Page 1

ecocirc XL

ecocirc XLplus

ELECTRONIC DRIVE MANUAL

Page 2

1 Introduction

1

2

3

The electronic drive described in this manual controls

both ecocirc XL and ecocirc XLplus circulators; the

drive’s main features are:

sensorless motor control

sine wave modulated PWM

2 micro-controllers:

one dedicated to motor control

one implementing the following features:

- several operating and control modes

- night mode operation

- 0-10V analog input signal control

- PWM input signal control1

- 4-20mA pressure sensor control

- external temperature sensor control2

- external start/stop signal control

- fault signal control

- connection to Modbus control

systems2

- connection to Bacnet control systems3

multiple alarms and errors detection and

control

multiple pump status indication

optional Wireless module control2

optional RS485 module control2

In the next chapters, a detailed description of ecocirc

XL family drives’ features will follow.

Only on plug-connected models, see 1.1

Only on ecocirc XLplus

Only on ecocirc XLplus terminal-connected models, see 1.1

Page 3

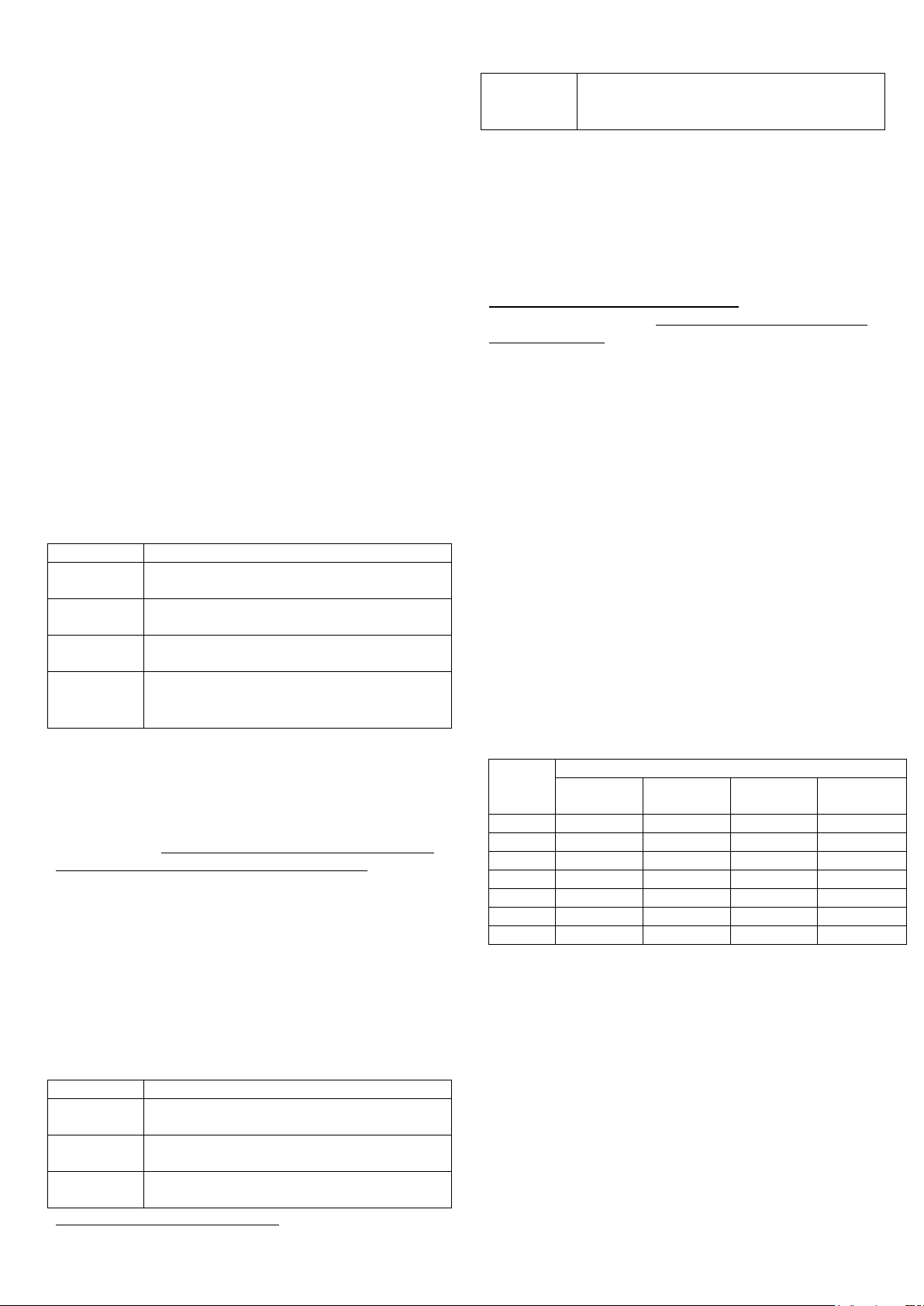

Circulator model

Options

Electrical connection

ecocirc XL/XLplus 25-40

(B)

Plug

ecocirc XL/XLplus 25-60

(B)

Plug

ecocirc XL/XLplus 25-80

-

Terminal

ecocirc XL/XLplus 25-100

-

Terminal

ecocirc XL/XLplus 32-40

(B)

Plug

ecocirc XL/XLplus 32-60

(B)

Plug

ecocirc XL/XLplus 32-80

(F) (B)

Terminal

ecocirc XL/XLplus 32-100

(F) (B)

Terminal

ecocirc XL/XLplus 32-120 F

(D) (B)

Terminal

ecocirc XL/XLplus 40-80 F

(D)

Terminal

ecocirc XL/XLplus 40-100 F

(D)

Terminal

ecocirc XL/XLplus 40-120 F

(D) (B)

Terminal

ecocirc XL/XLplus 50-80 F

(D) (B)

Terminal

ecocirc XL/XLplus 50-100 F

-

Terminal

ecocirc XL/XLplus 50-120 F

(D) (B)

Terminal

ecocirc XL/XLplus 65-80 F

(D) (B)

Terminal

ecocirc XL/XLplus 65-120 F

(D) (B)

Terminal

ecocirc XL/XLplus 80-120 F

(D)

Terminal

ecocirc XL/XLplus 100-120 F

-

Terminal

All the subsequent circulators must be considered XLplus models

ecocirc XL 20-35

(B)

Terminal

ecocirc XL 36-45

(B)

Terminal

ecocirc XL 15-75

(B)

Terminal

ecocirc XL 55-45

(B)

Terminal

ecocirc XL 20-140

(B)

Terminal

ecocirc XL 65-130

(B)

Terminal

ecocirc XL 40-200

(B)

Terminal

ecocirc XL 70-145

(B)

Terminal

ecocirc XL 40-275

(B)

Terminal

ecocirc XL 95-125

(B)

Terminal

ecocirc XL 27-375

(B)

Terminal

ecocirc XL 105-155

(B)

Terminal

ecocirc XL 45-340

(B)

Terminal

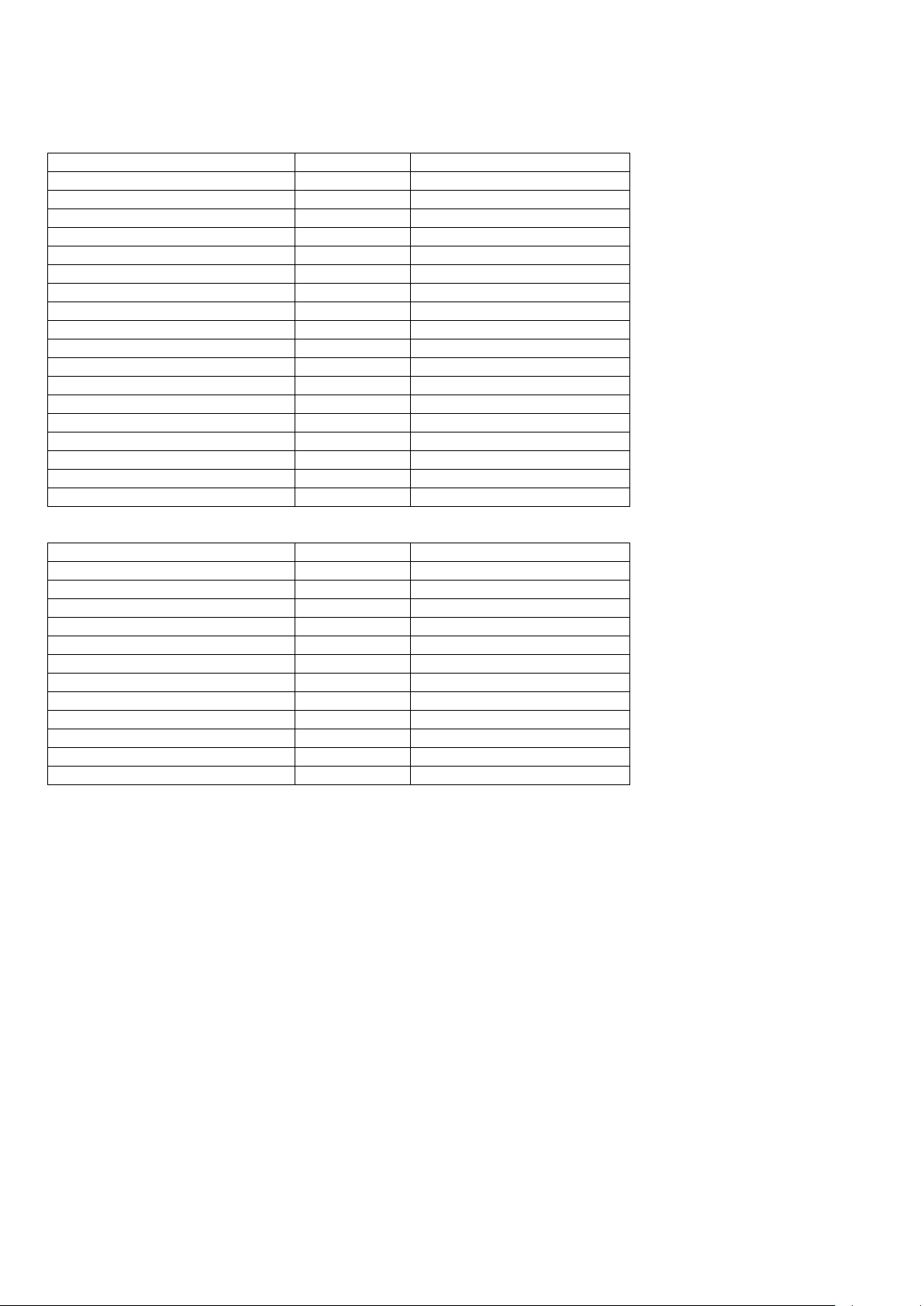

1.1 Product Range

B = Bronze

F = Flanged

D = Twin

Page 4

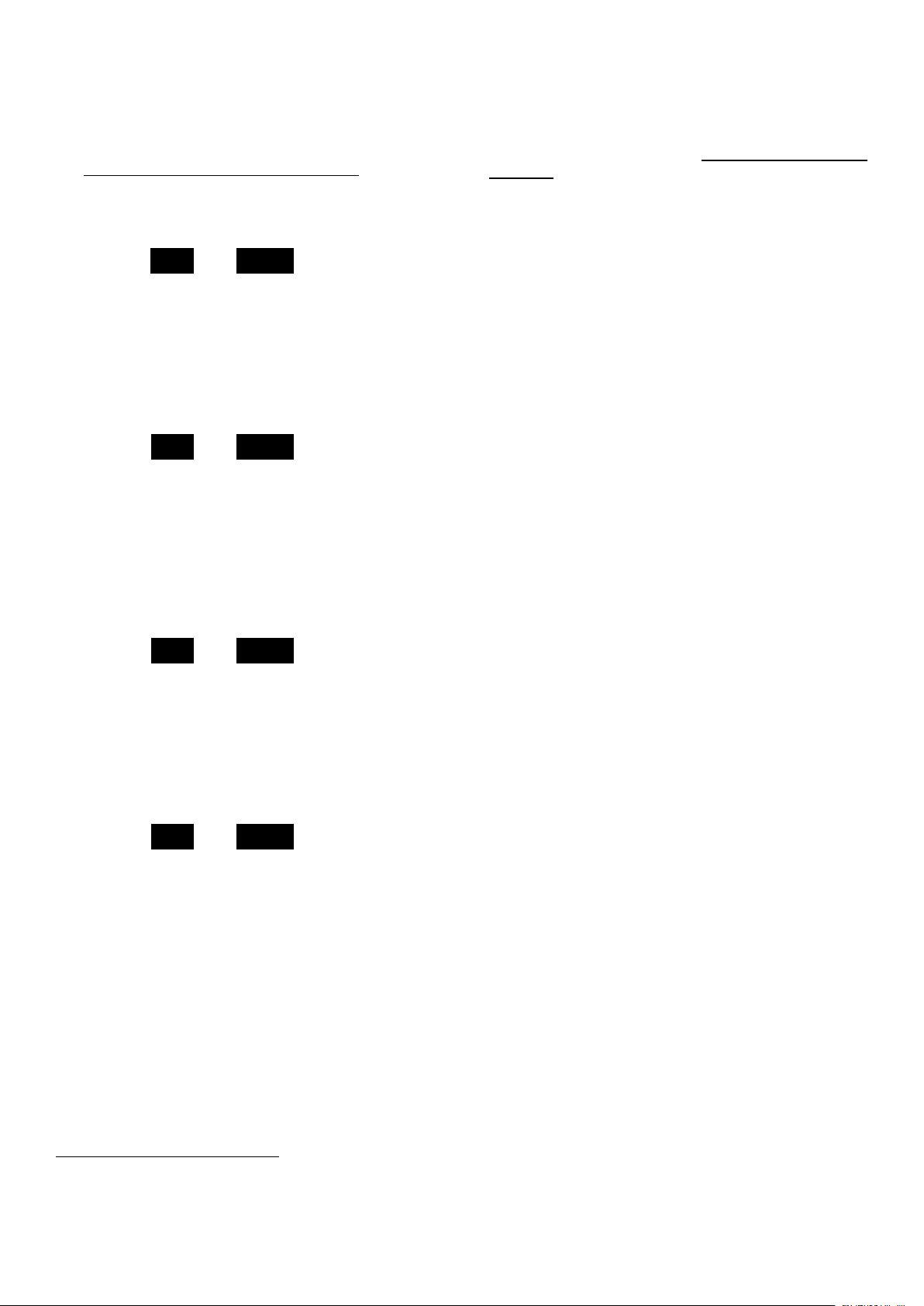

ecocirc XL /

XLplus

Voltage

rating

Nominal

max input

current

Recommen

ded line

protection

[A]

[A]

25-80

25-100

32-80

32-100

40-80

40-100

50-100

36-45

15-75

1 230V

50/60Hz

<2

3

32-120

40-120

50-80

65-80

55-45

1 230V

50/60Hz

<3

4

50-120

65-120

65-130

1 230V

50/60Hz

<5

6

80-120

100-120

70-145

1 230V

50/60Hz

<9

10

Plug

connector

M12 (1)

Cable Ø

2÷5mm

M12 (2)

Cable Ø

2÷5mm

Power supply

3x

0.75÷1.5

mm2

(2P+T)

Fault signal

2x

0.75÷1.5

mm2

- Analog 010V

- External

pressure

sensor

- External

temperature

sensor

- External

start/stop

If NO fault

signal on

this cable

gland.

Multi-wire

control

cable,

number of

wires

according

to number

of control

circuits.

Shielded if

necessary

Multi-wire

control

cable,

number of

wires

according

to number

of control

circuits.

Shielded if

necessary

Communicati

on bus

Bus cable

M20 Cable

Ø 5÷13mm

M16 (1)

M16 (2)

Power supply

3x

0.75÷2.5

mm2

(2P+T)

- Power

supply

- Fault signal

5x

0.75÷1.5

mm2

(4P+T)

Fault signal

2x

0.75÷1.5

mm2

2 Electrical installation

Power Supply: 1 x 230V ±10%, 50/60Hz

Check that the power supply line is provided with:

A mains isolator switch with a contact gap of at

least 3mm

A high-sensitivity (HS) 30mA differential switch

(RCD – Residual Current Device), suitable for

earth fault currents with DC or pulsating DC

content (preferably Type B).

If an automatic circuit breaker (CB) is required,

use an automatic circuit breaker with C-type

characteristic curve.

a. Connect the ground (earth) lead; be sure

that the ground (earth) lead is longer than

the phase leads

b. Connect the phase leads

For cable requirements and organization of wiring

harness inside the cable glands, refer to par. 2.3

Wiring harness.

2.2 I/O connection

1. Open the terminal block removing the screws

2. Connect the appropriate cable according to the

terminal block diagram. See Figure 8, Figure 9 and

the requirements of par. 2.3 and 2.4.

2.3 Wiring harness

For plug-connected models

2.1 Power Supply connection

For plug-connected models, see Figure 6 and follow

the subsequent steps:

1. Open the connector cover and insert the cable

inside the cable gland

2. Pull down the contact retention spring

3. Connect the cable according to the wiring diagram

4. Align the two parts of the connector

5. Push the two parts one inside the other

6. Close the connector and tight carefully the cable

gland

For terminal-connected models, see Figure 5 and

follow the subsequent steps:

1. Open the terminal block cover removing the

screws

2. Insert the cable inside the M20 cable gland

3. Connect the cable according to the wiring diagram

(see Figure 7 and Figure 9)

Table 1

Table 2

For terminal-connected models

Page 5

- Analog 010V

- External

pressure

sensor

- External

temperature

sensor

- External

start/stop

If NO fault

signal on

this cable

gland.

Multi-wire

control

cable,

number of

wires

according

to number

of control

circuits.

Shielded if

necessary

Multi-wire

control

cable,

number of

wires

according

to number

of control

circuits.

Shielded if

necessary

Communicati

on bus

Bus cable

Function

Terminal

pair

Contact rating

See

par.

External

start/stop

The drive

provides 5VDC

through these

terminals: no

external voltage

must be

provided!

2.5.1

0-10V external

analog input

2.5.2

Fault signal

Max 250V at 2A

(inductive load)

2.5.3

4-20mA

pressure sensor

input

2.5.4

External

temperature

sensor4

The drive works

with a KTY83

temperature

sensor (1KΩ at

25°C)

2.5.5

Communication

bus (standard)4

TIA/EIA RS485

2.5.6

Communication

bus (optional)4

TIA/EIA RS485

2.5.7

Optional

Wireless /

RS485 module

2.5.8

4

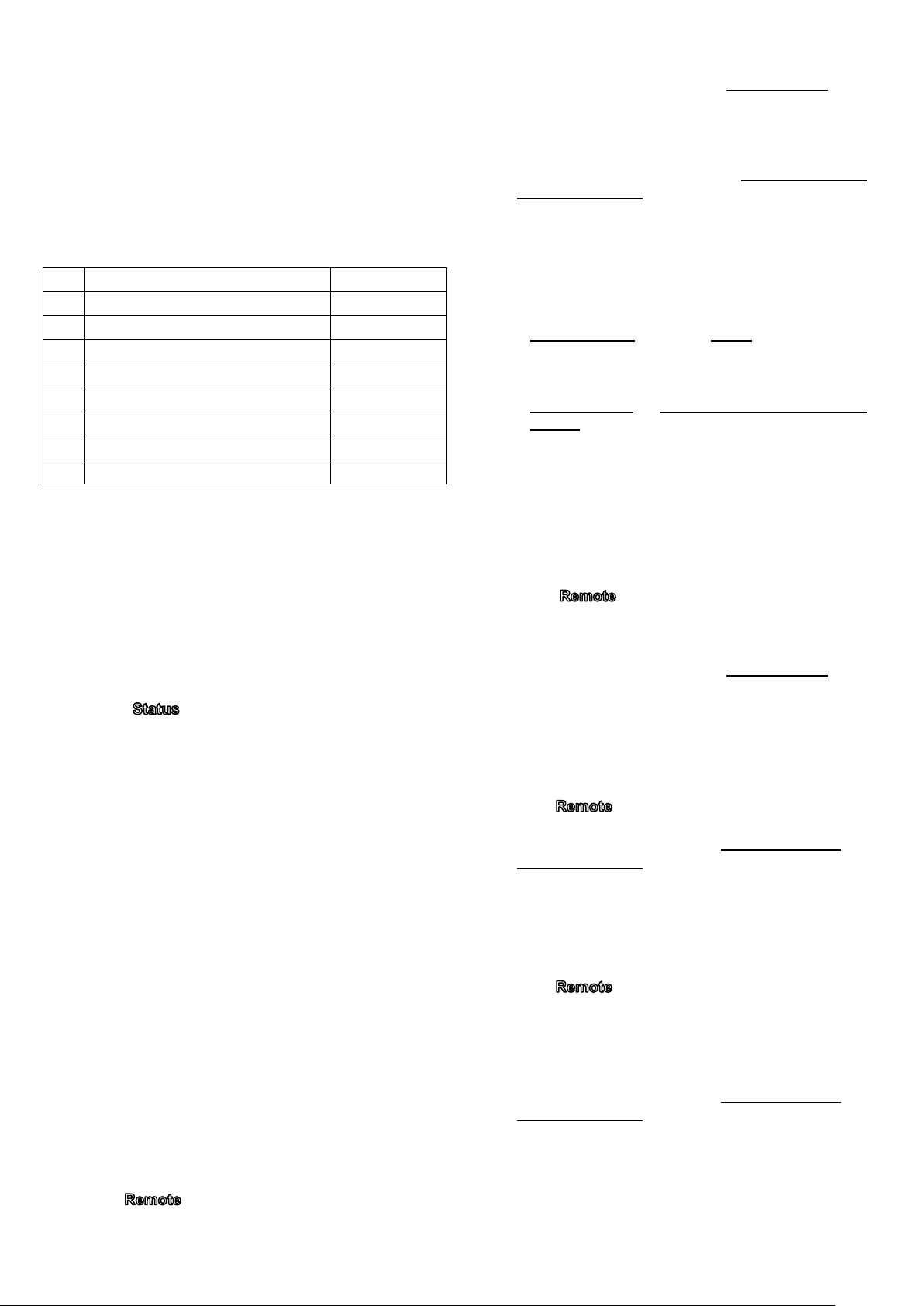

Vin

thres

holds

[V]

Speed

setpoint

[rpm]

when

Vin

Pump

status

when Vin

Po

int

Speed

setpoint

[rpm]

when

Vin

Pump

status

when Vin

Po

int

0

-

Input

disabled

-

-

Input

disabled

-

0.8

-

Input

disabled

- 0 OFF

1.19

-

Input

disabled

- 0 OFF

1.20 0 OFF

MIN

RUN

1.49 0 OFF

MIN

RUN

1.50

MIN

RUN

MIN

RUN

10.0

MAX

RUN

MAX

RUN

Table 3

2.4 Connection diagram

With reference to Figure 8 and Figure 9:

and , which is the factory setting, should be

maintained.

NOTICE

The drive provides 5VDC through these terminals: no

external voltage must be provided to these terminals!

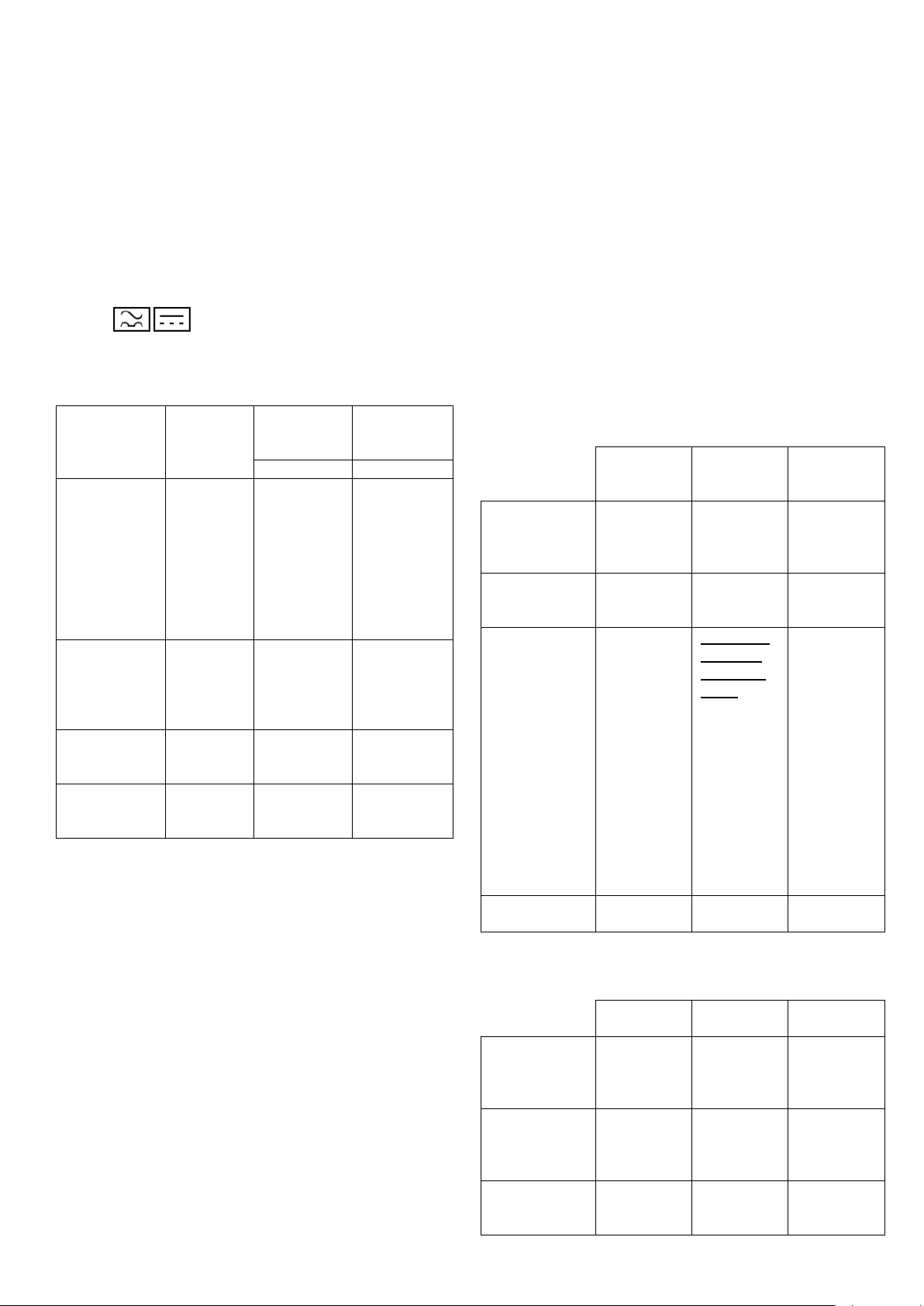

2.5.2 External analog input 0-10V []

An external analog signal 0-10V, applied to terminals

and , controls the circulator speed in a range from

0 to 100%, following a linear function as depicted in

Figure 1.

2.5 I/O description

2.5.1 External start/stop []

The circulator can be started or stopped via an

external potential-free contact or a relay connected to

terminals and . If no external start/stop switch is

connected, the connection jumper between terminals

Only on ecocirc XLplus

Table 4

Figure 1

In the below table a description of the milestones

shown in Figure 1.

Table 5

2.5.3 Fault signal []

The drive controls a relay for a potential-free fault

signal: in case of blocking error, the relay is activated

so that the terminals and are short circuited.

RATINGS

V

< 250VAC

max

I

< 5A (if resistive load)

max

I

< 2A (if inductive load)

max

Page 6

Interface

RS485 (TIA/EIA) optically isolated

Baud rate

4800 / 9600 (factory setting) / 14400 /

19200 / 38400 / 56000 / 57600 baud

Data

format

8 data bits, no parity, 1 stop bit

Protocol

Modbus RTU (factory setting)

Bacnet MSTP5

Address

1247 Modbus RTU

0 127 Bacnet MSTP5

ID #1 factory setting

Interface

RS485 (TIA/EIA) not isolated

Baud rate

4800 / 9600 (factory setting) / 14400 /

19200 / 38400 / 56000 / 57600 baud

Data

format

8 data bits, no parity, 1 stop bit

Protocol

Modbus RTU (factory setting)

Bacnet MSTP

5

Address

1247 Modbus RTU

0 127 Bacnet MSTP5

ID #1 factory setting

Priority

Possible settings

User

Interface

External

Start/Stop

External

0-10V

Bus signal

1 Stop 2

Regulation

3 Stop

4

Regulation

5 Stop

6

Regulation

7 Stop

2.5.4 External analog input 4-20mA []

The circulator can be equipped with a 4-20mA external

differential pressure sensor, connected to terminals

and , with the purpose of increasing the precision in

operating modes involved with pressure regulation.

For setting, in the drive, the correct pressure sensor

model used, see par. 4.3.5.3.

2.5.5 External temperature sensor []

The circulator can be equipped with an external KTY83

temperature probe (1KΩ at 25C), connected to

terminals and , with the purpose of measuring an

absolute or a differential water temperature, in

temperature dependent / influenced operating modes.

For setting, in the drive, the desired temperaturedependent control mode, see par. 6.1.2

2.5.6 Communication bus (standard)

[]

The circulator (model ecocirc XLplus only) can

communicate remotely through a built-in RS485 port,

whose characteristics are:

The aim of this additional communication bus is to

offer a connection to an external BMS, or to a generic

external device, even when the standard

communication bus (described in 2.5.6) is used for

dual pump operations (in case of a twin-head pump or

2x single-head pumps)

NOTICE

Don’t use this communication bus, implemented on

terminals , and , for connecting 2 pumps in dual

pump operations

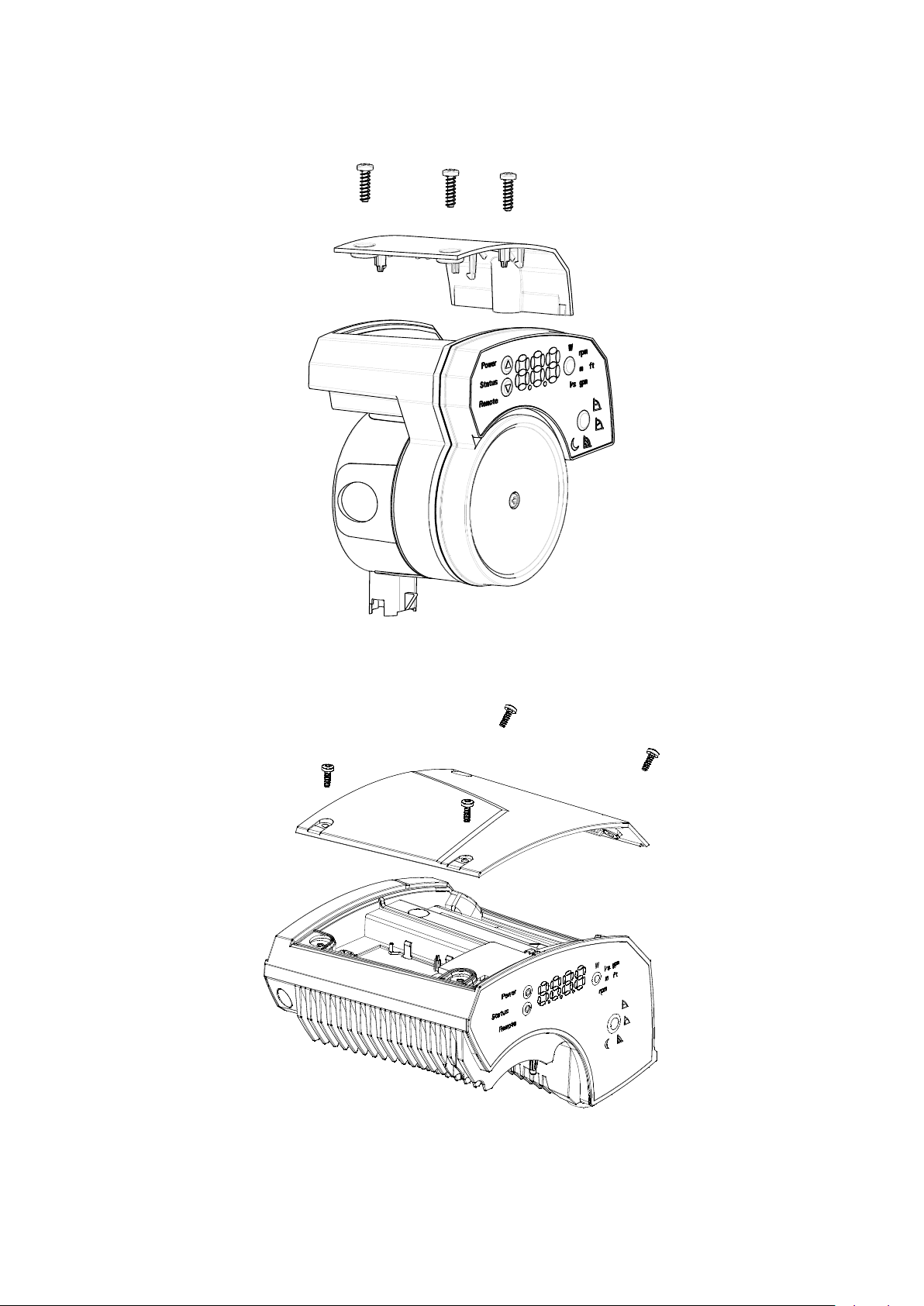

2.5.8 Optional wireless / RS485 module

[]

The drive can be equipped with

an optional Wireless module;

an optional RS485 module

Both the modules shall be plugged inside the drive

(see Figure 12), fixed by the provided clips and with

the cable connected to the connector (see par. 6.2

and 6.3).

For setting, in the drive, the correct communication

parameters, see par. 4.3.5.2.

NOTICE

This communication bus, implemented on terminals ,

and , is the only one which can be used for

connecting 2 pumps in dual pump operations (see par.

4.3.5.1)

2.5.7 Communication bus (optional)

[]

The circulator (model ecocirc XLplus only) can

communicate remotely through an optional RS485

port, available exclusively in case the optional Wireless

module or the optional RS485 module is installed;

main characteristics of this port are:

2.6 Settings priority

All the I/O signals, described in 2.5, can interact

together changing the behavior of the circulators they

are connected to: in particular, in case two or more

signals are enabled and active at the same time, the

circulator will operate according to the setting with the

highest priority.

Refer to the table below for the settings priority:

EXAMPLE 1

In case the external start/stop switch is open or

unconnected (External Start/Stop = Stop), the drive

shall not accept any regulation.

EXAMPLE 2

The circulator can be driven through the User Interface

only if no external signals are applied (to the provided

terminals) and no communication bus is connected

Only on ecocirc XLplus terminal-connected models

Page 7

6

7

8

9

3 First Start-up

Before operate the circulator, verify the correct

connection of the wirings.

1. Switch on the power supply to the pump

The drive light all the LEDs of the User Interface,

to allow a quick detection of any display

malfunction

2. (6) After few seconds, the drive will display the

message SIN (7) or SING (8)

While this message (“SIN” or “SING”) is displayed,

the drive gives the possibility to set the dual pump

operations’ parameters: if the user does not

change this setting, the device will default to the

factory setting (single-head pump) and proceed to

the next step.

For setting, in the drive, the correct dual pump

operations’ parameters see par. 4.3.5.1.

3. (6) After few seconds, the drive will display the

message CON (7) or CONN (8)

While this message (“COM” or “COMM”) is

displayed, the drive gives the possibility to set the

communication parameters: if the user does not

change this setting, the device will default to the

factory settings (9600baud, address = 1, no

optional module, Modbus RTU protocol) and

proceed to the next step.

For setting, in the drive, the correct communication

parameters see par. 4.3.5.2.

4. (9) After few seconds, the drive will display the

message PrE (7) or PrES (8)

While this message (“PRE” or “PRES”) is

displayed, the drive gives the possibility to set the

differential pressure sensor’s parameter: if the user

does not change this setting, the device will default

to the factory setting (differential pressure sensor

1.0bar) and proceed to the next step.

For setting, in the drive, the correct differential

pressure sensor’s parameter, see par. 4.3.5.3.

5. After few seconds, the drive will display the

message 4dG (7) or 4DEG (8)

While this message (“4DG” or “4DEG”) is

displayed, the drive is performing the first (out of 4)

cycle of the Air Purge procedure: if the user does

not stop this procedure, the device will finalize the

4 cycles (decrementing in each sub-phase the

countdown “4DG”-“3DG”-“2DG”-“1DG” or “4DEG”“3DEG”-“2DEG”-“1DEG”) and then proceed to the

next step.

To stop or start the Air Purge procedure, see

par.4.3.4.2

6. At the end of the Air Purge procedure, the pump

starts pumping in Constant Head control mode

(factory default)

For more information about Control Modes and

relative default value, see par. 4.3.3

NOTICE

All the steps from 1 to 5 are always the same at every

start-up, regardless it’s the first or not.

In step 6, the starting control mode of a generic (not

the first) start-up procedure is the last used before the

power-off.

Only on ecocirc XLplus

On plug-connected models

On terminal-connected models

Only if an external differential pressure sensor is connected to the

provided terminals (see 2.5.4)

Page 8

Control Mode button

See par. 4.3.3

Control Mode indicators (LEDs)

See par. 4.3.3

Parameter button

See par. 4.2

Parameter indicators (LEDs)

See par. 4.2

Setting buttons

See par. 4.3.1

Numeric display

Power indicator (LED)

See par. 4.1.1

Status indicator (LED)

See par. 4.1.2

Remote control indicator (LED)

See par. 4.1.3

4 Control Panel

For a description of buttons, indicators and display

present on the user interface, follow the table below

referring to Figure 10 (in case of plug-connected

models) and to Figure 11 (in case of terminalconnected models).

If the Remote (green) LED is permanently lit, then

the drive both

o detected a communication bus on the

provided terminals

o acknowledged the correct addressing

If the Remote (green) LED is blinking with 50%

duty every second, then the drive

o detected a communication bus on the

provided terminals

o has not been correctly addressed

Particular behaviors (in this condition) for this indicator

are the following

If the Remote (green) LED switches from being

permanently lit to being not lit, then the drive

didn’t detect any valid Modbus RTU message (at

least) for the last 5 seconds

If the Remote (green) LED switches from being

permanently lit to blinking with 50% duty every

second, then the drive has not been correctly

addressed (at least) for the last 5 seconds

4.1 LEDs description

4.1.1 Power indicator []

When the Power (green) LED is lit, the circulator is

supplied with power and the electronic devices are

operative

4.1.2 Status indicator []

If the LED is not lit, then the pump is

stopped or disabled and the pump motor is not

running.

If the Status (orange) LED is lit, then the pump is

still enabled and the pump motor is running,

because in presence of a non-blocking alarm

If the Status (red) LED is lit, then the pump is

stopped or disabled and the pump motor is not

running due to a blocking error

If the Status (green) LED is lit, then the pump is

running

4.1.3 Remote control indicator []

This indicator is used only on ecocirc XLplus

circulators, because it is related to the presence of any

kind of communication.

The way the Remote LED is lit (permanently) or blinks,

depends on several settings and conditions as below

4.1.3.1 Condition 1

If no optional wireless / RS485 module is used

(referring to par. 4.3.5.2, parameter “Module” is set to

value “None”) and the protocol for the communication

bus is Modbus RTU (parameter “Protocol” is set to

value “Modbus”)

If the LED is not lit, then the drive cannot

detect any valid Modbus message on the terminals

provided for the communication bus

4.1.3.2 Condition 2

If no optional wireless / RS485 module is used

(referring to par. 4.3.5.2, parameter “Module” is set to

value “None”) and the protocol for the communication

bus is Bacnet MSTP (parameter “Protocol” is set to

value “Bacnet”)

If the LED is not lit, then the drive didn’t

receive any valid request, coming from any other

Bacnet MSTP device, (at least) for the last 5

seconds

If the Remote (green) LED is permanently lit, then

the drive is exchanging information with any other

Bacnet MSTP device

4.1.3.3 Condition 3

If the optional wireless module is used (referring to par.

4.3.5.2, parameter “Module” is set to value “Wireless”)

If the LED is not lit, then the connection

with the wireless module is damaged or absent

If the Remote (green) LED is blinking with 10%

duty every second, then the drive is exchanging

information with the wireless module

4.1.3.4 Condition 4

If the optional RS485 module is used (referring to par.

4.3.5.2, parameter “Module” is set to value “RS485”)

If the LED is not lit, then either

o the connection with the RS485 module is

damaged or absent

o the drive didn’t receive any valid request,

coming from any other external device, (at

least) for the last 5 seconds

If the Remote (green) LED is blinking with 90%

duty every second, then both

o the RS485 module is correctly connected

o the drive is exchanging information with any

other external device

Page 9

4.2 Parameter LEDs description []

Referring to Figure 10 (in case of plug-connected

models) and to Figure 11 (in case of terminalconnected models), use the Parameter button to

change the displayed unit of measurements during

normal operation, following these logical flows:

Figure 2: On terminal-connected models

4.2.1 Power

When Power (input active electric power) is the

measurement selected:

The current power absorption from the power

line [watts] is displayed on the numeric display

The W indicator is permanently lit

4.2.2 Flow

When Flow (hydraulic water flow) is the measurement

selected:

The current water flow estimation [m3/h or US-

gpm] is displayed on the numeric display

The m

lit

3

/h (or gpm ) indicator is permanently

4.2.3 Head

When Head (hydraulic water head) is the

measurement selected:

The current water head estimation [meters or

feet of water head] is displayed on the numeric

display

The m (or ft ) indicator is permanently lit

4.2.4 Speed

When Speed (pump impeller speed) is the

measurement selected:

The current rotation speed measure

[revolutions per minute] is displayed on the

numeric display

The rpm indicator is permanently lit

NOTICE

Each hydraulic measure (Flow or Head) can be

singularly switched, between ISO and US units of

measure, by pressing the Parameter button

continuously for at least 2 seconds

4.3 Settings

4.3.1 Set points editing

Referring to Figure 10 (in case of plug-connected

models) and to Figure 11 (in case of terminalconnected models), use the Setting buttons to

change the set point corresponding to the currently

selected Control Mode (see par. 4.3.3)

1. Press shortly one of the Setting buttons

The actual set point is shown (blinking) for 4

seconds on the Numeric display , while the

relative unit of measurement is displayed on the

Parameter LEDs .

2. Change the value with the Setting buttons

A short button pressure will vary the set point by

one single step, but if a button is kept pressed, the

variation will progress automatically in the selected

direction, with an acceleration factor proportional

to the pressure time

3. Wait 4 seconds to store and activate the new

set point

When the change is confirmed, the Numeric

display stops blinking and gets back to the

measurement visualization active before entering

the edit operation

NOTICE

During the Set points editing (while the Numeric

display is blinking), any pressure of the Parameter

button is inhibited, therefore changing the

measurement selected is impossible. To do that, wait

till the end of the edit operation

4.3.2 Operating Modes

Referring to Figure 10 (in case of plug-connected

models) and to Figure 11 (in case of terminalconnected models), use the Setting buttons to

change the Operating mode from On (factory default)

to Off or vice versa.

4.3.2.1 On Off

1. Press shortly one of the Setting buttons

The actual set point is shown (blinking) for 4

seconds on the Numeric display , while the

relative unit of measurement is displayed on the

Parameter LEDs .

2. Change the value with the Down arrow button

, till reaching the minimum set point

The minimum set point can be easily reached

keeping pressed continuously the Down arrow

button

3. A further short pressure of the Down arrow

button sets the Off operating mode

When the operating mode is set to Off, on the

Numeric display the message OFF appears

4. Wait 4 seconds to store and activate the new

operating mode

When the change is confirmed, the message

OFF disappears, so that the Numeric display ,

the Parameters LEDs and the Control mode

Page 10

LEDs are not lit. Only the Power, Status and

Remote LEDs (, and ) remain active

according to what described in par. 4.1.

4.3.2.2 Off On

1. Press shortly the Up arrow button

The Numeric display , the Parameters LEDs

and the Control mode LEDs returns to show the

information according to the last settings before

the Off operating mode selection

2. Change the set point value with the Setting

buttons

After the transition from Off to On operating mode,

the set point (related to the actual control mode) is

equal to the minimum value: change it if

necessary.

4.3.3 Control Modes

Referring to Figure 10 (in case of plug-connected

models) and to Figure 11 (in case of terminalconnected models), short press the Control mode

button to select the desired control mode, following

this logical flow:

If the hydraulic working point requires the circulator to

be operated at a working point that exceeds the

electric power limits, then the target head will be derated to remain within the maximum power limitation

curve.

4.3.3.2 Proportional Pressure (Head)

The circulator pressure is continuously

increased/decreased depending on the

increased/decreased flow demand;

for setting up the desired maximum head of the pump

(H

), see par. 4.3.1.

set

When Proportional Pressure is the selected control

mode, the indicator is permanently lit

If the hydraulic working point allows the circulator to be

operated by regulating the head within the electric

power limits, then the target head will coincide with the

desired (set) head.

If the hydraulic working point requires the circulator to

be operated at a working point that exceeds the

electric power limits, then the target head will be derated to remain within the maximum power limitation

curve.

NOTICE

All the control modes can be combined with the Night

Mode function (see par. 4.3.4.1)

4.3.3.1 Constant Pressure (Head)

The circulator maintains a constant pressure at any

flow demand;

for setting up the desired head of the pump (H

), see

set

par. 4.3.1.

When Constant Pressure (which is the factory setting)

is the selected control mode, the indicator is

permanently lit

If the hydraulic working point allows the circulator to be

operated by regulating the head within the electric

power limits, then the target head will coincide with the

desired (set) head.

4.3.3.3 Fixed speed

The circulator maintains a fixed speed at any flow

demand;

for setting up the desired speed of the pump, see par.

4.3.1.

When Fixed Speed is the selected control mode, the

indicator is permanently lit

If the hydraulic working point allows the circulator to be

operated by regulating the speed within the electric

power limits, then the target speed will coincide with

the desired (set) speed.

If the hydraulic working point requires the circulator to

be operated at a working point that exceeds the

electric power limits, then the target speed will be derated to remain within the maximum power limitation

curve.

4.3.4 Special Functions

4.3.4.1 Night Mode

The Night Mode function cannot be used in cooling

systems.

Prerequisites:

The circulator is installed in the supply line

Page 11

10

11

The “night condition” can be detected with

good confidence if a higher-level control

system is set to change the supply

temperature

When Night Mode is active, by short pressing the

Control mode button as described in par. 4.3.3, the

Once the lock is active, by pressing any button the

drive displays the symbol (10) or (11);

unlocking the Control Panel, the drive will display the

symbol (10) or (11).

indicator is permanently lit

The Night Mode can be active in combination with

each one of the Control Modes described in par. 4.3.3

This function reduces the power consumption of the

circulator to the minimum when the heating system is

not running; an algorithm detects the proper working

conditions and automatically adjusts the speed of the

pump.

The pump returns to the original set point as soon as

the heating system restarts.

4.3.4.2 Air Purge

At each power-on, the drive performs (factory default)

an automatic Air Purge procedure, with the aim of

flushing air pockets from the circulator housing.

The Air Purge cycle will run the pump at fixed speed

for a predetermined length of time, followed by a

shorter period of minimum speed; this cycle will be

repeated 4 times (in total around 60sec), with the

message 4dG (10) or 4DEG (11) reporting the

corresponding decrementing counter (as described in

par. 3).

Referring to Figure 10 (in case of plug-connected

models) and to Figure 11 (in case of terminalconnected models),

the Air Purge can be skipped or started up (at

any time) by short pressing (for around 2 sec)

both the Setting buttons (Up and Down

arrow) together

the Air Purge can be permanently enabled or

disabled (at any time) by long pressing (for at

least 10sec) both the Setting buttons (Up

and Down arrow) together: by this operation, in

case of Air Purge initially enabled (factory

default), after 10sec the drive will display the

message DGOf (11). On the contrary, in

case of Air Purge initially disabled, after 10sec

the drive will display the message DGOn

(11).

4.3.4.3 Keypad Lock

Keypad Lock is a function with which the drive disables

all the buttons of the Control Panel, but maintains

running all the indicators and the numeric display.

The Control Panel can be locked/unlocked by pressing

simultaneously, and for two seconds, the Parameter

button and the Up arrow button .

In any case, the drive will automatically lock the user

interface after 10 minutes from the last button

pressure.

On plug-connected models

On terminal-connected models

4.3.5 Sub-Menus (Parameters)

4.3.5.1 Dual Pump Operations settings

Each electronic drive (model ecocirc XLplus only) can

be configured for being coupled with another one, so

that they start working in concert in dual pump

operations.

The dual pump operation is factory configured in case

of a twin-head pump, but can be set up even in case of

a spare part drive or if it’s necessary to have 2x singlehead pumps working in concert.

Prerequisites:

2x single-head pumps available with same part

number

3-wire bus cable, wired through the terminals

, and as described in par. 2.4 and par.

2.5.6, connecting the 2x single-head pumps

For a correct automatic configuration, follow the

subsequent procedure, setting first the pump selected

to be the master of the couple

1. Switch on the power supply to both the pumps

2. After few seconds, the drive will display the

message SIN (10) or SING (11).

3. While this message (“SIN” or “SING”) is

displayed, press shortly one of the Setting

buttons , in order to configure the circulator

as:

Single Head Pump (factory default): the

message SIN (10) or SING (11) is

flashing onto the Numeric Display

Twin (Dual) Slave Pump: the message

TSL (

the Numeric Display

Twin (Dual) Master Pump: the message

TNA (

the Numeric Display

4. Press shortly the Parameter button to

confirm and store the value selected

The Numeric Display stops flashing.

In case of Single Head Pump or Twin

(Dual) Slave Pump, the configuration is

finalized and the drive will proceed to the

next step as described in par. 3, step 2.

Only in case of Twin (Dual) Master

Pump, a new sub-menu is made available

(as described in the next steps) for setting

the dual pump operation

5. After few seconds, the drive will display the

message bUp (10) or bCUP (11).

6. While this message (“BUP” or “BCUP”) is

displayed, press shortly one of the Setting

buttons , in order to configure the dual pump

operation as:

10

) or TUSL (11) is flashing onto

10

) or TUNA (11) is flashing onto

Page 12

12

Backup Operation: the message bUp

(10) or bCUP (11) is flashing onto the

Numeric Display .

In this configuration, only the master pump

runs, while the second pump starts in case

of failure of the master pump.

Alternate Operation (factory default): the

message ALt (10) or ALtE (11) is

flashing onto the Numeric Display .

In this configuration, only one pump runs

at the time. The working time is switched

every 24 hours so that workload is

balanced between both pumps. The

second pump starts immediately in case of

failure.

Parallel Operation: the message PAr

(10) or PArA (11) is flashing onto the

Numeric Display .

In this configuration, both pumps run

simultaneously with the same set point.

The master pump determines the behavior

of the full system and is able to optimize

the performance. To guarantee the

required performance minimizing at the

same time the power consumption, the

master pump starts or stops the second

pump depending on the required head and

flow.

Forced Parallel Operation: the message

FOr (

10

) or FOrC (11) is flashing onto

the Numeric Display .

In this configuration, both pumps always

run simultaneously with the same set

point.

7. Press shortly the Parameter button to

confirm the value selected

The Numeric Display stops flashing: the

configuration is finalized and the drive will

proceed to the next step as described in par.

3, step 2.

Once the master pump is configured, the second pump

(slave) is then automatically configured by the master

pump, to testify it, the Remote (green) LED is

permanently lit.

In case the automatic configuration of the second

pump (slave) did not take effect ( LED not lit),

repeat the above procedure, from step 1 to step 4,

configuring the second pump to be a Twin (Dual)

Slave Pump.

NOTICE

Whenever a couple of pumps, connected in Dual

Pump Operations, are required to communicate

remotely with a BMS or a generic external device, then

the Optional Communication Bus, described in par.

2.5.7, shall be activated through the installation of an

optional module (see par. 2.5.8) exclusively into the

Master pump of the couple

4.3.5.2 Communication settings

Each electronic drive (model ecocirc XLplus only) can

communicate remotely through a built-in RS485 port,

as briefly described in par. 2.5.6.

Referring to Figure 10 (in case of plug-connected

models) and to Figure 11 (in case of terminalconnected models), the communications settings are

accessible following the subsequent procedure.

1. Switch on the power supply to the pump

2. After few seconds, the drive will display the

message CON (10) or CONN (11).

3. While this message (“COM” or “COMM”) is

displayed, press shortly the Parameter button

in order to configure the subsequent

parameters:

Baud Rate: the message bdr (10) or

bAUd (

Display : by mean of it, the

communication port baud rate is set to a

specific value.

Available values for this parameter are:

Protocol12: the message prOt is

displayed onto the Numeric Display : by

mean of it, the user can select a specific

protocol on the communication port.

Available values for this parameter are:

Address: the message Add (10) or

Addr (

Display : by mean of it, the circulator

address is set to a specific value (1 is the

factory default).

Available values for this parameter are:

Module: the message NdL (10) or

NOdU (

Display : by mean of it, the user

specifies the possible presence, into the

drive, of one optional module.

Available values for this parameter are:

4. Press the Parameter button to enter each

sub-menu, thus accessing to the next level.

11

) is displayed onto the Numeric

- 4.8 kbps

- 9.6 kbps (factory default)

- 14.4 kbps

- 19.2 kbps

- 38.4 kbps

- 56.0 kbps

- 57.6 kbps.

- Modbus NOd (factory default)

- Bacnet bAC.

11

) is displayed onto the Numeric

- [1247] (in case of Modbus

protocol)

- [0127] (in case of Bacnet

protocol)

11

) is displayed onto the Numeric

- None NON (10) or NONE (11)

(factory default)

- Wireless UFI (10) or UIFI (11)

- RS485 485

Only on ecocirc XLplus terminal-connected models

Page 13

5. Use the Setting buttons , in order to select

the desired value for every parameter

6. Press the Parameter button to confirm and

store the value selected

7. Press the Control mode button to exit each

sub-menu, thus returning to the previous level

If no buttons are pressed for 10 seconds, then the

pump exits the current menu and continues start-up

procedure. All the parameters changed without

confirmation are restored at former state.

4.3.5.3 Differential Pressure Sensor

When an external differential pressure is connected to

the circulator, as described in par. 2.5.4, then powering

on the circulator, as described in par. 3, a submenu is

made available for setting the differential pressure

sensor’s parameter.

Referring to Figure 10 (in case of plug-connected

models) and to Figure 11 (in case of terminalconnected models), the differential pressure sensor’s

settings are accessible following the subsequent

procedure.

1. Switch on the power supply to the pump

2. After few seconds, the drive will display the

message PrE (10) or PrES (11).

3. While this message (“PRE” or “PRES”) is

displayed, press shortly the Parameter button

in order to configure the subsequent

parameter:

Type: the message tYP (10) or tYPE

(11) is displayed onto the Numeric Display

: by mean of it, the user can select a

specific differential pressure range.

Available values for this parameter are:

- [01bar] dO1 (factory default)

- [02bar] d02

4. Press the Parameter button to enter each

sub-menu, thus accessing to the next level.

5. Use the Setting buttons , in order to select

the desired value for the parameter

6. Press the Parameter button to confirm and

store the value selected

7. Press the Control mode button to exit each

sub-menu, thus returning to the previous level

If no buttons are pressed for 10 seconds, then the

pump exits the current menu and continues start-up

procedure. All the parameters changed without

confirmation are restored at former state.

Page 14

Alarm

code

Description

Cause

A01

Water probe alarm

Fluid sensor

anomaly

A02

Water over-temperature

alarm

High temperature

on the fluid

A05

Data memory alarm

Data memory

corrupted

A06

External water temp.

probe alarm

External

temperature probe

anomaly

A07

Pressure sensor alarm

External pressure

sensor anomaly

A12

Twin pump

communication alarm

Twin pump

communication

lost

A20

Internal alarm

Error

code

Description

Cause

E01

Internal communication

error

Internal

communication

lost

E02

Motor overload error

High motor current

E03

DC-bus overvoltage error

DC-bus

overvoltage

E04

Trip control error

Motor stall

E05

EEPROM Data memory

error

EEPROM Data

memory corrupted

E06

Grid voltage error

Voltage supply out

of operating range

E07

Motor winding

temperature error

Motor thermal

protection trip

E08

Power module

temperature error

Inverter thermal

protection trip

E09

Generic Hardware error

Hardware error

E10

Dry-run error

Dry run detection

5 Fault finding

Referring to Figure 10 (in case of plug-connected

models) and to Figure 11 (in case of terminalconnected models), as briefly described in par. 4.1

In case of any alarm that allows the pump

to continue running, the display shows

alternatively alarm code (see par. 5.1) and

last quantity selected, while the status

indicator becomes orange

In case of a failure that stops the pumps,

the display shows the error code (see par.

5.2) permanently and the status indicator

becomes red

5.1 Alarm codes

5.2 Error codes

Page 15

6 Accessories

6.1 External Temperature Sensor

As briefly described in par. 2.5.5, the circulator can be

equipped with an external KTY83 temperature probe

(1KΩ at 25C), with the purpose of measuring an

absolute or a differential water temperature, in

temperature dependent / influenced control modes.

6.1.1 Water Temperature dependent

Control Modes – Setting parameters

The subset of parameters collected in Parameters

Table 2 (described in par. 8.2.1.2) is devoted to set the

Water Temperature dependent Control Modes; in

particular:

0x0030 - Temperature Control Mode

Defines if there’s a dependency of the control

modes on the temperature, and which kind of

dependency

o [= 0] None of the standard control mode

(described in par. 4.3.3) is affected or

influenced by the water temperature

o [= 1] The control modes usually

managing the differential pressure control,

Constant Pressure [ConstP] (see par.

4.3.3.1) and Proportional Pressure

[PropP] (see par. 4.3.3.2), are influenced

by water temperature ([ConstP]/T and

[PropP]/T)

o [= 2] The active control mode is

Constant Absolute Temperature [ConstT]

or Constant Differential Temperature

[ConstT], depending on the value of

Parameter “0x0033 – Temperature Probe”

0x0031 – Absolute Temperature Setpoint

The set-point followed by the system when

operating in Constant Absolute Temperature

[ConstT]

0x0032 – Differential Temperature Setpoint

The set-point followed by the system when

operating in Constant Differential Temperature

[ConstT]

0x0033 – Temperature Probe

Defines which temperature probe must be

considered as input for the temperaturedependent control mode selected

o [= 0] The control mode uses the internal

temperature probe’s input signal

o [= 1] The control mode uses the

auxiliary (external) temperature sensor’s

input signal (the external temperature

sensor must be connected)

o [= 2] The control mode calculates the

differential temperature between the

internal and the external sensor, and uses

the differential temperature as input signal

(the external temperature sensor must be

connected)

0x0034 – Temperature Slope

Defines how the Head set-point (when

ConstantΔP/T or PropΔP/T control modes are

active) reacts to the water temperature’s

increase/decrease

o [= 0] The Head set-point increases

when the temperature increases

o [= 1] The Head set-point decreases

when the temperature increases

0x0035 – Kp for Temperature Control

Is the proportional constant used in the PIregulator which leads the temperature control

0x0036 – Ki for Temperature Control

Is the integral constant used in the PI-regulator

which leads the temperature control

0x0037 – Temperature Control sampling time

Sampling time used in the temperature control

6.1.2 Water Temperature dependent

Control Modes

Using the setting parameters described in par. 6.1.1,

the Water Temperature dependent Control Modes are

then the following:

6.1.2.1 Constant Absolute Temperature [ConstT]

This control mode ensures a constant water

temperature. Constant temperature is a comfort control

mode that can be used in domestic hot-water systems

to control the flow to maintain a fixed temperature in

the system

In this control mode, the basic assumption is that the

circulator regulates (following the feedback of the

internal or external temperature sensor) the water

temperature in a point, on the return pipe of the

system, as close as possible to the consumer

(radiator, heat exchanger, …).

It is then clear that the ConstT control mode can be

deployed in the subsequent possible application

o ConstT for heating applications, using internal

temp. sensor

In this application the pump is installed in the

return pipe, and utilizes the internal temp. sensor

According to what described in par. 6.1.1, the

necessary correspondent settings are:

- 0x0030 - Temperature Control Mode = 2

- 0x0031 – Absolute Temperature Setpoint =

desired value in the range [20°C ÷ 110°C]

- 0x0033 – Temperature Probe = 0

- 0x0034 – Temperature Slope = 1

Page 16

o ConstT, for heating applications, using

external temp. sensor

In this application the pump is installed in the flow

pipe, and utilizes the external temp. sensor

According to what described in par. 6.1.1, the

necessary correspondent settings are:

- 0x0030 - Temperature Control Mode = 2

- 0x0031 – Absolute Temperature Setpoint =

desired value in the range [20°C ÷ 110°C]

- 0x0033 – Temperature Probe = 1

- 0x0034 – Temperature Slope = 1

o ConstT, in cooling applications, using internal

temp. sensor

In this application the pump is installed in the

return pipe, and utilizes the internal temp. sensor

According to what described in par. 6.1.1, the

necessary correspondent settings are:

- 0x0030 - Temperature Control Mode = 2

- 0x0031 – Absolute Temperature Setpoint =

desired value in the range [-10°C ÷ 19°C]

- 0x0033 – Temperature Probe = 0

- 0x0034 – Temperature Slope = 0

o ConstT, in cooling applications, using external

temp. sensor

In this application the pump is installed in the flow

pipe, and utilizes the external temp. sensor

According to what described in par. 6.1.1, the

necessary correspondent settings are:

- 0x0030 - Temperature Control Mode = 2

- 0x0031 – Absolute Temperature Setpoint =

desired value in the range [-10°C ÷ 19°C]

- 0x0033 – Temperature Probe = 1

- 0x0034 – Temperature Slope = 0

6.1.2.2 Constant Differential Temperature

[ConstΔT]

This control mode keeps the differential temperature of

the pumped liquid constant, changing the flow rate to

maintain the user-settable set-point

In this case, it’s unnecessary to discriminate between

heating and cooling application, because the

differential temperature is considered as absolute

value.

According to what described in par. 6.1.1, the

necessary correspondent settings are:

- 0x0030 - Temperature Control Mode = 2

- 0x0032 – Differential Temperature Setpoint =

desired value

- 0x0033 – Temperature Probe = 2

6.1.2.3 Constant pressure depending on water

temperature [ConstΔP/T]

In this control mode the drive alters the differential

pressure set-point the pump has to maintain,

depending on the measured fluid temperature, as

depicted in Figure 3

Figure 3

Referring to Figure 3

Tmin = 20C

Tmax = Absolute Temperature Setpoint (par.

0x0031)

Hsmin = 30% of Hsmax

Hsmax = Constant pressure set-point (settable

via User Interface, see par. 4.3.3.1)

The ConstΔP/T control mode can be evidently

deployed in the subsequent possible application

o ConstΔP/T, positive relation P/T, using internal

temp. sensor

According to what described in par. 6.1.1, the

necessary correspondent settings are:

- 0x0030 - Temperature Control Mode = 1

- 0x0031 – Absolute Temperature Setpoint =

desired value

- 0x0033 – Temperature Probe = 0

- 0x0034 – Temperature Slope = 0

- Control Mode = Constant Pressure (settable

via User Interface)

- Constant Pressure Setpoint = desired value

o ConstΔP/T, negative relation P/T, using internal

temp. sensor

According to what described in par. 6.1.1, the

necessary correspondent settings are:

- 0x0030 - Temperature Control Mode = 1

- 0x0031 – Absolute Temperature Setpoint =

desired value

- 0x0033 – Temperature Probe = 0

- 0x0034 – Temperature Slope = 1

- Control Mode = Constant Pressure (settable

via User Interface)

- Constant Pressure Setpoint = desired value

o ConstΔP/T, positive relation P/T, using external

temp. sensor

According to what described in par. 6.1.1, the

necessary correspondent settings are:

- 0x0030 - Temperature Control Mode = 1

- 0x0031 – Absolute Temperature Setpoint =

desired value

- 0x0033 – Temperature Probe = 1

- 0x0034 – Temperature Slope = 0

- Control Mode = Constant Pressure (settable

via User Interface)

- Constant Pressure Setpoint = desired value

Page 17

o ConstΔP/T, negative relation P/T, using

external temp. sensor

According to what described in par. 6.1.1, the

necessary correspondent settings are:

- 0x0030 - Temperature Control Mode = 1

- 0x0031 – Absolute Temperature Setpoint =

desired value

- 0x0033 – Temperature Probe = 1

- 0x0034 – Temperature Slope = 1

- Control Mode = Constant Pressure (settable

via User Interface)

- Constant Pressure Setpoint = desired value

6.1.2.4 Proportional pressure depending on

water temperature [PropΔP/T]

In this control mode the drive alters the proportional

pressure set-point the pump has to maintain,

depending on the measured fluid temperature

Referring to Figure 3

Tmin = 20C

Tmax = Absolute Temperature Setpoint (par.

0x0031)

Hsmin = 30% of Hsmax

Hsmax = Proportional pressure set-point

(settable via User Interface, see par. 4.3.3.2)

According to what already described in par. 6.1.2.3,

even the PropΔP/T control mode can be evidently

deployed in the subsequent possible application

o PropΔP/T, positive relation P/T, using internal

temp. sensor

According to what described in par. 6.1.1, the

necessary correspondent settings are:

- 0x0030 - Temperature Control Mode = 1

- 0x0031 – Absolute Temperature Setpoint =

desired value

- 0x0033 – Temperature Probe = 0

- 0x0034 – Temperature Slope = 0

- Control Mode = Proportional Pressure

(settable via User Interface)

- Proportional Pressure Setpoint = desired value

o PropΔP/T, negative relation P/T, using internal

temp. sensor

According to what described in par. 6.1.1, the

necessary correspondent settings are:

- 0x0030 - Temperature Control Mode = 1

- 0x0031 – Absolute Temperature Setpoint =

desired value

- 0x0033 – Temperature Probe = 0

- 0x0034 – Temperature Slope = 1

- Control Mode = Proportional Pressure

(settable via User Interface)

- Proportional Pressure Setpoint = desired value

o PropΔP/T, positive relation P/T, using external

temp. sensor

According to what described in par. 6.1.1, the

necessary correspondent settings are:

- 0x0030 - Temperature Control Mode = 1

- 0x0031 – Absolute Temperature Setpoint =

desired value

- 0x0033 – Temperature Probe = 1

- 0x0034 – Temperature Slope = 0

- Control Mode = Proportional Pressure

(settable via User Interface)

- Proportional Pressure Setpoint = desired value

o PropΔP/T, negative relation P/T, using external

temp. sensor

According to what described in par. 6.1.1, the

necessary correspondent settings are:

- 0x0030 - Temperature Control Mode = 1

- 0x0031 – Absolute Temperature Setpoint =

desired value

- 0x0033 – Temperature Probe = 1

- 0x0034 – Temperature Slope = 1

- Control Mode = Proportional Pressure

(settable via User Interface)

- Proportional Pressure Setpoint = desired value

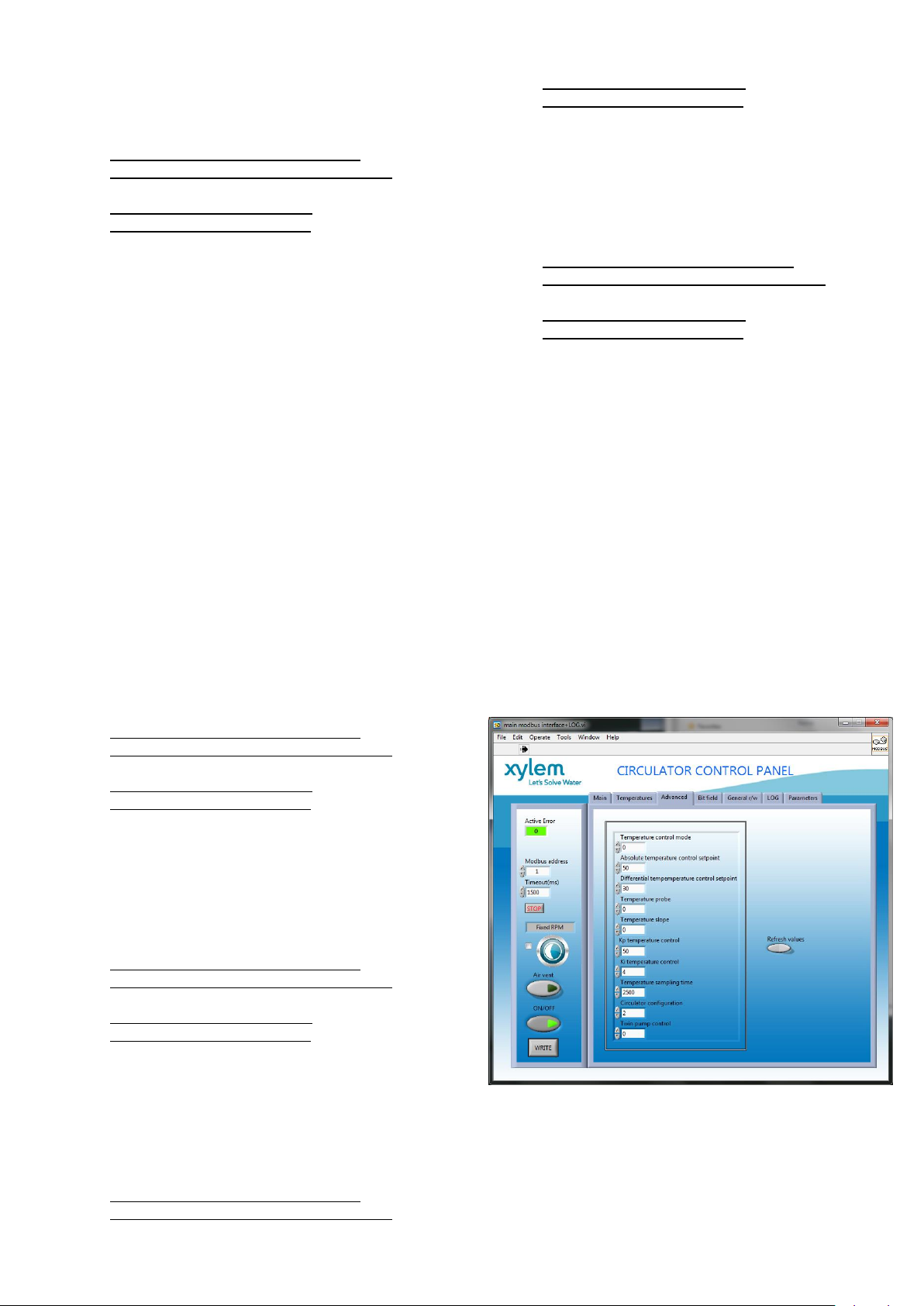

6.1.3 Water Temperature dependent

Control Modes – Circulator Control

Panel

In order to configure the desired Temperaturedependent control mode using Circulator Control

Panel, refer to the Advanced Tab

6.1.3.1 Advanced Tab

Collects two subset of parameters:

The subset used for advanced settings, as

described in this technical sheet at par. 8.2.1.2

The subset used for twin pump settings, as

described in this technical sheet at par. 8.2.1.3

Page 18

6.2 Wireless Module

Referring to Figure 12, once the module is connected,

is necessary to configure it by setting the parameter

“Module” to the value “Wireless”, as described in par.

4.3.5.2.

6.2.1 Wireless module use

When the wireless module is assembled into ecocirc

XLplus, and correctly configured, it generates a (type

902.11n) wireless network accessible (by a mobile,

tablet or a PC) using data (S/N and PWD) printed on

the label sticked on the side of the circulator’s drive

In particular,

Network name: “ecocircxl___S/N___” where

S/N is a 8 character word

Password: “xylem___PWD___” where PWD is

a 8 character word

To access then the circulator’s web pages using a

browser (on the external device connected), use the

web address “https://xylemecoxl” or type directly

“192.168.1.10”

6.3 RS485 Module

Referring to Figure 12, once the module is connected,

is necessary to configure it by setting the parameter

“Module” to the value “RS485”, as described in par.

4.3.5.2

Page 19

7 Appendix 1

Figure 4

Figure 5

Page 20

1

2

3

L

N

10 A

Figure 6

Figure 7

Page 21

4

5

7 8 9

11

12

13 14

16

17

18 19 20

21

P+

S+T+ T- S-

B A

G

N

D

P-

C

NO

Start / Stop

B

A

10

L N

C NO S+ P+ P- T+ T-15V B A GND B AS- GND

Start / Stop

Figure 8

Figure 9

Page 22

Figure 10

Figure 11

Figure 12

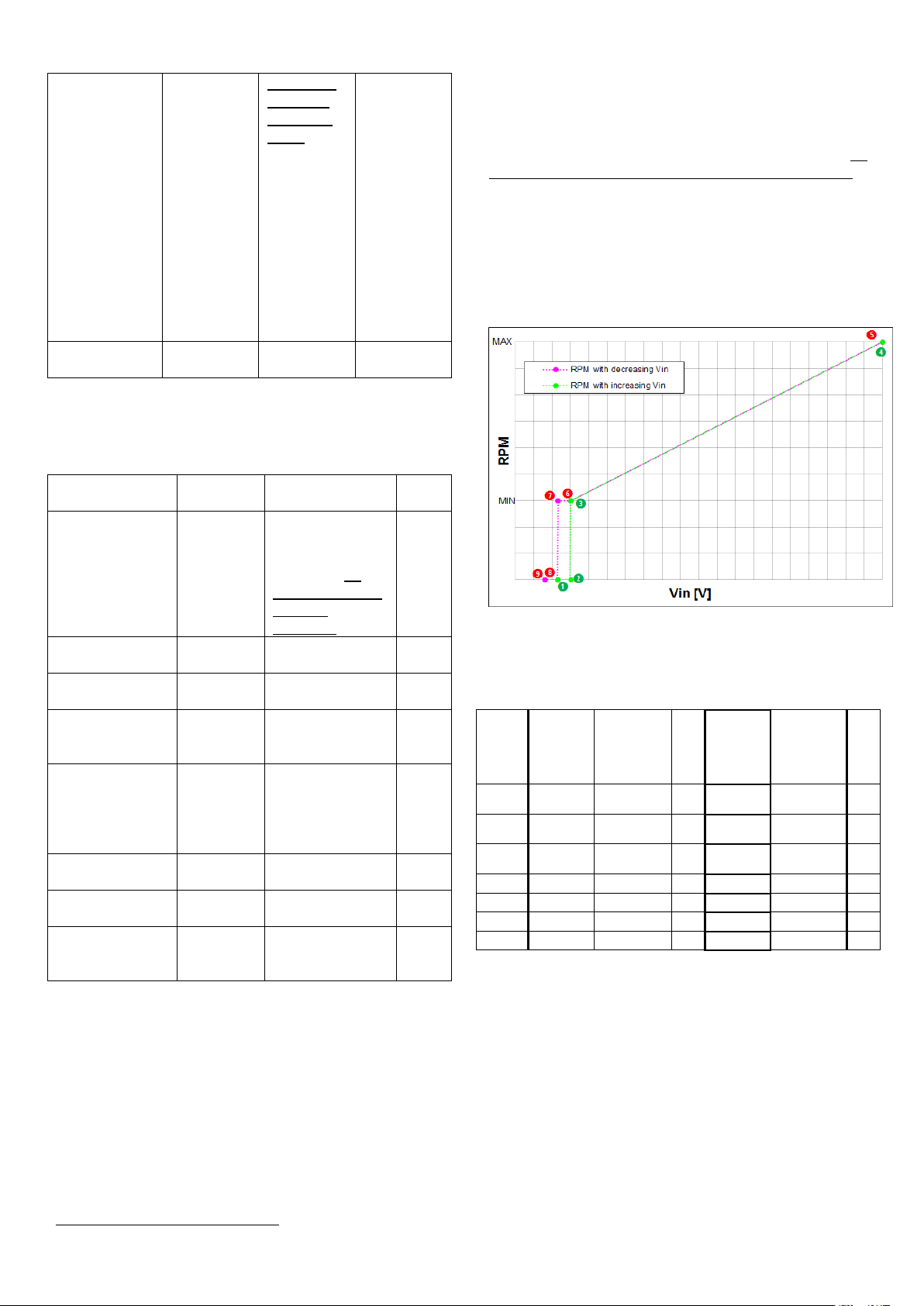

Page 23

MB. ADDRESS

(HEX)

PARAMETER DESCRIPTION

0x0000

OPERATING MODE

0 = OFF

1 = ON

0x0001

CONTROL MODE

1 = CONSTANT PRESSURE

2 = PROPORTIONAL PRESSURE

3 = CONSTANT CURVE

0x0002

NIGHT-MODE ACTIVATION

0 = NOT ACTIVE

1 = ACTIVE

0x0003

AIR VENTING PROCEDURE

0 = NOT ACTIVE

1 = ACTIVE

0x0004

PROPORTIONAL PRESSURE SETPOINT

(for CONTROL MODE = 2)

0x0005

CONSTANT PRESSURE SETPOINT

(for CONTROL MODE = 1)

0x0006

CONSTANT CURVE SETPOINT

(for CONTROL MODE = 3)

0x0007

AIR VENTING POWER ON

0 = NOT ACTIVE

1 = ACTIVE

MB. ADDRESS

(HEX)

PARAMETER DESCRIPTION

0x0030

TEMPERATURE CONTROL MODE

0 = NOT ACTIVE

1 = PROP. TEMPERATURE TO HEAD

2 = CONSTANT TEMPERATURE

0x0031

ABSOLUTE TEMPERATURE SETPOINT

0x0032

DIFFERENTIAL TEMPERATURE SETPOINT

0x0033

TEMPERATURE PROBE

0 = INTERNAL

1 = EXTERNAL

2 = DIFFERENTIAL

0x0034

TEMPERATURE SLOPE

0 = INCREASING

1 = DECREASING

0x0035

KP FOR TEMPERATURE CONTROL

0x0036

KI FOR TEMPERATURE CONTROL

0x0037

TEMPERATURE CONTROL SAMPLING TIME

MB. ADDRESS

(HEX)

INFORMATION DESCRIPTION

0x0200

INPUT POWER

0x0201

HEAD [H]

0x0202

FLOW [Q]

0x0203

SPEED

0x0204

WATER TEMPERATURE

MB. ADDRESS

(HEX)

PARAMETER DESCRIPTION

0x0060

CIRCULATOR CONFIGURATION

0 = TWIN MASTER

1 = TWIN SLAVE

2 = SINGLE

0x0061

TWIN PUMPS CONTROL MODE

0 = BACKUP

1 = ALTERNATE

2 = PARALLEL

8 Appendix 2 – Modbus

registers

8.1 Data Organization

The drive offers the below Modbus Virtual Memory

(see par. 8.2), based on a data set that can be divided

into 2 main subsets:

Parameters, that is “Readable and Writable”

data [R/W] used for setting a specific

behaviour, activating a function, writing data,

etc. inside the drive.

Information, that is “Readable” data [R], used

for acquiring values or feedbacks from the

drive

8.2 Modbus Virtual Memory

The complete data-set managed by the ecocirc XLplus

is accessible considering a Modbus Virtual Memory

made exclusively of Holding Registers, representing

both Parameters and Information: readable and

writable the Parameters, readable only the Information.

For a detailed description of the Modbus Virtual

Memory organization, refer to the related document

“ecocircXL - Modbus Parameters Table”.

8.2.1 Parameters Tables

8.2.1.1 Parameters Table 1

It is a set of parameters [R/W] used for standard

settings: generally the same operations or functions a

user can perform/activate through the user interface.

8.2.1.2 Parameters Table 2

It is a set of parameters [R/W] used for advanced

settings: these operations or functions cannot be

performed/activated through the user interface

8.2.1.3 Parameters Table 3

It is a set of parameters [R/W] used for twin pump

settings.

8.2.2 Information Tables

8.2.2.1 Information Table 1

It is a set of information [R] used for standard use:

generally the same data a user can acquire through

the user interface

Page 24

0x0205

EXTERNAL WATER TEMPERATURE

0x0206

WINDING 1 TEMPERATURE

0x0207

WINDING 2 TEMPERATURE

0x0208

WINDING 3 TEMPERATURE

0x0209

POWER MODULE TEMPERATURE

0x020A

QUADRATURE CURRENT

0x020B

BIT FIELDS STATUS I/O

0x020C

BIT FIELDS ALARM 1

0x020D

BIT FIELDS ALARM 2

0x020E

BIT FIELDS ERRORS

0x020F

ACTIVE ERROR CODE

MB. ADDRESS

(HEX)

INFORMATION DESCRIPTION

0x0230

MODBUS SLAVE ADDRESS

0x0231

WI-FI CLIENT/SERVER CONFIGURATION

0 = SERVER

1 = CLIENT

0x0232

PRESSURE SENSOR MODEL

0 = DIFF. PRESSURE SENSOR / Range 0 ÷ 1.0bar

1 = DIFF. PRESSURE SENSOR / Range 0 ÷ 2.0bar

0x0233

PROPORTIONAL PRESSURE MIN SETPOINT

0x0234

PROPORTIONAL PRESSURE MAX SETPOINT

0x0235

CONSTANT PRESSURE MIN SETPOINT

0x0236

CONSTANT PRESSURE MAX SETPOINT

0x0237

CONSTANT CURVE MIN SETPOINT

0x0238

CONSTANT CURVE MAX SETPOINT

0x0239

COMMUNICATION PROTOCOL

0 = MODBUS

1 = BACNET

0x023A

BAUD RATE

MB. ADDRESS

(HEX)

INFORMATION DESCRIPTION

0x0260

TWIN SLAVE DRIVEN CURVE

0x0261

TWIN SLAVE START/STOP

0 = STOP

1 = START

0x0262

TWIN SLAVE INPUT POWER

0x0263

TWIN SLAVE HEAD [H]

0x0264

TWIN SLAVE FLOW [Q]

0x0265

TWIN SLAVE SPEED

0x0266

TWIN SLAVE WINDING 1 TEMPERATURE

0x0267

TWIN SLAVE WINDING 2 TEMPERATURE

0x0268

TWIN SLAVE WINDING 3 TEMPERATURE

0x0269

TWIN SLAVE POWER MODULE TEMPERATURE

0x026A

TWIN SLAVE QUADRATURE CURRENT

0x026B

TWIN SLAVE BIT FIELDS ALARM 1

0x026C

TWIN SLAVE BIT FIELDS ALARM 2

0x026D

TWIN SLAVE BIT FIELDS ERRORS

8.2.2.2 Information Table 2

It is a set of information [R] used for advanced use:

generally these data cannot be accessed through the

user interface.

8.2.2.3 Information Table 3

It is a set of information [R] used for twin pump use:

generally these data cannot be accessed through the

user interface, and are available to the Twin Master for

managing the pump: in fact this table is visible only in

case the drive is configured as a Twin Pump Master

(see par. 4.3.5.1)

Page 25

1

Xylem Service Italia s.r.l.

Via Vittorio Lombardi, 14

Montecchio Maggiore VI

36075

Italy

Tel: (+39) 0444 707111

Fax: (+39) 0444 492166 ©2013 Xylem Inc.

Loading...

Loading...