Page 1

Watson-Marlow 825 and 840 User Manual 1

WATSON-MARLOW BREDEL MANUALS

Watson-Marlow

825 / 840 pumps

m-825-840-gb-03

1 Declaration of conformity 2

2 Declaration of incorporation 2

3 Two-year warranty 2

4 Information for returning pumps 3

5 Safety 3

6 Dimensions 4

7 Recommended operating

procedures 5

8 Installation 5

9 Tube fitting 6

10 Tube removal 7

11 Roller adjustment 8

12 CIP 8

13 SIP 9

14 High pressure operation 9

15 Tubing 9

16 Materials of construction 9

17 Specification 10

18 Spares 10

19 Flow rates 11

20 Occlusion setting 12

21 Product codes 12

22 Warning not to use pumps in

patient-connected applications 12

23 Publication history 12

24 Decontamination certificate 13

Contents

Page 2

Watson-Marlow 825 and 840 User Manual 2

1 Declaration of conformity

This declaration was issued for Watson-Marlow 825 and 840 pumps on

August 1, 2006. When this pump unit is used as a stand-alone pump it

complies with: Machinery Directive 2006/42/EC, Low Voltage Directive

2004/108/EC. See 8 Pump specifications.

2 Declaration of incorporation

When this pump unit is to be installed into a machine or is to be assembled with

other machines for installations, it must not be put into service until the relevant

machinery has been declared in conformity with the Machinery Directive 2006/42/EC

BS EN 60204-1.

Responsible person: David Cole, Managing Director, Watson-Marlow Limited,

Falmouth, Cornwall TR11 4RU, England. Telephone +44 (0) 1326 370370 Fax +44

(0) 1326 376009.

The information in this user guide is believed to be correct at the time of publication. However, Watson-Marlow Limited accepts no liability for errors or omissions.

Watson-Marlow Bredel has a policy of continuous product improvement, and

reserves the right to alter specifications without notice. This manual is intended for

use only with the pump it was issued with. Earlier or later models may differ. The

most up-to-date manuals appear on the Watson-Marlow website: http://www.watson-marlow.com

3 Two-year warranty

Watson-Marlow Limited warrants, subject to the conditions below, through either

Watson-Marlow Limited, its subsidiaries, or its authorised distributors, to repair or

replace free of charge, any part of this product which fails within two years of delivery of the product to the end user. Such failure must have occurred because of

defect in material or workmanship and not as a result of operation of the product

other than in accordance with the instructions given in this manual.

Conditions of and specific exceptions to the above warranty are:

Consumable items such as rollers and tubing are excluded.

Products must be returned by pre-arrangement, carriage paid, to Watson-

Marlow Limited, its subsidiaries, or its authorised distributor.

All repairs or modifications must have been made by Watson-Marlow Limited,

its subsidiaries or its authorised distributors or with the express permission of

Watson-Marlow Limited, its subsidiaries, or its authorised distributors.

Products which have been abused, misused, or subjected to malicious or acci-

dental damage or electrical surge are excluded.

Warranties purporting to be on behalf of Watson-Marlow Limited made by any

person, including representatives of Watson-Marlow Limited, its subsidiaries, or its

distributors, which do not accord with the terms of this warranty shall not be

binding upon Watson-Marlow Limited unless expressly approved in writing by a

Director or Manager of Watson-Marlow Limited.

Page 3

Watson-Marlow 825 and 840 User Manual 3

4 Information for returning pumps

Equipment which has been contaminated with, or exposed to, body fluids, toxoc

chemicals or any other substance hazardous to health must be decontaminated

before it is returned to Watson-Marlow or its distributors.

A certificate included at the rear of these operating instructions, or a signed statement, must be attached to the outside of the shipping carton.

This certificate is required even if the pump is unused. If the pump has been used,

the fluids that have been in contact with the pump and the cleaning procedure must

be specified, along with a statement that the equipment has been decontaminated.

5 Safety

In the interests of safety, these pumpheads and the products selected should only

be used by competent, suitably trained personnel after they have read and understood this manual, and considered any hazard involved. In the UK this person should

be familiar with the Health and Safety at Work Act 1974.

Any person who is involved in the installation or maintenance of the equipment

should be fully competent to carry out the work.

There are dangerous voltages (at mains potential)

inside the terminal box. If access is required, isolate

the pump from the mains before removing the terminal

box cover. Do not olace any part of the body inside the pumphead while the pump is running.

Page 4

Watson-Marlow 825 and 840 User Manual 4

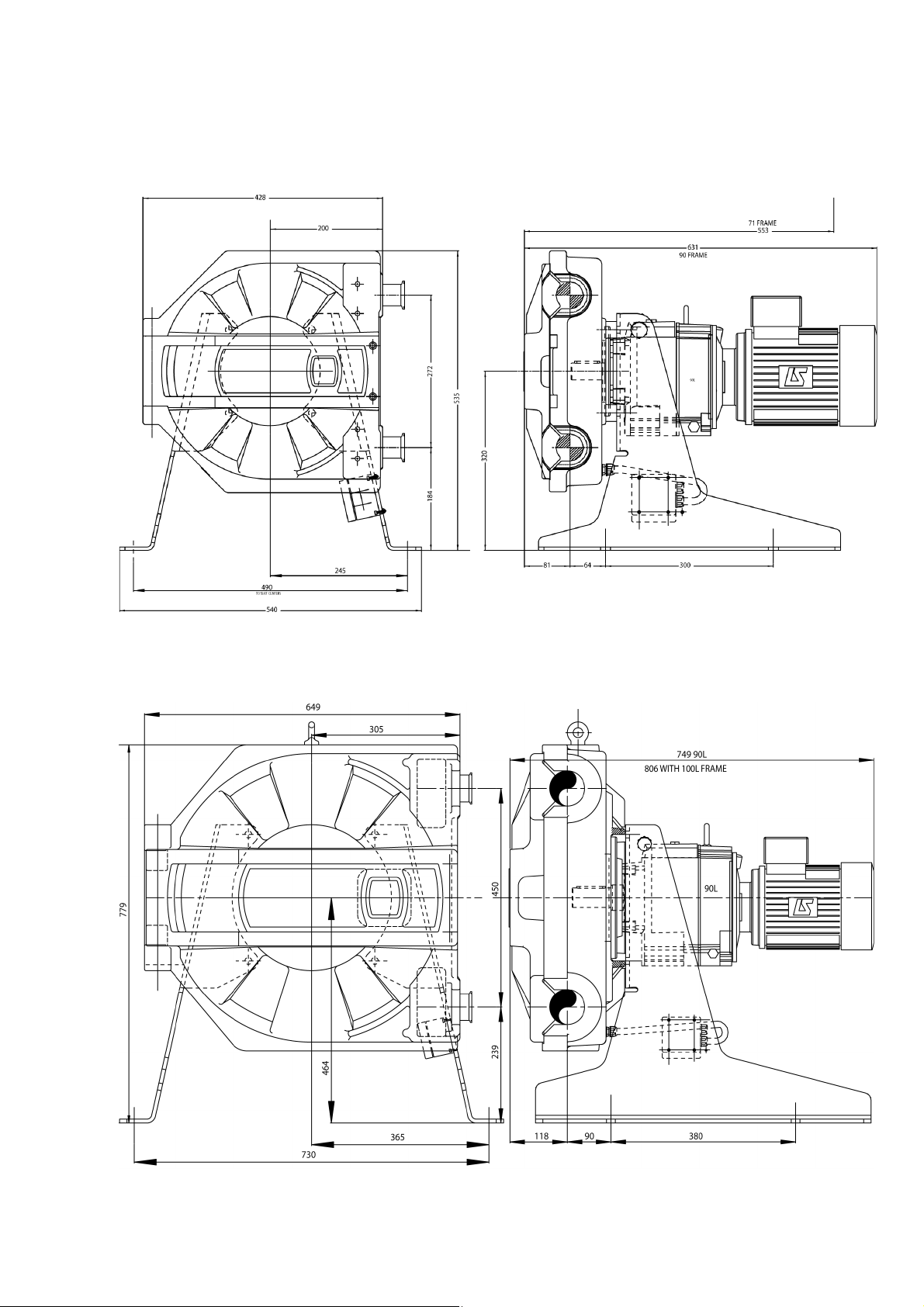

6 Dimensions in mm

825

840

Page 5

Watson-Marlow 825 and 840 User Manual 5

7 Recommended operating

procedures

Do keep delivery and suction tubes as short and direct as possible using a minimum

of swept bends

Do use suction and delivery pipes equal to or larger than the bore of the tube in the

pumphead. When pumping viscous fluids, the losses caused by increased friction can

be overcome by using pipe runs with a cross sectional area several times greater

than the pumping element.

Do keep the pumphead track and all moving parts clean and free from contamination and debris.

The self-priming nature of peristaltic pumps means valves are not required. Any

valves fitted must cause no restriction to flow in the pumping circuit.

If the rotor is run in an anticlockwise direction with both rocker mechanisms

unlocked no tube occlusion will occur. In this case the rocker mechanisms will snap

back from their disengaged position when losing contact with the tubing. No damage to the pumphead action will be caused by this, however it is not advisable to

allow this action to continue for a prolonged procedure.

8 Installation

Site the pump on a flat horizontal surface allowing a free flow of air around the

pump. Ensure there is 1m of straight tubing before the pumphead inlet and discharge ports.

When requested, motors fitted to Watson-Marlow pumps incorporate a thermal protection switch which may be used to provide indication of an over-temperature condition. Aside from this, a current overload relay should also be fitted to a contact

breaker. Connect the motor in accordance with the wiring diagram which will be

found in the motor terrminal box.

When a thermal protection switch is fitted in the motor, the leads will be found in

the motor terminal box. They should be connected to stop the pump if the switch

operates. The switch will open circuit at an over temperature condition. See picture

for the simplest connection.

All pumps may be fitted with a door indicator switch. This switch is rated 240V 0.5A

AC maximum power load 50W. This switch is not intended as a primary safety

device. Under normal operation the pumphead door is kept closed and this meets all

statutory requirements as a tool lockable fixed guard.

Do not connect the door switch a back up or any other switch gear with the terminal box of an explosion proof motor unless the switch has a suitable Exd rating for

the zone area in which it is to be mounted.

Page 6

Watson-Marlow 825 and 840 User Manual 6

9 Tube fitting

Insert tube couplings

Unlock one rocker assembly (top left)

Position rotor in pumphead (top right)

Locate one tube end in lower clamp and secure. Feed the tubing into pumphead

clockwise while folding in the unlocked rocker assembly.

Locate the other tube end into

upper clamp and secure (above

left)

Close door. Turn on power supply

to motor

Rotate rotor clockwise until

unlocked rocker assembly snaps

into engaged position (above

right)

Isolate the motor from the power

supply

Open pumphead door. Lock rock-

er assembly (top left)

Tighten door locking screws

(right)

Page 7

Watson-Marlow 825 and 840 User Manual 7

10 Tube removal

Isolate the motor from the power

supply

Undo the door locking screws (above

left)

Unlock the rocker assembly not in

contact with the tube using the locking knob (above right)

Close the pumphead door. Switch on

the power. Rotate rotor anticlockwise until unlocked rocker rests

against the tube (right)

Isolate the motor from the power

supply. Open pumphead door

Undo the tube clamps (right)

Clean pumphead door and face

Remove coupling from tubing (below

right)

Page 8

Watson-Marlow 825 and 840 User Manual 8

11 Roller adjustment

Loosen the roller locking nut (1) and undo rock-

er locking nuts (2)

Undo the roller spindle locking nuts

Rotate roller for occlusion adjustment (below).

Setting 2 represents the factory default setting.

12 CIP

When using a clockwise pumping direction and unlocked rockers no adjustment is

required. If rockers are locked for bi-directional pumping unlock one rocker mechanism. Rotate rotor anticlockwise until no tube occlusion occurs. The free flow of

cleaning agents through the tubing is now possible.

Ensure that no part of the body inside the pumphead

while the pump is running.

Page 9

Watson-Marlow 825 and 840 User Manual 9

13 SIP

Observe a 1m safety area to avoid possible scalding if a tube burst occurs. Monitor

the process continuously .

If a tube burst occurs shut down the process, do not touch the pumphead until a 10

minute cooling period has been observed. Ensure a 15 minute acclimatisation period is observed before running the pump following SIP.

Maximum permissible SIP process temperature is 135 C.

14 High pressure operation

Ensure rocker mechanisms are locked to avoid premature wear.

Observe a 1m safety area to avoid contact with high pressure jets in the case of

a tube burst.

Please note that only tubing elements and not continuous lengths of tubing can be

used for higher pressure operation.

No quick connectors are to be used with element tubing during high pressure

operation.

15 Tubing

No length of tubing which has previously been used as a pumping element should

be used in the transfer section due to the fact that it may be in a weakened condition.

16 Materials of construction

Description Material Finish

Pumphead body Aluminium Epoxy polyester powder coated white finish

Pumphead door Aluminium Epoxy polyester powder coated white finish

Pumphead rotor Aluminium Epoxy polyester powder coated

Rollers Stainless steel 316

Frame Stainless steel 304

Connectors Stainless steel 316

Door fixings High tensile steel

Motor fixings High tensile steel

Frame fixings Stainless steel

Rocker locking

knob, 840

Polypropylene

Rocker locking

knob, 825

Stainless steel

Ensure that the pumphead door is closed and tool-

locked before SIP cleaning

Page 10

Watson-Marlow 825 and 840 User Manual 10

17 Specification

Control range See pump specification label

Voltage/frequency See pump specification label

Power consumption See pump specification label

Operating temperature range 5C to 40C

Storage temperature range -40C to 70C

Noise 70dB(A) at 1m

Standards IEC 335-1, EN60529 (IP55)

Machinery Directive 2006/42/EC

Low Voltage Directive 2004/108/EC

Number 825 spare 840 spare Description

1 HFA1201A HFA1401A Tube clamp

2 HFA1205A HFA1405A Rocker assembly

3 HFA1206A HFA1406A Rotor assembly

4 HF1202C HF1402C Door

5 HF1005S HF1005S Window

6

(not shown)

HF1271S

HF1272S

HF1467S

HF1468S

Frame support RH

Frame support LH

7 HF1201C HF1401C Track

8 HFA1204A HFA1404A Roller assembly

9 HFA1202A HFA1202A Terminal box

18 Spares

Page 11

Watson-Marlow 825 and 840 User Manual 11

19 Flow rates

825

840

Page 12

Watson-Marlow 825 and 840 User Manual 12

20 Occlusion setting

825 840

Occlusion

setting

Roller to track

clearance

% tube over-

occlusion

Roller to track

clearance

% tube over-

occlusion

Bottom 17.0 6% 24.0 8%

Left 16.2 10% 23.1 11%

Right 15.7 13% 22.5 14%

Top 15.0 16% 21.7 17%

21 Product codes

825 Bioprene

Maximum working

presssure

Tube bore Product code

770mm long ± 3mm 2 bar 25mm 088.T250.E0P

770mm long ± 3mm 3.5 bar 25mm 088.T250.E0G

2310mm long 2 bar 25mm 088.T250.00P

2310mm long 3.5 bar 25mm 088.T250.00G

840 Bioprene

Maximum working

presssure

Tube bore Product code

1250mm long ± 4mm 2 bar 40mm 088.T400.E0P

1250mm long ± 4mm 3.5 bar 40mm 088.T400.E0G

22 Warning not to use pumps in

patient-connected applications

Warning: These products are not designed for use in, and should not be used for

patient-connected applications.

23 Publication history

m-825-840-gb-03.qxp: Watson-Marlow 825, 840

First published 07 06. This edition published 11 14.

Page 13

Watson-Marlow 825 and 840 User Manual 13

Your name

Company

Address

Postcode/zip Country

Telephone Fax

Product type Serial number

To speed the

repair, please

describe all

known faults

The product has ...

II Been used II Not been used

If the product has been used, please complete all the following sections.

If the product has not been used, please just sign this form.

Names of

chemicals handled

with product(s)

Precautions to be

taken in handling

these chemicals

Action to be taken

in the event of

human contact

I understand that the personal data collected will be kept confidentially

in accordance with the UK Data Protection Act 1998.

RGA number

Signature Your position

Date

Please print out, sign and fax to Watson-Marlow Pumps at +44 1326 376009.

24 Decontamination certificate

In compliance with the UK Health and Safety at Work Act and the Control of

Substances Hazardous to Health Regulations, you are required to declare the substances which have been in contact with product(s) you return to Watson-Marlow or

its subsidiaries or distributors. Failure to do so will cause delays. Please ensure that

you fax us this form and receive an RGA (Returned Goods Authorisation) before you

despatch the product(s). A copy of this form must be attached to the outside of the

packaging containing the product(s). Please complete a separate decontamination

certificate for each product. You are responsible for cleaning and decontaminating

the product(s) before return.

Loading...

Loading...