Page 1

EXO

User Manual

ADVANCED WATER QUALITY MONITORING PLATFORM

Item# 603789REF

Revision A

Page 2

e information contained in this manual is subject to

change without notice.

Eort has been made to make the information in

this manual complete, accurate, and current. e

manufacturer shall not be held responsible for errors or

omissions in this manual. Consult EXOwater.com for the

most up-to-date version of this manual.

Page 3

Table of Contents

1. Introduction

1.1 EXO1 Sonde Overview

1.2 EXO2 Sonde Overview

1.3 EXO Handheld Overview

1.4 EXO Sensors Overview and Specications

1.5 Conductivity/Temperature

1.6 Depth and Level

1.7 Dissolved Oxygen

1.8 fDOM

1.9 pH and ORP

1.10 Total Algae (Chlorophyll and Blue-green Algae)

1.11 Turbidity

2. Operation

2.1 Install Batteries

2.2 Install/Remove Sensors

2.3 Install/Remove Sensor Guard or Calibration Cup

2.4 Sonde States and LED Descriptions

2.5 Awake Sonde, Activate Bluetooth

Attach Sonde to Handheld

2.6 Field Cable

2.7 Bluetooth Wireless Communication

2.8 Install KOR Soware

Connect Sonde

2.9 USB

2.10 Bluetooth Link to PC

2.11 Data Collection Platform

2.12 Flow Cell

3. Handheld

3.1 Install Batteries

3.2 Power On/O Handheld

Attach Handheld to Sonde

3.3 Field Cable

3.4 Bluetooth Wireless Communication

Spot Sampling

3.5 View Live Data

3.6 Record Spot Sampling Data

3.7 Upload Data

3.8 GPS

4. KOR Software

4.1 Introduction to Navigation

4.2 Run Menu

4.3 Calibrate Menu

4.4 Deploy Menu

4.5 Sites Menu

4.6 Data Menu

4.7 Options Menu

4.8 Connections Menu

4.9 Help Menu

4.10 Data Files & File Locations

4.11 SDI-12

pg | 3

Page 4

5. Calibration

5.1 Introduction to Basic Procedure

5.2 Calibrating Conductivity/Temperature

5.3 Calibrating Dissolved Oxygen

5.4 Calibrating Depth

5.5 Calibrating pH

5.6 Calibrating ORP

5.7 Calibrating Turbidity

5.8 Calibrating Total Algae (Chlorophyll and Blue-green Algae)

5.9 Calibrating fDOM

5.10 Calibration Standards

5.11 Calibration Record Sheet

6. Maintenance

6.1 Sonde Storage, Short-term and Long-term

6.1 Sonde Maintenance

6.2 Install/Replace Sonde Batteries

6.3 Replace Sonde Bails

6.4 Update Sonde Firmware

6.5 Handheld Maintenance and Storage

6.6 Install/Replace Handheld Batteries

6.7 Update Handheld Firmware & KOR Soware on Handheld

6.8 Depth Sensor Storage and Maintenance

6.9 Standard Optical Sensors Maintenance and Storage

6.10 Conductivity/Temperature Sensor Maintenance and Storage

6.11 Dissolved Oxygen Sensor Storage, Maintenance and Rehydration

6.12 Sensor Cap Replacement

6.13 pH and ORP Sensor Storage, Maintenance and Rehydration

6.14 Sensor Module Replacement

6.15 Wiper Maintenance and Storage

6.16 Field Cable Maintenance and Storage

6.17 Antifouling Equipment Maintenance

Sacricial Anode

6.18 Connectors Maintenance and Storage

6.19 Flow Cell Maintenance

pg | 4

7. Health & Safety, Warranty, Service

7.1 Chemicals

Conductivity Solutions

pH Solutions

Zobell Solution

Turbidity Standard

Ultraviolet Light (fDOM Sensor)

7.2 Radio Frequency

7.3 Declarations of Conformity

7.4 Instrument Warranty

7.5 Instrument Cleaning & Packing Instructions

7.6 Recycling

Page 5

2.9

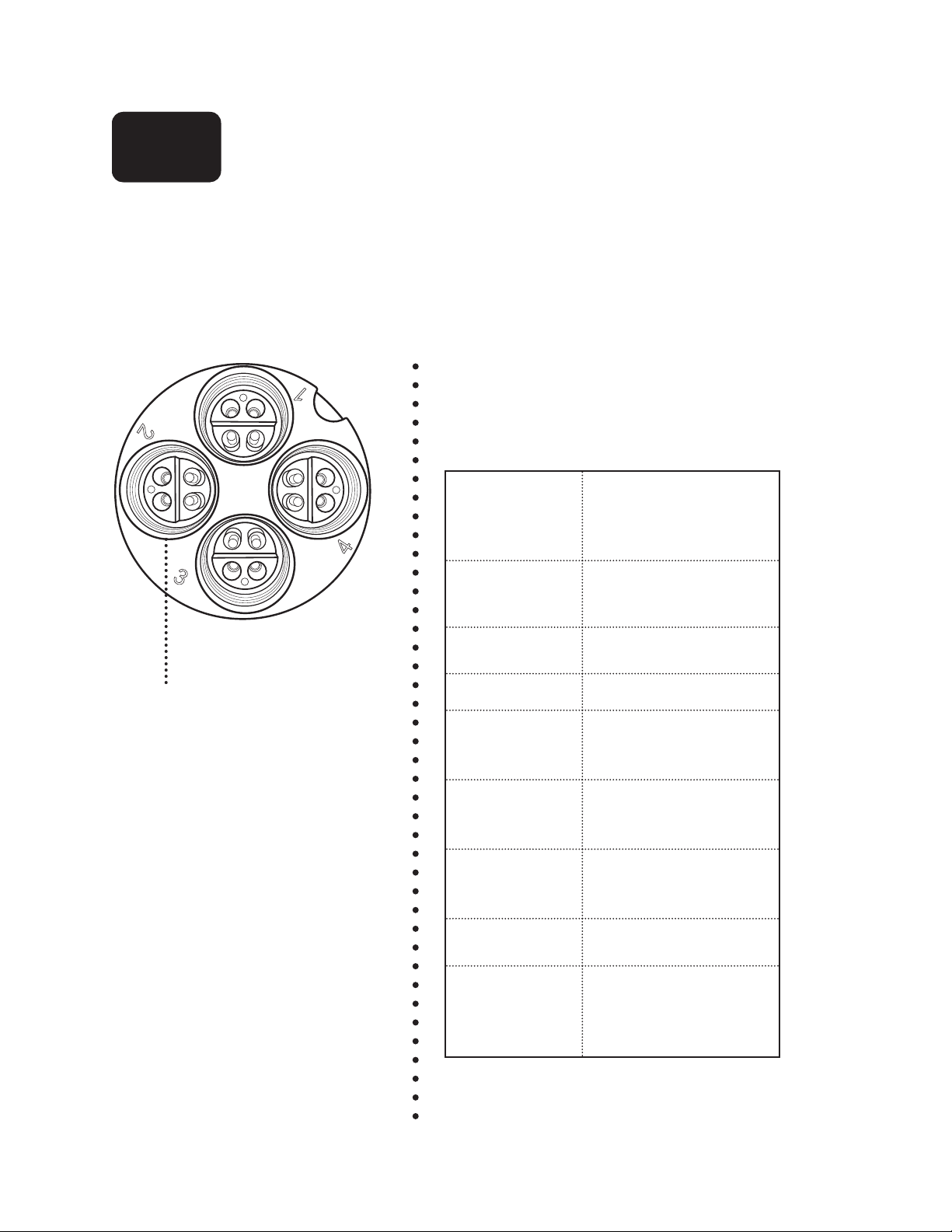

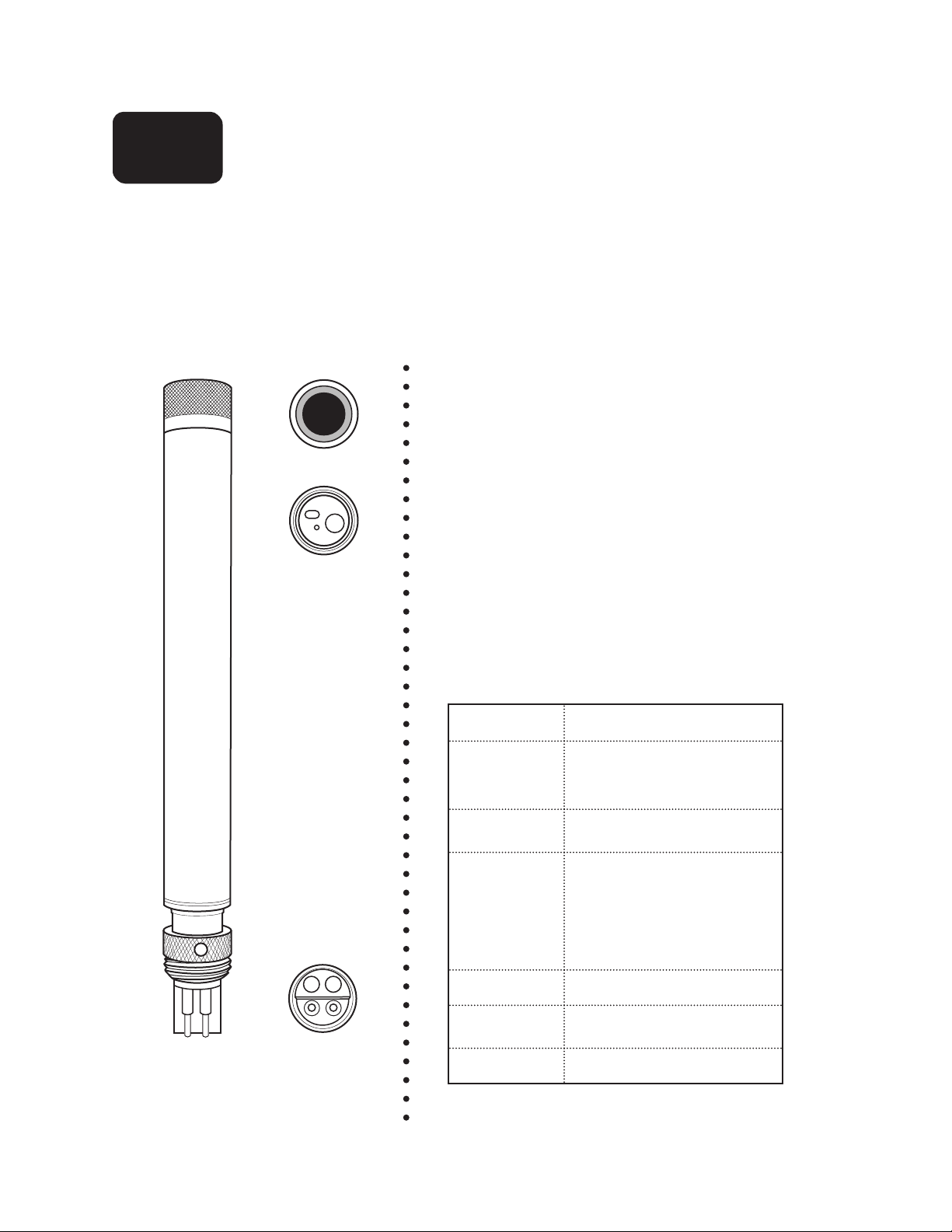

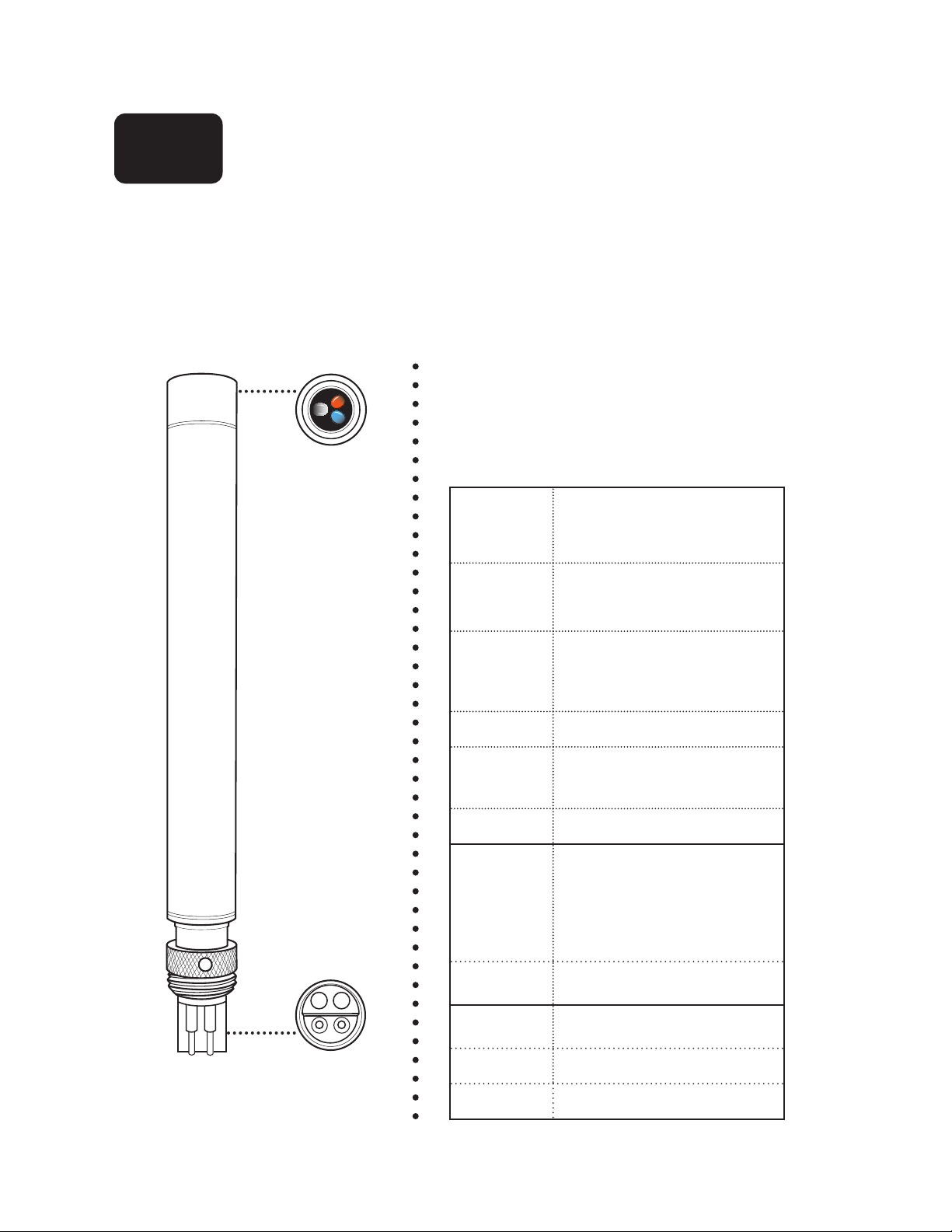

EXO 1 Sonde

1.1

Overview

e EXO1 sonde is a multiparameter instrument that collects water quality data. e sonde collects the

data with up to four user-replaceable sensors and an integral pressure transducer. Each sensor measures its

parameter via a variety of electrochemical, optical, or physical detection methods. Each port accepts any EXO

sensor and automatically recognizes its type. Depending on user-dened settings, the EXO1 will collect data

and store it onboard the sonde, transfer the data to a data collection platform (DCP), or relay it directly to

a user’s PC or EXO Handheld.

Users communicate with the sonde via a eld cable to an

EXO Handheld, Bluetooth® wireless connection to a PC or

EXO Handheld, or a USB connection (via communications

adapter) to a PC.

Specifications

Operating

Environment

Depth Rating

Medium

Material

Internal Logging

Memory Capacity

250 meters, 820 feet

Water

®

Xenoy

titanium, copper-nickel

alloy, 316 stainless steel

512 MB

, Lexan® , bronze,

Universal Sensor Ports

Software

Communications

Sonde

Adapters

Power

External

Internal

Temperature

Operating

Storage

Battery Life

Dimensions

Diameter

Length

Weight

Kor Interface Software

Bluetooth, Field Cable,

USB, RS-485;

USB, SDI -12/RS -232

9-16 VDC

2 D - size batteries

-5 to 50°C

+

-20 to

90 days typically

(see pg 78)

4.70 cm,1.85 in

64.77 cm, 25.50 in

1.65 kg, 3.63 lb

80°C

pg | 5

Page 6

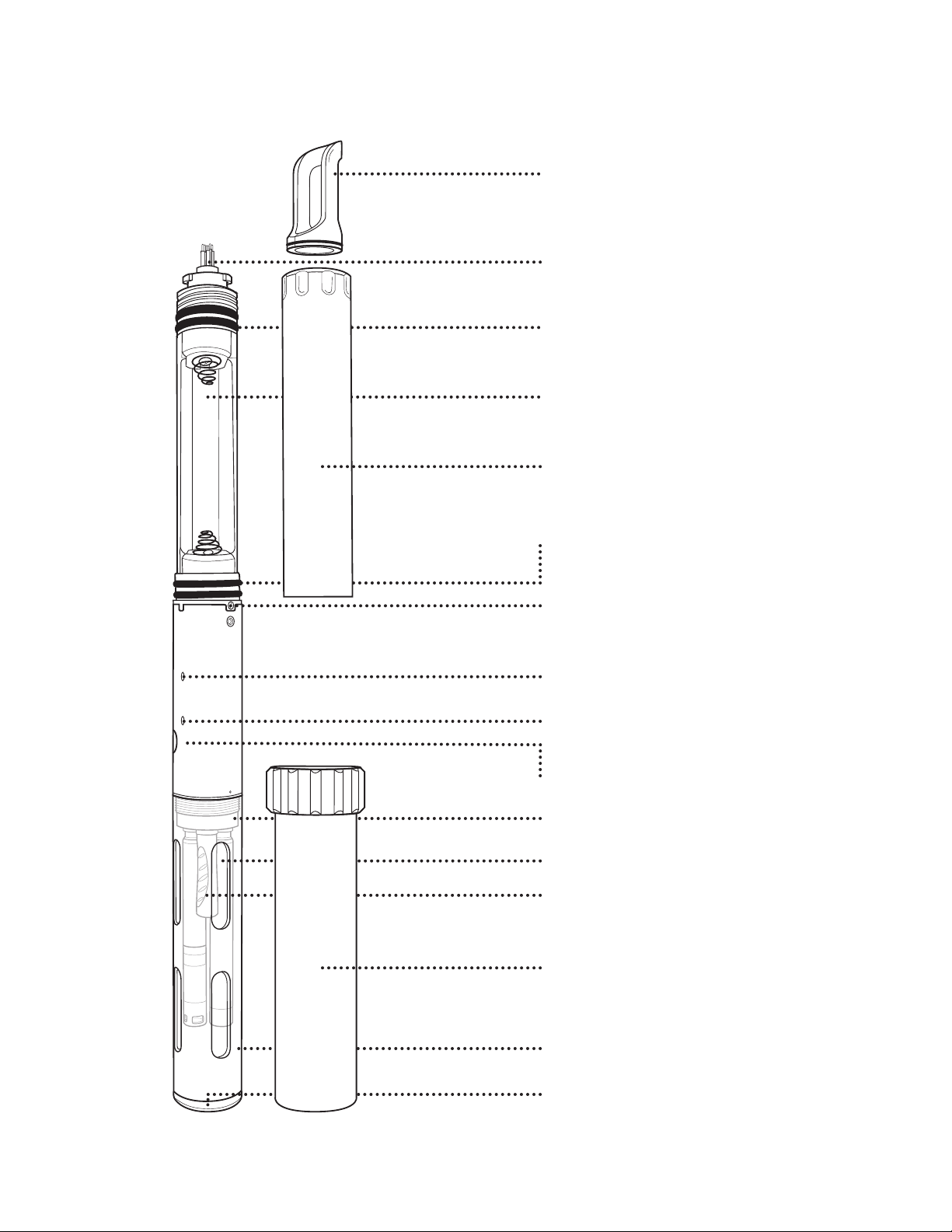

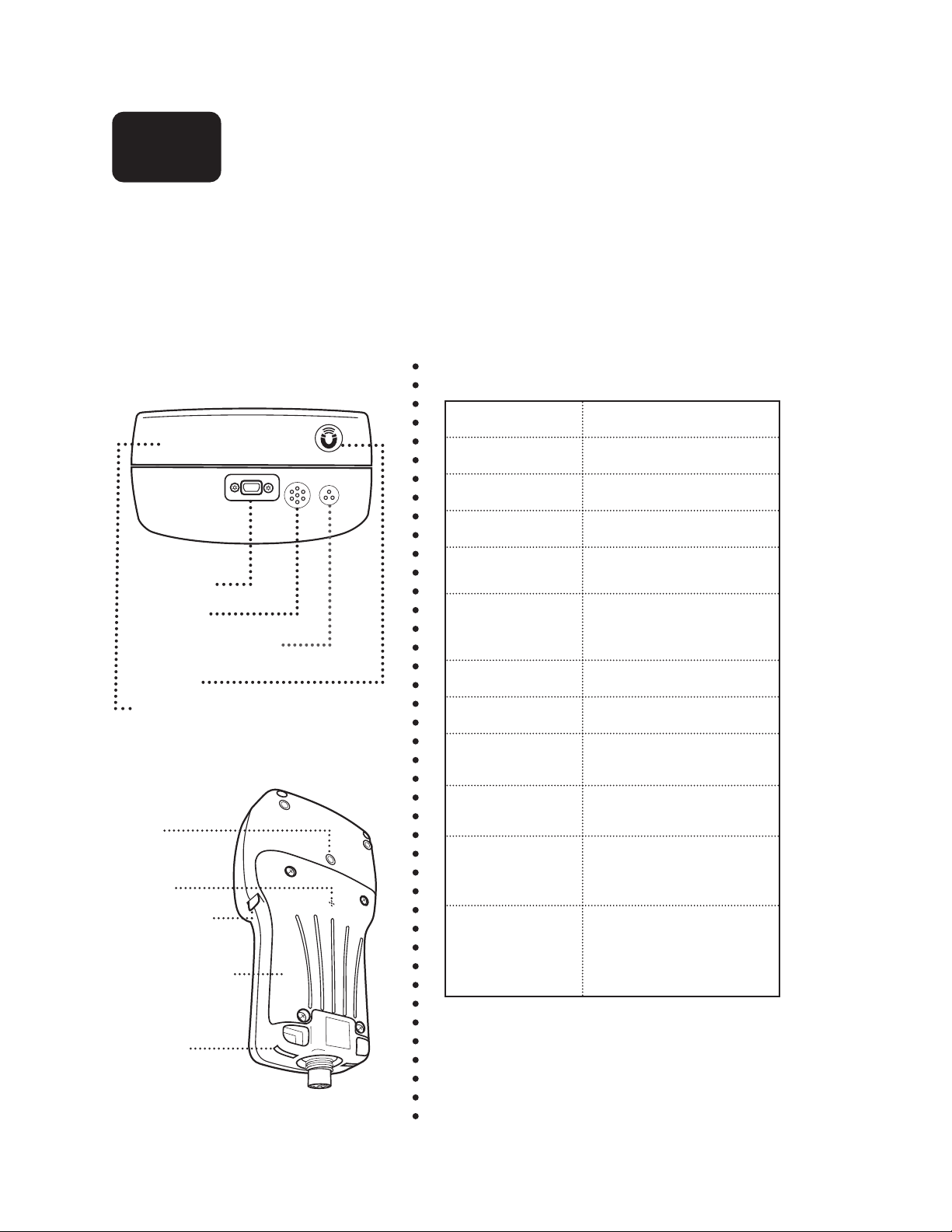

EXO1 Sonde

599501

Removable Bail

599473

6-Pin Cable Connector

Upper Battery

Compartment Seal

O-rings 599680

Battery Compartment

Battery Cover

Lower Battery

Compartment Seal

Pressure Transducer

Opening

Red LED Indicator

– Sonde

Status

Blue LED Indicator – Bluetooth

On/Off Magnetic Switch for

Power and Bluetooth

Bulkhead

Sensor

Port Plug

599475

Calibration Cup

599289

Sensor Guard

599333, 599563

pg | 6

Guard Weight

599471, 599365

Page 7

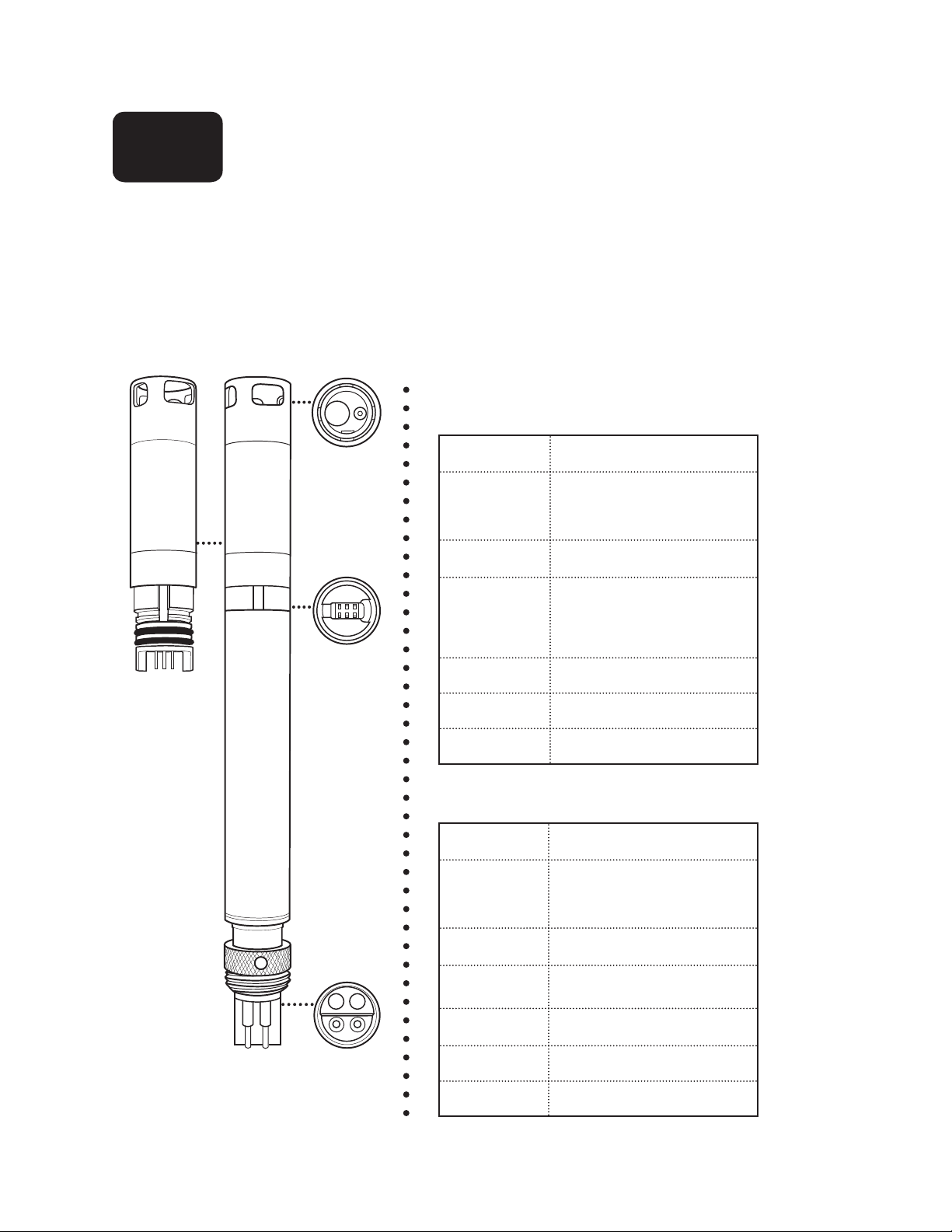

2.9

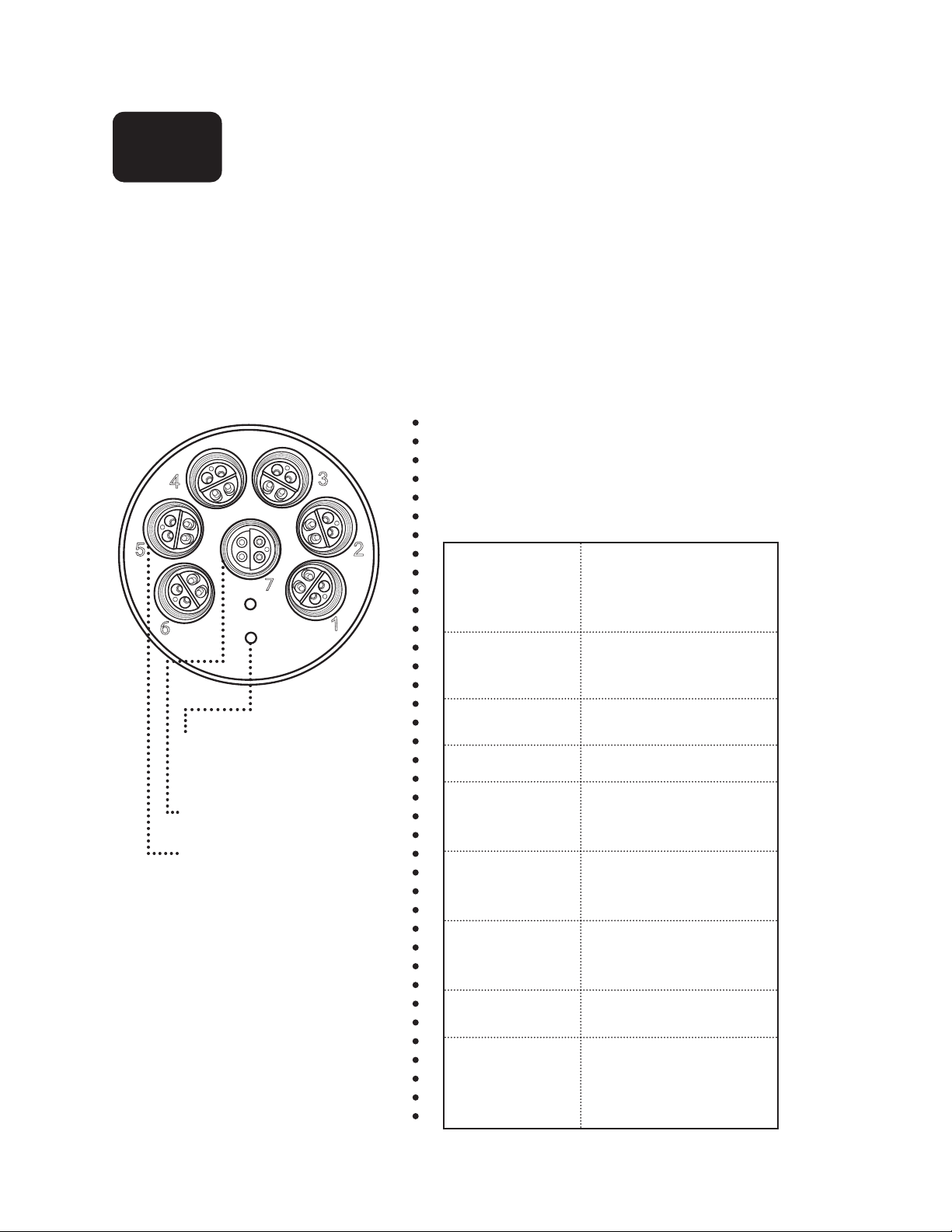

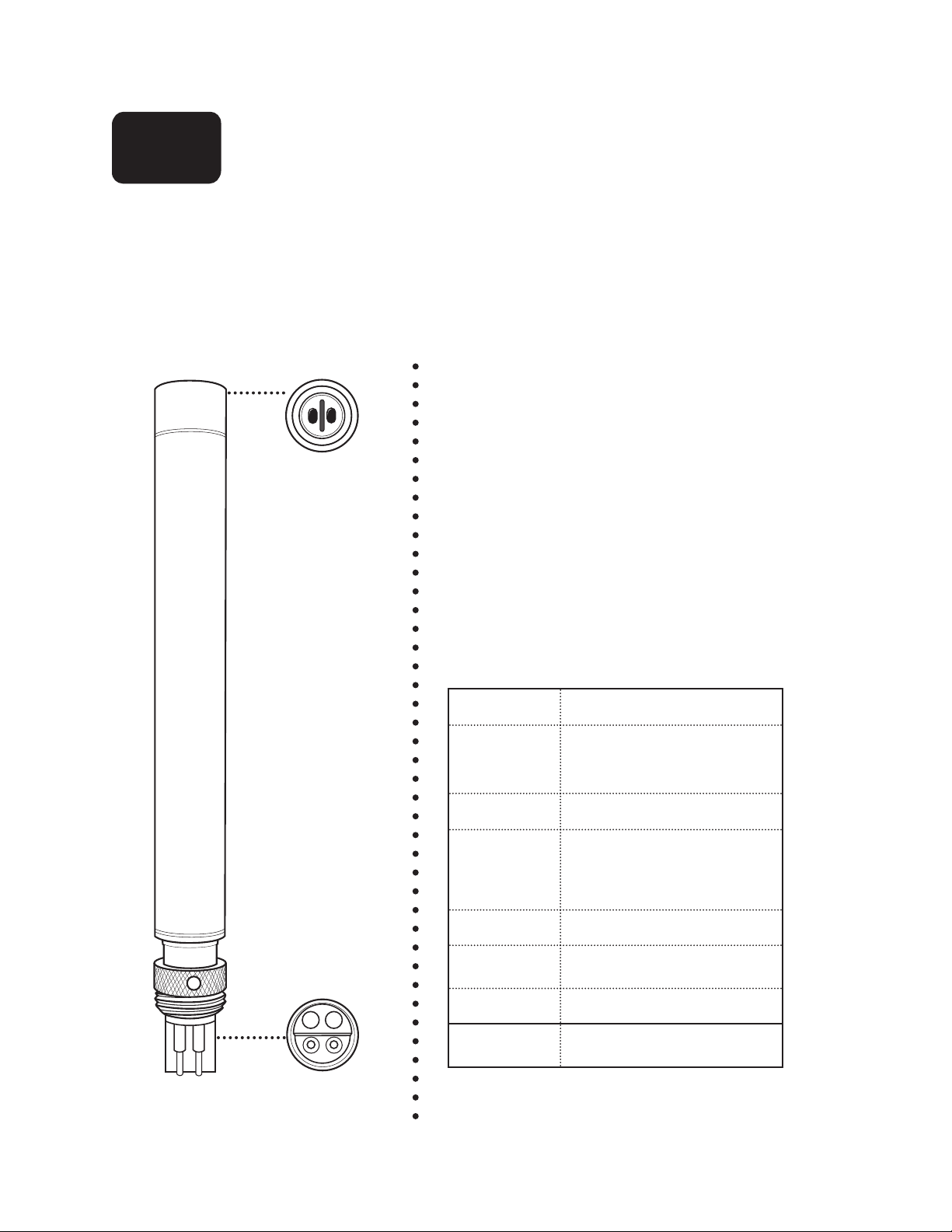

EXO2 Sonde

1.2

Overview

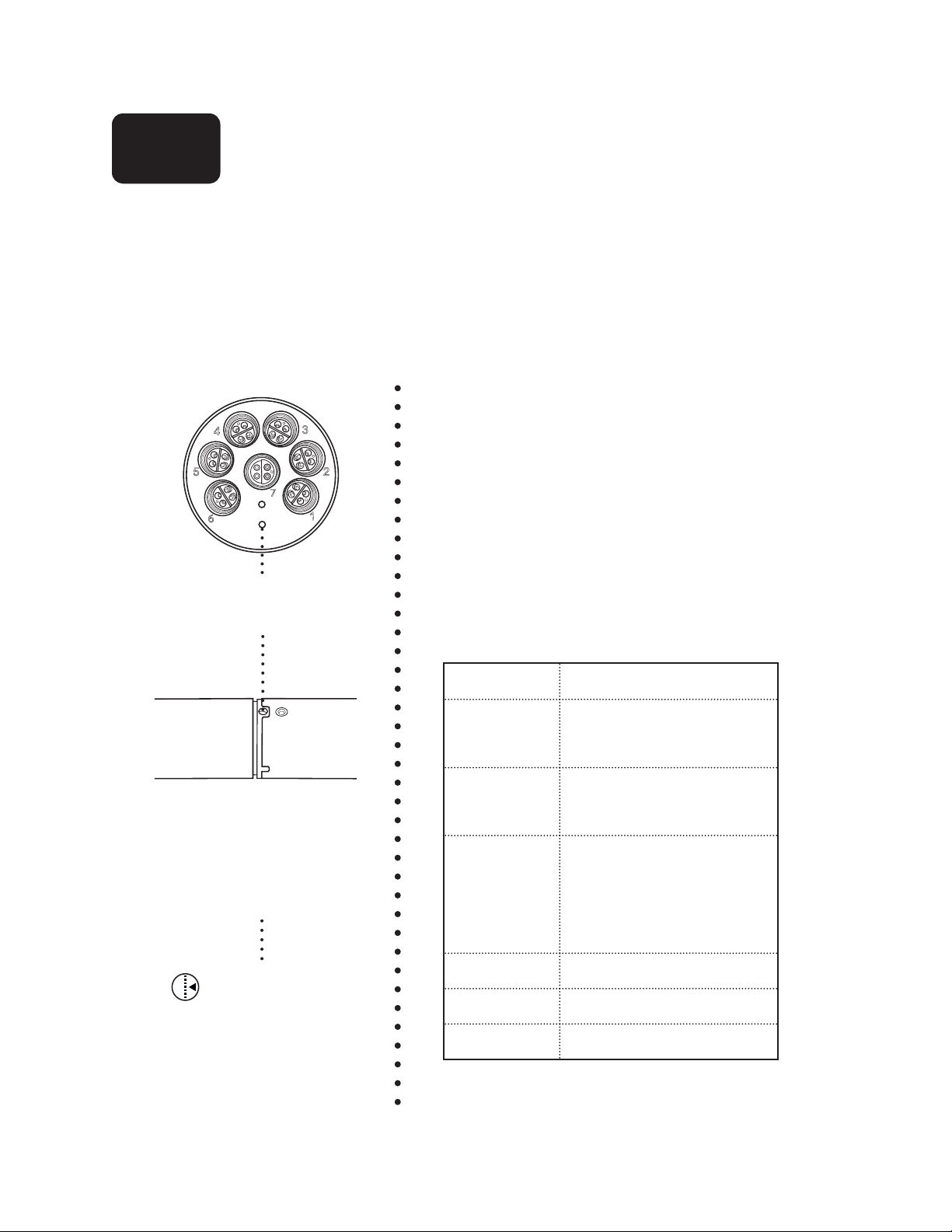

e EXO2 sonde is a multiparameter instrument that collects water quality data. e sonde collects the

data with up to six user-replaceable sensors and an integral pressure transducer. Each sensor measures its

parameter via a variety of electrochemical, optical, or physical detection methods. Each port accepts any EXO

sensor and automatically recognizes the type of sensor. Depending on user-dened settings, the EXO2 will

collect data and store it onboard the sonde, transfer the data to a data collection platform (DCP), or relay it

to a user’s PC or EXO Handheld via cable, USB connection, or Bluetooth connection.

In addition to six standard sensor ports, the EXO2 also has a bulkhead port for a central wiper (or an

additional sensor) and an auxiliary port on top of the sonde. is auxiliary port will allow the user to connect

the EXO2 to other EXO sondes.

Users communicate with the sonde via a eld cable to an

EXO Handheld, Bluetooth® wireless connection to a PC or

EXO Handheld, or a USB connection (via communications

adapter) to a PC.

Specifications

Operating

Environment

Pressure Transducer

Openings

Depth Rating

Medium

Material

Internal Logging

Memory Capacity

Software

250 meters, 820 feet

Water

Xenoy, Lexan, bronze,

titanium, copper-nickel

alloy, 316 stainless steel

512 MB

Kor Interface Software

Wiper/Sensor Port

Universal Sensor Ports

Communications

Sonde

Adapters

Power

External

Internal

Temperature

Operating

Storage

Battery Life

Dimensions

Diameter

Length

Weight

Bluetooth, Field Cable,

USB, RS-485;

USB, SDI -12/RS -232

9-16 VDC

4 D - size batteries

+

-5 to

-20 to

90 days typically

(see pg 80)

7.62 cm, 3.00 in

71.1 cm, 28.00 in

2.65 kg, 5.83 lb

50°C

+

80°C

pg | 7

Page 8

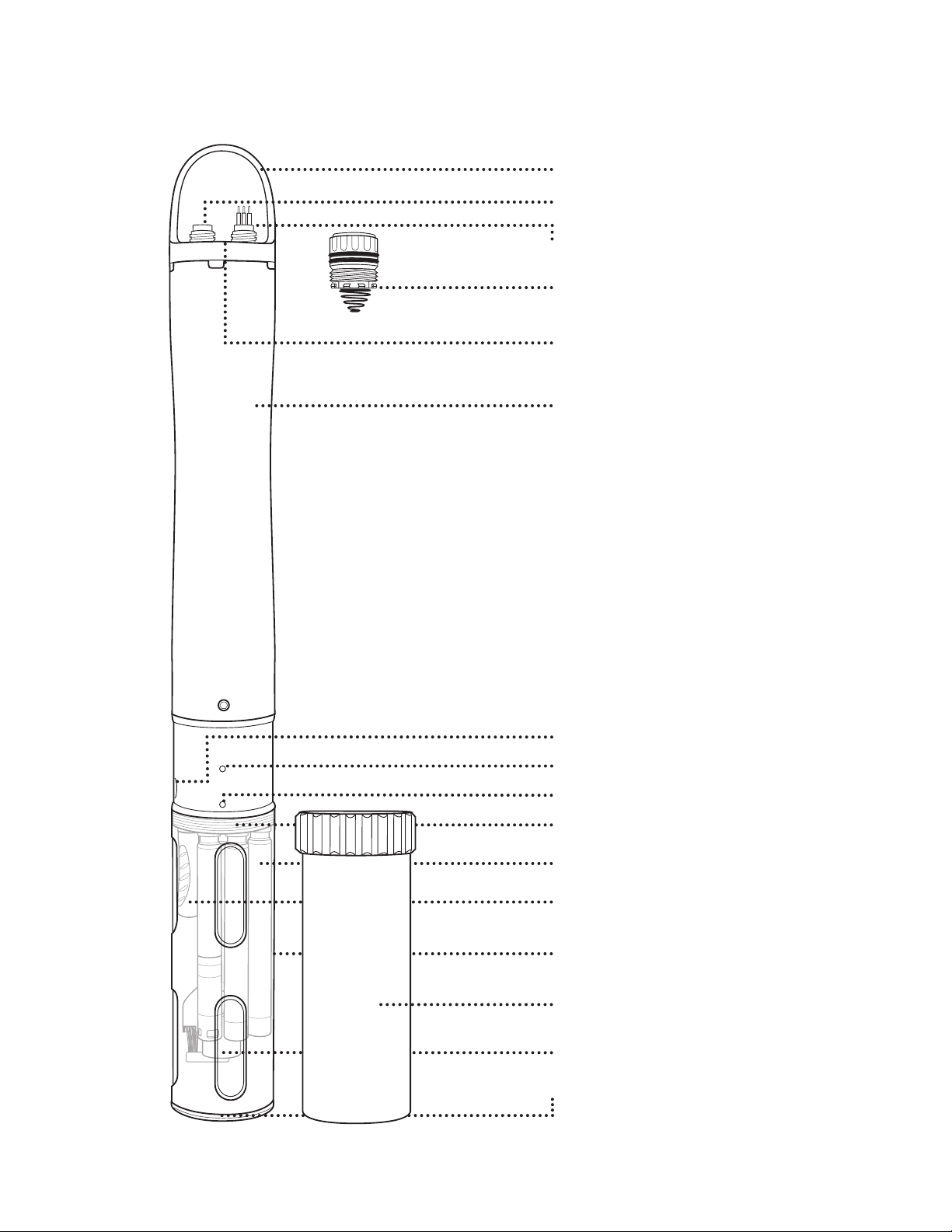

EXO2 Sonde

599502

Removable Bail

599474

Auxiliary Port

6-Pin Cable Connector

Battery Cap/Pressure Relief Valve

O-rings 599681

Battery Compartment Opening

Battery Compartment

pg | 8

On/Off Magnetic Switch for

Power and Bluetooth

Red LED Indicator

– Sonde

Status

Blue LED Indicator – Bluetooth

Bulkhead

Sensor

Port Plug

599475

Sensor Guard

599334, 599564

Calibration Cup

599316

Central Wiper

599549

Guard Weight

599472, 599366

Page 9

2.9

EXO Handheld

1.3

Overview

e EXO Handheld (HH) is a rugged, microcomputer-based instrument that allows the user to display sonde

readings, congure sondes, store and retrieve data, and transfer data from sondes to a computer. Equipped with

GPS, barometer, and custom operating system, the Handheld communicates via Bluetooth wireless technology,

eld cable, or USB connector. e unit utilizes an adjustable backlit screen for easy day or night viewing. Preinstalled KOR soware facilitates all user interaction and provides powerful control over data collection.

Top View

Specifications

US B Port

Speaker

Microphone is for future

functionality; not active yet

Magnet

GPS Antenna

Tripod Mount

(1)

Barometer

Vent

Handstrap

Mount

Battery Cover

(internal)

Back View

Barometer

GPS

Microphone

Audio Speaker

Operating

System

Material

Memory

Software

Communications

Power

Internal

Temperature

Operating

Storage

Dimensions

Width

Length

Weight w. batt.

Yes

Yes

Yes

Yes

Windows CE 5.0

Polymer,

rated to IP-67 in factory

tests

2 GB

Kor Interface Software

Bluetooth, Field Cable,

USB

4 C - size alkaline batteries

+

-5 to

-20 to

11.9 cm, 4.7 in

22.9 cm, 9.0 in

0.91 kg, 2.1 lb

50°C

+

80°C

Handstrap

Mount

pg | 9

Page 10

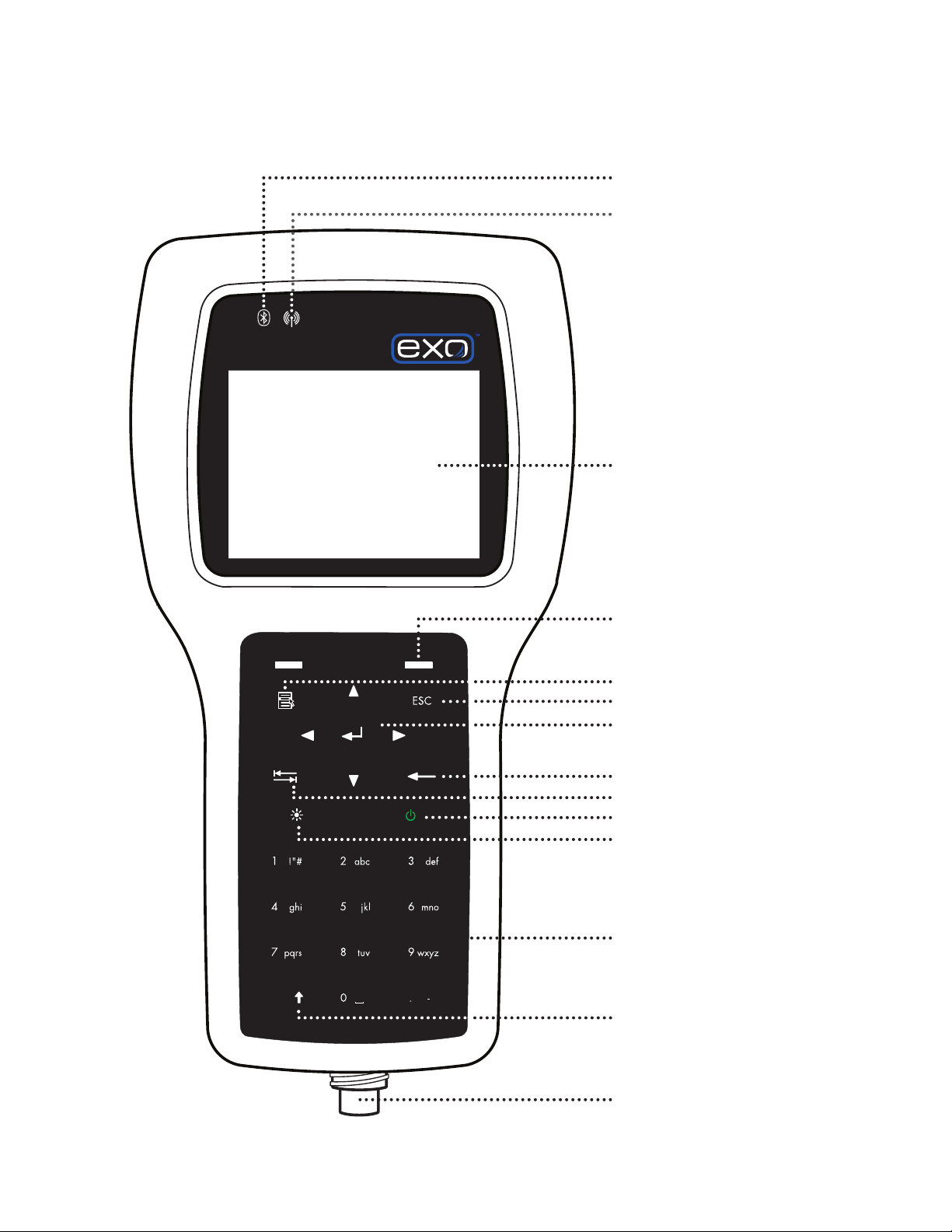

EXO Handheld

599150

Bluetooth Indicator

Wi-Fi Indicator is for future

functionality; not active yet

Daylight-viewable

LCD

Soft Keys (2)

Menu

Escape

Navigation Arrows (4)

& Return

Backspace

Tab

Power

Brightness

Alphanumeric

Keypad

Shift

pg | 10

Cable Connector

Page 11

EXO Sensors

1.4

Overview

e EXO product line includes nine sensors that detect a variety of physical, chemical, and biological

properties of natural water. EXO sensors are designed to collect highly accurate data under ever-changing

environmental conditions.

Data Filtering

All EXO sensors share some common embedded soware, including the ltering of real-time data. Sensors

acquire environmental data at a constant rate, and use this stream of data as the input to the ltering algorithm

that produces results seen by the user. EXO sondes collect data from the EXO sensors and are able to output

data at rates up to 4 Hz. e EXO sensor data ltering process consists of four components:

Basic Rolling Filter

e lter is fundamentally a rolling or window average of past acquired inputs to the lter, such that as a new

data value is added to the summation, the oldest data value is removed, and the total summation is divided

by the total number of data values. It is a simple average, just rolling or moving in time.

Adaptive Filtering

e drawback to a basic rolling lter is that response time to an impulse event is delayed, and the more entries

in the average summation, the longer the delay for the result to converge on the true value. To correct this,

the lter algorithm monitors the new data arriving and compares it to the current averaged result, looking

for indication of an impulse event. When new data deviates from the average by more than a predetermined

tolerance, the number of data entries within the rolling average is reduced to a minimum count and the

remaining values are ushed with the new data. e result is a snap to the new value, entirely eliminating

the inherent delay caused by the rolling average.

Outlier Rejection

Every time a newly acquired data value is added, the rolling average entries are scanned for outlier data.

Although such data has already been determined to fall within the tolerances dened above, the remaining

worst oenders are removed from the rolling average calculation. is outlier rejection allows for smoother

continuous data results.

Calibration Stability

During calibration, the ltering is active as described, plus an additional feature works to provide stability

feedback to the user. When the user attempts to calibrate a sensor, the sudden changes in environment

are perceived as impulses or plunge events and the ltering reacts accordingly. e results immediately

show the value of the solution, and aer a few moments, the lter incrementally engages fully and supplies

the smoothest data. However, as the sensor and the calibration solution work towards equilibrium, the

measurement may slowly dri. e sensor will monitor the results from the lter and determine if the

measurement is stable. It watches the results and calculates a slope from each and every result to the next.

Once the slope settles and is consistently at for approximately 30 seconds, the sensor is considered stable.

KOR is then notied and calibration can continue.

pg | 11

Page 12

Sensor Response Times

Response times for EXO sensors are based on laboratory testing. Actual response times in the eld may vary

depending on application.

Sensor Accuracy Specifications

To maintain accuracy specications for EXO sensor, we recommend that users calibrate sensors in the lab in

standards with temperatures as close to the ambient temperature of the eld water as possible.

pg | 12

Page 13

2.9

Conductivity/Temperature

1.5

Sensor Overview

e EXO combination conductivity and temperature sensor should be installed in a sonde in nearly all sonde

applications. Not only will this sensor provide the most accurate and fastest response temperature data, but

it will also provide the best data for the use in temperature compensation for the other EXO probes. e

conductivity data is used to calculate salinity, specic conductance, and total dissolved solids, and compensate

for changes in density of water (as a function of temperature and salinity) in depth calculations if a depth

sensor is installed.

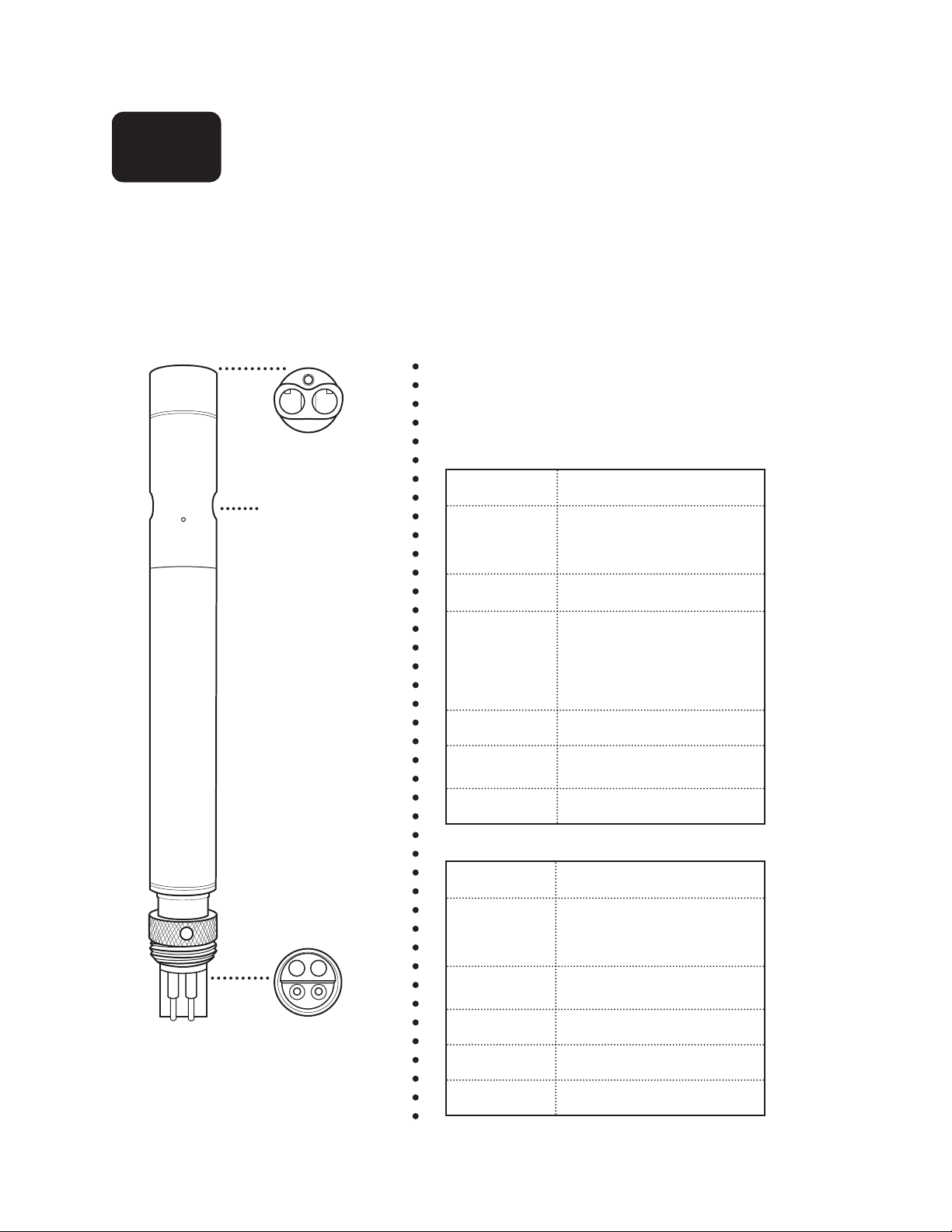

Temperature Thermistor

e temperature sensor uses a highly stable and aged

thermistor with extremely low-dri characteristics. e

Conductivity Cell

Specifications

Conductivity

Default Units

Temperature

Operating

Storage

Range

Accuracy

Response

Resolution

Sensor Type

Temperature

microSiemens/centimeter

-5 to +50°C

-20 to +80°C

0 to 200 mS/cm

0-100 mS/cm: ±0.5% of

reading or 0.001 mS/cm,

whichever is greater;

100-200 mS/cm: ±1% of

reading

T63<2 sec

0.0001 to 0.01 mS/cm

range-dependent

4-electrode nickel cell

(see pg 12)

(continued)

599870

Default Units

Temperature

Operating

Storage

Accuracy

Response

Resolution

Sensor Type

°Celsius

-5 to +50°C

-20 to +80°C

-5 to 35°C: ±0.01°C

35 to 50°C: ±0.05°C

T63<1 sec

0.001°C

Thermistor

pg | 13

Page 14

thermistor’s resistance changes with temperature. e measured resistance is then converted to temperature

using an algorithm. e temperature sensor receives a multi-point NIST traceable wet calibration and the

accuracy specication of 0.01˚C is valid for expected life of the probe. No calibration or maintenance of the

temperature sensor is required, but accuracy checks can be conducted and logged through the KOR interface

soware.

Conductivity Electrodes

e conductivity sensor uses four internal, pure-nickel electrodes to measure solution conductance. Two of

the electrodes are current driven, and two are used to measure the voltage drop. e measured voltage drop is

then converted into a conductance value in milliSiemens (millimhos). To convert this value to a conductivity

value in milliSiemens per cm (mS/cm), the conductance is multiplied by the cell constant that has units of

reciprocal cm (cm-1). e cell constant for the conductivity cell is approximately 5.5/cm ±10%. For most

applications, the cell constant is automatically determined (or conrmed) with each deployment of the system

when the calibration procedure is followed.

Temperature Compensation

EXO sensors have internal thermistors for quality assurance purposes. However, this internal temperature

is not logged or displayed. Turbidity uses the internal thermistor for temperature compensation, while all

other EXO sensors reference the C/T probe for temperature compensation. To display and log temperature,

a C/T probe must be installed in an EXO sonde.

pg | 14

Page 15

Depth

1.6

Sensor Overview

EXO measures depth of water with a non-vented strain gauge. A dierential strain gauge transducer

measures pressure with one side of the transducer exposed to the water and the other side exposed to a

vacuum. We calculate depth from the pressure exerted by the water column minus atmospheric pressure.

Factors inuencing depth measurement include barometric pressure, waterdensity, and temperature.

Calibration in the atmosphere “zeros” the sensorwith respect to the local barometric pressure. A change in

barometricpressure will result in a zero shi unless the transducer is recalibrated to the new pressure.

EXO sondes have intake openings to allow water to act on the strain gauge. e EXO1 intake is located in

the yellow section between the battery compartment and

label of the sonde. e EXO2 intake openings are two small

holes on the face of the sonde bulkhead.

Location of Depth Sensor

Depth sensors are not on center. When deploying the sonde

vertically, take care to ensure the sonde is redeployed in

same position. Oen a marker pin inside a PVC pipe is

used. In horizontal deployments, take care to ensure the

redeployments are always in the same orientation. is is

especially important for the EXO2 sonde because the depth

EXO 2 Depth Intake

EXO 1 Depth Intake

sensor is o-axis.

(continued)

Specifications

Depth Sensor Location relative

to other water quality sensors

(see EXO sonde label)

Depth Sensor Location

27.2 cm to WQ Sensors

Units

Temperature

Operating

Storage

Range

Accuracy

Response

Resolution

Sensor Type

PSI, Depth (m, ft, bar)

-5 to +50°C

-20 to +80°C

Shallow: 0 to 33 ft (10 m)

Medium: 0 to 328 ft (100 m)

Deep: 0 to 820 ft (250 m)

Shallow: ±0.04% FS (±0.013

ft or ±0.004 m)

Medium: ±0.04% FS (±0.13 ft

or ±0.04 m)

Deep: ±0.04% FS (±0.33 ft or

±0.10 m)

T63<2 sec

0.001 ft (0.001 m)

Stainless steel strain gauge

(see pg 12)

pg | 15

Page 16

Location of Depth Sensor (continued)

To assist with consistent horizontal orientation, the EXO2 sonde has

an indentation at the top of the sonde for a marker or positioning

pin.

e sonde should be installed with at least 1 cm of water above the

intake ports.

If a conductivity sensor is installed, the depth will be compensated

automatically for changes in the density of water as temperature

and salinity change.

Depth Configuration

EXO sondes must be ordered with a specic depth option: 0-10 m,

0-100 m, 0-250 m, or no depth. Once the depth selection is made,

the sonde’s depth sensor cannot be changed.

pg | 16

Page 17

2.9

Dissolved Oxygen

1.7

Sensor Overview

e principle of operation of the EXO optical Dissolved Oxygen sensor is based on the well-documented

concept that dissolved oxygen quenches both the intensity and the lifetime of the luminescence associated

with a carefully chosen chemical dye. e EXO DO sensor operates by shining a blue light of the proper

wavelength on this luminescent dye which is immobilized in a matrix and formed into a disk. e blue

light causes the immobilized dye to luminesce and the lifetime of this dye luminescence is measured via a

photodiode in the probe. To increase the accuracy and stability of the technique, the dye is also irradiated with

red light during part of the measurement cycle to act as a reference in the determination of the luminescence

lifetime.

When there is no oxygen present, the lifetime of the signal

is maximal; as oxygen is introduced to the membrane

surface of the sensor, the lifetime becomes shorter. us,

the lifetime of the luminescence is inversely proportional

Sensor Cap

Sensor without

Sensor Cap

to the amount of oxygen present and the relationship

between the oxygen pressure outside the sensor and the

lifetime can be quantied by the Stern-Volmer equation.

For most lifetime-based optical DO sensors, this SternVolmer relationship

((Tzero/T) – 1) versus O2 pressure

is not strictly linear (particularly at higher oxygen

pressures) and the data must be processed using analysis by

(continued)

599100,

599110

Specifications

Units

Temperature

Operating

Storage

Range

Accuracy

Response

Resolution

Sensor Type

% Saturation, mg/L

-5 to +50°C

-20 to +80°C

0 to 500% air sat.

0 to 50 mg/L

0-200%: ±1% reading or 1%

air sat., whichever is greater;

200-500%: ±5% reading

0-20 mg/L: ±1% of reading or

0.1 mg/L;

20-50 mg/L: ±5% reading

T63<5 sec

0.1% air sat.

0.01 mg/L

Optical, luminescence lifetime

(see pg 12)

pg | 17

Page 18

polynomial non-linear regression. Fortunately, the non-linearity does not change signicantly with time

so that, as long as each sensor is characterized with regard to its response to changing oxygen pressure, the

curvature in the relationship does not aect the ability of the sensor to accurately measure oxygen for an

extended period of time.

pg | 18

Page 19

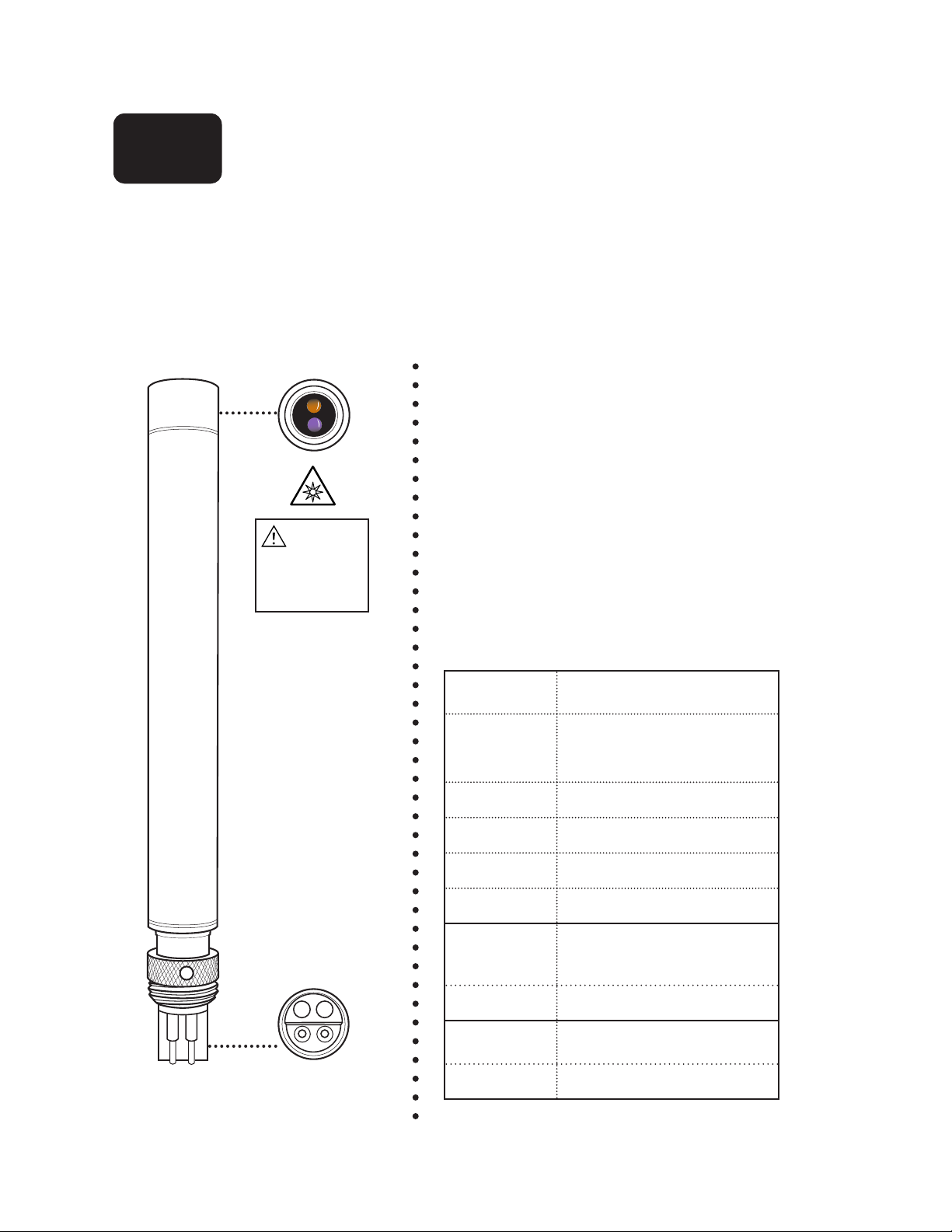

fDOM

1.8

Sensor Overview

e EXO fDOM (Fluorescent Dissolved Organic Matter) sensor is a uorescence sensor which detects the

uorescent component of DOM (Dissolved Organic Matter) when exposed to near-ultraviolet (UV) light.

Colored Dissolved Organic Matter

Users might wish to quantify colored dissolved oxygen matter (CDOM) in order to determine the amount of

light which is absorbed by stained water and thus is not available for the photosynthesis process carried out

by subsurface aquatic plants and algae. In most cases, fDOM can be used as a surrogate for CDOM.

Quinine Sulfate

A surrogate for fDOM is Quinine Sulfate, which, in acid

solution, uoresces similarly to dissolved organic matter.

e units of fDOM are quinine sulfate units (QSUs) where

1 QSU = 1 ppb quinine sulfate and thus quinine sulfate is

really a double surrogate for the desired CDOM parameter.

e EXO fDOM sensor shows virtually perfect linearity

2

=1.0000) on serial dilution of a colorless solution of

(R

WARNING

UV LIGHT

Do not look

directly at light.

quinine sulfate. However, on serial dilution of stained water

eld samples, the sensor shows some underlinearity. e

point of underlinearity in field samples varies and is

(continued)

599104

Specifications

Units

Temperature

Operating

Storage

Range

Response

Resolution

Sensor Type

Linearity

Detection Limit

Optics:

Excitation

Emission

Quinine Sulfate equivalents

(QSE), ppb

-5 to +50°C

-20 to +80°C

0 to 300 ppb QSE

T63<2 sec

0.01 ppb QSE

Optical, fluorescence

2

>0.999 for serial dilution

R

of 300 ppb Quinine Sulfate

solution

0.07 ppb QSE

365±5 nm

480±40 nm

(see pg 12)

pg | 19

Page 20

aected by the UV absorbance of the DOM in the water. Testing shows that underlinearity can occur at fDOM

concentrations as low as 50 QSU. is factor means that a eld sample with an fDOM reading of 140 QSU will

contain signicantly more than double the fDOM of a sample that reads 70 QSU. is eect—good linearity

in colorless quinine sulfate solution, but underlinearity in stained eld samples—is also exhibited by other

commercially available fDOM sensors and thus the performance of the EXO sensor is likely to be equivalent

or better than the competition while providing the advantages of easy integration into a multiparameter

package and automatic mechanical cleaning when used in monitoring studies with an EXO2 sonde.

pg | 20

Page 21

2.9

pH and ORP

1.9

Sensor Overview

Users can choose between a pH sensor or a combination pH/ORP sensor to measure these parameters. pH

describes the acid and base characteristics of water. A pH of 7.0 is neutral; values below 7 are acidic; values

above 7 are alkaline. ORP designates the oxidizing-reducing potential of a water sample and is useful for

water which contains a high concentration of redox-active species, such as the salts of many metals and strong

oxidizing (chlorine) and reducing (sulte ion) agents. However, ORP is a non-specic measurement—the

measured potential is reective of a combination of the eects of all the dissolved species in the medium.

Users should be careful not to overinterpret ORP data unless specic information about the site is known.

(continued)

Specifications

pH

Units

Temperature

Operating

Storage

Range

Accuracy

Response

Resolution

Sensor Type

ORP

Units

Temperature

Operating

Storage

pH units

-5 to +50°C

0 to 60°C

0 to 14 units

±0.1 pH units within ±10°C

of calibration temperature;

±0.2 pH units for entire temp

range

T63<3 sec

0.01 units

Glass combination electrode

millivolts

-5 to +50°C

0 to 60°C

(see pg 12)

EXOISE1, EXOISE2,

EXOISE5, EXOISE6,

599795, 599797

Range

Accuracy

Response

Resolution

Sensor Type

-999 to +999 mV

±20 mV in Redox standard

solution

T63<5 sec

0.1 mV

Platinum button

(see pg 12)

pg | 21

Page 22

Replaceable Sensor Module

e EXO pH and pH/ORP sensors have a unique design that incorporates a user-replaceable sensor tip

(module) and a reusable sensor base that houses the processing electronics, memory, and wet-mate connector.

is allows users to reduce the costs associated with pH and pH/ORP sensors by only replacing the relatively

inexpensive module periodically and not the more costly base.

e connection of the module to the sensor base is designed for one connection only and the procedure must

be conducted in an indoor and dry environment. Once installed the module cannot be removed until you

are prepared to replace it with a new module. See section 6.14 for detailed instructions.

Users must order either a pH or pH/ORP sensor. Once ordered the sensor is only compatible with like-model

sensor modules. For example, if a pH sensor is purchased initially, then the user must order a replaceable pH

sensor module in the future; it cannot be replaced with a pH/ORP module.

Electrodes

EXO measures pH with two electrodes combined in the same probe: one for hydrogen ions and one as a

reference. e sensor is a glass bulb lled with a solution of stable pH (usually 7) and the inside of the glass

surface experiences constant binding of H+ ions. e outside of the bulb is exposed to the sample, where the

concentration of hydrogen ions varies. e resulting dierential creates a potential read by the meter versus

the stable potential of the reference.

e ORP of the media is measured by the dierence in potential between an electrode which is relatively

chemically inert and a reference electrode. e ORP sensor consists of a platinum button found on the tip

of the probe. e potential associated with this metal is read versus the Ag/AgCl reference electrode of

the combination sensor that utilizes gelled electrolyte. ORP values are presented in millivolts and are not

compensated for temperature.

Amplification

Signal conditioning electronics within the pH sensor improve response and increase stability. Amplication

(buering) in the sensor head is used to eliminate any issue of humidity in the front-end circuitry and reduce

noise. Finally, the EXO pH sensor is insensitive to proximal interference during calibration due to having the

circuit next to the sensor and having a well-shielded pH signal.

pg | 22

Page 23

Total Algae (Chl & BGA-PC)

1.10

Sensor Overview

e EXO total algae sensor is a dual-channel uorescence sensor that generates two independent data sets;

one resulting from a blue excitation beam that directly excites the chlorophyll a molecule, present in all

photosynthetic cells, and a second from an orange excitation beam that excites the phycocyanin accessory

pigment found in blue-green algae (cyanobacteria). is orange excitation triggers a transfer of energy from

the phycocyanin to the central chlorophyll a, where photosynthesis is initiated.

Although blue-green algae contain chlorophyll a, the chlorophyll uorescence signal detected by in situ

uorometers is weaker than in eukaryotic phytoplankton. is results in an underestimate of algae biomass when

using a single-channel chlorophyll sensor when blue-green

algae are present. e EXO total algae sensor generates a more

accurate total biomass estimate of the planktonic autotrophic

a

and

community by exciting chlorophyll

Specifications

Units

Chlorophyll

BGA - PC

Temperature

Operating

Storage

Range

RFU, µg/L Chl

RFU, µg/L PC

-5 to +50°C

-20 to +80°C

Chl: ~0 to 400 µg/L Chl; 0 to

100 RFU

BGA-PC: 0 to 100 µg/L PC;

0 to 100 RFU

phycocyanin.

(continued)

599102

Response

Resolution

Sensor Type

Linearity

Detection

Limit

Optics:

Chl Excitation

PC Excitation

Emission

T63<2 sec

Chl: 0.01 µg/L Chl; 0.01 RFU

BGA-PC: 0.01 µg/L PC;

0.01 RFU

Optical, fluorescence

2

>0.999 for serial dilution

Chl: R

of Rhodamine WT solution from 0

to 400 µg/L Chl equivalents

BGA: R2>0.999 for serial dilution

of Rhodamine WT solution from 0

to 100 µg/L PC equivalents

Chl: 0.09 µg/L Chl

BGA-PC: 0.04 µg/L PC

.

470±15 nm

590±15 nm

685±20 nm

(see pg 12)

pg | 23

Page 24

e sensor generates data in three formats: RAW, RFU, and an estimate of the pigment concentration in μg/L.

e RAW value is a value unaected by user calibrations and provides a range from 0-100, representing the per

cent of full scale that the sensor detects in a sample.

RFU stands for Relative Fluorescence Units and is used to set sensor output relative to a stable secondary

standard, such as Rhodamine WT dye. is allows users to calibrate sensors identically; for example, calibrating

all sensors in a network to read 100 RFU in a concentration of Rhodamine WT dye. e sensors can then be

deployed and generate data that is relative to all other sensors. Once a sensor is retrieved, it can be checked

against that same standard to assess sensor performance, dri, or the potential eects of biofouling.

e μg/L output generates an estimate of pigment concentration. e relationship between μg/L and sensor’s

RAW signal should be developed through following standard operating procedures of sampling the water body

of interest, collecting sensor data from sample, and then extracting the pigment to establish a correlation. e

higher the temporal and spatial resolution of the sampling, the more accurate this estimate will be.

Chlorophyll

e EXO chlorophyll sensor operates on the in vivo uorescence principle with no disruption of the cells

required to obtain either spot readings or long-term data. e EXO sensor has an excellent detection limit as

determined under laboratory conditions and this advantage should be realized in many eld applications.

EXO chlorophyll readings show excellent linearity on serial dilution of a surrogate solution of Rhodamine WT

2

>0.9999) and this should ensure relative accuracy of eld chlorophyll readings, i.e., a chlorophyll reading

(R

of 100 units will represent twice the algal content of water with a chlorophyll reading of 50 units. Also, EXO

chlorophyll readings show very low interference from turbidity, allowing for more accurate determination of

algal content during rainfall events which release both sediment and algae into the water. e EXO chlorophyll

sensor also exhibits very low interference from dissolved organics, increasing data accuracy.

Blue-green Algae

e EXO BGA readings show excellent linearity on serial dilution of a surrogate solution of Rhodamine WT

2

>0.9999) and this should ensure relative accuracy of eld BGA-PC readings, i.e., a BGA-PC reading of 100

(R

units will represent twice the algal content of water with a BGA-PC reading of 50 units. A signicant advantage

of the EXO BGA-PC sensor is that its readings show less interference from turbidity and this will allow for

much more accurate determination of BGA-PC content during rainfall events which release both sediment

and algae into the water.

pg | 24

Page 25

2.9

Turbidity

1.11

Sensor Overview

Turbidity is the indirect measurement of the suspended solid concentration in water and is typically

determined by shining a light beam into the sample solution and then measuring the light that is scattered

o of the particles which are present. e suspended solid concentration is an important water quality factor

and is a fundamental measure of environmental change. e source of the suspended solids varies in nature

(examples include silt, clay, sand, algae, organic matter) but all particles will impact the light transmittance

and result in a turbidity signal.

e EXO Turbidity sensor employs a near-infrared light source and detects scattering at 90 degrees of the

incident light beam. According to ASTM D7315 method,

this type of turbidity sensor has been characterized as a

nephelometric near-IR turbidimeter, non-ratiometric

is method calls for this sensor type to report values in

formazin nephelometric units (FNU). FNU is the default

calibration unit for the EXO sensor but users are able to

change calibration units to nephelometric turbidity units

(NTU), raw sensor signal (RAW), or total suspended solids

(TSS) assuming the user enters the appropriate correlation

data.

e RAW value is a value unaected by user calibrations

and provides a range from 0-100, representing the per cent

of full scale that the sensor detects in a sample.

(continued)

#

.

599101

Specifications

Default Units

Temperature

Operating

Storage

Range

Accuracy

Response

Resolution

Sensor Type

Optics:

Excitation

#

ASTM D7315-07a “Test Method for Determination of

Turbidity Above 1 Turbidity Unit (TU) in Static Mode.”

FNU

-5 to +50°C

-20 to +80°C

0 to 4000 FNU

0-999 FNU: 0.3 FNU or

±2% of reading, whichever is

greater; 1000-4000 FNU: ±5%

of reading

T63<2 sec

0-999 NTU: 0.01 FNU

1000-4000 FNU: 0.1 FNU

Optical, 90° scatter

.

860±15 nm

(see pg 12)

pg | 25

Page 26

While all turbidity sensors will read consistently in formazin, other calibration solutions and eld readings

will vary between dierent models of turbidity sensors. ese dierences are thought to be a result of diering

optical components and geometries and the resulting detection of varying suspended sediment characteristics.

is eect is inherent in the nature of every turbidity sensor, and as a result readings between dierent model

turbidity sensors are likely to show dierent eld values even aer calibration in the same standards.

For long-term, in situ continuous monitoring of turbidity, the EXO2 sonde has a wiper to clean the turbidity

sensor to avoid sensor fouling and maintain accuracy.

pg | 26

Page 27

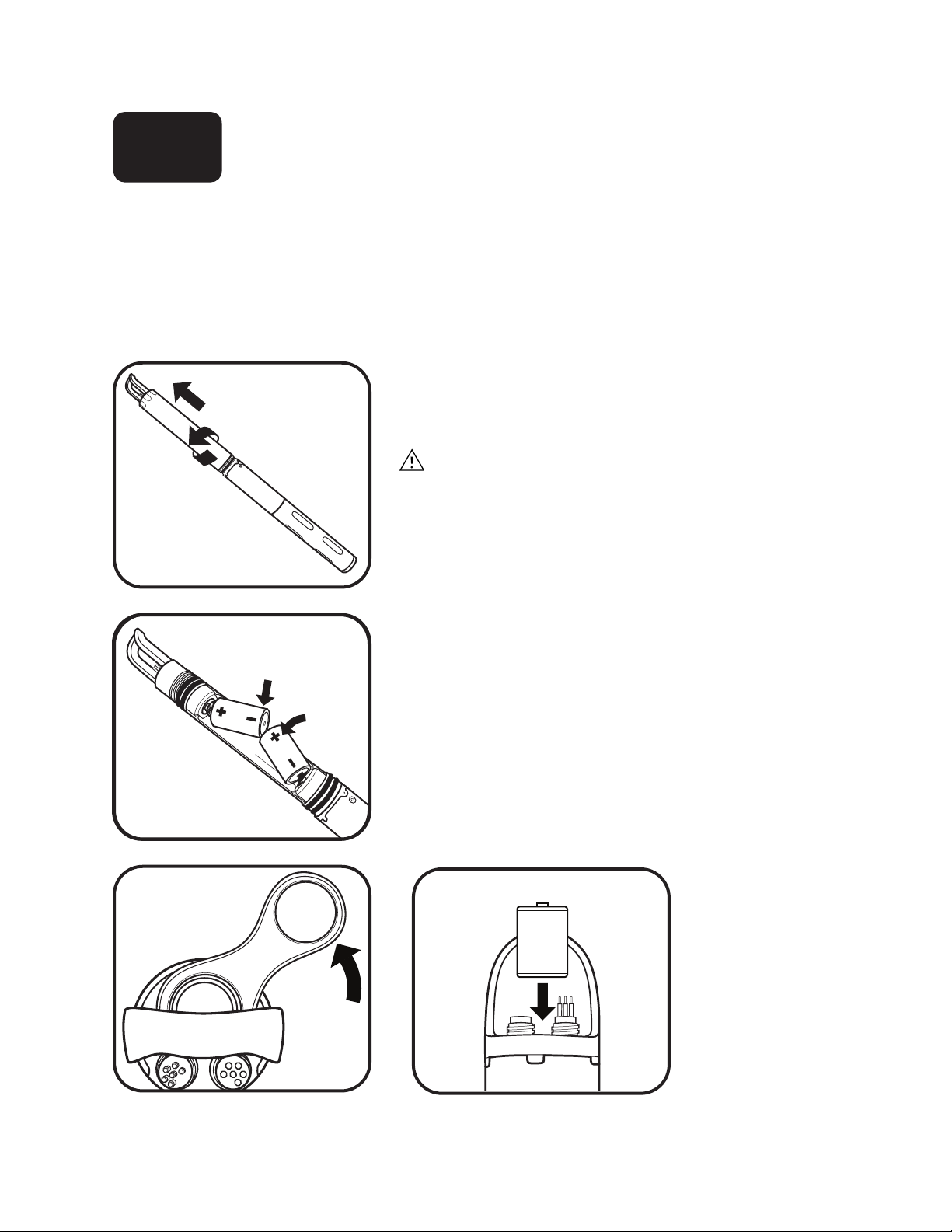

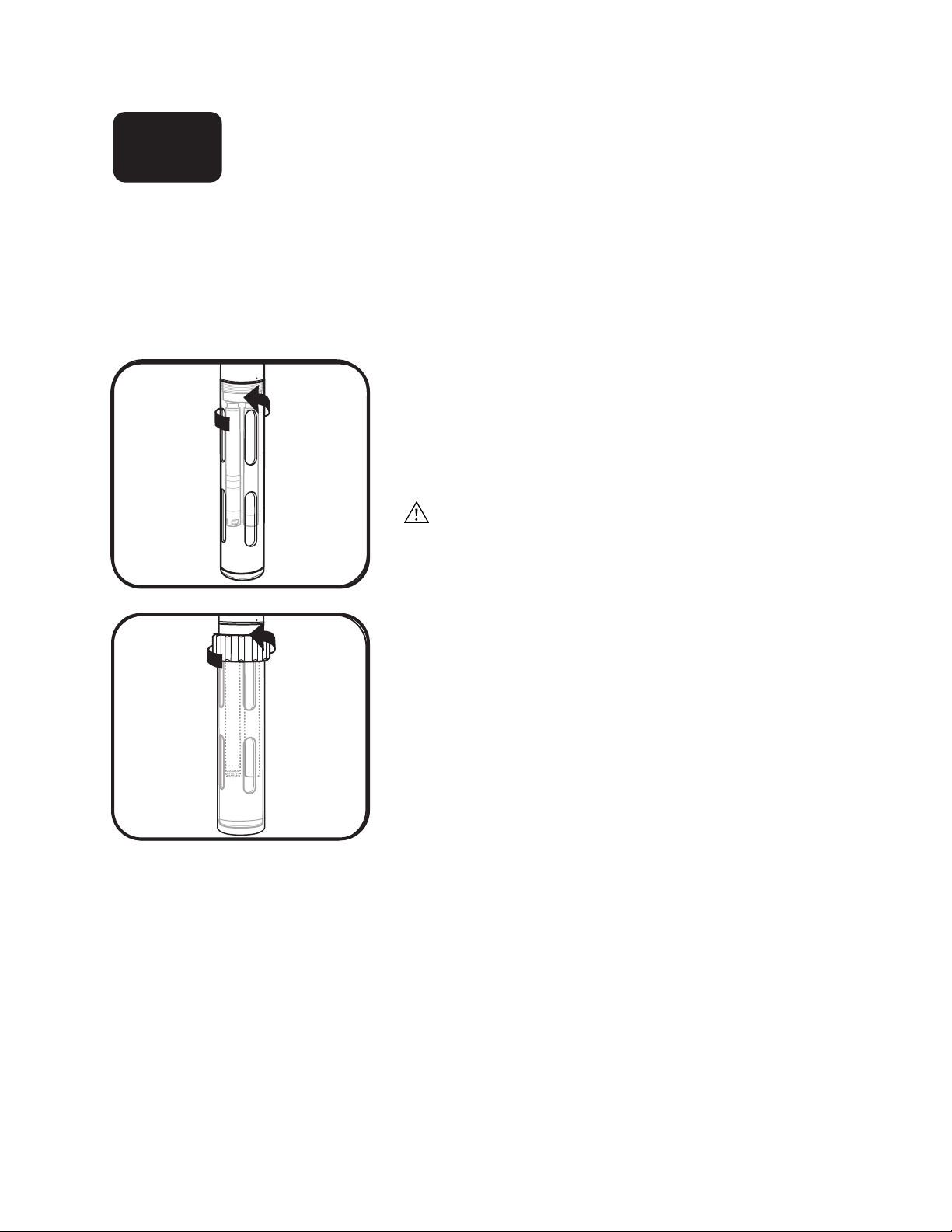

Install Batteries

2.1

e EXO1 Sonde uses two (2) D-cell alkaline batteries and the EXO2 Sonde uses four (4) D-cell alkaline

batteries as the recommended power source. Alternatively, the sonde may use rechargeable NiMH D-cell

batteries that you purchase. See detailed installation instructions Section 6.2

1. Remove battery cover.

EXO1: Twist the blue battery cover counterclockwise to

loosen, li up to remove.

nec essar y.

Do not remove the screws on the sonde’s electronics

compartment.

Use included wrench to loosen, if

EXO1

EXO2

EXO2: Unscrew and remove battery cap. Use included

wrench to loosen, if necessary.

2. Install batteries.

Insert the batteries with positive terminals (+) facing up

and negative terminals (-) facing down toward the probes.

3. Replace battery cover.

Replace the battery cover or cap and tighten until snug. Do

not overtighten.

pg | 27

Page 28

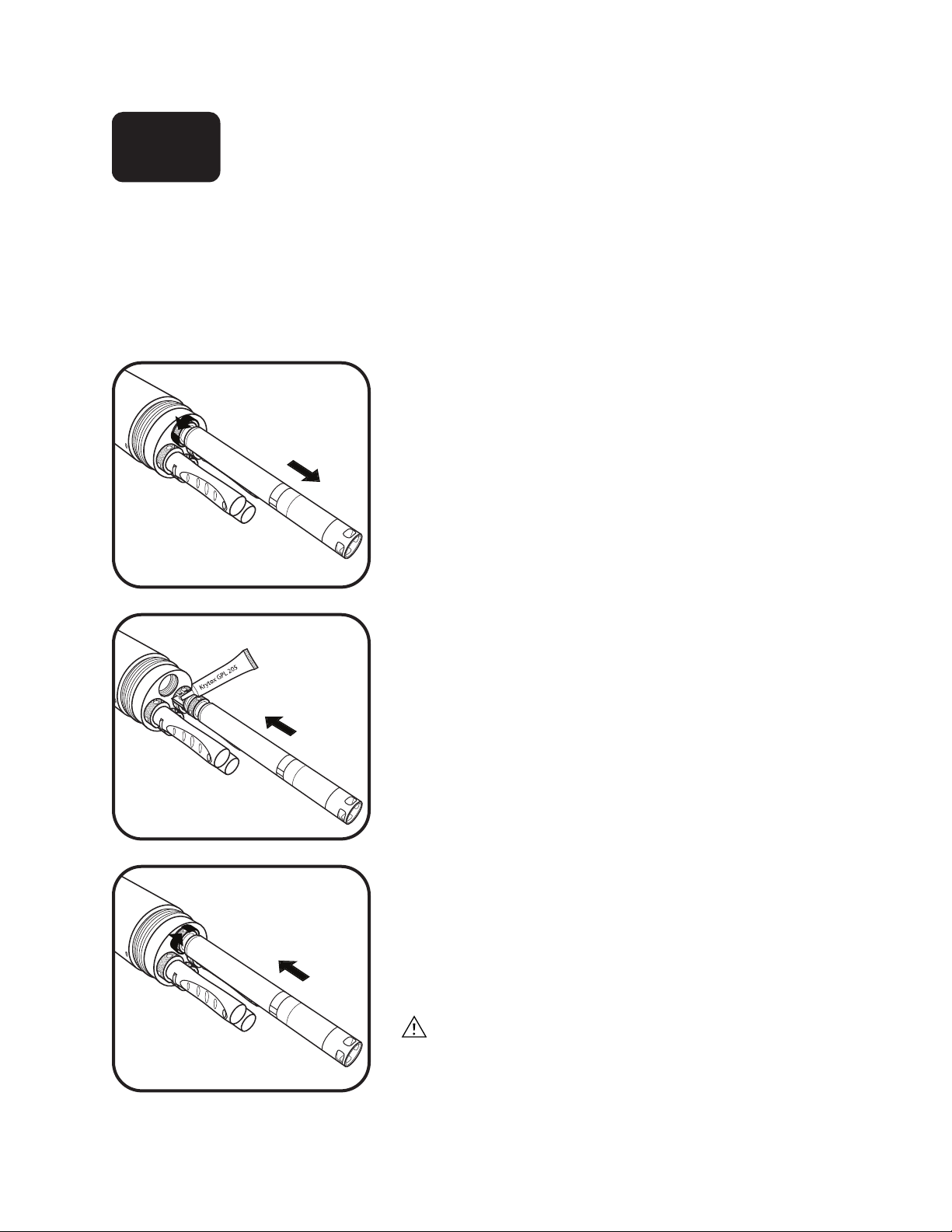

Install/Remove Sensors

2.2

EXO sensors have identical connectors and identify themselves via onboard rmware; therefore, users can

install any probe into any universal sonde port. e exception is the wiper for the EXO2 sonde, which must

be installed in the central Port 7. Individual ports are physically identied by an engraved number on the

sonde bulkhead. Although the probes are wet-mateable, users should clean, lubricate, and dry the sonde and

sensors connectors prior to installation or service, when possible.

1 Remove probe or port plug.

Remove the calibration cup and sensor guard from the

sonde. Place the sonde on a clean, at surface and prevent

it from rolling. R

and place on a clean surface.

If removing a sensor,

nut and rotate counterclockwise to loosen. Pull the probe

straight out of the port and place on a clean surface.

Remove hydration caps or buer bottles on probes. Wipe

dry with a clean, lint-free cloth.

emove port plugs by pulling straight out

use the probe tool in the locking

2 Clean port and install sensor.

Visually inspect the port for contamination. If the port

is dirty or wet, clean it with a clean, lint-free cloth or

compressed air. Apply a light coat of Krytox grease to the

rubber mating surfaces of the connector.

Insert the sensor into the port by properly aligning the

connectors’ pins and sleeves (male and female contacts);

then press them rmly together.

3 Tighten locking nut.

Taking care not to cross-thread the grooves, nger-tighten

the locking nut clockwise. When the nut is seated against

the bulkhead, tighten it with probe tool until snug. Once

sensors or plugs are installed, reinstall the sensor guard to

protect sensors from impact damage.

Take care not to twist the probe body when tightening

and loosening the locking nut. Excessive twisting of the

probe can damage the connector and is not covered under

warranty.

pg | 28

Page 29

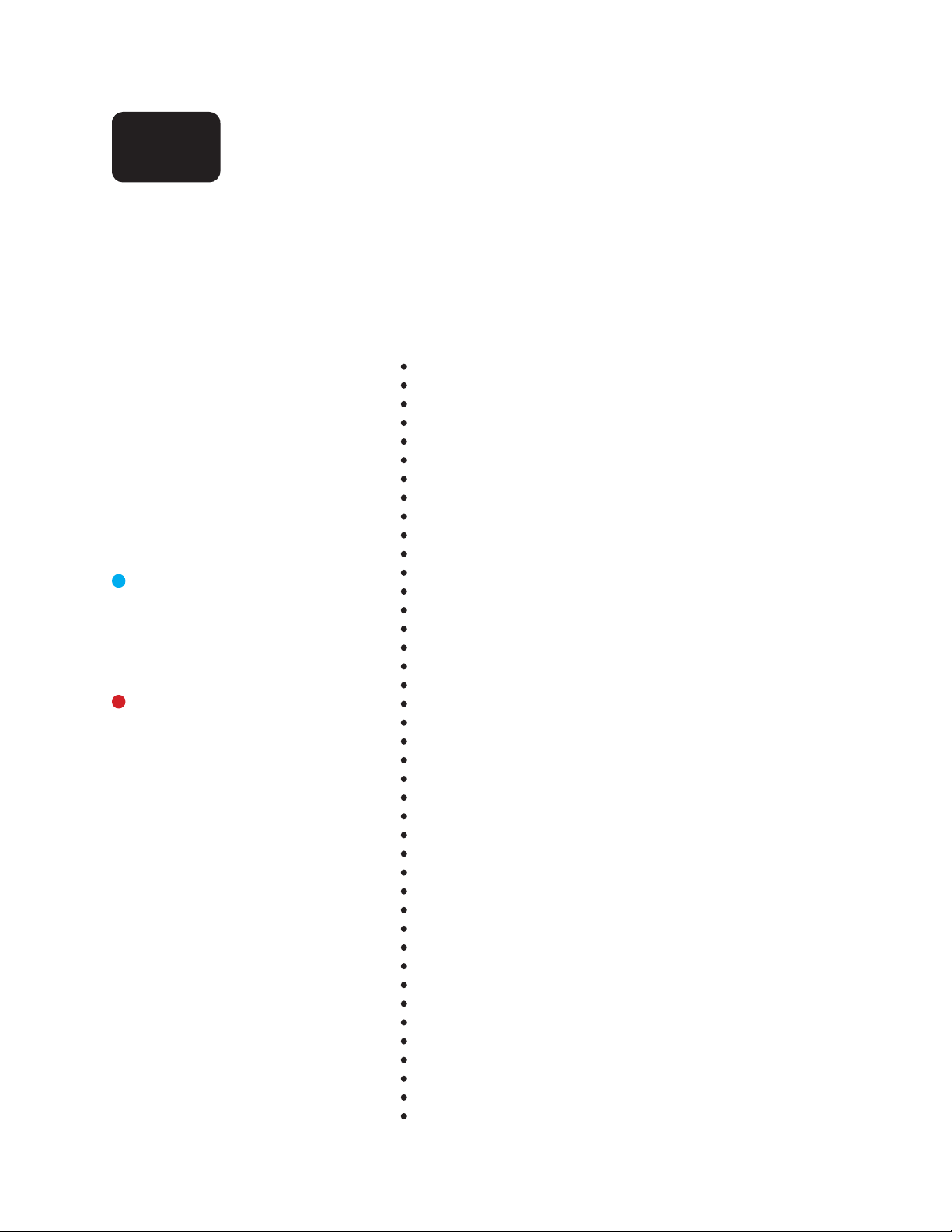

Install/Remove Guard or

2.3

Calibration Cup

Sonde guards protect EXO sensors from impact throughout deployment. Users should always install the guard

prior to data collection. e calibration cup (cal cup) is used for storage and calibration. We recommend

using two guards: one for eld deployments and a second used exclusively for calibrations. Using a second

guard will minimize calibration solution contamination (especially for turbidity) and calibration errors. EXO

calibration cups install over an installed sonde guard. is conguration reduces the amount of standards

required for calibration.

1 Install/remove sonde guard.

Install guard by threading it onto the sonde bulkhead

threads. Rotate the guard clockwise on the bulkhead to

install. Rotate it counterclockwise to remove. Always

use one guard for deployment/storage and the other for

calibration only.

Take care not to let the guard damage unguarded pH or

pH/ORP sensors when installing and removing.

2 Install/remove calibration cup.

Before installation, loosen (but do not remove) the

cup’s clamping ring. en, with the sonde guard already

installed, slide the cal cup over the guard until the bottom

of the guard rests against the bottom of the cal cup. Tighten

the ring until snug. To remove the cal cup, loosen the ring

by 1/4 turn and pull the guard free from the cup.

pg | 29

Page 30

Sonde States and

2.4

LED Descriptions

States

An EXO sonde is always in one of three operational states: O, Awake, and Asleep. ese states determine the

sonde’s current power usage and logging potential. When O , the sonde is not powered and cannot collect

data (no batteries installed, no topside power). Users can apply power to the sonde internally, using batteries,

or externally with an EXO eld cable attached from the topside port to an EXO Handheld, DCP or other

approved power source. Once power is applied to a sonde, it is either Awak e or Asleep.

When in an Asleep state, the sonde remains in a very low

States

Off: Not powered, no data

collection.

Asleep: Low power. Waiting for

command.

Awake: Full power. Ready to

collect.

LED Indicators

Blue LED – Bluetooth

None: Off, not active.

On Solid: On, not linked.

2 Hz Blink: On, successfully linked.

Red LED – Sonde State

None: Sonde is Off or Asleep

with logging disabled.

0.1 Hz Blink: Sonde is Asleep with

logging enabled.

1 Hz Blink: Sonde is Awake.

On: Sonde is Awake with faults.

power setting and waits for a user command or its next

scheduled logging interval. An Awake sonde is fully powered

and ready to collect data. Once awakened, a sonde remains

Awake for ve minutes aer its last communication via

Bluetooth or 30 seconds aer its last communication via

the topside port. e sonde also automatically awakens 15

seconds before its next scheduled logging interval.

LED Indicators

Each sonde has two LED indicators that show the sonde’s

status. The blue LED indicates the Bluetooth’s wireless

connection status. e red LED indicates the sonde’s current

state.

e Bluetooth light (blue) is activated by a magnet swipe at

the magnetic activation area. When the blue LED is o, the

Bluetooth is disabled. When the light is on continuously, the

Bluetooth is enabled, but no link has been established. When

the blue LED blinks at 2 Hz, the sonde’s Bluetooth is on, and

has established a link.

When the red sonde state LED is o, the sonde is either O

or Asleep and not logging. When it blinks at 0.1 Hz (once

every 10 seconds), the sonde is Asleep and logging is enabled.

When the red light blinks at 1 Hz, the sonde is Awak e and

has no faults. If the red light is lit continuously, the sonde is

Awake and has detected faults, such as problems with the

system that need to be xed prior to use.

pg | 30

Modes

Within the Awake state, the sonde has three modes, which

are activated via Kor soware. When “Inactive (O),” the

sonde does not log any data. In “Real-Time” mode, the

sonde continuously collects data at a user-specied interval

(default is 2 Hz). “Sample/Hold” mode allows users to easily

synchronize data between the sonde’s data logger and an

external data collection platform.

Page 31

Awaken Sonde,

2.5

Activate Bluetooth

Once power is applied to the sonde, internally or externally, users can awaken their sondes from Sleep state using

any of several methods. Primarily, users activate EXO sondes and the Bluetooth connections via a magnetic

switch installed in sonde’s electronics compartment. e sonde will automatically disable the connection and

go to sleep once it has not received a Bluetooth signal for 5 minutes or a signal from the topside connector

for 30 seconds. In order to activate their sondes, users should keep a magnet with them when setting up and

deploying sondes. For more information on sonde states and LEDs, please see Section 2.4.

1 Awaken sonde with magnet.

Users can make their sonde go to the Awake state by

holding a magnet at the magnetic activation area on the

sonde’s bulkhead (identied by the illustrated magnet

symbol on the label). Simply hold the magnet within

one (1) cm of the symbol until the LEDs activate. EXO

Handhelds and sensor tools contain embedded magnets

identied by the same symbol.

2 Awaken sonde without magnet.

Users can also make their sonde go to the Awake state

using any of the following methods.

• Cycling power to the sonde (uninstalling/installing

batteries).

• Communicating via the topside port.

• Inserting a sensor.

In addition to these manual methods, the sonde also

automatically awakens for scheduled unattended logging

(programmed in Kor).

3 Activate sonde’s Bluetooth.

Users activate Bluetooth by holding a magnet at the

magnetic activation area in the same way as described in

Step 1. In addition to magnetic activation, users can also

activate Bluetooth by:

• Cycling power to the sonde (uninstalling/installing

batteries).

• Enabling Bluetooth via a connection at the topside port

in Kor.

pg | 31

Page 32

Attach Sonde to Handheld

2.6

Field Cable

All EXO cables have 6-pin and wet-mateable connectors. Each cable also incorporates a strain relief

mechanism to alleviate stress on the connector. Read the Cable Maintenance section before rst-time use.

Because Bluetooth wireless will not pass through water, users must use the cable to connect to the sonde

when it is submerged and taking real-time eld readings that are being viewed by the user or logged by a

data collection platform.

1 Attach cable to sonde.

Apply a light layer of Krytox grease to the male pins on

the cable and the female connector on the sonde. Press in

the male 6-pin connector, then screw down the retaining

collar. Attach the cable’s strain relief to the sonde’s bail with

a carabiner. e cable’s strain relief should be positioned to

remove any weight-bearing from the actual connector and

retaining collar.

2 Attach cable to handheld.

Apply a light layer of Krytox grease to the male pins on the

handheld and the female connector on the cable. Press on

the female 6-pin connector, then screw down the retaining

collar. Connect the strain relief to the Handheld’s strap.

3 Discover sonde in KOR.

Upon startup of the Handheld, KOR soware searches for a

hard-wired connection to the sonde. If KOR discovers the

sonde it will request to connect to it.

pg | 32

Page 33

Attach Sonde to Handheld

2.7

Bluetooth Wireless

Users can wirelessly connect EXO sondes (above water) to the EXO Handheld using Bluetooth wireless. With

Bluetooth, users can reduce the amount of cables needed to operate their sonde. is wireless connection

has a typical range of 10 meters, but this range will uctuate depending on the operating environment. Users

cannot wirelessly connect through water.

In order to connect via wireless, both devices must be powered on.

1 Activate sonde’s Bluetooth.

Activate Bluetooth by holding a magnet at the magnetic

activation area. In addition to magnetic activation, users

can also activate Bluetooth by cycling power to the sonde

(remove/reinstall batteries).

2 Discover sonde in KOR.

Every time the Handheld powers on, it automatically

searches for a sonde via the hard-wired cable connection.

3 Rescan sonde.

If a wired connection is not found, and to manually

establish a connection to a sonde via Bluetooth, navigate to

the Connections menu in KOR soware on the Handheld.

Select Rescan. KOR will rescan and detect Bluetoothenabled sondes. Select the sonde from the list and then

click the Connect button.

pg | 33

Page 34

Install KOR Software

2.8

e desktop KOR soware is supplied will all EXO sondes on a USB ash drive. Installing the soware will

require Administrative privileges on the local PC. It is important to install KOR soware prior to using the

USB Signal Adapter, as the required drivers for the adapter are installed along with KOR soware.

NOTE: A “lite” version of KOR soware on the EXO handheld does not require any installation.

1 Install KOR software and drivers.

Insert USB drive and install soware using the startup.exe

le. Reboot the computer aer installation of the soware.

e program installs several items: EXO-KOR soware,

National Instruments supporting soware, and USB drivers

for the EXO USB adapter.

When complete, the program will reside in the root

Program menu (not in a subfolder) with the following icon:

Additionally, a folder called National Instruments will be

created; however this information will not be accessed

through the course of normal operation.

Minimum requirements:

Minimum requirements on a computer for KOR soware:

• Windows®XP (service pack 3) or newer Windows

operating platform (Windows®7 recommended)

• Microso .NET (any version from 2.0 through 3.5

Service Pack 1)

• 500 MB of hard disk space (1 GB recommended)

• 2 GB of RAM (4 GB recommended)

• Screen with resolution of 1280x800 or greater

• Available USB 2.0 port

• Internet access for soware updates

• Optional: Integral Bluetooth or USB dongle Bluetooth

adapter

2 Software updates

When they become available, updated versions of KOR

soware will be posted to www.EXOwater.com. Users

will need to register a free account to access the soware

download.

pg | 34

Page 35

Connect Sonde

2.9

USB

e USB signal output adapter (USB-SOA #599810) allows users to connect to an EXO sonde over a standard

USB connection. Although the USB-SOA is rugged and water resistant, users should protect its connectors

with the included cap when not in use. e SOA should never be submerged.

Prior to use, users must install KOR soware and its drivers on the associated PC. e USB-SOA will not

work without the drivers that accompany KOR See section 2.8.

1 Connect SOA to sonde.

Remove the plug from the 6-pin connector on the sonde.

Apply a light layer of Krytox grease to the male pins on the

sonde and the female connector on the USB-SOA. en

align the connector’s six pins and jackets, and press them

rmly together so that no gap remains.

2 Connect USB cable to SOA and PC.

Remove the protective cap from the USB end of the SOA,

and ensure that the connector is clean and dry. en insert

the small end of the provided USB cable into the SOA

connector and the large, standard side into one of the PC’s

USB ports.

Attaching the adapter to the PC causes a new device to be

recognized. Windows automatically installs the drivers

and creates a new port. Each new adapter that is attached

creates a new port.

Ports

KOR automatically scans ports for both USB adapters and

Bluetooth. To view the USB adapter and its associated

comm port, go to the Control Panel on your computer,

click Device Manager, then click Ports.

pg | 35

Page 36

Connect Sonde

2 .10

Bluetooth

Before users can communicate wirelessly with their EXO sondes, they must establish a Bluetooth link. All

EXO sondes are equipped with Bluetooth wireless. is technology provides a secure, two-way, reliable

communication channel with which users can communicate with their sondes above water without cables.

Many new computers are equipped with Bluetooth wireless installed internally; those without Bluetooth

can use a Bluetooth dongle (not included). Follow the manufacturer’s instructions for installing the dongle’s

soware and hardware. Administrative permissions and IT support may be required depending on the

adapter and your PC settings.

1 Install Bluetooth dongle (optional).

If your computer is not equipped with internal Bluetooth,

insert a Bluetooth dongle (not provided) into any of

the computer’s USB ports. Wait for the computer to

automatically install the device and its drivers. Once the

installation is complete, the computer should indicate that

the device is installed and ready to use.

e preferred Bluetooth conguration is Windows 7 with

native Windows Bluetooth drivers and soware.

2 Activate sonde’s Bluetooth.

Users activate Bluetooth wireless by holding a magnet

at the magnetic activation area. In addition to magnetic

activation, users can also activate Bluetooth by:

• Applying power to the sonde

• Enabling Bluetooth via KOR through a USB or eld

cable connection at the topside port.

See more information on sonde activation and LED

conditions in sections 2.4 and 2.5.

3a Establish Bluetooth link. (Win XP)

1.Open Control Panel>Bluetooth Devices.

2.Check “My device is setup and ready to be found,” then

click “Next.”

3.Locate the sonde from the options. e sonde name

should begin with YSI.

4.Select “Use passkey found in documentation,” and enter

the passkey 9876. Click “Next.”

5.Select Finish.

e device is now available in the “Devices” tab.

pg | 36

Page 37

3b Establish Bluetooth link. (Win 7)

1.Open Control Panel>Devices and Printers.

2.Select “Add a Device” from the top of the screen.

3.Locate the sonde name (starts with YSI) from the options.

4.Select “Enter the device’s pairing code,” then enter the

pairing code 9876. Click “Next.”

3c Alternative: Establish Bluetooth link.

(Win 7)

1.Launch KOR soware and click the Connections menu.

2.Click Rescan button.

3.Click Search Bluetooth button. is may take up to 40

seconds, and may require several attempts using the

Refresh button.

4.Select the device from the list and click Connect.

e sonde is now available in the Devices and Printers

screen.

4 Confirm successful link.

Once the device has been added, conrm that the device

appears in:

• Win XP -Devices tab of the BT Devices window

• Win 7 - Devices and Printers screen

If the device is not listed, attempt the establishment process

again.

is process establishes a secure wireless link between the

sonde and a PC. Once established, users will not need to

perform this process again in order to link with the sonde.

Users communicate with the sonde via the KOR soware.

Once this wireless link is established, use KOR to nd the

sonde and perform desired operations.

Ports

KOR automatically scans ports for both USB adapters

and Bluetooth. To view the comm port associated with

Bluetooth, go to the Bluetooth menu on your computer,,

click Show Bluetooth Devices, click on the device you

added, then click Properties.

pg | 37

Page 38

Connect Sonde

on reverse

3M

3M

2.11

Data Collection Platform (DCP)

is signal output adapter (SOA) allows users to connect an EXO sonde to a Data Collection Platform (DCP)

as well as power it via an external 12 V DC source (not included). Users wire a sonde cable with ying leads

into one side of the SOA and an SDI-12 /RS-232 output and power source into the other. Mount the SOA in

a humidity-controlled enclosure using the following recommended hardware, and never attempt to perform

electrical work beyond your experience.

1 Configure sonde.

Using KOR soware, go to the Deploy menu and choose

to deploy by opening a template or starting a custom

deployment. Click Edit, then go to the SDI-12 tab and

select your parameters and the SDI address. e sonde’s

default address is zero (0). Click save. Refer to Section 5

KOR Soware for more details.

2 Route cable.

Determine the sonde cable routing to the DCP, and protect

the cable from chafe damage and impact.

Route the cable through a sealing gland into the DCP, and

ensure that the seal is air-tight and water-tight.

3 Mount SOA.

Users can mount the SOA horizontally or vertically either

by the screw slots on the sides of the SOA or with the

included 3M adhesive strips. e screw slots were designed

to accept #4 wood screws but may accept other types and

sizes.

If the user opts to use adhesive strips, rst clean the

application surface with a 50:50 mixture of isopropyl

alcohol and water, then mount them in temperatures

between 21° and 38°C and allow the bond to cure for 72

hours if possible before attaching wires.

pg | 38

Page 39

4 C onnect flying lead cable to sonde.

10

12

14

16

18

20

Press in the male 6-pin connector, then screw down the

retaining collar. Attach the cable’s strain relief to the sonde’s

bail with a carabiner. e cable’s strain relief should be

positioned to remove any weight-bearing from the actual

connector and retaining collar.

5 Prepare wires.

Always follow proper safety precautions when performing

electrical work.

Properly strip the ends of the wire. Remove 0.25 inches

of insulation from each wire then twist the bared strands

together. All wires should be 18-24 AWG and are not

included with the SOA.

6 Insert wires into SOA.

Loosen the clamping screw with the supplied screwdriver,

insert the indicated wire into the terminal strip, and tighten

the clamping screw back down onto the exposed wire end.

Ensure that all strands are inserted to avoid short circuits.

Take care not to strip the slots in the heads of the screws.

• Connect DCP signal ground to SOA SDI ground terminal

(recommend black wire)

• Connect DCP SDI-12 data terminal for SOA SDI-12

terminal (recommend violet wire)

• Connect DCP output ground terminal to SOA power

ground terminal (recommend black wire)

• Connect DCP 12 VDC output to SOA 9-16 VDC input

terminal (recommend red wire).

pg | 39

Page 40

Sonde

Expansion

(Handheld)

Power

RS-232

SDI-12

+ 9-16V DC

- Ground

1 Amp Fuse

Voltage

esondeisdesignedtorunwith12-voltbatteries,with

supplyvoltagesbetween9and16VDC.

should be directly powered by a sealed battery or installed

as part of a remote solar system.

1-ampslow-blowfuseforprotection.

allwiringiscompleted.

When used with a solar system always ensure use of

12-volt solar regulator. Never connect the sonde directly to

solar panel; voltages above 16.5 volts will cause the sonde to

shut down and excessive voltage will permanently damage

the sonde and is not covered under warranty.

PowertheSOAthrougha

ese systems

Removethefuseuntil

pg | 40

Page 41

Connect Sonde

2.12

Flow Cell

ere are two versions of the EXO ow cell: EXO1 ow cell (#599080) and EXO2 ow cell (#599201). Flow

rate of the ow cell is typically between 100 mL and 1 L per minute. Maximum ow rate depends on tubing

type, size, and length. Maximum pressure for each ow cell is 25 psi.

Inspect sonde and flow cell.

Remove the sonde guard or calibration cup from the sonde

so that the sensors are exposed.

Make sure that the threads of the sonde and ow cell as

well as all o-rings are clean and free of any particles such as

sand, grit, or dirt.

Insert sonde into flow cell.

Outflow ..

Insert the sonde into the top of the ow cell. Be careful not

to bump or scrape the sensors on the sides of the ow cell.

Screw the sonde into the ow cell by turning the sonde

clockwise until it is hand-tightened into place; do not use

a tool.

Inflow ..

Connect tubing to flow cell.

Install the Quick Connect tube ttings onto the ow cell

by inserting them into the Quick Connect coupling body.

ey should snap into place.

Connect the tubing from your pump (not included) to the

Quick Connect tube ttings, making sure that the tubing is

pushed securely onto the ttings. e inow should be at

the bottom of the ow cell and the outow should be at the

top.

Keep ow cell vertical to purge it and ensure air release

from Conductivity/Temperature sensor.

Do not turn on water to the system until the ow cell is

securely connected.

pg | 41

Page 42

is page intentionally le blank

pg | 42

Page 43

Handheld

3.1

Install or Replace Batteries

e EXO Handheld (HHs) uses four (4) C-cell alkaline batteries as a power source. Users can extend battery

life by putting the HH in “Sleep” mode, when convenient, by pressing and holding the power button for less

than three seconds. Rechargeable Nickel Metal Hydride (NiMH) batteries can also be used. Battery life varies

depending on GPS and Bluetooth wireless use.

1 Remove battery cover panel.

e battery cover panel is located on the back of the HH.

To remove the panel, unscrew (counter-clockwise) the four

screws with a at or Phillips head screwdriver.

Note: e retaining screws are integrated into this panel

and are not independently removable. If replacement is

necessary, replace the entire assembly.

2 Insert/replace batteries.

Remove the old batteries and dispose of them according to

local ordinances and regulations. Install the new batteries

between the battery clips with their polarity (+/-) oriented

as shown on the bottom of the battery compartment.

If you use your own rechargeable batteries, they cannot

be charged inside the handheld; they should be charged

outside the handheld.

3 Reinstall battery cover panel.

Ensure that the rubber battery cover gasket is seated

properly, then replace the cover onto the back of the HH.

Tighten the four retaining screws back into their holes, but

do not overtighten.

pg | 43

Page 44

Power On/Off Handheld

3.2

Users can power on/o and awaken/put to sleep the EXO Handheld (HH) depending on use. In order to

use the HH, users must rst power it on. When nished with the HH, users should power it o to increase

its battery life. When temporarily not using the HH, users should put it to sleep, and awaken it when next

needed. e HH’s sleep mode is a low-power mode designed to increase its battery life. When nished with

the HH for a long period of time, users should power it o and remove the batteries.

1 Power on/awaken handheld.

With batteries installed, press and hold the power button

for one second. e Bluetooth wireless indicator will then

illuminate. Next the splash screen will appear then briey

go black (approximately 5 seconds) while the system starts

up. e HH will then automatically start Kor.

If the HH is asleep, users should briey press the power

button to awaken it.

2 Power off/put to sleep.

To power o the HH, users must press and hold the power

button for more than three seconds. Once the button has

been held long enough, the screen will power down and go

black.

To put the HH to sleep, press and hold the power button

for less than three seconds, and release it. e screen will

then go black.

pg | 44

Page 45

Attach Handheld to Sonde

3.3

Field Cable

All EXO cables have 6-pin and wet-mateable connectors. Each cable also incorporates a strain relief mechanism

to alleviate stress on the connector throughout deployment. Read the Cable Maintenance section before rsttime use. Although the cables are wet-mateable, users should dry the connectors prior to installation when

possible. Always protect connectors by leaving the cable or connector caps installed even when the connector

is not in use. Always attach the cable’s strain relief mechanism to the bail when the sonde is deployed.

1 Attach cable to sonde.

If needed, lightly grease the black rubber part of the

connector with Krytox grease. Press in the male 6-pin

connector, then screw down the retaining collar. Attach

the cable’s strain relief to the sonde’s bail with a carabiner.

e cable’s strain relief should be positioned to remove any

weight-bearing from the actual connector and retaining

collar.

2 Attach cable to handheld.

Apply a light layer of Krytox grease to the male pins on the

handheld and the female connector on the cable. Press on

the female 6-pin connector, then screw down the retaining

collar. Connect the strain relief to the Handheld’s strap.

3 Discover sonde in KOR.

Upon startup of the Handheld, KOR soware searches for a

hard-wired connection to the sonde. If KOR discovers the

sonde, it will request to connect to it.

pg | 45

Page 46

Attach Handheld to Sonde

3.4

Bluetooth Wireless

Users can wirelessly connect their EXO sondes (above water) to the EXO Handheld using Bluetooth wireless

communication. With Bluetooth, users can reduce the amount of cables needed to operate their sonde. e

wireless connection has a typical range of 10 meters, but this range will uctuate depending on the operating

environment. Users cannot wirelessly connect through water.

In order to connect via wireless, both devices must be powered on.

1 Activate sonde’s Bluetooth.

Users activate Bluetooth by holding a magnet at the

magnetic activation area. In addition to magnetic

activation, users can also activate Bluetooth by cycling

power to the sonde (remove/reinstall batteries).

2 Discover sonde in KOR.

Every time the Handheld powers on, it automatically

searches for a sonde via the hard-wired cable connection.

3 Rescan sonde.

If a wired connection is not found, and to manually

establish a connection to a sonde via Bluetooth, navigate to

the Connections menu in KOR soware on the Handheld.

Select Rescan. KOR will rescan and detect Bluetoothenabled sondes. Select the sonde from the list and then

click the Connect button.

pg | 46

Page 47

Spot Sampling

3.5

View Live Data

When connecting through the Handheld, KOR soware attempts to automatically connect to an available

sonde and start displaying current data in a live view. To manually access the live view from either the

Handheld or Desktop, go to the Run menu and choose “Dashboard.” Users can set view preference in the live

view menu to display numeric live data (default) or a graph view, where a maximum of two parameters can

simultaneously be plotted on the screen. For overview of KOR menus, see section 4; for overview of Handheld

keypad functions, see section 1.3

Data dashboard and graph

Users can toggle between numeric dashboard and live

graph views using a so key. e other so key may be used

to log information displayed on the screen.

Dashboard image at le; live graph image at middle le.

Parameter preference

Users can select which parameters to display in both graph

and dashboard modes by using the backspace and tab keys

on the Handheld keypad. If an expected parameter is not

available, rst set the appropriate units preference from the

Options | Units menu.

Advanced display settings

Adjust data display settings for both dashboard and live

graph modes in the Run menu. Select Settings to change

the settings for log mode (up to 100 points), graph type

(time series or vertical prole), sample interval (default is 1

sec), and default parameters to view.

pg | 47

Page 48

Spot Sampling

3.6

Record Spot Sampling Data

e sonde can be used for both continuous and spot-sampling applications. Spot-sampling readings are

refreshed in real-time on the Dashboard screens. e so keys on the Handheld allow logging of this

information. ere are two options when logging data: log a single point or continuous logging. Users may

select one of these options from the live view settings window. (Live view log settings should not be used

for deploying a sonde in continuous monitoring applications. Use the Deploy menu for these applications.)

1 Capture data.

To capture spot sample les, go to the Run menu and click

the so key below the Capture Data button.

Select a site from the list of your pre-programmed sites

on the Handheld. If no sites have been loaded in the

Handheld, skip this step. e site data is appended to the

data le.

Data is captured in a .cap le on the Handheld.

2 Name file.

Whether logging data a single point at a time or logging a

stream of data, information will be stored in a le specied

under the Options menu. If a unique le name is not

selected, then a default le is automatically created.

pg | 48

Page 49

Upload Data

3.7

from Handheld to PC

e EXO Handheld stores two dierent sets of sensor data les: Files uploaded from the sonde and les

manually logged into the Handheld from the live data mode. Both types of les can be sent to a PC via the

USB cable. Note that KOR Desktop soware must rst be installed on a computer before transferring les

from Handheld to PC.

1 Connect handheld to computer.

Plug the small end of the USB cable into the port on the

top side of the EXO Handheld. Plug the other end of the

USB cable into a port on your computer. Allow a minute for

Windows to recognize the Handheld as a removable drive

before the Handheld shows up in KOR soware.

2 Transfer files.

When the Handheld is connected to the PC, go to the

Options | Sync with Handheld menu in KOR Desktop

soware. Select Sync All and KOR will search all folders

and synchronize the les automatically. Or users can

select each folder separately and synchronize selected les

manually.

3 Delete files.

Directory Maintenance: Users can browse folders and

select les to delete from the Handheld. Deleting les is

optional.

pg | 49

Page 50

GPS

3.8

Upon startup of the Handheld, the GPS function automatically initiates a x of the location. is may take

some time. During this process, the Handheld should remain stationary and have a clear view of the sky. e

rst time a user powers on the Handheld, the GPS x can take up to a maximum of 20 minutes to obtain.

Enable GPS.

To manually enable GPS, go to the Options menu. Select

Handheld | Enable GPS | On. Click Apply. When GPS is

xed, a signal strength icon with green bars will appear. If

the bars are black, then no GPS signal is found.

Turn on/off GPS.

e GPS consumes battery power and can be turned o to

conserve battery life. To manage the GPS, go to the Options

| Handheld | GPS menu and select On or O.

To display GPS units on screen, go to the Options | Units

menu and select GPS Lati and GPS Long. When units are

selected, GPS data is displayed on screen only if the GPS is

turned on.

If the Handheld is stored for more than 10 days without

batteries installed, then the user will need to re-enter the

date and time. Additionally, it will take longer for the unit

to obtain a new GPS x.

pg | 50

Page 51

KOR Software

4.1

Users interface with the EXO sondes and handheld via KOR soware. Once the soware is installed and

a device is connected to a computer or an EXO handheld, launch the KOR soware. (KOR Installation

instructions, see section 2.8.)

Navigation

Both versions of KOR—Desktop KOR for computers and

KOR for the EXO handheld—have the same basic menu

structure. e main menu items are:

Run: is menu is used to display live data from the EXO

sonde either in numeric or graphical display.

Calibrate: is menu is used to calibrate the sensors

installed in the EXO sonde, aer the sonde is connected.

Deploy: Go to Deploy to set up the EXO sonde for logging

deployments. Settings such as logging interval and SDI12 congurations are in this menu, as well as starting and

stopping autonomous logging on the sonde.

Sites: Used to manage sites, this optional menu helps users

create site detail that may be associated with les logged in

the sonde.Not available now; future functionality.

Data: is menu enables le transfers from the EXO sonde

or handheld, and can also be used without a sonde to view

and export data les that were previously transferred to the

desktop or handheld.

Options: Application preferences, sonde settings, and

soware and rmware updates can be accessed through this

menu. e user can change display units here.

Connections: is menu allows the user to connect

to other sondes and devices, identify which probes are

installed in which ports, and update Bluetooth settings.

Help: is page links to support resources for using KOR.

Status icons: e icons in the top right of the KOR window

are information-only displays. e white box shows the

connected device by serial number and name, and the icons

show if an EXO sonde is connected and if it is currently in

logging mode. Check mark means it is and X means it is not.

pg | 51

Page 52

KOR Software

4.2

Run Menu

e Run menu displays real-time water quality data in numeric or graph formats, and has three main

submenus.

Dashboard

is real-time display shows data from connected devices.

e data appears in a default order of parameters in the

list. In the RUN menu, data is automatically buered, up to

1000 points, for all parameters that load into memory.

Capture Data: Use the Capture Data button to save a

snapshot of the data buer to the computer. e captured

data is automatically saved in the location specied in the

Settings submenu.

Wipe Sensors: In the Dashboard menu, it is possible to

manually activate the central wiper if the EXO2 sonde

is equipped with one. is feature can be helpful when

transferring the sensors into liquid; the wiper can help

remove any bubbles that may be trapped at the sensor faces.

Note: Menu functionality is the same, although visual display

dierences are found between KOR’s Desktop version (top) and

Handheld version (bottom).

Graph

is real-time display will graph one or two parameters

from the attached EXO device. e parameters are chosen

from the drop-down menu above the plot area. Only

parameters currently active in the attached device will be

available for plotting.

It is important to note the scale when viewing real-time

data in Graph mode. Due to the precise nature of EXO

sensors, very small micro-changes are visible in the graph.