Page 1

Publication PB 0188

Issue 2

Watson-Marlow high flow, high pressure pump

Installation and operating instructions

Pumphead/s: 919 Issue 1

925 Issue 1

940 Issue 1

945 Issue 1

900 series

Page 2

Contents

Declarations .................................................... Page 2

Safety .................................................... Page 3

Information for returning pumps .................................................... Page 3

Two year warranty .................................................... Page 3

Recommended operating procedures ............................................. Page 4

Part 1: Installation

Siting .................................................... Page 5

Pump connections .................................................... Page 5

Electrical connection .................................................... Page 6

Powered tube removal .................................................... Page 7

Powered tube fitting .................................................... Page 8

Manual tube removal .................................................... Page 9

Manual tube fitting .................................................. Page 10

Shoe adjustment .................................................. Page 13

Part 2: Operation

Flow rates .................................................. Page 14

Part 3: Appendices

Spares .................................................. Page 16

Materials of construction .................................................. Page 18

Specification .................................................. Page 18

Outline drawing .................................................. Page 19

Declaration of

conformity

Declaration of

incorporation

Decontamination certificate .................................................. Page 20

Declarations

When a 900 series drive unit, fitted with the 900 series pumphead is used as

a stand alone pump it complies with:

Machinery Directive 89/392/EEC EN60204-1

Low Voltage Directive 73/23/EEC EN61010-1

EMC Directive 89/336/EEC EN50081-1/50082-1

Responsible person: A S Balding, Managing Director, Watson-Marlow Limited,

Falmouth, Cornwall TR11 4RU, England.

Telephone 01326 370370 Fax 01326 376009

When the 900 series pumphead is to be installed into machines or assembled

with other machines for installations, it must not be put into service until the

relevant machinery has been declared in conformity with the provisions of the

machinery directive 89/392/EEC and EN60204-1.

Responsible person: A S Balding, Managing Director, Watson-Marlow Limited,

Falmouth, Cornwall TR11 4RU, England.

Telephone 01326 370370 Fax 01326 376009

Page 2

Page 3

Safety

In the interests of safety, this pump and the tubing selected should only be

used by competent, suitably trained personnel after they have read and

understood this manual, and considered any hazard involved.

Any person who is involved in the installation or maintenance of this

equipment should be fully competent to carry out the work. In the UK this

person should also be familiar with the Health and Safety at Work Act 1974.

Do not remove or open pumphead door whilst operating pump.

Do not place fingers inside pumphead.

Ensure the drive is inoperative before opening the pumphead door.

There are dangerous voltages (at mains potential) inside the motor. If access

is required, isolate the motor from the mains before removing the terminal box

cover.

Information for returning pumps

Any equipment which has been contaminated with, or exposed to, body fluids,

toxic chemicals or any other substance hazardous to health must be

decontaminated before it is returned to Watson-Marlow or its distributor.

A certificate (a suitable blank form is included at the rear of these operating

instructions), or signed statement, must be attached to the outside of the

shipping carton.

This certificate is required even if the pump is unused. If the pump has been

used, the fluids that have been in contact with the pump and the cleaning

procedure must be specified along with a statement that the equipment has

been decontaminated.

Two year warranty

Watson-Marlow Limited warrants, subject to the conditions below, through

either Watson-Marlow Limited, its subsidiaries, or its authorised distributors, to

repair or replace free of charge, including labour, any part of this product

which fails within two years of delivery of the product to the end user. Such

failure must have occurred because of defect in material or workmanship and

not as a result of operation of the product other than in accordance with the

instructions given in this manual.

Conditions of and specific exceptions to the above warranty are:

•

Consumable items such as tubing and glands are excluded.

•

Products must be returned by pre-arrangement carriage paid to Watson-

Marlow Limited, its subsidiaries, or its authorised distributor.

•

All repairs or modifications must have been made by Watson-Marlow

Limited, its subsidiaries, or its authorised distributors or with the express

permission of Watson-Marlow Limited, its subsidiaries, or its authorised

distributors.

•

Products which have been abused, misused, or subjected to malicious or

accidental damage or electrical surge are excluded.

Warranties purporting to be on behalf of Watson-Marlow Limited made by any

person, including representatives of Watson-Marlow Limited, its subsidiaries,

or its distributors, which do not accord with the terms of this warranty shall not

be binding upon Watson-Marlow Limited unless expressly approved in writing

by a Director or Manager of Watson-Marlow Limited.

Page 3

Page 4

Recommended operating procedures

DO

keep delivery and suction lines as short as possible.

DO use the minimum number of bends in rigid pipe runs. If there must be a

bend, use a swept bend and not a tight elbow.

DO

use suction and delivery pipelines with a bore equal to or larger than the

bore of the tube fitted in the pumphead. When pumping

losses caused by increased friction can be overcome by using pipe runs with

a cross sectional area several times greater than the pumping element.

DO

run at a slow speed when pumping viscous fluids.

DO

keep the track and sliding shoe clean.

DO ensure that the correct type and volume of coolant/lubricant is used.

viscous

fluids, the

DO NOT

peristaltic pumps are self priming and will hold their prime up to several

metres, so there may be no need for non-return or foot valves, nor for the

loading valves required on many other kinds of pumps.

Any valves fitted must cause no restriction. If electrically actuated valves are

fitted, they should be interlocked so that the pump will only run when the

valves are open. Fit an automatic by-pass if manual valves are installed.

Explosion proof motors should not be used in an environment where an

explosive gas-air mixture is continuously present or present for long periods.

DO NOT

proof motor.

The temperature of any part or surface of an explosion proof motor must

always remain below the ignition temperature of the gas-air mixture it is

operating in.

The connector elbow located at the top of the pump head, enables the pump

head to be drained of lubricant or any other substance in the case of tube

failure.

If the motor/gearbox used with this 900 series pumphead is not

supplied directly by Watson-Marlow, it is important to refer to the

maintenance manual supplied with the specific motor/gearbox.

fit valves in the suction or delivery line without considering that

connect door switches or any other switch gear with an explosion

Page 4

Page 5

Part 1: Installation

Siting

If the pump is to be lifted ensure that all standard rigging practices are

adhered to. This procedure should only be carried out by qualified

personnel only who are familiar with the Health and Safety at Work Act

1974.

The pump should be situated on a flat horizontal surface where there is free

air to circulate around it. Where the tubing is entering and leaving the

pumphead there should be least 1m of tube without a bend, a removable drop

out section to aid tube replacement, and if practical, this should be of a larger

diameter than the pump tubing.

Pump connections

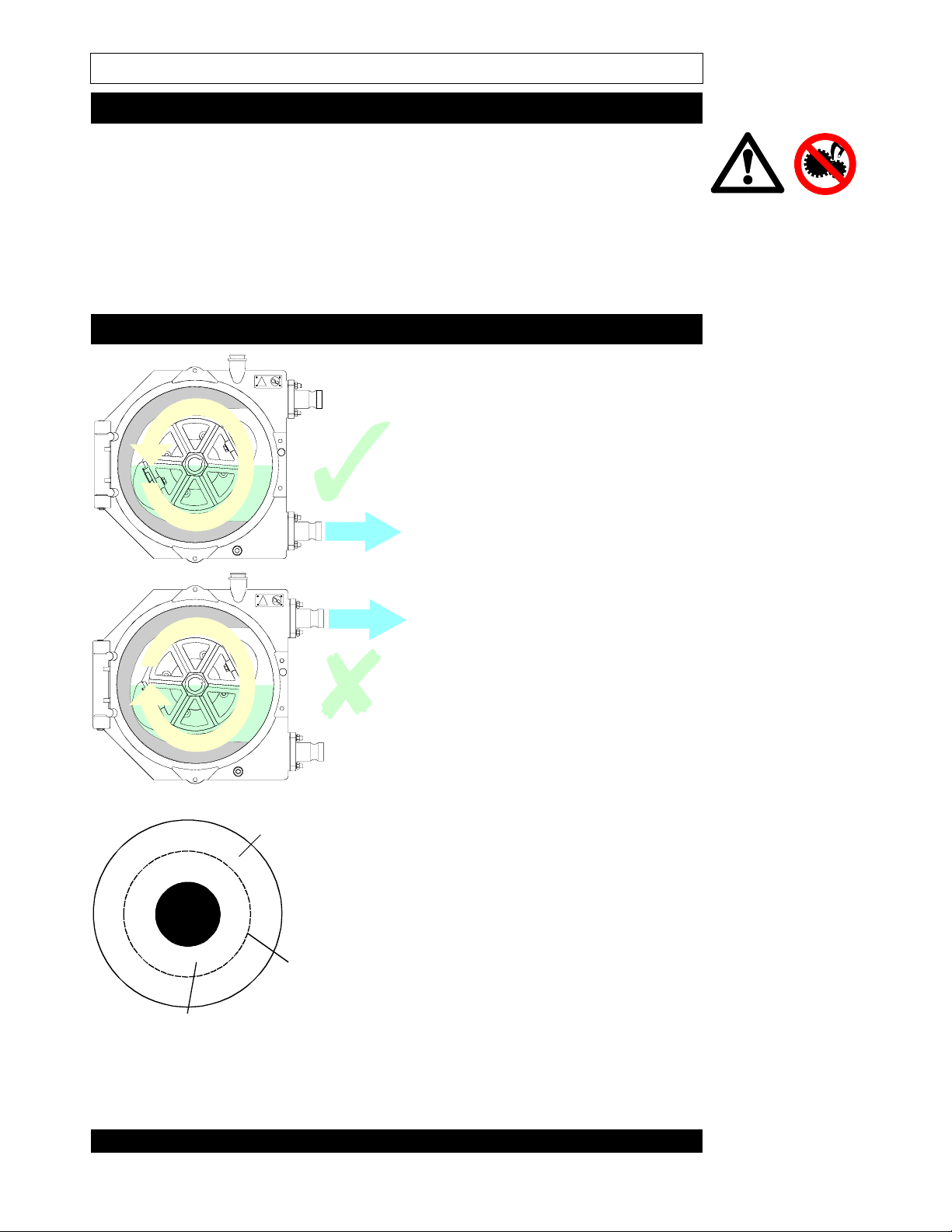

It is recommended that for

maximum tube life, the pump

should always be set up with the

delivery end of the tubing

connected to the lower casing

port of the pumphead and

immersed in cooling lubricant.

This may require the pump head

to be re-fitted to the correct

orientation for operation.

Natural rubber

Nylon

Reinforcing

Natural rubber

Food grade natural rubber

Food grade nitrile rubber

Neoprene rubber

EPDM

Page 5

If the main pipe run to the pump

is rigid pipe work, there should

be a drop out section or flexible

pipe work to allow the pump

tubing to be inserted and

withdrawn.

For working pressures over 7 bar,

always fit an outlet pulsation

damper. Watson-Marlow, or its

representative, can supply

pulsation dampers and will assist

with determining the type

required for your application.

900 Series tubing is available in

the combinations seen left for a

range of process requirements.

Page 6

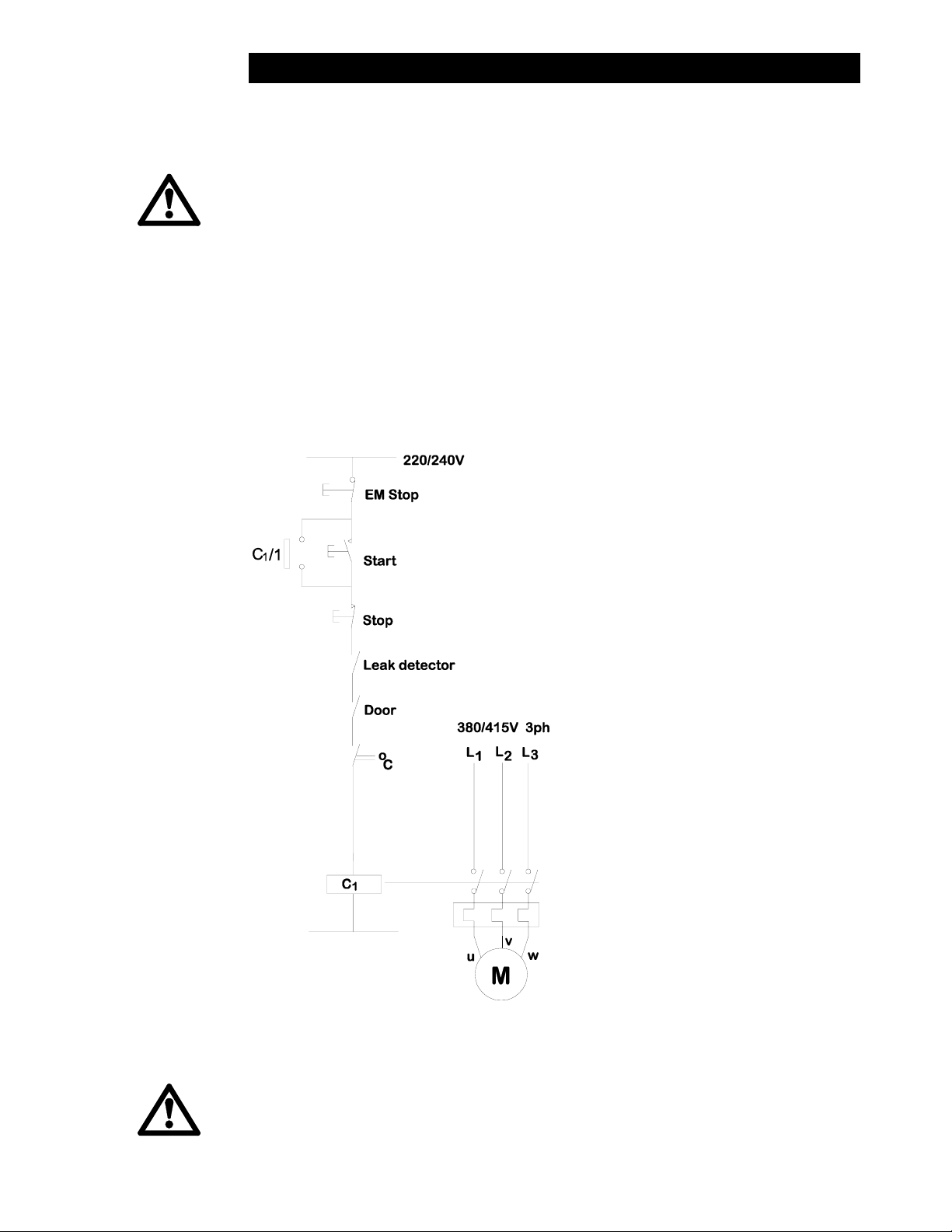

Electrical connection

In order to effectively protect the motor from overloads, appropriate motor

protection devices must be used. Motors fitted to the Watson-Marlow series of

pumps are manufactured with a motor temperature cut-out, but a current

overload relay should also be fitted to a contact breaker.

The motor should be connected by a qualified engineer who is

conversant with the appropriate regulations and they should ensure that

the voltage and frequency of the electrical supply corresponds with the

data on the motor plate.

Connect the motor in accordance with the wiring diagram which will be found

in the motor terminal box.

When a motor thermal protection switch is fitted in the motor, the leads will be

found in the motor terminal box. They should be connected to stop the pump if

the switch operates. The switch will open circuit at an over temperature

condition.

The diagram below shows the connection of the drive motor showing possible

ancillary switches and protections. It depends on the installation whether a

reversing switch and interlock with other equipment is included.

Care must be taken to ensure that

the motor terminal links are in the

correct position and that all

connections including the earth

connection are positioned

correctly and securely.

Ingress protection standard will be

compromised if the connection

box cover is not properly replaced

or if the cable gland is not

correctly fitted. Exd motors must

be connected with approved fitting

and practice.

All pumps, excluding those

intended for use in hazardous

atmospheres, may be fitted with a

door indicator switch. This switch

is rated 240V 0.5A AC Max. Power

load 50W Max. This switch is NOT

intended as a primary safety

device. Under normal operation the

pump door is kept closed and this

meets all statutory requirements

as a tool lockable fixed guard.

The switch may be used directly to

indicate that the door is open

during maintenance, or it may be

wired, following accepted fail safe

practices, into a customers start

up/shut down control system to

provide a back up to the Fixed Guard, whilst maintenance is being

carried out. However, all normal maintenance safety practices should

also be observed.

There are dangerous voltages (at mains potential) inside the motor. If

access is required, isolate the pump from the mains before removing the

cover.

Page 6

Page 7

Powered tube removal

Place a container under the

pumphead, then remove the

lubricant drainage plug and the

lubricant filler plug. Allow the

lubricant to drain from the

pumphead.

Loosen and remove the four

securing nuts on the lower casing

port connector using a 13mm

spanner.

If the pump is a variable speed

unit, run at a slow speed. Run the

pump anticlockwise until the

support ring, compression gland

and the compression ring are

outside of the pump.

Stop the pump and with two

levers, lever the connector out of

the tube, then slide off the support

and compression rings and the

compression gland. Remove the

four securing nuts on the upper

casing port connector using a

13mm spanner.

Reverse the direction of rotation of

the rotor to allow the tube to be

driven out of the pumphead.

Remove the four door locking

screws using the Allen key

supplied.

Page 7

Page 8

Powered tube fitting

Isolate the motor from the

mains supply before opening

the pumphead door.

Swing the pumphead door open.

Remove the tube from the

pumphead.

Check that there is no debris

inside the casing and that it is

clean. Check that the front casing

lubricant seal is not damaged,

then secure the door with the four

door locking screws and the Allen

key supplied ensuring the seal is

seated correctly.

Isolate the motor from the

mains supply before opening

the pumphead door.

Close and lock the pumphead

door with the four door locking

screws and Allen key supplied.

Take a new piece of tubing and

smear Silicone grease or tube

lubricating oil on the outside of the

tube. Connect motor to the mains

supply. Start the pump and with

care, feed the tube into the

pumphead following the

anticlockwise rotation of the rotor.

Continue feeding until the other

end of the tube is level with the

pump face. Stop the motor.

Slide the support ring (the shortest

ring), compression gland and the

compression ring (which has a

step to allow ease of location into

the tube port) onto the tube. Push

the connector into the pipe.

Repeat for the other end of the

tube.

➀

Connector ➁ Compression ring

➂ Support ring ➃ Tube

➄

Page 8

Compression gland

Page 9

Locate the upper port connector

with the securing nuts and the

Allen key supplied.

Rotate the rotor anticlockwise and

drive the other end of the tube out

of the lower casing port. Locate

the support ring, compression

gland and compression ring.

Locate the lower port connector

using the securing nuts and Allen

key supplied.

Replace the lubricant drainage

plug then fill the pumphead with

lubricant to the specified volume.

The window in the pumphead door

is a motion window and provides a

visual indication of the rotation of

the rotor within the pumphead.

This window should not be used

as lubricant level indicator.

Locate and secure the lubricant

filler plug.

Manual tube removal

Isolate the motor from the

mains supply before opening

the pumphead door.

Place a container under the

pumphead, then remove the

lubricant drainage plug and the

lubricant filler plug. Allow the

lubricant to drain from the

pumphead.

Remove the four door locking

screws with the Allen key

supplied. Swing the pumphead

door open.

Page 9

Page 10

Loosen the upper casing port

connector securing nuts using a

13mm spanner. Locate a spanner

on the cast hexagonal nut of the

rotor. Rotate the rotor clockwise

until one pump head shoe has left

contact with the tube completely

and the tubing has been forced

out of the upper casing port.

Lever the connector out of the

tube. Slide off the compression

ring and sealing gland.

Pull the end of the tube out of the

upper casing port and remove the

support ring. Whilst still holding

the tube, rotate the rotor

anticlockwise to enable the tube to

be withdrawn from the pumphead.

When the second shoe is clear of

the tube, remove the lower casing

port connector, compression ring

and sealing gland. Remove the

tube completely from the

pumphead along with the lower

support ring.

Manual tube fitting

Isolate the motor from the

mains supply before opening

the pumphead door.

Clean the inside and faces of both

casing ports, the compression and

support rings and sealing gland.

Clean the door sealing face

ensuring that the lubricant seal is

intact.

Page 10

Page 11

Take a new piece of tubing and

smear Silicone grease or tube

lubricating oil on the outside of the

tube. Insert the tube into the lower

casing port until it makes contact

with the rotor shoe.

Rotate the rotor whilst inserting the

tube to draw the remainder of the

tube into the pumphead. Continue

until approximately 100mm of tube

remains protruding through the

lower casing port.

Slide a support ring (the shortest

ring), a compression gland, and a

compression ring onto the tube.

Push the connector into the tube.

(See next illustration for detail).

➀

Connector ➁ Compression ring

➂

Support ring ➃ Tube

➄

Compression gland

Page 11

Page 12

Continue to rotate the rotor until the

lower tube connector is flush with

the port outer face. Tighten the

connector securing nuts to avoid

pulling the tube back through the

lower port.

Repeat connector fitting procedure

for the other end of the tube in the

upper casing port. Rotate the rotor

to ensure that the tube is seated in

the pumphead correctly.

Swing the pumphead door closed

and lock shut using the door

locking screws and the Allen key

supplied. Locate and secure the

lubricant drainage plug.

Replace the lubricant drainage plug

then fill the pumphead with lubricant

to the specified volume.

The window in the pumphead door

is a motion window and provides a

visual indication of the rotation of

the rotor within the pumphead. This

window should not be used as

lubricant level indicator.

Locate and secure the lubricant filler

plug.

Page 12

Page 13

Shoe adjustment

Normally when a pump is set up for an application there will be no need to readjust the shim setting.

The occlusion of the tube is

adjusted by varying the number of

shims that are between the shoe

and the rotor.

To add or remove shims loosen

the hexagon screw (13mm A/F)

several turns.

Check that the number of shims fitted under the sliding shoe is suitable for the

operating conditions of the pump.

25mm and 19mm

0-25 rpm

25-50 rpm

50-75 rpm

75-100 rpm 3310

40mm and 45mm 10-15 bar 5-10 bar 2-5 bar 0-2 bar

0-25 rpm 4321

25-50 rpm 4321

50-75 rpm

75-100 rpm

Increasing the number of shims under the sliding shoes will increase

tube occlusion for higher pressure operation.

This will reduce the overall tube life when compared to using fewer

shims for lower pressure operation. For temperatures above 60C - use

one shim less.

10-15 bar 5-10 bar 2-5 bar 0-2 bar

5431

4321

4321

3211

3211

Page 13

Page 14

Part 2: Operation

Flow rates

The following motor power/ tube life graphs apply to fixed speed units

only. For variable speed units the motors should be de-rated by 20%.

Page 14

Page 15

Page 15

Page 16

919/925

Part 3: Appendices

Spares

Spares

SW 0156 Door indicator switch 1

HF 1302C Door 1 11

HF 1005S Window 1 10

HF 1009S Shim 8 6

HF 1003C 919 rotor 1 7

* HF 1303C 925 rotor 1 7

FN 2806 Blanking plug 1 8

HF 1004C Shoe 2 9

HF 1305C Frame support B/RA 1 15

* HF 1304C Frame support FB/R 1 15

TT 0001 6mm A/F Allen key 1

099.0002.000 Lubricant 2 litres

OS0030 Seal 1 5

CN 0146 Coupling half 2 2

CN 0147 Coupling spider 2 1

HFA1305A Bareshaft adaptor 1 13

HF 1310T Bareshaft 1 14

BB 0045 Front bareshaft bearing 1 4

HF 1015T 919 8mm ring connector 1 12

HF 1012T 919 16mm ring connector 1 12

HF 1017M 919 compression gland 1 12

HF 1315T 925 8mm ring connector 1 12

HF 1312T 925 16mm ring connector 1 12

HF 1317M 925 compression gland 1 12

BB 0039 Rear bareshaft bearing 1 3

Description

Quantity Item

Page 16

Page 17

940/945

Spares

Description

Quantity Item

SW 0156 Door indicator switch 1

HF 1102S Door 1 6

HF 1005S Window 1 11

HF 1109S Shim 8 9

HF 1103C Rotor 1 10

FN 2806 Blanking plug 1 8

HF 1104T Shoe 2 7

HF 1123C Frame support B/RA 1 15

* HF 1105C Frame support FB/R 1 15

TT 0007 8mm A/F Allen key 1

OS 0030 Seal 1 5

099.0005.000 Lubricant 5 litres

CN 0144 Coupling half 2 1

HF 1120T Bareshaft 14

CN 0145 Coupling spider 1 2

HFA1105A Bareshaft adaptor 1 13

BB0046 Front bareshaft bearing 1 4

BB0042 Rear bareshaft bearing 1 3

HF 1115T

HF 1116T

HF 1117M

HF 1161T

HF 1162T

HF 1163M

940 8mm ring connector

940 16mm ring connector

940 compression gland

945 8mm ring connector

945 16mm ring connector

945 compression gland

112

112

112

112

112

112

Page 17

Page 18

Materials of construction

Description Material Comment

Pumphead Body

Pumphead Door

Pumphead Rotor Grey iron Epoxy polyester powder coat

Rotor Shoes Aluminium

Frame Mild steel Epoxy polyester powder coat

Flanges Mild steel, stainless

Studs for

connectors

Door fixings High tensile steel

Motor fixings High tensile steel

Frame fixings Stainless steel

Tube sealing

glands

Tube lubricant Glycerine Green in colour

Cast iron A high quality and strength cast

iron, with an epoxy polyester

powder coat finish

See separate section on flanges

steel, aluminium or

polypropylene

Stainless steel

Neoprene See section on tube connection

Specification

Control range See pump specification label

Voltage/frequency See motor specification label

Power consumption See motor specification label

Operating temperature range 5C to 40C

Storage temperature range -40C to 70C

Noise <70dBA at 1m

Standards IEC 335-1, EN60529 (IP55)

Machinery Directive:

89/392/EEC EN60204-1

Low Voltage Directive:

73/23/EEC EN61010-1

EMC Directive: 89/336/EEC

EN50081-1/50082-1

Page 18

Page 19

Outline drawing

410 (430)

620 (730)

NORMAL DIMENSIONS REPRESENT 919

DIMENSIONS IN BRACKETS REPRESENT 925

919/25

)

0

3

4

(

0

8

3

940/45

650

0

1

6

840

Page 19

Page 20

Decontamination certificate

g

g

g

Watson-Marlow Limited Health and Safety Declaration

1.0

This procedure is a legal requirement in the UK

and

be used when returning pumps and to Watson-Marlow (or its distributor) to

must

equipment for service at Watson-Marlow (or its that we have the information

3.0

Either fax this form or send by first class post

receipt of the

before

ensure

distributor). equipment.

2.0

Pumps returned for service must be cleaned.

You are responsible for their decontamination. outside

A further copy must be attached to the

of the shipping case.

Failure to complete the form or comply with the procedure will cause delays in servicing the equipment.

4.0

Company .......................................................................................................................................................

Address .......................................................................................................................................................

......................................................... Post Code........................................................

Telephone ......................................................... Fax number.....................................................

5.0

Please complete

the following sections

all

5.4

If substances are not hazardous nor toxic,

please complete section 5.4.1.

If substances are hazardous or toxic,

5.1

Pump Type....................................................... please complete section 5.4.2.

5.2

Serial number...................................................

5.4.1

I hereby confirm that the equipment specified

has not pumped nor come into contact with

any toxic or hazardous substances.

5.3

Details of substances pumped

Si

ned.............................................................

5.3.1

Chemical names: Name...............................................................

(a) ................................................................... Position...........................................................

(b) ................................................................... Date.................................................................

(c) ...................................................................

(d) ...................................................................

5.4.2

I hereby confirm that the only toxic or

hazardous substance(s) that the equipment

5.3.2

Precautions to be taken in handling these specified has pumped or come into contact

substances: with are those named, and that the

(a) ................................................................... information given is correct and the carrier

(b) ................................................................... has been informed if the consignment is of

(c) ................................................................... a hazardous nature.

(d) ...................................................................

Si

ned.............................................................

5.3.3

Action to be taken in the event of human Name..............................................................

contact: Position...........................................................

(a) ................................................................... Date................................................................

(b) ...................................................................

(c) ...................................................................

5.5

Carrier to be used

(d) ................................................................... ........................................................................

Delivery date

5.3.4

Cleaning fluid to be used if residue of ........................................................................

chemicals is found during servicing:

(a) ...................................................................

5.6

Fault description or any other information

(b) ................................................................... ........................................................................

(c) ................................................................... ........................................................................

(d) ................................................................... ........................................................................

........................................................................

........................................................................

IMPORTANT

Before returning any product for service, this form

be completed and sent to

must

Watson-Marlow, or its subsidiary, or its official distributor undertaking the service

Watson-Marlow Limited, Falmouth, Cornwall TR11 4RU, En

land. Tel 01326 370370, Fax 01326 376009

Page 20

Loading...

Loading...