Transmitter

Specifications

MJK Expert™ 1400 Level Transmitter has

about the same specifications as the 7070

model. In addition it has a ceramic, capacitive measuring system with a much higher

accuracy. Furthermore, Expert™ 1400 is

approved for use in explosion hazardous

areas: ATEX Ex ia IIC T6.

Model 1400 is very useful for level measurements in for example ground water bore

holes and in-fill sites, where explosion proof

transmitters are required.

MJK Expert™ 1400 Hydrostatic Level Transmitter

Nominal measuring range 0 - 0,3 m 0 - 1 m 0 - 3 m 0 - 5 m 0 - 10 m 0 - 30 m 0 - 100 m 0 - 300 m

Measuring principle Ceramic capacitive, relative pressure

Min. programmable range 0 - 0,3 m 0 - 0,3 m 0 - 1 m 0 - 3 m 0 - 3 m 0 - 10 m 0 - 30 m 0 - 90 m

Max. programmable range 0 - 1 m 0 - 1 m 0 - 3 m 0 - 10 m 0 - 10 m 0 - 30 m 0 - 100 m 0 - 300 m

Max. overpressure 4 bar 4 bar 6 bar 10 bar 10 bar 18 bar 40 bar 40 bar

Temperature range -20 °C to 40 °C

Temp. deviation, 0 point Better than ± 0.02 % / °C

Temperature deviation, FS Better than ± 0.01 % / °C

Linearity / Stability Better than ± 0.2 % FS / ± 0.2 % FS

Measurement accuracy

Long time stability Better than ± 0.1 % FS per year

Materials Housing: stainless steel (AISI 316 L), diaphragm: 96,6 % Al2O3/Cell packing: Viton

Supply voltage 10 - 30 V DC (12 - 30 V DC for cable lengths above 100 m)

Output signal 2-wire 4 - 20 mA (passive transmitter)

Cable 2 × 0,5 mm2 (pressure) + 5 x 0,15 mm2 (data), shielded, PUR insulation

Cable length 12 m 12 m 12 m 12 m 12 m 35 m 110 m 320 m

Enclosure IP 68, withstands a static pressure equal to max. overpressure.

Approvals

➀

Can be delivered with other cable lengths on request.

Better than ± 0.1 % FS @ +10 to 30 °C

Better than ± 0.2 % FS @ full temperature range

®

ATEX: II 2G EEx ia IIC T5/T6 and CE: EN61000-6-3/-4:2001, EN61000-6-1/-2:1999,

EN50014:1997 E, EN50020:2002

Order Numbers

Dimensions and

Accessories

Manual Expert 1400/3400 GB 0704

Order Numbers

203911 Expert™ 1400, range 0 - 0,3 mWG 203916 Expert™ 1400, range 0 - 30 mWG

203912

203913

203914

203915

Expert™ 1400, range 0 - 1 mWG 203917 Expert™ 1400, range 0 - 100 mWG

Expert™ 1400, range 0 - 3 mWG 203918 Expert™ 1400, range 0 - 300 mWG

Expert™ 1400, range 0 - 5 mWG 202925 Expert™ 1400, special meas. range

Expert™ 1400, range 0 - 10 mWG

MJK Expert™ 1400

Level Transmitter

All 1400 transmitters are Atex approved.

Cable bracket for MJK Expert™ 1400

Level Transmitter

(1 pc. is delivered with each transmitter)

MJK Automation A/S

12

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Page 13

Manual

60 mm

236 mm

135 mm

32 mm

Dia. 50 mm

1” NPT

Dia. 50 mm

135 mm

36 mm

Data Sheet for

Exper t™ 3400 Level

Transmitter

Specifications

MJK Expert™ 3400 Level Transmitter is

designed for use in waterworks, sewage

treatment plants and industrial applications

where accurate and long term stable level

measuring is required. It is very robust and

designed for applications in rough environments with aggressive chemicals and

aggressive fluids.

A major design feature is the programming

facility. With a standard USB interface and

a laptop computer, the servicing transmitter can be programmed on-the-fly to the

required measuring range.

MJK Expert™ 3400 Hydrostatic Level Transmitter

Nominal measuring range 0 - 0,3 m 0 - 1 m 0 - 3 m 0 - 5 m 0 - 10 m 0 - 30 m 0 - 100 m 0 - 300 m

Measuring principle Ceramic capacitive, relative pressure

Min. programmable range 0 - 0,3 m 0 - 0,3 m 0 - 1 m 0 - 3 m 0 - 3 m 0 - 10 m 0 - 30 m 0 - 90 m

Max. programmable range 0 - 1 m 0 - 1 m 0 - 3 m 0 - 10 m 0 - 10 m 0 - 30 m 0 - 100 m 0 - 300 m

Max. overpressure 4 bar 4 bar 6 bar 10 bar 10 bar 18 bar 40 bar 40 bar

Temperature range -20 °C to 40 °C

Temp. deviation, zero oint Better than ± 0.02 % / °C

Temperature deviation, FS Better than ± 0.01 % / °C

Linearity / Stability Better than ± 0.2 % FS / ± 0.2 % FS

Measurement accuracy Better than ± 0.1 % FS @ +10 to 30 °C. Better than ± 0.2 % FS @ full temperature range

Long time stability Better than ± 0.1 % FS per year

Materials Housing: stainless steel (AISI 316 L), diaphragm: 96,6 % Al2O3/Cell packing: Viton

Supply voltage 10 - 30 V DC (12 - 30 V DC for cable lengths above 110 m)

Output signal 2-wire 4 - 20 mA (passive transmitter)

Cable 2 × 0,5 mm2 (pressure) + 5 x 0,15 mm2 (data), shielded, PUR insulation

Cable length 12 m 12 m 12 m 12 m 12 m 35 m 110 m 320 m

Enclosure IP 68, withstands a static pressure equal to max. overpressure.

Approvals

➀

Can be delivered with other cable lengths on request.

ATEX: II 2G EEx ia IIC T5/T6, CE: EN61000-6-3/-4:2001, EN61000-6-1/-2:1999,

EN50014:1997 E, EN50020:2002

®

Order numbers

Dimensions and

Accessories

Manual Expert 1400/3400 GB 0704

Order Numbers

203951 Expert™ 3400, range 0 - 0.3 mWG 203957 Expert™ 3400, range 0 - 100 mWG

203952

203953

209954

203955

203956

Expert™ 3400, range 0 - 1 mWG 203958 Expert™ 3400, range 0 - 300 mWG

Expert™ 3400, range 0 - 3 mWG 203961 Expert™ 3400, range 0 - 0.3 m 1" RG top

Expert™ 3400, range 0 - 5 mWG 203962 Expert™ 3400, range 0 - 1 m 1" RG top

Expert™ 3400, range 0 - 10 mWG 203963 Expert™ 3400, range 0 - 3 m 1" RG top

Expert™ 3400, range 0 - 30 mWG 202925 Expert™ 3400 w/ special meas. range

MJK Expert™ 3400

Level Transmitter

Cable bracket for MJK model 3400

(1 pc. is delivered with each transmitter)

MJK Automation A/S

13

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Page 14

Manual

This page intentionally left blank.

Manual Expert 1400/3400 GB 0704

14

MJK Automation A/S

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Page 15

Manual

This page intentionally left blank.

Manual Expert 1400/3400 GB 0704

15

MJK Automation A/S

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Page 16

Manual

Manual Expert 1400/3400 GB 0704

16

MJK Automation A/S

Byageren 7

DK-2850 Naerum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Loading...

Loading...