Page 1

Installation and Operating Instruc-

tions for Electric heater-circulator

unit EPR

Page 2

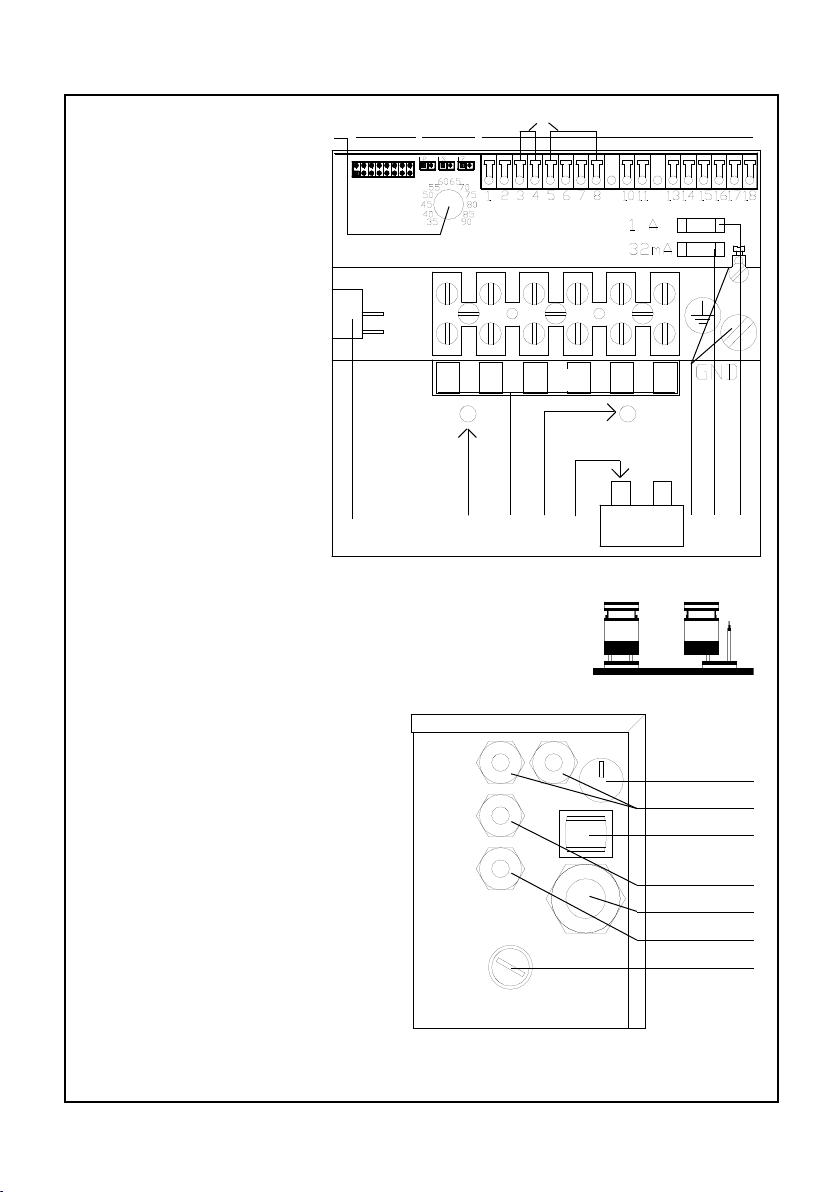

Instruction manual Laing Electric heater circulator unit

A Terminal strip for Mains

connection

E Ground terminal

F Fuse for pump

H Main switch

I Jumper wires for remote

control input and pump

module input

J Jumper 1 to 8

K Constant temperature

control

L LEDs

M Mounting screws for prin-

ted circuit board (behind

terminal bracket)

N Cable entry for Mains

connection

R Cable entry for control

and circulator

S Safety temperature limiter

U Fuse for control

V Terminals

Z Reset knob for safety

temperature limiter

S J L V

I

L1 L2 L3 N N N

H M A M T E U F

Jumperposition

closed open

Terminal usage

1,2 Remote control for heating

elements 2 and 3

3,4 Input from pump module

5,6 Remote control input

7,8 Remote control input

10,11 Potential free output for remo-

te trouble indicator

13,14 Power supply for daughter

board EPRBW

15,16 Power supply for circulator

17,18 used only for FP 5000 ER

models

See next to last page for jumper positions and error indicators.

2

K

R

H

R

N

R

Z

www.lainginc.com

Page 3

Instruction manual Laing Electric heater circulator unit

Contents

Applications ............................................................................................................... 5

Design of the EPR model .......................................................................................... 5

Technical Data ........................................................................................................... 6

Dimensional Drawing................................................................................................. 7

Performance Curve ................................................................................................... 7

Models Available ........................................................................................................ 8

Mounting .................................................................................................................... 9

Connection to the feed and return line ...................................................................... 9

Electrical Connection ............................................................................................... 10

Power Supply .......................................................................................................... 10

400V N3 Electrical Diagram .................................................................................... 10

230V N1 Electrical Diagram .....................................................................................

230V N3 Electrical Diagram .....................................................................................

The integrated control.............................................................................................. 12

Schematics of the integrated control ....................................................................... 12

Design of the Main Printed Circuit Board ................................................................ 13

Main switch .............................................................................................................. 14

Fuses ....................................................................................................................... 14

Constant temperature control .................................................................................. 14

Overheating Protection ............................................................................................ 14

Program selection for the switching sequence of the heating elements ................. 15

Pump shut-off ......................................................................................................... 17

Deactivating heating elements ................................................................................ 17

Remote control of the second and third heating element ........................................ 17

Control input ............................................................................................................ 18

Room temperature guided control ........................................................................... 18

Outside temperature guided control ........................................................................ 20

Safety temperature limiter ....................................................................................... 20

Electronic means to prevent dry running ................................................................. 21

Circulator operation control ..................................................................................... 21

Malfunction detector ................................................................................................ 22

Attachment of the sensor for the remote control ..................................................... 23

Indirect domestic hot water heating with the Electric heater-circulator EPR ........... 24

Hydraulic connection of the EPR for domestic hot water heating............................ 25

Electrical connection of the EPR for domestic hot water heating ............................ 26

Control method 1 ..................................................................................................... 26

Control method 2 ..................................................................................................... 27

Operation of heating elements with a load shedding device ................................... 28

Filling of the system ................................................................................................. 30

Pressure and leak tests ........................................................................................... 30

Starting operation .................................................................................................... 30

Replacement of the circulation pump ...................................................................... 31

Replacement of the safety temperature limiter STBR ............................................. 31

Replacement of the main circuit board EPRH ......................................................... 32

Important Notices .................................................................................................... 32

Important Notice: How to avoid overheating............................................................ 32

Important Notice: In the event of safety temperature limiter failure ......................... 33

Important Notice: For proper connection to a oor heating system ......................... 33

Factory settings ....................................................................................................... 33

11

11

www.lainginc.com

3

Page 4

Instruction manual Laing Electric heater circulator unit

Applications

Electric heater circulator units Model EPR can be applied in all cases where

electric heating has to be installed in a small space to heat an apartment or

a single or multiple family house.

This applies to direct electrical heating as well as for electrical heating with

a heat storage.

A further application exists in connection with room additions where the

electric heating can supplement the existing hydronic heating.

The Electric heater-circulator is also very well suited to heat domestic

hot water. The application for heating of domestic hot water is described in

“Indirect domestic hot water heating - Application”.

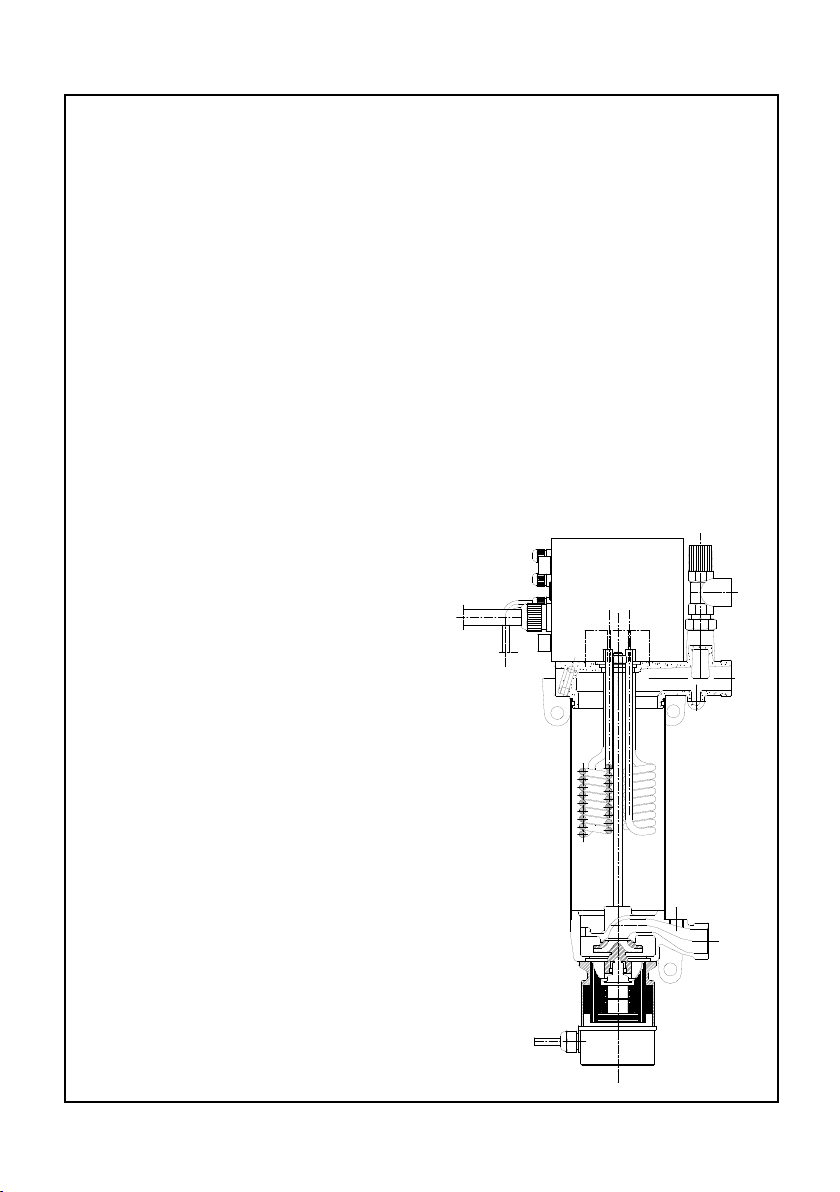

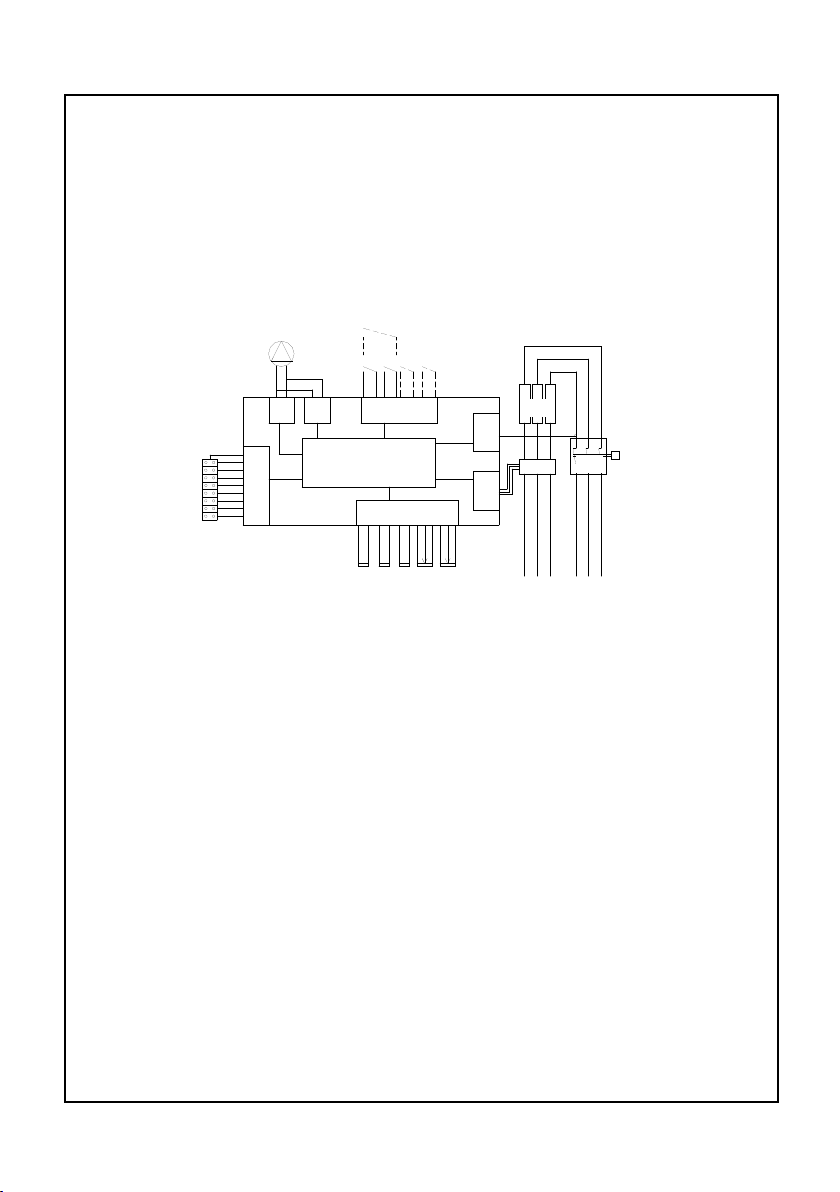

Design of the EPR model

The Electric heater circulator model EPR consists of a circulator pump, an

electric heater with three heating elements and an electronic microprocessor

control.

The spherical motor circulator

operates almost noiselessly and stays

quiet over its lifetime.

The arrangement of the pump below the heating elements guarantees

good heat conductivity from the heating elements since the swirl created

by the impeller extends over the length

of the heating elements. This avoids

overheating of the heating element

surfaces.

The water for the heating loop is drawn

in by the circulator, conveyed along

the heating elements and discharged

through the discharge port at the

upper part of the housing. The inlet

has an additional 3/8” port, to which

an expansion tank can be connected.

An automatic air vent and a pressure

relief valve communicate with the

outlet port.

Mounting eyelets are included in

the castings of the unit.

4

www.lainginc.com

Page 5

Instruction manual Laing Electric heater circulator unit

The Electric heater circulator units EPR 6 to EPR 15 differ only in the performance of the electrical heating elements and the distance between the ports.

EPR 6 has a heating performance of 6000 W, EPR 9 has 9000 W, EPR 12

has 12000 W and EPR 15 has 15000W.

The control unit, which controls a variety of control and safety functions, is

arranged on top of the Electric heater circulator.

Technical Data

Model EPR EPR EPR EPR

6 9 12 15

Pmax. 87 PSI

Tmax. 194°F

Connection on water side Union 1” male

Weight 21.8 lb 22.5 lb 23.8 lb 24.5 lb

Pump

Max. Head 4.6 PSI

Max. Flow 14.9 GPM

Motor

Design Shaftless spherical motor

Watts Input 99 W

Motor performance 35W

Volts AC 230 V

Amperes 0.43 A

Electric Heater

Electrical performance 6 kW 9 kW 12 kW 15 kW

Number of heating elements 3 3 3 3

Heat capacity per element 2 kW 3 kW 4 kW 5 kW

Voltage 400 V, 3P 400 V, 3P 400 V, 3P 4 0 0 V,

3P

Amperes 8.7 A 13.0 A 17.4 A 21.6 A

Connection Y Y Y Y

Safety Temperature Limiter

Maximum temperature 203°F+/- 5 K

www.lainginc.com

5

Page 6

Instruction manual Laing Electric heater circulator unit

0

2

4

6

8

10

12

0 2 4 6 8 10 12 14

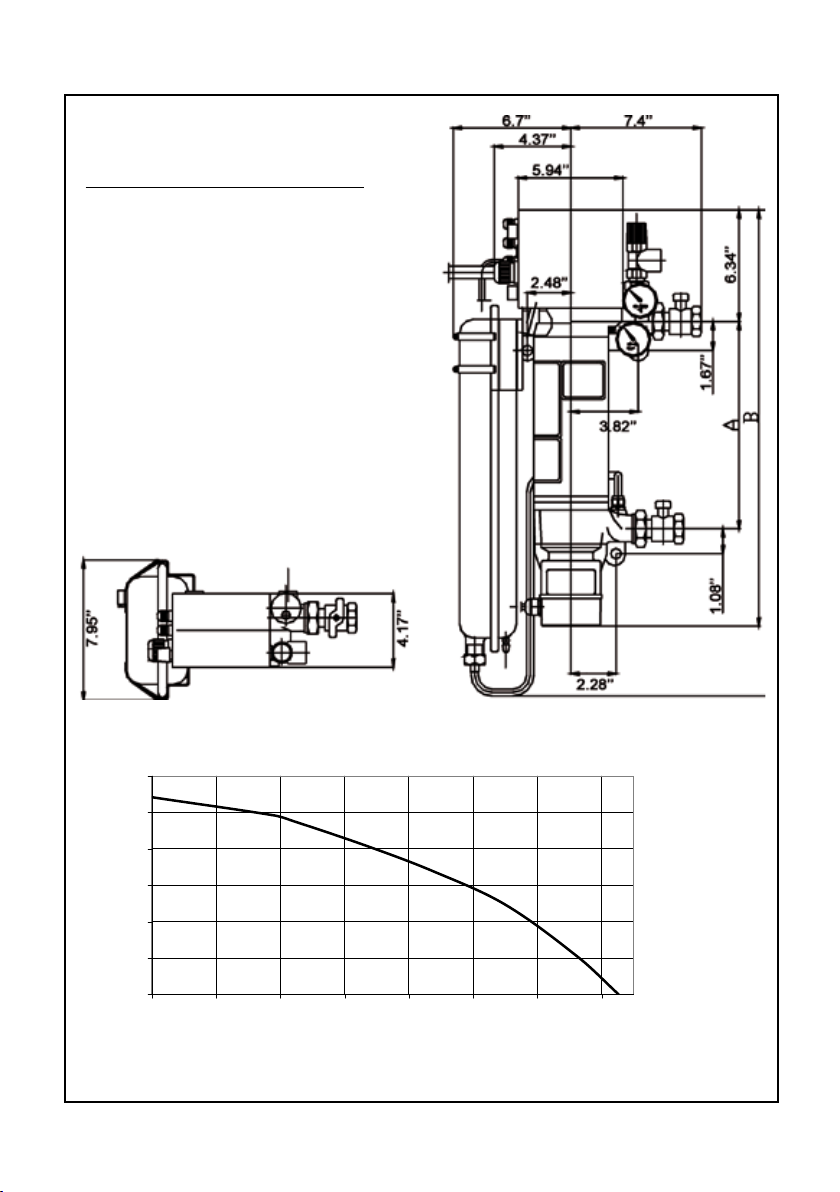

Dimension Drawing

Dimension

Model A B

EPR 6 11.8’’ 23.66’’

EPR 9 11.8’’ 23.66’’

EPR 12 14.37’’ 26.2’’

EPR 15 14.37’’ 26.2’’

Pump curve

Pump head (ft)

6

Flow rate (GPM)

www.lainginc.com

Page 7

Instruction manual Laing Electric heater circulator unit

Mounting

For safety reasons, the Electric heater circulator must be mounted on a

reproof base. In addition, the unit must be installed with the circulator

motor pointing downwards!

The unit must be attached to a at wall with the help of the mounting eyelets

arranged at the top of the unit and at the pump housing. To avoid noise transfer to the wall, both sides of the mounting eyelets have to be covered with

rubber insulators. The rubber insulators are supplied with the Electric heater

circulator unit and have to be mounted in such a way that no metal contact

exists between the castings and the fastening screw. In addition, no part of

the Electric heater circulator unit - for example the outer shell or the pump

- should be in contact with the wall.

The Electric heater circulator should be mounted at least 2.4’’ above the

oor to allow replacement of the circulator motor if necessary.

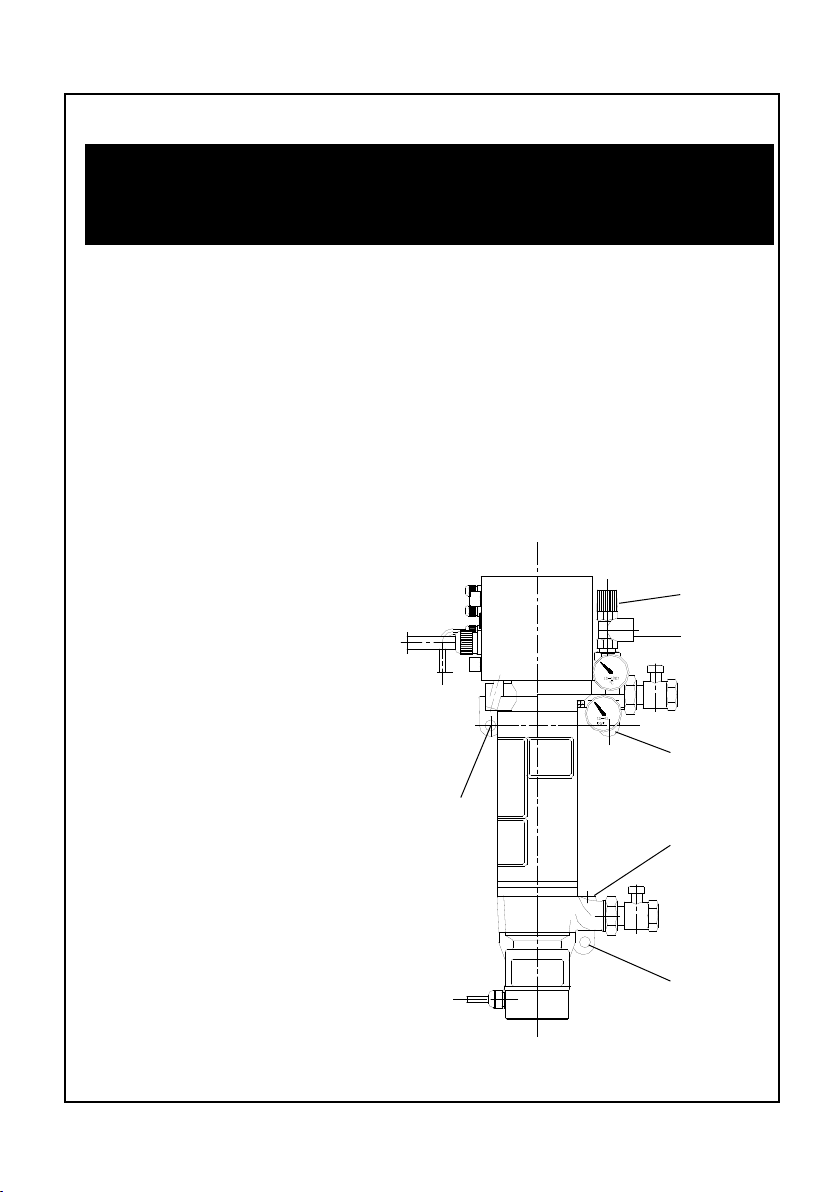

Connection to the feed and return line

The unit is connected to the heating loop by 1” male threaded t-

Air vent

tings. The feed line is at the top of

the unit, the return line at the bottom. The expansion tank should

be connected to the 3/8” port next

to the return line. If the expansion

tank cannot be connected there, it

should be connected somewhere

else in the return line, but not in

the feed line. There are two ˝”

ports at the top of the unit. The

automatic air vent for the heating

circuit is connected to the ˝” port

Mounting

eyelet

Safety relief

valve

Heating

loop feed

side

Mounting

eyelet

Connection

for expansion tank

closest to the wall, the pressure

relief valve to the port in front.

When the Electric heater cir-

Heating

loop return

side

culator unit is used solely for oor

heating, the chapter “Important

Notice: Proper connection to a

Mounting

eyelet

oor heating system” has to be

observed.

Connection EPR series

www.lainginc.com

7

Page 8

Instruction manual Laing Electric heater circulator unit

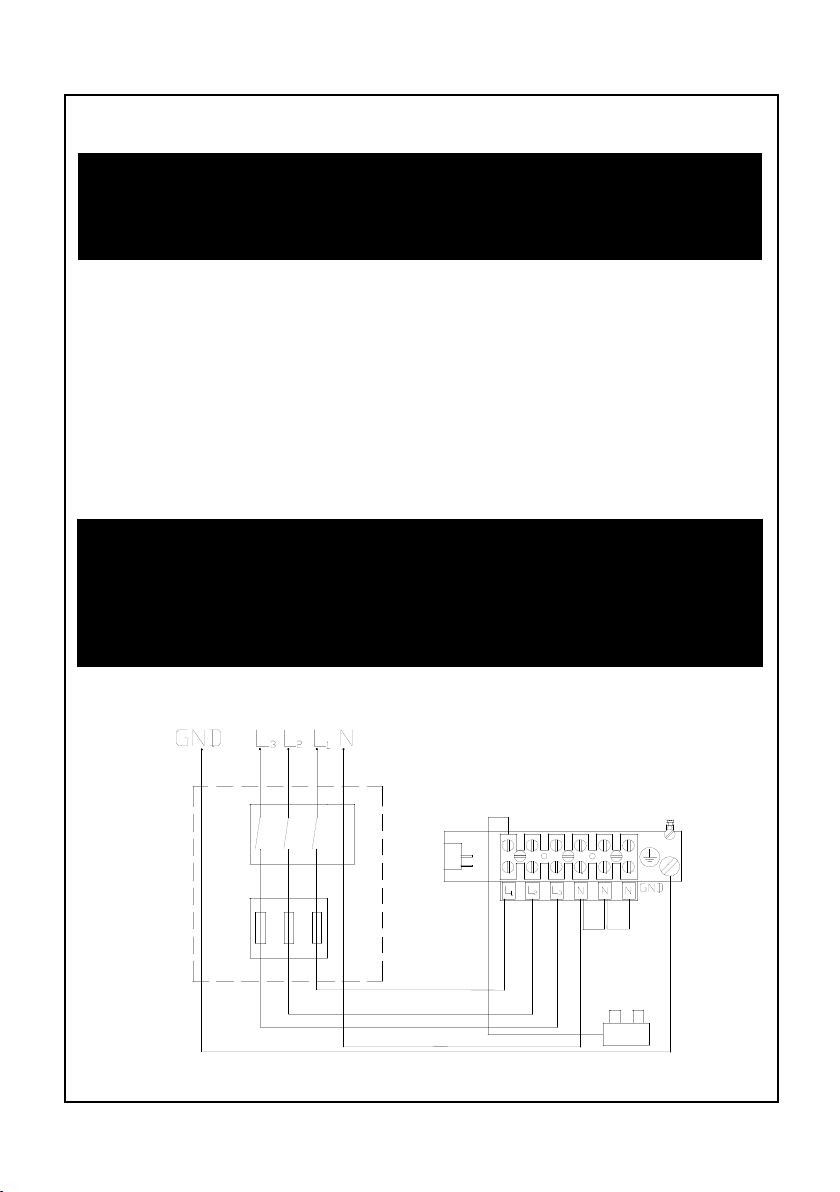

Electrical Connection

Notice: The electrical connection has to be performed by a licensed

electrician!

The pump must not be operated without water.

To make the electrical connections, the control box at the top of the heater

has to be opened by removing the 4 screws. A cable with a sufcient cross

section for the performance of the Electric heater circulator unit has to be

inserted through the strain relief and connected to the input terminal (see

Electrical Diagram below)

The circulator is already wired to the control box.

Power Supply

The Electric heater-circulator is designed for three different kinds of power

supply. In all cases the following information has to be taken into account:

The electronic switches integrated into the Electric heater circulator unit do

not separate the heating elements from the power supply. Therefore, a master

switch that interrupts all phases has to be installed in an accessible place,

taking into account all applicable safety codes.

As a protection for the semiconductor relays each phase has to have a fast

acting fuse.

400V N3 Electrical Diagram

230V N1 Electrical Diagram

8

T

www.lainginc.com

Page 9

Instruction manual Laing Electric heater circulator unit

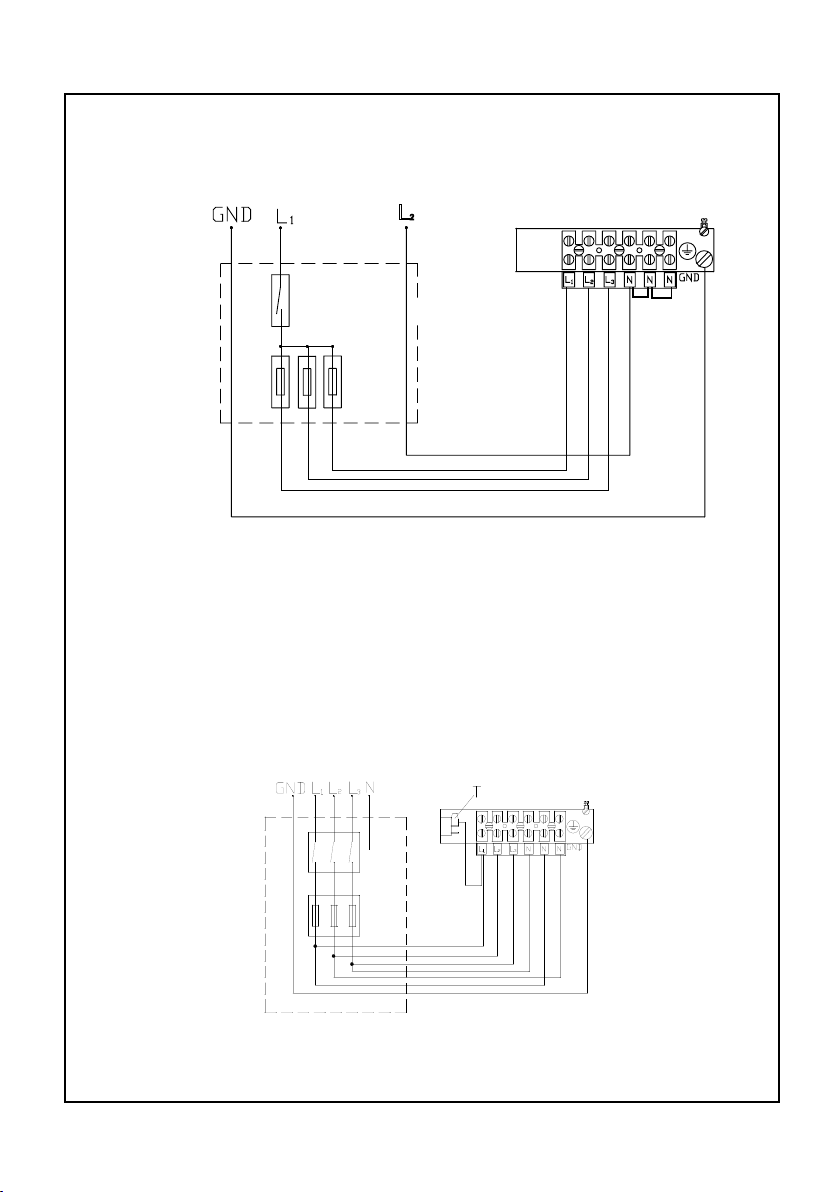

L2

In this case, the Electric heater circulator unit has to be connected with 7 leads

to protect each of the semiconductor relays separately. After this has been

done, the leads are combined into one phase.

230V N3 Electrical Diagram

In this case, it is important to ensure the proper phase sequence of the connectors 1 to 3 and 4 to 6.

The integrated control

T

T

www.lainginc.com

9

Page 10

Instruction manual Laing Electric heater circulator unit

The integrated microprocessor control in the housing on top of the Electric

heater circulator unit performs a variety of control functions for a large number

of applications.

The heating elements are noiselessly switched by electronic relays.

Schematics of the integrated control

The block diagram shows the control in schematic presentation

PI G IS W

TI

Y MP X Q

O

RA

B C D P TS

B Temperature sensor for feed temperature

C Temperature sensor for the safety temperature limiter

D Temperature sensor for the semiconductor relays

G Pump operation control logic

IS Input for external control and remote control

MP Microprocessor

O Control for the semiconductor relays

P Potentiometer for constant temperature setting

PI Pump performance control

Q Safety temperature limiter

RA Analog inputs for temperature sensors and temperature pre-selection

T Potentiometer for safety temperature setting

TI Safety temperature limiter control logic

W Heating elements

X Semiconductor relays

Y Jumper settings for operation mode

Temperature sensor B monitors the temperature of the feed line water and

10

www.lainginc.com

Page 11

Instruction manual Laing Electric heater circulator unit

passes the information on to the microprocessor. The microprocessor then

activates the solid state relays which in turn activate the heating elements

according to the jumper selected program. An independent sensor C also

monitors the temperature of the feed line water and switches the pump off

when the temperature exceeds a pre-set temperature.

A further sensor D monitors the temperature of the solid state relays and

turns off the heating elements in case of overheating.

A special control logic veries the rotation of the circulator and prevents

the heating elements from being turned on if the circulator is not running.

The safety temperature limiter turns the heating elements off permanently - independent of the electronic control - when the temperature exceeds 194°F.

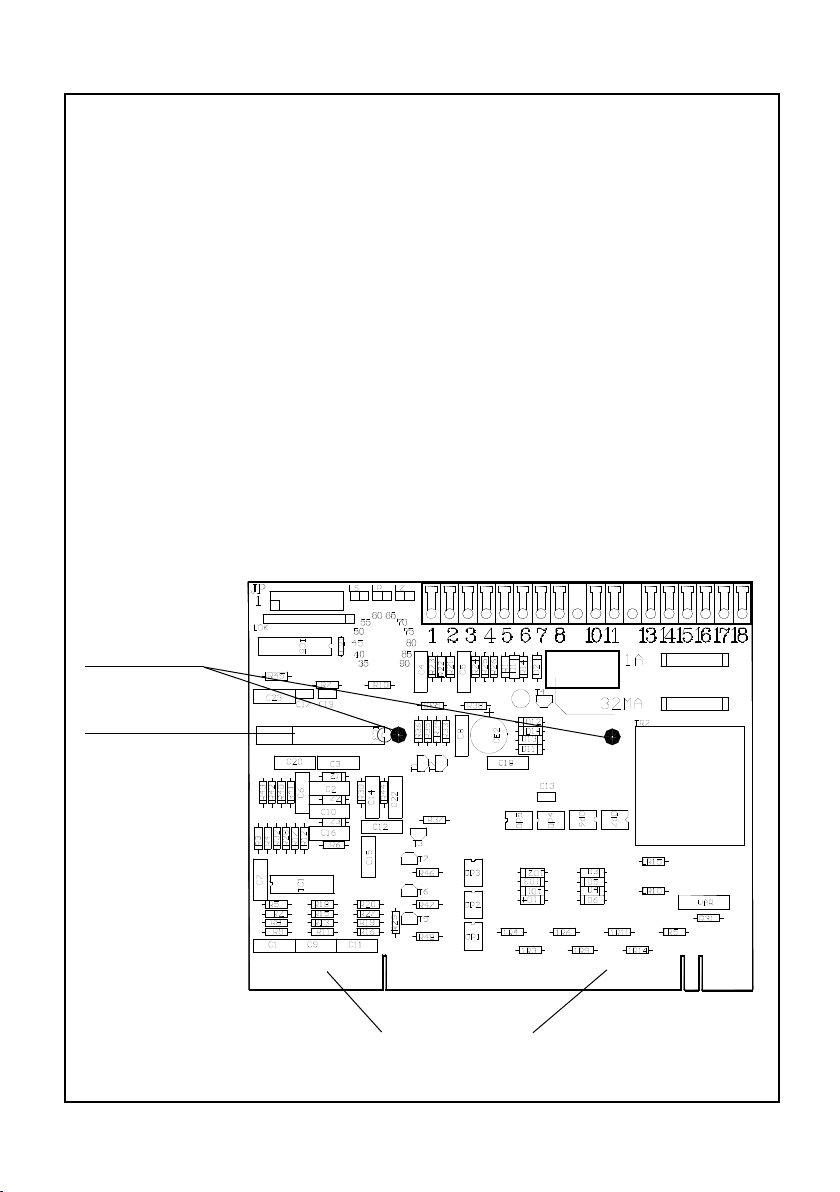

Design of the Main Printed Circuit Board

(See also page 2)

Fastening

points

Processor

Connector for

www.lainginc.com

solid state relays, power supply and sensors.

11

Page 12

Instruction manual Laing Electric heater circulator unit

Functions

Main switch

The Electric heater circulator unit contains a main switch H which powers the

eloctronic control and thereby also controls on – off operation of the heating

elements. The main switch does not separate the unit from the main power

supply. This separation must be provided on site, taking in consideration all

applicable safety codes.

Fuses

To protect the electronic components, the control contains two fuses. The 35mA

fuse protects the processor control, the 1A fuse protects the circulator.

Constant temperature control

The constant temperature control function maintains the feed temperature

of the Electric heater circulator unit at a pre-set level. This is achieved by

measuring the outlet temperature and activating the three heating elements

in accordance with the selected program (See “Program selection for the

switching sequence of the heating elements ”).

The integrated constant temperature function is always activated. Therefore, whenever an external control is used, the constant temperature has to be

set at or above the maximum temperature required by the external control.

The constant temperature can be set with the control knob K at the outside

of the housing. The range is from 86°F to 185°F.

When the electronic safety temperature limiter function is activated, the

selected constant temperature should always be at least 10K lower than

the safety temperature. Otherwise, under unfavorable conditions, the safety

temperature limiter function could be activated, which would shut down the

unit.

Overheating Protection

When the Electric heater circulator unit is used in connection with oor heating

it is strongly recommended to activate the integrated overheating protection

in order to avoid overheating damages due to failure of the control.

To activate this function, jumper 8 needs to be closed. The safety tempe-

rature should be set to the highest permissible temperature for the oor in a

range between 203°F and 194°F at the potentiometer S. This temperature

must be higher than the maximum temperature reached by the oor heating

system under normal conditions!

If activated, the control monitors the feed line temperature with an additional

12

www.lainginc.com

Page 13

Instruction manual Laing Electric heater circulator unit

sensor C and switches off the circulator of the Electric heater circulator unit

if this temperature exceeds the set temperature. This ensures that - indepen-

dent of the function of the control – overheating of the oor heating pipes is

avoided.

Program selection for the switching sequence of the heating elements

The Electric heater circulator unit has three heating elements, each of which

has its own solid state relay. If heat is required, it is normally neither desired

nor necessary that all heating elements are switched on simultaneously.

While this would load all three phases fully, the activation of all three heating

elements could cause overheating at times of off-peak heat demand.

Therefore, several methods can be selected by which the heating elements

will not be switched on at the same time, but staged over time. Moving the

rst jumper between the pins 1 to 4 will perform this task. However, only one

of these jumpers should be closed at any time. If by mistake several jumpers

have been installed, the red and yellow LEDs start blinking and the unit will

not operate.

An overall view of the jumper settings for the switching sequence can be

found on the second to last page of this manual.

A The heating elements will always be switched on simultaneously. This kind

of function can be used with all temperature control methods. If the utility

company does not allow the switching of individual heating elements, this

function must be selected. The disadvantage is that all heating elements

are activated simultaneously and that all three phases are fully loaded even

if the heat requirement is low. If the heat requirement is low, this method

can also lead to overtemperature. To select this function, jumper 1 must

be closed and jumpers 2, 3 and 4 must be open.

B The heating elements are activated depending on the temperature. This

function is only applicable in combination with the integrated constant

temperature control and with room temperature guided control which uses

the constant temperature function.

This function cannot be used with an outside temperature guided control or

another remote control that regulates the feed temperature of the Electric

heater circulator unit.

When the feed temperature is 2K below the set temperature of the con-

stant temperature control, the rst heating element is switched on. If the

temperature drops another 3K, the second heating element is activated.

www.lainginc.com

13

Page 14

Instruction manual Laing Electric heater circulator unit

Another 3K lower, the third heating element is turned on. All heating ele-

ments stay on until the set temperature has been reached.

To select this function, the second jumper must be closed and jumpers 1,

3 and 4 must be open.

This control method has been implemented since it is customary in some

countries. If permitted, control function D is normally preferable.

C The heating elements are activated one after another. This control function

is applicable to all temperature control applications and should always be

used when the feed line temperature is controlled by a remote control,

for instance by an outside temperature guided control, or when the utility

company does not require that all phases are switched on at the same

time. In this case, this method guarantees the highest degree of heating

comfort. When the control detects that heat is needed, rst one heating

element is switched on, after two minutes the second, and after another

two minutes the third.

To select this function, jumper 3 must be closed, jumpers 1, 2 and 4 must

be open.

D The heating elements are activated depending on the heat load. This con-

trol function is recommended in combination with the integrated constant

temperature control, and also with a room temperature guided control,

since this also uses the constant temperature function. This function cannot

be used in combination with an outside temperature guided control that

controls the feed line temperature of the Electric heater circulator unit.

When heat is required, the rst heating element is activated. After a sta-

bilizing time of approximately one minute, the control checks whether the

temperature is increasing or decreasing. If the temperature is increasing,

no further heating elements will be switched on. If the temperature is still

decreasing, the second heating element is turned on. After another minute,

the temperature change will be checked again, and if necessary, the third

heating element will be switched on. All activated heating elements will

stay on until the set temperature has been reached.

If the actual feed line temperature differs considerably from the set tempe-

rature (for instance when the heater is switched on), after approximately

one minute all heating elements will be turned on automatically.

To select this function, jumper 4 must be closed and jumpers 1,2 and 3

must be open.

14

www.lainginc.com

Page 15

Instruction manual Laing Electric heater circulator unit

Pump shut-off

The integrated control is equipped with a pump shut-off option which can be

activated by closing jumper 5.

If the pump shut-off function is not activated, the pump operates always when

the main switch of the control is switched on. If the pump shut-off switch is

activated, the pump only starts when heat is required and runs for about two

more minutes after the heating has been turned off, so that all residual heat

from the heating elements will have been dissipated.

As a general rule, the pump shut-off option should be activated in heating

systems with radiators, while the pump should run continuously in oor heating

applications.

This pump shut-off function is independent from the pump switching of

the pump shut-off module of a zone control, which prevents the pump from

operating when all zone valves are closed. If such a function is desired, a

pump shut-off module is required.

Deactivating heating elements

The Electric heater circulator unit contains three heating elements, which can

be automatically energized by the control. If not all three heating elements are

needed for an application, the second heating element can be deactivated

by opening jumper 6 and heating element 3 can be deactivated by opening

jumper 7. The deactivated heating elements are no longer activated by the

control, unless they are activated by a remote control system.

Remote control of the second and third heating element

This function makes it possible to control the second and third heating elements, which would mean providing one third or two thirds of the heating

capacity, via an external contact.

It can be used to avoid a high peak load in the electric supply line. The

second and/or the third heating element can, for example, be switched off

when the hot water heater is being reheated or when the oven hot plates are

simultaneously in use. The same applies when the Electric heater circulator

unit is operated in a grid with peak demand usage limitations. In this case,

one third or two thirds of the heat capacity can be switched off at peak load

times.

It should, however, be taken into account that the heating elements – even

when they are switched on via the external contact – are only active when

the control signals a heat requirement or when the control, according to the

chosen program for the switching sequence, activates this heating element.

In case all heating elements should be switched by a remote control, the

www.lainginc.com

15

Page 16

Instruction manual Laing Electric heater circulator unit

control entrance should be used (terminals 5 and 6).

To operate the second heating element by remote control, the heating

element has to be deactivated rst by opening jumper 6. The same applies

to the third heating element. In this case jumper 7 has to be opened. Now a

non energized switch can be attached to terminal 1 and 2. Closing this switch

will activate the deactivated heating elements.

Control input

When the Electric heater circulator unit should be controlled by a remote control

unit, this control must be connected to terminals 5 and 8 with a potential free

switch. If two remote controls are to operate in series, one can be connected

to terminals 5 and 6, the other one to terminals 7 and 8. The terminals 6 and

7 are connected internally. For this function, the bridge between terminals 5

and 8 has to be removed. All active heating elements will be switched on and

off by this input in accordance with the selected switching sequence.

The constant temperature control function stays always active. This means

that the set constant temperature must be set at or above the maximum

temperature called for by the remote control (see also “Outside temperature

guided control”)

Room temperature guided control

In connection with a room thermostat RT or a room thermostat with timer RTU,

it is possible to control the Electric heater circulator unit from one room of the

house. In this case, the room thermostat or the thermostat with timer must be

connected to the control input of the Electric heater circulator unit. The room

thermostat or the thermostat with timer should be located in the main room

since it will control the entire heating system.

The thermostat should not be located close to windows, radiators, outside

walls or similar distorting inuences.

The thermostat should be connected according to the electrical diagram

provided with it.

16

www.lainginc.com

Page 17

Instruction manual Laing Electric heater circulator unit

The desired room temperature must be set at the room thermostat. Similarly, the room thermostat with timer should also be properly set. It should be

understood that the room thermostat with timer allows only one lower room

temperature level, which then will be activated by the timer. There will be no

corresponding decrease in the feed line temperature.

Instructions for the operation of the room thermostat with timer should be

taken from the manual provided with the unit.

The desired constant temperature for the feed line water, with which the

heating system will be heated until the room temperature has been reached,

must be set at the setting knob K.

The heating surfaces then will be heated with the preset constant temperature until the preset room temperature has been reached. The heating

elements will then be turned off.

It is important that the set constant temperature is always lower than the

maximum permissible feed temperature. This is especially important for oor

heating applications.

Electrical Diagram RT

Electrical Diagram RTU

www.lainginc.com

17

Page 18

Instruction manual Laing Electric heater circulator unit

Outside temperature guided control

In connection with the outside temperature guided control AR 1000 d it is

possible to control the feed line temperature dependent upon the outside

temperature.In this case the switching terminal of the control unit must be

connected to the control input ot the Electric heater circulator unit and the

feed line sensor must be attached to the correct place at the top part of the

Electric heater circulator unit.(See also chapter “Installation of the feed line

sensor”).

The connection should be made according to the electrical diagram provided with the unit. The settings of the outside temperature guided control

should be taken from the relevant manual.

The constant temperature control is always active. The constant temperature has to be set at least as high as the highest temperature requested by

the outside temperature guided control.

Electrical Diagram AR 1000 d

Safety temperature limiter

In order to protect the Electric heater-circulator from overheating, it is equipped

with a safety temperature limiter, which in case of overheating separates one

side of the heating element permanently from the grid.

When the safety temperature limiter had been activated, it has to be reset

manually by pressing knob Z.

The safety temperature limiter reacts only when there is a malfunction in the

system. Therefore, as a rst step, the malfunction that caused the activation

of the safety temperature limiter has to be corrected.

When the activation of the safety temperature limiter was caused by operating the Electric heater-circulator without water, it is possible that the safety

switch could be damaged permanently. In this case it is impossible to reset the

safety temperature limiter, it has to be replaced. (See chapter “Replacement

of the safety temperature limiter STBR”).

18

www.lainginc.com

Page 19

Instruction manual Laing Electric heater circulator unit

Electronic means to prevent dry running

The Electric heater-circulator can only be operated when it is lled with water

and the circulator is running.

To protect the heating elements when the Electric heater-circulator is ac-

cidentally switched on without being lled with water, or when there is still a

lot of air in the system, the control system has electronic dry run protection,

which turns the heating elements off and gives a warning via the LED’s when

the temperature rises too fast.

In this case the red LED lights up, the yellow stays switched off. To reset

the system, the unit has to be switched off and then on. If the temperature

of the heating elements has fallen below the maximum temperature allowed

by the constant temperature control after the unit has been switched off, the

heater can be activated again. If the temperature is still too high, the unit has

to stay off until the heating elements have cooled down. Of course, the unit

has to be lled with water and the air has to be vented. (See chapter “Filling

of the system”).

The electronic dry run protection safeguards the safety temperature limiter

since in a dry run it could be permanent damaged. When the Electric heater-circulator is turned on and off several times after the electronic dry run

protection was activated, the safety temperature limiter can nevertheless be

damaged. Therefore, after the dry run protection was activated the system

rst has to be lled with water and the air has to be vented before the unit is

switched on again.

Circulator operation control

To avoid the possibility that the heating elements could be switched on while

the circulator is not running, the control is equipped with a circulator operation

control. This means, that each time before the heating elements are turned

on, the control checks whether the rotor of the circulator is rotating. If the rotor

is blocked by dirt or if the bearing of the circulator is totally worn, the control

recognizes it and the heating elements will not be switched on.

In this case the circulator will be energized for about one minute. The control then tests again whether the rotor is rotating or not. If the rotor still does

not rotate, the same procedure is repeated ten times. If the rotor still does

not rotate, the control signals malfunction, which is indicated by the blinking

of the red LED and shining of the yellow LED.

In this case the circulator has to be removed to nd the cause for the

malfunction. (See also chapter “Replacement of the circulation pump”).

www.lainginc.com

19

Page 20

Instruction manual Laing Electric heater circulator unit

Malfunction detector

The control recognizes the following malfunctions:

(the green LED always shines when the main switch is turned on and there

is a connection to the grid; the yellow LED shines when the control requests

heat and the heating elements are activated.)

Malfunction Signal red LED yellow LED

Circulator malfunction blinking on

Excess temperature cutout on on

Safety temperature limiter blinking off

Dry run on off

Jumper 1 to 4 wrong position blinking blinking

The malfunction signal “Jumper 1 to 4 wrong position” means that more than

one jumper is closed or all four jumpers are open. Only one of the jumpers 1

to 4 must be closed.

Beside the indication of the malfunction through the LED’s on the upper side

of the control box, each function effects the closing of a relay which bridges

the contacts 10 and 11. This makes it possible to sound an alarm at each malfunction of the Electric heater-circulator, or to activate other heating systems

or to inform an overriding control.

Electrical diagram to address a horn with the alarm output

20

www.lainginc.com

Page 21

Instruction manual Laing Electric heater circulator unit

Attachment of the sensor for the remote control

The sensor for the control of the feed line temperature for an outside temperature guided control can be mounted either on the upper part of the housing

that has a hole for a round sensor, or at the feed line of the heating loop, or

in the upper part of the tubular shell of the Electric heater-circulator.

If the sensor is attached to the feed line or to the manifold, one has to take

care that the sensor is in intimate contact with the feed line with the help of

heat conducting paste (in no case should the sensor be attached to a plastic

part). If the sensor is attached to the manifold of the feed line, the sensor has

to be placed before the rst loop.

If the sensor is attached to the tubular shell one has to take care that the

total surface of the sensor facing the shell is in direct contact and that the

sensor is attached to the upper section of the shell!

Se nso r mou nting in the

immersion shell:

The sensor will be inserted

into the hole at the upper

part of the Electric heatercirculator with heat transfer

paste.

The sensor for the control can be mounted according to the

www.lainginc.com

Senso r mo unt ing at the

tubular shell:

The sensor has to be attached as high as possible

on the tubular shell. Attention must be paid to insuring

good heat transfer contact.

Senso r mo unt ing at the

feed pipe:

possibilities shown here.

The sensor has to be attached before the outlet

of the rst loop and has to

have contact to metal.

21

Page 22

Instruction manual Laing Electric heater circulator unit

Indirect domestic hot water heating with the Electric heater-circulator

EPR

Indirect domestic hot water heating

During the heating period the heating of the domestic hot water normally

is performed by the domestic hot water heater that is essentially a heat

exchanger. When hot water is needed, the water from the hydronic heating

circuit is conveyed through this heat exchanger by activating the hot water

heater priority circuit control. This means that the circulator for the heating

circuit is shut off and the charging circulator for the domestic hot water heater

is switched on. In addition the temperature of the boiler will be increased to

the temperature necessary to heat the domestic hot water.

However, this system can only be operated economically during the heating period. Outside the heating period it is uneconomical to run the boiler

just for heating of the domestic hot water. Therefore it is customary, to have

an electric heating element beside the heat exchanger within the boiler that

heats the domestic hot water outside the heating period.

This method is problematic when the water is extremely corrosive or when

the water is hard. It is possible that the heating elements survive only a few

month in such a situation.

In these cases it is advantageous to heat the hot water heater outside the

heating period also with electricity but indirectly via the Electric heater-circulator EPR that is ideal for this application.

By adding an additional printed circuit the Electric heater-circulator EPR

can easily be integrated into existing controls.

Starting operation of the domestic hot water heating and adaptation to

seasonal change

To start the Electric heater-circulator the constant temperature has to be set

to the desired value, normally about 158°F. The circulator then has to be switched to time delay (close jumper 5) for the switching sequence of the heating

elements D, which means, jumper 1,2 and 3 must be open, jumper 4 has to

be closed. Now the Electric heater-circulator is ready for operation.

To change to the heating season when the boiler is in operation, the main

switch has to be shut off while outside the heating season the main switch

has to be turned on. In this latter case the heating of the domestic hot water

is performed by the Electric Heater-circulator. Even outside the heating period

the boiler control has to stay operational.

22

www.lainginc.com

Page 23

Instruction manual Laing Electric heater circulator unit

Hydraulic connection of the EPR for domestic hot water heating

As can be seen from the following diagrammatic drawings, the Electric heatercirculator will be connected in parallel to the boiler and to the heat exchanger

of the hot water heater. To avoid ow through the boiler while heating with

the Electric heater-circulator and vice versa, the boiler as well as the Electric

heater-circulator is connected via a check valve.

Sinc e th e he a t ing

syst e m is al r e ady

equipp e d wi t h an

expansion tank, the

Electric heater-circulator does not need a

separate expansion

tank. The pressure

relief valve integrated

into the Electric heater-circulator serves

as security.

T o s w i t c h

between boiler-heating and electrical

heating nothing has

to be changed on the

hydraulic installation.

One has only to take

care that instead of

the hot water heater

circulator the Electric

heater-circulator has

to be switched on

as described in the

following chapter.

Hydraulic diagram for control process 1

www.lainginc.com

Hydraulic diagram for control process 2

23

Page 24

Instruction manual Laing Electric heater circulator unit

Electrical connection of the EPR for domestic hot water heating

Following two possibilities are described for the connection of the EPR. To

guarantee proper operation the exact function of the boiler control has to be

known.

During the summer boiler controls with domestic hot water priority circuit

control operate by detecting the domestic hot water heater temperature. If

the detected temperature falls below the desired temperature there are two

versions of operation:

The control starts the burner and the hot water heater feed pump at the

same time. If this is the case, it is easily possible to install the Electric heatercirculator EPR as described below under “Control method 1”. No additional

sensor in the hot water heater is necessary.

The control rst turns on the burner and activates the water heater feed

pump only when the temperature of the water heater is at least 122°F. Since

the burner is switched off during summer time, the control of the domestic hot

water heater is only possible with an additional sensor in the hot water heater.

In this case one has to follow the diagram described under “Control method

2”.

For both control methods the additional printed circuit board Type EPRBW

will be needed when the Electric heater-circulator is used to heat the domestic

hot water. After removing the cover of the control box this circuit board has

to be connected to the terminals 5, 8, 13 and 14 of the main printed circuit

board.

Control method 1

The wiring has to be performed according to the wiring diagram shown below, whereby the leads of the hot water heater feed pump loop through the

control of the Electric heater-circulator. The lead III of the pump coming from

the boiler will be connected to ground and phase at CS1. Lead II leading

to the pump will be connected to CS2. In addition a control lead IV will be

connected to CS3, which prevents the boiler from turning on as long as the

electric heating is activated.

As long as the electric heating is switched off via the main switch the relay

on the additional printed circuit board is de-energized and the lead wire for

the hot water heater feed pump is properly connected. In addition the control

contact of this relay is closed for the burner, so that the boiler now takes care

of the heating of the domestic hot water. In this case the check valve of the

Electric-heater-circulator is closed and the check valve to the boiler is open

as long as the hot water heater feed pump is running.

As soon as the main switch of the Electric heater-circulator is turned on,

24

www.lainginc.com

Page 25

Instruction manual Laing Electric heater circulator unit

the relay on the additional printed circuit board closes and switches the lead

from the hot water heater feed pump to

the control inlet of the Electric heatercirculator. At the same time the control

lead for the boiler is interrupted, which

ensures that the boiler and the Electric

heater-circulator cannot be working at

the same time.

Each time the boiler control switches

open with EPR on

on the hot water heater feed pump,

the Electric heater-circulator is turned

on instead.

Wiring diagram control method 1

Control method 2

For this control method it is necessary to install an additional thermostat into

the hot water heater that closes when heat for the hot water heater is needed.

The wiring has to be performed according to the diagram below, whereby

the additional heater thermostat has to be connected to the terminal CS4. A

control lead IV has to be connected to CS3 which prevents the burner from

turning on when the electric heating is active.

As long as the electric heating is switched off via the main switch the relay

on the additional printed circuit board is

de-energized and the control contact of

this relay.

for the burner is closed, so that the

boiler now performs the heating of the

domestic hot water. In this case the

check valve of the Electric heater-circulator is closed and the check valve

for the boiler is open as long as the hot

water heater feed pump is running. As

soon as the main switch of the Electric

heater-circulator is closed, the relais

on the additional printed circuit board

open with EPR on

closes and separates the control lead

to the burner. Now the Electric heater-circulator will be controlled via the

additional thermostat installed within

the hot water heater.

Wiring diagram control method 2

www.lainginc.com

25

Page 26

Instruction manual Laing Electric heater circulator unit

Operation of heating elements with a load shedding device

The control of the electric heater circulator unit is perfectly suited for operation

with a load shedding device.

Normally, utility companies will provide a load shedding device with a potential

free contact which is closed when electrical heating is permitted and open

when electrical heating is not permitted.

- If the load shedding device should not control all heating elements, the

switching contact RR of the load shedding device needs to be connected

to terminals 1 and 2 of the electric heater circulator unit. In this case, the

main power should be connected as described in the chapter “Power

Supply“.

In this case, the rst heating element is always activated when heating

is required, and for the second and third heating element jumpers 6 and

7 control whether they are controlled by the load shedding device. If the

appropriate jumper is closed, the element heats always when heat is requested. If it is open, the heating element only heats when in addition to

the heat request

the contact between terminal 1

and 2 is closed.

In this way, it is

possible to control

one third or two

thirds of the total

heating power by

a load shedding

device.

26

Wiring schematics for load shedding device if only one

or two heating elements are to be controlled by the

load shedding device.

www.lainginc.com

Page 27

Instruction manual Laing Electric heater circulator unit

- If all three heating elements should be controlled by a load shedding

device, the unit needs to be connected according to the diagram below.

The diagram shows the connection for 3-phase 400 Volt operation. For

other supply voltages, the corresponding diagram shown under “main

power connection“ should be modied accordingly.

If all three elements are controlled by a load shedding device, a separate

power supply is needed for the control and the circulator pump, so that

these two can operate independent of the load shedding device. This is

necessary since an operation of the unit without deferred pump shutdown

can lead to overheating conditions when the elements are deenergized.

Remove the jumper wire

between Mains terminal

1 and terminal T on the

main switch. Attach the

separate power supply

to terminal T. A separate

switch H1 controls the

operation of pump and

control as well as the contactor for the main power

supply.

If the load shedding device RR is open but the

switch H1 and the main

switch of the electric heater cir-culator unit are on,

the control and the pump

will operate. When the

co ntact RR is closed,

the external contactor

closes and the heating

elements are activated in

accordance with heating

require-ments and selected heating program.

Wiring schematics for control of all heating elements by load shedding device

www.lainginc.com

27

Page 28

Instruction manual Laing Electric heater circulator unit

Filling of the system

One has to take care that the whole system is completely lled.

In lling and bleeding of a oor heating system one has to take into con-

sideration that the gases released from the water have no opportunity to

accumulate for instance in radiators as in other heating systems. In a oor

heating the gases will always circulate in the heating loops. In cases with high

emission of gas the circulator may stop running, whereby the bearing, due to

dry running, can be damaged. Therefore one has to take care that after about

two weeks the collected gases are completely vented, and that a comparable

amount of water is added.

The electric heating should only be started after complete lling and bleeding of the system.

Pressure and leak tests

When pressure-testing the system, the expansion tank, the pressure relief

valve, and the manometer should never be exposed to the pressure necessary

to perform the pressure test. These parts have to be removed and the holes

have to be plugged.

Starting operation

The system can only be started when it is completely lled and when the

control system has been tested. When using a remote control one has to

make sure that the feed line sensor is attached to the feed line. In addition

one has to take care that the jumper of the control are in the right position to

guarantee the desired functions.

If these preconditions are fullled, the pump can be switched on rst by

setting the constant temperature at knob K at the lowest value and by activating the main switch. It is possible that there could be some noise in the

system due to residual air. If this noise does not stop after a few minutes or

if no liquid is circulated by the pump, the pump should be switched on and

off several times (about 10 seconds off, 20 seconds on) to enhance the air

venting. If this method does not succeed after about 10 minutes, the lling of

the system has to be repeated since apparently there is still a large amount

of air in the system.

In no case should the pump run longer than a few minutes in a system

inadequately vented since the bearing can be damaged.

After a successful start of the pump in a oor heating system the unit should

run for about 24 hours without heating to give the water time to get rid of

the gases. After this time the heating should start by slowly increasing the

28

www.lainginc.com

Page 29

Instruction manual Laing Electric heater circulator unit

feed line temperature via the constant temperature setting. During the whole

starting operation the system has to be controlled and the water which is

diminished by the release of the gases has to be replaced and the gases

have to be vented.

If this advice is not followed, there is the danger that the air accumulates in

the pump and interrupts the circulation of the pump. In this case the bearing

can also be damaged.

Replacement of the circulation pump

In case it is necessary to open or replace the circulator of the Electric heatercirculator, the Electric heater-circulator has to be separated from the grid and

the water has to be drained.

If the Laing Compact station is used, the return line valves of all heating

loops have to be closed and a hose has to be attached to the lower KFE

tap. After opening the KFE tap about 0.9 to 1.8 Gallons of water will be

discharged.

Now the pump has to be taken off by unscrewing the two fastening screws.

When the pump is removed it should not be tilted too much since otherwise the

rotor might fall out and could be damaged. After the pump has been removed

the rotor can be drawn off upwards and can be tested for dirt of scaling.

In replacing the pump the rotor has to be replaced before the seal ring otherwise there could be damage. Before the Electric heater-circulator is started

again the air has to be vented in any case.

Replacement of the safety temperature limiter STBR

To replace the switching module of the safety temperature limiter the leads

of the safety temperature limiter have to be marked and than disconnected.

Thereafter, the switching module has to be removed by unscrewing the nut

around the reset knob Z at the outside of the control box . Then the capillary

has to be carefully removed from the immersion shell. One has to take into

account that the temperature sensors are also contained in the immersion

shell.

Afterwards, the temperature sensors have to be removed from the old

capillary and be attached to the new capillary in the same position directly

above the thick area of the capillary. This point is very important since an

improper mounting can lead to a malfunction of the control.

Then the capillary has to be carefully replaced into the immersion shell

www.lainginc.com

29

Page 30

Instruction manual Laing Electric heater circulator unit

until it touches the bottom. Thereafter, the safety temperature limiter has to be

secured by the nut and the leads have to be connected to the same positions

as before.

Replacement of the main circuit board EPRH

To replace the main circuit board the Electric heater-circulator has to be disconnected from the grid and thereafter, the cover from the terminal box has

to be removed.

Then two snap connectors M have to be disengaged by pressing with a screw

driver from above on the tongue of the connector (see page …). Thereafter

the circuit board can be pulled out. One has to take care that the leads that

are pinned to the circuit board will not get stuck. When the circuit board has

been moved up high enough, the leads can be removed.

Before the circuit board is reinserted, the plugs have to be fully inserted into

the board. One has to make sure that the slots in the circuit board t into the

bars of the plugs.

Thereafter the circuit board is pushed downwards until the snap connectors

are in the right position and the board can be snapped in.

Important Notices

Important Notice: How to avoid noise problems

Since the Electric heater-circulator is often used in living quarters, it is especially important to avoid noise. In this respect it is very important that the

Electric heater-circulator and the connected pipes are always joined by rubber

isolatorsto avoid direct sound transmission. This applies also to pipes installed

inside the walls.

Important Notice: How to avoid overheating

To avoid overheating of the Electric heater-circulator it is obligatory that

during the heating cycle the Electric heater-circulator is continuously lled

with water. If the feed line or the return line will be shut off as for instance in

a oor heating system, in which all loops have a zone control, the optionally

available Laing Zone module with pump shut off has to be installed. This will

shut off the pump until a through ow is possible again. In heating systems

with radiators a relief valve has to be installed.

Important Notice: In the event of safety temperature limiter failure

When the safety temperature limiter will become very hot, as can be the case

when the Electric heater-circulator is switched on and off several times without

being lled with water, the safety temperature limiter will switch off once more

30

www.lainginc.com

Page 31

Instruction manual Laing Electric heater circulator unit

to avoid a further overheating. However, it may not be possible to switch it

on again since the high temperatures may have destroyed the element. This

damage is recognizable when the knob of the switch for the safety temperature

limiter cannot be engaged any more. If this is the case, the safety temperature

limiter has to be replaced.

Important Notice: For proper connection to a oor heating system

All parts of the Electric heater-circulator and all other components which are

part of the Laing compact- or central stations, which come in contact with the

liquid conveyed are corrosion resistant. Therefore it is possible to provide

a direct oor heating system connection even if the pipes are not diffusion

protected.

However, this applies only when the whole oor heating loop consists of

corrosion resistant material. In any case installations having corroding materials such as iron expansion tanks, iron pipes or radiators should be avoided.

In such installations – even when they are diffusion protected – excessive

corrosion will occur in a short time on the iron parts which in turn can lead to

other damages and even water leaks in the system. In these systems only a

separation between the systems can solve the problem.

Factory settings

Constant temperature control 122°F

Safety temperature cutout 140°F

Jumper 1 closed

Jumper 2 open

Jumper 3 open

Jumper 4 open

www.lainginc.com

Jumper 5 open

Jumper 6 closed

Jumper 7 closed

Jumper 8 closed

31

Page 32

Instruction manual Laing Electric heater circulator unit

Switching sequence Jumper 1 2 3 4

A Simultaneous switching closed open open open

B Switching in temperature steps open closed open open

C Switching staged over time open open closed open

D Switching depending on a gradient open open open closed

In connection with an outside temperature guided control only A and C can

be used.

Jumper Function jumper closed Function jumper open

5 After switching off the heating Circulator runs always as long

elements the circulator runs as the main switch is turned on

another two minutes

6 Second heating element Second heating element

activated deactivated

7 Third heating element Third heating element

activated deactivated

8 Overheating safety switch Safety temperature switch not

activated activated

Malfunction reports and LED’s

(the green LED is always on when the main switch is turned on and there is

a connection to the grid, the yellow LED is on when the control requests heat

and when the heating elements are activated.)

Malfunction Signal red LED yellow LED

Circulator malfunction blinking on

Excess temperature cutout on on

Safety temperature limiter blinking off

Dry operation on off

Jumper 1 to 4 wrong position blinking blinking

The malfunction signal “Jumper 1 to 4 wrong position” means that more than

one jumper is closed or all four jumpers are open. From the jumpers 1 to 4

only one jumper must be closed.

32

www.lainginc.com

Page 33

Instruction manual Laing Electric heater circulator unit

www.lainginc.com

33

Page 34

Instruction manual Laing Electric heater circulator unit

34

www.lainginc.com

Page 35

Instruction manual Laing Electric heater circulator unit

www.lainginc.com

35

Page 36

290607 Subject to change without notice · Errors and omissions exceptetd

Phone: (619) 575-7466 · Fax: (619) 575-2739 · E-Mail technicalsupport@lainginc.com

Laing Thermotech, Inc. · 830 Bay Blvd. Suite #101 · Chula Vista, CA 91911

or customerservice@lainginc.com · Internet: www.lainginc.com

Loading...

Loading...