Page 1

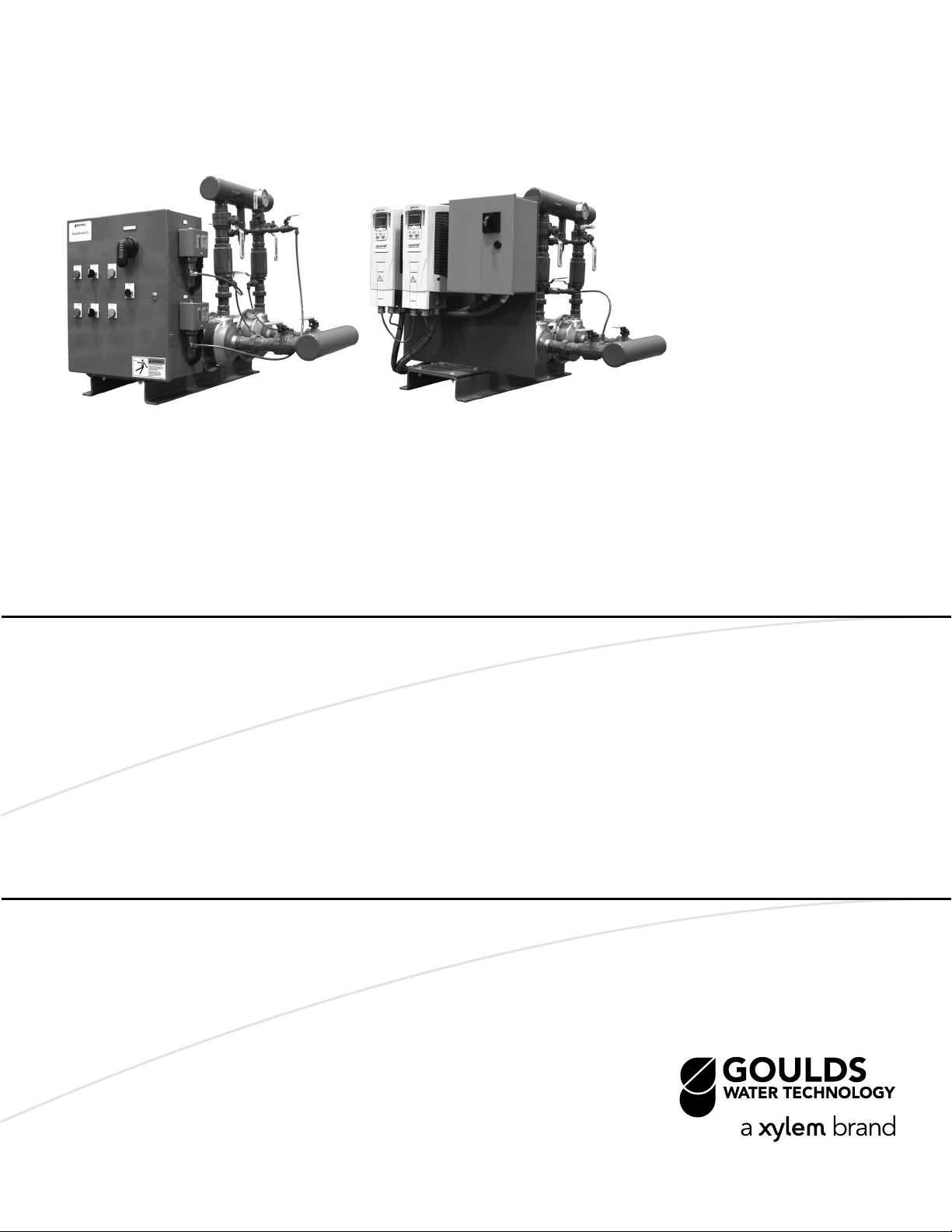

Installation,

Constant Speed Variable Speed

Operation, and

Maintenance Manual

AquaBoost CS and VS Pumping

Packages

Page 2

Page 3

Table of Contents

Introduction and Safety.........................................................................................................................3

Introduction..........................................................................................................................................3

Safety.....................................................................................................................................................3

Safety terminology and symbols....................................................................................................3

Environmental safety........................................................................................................................4

Recycling guidelines........................................................................................................................5

User safety............................................................................................................................................5

Precautions during work..................................................................................................................5

Wash the skin and eyes....................................................................................................................6

Product warranty.................................................................................................................................6

Transportation and Storage..................................................................................................................7

Inspect the delivery.............................................................................................................................7

Inspect the package.........................................................................................................................7

Inspect the unit..................................................................................................................................7

Transportation guidelines..................................................................................................................7

Lifting methods.................................................................................................................................7

Storage guidelines..............................................................................................................................7

Storage location................................................................................................................................7

Long-term storage............................................................................................................................7

Table of Contents

Product Description...............................................................................................................................9

General description............................................................................................................................9

Operational limits.............................................................................................................................9

Package information........................................................................................................................9

Nameplate information....................................................................................................................12

Owner's information......................................................................................................................13

Installation.............................................................................................................................................14

Field connections..............................................................................................................................14

Field piping diagrams....................................................................................................................15

Wiring diagrams.............................................................................................................................19

Earth (ground) connections.............................................................................................................25

Pump package location guidelines................................................................................................25

Foundation requirements................................................................................................................25

Level the base on a concrete foundation.......................................................................................26

Connect the optional storage tank.................................................................................................26

Connect the optional low-suction pressure switch.......................................................................27

Piping checklist..................................................................................................................................27

Fastening.........................................................................................................................................28

Commissioning, Startup, Operation, and Shutdown......................................................................29

Preparation for startup.....................................................................................................................29

Final installation checks.................................................................................................................29

Final adjustments............................................................................................................................30

Pump package operation description............................................................................................32

Constant speed operation............................................................................................................32

Variable speed operation..............................................................................................................37

Maintenance.........................................................................................................................................38

Precautions.........................................................................................................................................38

Monthly maintenance.......................................................................................................................38

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 1

Page 4

Table of Contents

Troubleshooting...................................................................................................................................39

Pump station troubleshooting.........................................................................................................39

The pump station does not power up.........................................................................................39

The station powers up, but the pumps do not run....................................................................39

The pumps run but do not build desired pressure....................................................................40

The pump station experiences excessive vibration...................................................................41

The pump station does not shut down and no water is used...................................................41

The pump station cycles or hunts erratically...............................................................................42

Other Relevant Documentation or Manuals.....................................................................................43

Manuals for AquaBoost components.............................................................................................43

2 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 5

Introduction and Safety

Introduction

Purpose of this manual

The purpose of this manual is to provide necessary information for:

• Installation

• Operation

• Maintenance

CAUTION:

Read this manual carefully before installing and using the product. Improper use of the

product can cause personal injury and damage to property, and may void the warranty.

NOTICE:

Save this manual for future reference, and keep it readily available at the location of the

unit.

Introduction and Safety

Safety

WARNING:

• The operator must be aware of safety precautions to prevent physical injury.

• Any pressure-containing device can explode, rupture, or discharge its contents if it is

over-pressurized. Take all necessary measures to avoid over-pressurization.

• Operating, installing, or maintaining the unit in any way that is not covered in this manual

could cause death, serious personal injury, or damage to the equipment. This includes

any modification to the equipment or use of parts not provided by Xylem. If there is a

question regarding the intended use of the equipment, please contact an Xylem

representative before proceeding.

• This manual clearly identifies accepted methods for disassembling units. These methods

must be adhered to. Trapped liquid can rapidly expand and result in a violent explosion

and injury. Never apply heat to impellers, propellers, or their retaining devices to aid in

their removal.

• Do not change the service application without the approval of an authorized Xylem

representative.

CAUTION:

You must observe the instructions contained in this manual. Failure to do so could result in

physical injury, damage, or delays.

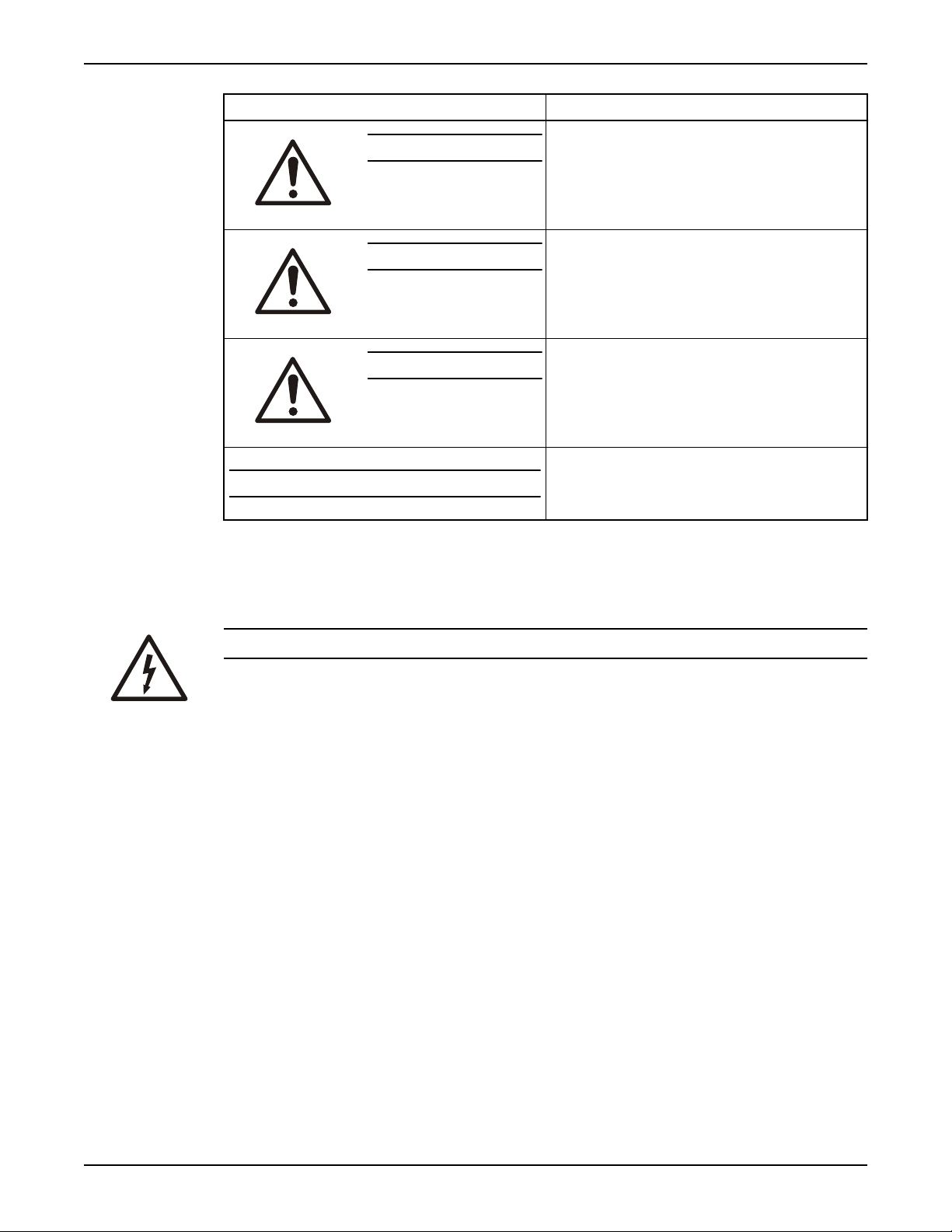

Safety terminology and symbols

About safety messages

It is extremely important that you read, understand, and follow the safety messages and

regulations carefully before handling the product. They are published to help prevent

these hazards:

• Personal accidents and health problems

• Damage to the product

• Product malfunction

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 3

Page 6

Introduction and Safety

Hazard levels

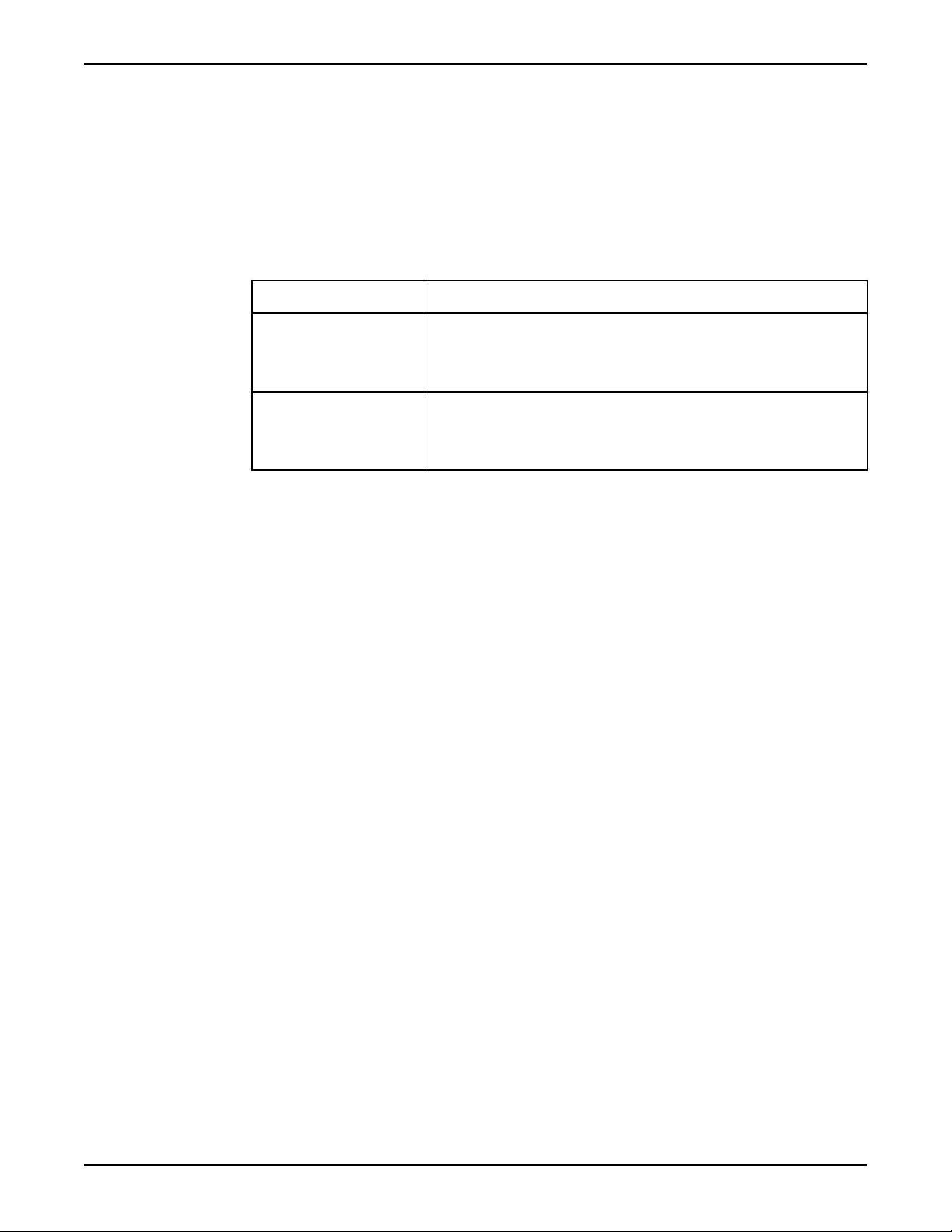

Hazard level Indication

Hazard categories

DANGER:

WARNING:

CAUTION:

NOTICE:

Hazard categories can either fall under hazard levels or let specific symbols replace the

ordinary hazard level symbols.

Electrical hazards are indicated by the following specific symbol:

A hazardous situation which, if not avoided, will result in

death or serious injury

A hazardous situation which, if not avoided, could result

in death or serious injury

A hazardous situation which, if not avoided, could result

in minor or moderate injury

• A potential situation which, if not avoided, could

result in undesirable conditions

• A practice not related to personal injury

Electrical Hazard:

These are examples of other categories that can occur. They fall under the ordinary hazard

levels and may use complementing symbols:

• Crush hazard

• Cutting hazard

• Arc flash hazard

Environmental safety

The work area

Always keep the station clean to avoid and/or discover emissions.

Waste and emissions regulations

Observe these safety regulations regarding waste and emissions:

• Appropriately dispose of all waste.

• Handle and dispose of the processed liquid in compliance with applicable

environmental regulations.

• Clean up all spills in accordance with safety and environmental procedures.

• Report all environmental emissions to the appropriate authorities.

4 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 7

Electrical installation

Recycling guidelines

User safety

General safety rules

Introduction and Safety

WARNING:

Do NOT send the product to the Xylem manufacturer if it has been contaminated by any

nuclear radiation. Inform Xylem so that accurate actions can take place.

For electrical installation recycling requirements, consult your local electric utility.

Always follow local laws and regulations regarding recycling.

These safety rules apply:

• Always keep the work area clean.

• Pay attention to the risks presented by gas and vapors in the work area.

• Avoid all electrical dangers. Pay attention to the risks of electric shock or arc flash

hazards.

• Always bear in mind the risk of drowning, electrical accidents, and burn injuries.

Safety equipment

Use safety equipment according to the company regulations. Use this safety equipment

within the work area:

• Hard hat

• Safety goggles, preferably with side shields

• Protective shoes

• Protective gloves

• Gas mask

• Hearing protection

• First-aid kit

• Safety devices

Electrical connections

Electrical connections must be made by certified electricians in compliance with all

international, national, state, and local regulations. For more information about

requirements, see sections dealing specifically with electrical connections.

Precautions during work

NOTICE:

Never operate a unit unless safety devices are installed. Also see specific information

about safety devices in other chapters of this manual.

Observe these safety precautions when you work with the product or are in connection

with the product:

• Never work alone.

• Always wear protective clothing and hand protection.

• Stay clear of suspended loads.

• Always lift the product by its lifting device.

• Beware of the risk of a sudden start if the product is used with an automatic level

control.

• Beware of the starting jerk, which can be powerful.

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 5

Page 8

Introduction and Safety

• Rinse the components in water after you disassemble the pump.

• Do not exceed the maximum working pressure of the pump.

• Do not open any vent or drain valve or remove any plugs while the system is

• Never operate a pump without a properly installed coupling guard.

Wash the skin and eyes

pressurized. Make sure that the pump is isolated from the system and that pressure is

relieved before you disassemble the pump, remove plugs, or disconnect piping.

Follow these procedures for chemicals or hazardous fluids that have come into contact

with your eyes or your skin:

Condition Action

Chemicals or hazardous

fluids in eyes

Chemicals or hazardous

fluids on skin

Product warranty

Coverage

Xylem undertakes to remedy faults in products from Xylem under these conditions:

• The faults are due to defects in design, materials, or workmanship.

• The faults are reported to an Xylem representative within the warranty period.

• The product is used only under the conditions described in this manual.

• The monitoring equipment incorporated in the product is correctly connected and in

use.

• All service and repair work is done by Xylem-authorized personnel.

• Genuine Xylem parts are used.

• Only Ex-approved spare parts and accessories authorized by Xylem are used in Exapproved products.

1. Hold your eyelids apart forcibly with your fingers.

2. Rinse the eyes with eyewash or running water for at least 15 minutes.

3. Seek medical attention.

1. Remove contaminated clothing.

2. Wash the skin with soap and water for at least 1 minute.

3. Seek medical attention, if necessary.

Limitations

The warranty does not cover faults caused by these situations:

• Deficient maintenance

• Improper installation

• Modifications or changes to the product and installation made without consulting

Xylem

• Incorrectly executed repair work

• Normal wear and tear

Xylem assumes no liability for these situations:

• Bodily injuries

• Material damages

• Economic losses

Warranty claim

Xylem products are high-quality products with expected reliable operation and long life.

However, should the need arise for a warranty claim, then contact your Xylem

representative.

6 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 9

Transportation and Storage

Inspect the delivery

Inspect the package

1. Inspect the package for damaged or missing items upon delivery.

2. Note any damaged or missing items on the receipt and freight bill.

3. File a claim with the shipping company if anything is out of order.

If the product has been picked up at a distributor, make a claim directly to the

distributor.

Inspect the unit

1. Remove packing materials from the product.

Dispose of all packing materials in accordance with local regulations.

2. Inspect the product to determine if any parts have been damaged or are missing.

3. If applicable, unfasten the product by removing any screws, bolts, or straps.

For your personal safety, be careful when you handle nails and straps.

4. Contact your sales representative if anything is out of order.

Transportation and Storage

Transportation guidelines

Lifting methods

WARNING:

• Assembled units and their components are heavy. Failure to properly lift and support

this equipment can result in serious physical injury and/or equipment damage. Lift

equipment only at the specifically identified lifting points. Lifting devices such as

eyebolts, slings, and spreaders must be rated, selected, and used for the entire load

being lifted.

• Crush hazard. The unit and the components can be heavy. Use proper lifting methods

and wear steel-toed shoes at all times.

Storage guidelines

Storage location

The product must be stored in a covered and dry location free from heat, dirt, and

vibrations.

NOTICE:

• Protect the product against humidity, heat sources, and mechanical damage.

• Do not place heavy weights on the packed product.

Long-term storage

If the unit is stored for more than 6 months, these requirements apply:

• Store in a covered and dry location.

• Store the unit free from heat, dirt, and vibrations.

• Rotate the pump shaft by hand several times at least every three months.

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 7

Page 10

Transportation and Storage

Treat bearings and machined surfaces so that they are well preserved. Refer to the drive

unit and coupling manufacturers for their long-term storage procedures.

For questions about possible long-term storage treatment services, please contact your

local Xylem sales representative.

8 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 11

Product Description

3

2

4

6

5

1

RS000002

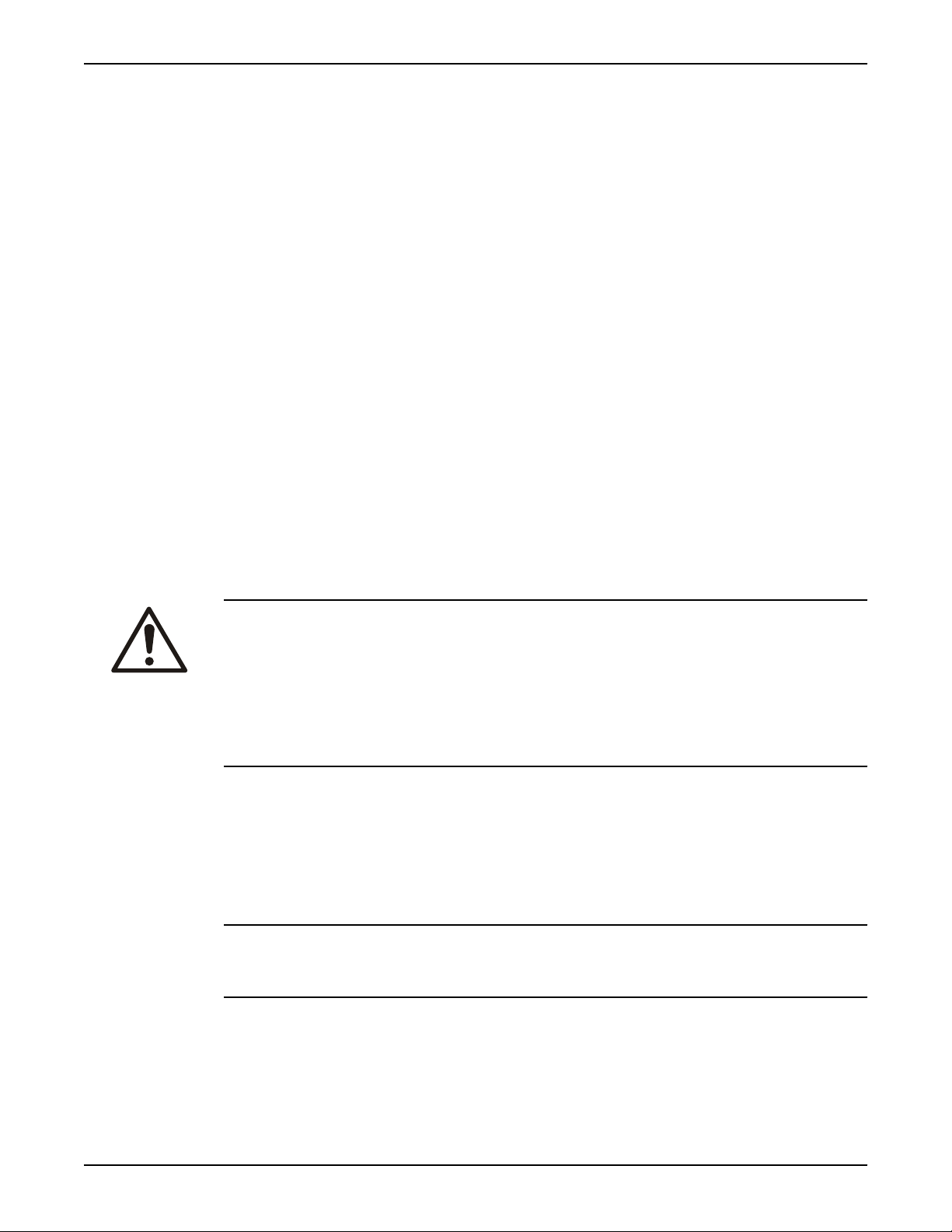

General description

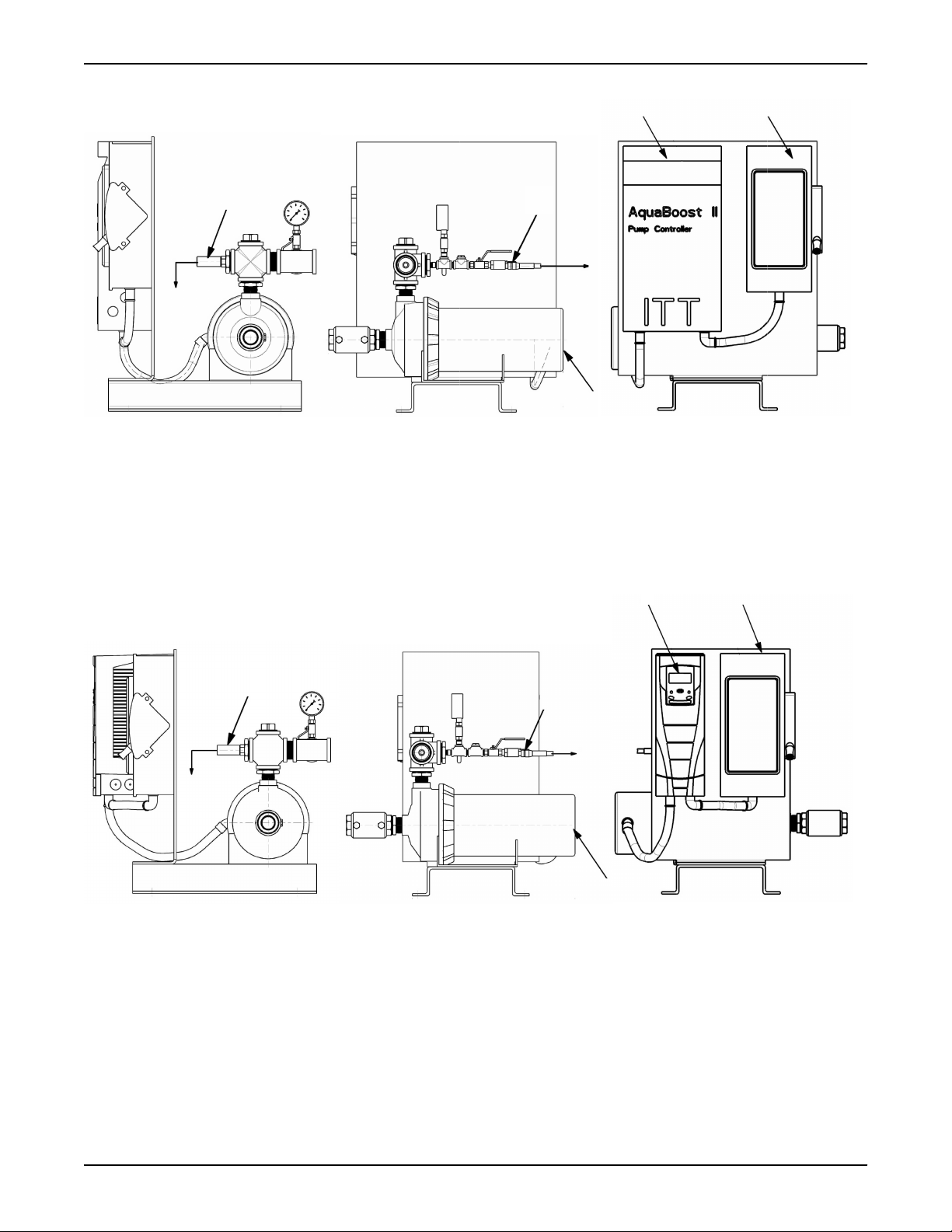

AquaBoost CS pumping package

Depending upon the pumping capacity required, a simplex (one-pump) type or a duplex

(two-pump) type is used. In both types, a pressure switch starts and stops the pump.

The AquaBoost Constant Speed pumping package operates pumps across the line to

increase the domestic water pressure up to 55 psi above that of the city water pressure.

AquaBoost VS pumping package

The AquaBoost Variable Speed pumping package can precisely match the pump

discharge pressure to the system pressure by varying the speed of the pump. This is

accomplished by using the variable-speed controllers such as the AquaBoost II and

Aquavar CPC.

The pressure transducer monitors the system pressure, allowing the controller to start and

regulate the pump speed. AquaBoost VS is available in simplex and duplex configurations.

Operational limits

Ambient temperature and humidity

All electrical equipment is susceptible to failure if operated in ambient temperatures

outside of its rating. Do not operate the unit outside these extremes.

Product Description

Characteristic Specification

Operating temperature range 32°F to 105°F (0°C to 40°C)

Maximum relative humidity 95% non-condensing

Package information

AquaBoost CS simplex

1. Pump: NPE with TEFC motor

2. Control panel with disconnect switch

3. Pressure switch

4. Temperature limit switch

5. Check valve, stainless steel

6. Stainless steel pump trim assembly

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 9

Page 12

3

2

5

4 6

1

RS000003

5

3

2

4

1

6

7

RS000004

Product Description

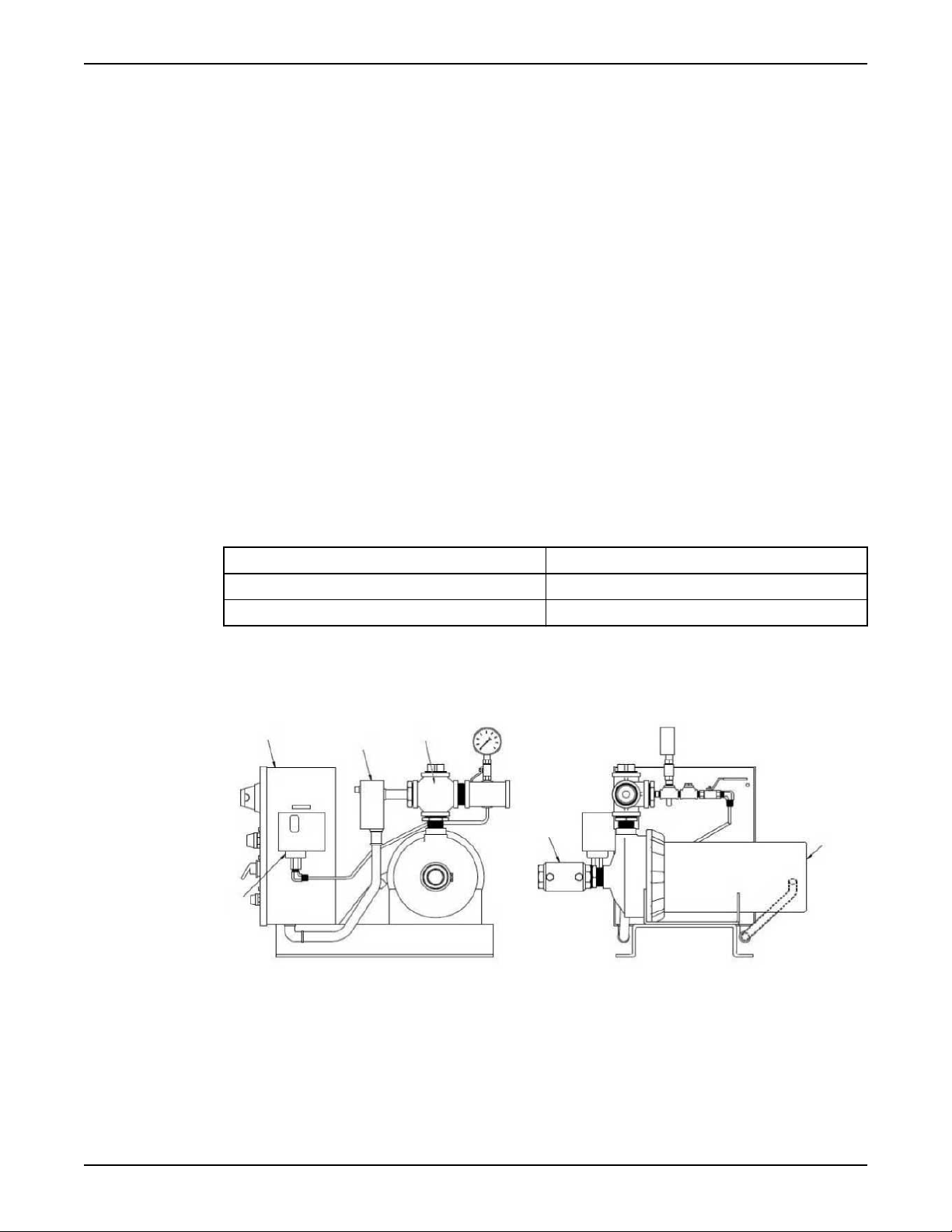

AquaBoost CS duplex

AquaBoost VS simplex

1. Pump: NPE with TEFC motor

2. Control panel with disconnect switch

3. Pressure switch, one per pump

4. Temperature limit switch

5. Discharge header: copper L-type

6. Suction header: copper L-type

This variable-speed configuration uses the AquaBoost II controller model 1151AB2 or 2AB2 (for single-phase

power supply: 115V – 0.75 hp; 230V – 1.5 to 2 hp range).

1. Pump: NPE with TEFC motor

2. AquaBoost II controller

3. Transducer assembly

4. Safety switch

5. Temperature relief valve

6. To drain

7. To controller

10 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 13

5

3

1

2

4

6

7

RS000005

5

3

1

6

7

2

4

RS000006

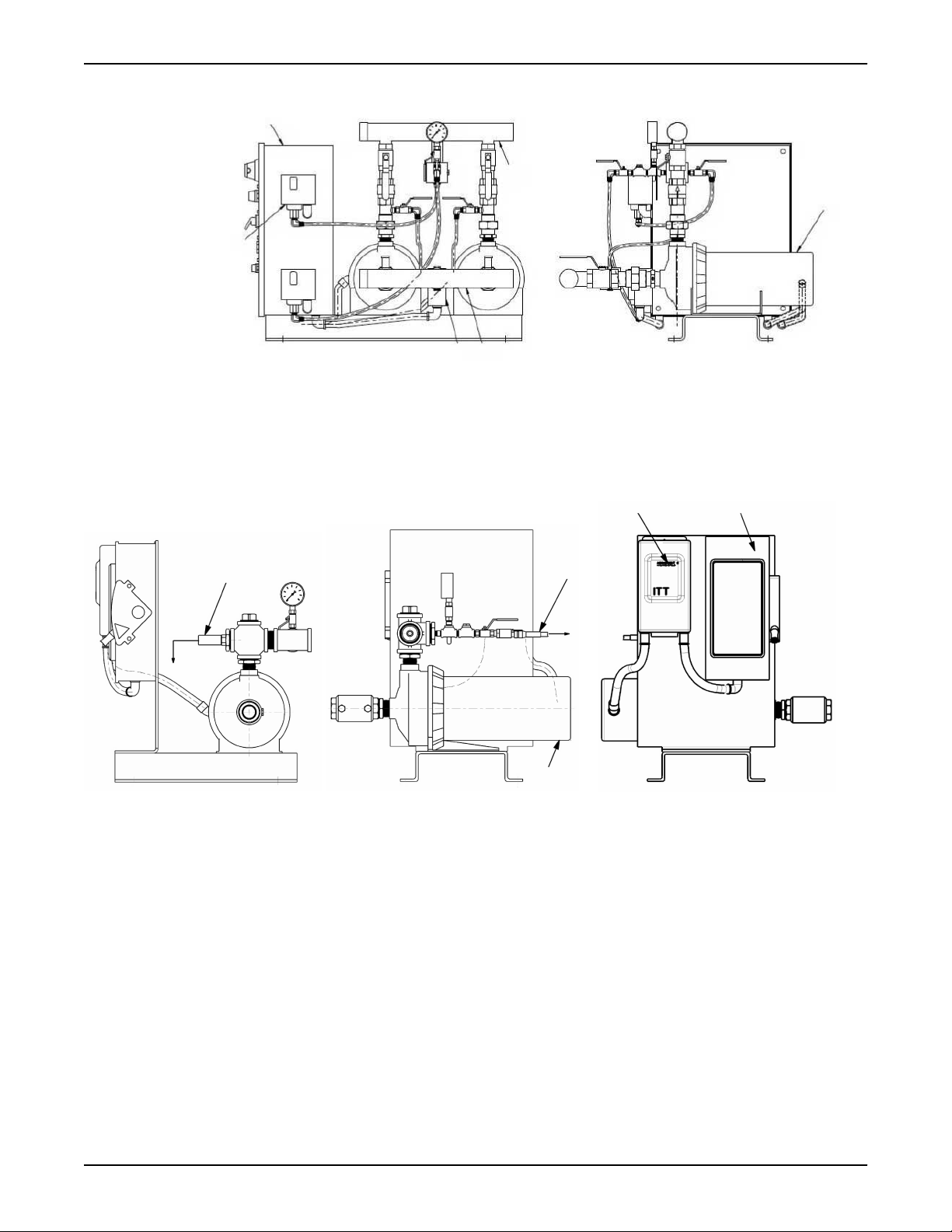

Product Description

This variable-speed configuration uses the AquaBoost II controller model 3AB2 or 5AB2 (for single-phase

power supply: 3V – 5 hp motors).

1. Pump: NPE with TEFC motor

2. AquaBoost II controller

3. Transducer assembly

4. Safety switch

5. Temperature relief valve

6. To drain

7. To controller

This variable-speed configuration uses the Aquavar CPC controller (for 3–phase power supply: 1.5 to 5 hp

range).

1. Pump: NPE with TEFC motor

2. Temperature relief valve

3. Transducer assembly

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 11

4. Aquavar CPC controller

5. Safety switch

6. To drain

7. To controller

Page 14

2

3

5

6

7

7

4

1

8

9

RS000007

Model number

Serial number

Voltage

Phase

Hz

SCCR

FLA

Max. HP

Product Description

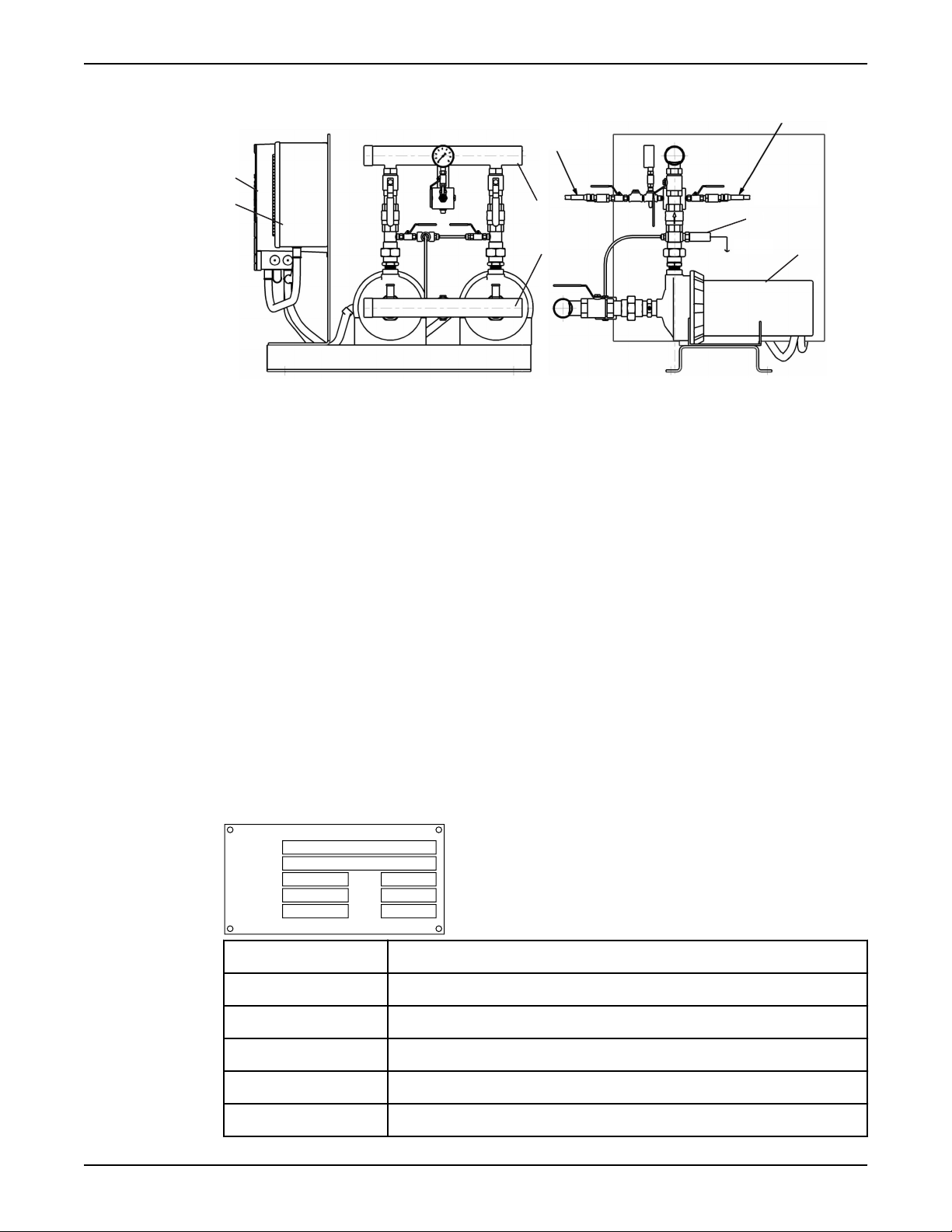

AquaBoost VS duplex

This variable-speed duplex configuration uses the Aquavar CPC controller (for 3–phase

power supply: 1.5 to 5 hp range).

1. Pump: NPE with TEFC motor

2. Safety switch single-point power panel

3. Aquavar CPC controller

4. Temperature relief valve

5. Discharge header: copper L-type

6. Suction header: copper L-type

7. Pressure transducer assembly

8. To controller

9. To drain

Nameplate information

Nameplate

Every pump station has a nameplate that provides information about the pump station.

The pump station nameplate is located on the outside of the control enclosure door.

When ordering spare parts, please be prepared to identify the nameplate information

when contacting the factory.

• Model

• Size

• Serial number

• Item numbers of the required parts

Nameplate field Explanation

Model number The model number of the pump station

Serial number The serial number of the pump station

Voltage Input voltage required for the pump station

Phase Single-phase or 3–phase

Hz Frequency

12 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 15

Nameplate field Explanation

SCCR Short circuit current rating

FLA Full load amps

Max. HP Maximum horsepower

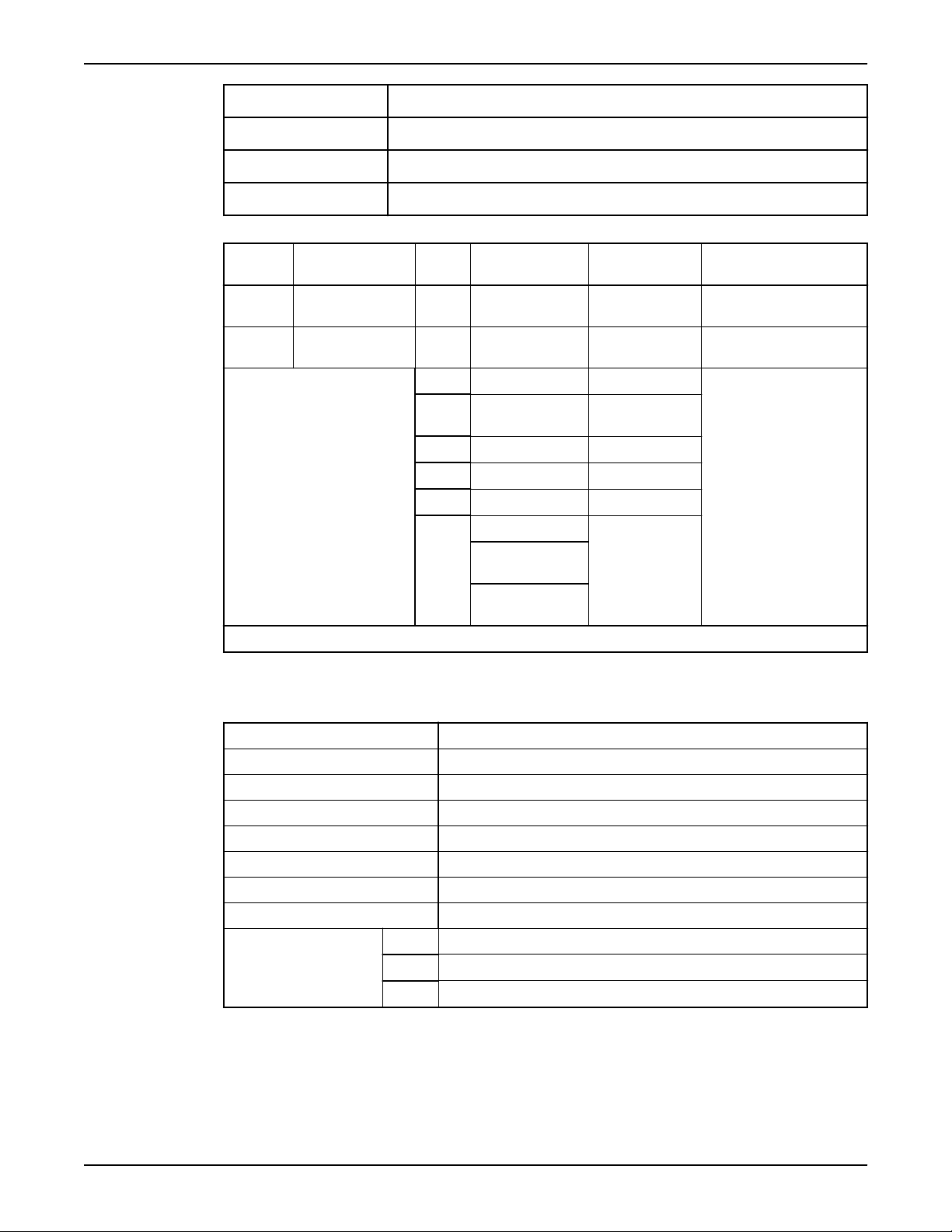

Model number designation

Number of

pumps

1 A (1x1-1/4, 3600) 05 =

2 B (1-1/4x1-1/2,

*Variable speed only

Product Description

Pump model / rpm HP Voltage / Phase Impeller diameter

(inches)

1 = 115/1/60 A = 4-5/8 –CS = constant speed

1/2

3600)

07 =

3/4

2 = 208/3/60 B = 5-1/16 –VS = variable speed

10 = 1 3 = 380/3/50 C = 5-3/16

15 =

4 = 460/3/60 D = 5-3/4

1.5

20 = 2

30 = 3

50 = 5

5 = 575/3/60 E = 5-15/16

6 = 230/1/60 F = 6-1/8

7 = other Z = other

8 = 230/3/60

A = 208–

230/3/60*

B = 208–

230/1/60*

Control

Owner's information

Fill in the right-hand column with the information specific to your pump station.

AquaBoost CS/VS model number

Pump model number

Pump serial number

Control panel model number

Dealer

Dealer phone number

Date of purchase

Date of installation

Electrical ratings at startup Current

Voltage

Phase

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 13

Page 16

Installation

Installation

Field connections

Review the field piping diagrams and wiring diagrams before you install and operate the

unit.

Electrical precautions

WARNING:

Electrical shock hazard. The electrical supply must match the control panel nameplate

specification. Incorrect voltage can cause a fire, which damages the electrical components

and voids the warranty. Failure to follow these instructions could result in serious personal

injury or death, or property damage.

NOTICE:

Electrical connections must be made by certified electricians in compliance with all

international, national, state, and local rules.

Power wiring

Select power wire types and sizes based upon conformance with the National Electrical

Code and all local codes and restrictions. In addition, only copper (Cu) wire rated for at

least 167°F (75°C) can be used for the power connections. Refer to the input current as

listed on the motor nameplate when sizing wire.

Power supply requirements

The power supply required for the AquaBoost CS unit depends on its model number. It

can be one of the following with a dedicated ground wire:

• 115/1/60

• 230/1/60

• 208, 230, 460/3/60

• 380/3/50

• 575/3/60

The power supply required for the AquaBoost VS unit depends on its model number. It

can be one of the following with a dedicated ground wire:

• 115/1/60

• 230/1/60

• 208, 230, 460, 575/3/60

• 380/3/50

WARNING:

Electrical shock hazard. Conduit grounds are not adequate. You must attach a separate

earth (ground) wire to the earth (ground) lug provided in the enclosure in order to avoid

potential safety hazards. Failure to follow these instructions can result in serious personal

injury, death, or property damage.

Input voltage tolerance

The input voltage tolerance is ±10% of the voltage indicated on the nameplate.

14 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 17

Overload protection for constant-speed units

1

2

3

4

5

6

7

8

9

10

Motor type Overload protection Description

Single-phase Internal

Installation

• Disconnecting means

• Fuses for short-circuit protection

Three-phase External in the control panel

Overload protection for variable-speed units

Variable-speed units have a single-point power panel with fuses for protection against

voltage spikes. In addition, the controllers have inherent features that protect the unit

against:

• short circuit

• undervoltage

• overload

• motor temperature

• dead heading

• run out

• suction loss

• sensor fault

• bound pump

• overvoltage

• static discharge

Field piping diagrams

• Disconnecting means

• GV2Ps / manual starters with

thermal overload for short-circuit

protection in the control panel

AquaBoost CS simplex

Typical field piping arrangement for the AquaBoost Constant Speed simplex pumping

package.

1. Anchor the pipe securely if vibration eliminators are used.

2. If a bypass line is installed, then this valve must be kept closed during normal operation. Do not install a

3. Suction gauge, recommended

4. Optional tank

check valve.

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 15

Page 18

1

2

3

4

5

6

7

8

9

10

RS000010

Installation

_ _ _ _ Dashed lines indicate field installation.

AquaBoost CS duplex

5. Discharge gauge

6. Optional pressure reducing valve

7. Vibration eliminator

8. 1/4 in. inlet tap on the check valve for low-suction pressure switch

9. City supply

10. To system

Typical field piping arrangement for the AquaBoost Constant Speed duplex pumping

package.

1. 1/4 in. tap on the suction manifold for low-suction pressure switch

2. Optional tank

3. Discharge gauge

4. Optional pressure reducing valve

5. Vibration eliminator

6. Anchor the pipe securely if vibration eliminators are used.

7. If a bypass line is installed, then this valve must be kept closed during normal operation. Do not install a

check valve.

8. Suction gauge, recommended

9. City supply

10. To system

_ _ _ _ Dashed lines indicate field installation.

16 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 19

AquaBoost VS simplex

1

2

3

4

5 6

7

8

10

9

RS000011

Installation

Typical field piping arrangement for the AquaBoost Variable Speed simplex pumping

package.

1. Anchor the pipe securely if vibration eliminators are used.

2. If a bypass line is installed, then this valve must be kept closed during normal operation. Do not install a

check valve.

3. Suction gauge, recommended

4. Optional tank

5. Discharge gauge

6. Vibration eliminator

7. 1/4 in. inlet tap on the check valve for low-suction pressure switch

8. Controller: AquaBoost II or Aquavar CPC

9. City supply

10. To system

_ _ _ _ Dashed lines indicate field installation.

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 17

Page 20

1

2

3 4 5

6

7

8

9

10

RS000012

Installation

AquaBoost VS duplex

Typical field piping arrangement for the AquaBoost Variable Speed duplex pumping

package.

1. 1/4 in. tap on the suction manifold for low-suction pressure switch

2. Optional tank

3. Discharge gauge

4. Vibration eliminator

5. Anchor the pipe securely if vibration eliminators are used.

6. If a bypass line is installed, then this valve must be kept closed during normal operation. Do not install a

check valve.

7. Suction gauge, recommended

8. Controller: Aquavar CPC

9. City supply

10. To system

_ _ _ _ Dashed lines indicate field installation.

18 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 21

Wiring diagrams

RS000013

AquaBoost CS simplex – 230/1/60 up to 5 hp

Installation

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 19

Page 22

Installation

AquaBoost CS simplex – 575/460/208-230/3/60, 380/3/50 up to 5 hp

20 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 23

AquaBoost CS simplex – 115/1/60 up to 2 hp

RS000015

Installation

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 21

Page 24

RS000016

Installation

AquaBoost CS duplex – 575/460/208-230/3/60, 380/3/50 up to 5 hp

22 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 25

AquaBoost CS duplex – 115/1/60 up to 1.5 hp

Installation

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 23

Page 26

RS000018

Installation

AquaBoost CS duplex – 230/1/60 up to 3 hp

24 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 27

Earth (ground) connections

WARNING:

Electrical shock hazard. Conduit grounds are not adequate. You must attach a separate

earth (ground) wire to the earth (ground) lug provided in the enclosure in order to avoid

potential safety hazards. Failure to follow these instructions can result in serious personal

injury, death, or property damage.

A grounding terminal is provided for a dedicated earth (ground) wire connection. You

must follow all provisions of the National Electrical Code and local codes.

Pump package location guidelines

WARNING:

Assembled units and their components are heavy. Failure to properly lift and support this

equipment can result in serious physical injury and/or equipment damage. Lift equipment

only at the specifically identified lifting points. Lifting devices such as eyebolts, slings, and

spreaders must be rated, selected, and used for the entire load being lifted.

Guideline Explanation/comment

Make sure that the space around the pump package is

sufficient.

If you require lifting equipment such as a hoist or tackle,

make sure that there is enough space above the pump

package.

Protect the unit from weather and water damage due to

rain, flooding, and freezing temperatures.

Do not install and operate the equipment in closed

systems unless the system is constructed with properlysized safety and control devices.

Installation

This facilitates ventilation, inspection, maintenance, and

service.

This makes it easier to properly use the lifting equipment

and safely remove and relocate the components to a safe

location.

This is applicable if nothing else is specified.

Acceptable devices:

• Pressure relief valves

• Compression tanks

• Pressure controls

• Temperature controls

• Flow controls

If the system does not include these devices, consult the

engineer or architect in charge before you operate the

pump.

Take into consideration the occurrence of abnormal noise

and vibration.

The best pump location for noise and vibration

absorption is on a concrete floor with subsoil underneath.

Foundation requirements

Requirements

• The foundation must be able to absorb any type of vibration and form a permanent,

rigid support for the unit.

• The foundation must weigh at least 2-1/2 times the weight of the pump unit.

• Provide a flat, substantial concrete foundation in order to prevent strain and distortion

when you tighten the foundation bolts.

• Sleeve-type and J-type foundation bolts are most commonly used. Both designs allow

movement for the final bolt adjustment.

• Tie the concrete pad in with the finished floor.

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 25

Page 28

1

2

RS000019

1

2

RS000021

1

2

RS000020

1

2

RS000022

Installation

Level the base on a concrete foundation

1. Place the pump package on its concrete foundation.

2. Place 1.00 in./(25.40 mm) thick steel shims or wedges on both sides of each anchor

bolt in order to support the pump package.

Make sure you also place the shims or wedges midway between the bolts.

This also provides a means of leveling the base.

Connect the optional storage tank

1. If the unit is a simplex configuration, then install the tank to the top connection of the

discharge cross as shown:

Constant speed Variable speed

1. Storage tank

2. Discharge gauge

1. Storage tank

2. Discharge gauge

2. If the unit is a duplex configuration, then connect the tank to the discharge manifold as

shown:

Constant speed Variable speed

1. Storage tank

2. Discharge gauge

1. Storage tank

2. Discharge gauge

26 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 29

3. Precharge the tank according to the tank-specific IOM.

1

RS000023

1

RS000025

1

RS000024

1

RS000026

Connect the optional low-suction pressure switch

1. If the unit is a simplex configuration, then install the low-suction pressure switch piped

to the 1/4 in. inlet tap on the check valve as shown:

Constant speed Variable speed

Installation

2. If the unit is a duplex configuration, then install the low-suction pressure switch piped

Piping checklist

WARNING:

• The heating of water and other fluids causes volumetric expansion. The associated forces

can cause the failure of system components and the release of high-temperature fluids.

In order to prevent this, install properly sized and located compression tanks and

pressure-relief valves. Failure to follow these instructions can result in serious personal

injury or death, or property damage.

• Avoid serious personal injury and property damage. Make sure that the flange bolts are

adequately torqued.

• Never force piping to make a connection with a pump.

1. 1/4 in. inlet tap on check valve

1. 1/4 in. inlet tap on check valve

to the 1/4 in. tap on the suction manifold as shown:

Constant speed Variable speed

1. 1/4 in. inlet tap on check valve

1. 1/4 in. inlet tap on check valve

Check Explanation/comment Checked

Check that the suction and discharge pipes are

supported independently by use of pipe hangers near

This eliminates pipe strain on the pump

station.

the pump station.

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 27

Page 30

Installation

Check Explanation/comment Checked

Fastening

Check that there is a strong, rigid support for the

suction and discharge lines.

Check that the suction or discharge lines are not

forced into position.

Check that fittings for absorbing expansion are

As a rule, ordinary wire or band hangers are not

adequate to maintain proper alignment.

Component failure will result if suction or

discharge lines are forced into position.

This helps to avoid strain on the pump.

installed in the system when considerable

temperature changes are expected.

Check that eccentric reducers, if used, are installed

This eliminates air pockets.

with the flat side on top.

Check that a three-valve bypass has been installed

This is a recommended field option.

between the suction and discharge connections.

Check that the piping to which optional vibration

This is necessary for maximum effectiveness.

eliminators are connected is properly anchored to the

floor.

WARNING:

• Only use fasteners of the proper size and material.

• Replace all corroded fasteners.

• Make sure that all fasteners are properly tightened and that there are no missing

fasteners.

28 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 31

Commissioning, Startup, Operation, and Shutdown

Commissioning, Startup, Operation,

and Shutdown

Preparation for startup

DANGER:

Electrical hazard sufficient to kill. Always disconnect and lock out the power before you

service the unit.

WARNING:

• Failure to follow these precautions before you start the unit will lead to serious personal

injury and equipment failure.

• Always disconnect and lock out power to the driver before you perform any installation

or maintenance tasks. Failure to disconnect and lock out driver power will result in

serious physical injury.

• Operating the pump in reverse rotation can result in the contact of metal parts, heat

generation, and breach of containment.

Precautions

NOTICE:

• Verify the driver settings before you start any pump.

You must follow these precautions before you start the pump:

• Flush and clean the system thoroughly to remove dirt or debris in the pipe system in

order to prevent premature failure at initial startup.

• If temperatures of the pumped fluid will exceed 200°F (93°C), then warm up the pump

prior to operation. Circulate a small amount of fluid through the pump until the casing

temperature is within 100°F (38°C) of the fluid temperature.

At initial startup, do not adjust the variable-speed drivers or check for speed governor or

over-speed trip settings while the variable-speed driver is coupled to the pump. If the

settings have not been verified, then uncouple the unit and refer to instructions supplied

by the driver manufacturer.

Final installation checks

Installation checklist

CAUTION:

Serious damage to the pump may result if it is started dry. Make sure that the pump is

completely filled with liquid before it is started.

Check Checked

Check that the unit base is properly leveled and secured.

Check that all lubrication points are properly lubricated.

Check that the shut-off valves to the suction and discharge lines are open.

Check that the system is purged of debris and air. This includes the pumps and PRVs.

Check that the pump and motor shafts are properly aligned.

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 29

Page 32

Commissioning, Startup, Operation, and Shutdown

Check Checked

Check that the pump rotation is correct.

Final piping checklist

Check Checked

Check that the bypass valve is closed, if used.

Check that the piping is properly supported. This prevents strain on the unit.

Electrical wiring and control checklist

WARNING:

• Electrical shock hazard. Conduit grounds are not adequate. You must attach a separate

earth (ground) wire to the earth (ground) lug provided in the enclosure in order to avoid

potential safety hazards. Failure to follow these instructions can result in serious personal

injury, death, or property damage.

• Always disconnect and lock out power to the package and the driver before you perform

any installation or maintenance tasks. Failure to disconnect and lock out driver power will

result in serious physical injury.

NOTICE:

Electrical connections must be made by certified electricians in compliance with all

international, national, state, and local rules.

Check Checked

Check that the feeder line voltage corresponds to the unit voltage. Check the unit

nameplate or motor terminal connection.

Check that the feeder wires are correctly sized according to local and NEC codes.

Final adjustments

Make the final adjustments on these adjustable devices in order to match the exact system

requirements.

Low-suction pressure switch (optional)

WARNING:

Always disconnect and lock out power to the package and the driver before you perform

any installation or maintenance tasks. Failure to disconnect and lock out driver power will

result in serious physical injury.

The pressure switch is piped into the suction line. An adjusting dial is located inside of the

control. This adjustment controls the low-suction cutout. The differential pressure setting is

fixed at 1.5 psi. Therefore cut-in pressure will be the switch setting plus 1.5 psi.

Although the scale is calibrated in psi, it may not correspond exactly to the actual suction

gauge indication. Therefore, for critical installations, the setting should be adjusted

according to the gauge reading. The approximate settings should be set prior to placing

the unit in operation in order to suit the pressure conditions at the installation.

30 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 33

System pressure switches for constant speed units

1 2

RS000032

WARNING:

Always disconnect and lock out power to the package and the driver before you perform

any installation or maintenance tasks. Failure to disconnect and lock out driver power will

result in serious physical injury.

The simplex unit has one switch and the duplex unit has two switches: one for each pump.

Each switch is piped to the discharge piping.

Two adjusting screws are located on the top of the control. Facing the switch, the screw on

the right-hand side sets the cutout pressure. Make this adjustment first.

The screw to the left and towards the front sets the cut-in point. Turn this screw until the

proper cut-in pressure is obtained.

Commissioning, Startup, Operation, and Shutdown

1. The silver adjusting screw on the left front is for cut-in adjustment.

2. The yellow adjusting screw on the right is for cutout adjustment.

Although the scales are calibrated in psi, they may not correspond exactly to the actual

discharge gauge indication. Therefore, for critical installations, adjust the settings

according to the gauge reading.

For the proper settings of the system pressure switches on a duplex unit, see the wiring

diagram for AquaBoost CS duplex – 575/460/208-230/3/60, 380/3/50 up to 5 hp (page

22).

Minimum run timer

For a constant speed simplex unit the minimum run timer is set at the factory to 5 minutes.

Verify the setting before placing the unit into operation; adjust if a shorter minimum run

time is desired.

For the constant speed duplex unit, use the programmable pump sequence control

module to set the minimum run timer for each pump.

Programmable pump sequence control module settings

The constant speed duplex package uses a smart relay as its control module.

This table shows the user-adjustable settings of the smart relay. You can manually set

parameters using the backlit LCD display and buttons.

Parameter description Default setting

Lead pump minimum run timer 30 0-999

Lag pump minimum run timer 30 0-999

Lead pump start delay timer 1 0-99

Lag pump start delay timer 5 0-99

(seconds)

Variable range

(seconds)

Field setting

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 31

Page 34

Commissioning, Startup, Operation, and Shutdown

Parameter description Default setting

Pump fail to start proof timer 5 0-99

Low suction/high temperature off proof timer 5 0-99

Low suction/high temperature on proof timer 5 0-99

Duty/standby 0

Staging on proof timer 30 0-99

For more details on these settings see Sequence of operation for the duplex pumping

system (page 36).

Aquastat

The aquastat for high temperature cutout is set at the factory for 100°F (38°C). Adjust the

setting if a different cutout temperature is desired. Do not set the switch above 225°F

(107°C).

Optional tank

A variety of different tanks can be used with either the simplex or duplex units. Refer to the

specific IOM that was shipped with the tank for installation and operating instructions.

Pump package operation description

(seconds)

Variable range

(seconds)

0 = disabled

1 = enabled

Field setting

CAUTION:

A unit that shows symptoms of possible problems, such as overflow, noise, leaks,

vibrations, or continual operation, must be corrected immediately.

Constant speed operation

Constant speed simplex – for capacities up to 110 gpm

Condition Description

The city water pressure falls below the setting of the

system suction pressure switch (2PS).

The system pressure rises above the setting of the system

pressure switch.

Constant speed duplex – for capacities up to 220 gpm

Condition Description

The city water pressure falls below the setting of the

system suction pressure switch (2PS).

The system pressure rises above the setting of the system

pressure switch.

The system demand increases beyond the capacity of the

lead pump and the system pressure does not satisfy the

pressure switch settings.

The system pressure rises above the settings of Pump 1

and Pump 2 discharge pressure switches (2PS and 3PS).

The pump starts through a power relay.

The pump stops, provided the minimum run timer has

expired.

The lead pump starts through a power relay.

The lead pump stops, provided the minimum run timer

has expired.

The system automatically starts the lag pump and both

pumps run.

Both pumps stop, provided the minimum run timers

have expired.

32 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 35

Condition Description

The lead pump fails.

Conditions that cause the unit to cut out

Simplex and duplex units run when there is demand unless one of the following conditions

occurs:

Condition Description Resolution

Low city pressure The optional low-suction pressure

Pump deadheading The high temperature cutout switch

switch (1PS) trips.

trips.

Commissioning, Startup, Operation, and Shutdown

The lag pump starts and acts as the lead pump.

To reinstate the lead pump do the following:

1. Before fixing the failed pump, turn the HOA

switch to the OFF position.

2. After the lead pump has been fixed, place the

lead pump HOA into the AUTO position and then

press the RESET button to reset the unit.

3. The pump returns to its operational state.

The low suction condition resets automatically

when the city pressure returns to an acceptable

level.

The unit resets automatically when there is demand

by drawing cooler water through the unit and

across the temperature sensor. This cools the sensor

and causes it to change state and restart the pump.

For a manual purge run the unit in Hand mode for

about 5 seconds. Then put the unit back into Auto

mode for normal operation.

The smart relay control module

The AquaBoost CS duplex pumping package uses a smart relay for its control module. You

can adjust control settings via the front panel of the smart relay.

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 33

Page 36

1 2

Q1

1 2

Q2

1 2

Q3

1 2

Q4

8

7

6

5

4

Outputs

Q1…Q4: Relay 8A

1 2 3

Inputs I1…I6

100…240VAC

100…240VAC

L N

I1 I2 I3 I4 I5 I6

SR2A101FU

Menu / OK

RS000027

1

2

RS000028

Commissioning, Startup, Operation, and Shutdown

Smart relay front panel

1. Screw terminal block for the power supply

LCD display

2. LCD display

3. Screw terminal block for discrete inputs

4. Slot for backup memory or PC connection cable

5. Shift key, white

6. Menu/OK key, green, for selection and confirmation

7. Relay output screw terminal block

8. Navigation Z push buttons, gray

This illustration show an example of LCD display elements in the input-output screen:

1. Program version

2. Contextual menus, pushbuttons, icons that indicate operating modes

34 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 37

Control keys

RS000029

RS000031

The keys located on the front panel of the smart relay are used to configure, program, and

control the application and to monitor the progress of the application.

• The shift key is the white key located on the right side of the LCD screen.

• The green Menu/OK key is used for all confirmations: menu, sub-menu, program,

parameter.

• The gray keys, labeled Z1 through Z4, have arrows below them indicating the

directions of navigation.

Navigate through user-adjustable parameters

Commissioning, Startup, Operation, and Shutdown

When the controller is turned on, the Lead Pump Minimum Run Timer screen appears:

• Press the left-most gray key, Z1, in order to navigate to other user-adjustable

parameters.

Modify parameters

1. In order to modify the preset value, press and hold the white shift key and press the

right-most navigation key, Z4.

The current preset value will start to blink.

2. Modify the parameter value with the up and down arrow keys.

3. When the desired value is displayed, confirm the changes by pressing the green

Menu/OK button.

Navigate to and from the main screen

• Continuously press the Z1 left arrow key until the main screen appears:

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 35

Page 38

Commissioning, Startup, Operation, and Shutdown

• From the main screen, press the Z1 left arrow key two times to go to the user-adjustable

parameters screen.

The Lead Pump Minimum Run Timer screen will appear.

Sequence of operation for the duplex pumping system

Starting the lead pump

The lead pump can be started from either of the two pressure switches (2PS or 3PS) that

are provided on the right-hand side of the controller. The same applies to the lag pump.

This provides redundancy in the event of a failure of either pressure switch. Fully automatic

alternation is included in the standard controller. Pumps alternate any time that both

pumps stop.

Staging pumps together

Pumps can stage together if the pressure switch indicates that the system pressure is

unable to meet the required demand. This is the default setting of 0, which means that the

duty/standby switch is disabled. The pump stage/de-stage function is disabled when the

duty/standby switch is enabled by switching the setting to 1. When the duty/standby

switch is enabled, only one pump can run at a time; the other pump remains in standby

state.

Maintaining system pressure

If two pumps are running together to maintain the required system pressure, and the

system pressure increases, the system de-stages (stops) the lag pump. After the lag pump

has been de-staged and system pressure is still maintained, the system then stops the lead

pump as well.

The time interval between the lead pump stop and the lag pump stop must be at least 30

seconds. This is a fixed timer and no adjustments can be made.

Start delay

The start delay timer for both lead and lag pumps is a user-adjustable parameter that

prevents short cycling of pumps or false starting of pumps. The start delay timer for the lag

pump starts after the lead pump starts so that it is impossible for both pumps to be started

at the same time.

Minimum run time

Each pump has a minimum run timer. Pumps continue to run during that minimum run

time unless a failure occurs, such as pump failure or overload. The pump minimum run

timer is a user-adjustable parameter. Pump failure can be detected by a differential

pressure switch or by an overload failure. The pump fail proof timer is a user-adjustable

parameter.

Pump failure

When one pump is running and the system detects a failure on that pump, the system

stops the failed pump. The system then automatically switches to the other pump and

replaces the failed pump in order to meet the system demand. When pump failure occurs,

the pump failure indicator light illuminates.

Before you fix the failed pump, put the HOA switch in the OFF position. After the failed

pump is fixed, put the HOA switch in the Auto position.

You must manually reset the pump. Press the RESET button to turn off the pump failure

indicator light and return that pump to operational state.

Low-suction or high-temperature shutdown

A low-suction/high-temperature shutdown proof timer provides instantaneous shutdown

and prevents immediate restarting of the pumps. The proof time is adjustable between 0

to 99 seconds; the default setting is 5 seconds.

36 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 39

When a low-suction or high-temperature thermal cutout situation occurs, the red light

indicator illuminates. An auto reset feature is provided in order to return the pumps to

operational state.

Variable speed operation

Variable speed simplex – for capacities up to 110 gpm

The pressure transducer monitors the system pressure and sends a feedback signal to the

controller. Depending upon the feedback, the controller then changes the speed of the

pump.

Condition Description

The system pressure falls below the set point. The pump starts automatically and pump speed

The system pressure rises above the set point. The pump automatically reduces speed until the system

Variable speed duplex – for capacities up to 220 gpm

The pressure transducer monitors the system pressure and sends feedback signal to the

controller. Depending upon the feedback, the controller changes the speed of the pump

or stages/de-stages the other pump.

Commissioning, Startup, Operation, and Shutdown

continues to ramp up until the system pressure satisfies

the set point.

pressure reaches the set point, provided the minimum

run timer has expired.

Condition Description

The system pressure falls below the set point. The pump starts automatically and pump speed

The system pressure rises above the set point. The pump automatically reduces speed until the system

Low-suction pressure switch

Simplex and duplex units will run when there is demand unless the optional low-suction

pressure switch trips due to low city pressure.

The low-suction condition resets automatically when city pressure returns to an acceptable

level.

Temperature relief valve

The variable-speed units have a temperature relief valve that senses water temperature

inside the pump.

The valve opens and closes depending on the water temperature. This modulating action

maintains a relatively constant fluid temperature even as operating conditions vary.

Condition Description

The water temperature exceeds the valve opening

temperature, typically 120ºF (49°C).

The water temperature falls below the opening

temperature by 10º F (5.5°C).

continues to ramp up until the system pressure satisfies

the set point.

pressure reaches the set point, provided the minimum

run timer has expired.

The valve automatically opens to allow relatively cooler

supply water to refill the pump as the hot water is

discharged to the drain or low pressure return.

The valve automatically closes in order to conserve water

and reduce waste.

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 37

Page 40

Maintenance

Maintenance

Precautions

DANGER:

Electrical hazard sufficient to kill. Always disconnect and lock out the power before you

service the unit.

WARNING:

• This manual clearly identifies accepted methods for disassembling units. These methods

must be adhered to. Trapped liquid can rapidly expand and result in a violent explosion

and injury. Never apply heat to impellers, propellers, or their retaining devices to aid in

their removal.

• Make sure that each pump and the package are isolated from the system and that

pressure is relieved before you disassemble the pump, remove plugs, open vent or drain

valves, or disconnect the package piping.

• Always disconnect and lock out power to the package and the driver before you perform

any installation or maintenance tasks. Failure to disconnect and lock out driver power will

result in serious physical injury.

• Crush hazard. The unit and the components can be heavy. Use proper lifting methods

and wear steel-toed shoes at all times.

Monthly maintenance

Motor lubrication checks

• For grease-filled bearings, make sure that grease is not all over the inside of the motor

and in the bottom of the motor. This could be a sign of overfilling. Refer to the

lubrication instructions from the motor manufacturer.

Close-coupled pumps

• For a horizontal pump, verify that the mechanical seal is not leaking between the pump

and the motor.

Sound and visual checks of the whole station

• Listen for any odd sounds that rub or grind, electrical arcing, and check for anything

that is binding or unusual. These conditions can indicate a serious problem.

Note that there is going to be some harmonic vibration with the pumps and motor.

Listen for excessive vibration or noise as this requires immediate service. Do not

operate the pump if there is excessive vibration.

• Confirm that the building cooling and ventilation systems are operating and clear of all

obstructions. The maximum operating range for equipment is 104°F (40°C).

• Verify that water, grease, oil, and hardware are not leaking or loose on the pump

station.

Station skid

• Visually inspect for leaks in the station piping, valves, and other components.

• Visually inspect the piping and skid for any stress cracks in the welds.

• Visually inspect the station for loose or damaged paint or areas of rust.

38 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 41

Troubleshooting

Pump station troubleshooting

DANGER:

• Personal injury hazard. Troubleshooting a live control panel exposes personnel to

hazardous voltages. Electrical troubleshooting must be done by a qualified electrician.

Failure to follow these instructions will result in serious personal injury, death, and/or

property damage.

• Electrical hazard sufficient to kill. Always disconnect and lock out the power before you

service the unit.

WARNING:

Electrical connections must be made by certified electricians in compliance with all

international, national, state, and local rules.

Note that some troubleshooting procedures apply to only constant speed systems or only

variable speed systems.

Troubleshooting

The pump station does not power up

Cause Remedy

The site voltage does not match the pump station

voltage.

Line-to-line voltage is not balanced. Check incoming voltage and amperage. Line-to-line

The power fuses are blown or breakers are tripped. Check power fuses and breakers. Breakers are shipped in

The pump station is not properly grounded (earthed). Check that proper grounding (earthing) techniques have

There is a fault. Check for fault codes or fault lights on the PLC. Correct

The station powers up, but the pumps do not run

Cause Remedy

Pumps are not enabled. Check the PLC to make sure that the pumps are enabled.

The desired pressure is satisfied. Check to see if the desired pressure is satisfied. If the

There is a fault. Check for fault codes or fault lights on the PLC. Correct

The motor is tripped. Check for a tripped motor thermal protector. Allow motor

The fuses are blown or breakers are tripped. Check circuit breaker and fuses.

Transducer isolation valves are closed. Make sure that the transducer isolation valves are in the

Automatic mode is faulty. Check to see if the pump can be run in Manual mode on

Make sure that the site voltage matches the pump station

design voltage.

voltage should be balanced. Line-to-ground voltage

should also be balanced.

the OFF position. Replace blown fuses.

been used for the pump station.

the fault.

Check for faults. Correct any faults.

actual pressure is greater than the set point pressure,

then the pumps are automatically stopped.

the fault.

to cool, and then reset the thermal protector.

open position.

the PLC.

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 39

Page 42

Troubleshooting

Cause Remedy

The impeller is bound. Check to see if you can turn the pump by hand. Check for

A pressure transducer is faulty. Replace faulty pressure transducers.

Motor wiring is loose. Make sure that motor wiring is securely connected.

Motor windings have lost insulation strength. Test the motor leads with a megger in order to check the

Variable speed drive is wired incorrectly. Check corresponding variable speed drive. Make sure

Motor is defective. Repair or replace motor.

Troubleshoot the pump operation

If the pump still does not operate after you have checked initial causes, then use this

procedure to further investigate and correct the problem.

1. Momentarily turn the HOA switch to the HAND position and then back to OFF. Does

the starter pull in?

• If the starter does not pull in, then go to the next step.

• If the starter does pull in, then go to the last step.

2. Turn the HOA switch to the HAND position. Check the voltage across the terminals for

the coil in the starter.

• If voltage is present and the starter is not pulled in, the coil is defective and must be

replaced.

• If no voltage is present, then go to the next step.

3. With the HOA still in the HAND position, check the voltage between the hot side of the

starter coil and the neutral (white) wire. 120 volts should be measured.

• If no voltage is measured, then check incoming power and fuses.

• If voltage is measured, then go to the next step.

4. With the HOA still in the HAND position, check the voltage between the hot side of the

coil and the neutral (white) wire for overload block. 120 volts should be measured.

• If voltage is measured, then replace the GV2P block.

• If no voltage is present, then contact your local Goulds Pumps representative to

service the control circuit.

5. With the starter pulled in, check the voltage at the bottom of the GV2P block. The

voltage should be the same as the incoming power.

• If no voltage is present, then replace the starter.

• If voltage is present, then contact an electrician to check the leads and motor.

a bound impeller.

motor windings.

drive is wired correctly.

For electrical troubleshooting of variable speed units, refer to the manuals of the

corresponding variable speed controllers.

The pumps run but do not build desired pressure

Cause Remedy

Pumps are running off their design curve. Check the application. Is the system running in an open

discharge condition (excessive flow rate)? For example, is

the system filling a large irrigation line for the first time

of the season?

Pumps are running at less than full speed. Check to see if the pumps are running at full speed. If

they are running less than full speed, they could be

experiencing electrical issues. Check the panel for power

status.

The inlet pressure does not match the project

specifications.

A pipe is broken. Check for broken pipes.

40 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Check to see if the inlet pressure matches the project

specifications. Variations in inlet pressure can have

detrimental effects on performance.

Page 43

Troubleshooting

Cause Remedy

The transducer isolation valves are closed. Check to be sure that the transducer isolation valves are

in the open position.

The NPSH is insufficient. Check the NPSH. Are proper flooded conditions or

positive pressure being delivered to the pump station?

Check for air in the supply lines. Check for properly filled

supply tanks (if applicable). Excessive suction lift or

piping losses will limit the life expectancy of the pumps.

The pump station has lost its prime. Check to be sure that the pump station has been primed

properly. Make sure that all pumps and components are

properly filled with water.

The pump rotation is incorrect. Check the pump rotation. Proper rotation is indicated on

the pump volute. (See the pump IOM.)

A suction or discharge valve is closed or clogged. Check the isolation valves and check valves. Are all

suction/discharge valves open? Could any valves be

plugged? Could the pumps be plugged?

The motor is not operating at the rated RPM. Check the voltage and amperage. Check for possible

phase loss to the motor.

The impeller is worn or plugged. Take the pump to an authorized pump repair facility.

The pump bearings are worn. Take the pump to an authorized pump repair facility.

The pump station experiences excessive vibration

Cause Remedy

The motor, pump, or piping is loose. Make sure that all fasteners and components are

properly tightened.

Pump station vibration dampers are missing or

improperly installed.

Pumps are running off their design curve. Check the application. Is the system running in an open

Air or gases are present in the pumped liquid. Check water supply lines and tanks. Check for air or gases

Discharge piping is plugged. Check discharge piping/valves. Could the piping be

Supply piping has excessive suction/lift conditions or

friction loss.

The impeller is bound or worn. Take the pump to an authorized pump repair facility.

Pumps and pipes are not properly aligned. Correct the alignment between pumps and pipes.

Check for properly installed pump station vibration

dampers.

discharge condition (excessive flow rate)? For example, is

the system filling a large irrigation line for the first time

of the season?

in liquid. Bleed the lines.

plugged? Could the pump be plugged? Are the isolation

valves open? Clear any clogs.

Check for excessive suction/lift conditions or friction loss

on supply piping.

The pump station does not shut down and no water is used

Cause Remedy

The pump station is in Hand or Manual mode. Put the system in the AUTO position.

The system pressure is set beyond capability of the

station.

The RTDs are incorrectly installed. Check to make sure that the RTDs are installed correctly.

There are leaks or broken pipes. Check for broken pipes or leaks. Does the system

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 41

Check the system set pressure. Is this duty point beyond

the capability of the pump station?

(CS only)

pressure decrease if the pump station is turned off?

Page 44

Troubleshooting

Cause Remedy

The diaphragm tank is faulty. Check for a properly installed diaphragm tank. Has the

The pressure transducers are faulty. Check the pressure transducers. Does the actual

The VFDs are in Local mode. Put the VFDs in Remote mode.

A check valve is malfunctioning. Check for malfunctioning check valves. Does the system

The pump station cycles or hunts erratically

Cause Remedy

The pumps are oversized for the current demand. Check the application. Possibly increase the size of the

The inlet pressure is fluctuating. —

There are leaks or broken pipes. Check for broken pipes or leaks. Does the system

The diaphragm tank is faulty. Check for a properly installed diaphragm tank. Has the

The pressure transducers are faulty. Check the pressure transducers. Does the actual

A check valve is malfunctioning. Check for malfunctioning check valves. Replace faulty

There is an error in the PLC programming. Check the customer programming on the PLC. Correct

tank failed? Has the tank been charged to the proper

operating pressure before installation? (~10 psi below

the desired set point)

mechanical gauge pressure match the pressure

displayed on the VFDs and the PLC?

hold pressure when the pump package is shut down?

Replace faulty valves.

bladder tank for low demand situations.

pressure decrease when the pump station is turned off?

tank failed? Has the tank been charged to the proper

operating pressure before installation? (~10 psi below

the desired set point)

mechanical gauge pressure match the pressure

displayed on the VFDs and the PLC?

valves.

any errors.

42 AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual

Page 45

Other Relevant Documentation or Manuals

Other Relevant Documentation or

Manuals

Manuals for AquaBoost components

Further information pertaining to the installation, operation, and maintenance of your

AquaBoost Pumping System can be found in the IOMs provided for the associated

equipment:

Equipment Manual

Goulds Pumps Model NPE IM013

Aquavar CPC IM167

Aquaboost II 3AB2-5AB2 IM183

Aquaboost II 115AB2-2AB2 IM156

Tank Model-specific

AquaBoost CS and VS Pumping Packages Installation, Operation, and Maintenance Manual 43

Page 46

Page 47

Page 48

Xylem |’zīləm|

1) The tissue in plants that brings water upward from the roots

2) A leading global water technology company

We're 12,500 people unified in a common purpose: creating

innovative solutions to meet our world's water needs. Developing new

technologies that will improve the way water is used, conserved, and

re-used in the future is central to our work. We move, treat, analyze,

and return water to the environment, and we help people use water

efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with

customers who know us for our powerful combination of leading

product brands and applications expertise, backed by a legacy of

innovation.

For more information on how Xylem can help you, go to xyleminc.com

Xylem Inc.

2881 East Bayard St. Ext., Suite A

Seneca Falls, NY 13148

Tel. 1-800-453-6777

Fax 1-888-322-5877

www.xyleminc.com/brands/

gouldswatertechnology

S100057_1.0_en.US_2012-7_IOM_AquaBoost

Visit our Web site for the latest version of this

document and more information

The original instruction is in English. All nonEnglish instructions are translations of the original

instruction.

©

2012 Xylem Inc.

Goulds is a registered trademark of Goulds

Pumps, Inc. and is used under license.

Loading...

Loading...