Laboratory

conductivity meter

CG 853P

Operating Manual

ba12246e_2 09/99

Conductivity meter with integrated printer

77

Accuracy when

going to press

All details contained in this operating manual are valid data

at the time of going to press. However, SCHOTT may add

details for both technical and commercial reasons, or in order to fulfil legal requirements of different countries. This

does not affect the characteristics described.

Warranty

declaration

The designated instrument is covered by a warranty of three

years from the date of purchase.

The instrument warranty extends to manufacturing faults

that are determined within the period of warranty.

The warranty excludes components that are replaced during

maintenance such as batteries, etc.

The warranty claim extends to restoring the instrument to

readiness for use but not, however, to any further claim for

damages. Improper handling or unauthorized opening of the

instrument invalidates any warranty claim.

To ascertain the warranty liability, return the instrument and

proof of purchase together with the date of purchase freight

paid or prepaid.

78

Copyright

© Hofheim SCHOTT Geräte GmbH 1999

Reprinting - even as excerpts - is only allowed with the

explicit written authorization of SCHOTT Geräte GmbH,

Hofheim.

Printed in Germany.

List of contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

1.1 Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

1.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

1.3 Sockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

1.4 Declaration of Conformity . . . . . . . . . . . . . . . . . . .85

1.5 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

2.1 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . .92

2.2 General safety instructions . . . . . . . . . . . . . . . . . .92

3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4.1 Switch on the instrument . . . . . . . . . . . . . . . . . . . .97

4.2 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

4.2.1 Conductivity . . . . . . . . . . . . . . . . . . . . . . .101

4.2.2 Salinity . . . . . . . . . . . . . . . . . . . . . . . . . . .102

4.2.3 TDS (total dissolved solids) . . . . . . . . . . .103

4.2.4 Printing/transmitting measured values . .105

4.3 Determining/setting up the cell constant [C] . . . .106

4.4 Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

4.4.1 Manual storage . . . . . . . . . . . . . . . . . . . . .117

4.4.2 Switching on AutoStore (Int 1) . . . . . . . . .119

4.4.3 Outputting the data storage . . . . . . . . . . .121

4.4.4 Clearing the storage . . . . . . . . . . . . . . . . .127

4.5 Data transmission . . . . . . . . . . . . . . . . . . . . . . . .128

4.5.1 Data transmission interval (Int 2) . . . . . . .128

4.5.2 Recorder (analog output) . . . . . . . . . . . . .130

4.5.3 PC/external printer (RS232 interface) . . .131

4.6 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

4.7 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

79

List of contents

5 Maintenance, cleaning, disposal . . . . . . . . . . . 139

5.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

5.1.1 Changing the batteries . . . . . . . . . . . . . . .140

5.1.2 Replacing the roll of printer paper . . . . . .141

5.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

5.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

6 What to do if... . . . . . . . . . . . . . . . . . . . . . . . . . . 143

7 Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

80

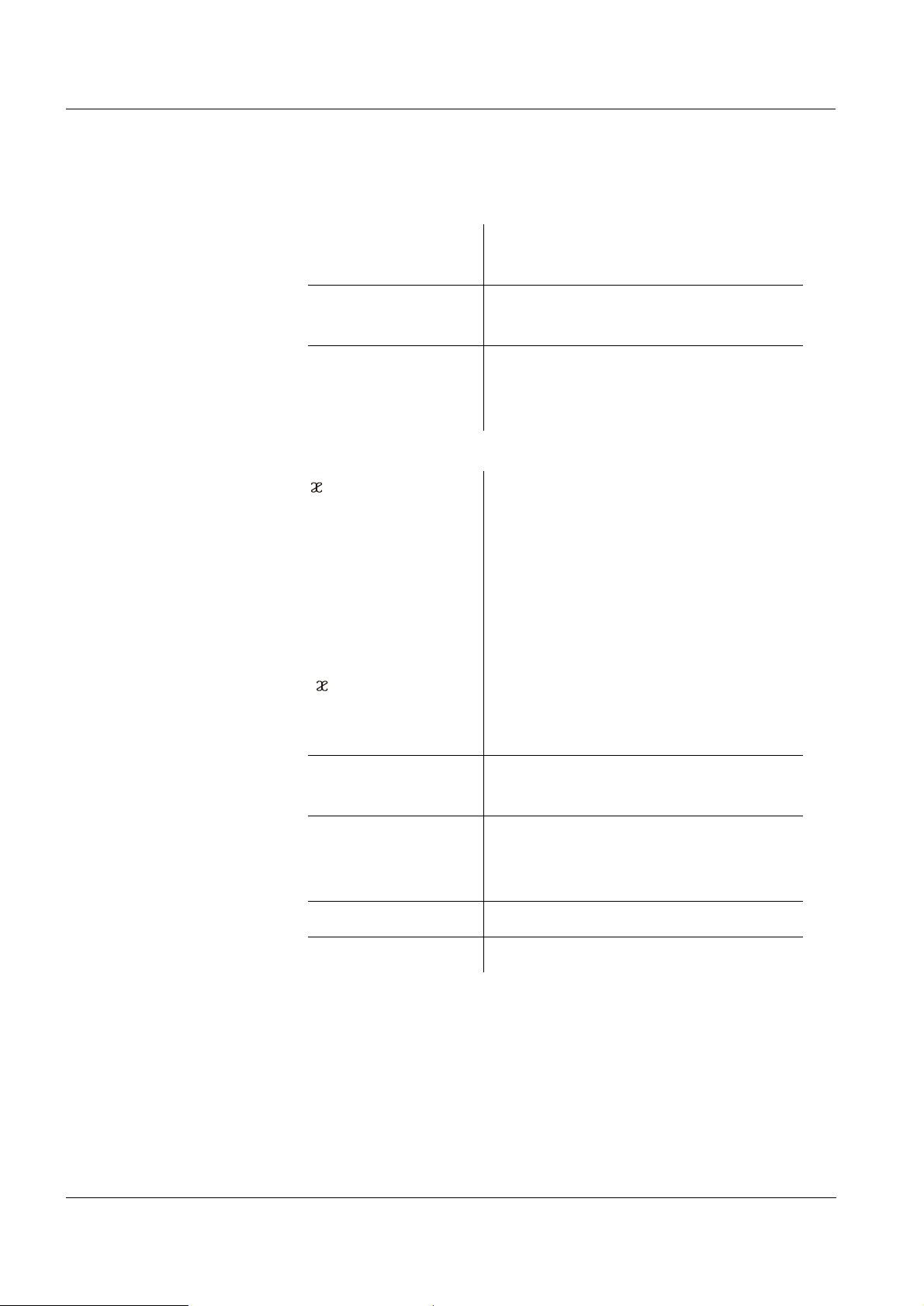

1Overview

Overview

The compact

perform conductivity measurements rapidly and reliably.

The

CG 853P

fort, reliability and measuring safety for all applications.

The integrated printer enables the measurements to be

documented in compliance with GLP.

The proven procedures to determine or set up the cell constant support your work with the conductivity meter.

4

CG 853P

provides the highest degree of operating com-

precision conductivity meter lets you

3

2

1

1 Keypad

2 Display

3 Sockets

4 Printer

Note

The measuring instrument can also be delivered as part of

a set. Information on this and other accessories is available

in the SCHOTT general catalog.

81

Overview

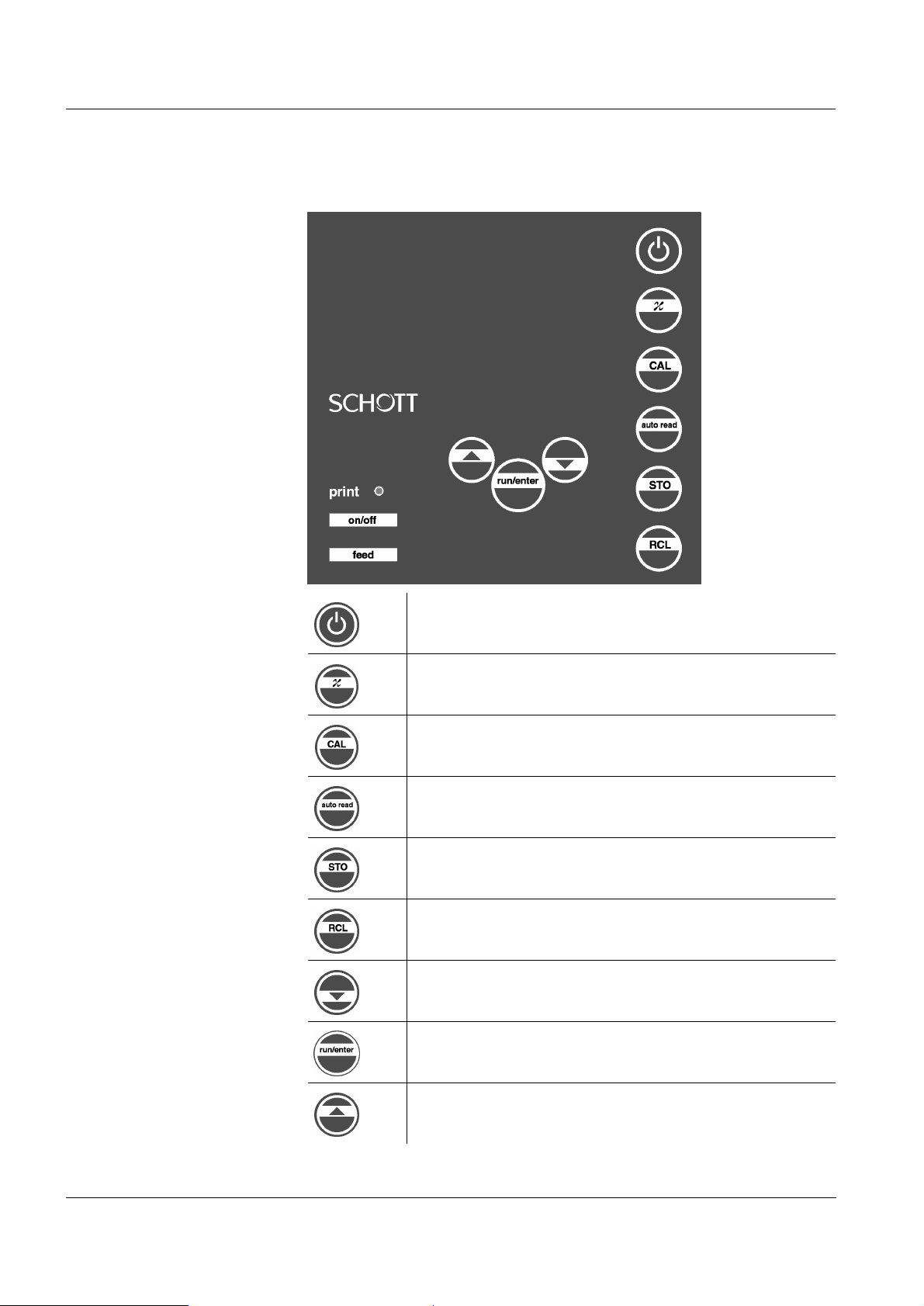

1.1 Keyboard

Measuring instrument ON/OFF

<on/off>

Select measuring mode

ì>

<

Set up or determine cell constant; select

temperature compensation <CAL>

Activate/deactivate AutoRead function

<auto read>

Store measured value

<STO>

Display/transmit measured values

<RCL>

Reduce values, scroll

▼>

<

Confirm inputs, start AutoRead

<run/enter>

82

Increase values, scroll

▲>

<

Overview

Print LED

Red: printer off (offline) or malfunction

Green: printer ready for operation (online)

Printer ON/OFF

<print on/off>

Paper feed/line feed

(Printer off - Print LED lights up red)

<feed>

83

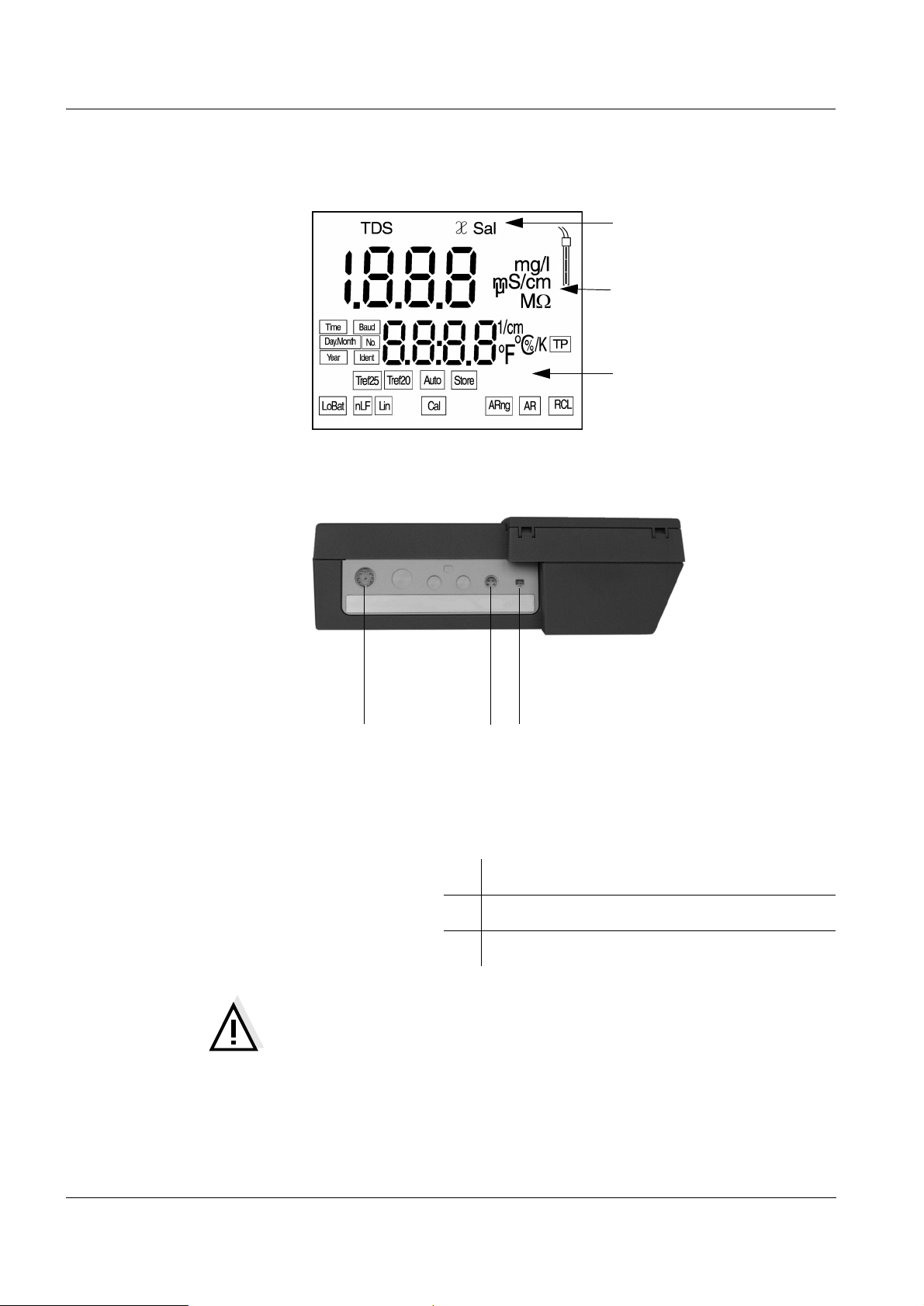

Overview

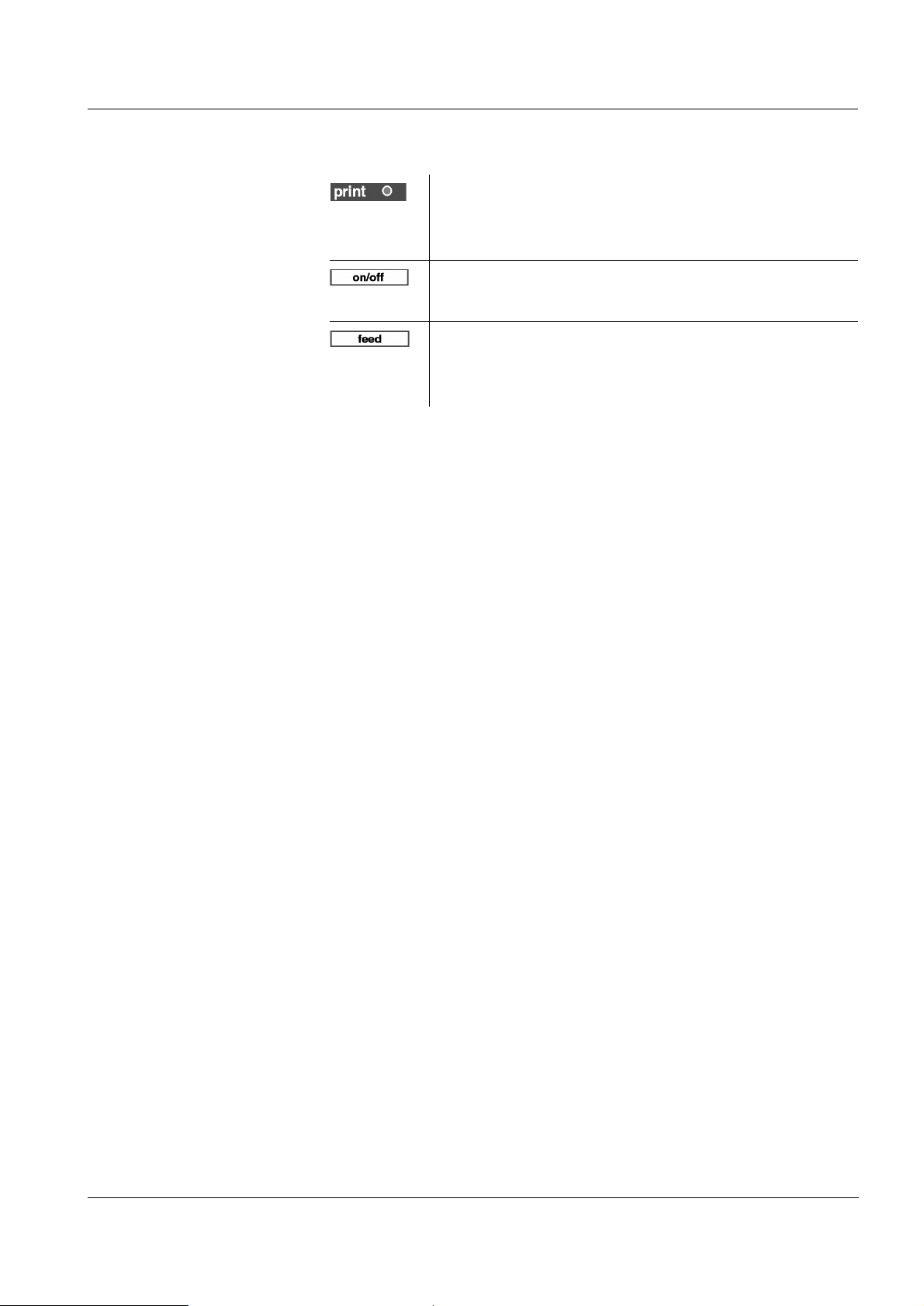

1.2 Display

Status line

Measured value display

Function and

temperature displ a y

1.3 Sockets

123

Connections:

1 8 pole socket with pin contacts

2 RS 232 interface/analog output

3 Plug-in power supply

Caution

Only connect probes to the instrument that cannot feed

excessive voltages or currents (> SELV and > circuit with

current limiter).

Almost all commercial electrodes - especially SCHOTT

electrodes - meet these requirements.

84

1.4 Declaration of Conformity

Overview

29.03.99

SCHOTT Geräte GmbH

Im Langgewann 5

D 65719 Hofheim am Taunus

Deutschland, Germany, Allemagne

29. März, March 29rd, 29, Mars, 1999

AGQSF0000-A060-00/990329

85

Overview

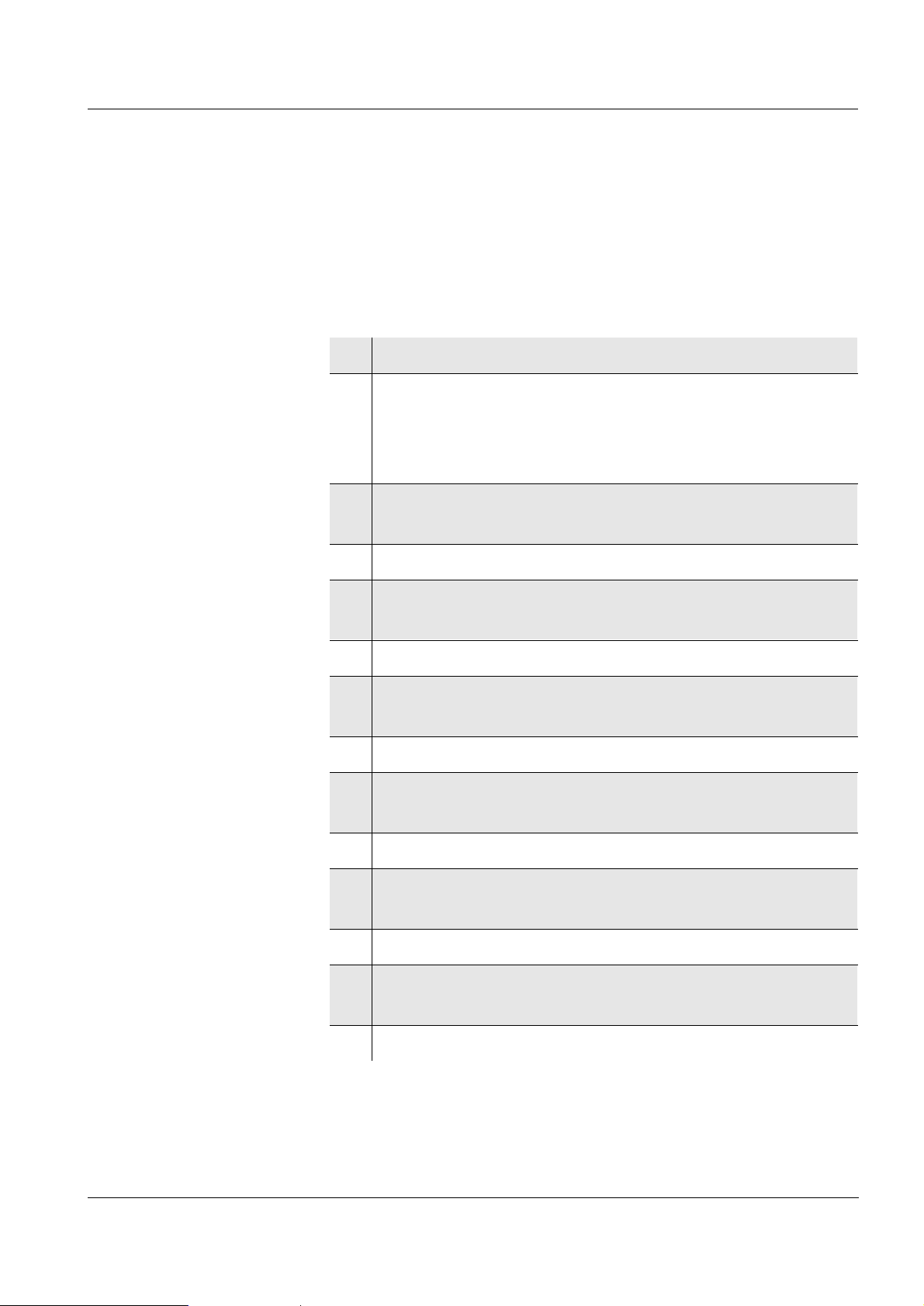

1.5 Technical data

Ambient

temperature

Measuring ranges

and resolution

Storage temperature

Operating temperature

Allowable relative

humidity

[µS/cm]

[mS/cm]

- 25 °C ... + 65 °C

0 °C ... + 55 °C

Annual mean: < 75 %

30 days/year: 95 %

Other days: 85 %

0.000 ... 1.999

(only with 0.01 cm

-1

cell constant )

0.00 ... 19.99

-1

(only with 0.01 cm

0.1 cm

-1

cell constant )

constant and

0.0 ... 199.9

0 ... 1999

0.00 ... 19.99

0.0 ... 199.9

0 ... 500

SAL 0.0 ... 70.0 according to the IOT

table

TDS [mg/l] 0 ... 1999

Factor can be set in the range

0.40 ... 1.00

T [°C] − 5.0 ... + 100.0

T [°F] + 23.0 ... + 212.0

86

Overview

Measuring accuracy

(± 1 digit)

Given as measuring uncertainty at a confidence level of

95%. All accuracies additionally depend on the accuracies

of the measuring probes.

No compensation:

Accuracy± 0.5 %

Non-linear compensation :

AccuracyTest sample temperature

± 0.5 %0 °C ... 35 °C

according to EN 27 888;

± 0.5 % 35 °C ... 50 °C

extended nLF function according to

SCHOTT measurements

Linear compensation :

AccuracyTest sample temperature

± 0.5 % 10 °C ... 75 °C

(the accuracy percentage always refers

to the measured value!)

SAL Range 0.0 ... 42.0

AccuracyTest sample temperature

± 0.1at 5 °C ... 25 °C

± 0.2 at 25 °C ... 30 °C

TDS [mg/l] 1

T [°C] NTC 30:

Accuracy± 0.1

PT 1000:

AccuracyOperating temperature

± 0.5 0 °C ... 15 °C

± 0.1 15 °C ... 35 °C

± 1 35 °C ... 55 °C

87

Overview

Measuring accuracy

(± 1 digit)

(Continuation)

Cell constant,

to be set

Cell constant,

calibrated

Reference tempera-

ture, selectable

T [°F] NTC 30:

Accuracy± 0.2

PT 1000:

AccuracyOperating temperature

± 0.9 at 32 °F ... 59 °F

± 0.2at 59 °F ... 95 °F

± 1.8 at 95 °F ... 131 °F

C [cm

-1

] 0.01

0.1

0.250 ... 2.500

C [cm

-1

] 0.450 ... 0.500

0.800 ... 1.200

T

REF [°C] 20

25

Temperature input

Dimensions and

weight

Manual [°C] - 5 ... +100

Length [mm] 240

Width [mm] 285

Height [mm] 85

Weight [kg] Approx. 1.3

(without plug-in power supply unit)

88

Overview

Power supply

Batteries 4 x 1.5 V AA type alkaline manga-

nese batteries

Runtime Approx. 3000 operating hours

Mains power supply Connection max. overvoltage cat-

egory II:

Plug-in power supply (Euro plug):

Type no.: Z851

Order no.: 28 520 4897

FRIWO FW3288, 11.8134

Friwo Part No. 1816492

Input: 230V ~ / 50 Hz / 23 VA

Output: 6 V = / 1,8 A /10,8 VA

Plug-in power supply (US plug):

Type no.: Z852

Order no.: 28 520 4901

FRIWO FW3288, 11.8451

Friwo Part No. 1816493

Input: 120V ~ / 60 Hz / 21,5 VA

Output: 6 V = / 1,8 A

EMC and

VDE norms

Plug-in power supply (UK plug):

Type no.: Z849

Order no.: 28 520 4975

FRIWO FW3288, 11.8453

Friwo Part No. 1770896

Input: 230V ~ / 50 Hz / 23 VA

Output: 6 V = / 1,8 A

Interference emission

(generic standard)

Interference immunity

EN 50081-1

FCC class A

EN 50082-1

(generic standard)

Protective class 3, EN 61010-1

Climatic class 2, VDI/VDE 3540

89

Overview

Test marks TÜV GS, UL/CUL, CE

Display Multifunctional LCD

Keypad Foil keypad (Polyester)

Data storage Ring store for 200 value pairs, conductivity/salinity/TDS,

temperature

Temperature

compensation

Connectors

Printer

Automatic with Pt

1000/NTC (30 k

W)

-5 ... 100.0 °C

Manual input -5 ... 100 °C resolution 1K

Measuring cell 8 pole socket with pin contacts

RS interface/

analog output

Bidirectional RS 232 interface or

analog output with autom. recognition of the PC, printer, or recorder

connected

Plug-in power supply 2 pole special Friwo

Print principle Matrix thermoprint

Signs per line 26

Printing width 46.1 mm

90

Width of printing paper 58 mm

Printing speed 40 signs/sec

Safety

2 Safety

This operating manual contains basic instructions that you

must follow during the commissioning, operation and maintenance of the instrument. Consequently, all responsible

personnel must read this operating manual before working

with the instrument.

The operating manual must always be available within the

vicinity of the instrument.

Target group This measuring instrument was developed for use in the lab-

oratory.

Thus, we assume that, as a result of their professional training and experience, the operators will know the necessary

safety precautions to take when handling chemicals.

Symbols used

Caution

indicates instructions that have to be followed to prevent

damage to your instrument.

Warning

indicates instructions that have to be followed to protect

yourself and the instrument from dangerous electrical voltage.

Note

Indicates notes that draw your attention to special features.

Note

Indicates cross-references to other documents, e.g. application reports, operating manuals of measuring cells, etc.

91

Safety

2.1 Authorized use

This instrument is authorized exclusively for measuring the

conductivity, salinity, temperature and TDS (total dissolved

solids) in the laboratory.

The technical specifications as given in the section

ECHNICAL DATA, must be observed. Only the operation

1.5 T

and running of the measuring instrument according to the

instructions given in this operating manual is authorized.

Any other use is considered unauthorized.

2.2 General safety instructions

This instrument is constructed and tested in compliance with

the EN 61010-1 safety regulations for electronic measuring

instruments.

It left the factory in a safe and secure technical condition.

Function and

operational safety

The smooth functioning and operational safety of the instrument can only be guaranteed if the generally applicable

safety measures and the specific safety instructions in this

operating manual are followed.

The smooth functioning and operational safety of the instrument can only be guaranteed under the climatic conditions

specified in the section 1.5 T

ECHNICAL DATA.

If the instrument was transported from a cold environment to

a warm environment, the formation of condensate can lead

to the faulty functioning of the instrument. In this event, wait

until the temperature of the instrument reaches room temperature before putting the instrument back into operation.

Caution

The instrument is only allowed to be opened by personnel

authorized by SCHOTT.

92

Safety

Safe operation If safe operation is no longer possible, the instrument must

be taken out of service and secured against inadvertent

operation.

Safe operation is no longer possible if:

l the instrument has been damaged in transport

l the instrument has been stored under adverse conditions

for a lengthy period of time

l the instrument is visibly damaged

l the instrument no longer operates as described in this

manual

If you are in doubt contact the supplier of the instrument.

Obligations of the

operator

The operator of this measuring instrument must ensure that

the following laws and guidelines are observed when using

dangerous substances:

l EEC directives for protective labor legislation

l National protective labor legislation

l Safety regulations

l Safety datasheets of the chemical manufacturer.

93

Safety

94

Commissioning

3 Commissioning

Perform the following activities for initial comissioning:

l Set the date and time

l Connect the plug-in power supply (for printer functions).

Setting the date

and time

1 Press and hold down the <ì> key.

2 Press the <on/off> key.

The

display test

appears briefly on the display.

The measuring instrument then switches automatically to the setting of the baud rate.

3 Press the <run/enter> key repeatedly until the date

flashes on the display.

4 Set today’s date by pressing <

▲> <▼>.

5 Confirm with <run/enter>.

The date (month) flashes on the display.

6 Set the current month by pressing <

▲> <▼>.

7 Confirm with <run/enter>.

The year appears on the display.

8 Set the current year by pressing <

▲> <▼>.

9 Confirm with <run/enter>.

The hour field flashes on the display.

10 Set the current time by pressing <

▲> <▼>.

11 Confirm with <run/enter>.

The minutes field flashes on the display.

12 Set the current time by pressing <

▲> <▼>.

13 Confirm with <run/enter>. The measuring instrument

then switches to the measuring mode.

14 Switch off the instrument by pressing <on/off>.

95

Commissioning

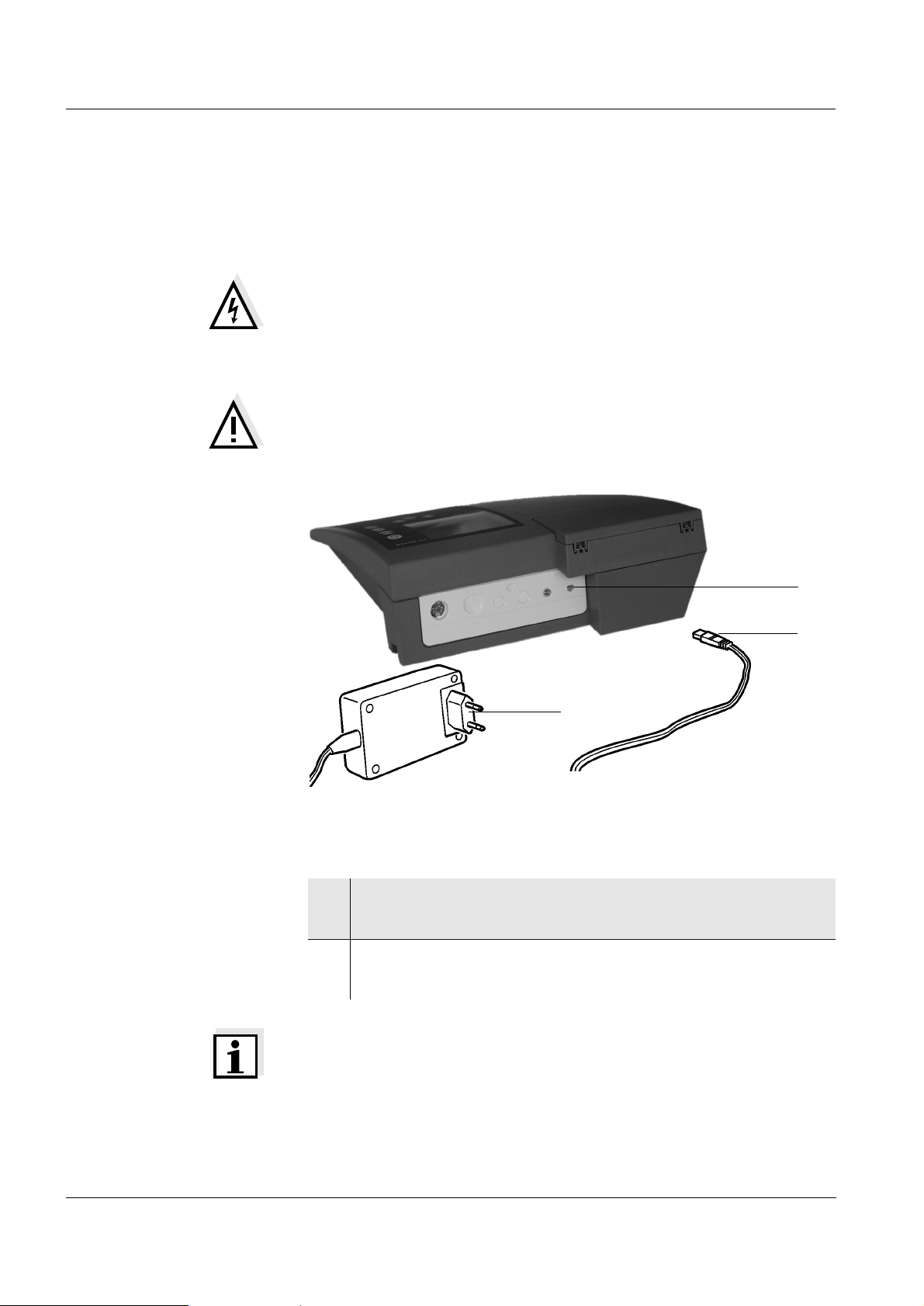

Connecting the

plug-in power

supply

The plug-in power supply supplies the pH meter with low

voltage (7.5 V ... 12 V DC).

Warning

The line voltage on site must lie within the input voltage

range of the original plug-in power supply unit (see section

1.5 T

ECHNICAL DATA).

Caution

Use original plug-in power supplies only

(see section 1.5 T

ECHNICAL DATA).

2

1

3

1 Insert the plug (1) into the socket (2) of the conductiv-

ity meter.

2 Connect the original SCHOTT plug-in power supply

(3) to an easily accessible mains socket.

Note

You can also perform measurements without a plug-in

power supply. However, the functions of the integrated

printer can only be used with connected plug-in power supply.

96

Operation

4Operation

4.1 Switch on the instrument

1 Place the instrument on a flat surface and protect it

against intense light and heat.

2 Connect the conductivity measuring cell to the instru-

ment.

3 Press the <on/off> key.

display test

The

The instrument then switches automatically to the

previously selected measuring mode.

4 Check or determine the cell constant [C]. The proce-

dure is described in section 4.3, on page 106.

appears briefly on the display.

Note

The instrument has an energy saving feature to avoid

unnecessary battery depletion.

The energy saving feature switches the instrument off if no

key has been pressed for an hour.

The energy saving feature is not active:

l if the power is supplied by the plug-in power supply

l if the

l if a PC is connected

l if the recorder cable is connected

l if the printer cable is connected

AutoStore

function is active

(for external printers)

97

Operation

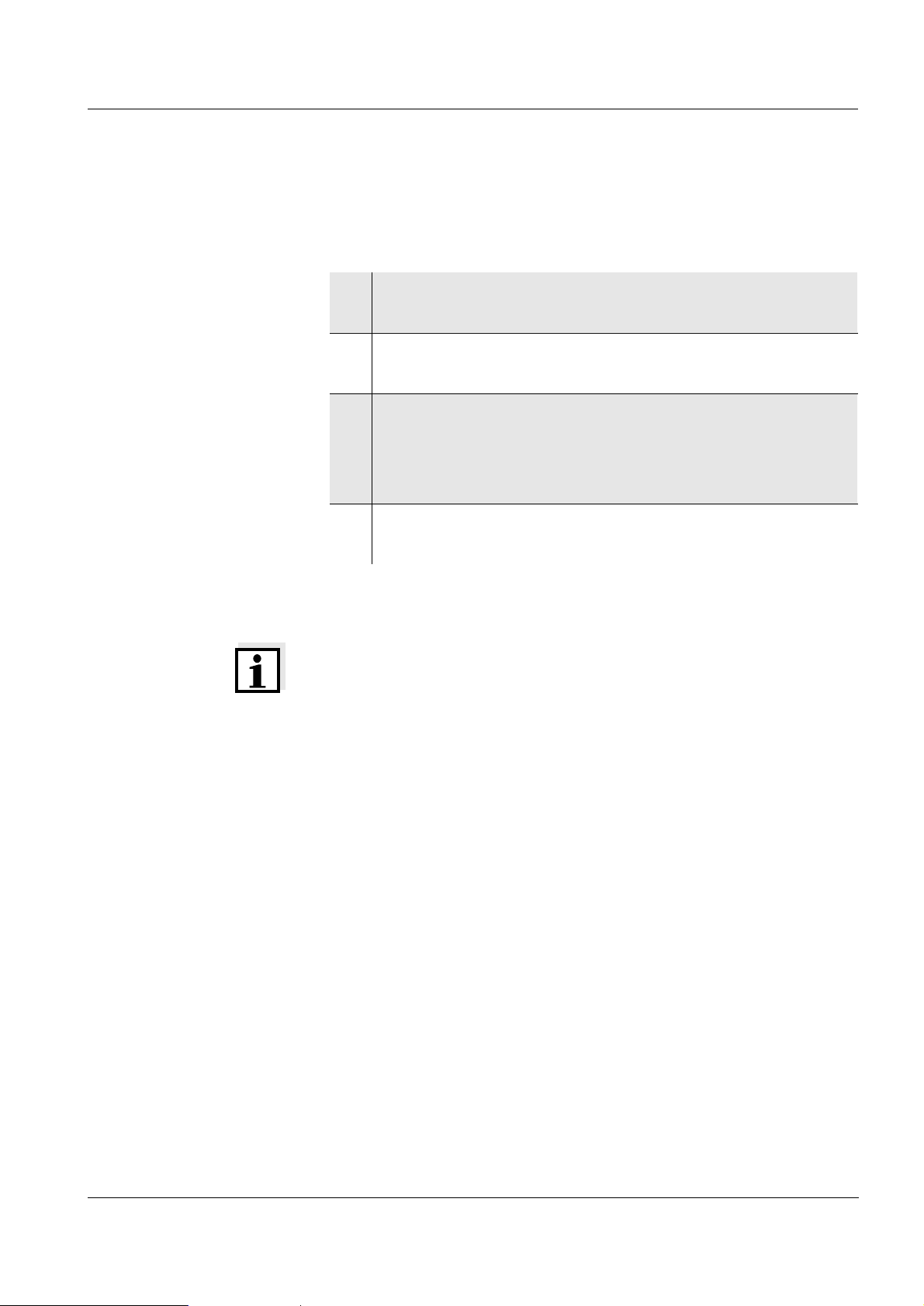

Checking the cell

constant

1 Press the <CAL> key repeatedly until LF CELL is dis-

played.

2 Press the <run/enter> key.

The previously selected cell constant ist displayed,

e. g. 0.475 cm

-1

with a calibrated cell constant.

3 To return to the measuring mode: press the <ì> key

when the correct cell constant ist displayed.

4 If a different cell constant is to be set, proceed ac-

cording to section 4.3 D

CELL CONSTANT [C].

ETERMINING/SETTING UP THE

98

4.2 Measuring

Operation

Preparatory

activities

Temperature probe Measurements can be performed with and without a temper-

Perform the following activities when you want to measure:

1 Connect the measuring cell to the instrument.

2 Adjust the temperature of the test solutions or mea-

sure the current temperature if the measurement is

made without a temperature probe.

3 Calibrate the instrument with the measuring cell or

check the cell constant set up.

4 Select the measuring mode by pressing <

Caution

When connecting an earthed PC/printer, measurements

cannot be performed in earthed media as incorrect values

would result.

The RS232 interface is not galvanically isolated.

ature probe. A connected temperature probe is indicated by

TP on the display.

If you want to use a SCHOTT conductivity measuring cell

without a temperature probe, you have to connect it with an

adapter (available at SCHOTT).

ì>.

Note

The conductivity meter automatically recognizes the type of

the temperature probe used. As a result, you can connect

electrodes with the NTC30 or Pt1000.

The temperature measurement is absolutely essential for a

reproducible conductivity measurement. If the measurement is made without a temperature probe, proceed as follows:

1 Determine the current temperature using a thermom-

eter.

2 Set up the temperature by pressing <

▲> <▼>.

99

Operation

AutoRead AR

(Drift control)

The

AutoRead

function (drift control) checks the stability of

the measurement signal. The stability has a considerable

effect on the reproducibility of the measured value.

1 Call up the measuring mode by pressing <ì>.

2 Activate the AutoRead function by pressing

<auto read>.

The current measured value is frozen (Hold function).

3 Start the AutoRead function by pressing

<run/enter>.

AR flashes on the display until a stable measured value is reached.

This measured value is transmitted to the interface.

.

100

4 If necessary, start the next AutoRead measurement

by pressing <run/enter>.

5 To terminate the AutoRead function: Press the

<auto read> key.

Note

The current AutoRead measurement (with acceptance of

the current value) can be terminated at any time by pressing

<run/enter>.

Operation

4.2.1 Conductivity

To measure the conductivity, proceed as follows:

1 Perform the preparatory activities according to sec-

tion 4.2.

2 Immerse the conductivity measuring cell into the test

sample.

3 Press the <ì> key until appears in the status dis-

play. The conductivity value appears on the display.

4 If necessary, set the temperature by pressing

<

▲><▼> (see section 4.2, page 99).

5 Perform an AutoRead measurement according to

section 4.2.

101

Operation

4.2.2 Salinity

To measure the salinity, proceed as follows:

1 Perform the preparatory activities according to sec-

tion 4.2.

2 Immerse the conductivity measuring cell into the test

sample.

3 Press the <ì> key repeatedly until Sal appears in the

status line. The salinity value of the sample appears

on the display.

4 If necessary, set the temperature by pressing

▲><▼> (see section 4.2, page 99).

<

5 Wait for a stable measured value.

102

6 Perform an AutoRead measurement according to

section 4.2.

Operation

4.2.3 TDS (total dissolved solids)

To measure the TDS, proceed as follows:

1 Perform the preparatory activities according to sec-

tion 4.2.

2 Immerse the conductivity measuring cell into the test

sample.

3 When measuring with an integrated temperature

probe continue with step 4.

When measuring without temperature probe:

– Determine the temperature of the test sample using

a thermometer

– Press the <

ì> key repeatedly until appears in

the status line

– Enter the temperature using <

4 Press the <

ì> key repeatedly until TDS appears in

▲> <▼>.

the status line. The TDS value of the sample appears

on the display.

5 Set up the TDS factor (0.40 ... 1.00) using <▲> <▼>.

6 Wait for a stable measured value.

103

Operation

7 Perform an AutoRead measurement according to

section 4.2.

104

Operation

4.2.4 Printing/transmitting measured values

Measured values (data records) can be:

l printed on the integrated printer or

l transmitted to the interface.

Note

To print, you must switch on the printer using the Print key

<print on/off> (Print LED lights up green).

To transmit to the interface, you must connect the interface

cable. The integrated printer is then switched off automatically.

You can print measured values (data records) in 3 ways:

l Switch on the data transmission (Int 2) (see page 128)

– After expiry of the selected interval, the current data

record is sent to the printer/interface.

l Switch on AutoStore (Int 1) (see page 119)

– After expiry of the selected interval, the current data

record is sent to the printer/interface and in addition is

stored in the data store of the instrument

– AutoStore (Int 1) covers the

data transmission

interval

(Int 2).

l Press the <run/enter> key

This manually triggers a printout of the current measured

values at any time - independently of the selected intervals.

Note

If you connect a recorder (analog output), both the output to

the integrated printer and the digital output are switched off.

105

Operation

4.3 Determining/setting up the cell constant [C]

Why determine/set

up the cell

constant?

Determining the cell

constant

(calibration in

control standard)

Due to ageing, the cell constant slightly changes. As a

result, an inexact measured value is displayed. Calibration

determines the current value of the cell constant and stores

this value in the instrument.

Thus, you should calibrate at regular intervals.

You can determine the cell constant of the conductivity measuring cell in the range 0.450 ... 0.500 cm

-1

cm

by calibrating in the control standard or set it up manu-

ally in the range 0.250... 2.500 cm

-1

select one of the fixed cell constants 0.1 cm

-1

or 0.800 ... 1.200

. Additionally, you can

-1

or 0.01 cm-1.

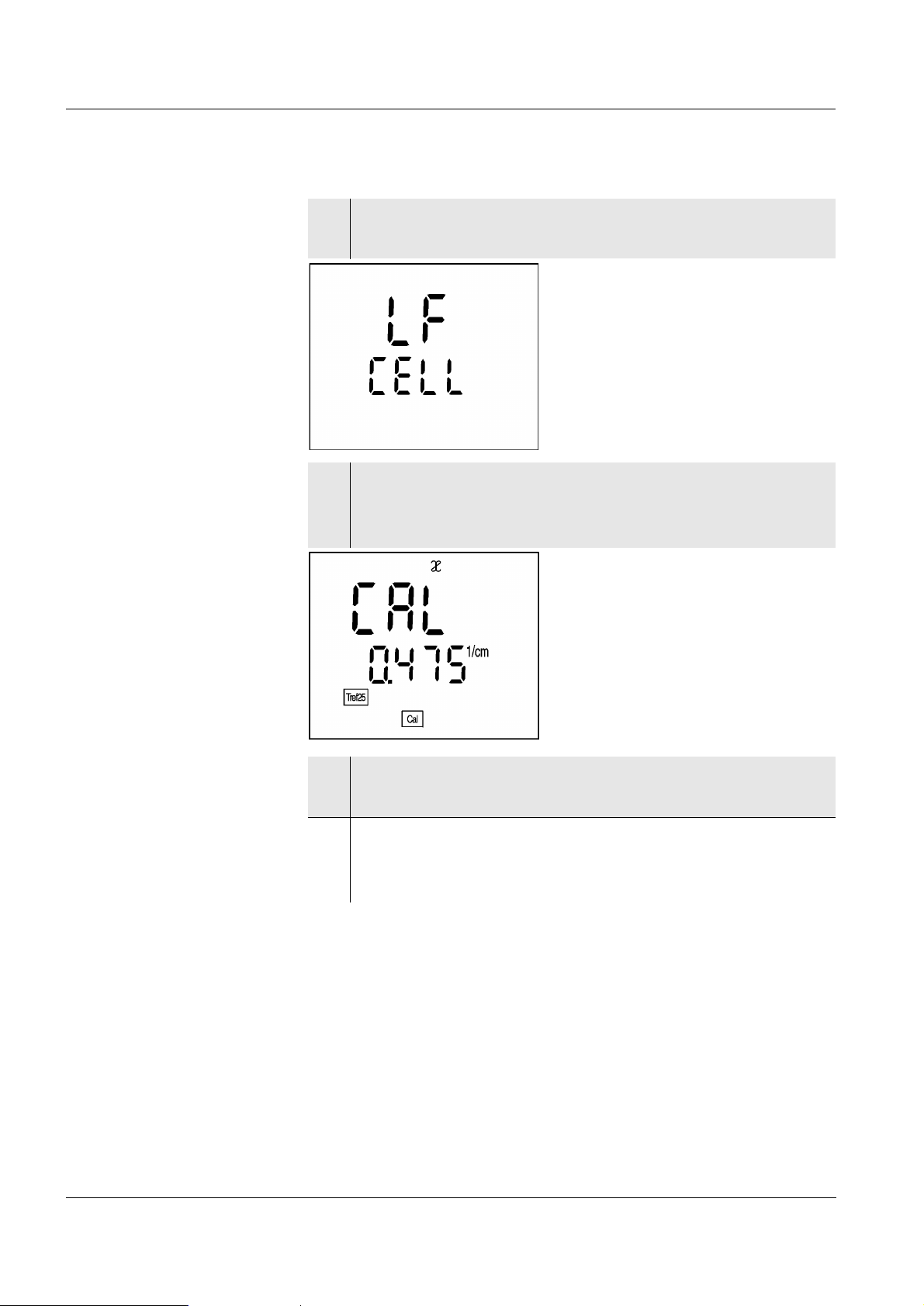

Determine the cell constant as follows:

1 Press the <CAL> key repeatedly until LF CELL ap-

pears on the display.

106

2 Press the <run/enter> key repeatedly to go to the

"Determining/ setting up the cell constant" function.

3 Press the <CAL> key repeatedly until the following is

displayed.

Operation

4 Immerse the measuring cell into the 0.01 mol/l KCL

control standard.

5 Press the <run/enter> key.

– If no temperature probe is connected, enter the

current temperature of the solution using <

▲> <▼>

and confirm with <run/enter>

– If a temperature probe is connected, the AR

measurement to determine the cell constant starts.

flashes until a stable signal is achieved. The

determined cell constant ist displayed; the

measuring instrument automatically stores the cell

constant.

Note

If error message appears see chapter 6 W

HAT TO DO IF...

AutoRead During calibrating, the

activated. The AR display flashes. The calibration procedure

is finished when the AR display stops flashing.

AutoRead

function is automatically

107

Operation

Note

This method of automatically determining the cell constant

by calibrating in the 0.01 mol/l KCL control standard can

only be used for measuring cells with a cell constant in the

-1

range 0.450 ... 0.500 cm

or 0.800 ... 1.200 cm-1.

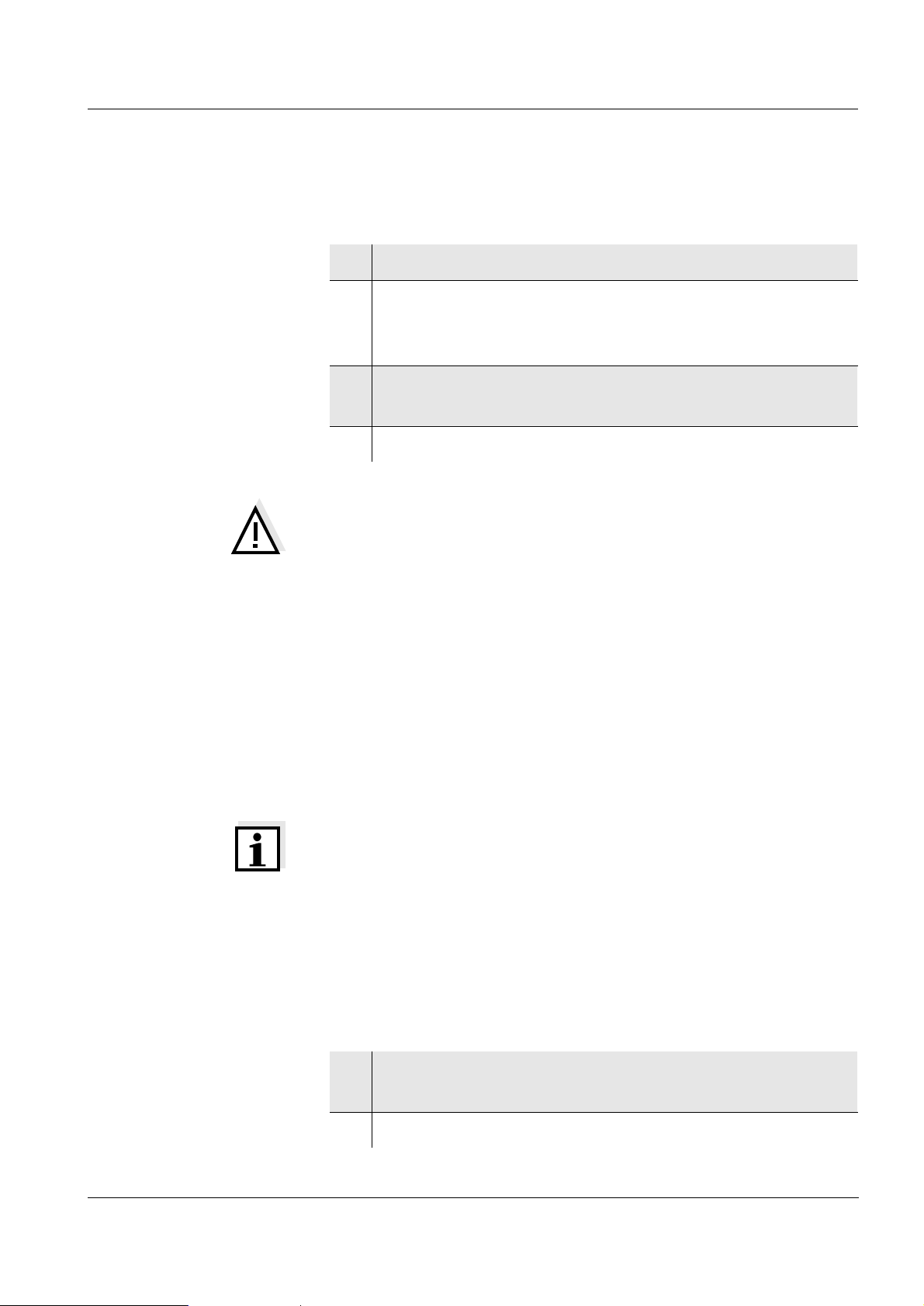

Calibration

evaluation

After calibrating, the instrument automatically evaluates the

current condition of the calibration.

The evaluation appears on the display.

Display Cell constant [cm-1]

0.450 ... 0.500 cm

0.800 ... 1.200 cm

-1

-1

outside of the ranges

0.450 ... 0.500 cm

-1

or

Perform error elimination

0.800 ... 1.200 cm

-1

according to chapter

6W

HAT TO DO IF...

Calibration protocol The calibration protoc ol con tai ns the cal ibr ati on dat a of the

current calibration.

108

Note

You can automatically print out a calibration protocol after

the calibration. To do so, switch on the printer before the calibration (Print LED lights up green). After a valid calibration,

the protocol is printed.

CALIBRATION PROTOCOL

14.04.99 11:37

Device No.: 99990000

CALIBRATION CONDUCTIVITY

Cal Time: 14.04.99 / 11:37

Cal Interval: 180d

Cal Std.: 0.01 mol/l KCL

40.0 °C

Conduct./Tref25: 1413µS/cm

Cell Const : 0.975 1/cm

Probe : +++

Operation

Calibration interval

(Int 3)

Setting the

calibration interval

The flashing sensor symbol reminds you to calibrate regularly. After the selected calibration interval (Int 3) expires,

the sensor symbol flashes. Measurements can continue.

Note

To ensure the high measuring precision of the measuring

system, perform a calibration after the calibration interval

expires.

The calibration interval (Int 3) is set to 180 days in the factory. The interval can be changed (1 ... 999 days):

1 Switch off the instrument.

2 Press <

3 Press the <on/off> key.

The

The instrument then switches automatically to the

configuration level.

ì> and hold down the key.

display test

appears briefly on the display.

4 Press the <run/enter> key until Int 3 appears on the

display.

5 Press <▲> < ▼> to set the required time interval until

the next calibration.

6 Confirm with <run/enter>.

7 Change to the measuring mode by pressing <ì>.

109

Operation

Setting up the cell

constant manually

To set up the cell constant manually, proceed as follows:

1 Press the <CAL> key repeatedly until LF CELL ap-

pears on the display.

2 Press the <run/enter> key.

3 Press the <CAL> key repeatedly until the cell con-

stant to be set, e. g. 0.475 cm

-1

is displayed:

110

4 Set up the cell constant to be used by pressing

▲><▼>, e. g. 0.614 cm

<

-1

.

5 To return to the measuring mode: press the <ì> key.

Operation

Note

The cell constant to be set up must either be taken from the

operating manual of the measuring cell or is printed on the

measuring cell.

Selecting the

0.1 cm

-1

cell constant

-1

To select the 0.1 cm

cell constant proceed as follows:

1 Press the <CAL> key repeatedly until LF CELL ap-

pears on the display.

2 Press the <run/enter> key.

3 Press the <CAL> key repeatedly until the 0.100 cm

cell constant appears on the display.

-1

4 To return to the measuring mode: press the <ì> key.

111

Operation

Selecting the

0.01 cm

-1

cell constant

To select the 0.01 cm

-1

cell constant proceed as follows:

1 Press the <CAL> key repeatedly until LF CELL ap-

pears on the display.

2 Press the run/enter> key.

3 Press the <CAL> key repeatedly until the 0.010 cm

cell constant appears on the display.

-1

112

4 To return to the measuring mode: press the <ì> key.

Operation

Setting up the

temperature

compensation TC

ips Select the following temperature compensations to work

The calculation of the temperature compensation is based

on the preset reference temperature, Tref 20 or Tref 25 (see

chapter 4.6 C

ONFIGURATION).

You can select one of the following temperature compensations:

l Non-linear temperature compensation "nLF"

according to DIN 38404 or EN 27 888

l linear temperature compensation "Lin" with a

coefficient that can be set in the range 0.001 ... 3.000 %/K

l no temperature compensation

Note

with the test samples given in the table:

Application

notes

Test sample Temperature

compensation TC

Natural water

(ground water,

surface water,

nLF

according to DIN 38404

EN 27 888

drinking water)

Ultrapure water nLF

according to DIN 38404

EN 27 888

Other aqueous

solutions

Set linear

temperature coefficient

0.001 ... 3.000 %/K

Salinity

(seawater)

Automatically nLF according to IOT

Display

indicator

Sal,

113

Operation

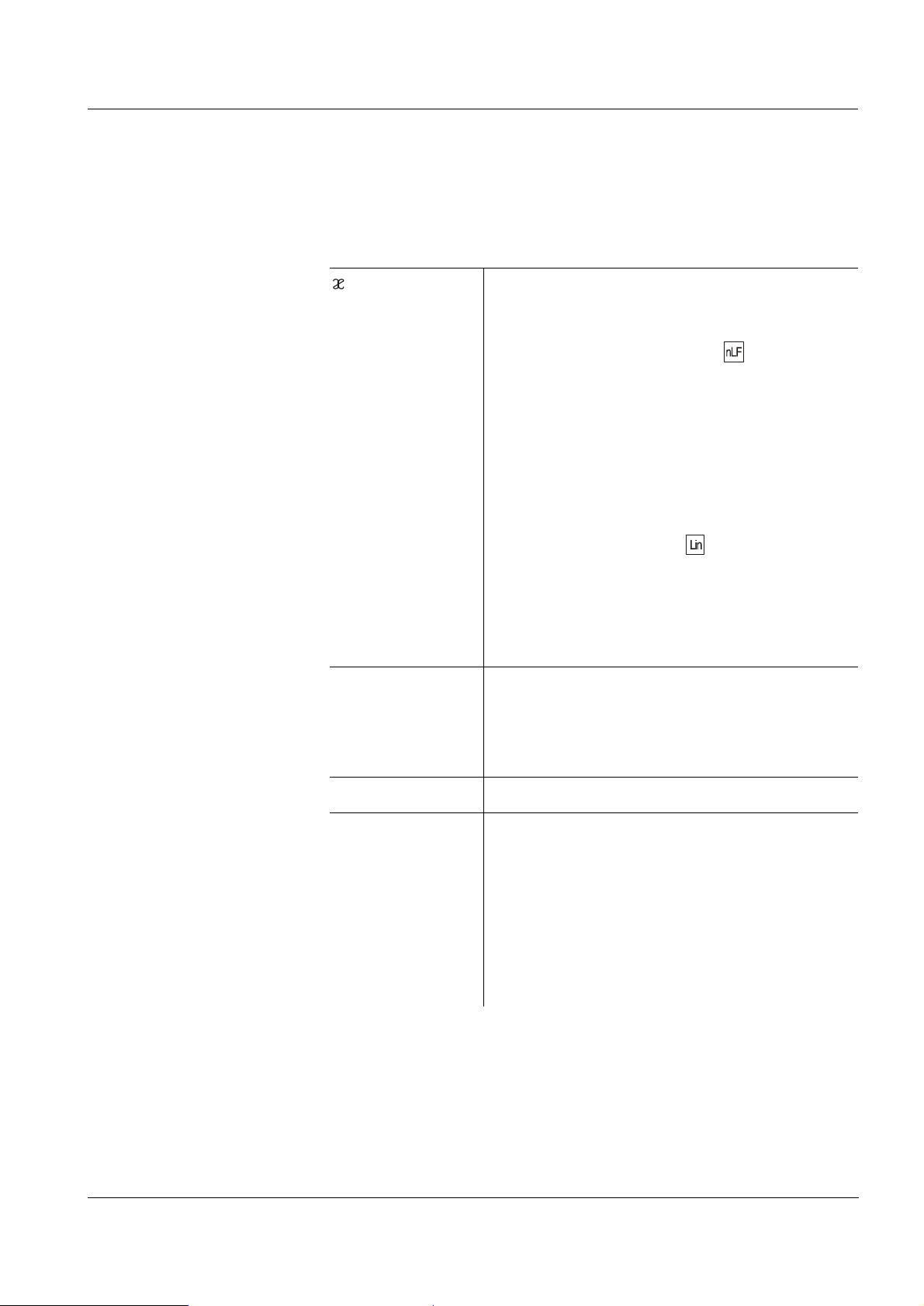

Selecting the non-

linear temperature

compensation

To select the non-linear temperature compensation proceed

as follows:

1 Press the <CAL> key repeatedly until LF tc appears

on the display.

2 Press the <run/enter> key.

3 Press the <CAL> key repeatedly until nLF appears

on the display.

114

4 To return to the measuring mode: press the <ì> key.

Operation

Selecting the linear

temperature

compensation

To select the linear temperature compensation proceed as

follows:

1 Press the <CAL> key repeatedly until LF tc appears

on the display.

2 Press the <run/enter> key.

3 Press the <CAL> key repeatedly until the adjustable

linear temperature coefficient appears on the display.

4 Set up the temperature coefficient, e. g. 1.880 %/K

using <

▲> <▼>.

5 To return to the measuring mode: press the <ì> key.

115

Operation

Switching off the

temperature

compensation

To switch off the temperature compensation proceed as follows:

1 Press the <CAL> key repeatedly until LF tc appears

on the display.

2 Press the <run/enter> key.

3 Press the <CAL> key repeatedly until the following

display appears.

116

4 The temperature compensation has been switched

off.

5 To return to the measuring mode: press the <

ì> key.

Operation

4.4 Storing

The conductivity meter has an internal data storage device.

Up to 200 data records can be stored in it.

A complete data record consists of:

l Memory location

l Date

l Time

l Measured value

l Temperature

l I.D. number

You can transmit measured values (data records) to the

data storage in 2 ways:

l Manual storage

l Switching on the AutoStore function (Int 1), see page 119

4.4.1 Manual storage

You can transmit a measured value to the data storage as

follows:

1 Press the <STO> key.

The current number of the next free memory location

appears on the display.

117

Operation

2 Confirm with <run/enter>.

The display changes to the input of the I.D. number.

3 Enter the required I.D. number (1 ... 999) by pressing

<

▲> <▼>.

4 Confirm with <run/enter>.

The instrument changes to the measuring mode.

*(+,, message This message appears if all 200 memory locations are full.

You have the following options:

Store the current measured value.

The oldest measured value (memory

Press

<run/enter>

location 1) is overwritten by this

Return to the measuring mode without

Press any key

storing

Output the data storage See section 4.4.3

Delete the data storage See section 4.4.4

118

Operation

4.4.2 Switching on AutoStore (Int 1)

The storage interval (Int 1) determines the time interval

between automatic storage processes.

After the time interval expires, the current data record is

transmitted to the data storage and to the interface.

The storage interval (Int 1) is set to OFF in the factory.

Thus, the

AutoStore

function is switched off.

To switch the function on, set up a time interval (5 s, 10 s,

30 s, 1 min, 5 min, 10 min, 15 min, 30 min, 60 min).

Note

If the

AutoStore

function is active, the setting of the data

transmission interval (int 2) is ineffective (see page 128).

Setting the storage

interval

1 Press and hold down the <run/enter> key.

2 Press the <STO> key. Int 1 appears on the display.

3 Press the <▲> <▼> keys to set up the required time

interval between storage processes.

4 Confirm with <run/enter>.

The number of free memory locations appears on the

display.

119

Operation

5 As soon as all 200 memory locations are full, the Au-

toStore function is terminated (Int 1 = OFF).

If too few storage locations are available for your

measurements:

– backup the data storage (see page 121) and

– clear the data stored (see page 127).

6 Confirm with <run/enter>.

The prompt for the I.D. number appears on the display.

7 Press <▲> <▼> to set the required I.D. number.

8 Confirm with <run/enter>.

The instrument changes to the measuring mode and

starts the measuring and storage procedure.

AutoStore

flashes on the display.

120

Note

The

AutoStore

function is interrupted if you perform other

functions, e.g. output data storage.

After completing the other function, the

AutoStore

function

continues. However, as a result, gaps can occur in the

recording of the measured values.

Operation

Switching off the

AutoStore

Outputting to the

display

Switch off the

l Setting the storage interval (Int 1) to OFF or

l Switch the conductivity meter off and on again.

AutoStore

function by:

4.4.3 Outputting the data storage

The contents of the data storage can be output to the:

l display

l interface

1 Press the <RCL> key repeatedly until

Sto disp

ap-

pears on the display.

2 Press the <run/enter> key.

A measured value appears on the display.

The I. D. number of the data record appears for approx. 2 s.

121

Operation

3 After 2 s the respective temperature of the data

record appears on the display. Stored data records

are displayed together with the RCL display indicator.

You can perform the following activities:

Display further parameters of the data

record (I.D. no., date, time, memory loca-

Press

<run/enter>

tion)

Advance one data record (memory location) Press <

Go back one data record (memory location) Press <

▲>

▼>

122

Operation

Note

If you want to find a specific parameter (e.g. date), proceed

as follows:

1 Press the <RCL> key repeatedly until

Sto disp

pears on the display.

2 Press the <run/enter> key.

A measured value appears on the display.

The I. D. number of the data record appears for approx. 2 s.

3 After 2 s the respective temperature of the data

record appears on the display.

ap-

4 Select the parameter (e.g. date) by pressing

<run/enter>.

5 Press <

▲> or <▼> repeatedly until the required date

appears on the display.

After approx. 2 s, the temperature of the displayed

measured value appears.

123

Operation

Outputting to the

interface

1 Press the <RCL> key repeatedly until

pears on the display.

2 Press the <run/enter> key.

The protocol of the last calibration is transmitted to

the printer/RS interface. In the meantime,

appears on the display.

Following the calibration protocol, the complete contents of the storage is transmitted to the interface.

Sto SEr

Sto CAL

ap-

Note

You can cancel the transmission by pressing <

<run/enter>.

ì> or

124

Operation

Sample printout

CALIBRATION PROTOCOL

14.04.99 11:37

Device No.: 99990000

CALIBRATION CONDUCTIVITY

Cal Time: 14.04.99 / 11:37

Cal Interval: 180d

Cal Std.: 0.01 mol/l KCL

23.0 °C

Conduct./Tref25: 1413 µS/cm

Cell Const : 0.975 1/cm

Probe: +++

No. 1:

01.01.99 00:04

2.40 mS/cm 25 °C

Tman

nLF

Tref25 C = 0.475 1/cm

Ident : 1

No. 2:

10.01.99 10:09

2.40 mS/cm 25.3 °C

Tauto

nLF

Tref25 C = 0.475 1/cm

Ident : 1

No. 3:

12.01.99 01:48

2.40 mS/cm 21.6 °C

Tauto

nLF

Tref25 C = 0.475 1/cm

Ident : 1

The printout

contains:

l Calibration protocol:

– Date/time of the printout

– Instrument number (Device No.)

– Date/time of the calibration (Cal Time)

– Calibration interval (Cal Interval)

– Calibration standard 0.01 mol/l KCL (Cal Std.) [°C/F]

– Conductivity of the calibration standard at 25 °C

(Conduct./Tref25)

– Cell constant (Cell Const)

– Probe evaluation (Probe)

125

Operation

l Contents of the measuring storage:

– Number of the storage location (No.)

– Date/time of measurement

– Measured value/unit (mS/cm) [°C/F]

– Automatic/manual temperature measurement

(Tauto/Tman)

– Temperature compensation (nLF)

– Tref

– Cell constant (1/cm)

– AutoRead function (AR)

– I.D. number (Ident)

126

Operation

4.4.4 Clearing the storage

This function can erase the stored data records. 200 memory locations will then become available again.

Note

Clear store

The

function only appears if data records have

already been stored in the storage. Otherwise, the conductivity meter automatically changes to the measuring mode.

In order to delete all the data records, proceed as follows:

1 Switch off the instrument.

2 Press and hold down the <STO> key.

3 Press the <on/off> key.

The

display test

appears briefly on the display.

4 Confirm the clearing process by pressing

<run/enter>.

Pressing any other key stops the clearing process

and the data records remain in the storage.

Note

The calibration data remain in the storage and can be called

up via the calibration protocol.

127

Operation

4.5 Data transmission

You can use the following options to transmit data:

l One of the following options:

– The

AutoStore

periodically (

function (page 119) is used to

Int 1

storage interval) save measured

values internally and output them on the interface.

– The

data transmission interval (Int 2)

function is used to

periodically output measured values to the interface

(see below).

l The

Output data store

function (page 121) is used to output calibration data and stored measured values to the interface.

l The analog recorder output (page 130) is used to output

measured values as voltages.

4.5.1 Data transmission interval (Int 2)

The interval for the data transmission (Int 2) determines the

time interval between automatic data transmissions. After

the time interval expires, the current data record is transmitted to the printer/RS interface.

128

Note

The setting of the interval (Int 2) only has an effect when the

storage interval (

AutoStore

function) is switched off.

Operation

Setting the

data transmission

interval

The interval is set to OFF in the factory.

To start the data transmission, set up an interval (5 s, 10 s,

30 s, 1 min, 5 min, 10 min, 15 min, 30 min, 60 min):

1 Press and hold down the <run/enter> key.

2 Press the <auto read> key.

Int 2 appears on the display.

3 Press <▲> <▼> to set up the required time interval

between storage processes.

4 Confirm with <run/enter>.

The instrument changes automatically to the measuring mode.

Note

If the

AutoStore

function is active, the data transmission is

performed according to the setting of the storage interval

(Int1). Set the storage interval (Int1) to OFF to activate the

data transmission

interval (Int2).

Note

You can also set the

Configuration

menu (see page 128).

data transmission

interval (Int2) in the

129

Operation

/

4.5.2 Recorder (analog output)

You can transmit the data to a recorder via the analog output. Connect the analog output to the recorder via the Z394

interface cable.

The data output switches automatically to

recorder output

.

Socket assignment

Conductivity

resistance

1 Free

2 Plug coding

3 Ground

4 Analog output

(Internal resistance < 5 Ohm)

Note

Activate the analog output by connecting 2 and 3 or use the

original cable.

The signal range of the analog output depends on the measured parameter and the measuring range:

Measuring range Voltage Resolution

0.000 ... 1.999 µS/cm 0 ... 1999 mV 1 mV

0.00 ... 19.99 µS/cm 0 ... 1999 mV 1 mV

0.0 ... 199.9 µS/cm 0 ... 1999 mV 1 mV

130

Salinity

TDS

0 ... 1999 µS/cm 0 ... 1999 mV 1 mV

0.00 ... 19.99 mS/cm 0 ... 1999 mV 1 mV

0.0 ... 199.9 mS/cm 0 ... 1999 mV 1 mV

0 ... 500 mS/cm 0 ... 500 mV 1 mV

Measuring range Voltage Resolution

0 ... 70.0 0 ... 700 mV 1 mV

Measuring range Voltage Resolution

0 ... 1999 mg/l 0 ... 1999 mV 1 mV

Operation

4.5.3 PC/external printer (RS232 interface)

You can transmit data to a PC or an external printer via the

RS232 interface.

Connect the interface to the instrument via the Z395 cable

(PC) or Z391 cable (external printer).

The data output switches automatically to

RS232

.

Note

The RS232 interface is not galvanically isolated.

If it is connected to an earthed PC/printer, measurements

cannot be made in earthed media as this would give incorrect results!

Socket assignment

Set up the following transmission data on the PC/printer:

Baud rate Selectable between:

1200, 2400, 4800, 9600

Handshake RTS/CTS + Xon/Xoff

PC only:

Parity None

Data bits 8

Stop bits 1

1 CTS

2 RxD

3 Ground

4 TxD

131

Operation

4.6 Configuration

You can adapt the conductivity meter to your individual

requirements. To do this, the following parameters can be

called up/changed (the status on delivery is marked in bold):

Baud rate 1200, 2400, 4800. 9600

Data transmission inter-

val (Int 2)

Calibration interval (Int 3) 1 ... 180 ... 999 d

AutoRange ARng yes, no

TREF 25/TREF 20 t25 or t20

Measured values given

as conductivity or resistance values

Temperature unit °C or °F

Date/time as required

Note

You can leave the configuration menu at any time.

Parameters that have already been changed are stored.

To do this, press the <

OFF, 5 s, 10 s, 30 s,

1 min, 5 min, 10 min,

15 min, 30 min, 60 min

S/cm or M

Ω

ì> key.

132

1 Switch off the instrument.

2 Press and hold down the <

3 Press the <on/off> key.

The display test

The instrument then switches automatically to the

setting of the baud rate.

appears briefly on the display.

ì> key.

Baud rate

Data transmission

interval

Operation

4 Set up the required baud rate by pressing <▲> <▼>.

5 Confirm with <run/enter>.

Int 2 appears on the display.

6 Set up the required time interval by pressing

<

▲><▼>.

7 Confirm with <run/enter>.

Int.3

appears on the display.

133

Operation

Calibration

interval

ARng (AutoRange)

8 Set up the required time interval by pressing

▲><▼>.

<

9 Confirm with <run/enter>.

ARng appears on the display.

10 With <▲> <▼> select between YES and no.

11 Confirm with <run/enter>.

t25 appears on the display.

134

Reference

temperature

Conductivity

Operation

12 With <▲> <▼> select between t25 and t20

.

13 Confirm with <run/enter>. LF appears on the display.

Temperature unit

14 With <▲> <▼> select between S/cm and MΩ.

15 Confirm with <run/enter>.

USE °C appears on the display.

16 Select between °C and °F by pressing <▲> <▼>.

17 Confirm with <run/enter>.

The date flashes on the display.

135

Operation

Date and time

18 Set today’s date by pressing <▲> <▼>.

19 Confirm with <run/enter>.

The date (month) flashes on the display.

20 Set the current month by pressing <▲> <▼>.

21 Confirm with <run/enter>.

The year appears on the display.

136

22 Set the current year by pressing <▲> <▼>.

23 Confirm with <run/enter>.

The hours flash on the display.

24 Set the current time by pressing <▲> <▼>.

25 Confirm with <run/enter>.

The minutes flash on the display.

26 Set the current time by pressing <▲> <▼>.

27 Confirm with <run/enter>.

The instrument changes automatically to the conduc-

tivity measuring mode.

Operation

4.7 Reset

You can reset (initialize) measuring and configuration

parameters separately from one another.

Measuring

parameters

The following measuring parameters (Cond InI) are reset to

the values they had on delivery:

Measuring mode

Cell constant 0.475 cm

0.475 cm

Temperature

nLF

-1

(calibrated)

-1

(set up)

compensation

Reference temperature

Temperature coefficient of

2.000 %/K

the linear temperature compensation

TDS factor 1.00

Note

When the measuring parameters are reset, the calibration

data are lost. After the parameters have been reset, calibrate!

Configuration

parameters

The following configuration parameters (InI) are reset to the

values they had on delivery:

Baud rate 4800

Interval 1

OFF

(automatic storing)

Interval 2

OFF

(for data transmission)

137

Operation

Resetting

measuring

parameters

1 Press and hold down the <run/enter> key.

2 Press the <CAL> key.

3 Use <▲> <▼> to toggle between no and yes.

yes: reset measuring parameters.

no: retain settings.

Resetting

configuration

parameters

4 Confirm with <run/enter>.

The instrument changes to the configuration parameters.

5 Toggle between no and yes by pressing <▲> <▼>.

yes: reset configuration parameters.

no: retain settings.

6 Confirm with <run/enter>.

The instrument changes automatically to the conductivity measuring mode.

138

Maintenance, cleaning, disposal

5 Maintenance, cleaning, disposal

5.1 Maintenance

The maintenance tasks are restricted to the following activities:

l replacing the batteries and

l replacing the roll of printer paper.

Note

See the relevant operating manual of the electrode for

instructions on maintenance.

139

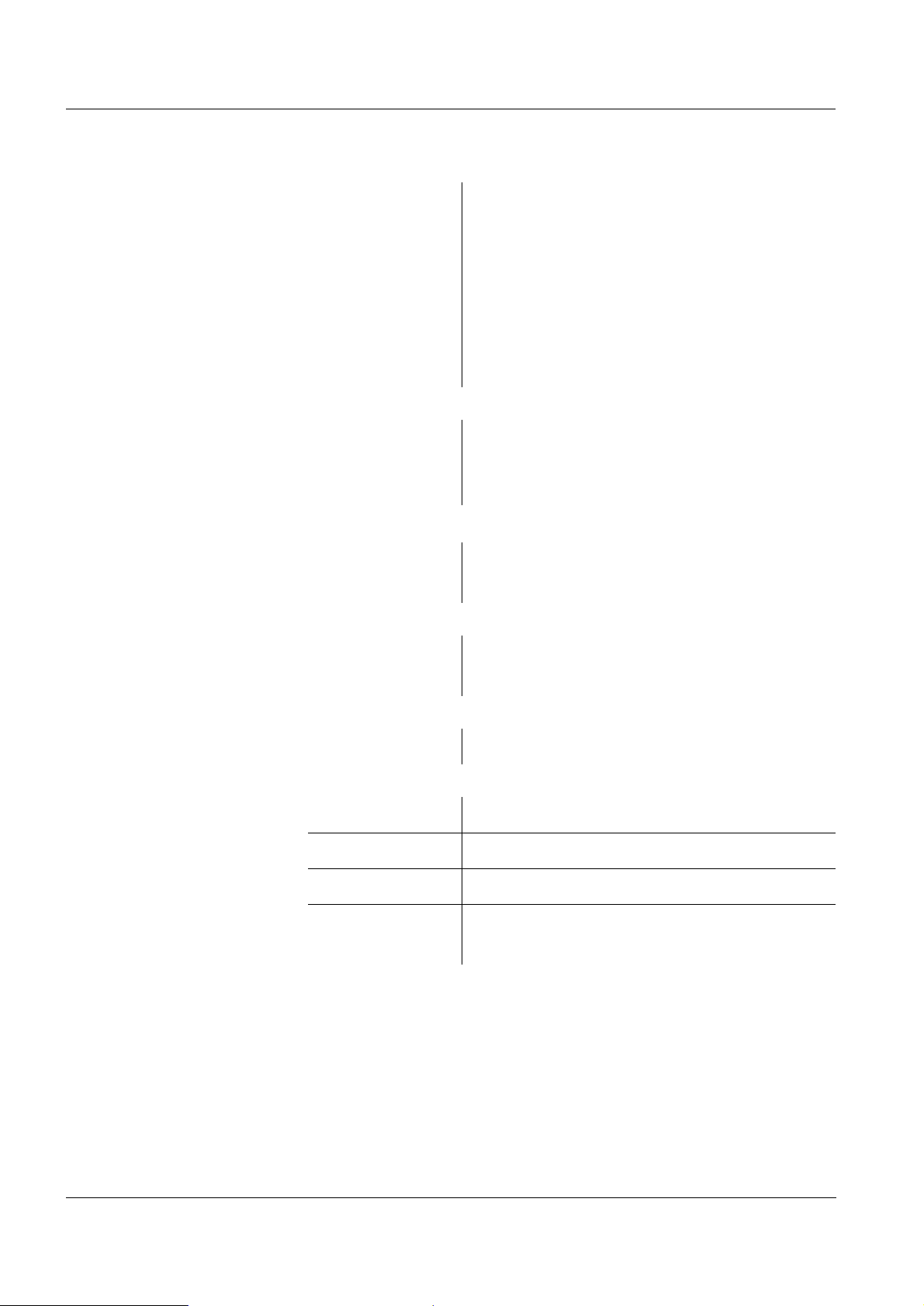

Maintenance, cleaning, disposal

5.1.1 Changing the batteries

1 Open the battery compartment (1) on the underside

2 Remove the four batteries from the battery compart-

3 Insert four new batteries (Type Mignon AA) into the

4 Close the battery compartment (1).

5 Set up the date and time according to chapter 3 COM-

of the instrument.

ment.

battery compartment.

The date (day) flashes on the display.

MISSIONING.

1

Caution

Make sure that the poles of the batteries are the right way

round.

± signs in the battery compartment must correspond to

The

± signs on the batteries.

the

Only use leakproof alkaline manganese batteries.

140

Maintenance, cleaning, disposal

5.1.2 Replacing the roll of printer paper

1 Switch off the printer (Print LED lights up red).

2 Open the lid of the printer (1).

3 Remove the empty roll of paper (2).

4 Insert the new roll of paper:

– Fold the leading edge of the paper inwards and

thread it into the printer (3) from underneath.

– Press the <feed> Print key (paper feed).

5 Close the lid of the printer (1).

1

2

3

Note

Only use original SCHOTT HQ thermal paper. Information

on this is given in the SCHOTT general catalog.

141

Maintenance, cleaning, disposal

5.2 Cleaning

Occasionally wipe the outside of the measuring instrument

with a damp, lint-free cloth. Disinfect the housing with isopropanol as required.

Caution

The housing is made of synthetic material (ABS). Thus,

avoid contact with acetone or similar detergents that contain

solvents. Remove any splashes immediately.

5.3 Disposal

Packing The measuring instrument is sent out in a protective trans-

port packing.

We recommend: Keep the packing material. It protects the

instrument against damage during transport.

Batteries This note refers to the battery regulation that applies in the

Federal Republic of Germany. We would ask end-consumers in other countries to follow their local statutory provisions.

Note

In compliance with §14 of the B

ATTERY REGULATION, we

would like to point out that this instrument contains batteries.

Batteries that have been removed must only be disposed of

at the recycling facility set up for this purpose or via the retail

outlet.

It is illegal to dispose of them in household refuse.

Measuring

instrument

Dispose of the measuring instrument as electronic waste at

an appropriate collection point. It is illegal to dispose of them

in household refuse.

142

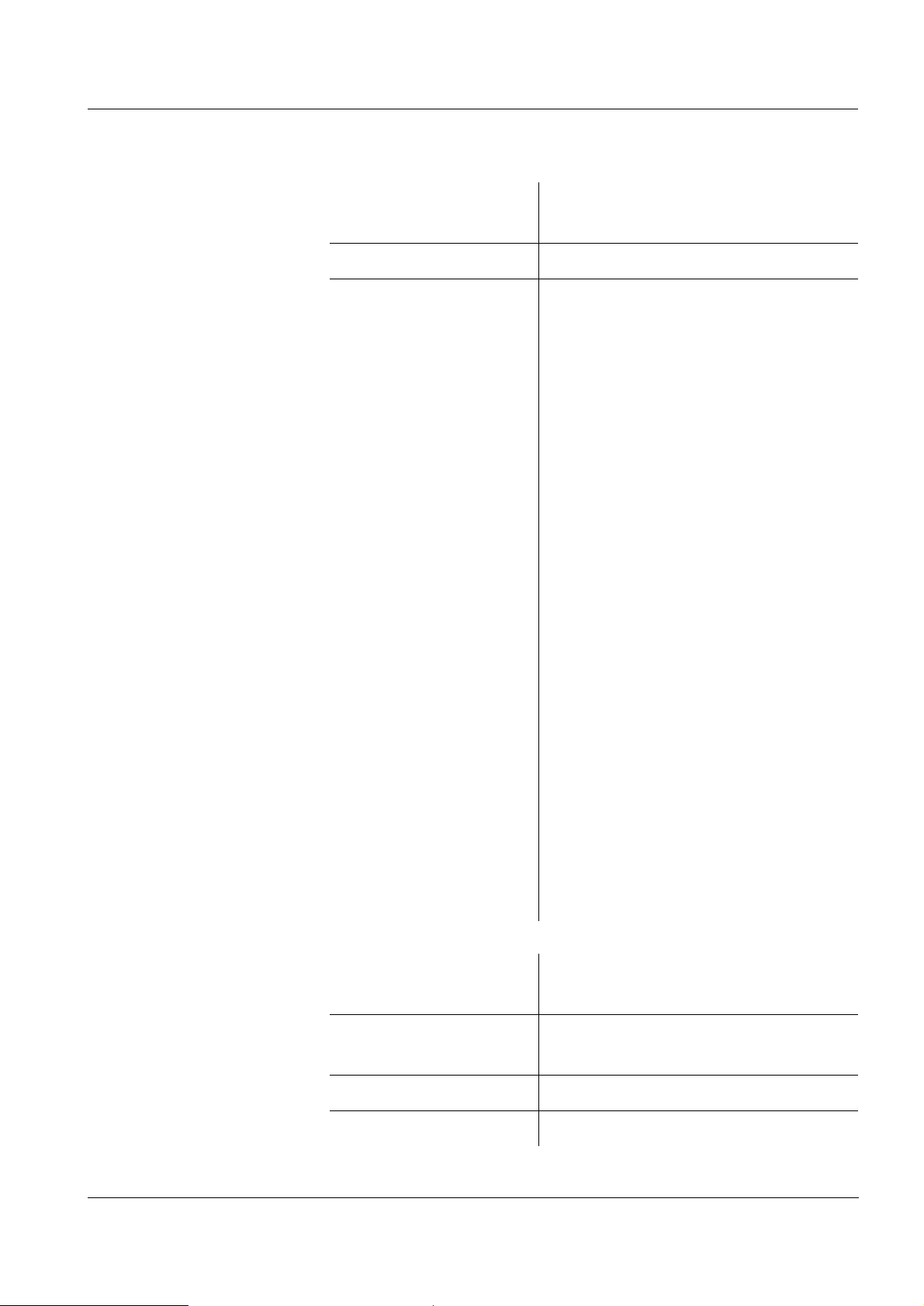

Error message,

What to do if...

6 What to do if...

Cause Remedy

I/

Error message,

LoBat

Instrument does not

react to keystroke

– Measuring cell not

connected

– Connect measuring

cell

– Cable broken – Replace electrode

Cause Remedy

– Measuring cell

contaminated

– Unsuitable calibration

solution

– Clean measuring cell;

if necessary, replace it

– Check calibration

solutions

Cause Remedy

– Batteries almost

depleted

– Replace batteries

(see section 5.1

M

AINTENANCE)

Cause Remedy

– Operating state

undefined or EMC

electric stress unallowed

– Processor reset:

Press the <auto read>

key and switch on

instrument

*(

display

Cause Remedy

– Timeout of the interface – Check connected

instrument

143

What to do if...

Integrated printer

does not print

Cause Remedy

– Printer switched off – Switch on printer

Integrated printer

prints automatically

Print key <feed>

does not react

– No mains power supply

connected

– Interface cable

– Connect mains power

supply

– Unplug cable

connected

– No paper available – Replace roll of paper

AutoStore

–

switched on with a longer

function is

– Switch off

AutoStore

function (see page 121)

interval duration (Int 1)

Cause Remedy

–

AutoStore

(Int 1) or

transmission

function

Data

(Int 2) is

– Switch off functions

(see page 121/page 128)

switched on

Cause Remedy

– Printer is switched on – Switch off printer

Printer operating -

paper not

being printed

*(+,,

message

144

– Interface cable

– Unplug cable

connected

Cause Remedy

– Paper inserted with

wrong side upwards

– Turn the roll of paper

around and insert it with

the other side upwards

Cause Remedy

– All 200 memory

locations are full

– Output data storage and

clear data storage

(see page 127)

Lists

7Lists

This chapter provides additional information and orientation

aids.

Abbreviations The list of abbreviations explains abbreviations that appear

on the display or when dealing with the instrument.

Specialist terms The glossary briefly explains the meaning of the specialist

terms. However, terms that should already be familiar to the

target group are not described here.

Index The index helps you find the topics that you are looking for.

145

Lists

Abkürzungsverzeichnis

Conductivity value

ABS Plastic housing

AR AutoRead (drift control)

ARng Automatic range switching

Measuring instrument measures with high-

est resolution

AutoStore Automatic storing

Baud Baud rate

C Cell constant cm

-1

Cal Calibration

CELL Cell constant

disp Display

Output of the data storage on the display

E3 Error message (see chapter 6 W

IF...)

Ident I. D. number

InI Initialization

Resets individual basic functions to

the status they had on delivery

Int Interval

Lin Linear temperature compensation

LoBat Low Battery

Batteries are almost empty

HAT TO DO

146

nLF Non-linear temperature compensation

OFL Overflow

Display range exceeded

Sal Salinity

SELV Safety Extra Low Voltage

Sto CIr Clear storage

Sto disp Output of the data storage on the display

Sto Full Memory full

Sto SEr Output of the data storage to the printer/

interface

Tauto Automatic temperature measurement

TC Temperature coefficient

TDS Total dissolved solids

TP Temperature Probe

Temperature measurement active

Tref 20/T20 Reference temperature 20 °C

Lists

Tref 25/T25 Reference temperature 25 °C

°C Temperature unit °Celsius

°F Temperature unit Fahrenheit

147

Lists

Glossary

AutoRead Monitors the electrode drift and releases the measured

value only after the stability criterion has been reached. In

this way, this procedure ensures the highest degree of precision and reproducibility.

Calibration The cell constant is determined through calibration. To do

so, the conductivity measuring cell is immersed into a series

of aqueous salt solutions with exactly known electric conductiviy. The relevant conductivity values are determined

using the conductivity measuring instrument.

Cell constant Linear factor describing the geometrical dimensions of a

measuring cell and its electrodes.

l With the value of the cell constant you can roughly de-

scribe the application range of a conductivity measuring

cell.

l The cell constant is determined through calibration in one

or several calibration solutions.

Conductivity The conductivity value is a sum parameter for the ion con-

centration of a test sample.

Control standard

solution

Solution with a known conductivity to determine or check the

conductivity.

Drift control See AUTOREAD.

148

Reference

temperature

In order to compare values measured at different temperatures, the values have to be converted to a fixed tempera-

ture. This temperature is 25 °C, or, as an exception, 20 °C.

Lists

Resistance All substances (solids, liquids, or gases) with mobile charge

carriers like for example electrons or ions have a finite ohmic

resistance, which means they have an electric conductance

that can be measured or an electric conducitivtiy.

Salinity The salinity is a sum parameter especially for seawater;

it gives the salt content of seawater.

Temperature

compensation (TC)

Test sample The substance to be measured. It can be liquid or solid.

Total dissolved

solids (TDS)

The temperature has a very strong impact on the electrical

conductivity. To be able to compare measured values, it is

necessary to temper or convert the test sample to a reference temperature.

Mass that remains of the substances dissolved in an aqueous solution after a fixed filtering and drying procedure, as

far as these substances are not volatile under the conditions

of this procedure. The total dissolved solids refer to the volume of the filtered aqueous sample used und are given in

mg/l.

149

Lists

150

Index

Lists

A

analog output 130

authorized use 92

AutoRange 134

AutoRead 100

AutoStore 119

B

batteries

replacing 139

battery compartment 140

baud rate, setting 133

C

calibration 106

interval 109

protocol 108

calibration evaluation 108

cell constant 98, 106

changing the batteries 140

cleaning 142

commissioning 95

condition on delivery 137

conductivity 135

conductivity measurement 101

conductivity/resistance 130

D

data record 117

data transmission (interval) 129

date, setting 136

display 84

disposal 142

drift control 100

E

energy saving feature 97

error messages 143

I

initialize 137

interval

calibration (Int 3) 109

storing (Int 1) 119

K

keys 82

L

linear temperature compensation 113,

115

LoBat 143

M

maintenance 139

manual storing 117

measuring 99

measuring precision 109

N

no temperature compensation 113

non-linear temperature compensation

113, 114

O

operation 97

operational safety 92

output data storage 121

P

paper roll

replacing 139

place of the instrument 97

plug-in power supply

connecting 96

printing

calibration protocol 108

measured values 105

151

Lists

R

recorder output 130

reference temperature 135

replacing the roll of printer paper 141

reset 137

RS232 interface 131

S

safety 91

safety precautions 91

salinity 130

salinity measurement 102

sockets 84

storing 117

T

TDS 130

TDS (total dissolved solids) 103

temperature compensation 113

linear 115

non-linear 114

setting 113

switch off 116

temperature probe 99

temperature unit 135

time

setting 95

time, setting 136

total dissolved solids measurement 103

transmit data 128

W

What to do if... 143

152

Loading...

Loading...