Page 1

Watson-Marlow Bredel E-Manuals

Search manual for ...

Go

WATSON-MARLOW BREDEL E-MANUALS

m-624di-gb-01

Watson-Marlow 624Di pumps

Clickable index

1. Declaration of conformity

2. Declaration of incorporation

3. Warranty

4. Information for returning pumps

5. Safety

6. Recommended operating

procedures

7. Installation

8. Rear panel recess

9. Troubleshooting

10. User interfacing

11. Dosing procedure

12. Calibration procedure

13. Manual operation

14. Auto operation

15. Setup

16. Remote control

17. Care and maintenance

18. Guard safety warnings

19. Specification

20. Drive spares

21. 620RE, 620RE4 and 620R Key

safety information

22. 620RE, 620RE4 and 620R Safeguarding

23. 620RE, 620RE4 and 620R

Pumping conditions

24. 620RE, 620RE4 and 620R Pump

installation

25. 620RE, 620RE4 and 620R

General operation

26. 620RE and 620RE4 tube element loading

27. 620RE, 620RE4 and 620R Continuous tube

loading

28. 620RE, 620RE4 and 620R Tube element or

continuous tube removal

29. 620RE, 620RE4 and 620R Maintenance

30. 620RE, 620RE4 and 620R CIP and SIP

31. 620RE, 620RE4 and 620R Pumphead spares

32. 625L Pumphead

33. 625L Installation

34. 625L Tube loading

35. 625L Care and maintenance

36. 625L Track adjustment

37. 625L Pumphead spares

38. 625L Operation

39. 625L Error Messages

40. 620RE, 620RE4 and 620R Technical data

41. Flow rates

42. Dimensions in mm

43. 620R product codes

44. 620RE and 620RE4 LoadSure product codes

45. 620R dosing guidelines

46. 625L dosing guidelines

47. 625L product codes

48. 625L (4mm) product codes

49. 625L Y-piece product codes

50. Trademarks and disclaimer

51. Patient-connected use: warning

52. Publication history

53. Decontamination certificate

Double clicking anywhere in the manual will take you back to this index.

Declaration of conformity

When this pump unit is used as a stand-alone pump it complies with: Machinery

Directive 98/37/EC EN60204-1, Low Voltage Directive 73/23/EEC EN61010-1, EMC

Directive 89/336/EEC, EN50081-1/EN50082-1.

Declaration of incorporation

When this pump unit is to be installed into a machine or is to be assembled with other

machines for installations, it must not be put into service until the relevant machinery has

been declared in conformity with the Machinery Directive 98/37/EC EN60204-1.

Responsible person: Christopher Gadsden, Managing Director, Watson-Marlow Limited,

Falmouth, Cornwall TR11 4RU, England. Telephone +44 (0) 1326 370370 Fax +44 (0)

1326 376009.

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 2

Watson-Marlow Bredel E-Manuals

Two year warranty

Watson-Marlow Limited warrants, subject to the conditions below, through either WatsonMarlow Limited, its subsidiaries, or its authorised distributors, to repair or replace free of

charge, including labour, any part of this product which fails within two years of delivery of

the product to the end user. Such failure must have occurred because of defect in material

or workmanship and not as a result of operation of the product other than in accordance

with the instructions given in this manual.

Conditions of and specific exceptions to the above warranty are

Consumable items such as tubing and rollers are excluded.

Products must be returned by pre-arrangement carriage paid to Watson-Marlow Limited,

its subsidiaries, or its authorised distributor.

All repairs or modifications must have been made by Watson-Marlow Limited, its

subsidiaries, or its authorised distributors or with the express permission of WatsonMarlow Limited, its subsidiaries, or its authorised distributors.

Products which have been abused, misused, or subjected to malicious or accidental

damage or electrical surge are excluded.

Warranties purporting to be on behalf of Watson-Marlow Limited made by any person,

including representatives of Watson-Marlow Limited, its subsidiaries, or its distributors,

which do not accord with the terms of this warranty shall not be binding upon WatsonMarlow Limited unless expressly approved in writing by a Director or Manager of WatsonMarlow Limited.

Information for returning pumps

Equipment which has been contaminated with, or exposed to, body fluids, toxic chemicals

or any other substance hazardous to health must be decontaminated before it is returned

to Watson-Marlow or its distributor. A certificate included at the rear of these operating

instructions, or signed statement, must be attached to the outside of the shipping carton.

This certificate is required even if the pump is unused. If the pump has been used, the

fluids that have been in contact with the pump and the cleaning procedure must be

specified along with a statement that the equipment has been decontaminated.

Safety

In the interests of safety, this pump and the tubing selected should only be used by

competent, suitably trained personnel after they have read and understood this manual,

and considered any hazard involved.

Any person who is involved in the installation or maintenance of this equipment should be

fully competent to carry out the work. In the UK this person should also be familiar with

the Health and Safety at Work Act 1974.

This symbol, used on the pump and in this manual, means: Caution, risk

of electric shock.

This symbol, used on the pump and in this manual, means: Caution, refer

to accompanying documents.

This symbol, used on the pump and in this manual, means: Do not allow

fingers to contact moving parts.

There are dangerous voltages (at mains potential) inside the

pump. If access is required, isolate the pump from the mains

before removing the cover.

Recommended operating procedures

DO keep delivery and suction lines as short as possible using a minimum number of swept

bends.

DO use suction and delivery pipelines with a bore equal to or larger than the bore of the

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 3

Watson-Marlow Bredel E-Manuals

tube fitted in the pumphead. When pumping viscous fluids, the losses caused by increased

friction can be overcome by using pipe runs with a cross sectional area several times

greater than the pumping element.

DO fit an extra length of pump tube in the system to enable tube transfer. This will extend

tube life and minimise the downtime of the pumping circuit.

DO keep the track and rollers clean.

The self-priming nature of peristaltic pumps means valves are not required. Any valves

fitted must cause no restriction to flow in the pumping circuit.

When using Marprene tubing, after the first 30 minutes of running, re-tension the tube in

the pumphead. Open the guard, hold the tubing at one port whilst pulling the tube tight

through the second port. This is to counteract the normal stretching that occurs with

Marprene which can go unnoticed and result in poor tube life.

Tube selection The chemical compatibility list published in the Watson-Marlow catalogue

is only a guide. If in doubt about the compatibility of a tube material and the duty fluid,

request a tube sample card for immersion trials.

Installation

The 624Di is suitable for single-phase mains electricity supplies only.

To ensure correct lubrication of the gearbox the pump should be run only while its feet are

standing on a horizontal surface. The pump should be positioned to allow a free flow of air

around it.

Remove the small transparent plate on the rear panel to gain access to the voltage

selector and terminal block.

Set the voltage selector to either 120V for 100-120V 50/60Hz single-phase AC

supplies or 240V for 220-240V 50/60Hz single-phase AC supplies.

Route the mains supply cable through the entry point to the right of the recess, and

couple the cable to the terminal block as shown on the rear panel.

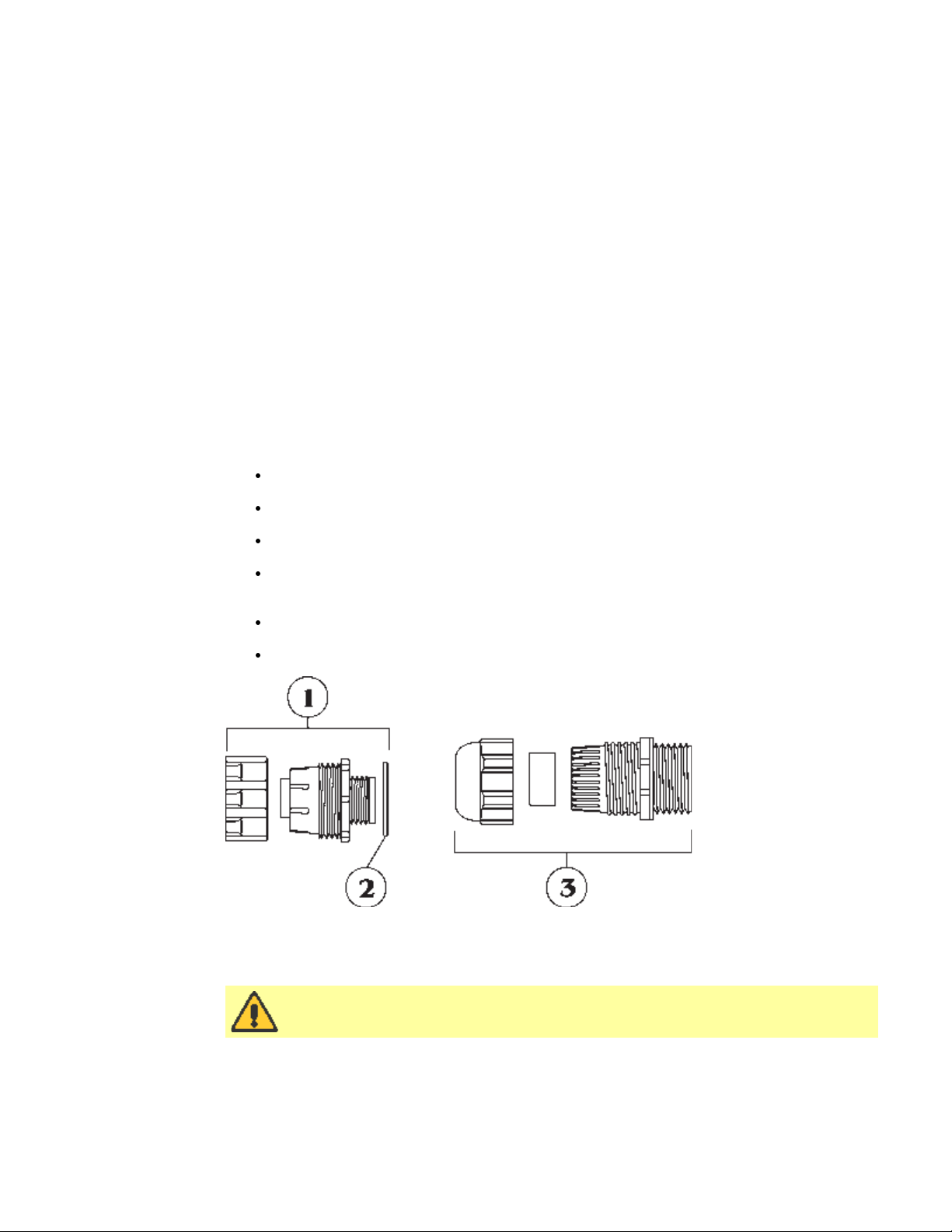

There are two alternative connectors. One accepts 20mm rigid or flexible conduit,

and the other accepts three core 0.75 square millimetre PVC sheathed mains cable

(via the screwed adapter supplied) so that a mains lead can be used.

Ensure that the mains lead is securely retained in the strain relief gland so that IP55

ingress protection is maintained.

Securely replace the transparent plate and the gasket over the recess.

1. Armoured cable strain relief gland GR 0018

2. Washer GR 0019

3. Strain relief gland SL0020

Ingress protection standard will be compromised if the transparent plate

is not replaced.

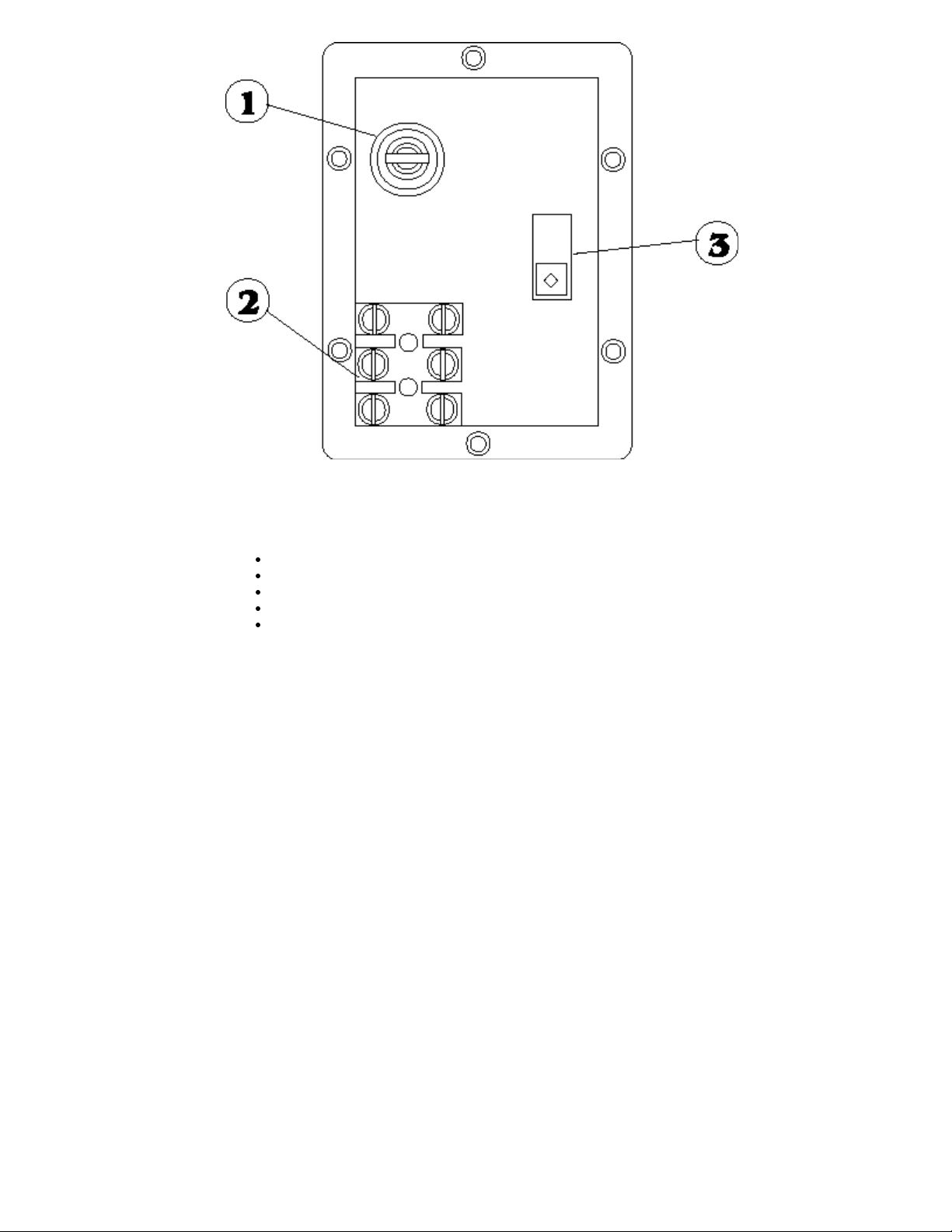

Rear panel recess

The pump rear panel recess houses the following:

1. Fuse holder

2. Terminal block

3. Voltage selection switch

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 4

Watson-Marlow Bredel E-Manuals

to ensure the highest accuracy possible.

Troubleshooting

Should the pump fail to operate, make the following checks to determine whether or not

servicing is required.

Check that the power switch is on.

Check the mains supply is available at the pump.

Check the voltage selector switch is in the correct position.

Check the fuse in the mains socket.

Check that the pump is not stalled by incorrect fitting of tubing.

User interfacing

When powering-up the pump the user will be taken into the main menu.

Use the Step key to move between menu options. Use the Enter key to confirm settings.

Use the number keys to enter in settings. Use the Up or Down key to increase or decrease

set values in the pump software i.e. ramp settings, date, rpm etc.

Dose permits the set-up of dose programs for dispensing. A dose can be initiated by using

the Start button or external switching. The pump will allow up to 26 dosing programs to be

stored and recalled at any time. A printer can be connected to the pump for recording of

dispense runs. Batch and operator codes must be entered when using a printer.

Cal allows the pump to be calibrated for accurate dosing.

Manual allows continuous transfer/fluid metering via keypad control.

Auto enables analogue or RS232 control.

Setup displays and controls the user and factory settings for the correct operation of the

pump.

The speed/volume flow rate of the drive is governed by the pumphead and tubing selected.

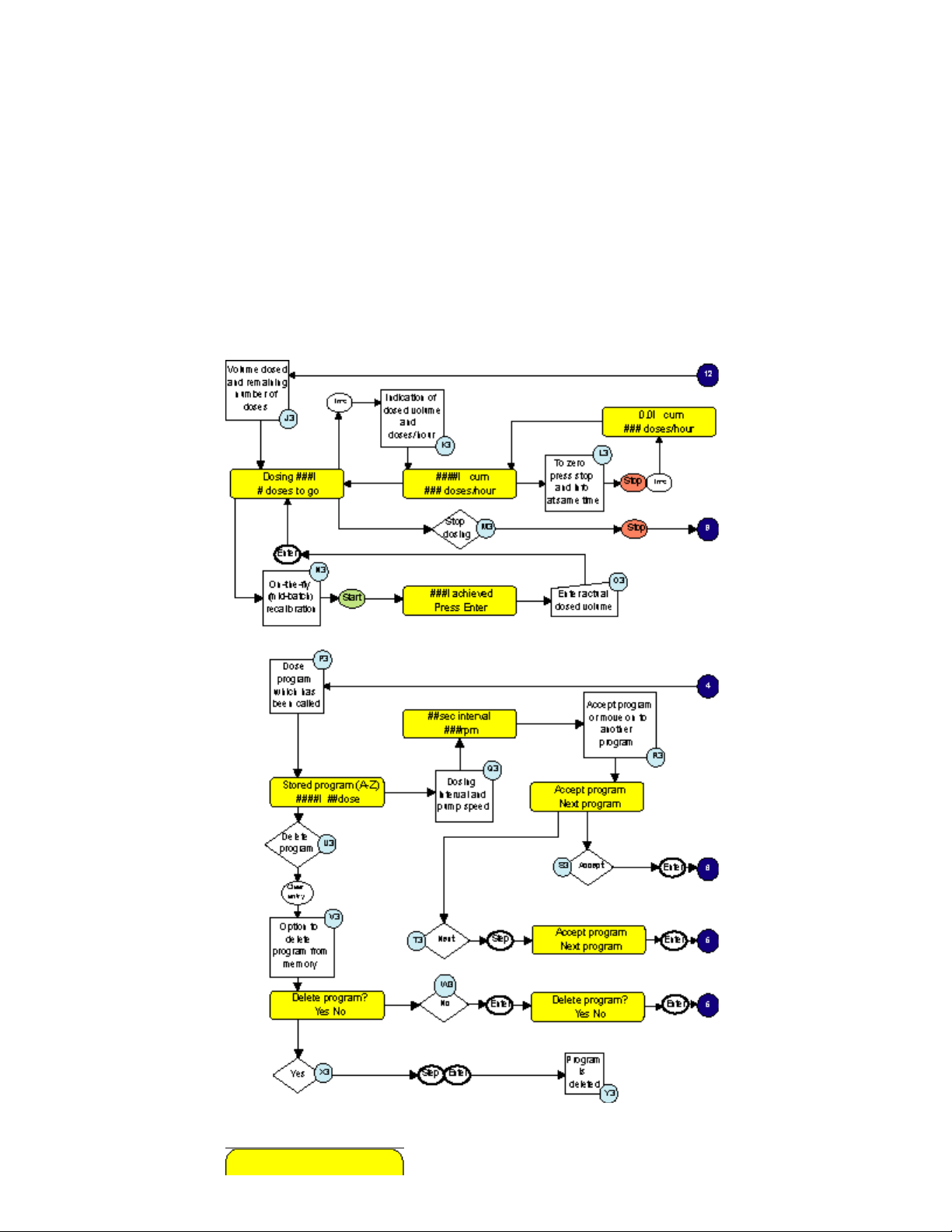

Dosing procedure

The Dosing program is outlined in the technical data section of the operating instruction in

a flow chart format. Each step in the procedure is described to provide full understanding of

the procedure.

Within the technical data section are mean values for dose time guidelines and accuracy

figures recorded using Silicone tubing at zero suction and pressure. For the highest

accuracy use small-bore tubing and maximum roller passes. Always use a calibration dose

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 5

Watson-Marlow Bredel E-Manuals

Print audit routines

If a printer is connected, the completion of a dose run will automatically call the print

routine. The first request will be to enter the operator ID.

Up to 16 characters can be entered. Digits and the decimal point are entered directly from

the keypad. Alpha characters are entered by pressing Up or Down which call A to Z and Z

to A respectively in circular rotation.

An alpha character is embedded by pressing Step. A numeric character is entered by

pressing Step, any other numeric character, the decimal point or Up or Down.

On pressing Enter, the pump will request the input of a batch number.

Again, up to 16 characters can be entered as for the operator ID. When Enter is again

pressed, the following information is printed out: date, time, dose size, specific gravity,

dose interval, number of doses, initial ml/rev, recalibration data, operator ID, batch

number and number of doses delivered.

Following the print-out a repeat dose option will be given.

Single dose command

Single doses can be dispensed on demand, with a count of the number of doses being

kept.

Set the interval time to 0 SECONDS and the number of doses to 1.

To start single dosing, press Start or use an external start dose switch. The display will

indicate the total number of completed doses up to a maximum of 99,999, after which the

counter will restart at 0: dose 100,001 would be shown as 1.

Calibration procedure

Calibration of the 624Di is based on informing the pump under Cal of the pumphead and

tubing which are to be used. Alternatively a calibration dose can be used. The calibration

dose will run for a maximum of 4 minutes, but can be stopped at any time up to 4

minutes. The longer the calibration dose, the more accurate the calibration. Entering into

the pump the physical volume or mass to complete the procedure will allow the pump to

take into account ambient conditions and also the viscosity of the fluid.

Manual operation

Switch power on.

Change the set speed by pressing the Up or Down key. The minimum speed of the

624Di is 4 rpm.

Change direction by pressing the CW/CCW key. Indication of direction of rotation is

provided via the LCD display.

Select the maximum speed: press the Up key and the Max key together. Select the

minimum speed: press the Down key and the Max key together.

Press Start to start the pump. Press Stop to stop the pump.

Auto operation

The pump will accept external control signals through the 25-pin cage clamp connector on

the back panel. Remove the cover plate, ensuring that the gasket is not damaged. Feed

the control wires through the cable glands and connect via the sprung cage clamps.

Analogue

This function enables the pump speed to be controlled via an external analogue process

signal. Pressing Enter at analogue will call a confirmation of the analogue control signal

settings. These can be reset under Setup (see section covering pump setup).

RS232

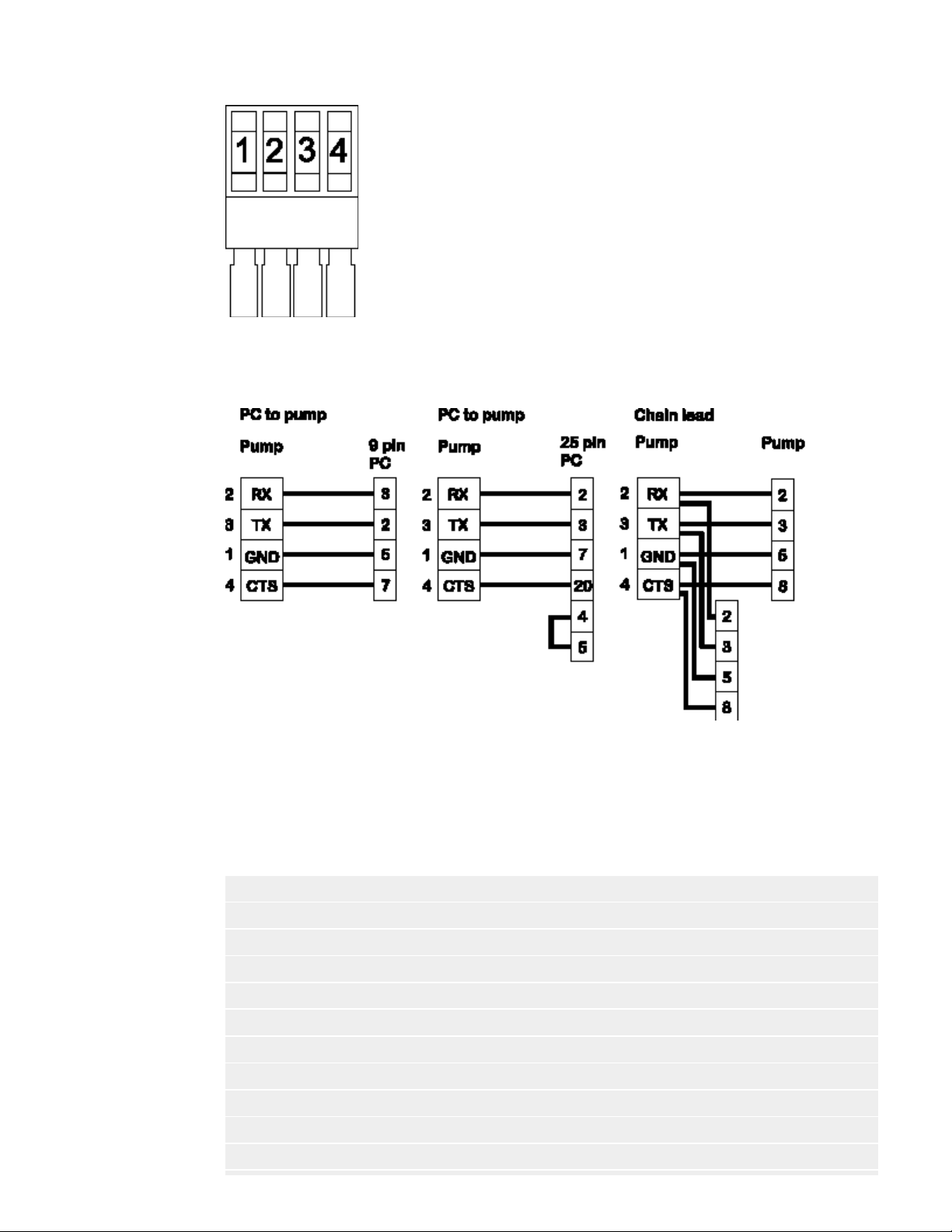

This facility gives full pump functionality under RS232 closed loop control via the 4-pin

cage clamp. Up to 16 pumps can be linked while retaining individual pump control by using

lead PR0036. A network kit is available from Watson-Marlow which includes Pumpnet 2, a

DOS-compatible control program, and leads.

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 6

Watson-Marlow Bredel E-Manuals

Step to Network in the Main menu and press Enter. The pump will now be under RS232

control. The keypad Stop key will act as an emergency stop and disable RS232 settings if

pressed.

Above: Connections for RS232 signals: 1 = GND, 2= RX, 3 = TX, 4 = CTS

Below: RS232 cabling shown for CTR handshake. Use only twin shielded RS232

cables.

RS232 settings

Baud = 9600; Stop bits = 2; Data bits = 8; Parity = None; Handshake = CTR or

None; Auto echo = On.

The following codes will operate the 624Di under RS232 control. They must be directed to

the pump from a computer serial port (or equivalent). Always terminate each command

with a RETURN (ASCII CHR13).

nSPxxx Load speed setting xxx to pump number n

nSI Increment speed by 1rpm for pump n

nSD Decrement speed by 1rpm for pump n

nGO Start pump number n

nST Stop pump number n

nRC Change rotation direction for pump n

nRR Set clockwise direction for pump n

nRL Set counter-clockwise direction for pump n

nDOxxxxx,yyy Set dose for pump number n in tachometer pulses (note 3)

nRS Show status for pump number n (note 4)

nZY Show status if pump n STARTed 1 or STOPped 0

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 7

Watson-Marlow Bredel E-Manuals

nTC Clear tachometer counter

nRT Read tachometer counter

nCA Clear existing display; followed by:

nCH "Home" cursor; followed by:

nW{text line 1}~{text line 2}@ (@ = terminator)

Notes on control codes

1 n = pump number set in SETUP. For the command to operate on all networked pumps

2 There are 1046 tacho pulses per revolution at the maximum drive speed of 200rpm.

3 nDOxxxxxxxx where xxxxxxxx is any integer and is the target dose in tacho pulses.

This can be extended to nDOxxxxxxxx,yyy where yyy is a "kick back" in tacho pulses

4 A show status command will prompt the 624Di to return a text string of the following

[pump type] [ml/rev] [pumphead] [tube size] [speed] [cw/ccw] [P/N] [pump number]

5 All networked pumps with the same n will respond to the same command.

6 There should be at least 10mS between consecutive commands.

7 When using the # to address all pumps, ensure that it will not generate a reply, eg

For writing to pump number n display

simultaneously, use # before the command.

with a limit of 255 (about 1 revolution on a 200rpm drive).

layout:

[tacho count as a single integer] [stopped/running, 0 /1] [! = delimiter]

eg 625Di 0.7 625L 4.8mm 100 CW P/N 1 157810 1 !

nSS; the result will be unpredictable.

This is a typical short program for pump number 2:

OPEN "COM1:9600,N,8,2,CDO,CSO,DSO,OP10000" FOR RANDOM AS #1

PRINT #1, "2SP220" + CHR$(13)

DELAY (command depends on language being used)

PRINT #1, "2GO" + CHR$(13)

DELAY 5000

PRINT #1, "2ST" + CHR$(13)

CLOSE #1.

Setup

ROM - provides user with software identification.

Date/Time - Set during manufacture but can be reset to user requirements.

Beep - Audible signal on/off.

Ramp - Rate of acceleration/deceleration of the pump to/from maximum set speed at the

beginning/end of a dose. 0 setting signifies no acceleration delay to maximum speed, 5

signifies the longest acceleration delay to maximum speed.

Drip - Brief reversal of the motor on dose completion ensures no extra drips of fluid are

dispensed. 0 means no reverse and 5 means maximum reverse.

Baud - Speed of signal transmission. Default setting 9600, range of setting include 1200,

2400, 4800, 9600.

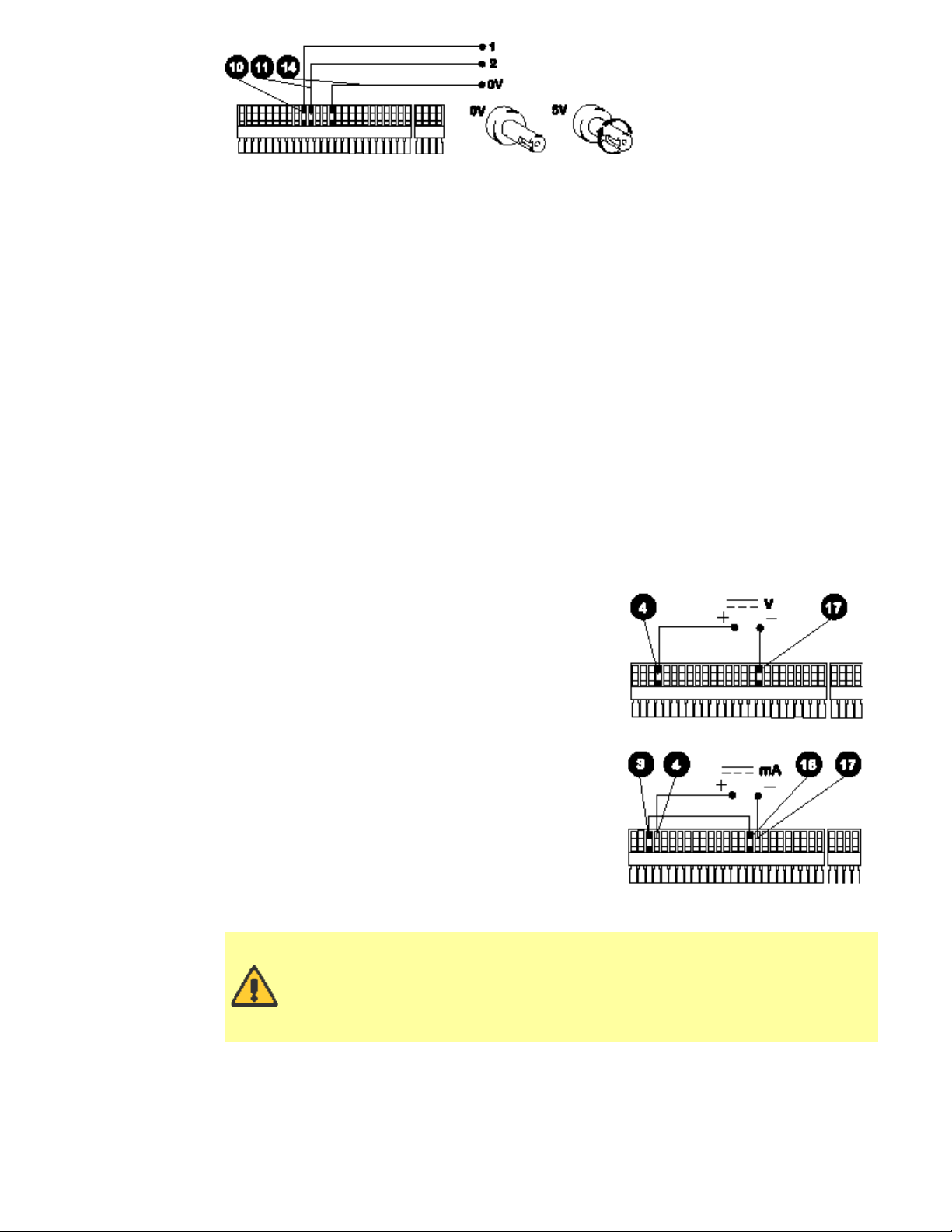

Auxiliary - Monitor the pump dosing or motor state/direction of rotation using 2 high (5V)

/low (0V) auxiliary signals outputted via the pumps 25 pin cage clamp connector. Auxiliary

signals can be used, for example, to command a turntable or conveyor to move when a

dose has been completed.

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 8

Watson-Marlow Bredel E-Manuals

Line 1 can be set to change state every time the motor runs, or only when the motor runs

to dispense a dose. The signal can be set high or low when the motor runs. Line 2 changes

state when the pump direction is changed. The screens allow the signal to be set high or

low when the output shaft rotates clockwise.

Pump - When under RS232 control each individual pump must be identified. Select a

number from 1-16.

Max - Sets when the pump can be primed at maximum speed. Standard setting means

Max is enabled during Manual and Setup. Always enabled means the unit can be primed at

any time.

Default - Press Enter at "Yes" to restore factory defaults.

Autostart - If set to On when in Manual mode only, Autostart will allow the pump to

restart pumping automatically after power-up following a mains supply interruption. If set

to Off the pump will restart and return to the Main Menu.

Signal - Step to the desired process signal for analogue control and press Enter. Options

available are 4-20mA, 0-10mA, 0-20mA, 0-5V, 0-10V These signal ranges correspond to

0-200rpm speed control. A confirmation screen will verify settings chosen. If the signal

type required is not shown then use the "program" option to enter in the required signal

levels. The pump is controllable by an analogue process signal of up to 30V or 32mA. The

pump will provide an increasing flow rate for a rising control signal (non-inverted response)

or an increasing flow rate for a falling control signal (inverted response).

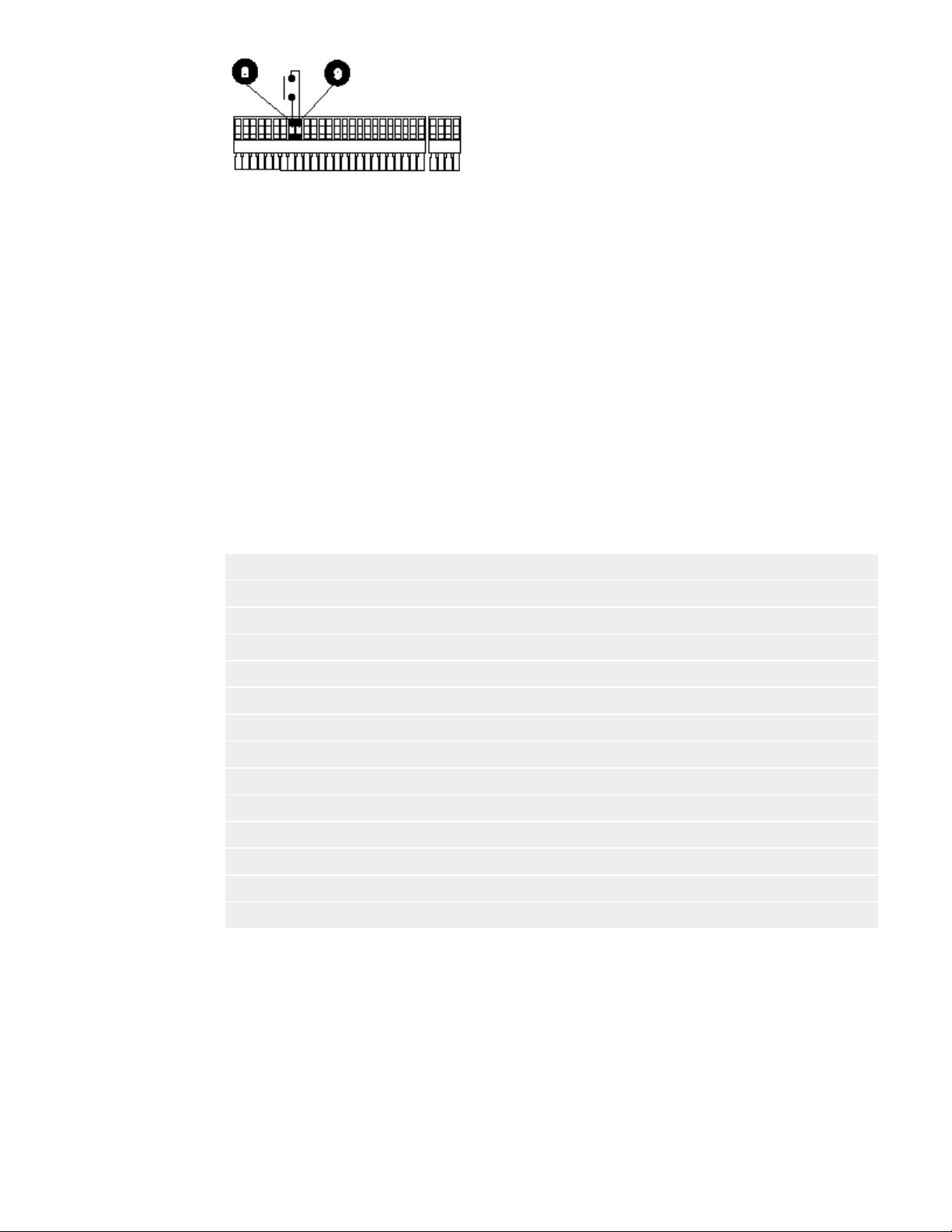

For voltage modes a stable, variable DC voltage

source can be used in conjunction with a DC

voltmeter, (max 30V DC). (Refer to the 25 pin cage

clamp connector wiring detail as an example of

control circuitry) Circuit impedance 100kW. Polarity

set for non-inverted response. Reverse polarity for

inverted response.

For current modes the same DC source can be used

in conjunction with a DC milliampere meter,

(maximum 32mA). (See 25 pin cage clamp connector

detail). Circuit impedance 250W. Polarity set for noninverted response. Reverse polarity for inverted

response.

Trim - This function will match the pump's signal

conditioner to the analogue process control signal if

they do not fully coincide. The user will be asked to

apply zero, 20% and the maximum voltage or

current that is required to be the control signal. Press

Enter after adjusting the process signal to each input level.

Never apply mains voltage across pins on the 25-pin cage clamp

connector. Up to 5V TTL may be applied to pins 7 and 5, but do not apply

voltage across any other pins. Failure to heed this warning could cause

permanent damage not covered by warranty. Do not use the mains

power switch to control the pump for a high repetition of stop starts.

The auto-control facility should be used.

Remote control

Pause dose This function will pause a dose for as long as a remote switch remains closed

then allows the dose to continue when the switch is opened. Under Manual mode it will

also act as a remote stop/start. Connect remote switch as in the Stop/Start diagram. Open

to run pump, close to pause or stop pump.

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 9

Watson-Marlow Bredel E-Manuals

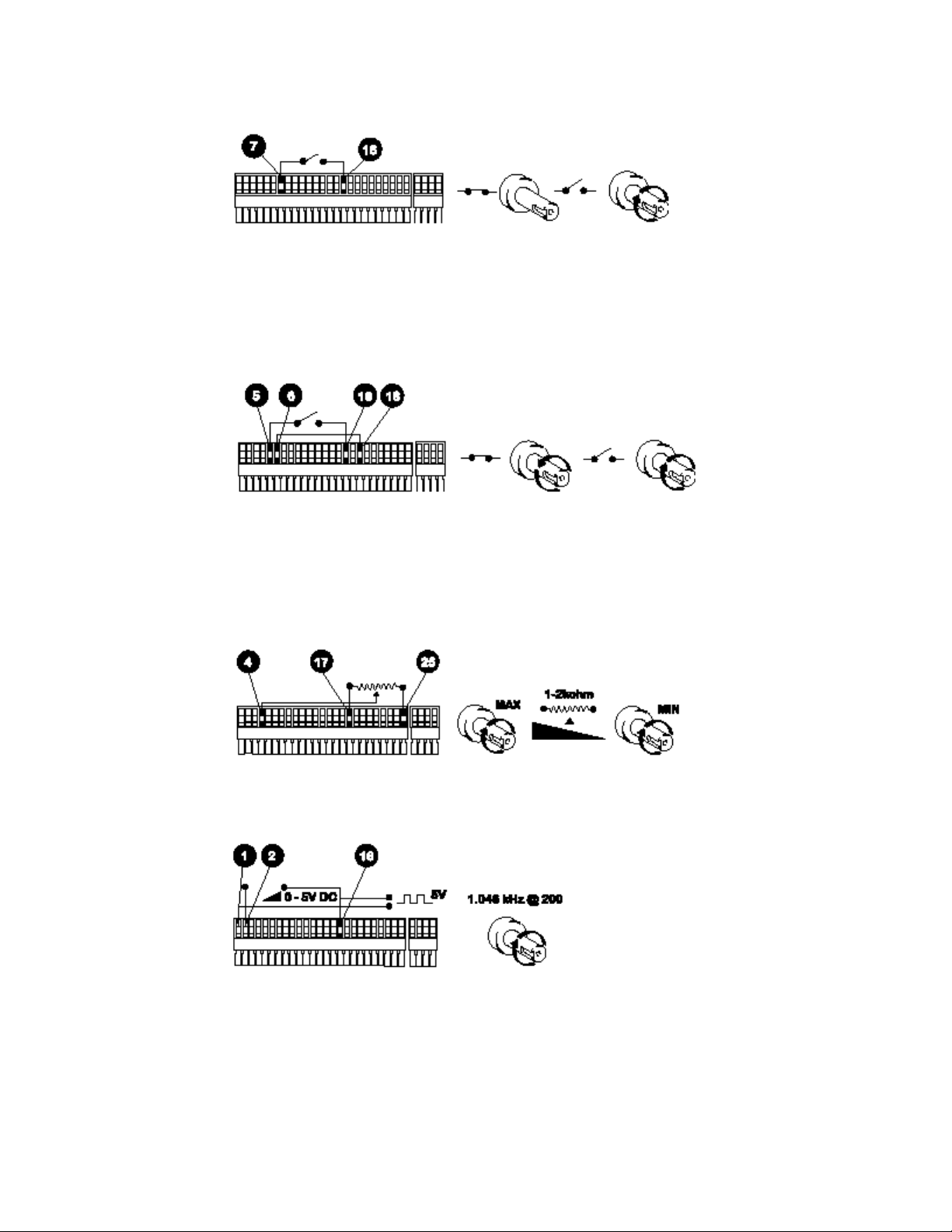

Stop/Start Connect remote switch between pins 7 and 16 of the 25-pin cage clamp

connector. A TTL compatible logic input (Low 0V, High 5V) may be applied to pin 7. Low

input stops the pump, high input runs the pump. With no connection, the pump will default

to running.

Direction Connect remote switch between pins 5 and 16 and disable the front panel

reversing control by linking pins 6 and 18 of the 25 pin cage clamp connector. Open switch

for clockwise rotation, close for counter-clockwise. Alternatively a TTL compatible logic

input (Low 0V, High 5V) may be applied to pin 5. Low input will run the pump in a counterclockwise direction, High input in a clockwise rotation. No connection; the pump will default

to clockwise rotation.

Speed A remote potentiometer nominally 1kW and 2kW minimum 0.25W should be wired

as shown. When using a remote potentiometer, do not apply a voltage/current control

input signal at the same time. The pump must be calibrated for 0-12V analogue signal

control under the "PROGRAM" option of Signal in Setup. Alternatively, the potentiometer

may be used for the calibration procedure, instead of using the minimum and maximum

analogue process signal settings, if it is set to its minimum and maximum positions.

Tachometer output This facility can be used to indicate motor speed or total the number

of motor revolutions.

Footswitch A footswitch or handswitch will initiate the dose. The 624Di includes software

protection against spurious signals caused by bouncing of the switch contacts. This feature

is permanently activated (software setting fixed on "other") and only switches without

hardware debouncing should be used.

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 10

Watson-Marlow Bredel E-Manuals

Care and maintenance

The only scheduled maintenance required for the 624Di is inspection of the motor brushes

and their replacement before their length is less than 6mm. The life of the brushes will

depend on the duty of the pump, but is expected to be a minimum of 3,000 hours at

maximum speed.

If the pump requires cleaning, use a mild solution of detergent in water after removing the

pumphead. Do not use strong solvents.

For gearbox rebuilds, use Lubriplate GR-132 (Bodine reference LG-23) only. This is a

lithium combination type thickener, NL GI No.1 grade, non-corrosive extreme pressure

lubricant. This product is water-resistant and resistant to a large degree to most other

contaminants.

Guard safety warnings

The 624Di will be remotely stopped and display a warning if the guard is opened during

operation. This safety feature is enabled under Manual, Dose, Analogue and RS232

operation.

Specification

Maximum rotor speed 200 rpm

Power supply 100-120/220-240V /1/ 50/60Hz

Control range 50:1

Power consumption 300 VA

Fuse rating Type T (anti-surge) 5A

Operating temperature range 5C to 40C

Storage temperature range -40C to 70C

Weight 605Di/R 24.75kg (55lbs)

Weight 605Di/L 30.75kg (68lbs)

Noise <72dBA at 1m

Standards EN60529 (IP55)

Machinery directive 98/37/EC EN60204-1

Low voltage directive 73/23/EEC EN61010-1

EMC directive 89/336/EEC EN50081-1/EN50082-1

Specific drive performance details such as loaded drive speed variation against mains

supply voltage fluctuation and drive stability from a cold start to normal operating

temperature are available on request. For further information please contact WatsonMarlow Technical Support Department.

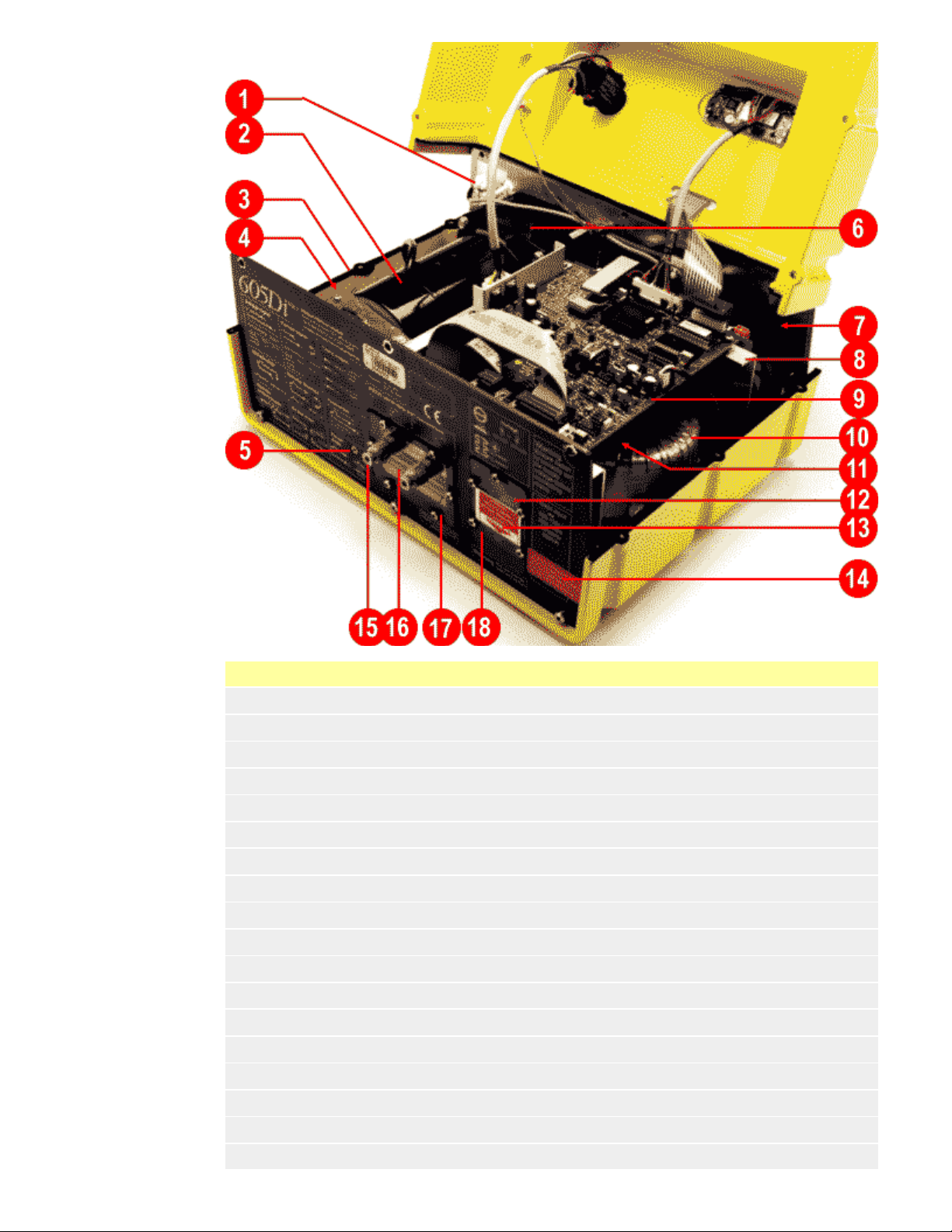

Drive spares

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 11

Watson-Marlow Bredel E-Manuals

Number Spare Description

1 TM0020 Terminal block 10A 12-way

2 BM0015 Motor brush

3 MR0691S Gasket

4 MN0787M Tacho disc

5 FN0271 M4 screw

6 MG0605 Motor/gearbox

7 MRA0194A Pcb H bridge

8 MR0289S Chassis

9 MRA0269A Pcb cardinal

10 MRA0198A Transformer

11 FA0002 Filter

12 MR0669S Window cover

13 FS0043 Fuse 5A T type

14 CP0005 Blanking plug OD 20mm

15 CP0020 Blanking plug

16 MN1086S Window cover

17 MN1087S Window gasket

18 MR0771S Window gasket

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 12

Watson-Marlow Bredel E-Manuals

620RE, 620RE4 and 620R Key safety information

Before opening the pumphead guard please ensure that the

following safety directions are followed.

For close-coupled drives, ensure that the pump is isolated from mains voltage.

Ensure that there is no pressure in the pipeline.

If a tube failure has occurred, ensure that any product in the pumphead has been

allowed to drain through the controlled waste to a suitable drain.

Ensure that protective clothing and eye protection are worn if hazardous products

are being pumped.

620RE, 620RE4 and 620R Safe-guarding

Primary safety on 620 series pumps is provided by the tool-lockable pumphead

guard. On electrically-powered cased 600 series pumps, secondary (backup)

protection is provided in the form of an electrical interlock which stops the pump if

the pumphead guard is opened (and only for so long as the guard is opened). The

electrical interlock on cased pumps should never be used as primary protection.

Always disconnect the mains power supply to the pump before opening the

pumphead guard.

Only primary protection through the tool-lockable guard is provided on pneumatically

powered 620 series cased pumps. Only primary protection through the tool lockable

pumphead guard is provided on 620 series pumps fitted with industrial AC motors,

but an interface kit to allow mains power to be switched by the pumphead guard

interlock is available as an extra-cost option.

620RE, 620RE4 and 620R Pumping conditions

Pressure and viscosity

All pressure values in this operating instruction, from which performance and life

figures have been calculated relate to peak pipeline pressures.

Although rated to 4 bar working pressure, this pump will generate in excess of 4 bar

working pressure if pipeline restrictions are in place. In instances where it is critical

that a working pressure of 4 bar is not exceeded, pressure relief valves should be

installed in the pipeline.

For pumping duties of 2-4 bar pressure, only close coupled pumps should be used,

fitted with 73 Shore hardness Marprene/Bioprene or standard STA-PURE tube

elements. "M" in the tube element’s product order code denotes suitability for high

pressure use.

When pumping duties of 0-2 bar pressure, use close coupled or cased pumps fitted

with 64 Shore hardness elements or the standard range of continuous peristaltic

pump tubing.

Viscosity handling is maximised by using 73 Shore hardness Marprene/Bioprene or

STA-PURE tube elements in the pumphead.

Ensure that there is always a minimum of one metre of smooth bore flexible tubing

connected to the discharge port of the pumphead. This will help minimise any

impulse losses and pulsation in the pipeline. This is especially important with viscous

fluids and rigid pipework.

620RE, 620RE4 and 620R Pump installation

A correctly engineered installation will promote the best possible tube life, so please ensure

that the following guidelines are followed:

Avoid tight pipeline bends, pipe reducers and excessive lengths of smaller bore

tubing than that in the pumphead, particularly in pipelines on the suction side.

Ensure that connecting pipe work and fittings are suitably rated to handle the

predicted pipeline pressure.

If rigid pipe work comes in close proximity to the pumphead, a drop out section of

pipe work will simplify tube replacement.

Ensure that the controlled waste blanking plug is in position if the controlled waste

port is not in use. See below.

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 13

Watson-Marlow Bredel E-Manuals

It is advisable to use controlled waste pipe work if pumping hazardous, aggressive

or abrasive fluids or products which will harden in contact with air.

When connecting waste pipe work to the controlled waste port using the coupling

adaptor supplied, ensure that there is adequate clearance underneath the

pumphead. Waste pipe work should run to a suitable container or drain.

The leak detector installation procedure is included in the leak detector kit.

If unsure of an installation please contact your local Watson-Marlow Technical

Support Office for further assistance.

620RE, 620RE4 and 620R General operation

Opening the pumphead guard

Unlock the guard with a 5mm Allen key or a screw driver.

Open the guard to its full extent. This creates the maximum clearance between the

tube ports and guard to remove the tubing.

Engaging/disengaging the rollers

The extent of travel of the roller release levers is indicated below. Do not try and

force the levers beyond their normal extent of travel as this will damage the rotor.

To engage the rollers snap the roller release levers counter clockwise making sure

that the rollers locked out against the tubing. To disengage the rollers, snap the

release levers clockwise to their disengaged position. For high pressure tubing

elements or four roller pumpheads, the 5mm Allen key can be used to aid leverage

when engaging/disengaging the rollers with the release levers.

Make sure that fingers are clear of the front face of the rotor hub

when using the roller release levers.

Pre-load checks

Before loading tubing, ensure that all rollers rotate freely, that the tube ports and

location grooves are clean and that if in use, the controlled waste pipe work is free

of any obstructions.

Closing the pumphead guard and start-up

Ensure that the guard seal is clean, replacing it if necessary.

Ensure that the rollers are engaged and locked out against the tubing

Close the guard and push it against the track until the latch engages.

Connect suitable pipe work to the pumphead using the appropriate connectors for

the tube element.

Continuous tubing clamp location in 620R pumpheads

Select the appropriate tube clamp set for the tubing size to be used.

Locate the two "U"-shaped track clamp halves into the pumphead ports (The "U"shape ensures correct loading)

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 14

Watson-Marlow Bredel E-Manuals

Locate the corresponding guard clamp halves which have raised "T" locating

sections, into the slots on the inner guard face above and below the guard hinge.

Push and slide into their locked position.

Closing the guard will align the two halves of the clamp around the tubing.

620RE and 620RE4 tube element loading

620RE element pumpheads are factory set to accept Watson-Marlow LoadSure tube

elements. Pumping performance will be adversely affected if LoadSure elements are

not used.

Disengage rollers

Locate one of the "D"-shaped flanges into the lower port. (The "D" flange ensures

that the element can only be loaded correctly).

Wrap the tube element around the disengaged rollers of the rotor.

Locate the second "D"-shaped flange into the upper port.

Ensure the flat face of each "D" flange sits flush to the flange sealing face of the

track.

Engage rollers

Close the guard and push it against the track until the latch engages.

Tube element loading

620RE, 620RE4 and 620R Continuous tube loading

620R continuous tubing pumpheads are factory set to accept Watson-Marlow 600

series 3.2mm wall tubing. Pumping performance will be adversely affected if

Watson-Marlow tubing is not used.

Select the tube clamp set which is correct for the tubing size to be used.

Disengage rollers

Locate one end of the tubing into the lower port "U" clamp and hold firmly in

position.

Wrap the tubing tightly around the retracted rollers, making sure that there is no

twisting through its length.

Locate the other end of the tubing into the upper port "U" clamp.

Hold both ends of the tubing in one hand maintaining tension around the retracted

rollers.

Engage rollers

Close the guard and push it against the track until the latch engages

Ensure that continuous tubing is not loosely clamped at the pumphead ports.

Ensure that when the pump is re-started all of the rollers have re-engaged. A roller

which has not re-engaged will "click" continuously. No damage will occur if this

happens but the roller should be re-engaged manually using the 5mm Allen key.

Please refer to the Troubleshooting section.

Continuous tube loading

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 15

Watson-Marlow Bredel E-Manuals

620RE, 620RE4 and 620R Tube element or continuous tube removal

Unlock the guard and disengage the rollers.

Disconnect the tubing from the external pipeline.

Remove the tubing from the pumphead.

620RE, 620RE4 and 620R Maintenance

Scheduled maintenance

The stainless steel pumping rollers run on sealed bearings and do not require

lubrication.

Remove the rotor and lubricate the follower rollers and roller engaging mechanisms

with a lithium-based grease. This should be carried out every six months for

intermittent duties and every three months for 24 hour duties.

If fluid is spilled inside the pumphead, flush the pumphead out with water and mild

detergent as soon as possible. If specific cleaning agents are required to clean the

spillage, please consult Watson-Marlow Technical Support Office before proceeding,

in order to confirm chemical compatibility.

If the rotor needs to be removed, refer to the guidelines below.

Roller adjustment

620 pumpheads have provision for adjustment to reset the roller/track gap to compensate

for wear after extended service in arduous applications.

Roller/track gaps can only be accurately judged without tubing in the pumphead. The gap

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 16

Watson-Marlow Bredel E-Manuals

should be 4.6mm for 3.2mm wall tubing and 5.5mm for LoadSure elements.

If the gap is more than 0.2mm greater than these dimensions, the following may be

carried out:

Note the number on the roller arm to which the engraved line on the hexagonheaded main roller pin corresponds.

Remove the circlip (snap-ring) and roller pin.

Relocate the main roller pin, resetting the engraved line to one number lower. For

example, if the engraved line was at "-1", reset it to "-2" to reduce the roller track

gap.

Ensure the roller pin is correctly seated into the roller arm thrust washer. Replace

the circlip.

Rotor removal and re-location

Remove the rotor cover and central locating bolt using a 5mm Allen key. Pull the

rotor off the keyed shaft, remove the key and clean thoroughly. Do not use tools to

lever the rear face of the rotor away from the inner face of the track, it should come

off by hand.

To replace the rotor, locate the key into the keyway and apply a thin layer of grease

over the shaft and key. Align the keyway of the rotor to the shaft key and slide the

rotor into position, ensuring that a positive "stop" is achieved and ensure that the

full length of the drive shaft is fitted into the rotor.

Do not force the rotor into position. The rotor will slide into place easily if correctly

aligned.

Tighten the hexagonal locating bolt to a nominal torque of 10Nm using a 5mm Allen

key.

The rotor bolt, which is impregnated with "Loctite 218" thread lock, should be

subjected to a maximum of three removals/relocations before renewal. To avoid

rotor bolt renewal after three removals, apply "Loctite 222" thread lock to the rotor

thread before relocation. This is critical to ensure prolonged, secure location of the

rotor hub to the drive shaft. Failure to complete this action will invalidate the

terms and conditions of the pumphead warranty.

Replace the rotor cover.

When closing the guard, check it does not make contact with the rotor. If it does, then the

rotor has been fitted incorrectly. Re-open the guard, remove and refit the rotor, and close

the guard.

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 17

Watson-Marlow Bredel E-Manuals

Track removal (cased drives)

Remove the rotor.

Disconnect the controlled waste pipework if attached.

Loosen the two track-retaining screws using a screwdriver.

Withdraw the track slightly from the front plate to expose the guard interlock

connection.

Disconnect the guard interlock by manually removing the cable plug from the track.

Withdraw the track fully from the cased drive.

Track re-location (cased drives)

Ensure that the track is clean and that the spacer washer and gearbox boss

alignment rings are still in position.

Offer the track up to the front panel of the cased drive and re-connect the guard

interlock cable plug.

Fit the track over the gearbox boss.

Align the track horizontally so that the location holes are aligned with the front plate

threaded holes.

Tighten the two retaining screws using a screwdriver.

Re-connect the guard interlock controlled waste pipework if required.

620RE, 620RE4 and 620R CIP and SIP

General

Unlock the guard and disengage the rollers within the tube zone.

Close the guard and squeeze against the track until the latch clicks.

Observe a 1m safety area.

CIP

LoadSure tube elements and continuous tubing can be cleaned using CIP processes.

Ensure that the tubuing material is chemically compatible with the cleaning agent

that is to be used.

If cleaning agents are spilled over the pumphead, wash down immediately.

Ensure that controlled waste pipework is fitted to allow a safe release of cleaning

agent in the event of a tube failure.

SIP

Only STA-PURE tube elements can be used in a steam in place sterilisation

processes.

STA-PURE tubing elements can be sterilised to 3A Class two and FDA minimum

recommended standard which is 121C (250F) at 1bar (14.5 psi) saturated steam for

20 minutes.

Monitor the process continuously .

If a tube failure occurs, shut down the process. Do not touch the pumphead until a

20 minute cooling period has been observed.

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 18

Watson-Marlow Bredel E-Manuals

Ensure a 20 minute acclimatisation period is observed before running the pump

following SIP.

Ensure that controlled waste pipework is fitted to allow a safe release of steam in

the event of a tube failure..

Ensure a 1m safety zone is maintained around the pumphead during SIP cycles.

Ensure that the pumphead door is closed and locked before SIP

cleaning commences.

620RE, 620RE4 and 620R Pumphead spares

Number Spare Description

1 Tube clamp pack: p/n 069.4101.000

2 MR2052C Oddie fastener

2 MR2053B Clip: Oddie retainer

2 MR2054T Oddie washer

2 SG0021 Oddie spring

2 CX0150 Oddie circlip (snap ring)

3 MRA0251A Track assembly (continuous pumphead) - includes guard

3 MRA0297A Track assembly (element pumphead) - includes guard

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 19

Watson-Marlow Bredel E-Manuals

3 MR2000C Track

4 MRA0249A Roller assembly element pumphead

<4> MRA0250A Roller assembly continuous pumphead

5 MR2027T Controlled waste threaded fitting 620R

6 MR2028M Controlled waste port blanking plug

7 MR2018T Hinge pin

8 MR2055M Rotor cover

9 MR2021B Seal - guard

10 MR2002M Guard without latch and seal

11 MR2015T Follower roller spindle

12 CX0148 Roller assembly circlip (snap-ring) E type 6 dia

12 MR2014T Stainless steel roller spindle

12 MR2010T Thrust washer

13 MR2096T Controlled waste threaded fitting locking nut

14 MRA0320A Rotor assembly 2-roller element

14 MRA0321A Rotor assembly 4-roller element

14 MRA0322A Rotor assembly 2-roller continuous

15 MR2058B Grommet - door switch

16 XX0220 Key - metal

17 MR2029T Cased drive MG605 shaft/rotor hub spacer

18 MR2059T Adaptor - Bodine (white polypropylene ring)

19 FN0488 Cased drive track locating screw M6x10 locating bolt

20 FN0523 Close-coupled track locating screw M6x20 locating bolt

21 FN0581 Rotor locating washer M6

22 FN0520 Rotor locating bolt M6 x 25

23 TT0006 5mm Allen key

24 MA0017 Guard magnet

CN0187 Plug blanking 10.72M

MRA0268A Cased drive door switch assembly

MRA0279A Close-coupled door switch assembly

625L Pumphead

The twin offset track design of the 625L utilises 4.0mm wall double-Y tube elements to

overcome pulsation for accurate dosing and dispensing. The 625L accepts Silicone and

Marprene tubing up to 16.0mm bore. Use 4.0mm wall tube for transfer for the highest

performance and improved viscous fluid handling.

Alternatively the 625L will run with two separate tubes although some channel to channel

variance and minimal pulsation may be experienced. For separate tube fitting or twin tube

inlet to single tube outlet fitting tube clamping blocks must be used.

625L Installation

Remove the mounting plate cover and track from the 625L. Locate 625L to pump. Tighten

top and bottom mounting plate screws. To remove the pumphead lift off the mounting

plate cover and track, loosen the top and bottom mounting plate securing screws and ease

pumphead away from the pump.

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 20

Watson-Marlow Bredel E-Manuals

625L Tube loading

Double-Y element

Lift the track locating levers and remove the track. Locate one end of double-Y element

over one of the 625L clamping pegs. Stretch the element over the rotor and locate the

other end of the element over the second 625L clamping peg. Replace the track and push

down the track locating levers. (See pumphead installation).

Twin inlet tubes

Lift the track locating levers and remove the track. Twist and remove the 625L inlet

clamping peg. Connect the twin inlet tubes and outlet tube using the appropriate Y-piece

connector and clamps. Fit the inlet tubes into the correct size clamping block. Locate the

clamping block onto the 625L (push down and twist locking fastener to secure). Stretch the

tubes over the rotor and locate the Y-piece end of the element over the second 625L

clamping peg. Replace the track and push down the track locating levers.

Two independent tubes

Lift the track locating levers and remove the track. Twist and remove the 625L clamping

pegs. Fit the two tubes into the correct size clamping blocks. Distance between blocks =

230mm for up to 8.0mm bore; 240mm for 12.0mm and 16.0mm bore. Fit the inlet tube

clamping block to the 625L. Stretch the tubes over the rotor and fit second tube clamping

block to the 625L. Replace the track and push down the track locating levers. When using

Marprene it is important to check the distance between the clamping blocks after 30

minutes running time.

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 21

Watson-Marlow Bredel E-Manuals

625L Care and maintenance

Check all moving parts for freedom of movement occasionally. If aggressive fluids are spilt

onto the pumphead, clean using a mild detergent only.

625L Track adjustment

The track is set for 4.0mm wall tubing up to 16.0mm bore. Alteration of this setting using

the pan head screws may be necessary to optimise performance if non-standard tubing is

used. The factory setting is 20.3mm vertically from the rotor side of the sprung track to

the top of the track cover.

625L Pumphead spares

Number Spare Description

1 MRA0141A Track assembly

2 MR0851S Cover plate

3 SW0050 Proximity switch

4 MRA0143A Adaptor

5 BB0018 Shaft bearing

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 22

Watson-Marlow Bredel E-Manuals

6 MRA0150A Rotor assembly

7 MR0850S Front plate

8 MRA0144A Tuibe locating peg

069.4001.000 Tube clamp set

625L Operation

User

decision

Instruction

reference

Quick start

A. Switch on power to drive.

B. User decision to calibrate.

C. Indication of head and tubing to which pump is currently calibrated.

D. If set-up not correct change existing set-up.

E. Select head and tubing.

F. Choose the pumphead required.

G. Choose the tube size. Selection confirmed.

H. Select Dose from Main menu.

I. Set a new dose program.

J. Set the volume or weight to be dosed.

K. Set the time interval between doses.

L. Set the number of doses to be dispensed.

M. Set the pump speed or volume flow rate.

N. Proceed to dose with using set parameters.

O. Verification of interval between doses and pump speed.

P. Verification of volume and number of doses, press Start.

Pump screen

display

Terminal Operation Flow

connector

Keypad functions

Manual

input

Quick start

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 23

Watson-Marlow Bredel E-Manuals

Recall program

Q. Recall previously set program from memory.

R. Select required program.

S. Verification of selected dose program.

T. Verification of interval between dose shots and pump speed.

U. User decision to accept chosen program. Repeated verification of dose parameters.

Recall program

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 24

Watson-Marlow Bredel E-Manuals

Record program

V. Pump starts.

W. User decision to record a set of dose program settings.

X. Select the memory location.

Y. Small case letters indicate an empty memory location.

Z. Verification of saved dose program.

A1. Verification of time interval between dose shots and pump speed.

B1. Verification of volume and number of doses, press Start

C1. Pump starts dosing.

Record program

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 25

Watson-Marlow Bredel E-Manuals

Calibration

D1. Indication of previous calibration (if completed).

E1. Decision to calibrate pump to new pumphead and tubing size.

F1. Select the pumphead and tubing which is fitted to pump.

G1. Confirmation of user selections. Maximum pump speed is governed by pumphead

fitted.

H1. Decision to calibrate pump using a calibration dose.

I1. Enter calibration speed and direction.

J1. Pump starts to calibrate. Press stop when ready.

K1. After 15 seconds pump will prompt user to stop calibrating.

L1. Measure and then enter the actual volume that has been dosed during calibration.

M1. Indication of pumphead, ml/rev and maximum rpm which is governed by the

pumphead.

Calibration

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 26

Watson-Marlow Bredel E-Manuals

Dose (1)

N1. Switch on pump and Main menu is called .

O1. User chooses dose option.

P1. Recal program option available only if program has previously been saved.

Q1. User recalls a preset program. Large case letters denote a stored program

R1. Decision to set a new dose program.

S1. Enter dose volume in ml (0.001L<Dose<9999L).

T1. Enter dose weight in grams (0.001kg<Dose<9999kg).

U1. Set the specififc gravity of the fluid (Maximum 5.0).

V1. Dose is too small for pump (Minimum dose set should require 5 rotor revolutions).

W1. Dose is too small for tubing.

X1. Dose is ok for setup.

Y1. Set time interval between doses (0.1s<Time<6550s).

Z1. Set total number of doses (up to 9999 doses).

Dose (1)

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 27

Watson-Marlow Bredel E-Manuals

Dose (2)

A2. Set drive speed.

B2. Set volume flow rate.

C2. Set direction of rotation of drive.

D2. Proceed to dose or save program.

E2. Proceed to dose.

F2. Record program.

G2. Set the memory location for the dose parameters.

H2. Choosing a capital letter will call the existing program settings within that memory

location.

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 28

Watson-Marlow Bredel E-Manuals

I2. Choosing a small case letter will call the dose settings to be saved.

J2. Indication of dosing interval and pump speed.

K2. Overwrite existing program or save to different memory location.

L2. Decision to choose new memory location.

M2. Decision to overwrite existing program.

Dose (2)

Dose (3)

N2. Dose program called for use.

O2. Indication of dosing time interval and pump speed.

P2. Volume/weight set and number of dose shots. Press start.

Q2. Pump starts dosing run.

R2. Option to restart dosing, re-calibrate pump or exit from dosing.

S2. Restart dosing.

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 29

Watson-Marlow Bredel E-Manuals

T2. Decision to re-calibrate pump.

Dose (4)

U2. Prompt to enter volume which pump is physically dosing during each shot.

V2. Measure and then enter manually the actual volume/weight which has been dosed.

W2. Default tolerance limit of +/-25% of pre-set dose volume on actual dosing volume

entered.

X2. Decision to exit from dose program.

Y2. The dosing batch is paused. Option to restart or stop.

Z2. Decision to re-start dosing.

A3. Decision to stop dosing.

B3. Indication of volume/weight dosed and number of doses completed.

C3. Option to restart dosing or return to Main menu.

D3. Return to Main menu.

E3. Start dosing.

F3. Unsaved dose settings will be called.

G3. Saved dose setting will be called.

H3. Indication of dose program which has been called.

I3. Dosing time interval and start prompt.

Dose (3)

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 30

Watson-Marlow Bredel E-Manuals

Programs and setup lost

J3. Indication of volume/weight dosed and number of doses remaining.

K3. Indication of volume/weight dosed and number of doses/hour.

L3. Option to zero the cumulative volume register.

M3. Decision to stop dosing.

N3. On-the-fly (mid batch) re-calibration facility.

O3. Enter actual volume dosed and pump will re-calibrate itself over 5 dose shots.

P3. Indication of dose volume/weight and number of doses in program called.

Q3. Verification of time interval between dose shots and pump speed.

R3. Accept called program for dose or choose another program from memory.

S3. Decision to accept program.

T3. Move to next program in memory.

U3. Decision to delete program from memory.

V3. Option to delete program from memory.

W3. Decision to not delete program.

X3. Decision to delete program.

Y3. Program is deleted.

Dose (4)

625L Error Messages

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 31

Watson-Marlow Bredel E-Manuals

press enter

This screen indicates corruption of the RAM or that the EPROM has been changed. In either

case pressing Enter will re-initialise the RAM and clear the error.

check drive and

setup now

This screen indicates that the motor has stalled or that a loss of tachometer pulses has

been selected. Clear the cause of stalling and power the pump off and on. If the error

persists seek qualified assistance.

Rs232 parameter

error

Signifies an illegal command string when under RS232 control.

data corrupted!

recalibrate

A corruption of data has been detected. Switch unit off and on. Re-calibrate using Head

and Tubing first followed by a calibration dose if necessary.

620RE, 620RE4 and 620R Technical data

Performance envelope of the 620R, 620RE and 620RE4 mark II rotor

Flow rates

Flow rates for the 624Di/R and 624Di/L were obtained pumping water at 20C with

negligible suction and delivery pressures (unless otherwise stated). Where an application is

critical, the flow rate should be determined under operating conditions. The important

factors are suction and delivery pressures, temperature and fluid viscosity.

620RE, 620RE4 and 620R Flow rates

Tube bore Tube number - # rpm Pressure (+) Suction (-)

Note: Flow rates quoted have been rounded for simplicity, but are accurate to within 5% well within the normal tubing tolerance variation of flow rate. They should therefore be

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 32

Watson-Marlow Bredel E-Manuals

taken as a guide. Real flow rates in any application must be determined empirically.

620R

Flow rates: Marprene, Bioprene

mm 6.4 9.6 12.7 15.9

inch 1/4 3/8 1/2 5/8

# 26 73 82 184

4-200 (l/min) 0.05 - 2.6 0.10 - 5.0 0.16 - 8.0 0.21 - 10

4-200 (USGPM) 0.01 - 0.7 0.03 - 1.3 0.04 - 2.1 0.06 - 2.6

Flow rates: Silicone

mm 6.4 9.6 12.7 15.9

inch 1/4 3/8 1/2 5/8

# 26 73 82 184

4-200 (l/min) 0.05 - 2.4 0.11 - 5.4 0.17 - 8.4 0.22 - 14

4-200 (USGPM) 0.01 - 0.6 0.03 - 1.4 0.04 - 2.2 0.06 - 3.6

Flow rates: Neoprene, STA-PURE

mm 6.4 9.6 12.7 15.9

inch 1/4 3/8 1/2 5/8

# 26 73 82 184

4-200 (l/min) 0.05 - 2.4 0.10 - 5.0 0.16 - 8.0 0.24 - 12

4-200 (USGPM) 0.01 - 0.6 0.03 - 1.3 0.04 - 2.1 0.06 - 3.2

620RE

Flow rates: Marprene TM, Bioprene TM

mm 12 17

4-200 (l/min) 0.15 - 7.4 0.24 - 12

4-200 (USGPM) 0.04 - 2.0 0.06 - 3.1

Flow rates: Marprene TL, Bioprene TL

mm 12 17

LoadSure LoadSure

LoadSure LoadSure

4-200 (l/min) 0.15 - 7.4 0.27 - 13

4-200 (USGPM) 0.04 - 2.0 0.07 - 3.6

Flow rates: Silicone

mm 12 17

4-200 (l/min) 0.15 - 7.7 0.24 - 12

4-200 (USGPM) 0.04 - 2.0 0.06 - 3.2

Flow rates: Neoprene, STA-PURE

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

LoadSure LoadSure

Page 33

Watson-Marlow Bredel E-Manuals

mm 12 17

LoadSure LoadSure

4-200 (l/min) 0.16 - 8.0 0.29 - 14

4-200 (USGPM) 0.04 - 2.1 0.08 - 3.8

620RE4

Flow rates: Marprene TM, Bioprene TM

mm 12 17

LoadSure LoadSure

4-200 (l/min) 0.13 - 6.3 0.16 - 8.2

4-200 (USGPM) 0.03 - 1.7 0.04 - 2.2

Flow rates: Marprene TL, Bioprene TL

mm 12 17

LoadSure LoadSure

4-200 (l/min) 0.13 - 6.3 0.19 - 9.4

4-200 (USGPM) 0.03 - 1.7 0.05 - 2.5

Flow rates: Silicone

mm 12 17

4-200 (l/min) 0.13 - 6.6 0.17 - 8.5

4-200 (USGPM) 0.03 - 1.7 0.05 - 2.3

Flow rates: Neoprene, STA-PURE

mm 12 17

4-200 (l/min) 0.14 - 6.8 0.20 - 10

4-200 (USGPM) 0.04 - 1.8 0.05 - 2.7

Dimensions in mm

624Di/R

LoadSure LoadSure

LoadSure LoadSure

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 34

Watson-Marlow Bredel E-Manuals

624Di/L

620R product codes

mm inch # Marprene Bioprene

6.4 1/4 26 902.0064.032 903.0064.032 910.0064.032 913.0064.032

9.6 3/8 73 902.0096.032 903.0096.032 910.0096.032 913.0096.032

12.7 1/2 82 902.0127.032 903.0127.032 910.0127.032 913.0127.032

15.9 5/8 184 902.0159.032 903.0159.032 910.0159.032 913.0159.032

mm inch # STA-PURE Neoprene Butyl Tygon

6.4 1/4 26 960.0064.032 920.0064.032 930.0064.032 950.0064.032

9.6 3/8 73 960.0096.032 920.0096.032 930.0096.032 950.0096.032

12.7 1/2 82 960.0127.032 920.0127.032 930.0127.032 950.0127.032

15.9 5/8 184 960.0159.032 920.0159.032 930.0159.032 950.0159.032

Gore

Peroxide

silicone

Platinum

silicone

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 35

Watson-Marlow Bredel E-Manuals

mm inch # Fluorel fluoroelastomer

/PTFE

6.4 1/4 26 970.0064.032 965.0064.032

9.6 3/8 73 970.0096.032 965.0096.032

12.7 1/2 82 970.0127.032 965.0127.032

15.9 5/8 184 970.0159.032 965.0159.032

620RE and 620RE4 LoadSure product codes

12mm

DIN 15

STA-PURE 960.0120.PFD 960.0120.PFT 960.0170.PFD 960.0170.PFT

Gore

fluoroelastomer

/PTFE

Bioprene TM 903.M120.PFD 903.M120.PFT 903.M170.PFD 903.M170.PFT

Bioprene 903.0120.PFD 903.0120.PFT 903.0170.PFD 903.0170.PFT

Platinum

silicone

Marprene TM 902.M120.PPC 902.M170.PPC

Marprene 902.0120.PPC 902.0170.PPC

Peroxide

silicone

Neoprene 920.0120.PPC 920.0170.PPC

620R dosing guidelines

965.0120.PFD 965.0120.PFT 965.0170.PFD 965.0170.PFT

913.0120.PFD 913.0120.PFT 913.0170.PFD 913.0170.PFT

12mm

Cam and Groove

3/4in

910.0120.PPC 910.0170.PPC

12mm

Tri-clamp 3/4in

17mm

Cam and Groove

3/4in

17mm

DIN 15

17mm

Tri-clamp

3/4in

L ? s ?

ml (± 1%) 50 100 250 500 1000 2500

mm

~ s (sec) 1.5 1.6 2.2 2.8 5.2 12.5

ml (± 2%) 50 100 250 500 1000 2500

mm

~ s (sec) 1.0 1.1 1.6 2.8 5.2 12.5

625L dosing guidelines

L ? s ?

ml (± 0.5%) 200 500 1000 2000 5000

mm

~ s (sec) 1.8 3.5 7.1 14.1 35.3

ml (± 1%) 200 500 1000 2000 5000

mm

~ s (sec) 1.4 3.5 7.1 14.1 35.3

ml (± 2%) 200 500 1000 2000 5000

6.4 9.6 12.7 15.9 15.9 15.9

9.6 12.7 15.9 15.9 15.9 15.9

12.0 16.0 16.0 16.0 16.0

16.0 16.0 16.0 16.0 16.0

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 36

Watson-Marlow Bredel E-Manuals

mm

~ s (sec) 1.4 3.5 7.1 14.1 35.3

625L product codes

< tr>

mm

8.0 960.E080.K40 965.E080.K40 913.AE80.K40 902.E080.K40

12.0 960.E120.K40 965.E120.K40 913.A12E.K40 902.E120.K40

16.0 960.E160.040 965.E160.040 913.A16E.040 902.E160.040

625L (4mm) product codes

< tr>

mm

8.0 903.0080.040 913.A080.040 902.0080.040

12.0 903.0120.040 913.A120.040 902.0120.040

STA-PURE

Bioprene

16.0 16.0 16.0 16.0 16.0

Gore

fluoroelastomer

Platinum

silicone

Platinum

silicone

Marprene

Marprene

16.0 903.0160.040 913.A160.040 902.0160.040

625L Y-piece product codes

mm

8.0 999.3096.K00

12.0 999.3120.K00

16.0 CN0125

Trademarks and disclaimer

Watson-Marlow, Loadsure, Bioprene and Marprene are trademarks of Watson-Marlow

Limited.

TYGON is a trademark of the Saint Gobain Performance Plastics Company.

STA-PURE is a trademark of W L Gore & Associates.

The information contained in this document is believed to be correct but Watson-Marlow

Limited accepts no liability for any errors it contains, and reserves the right to alter

specifications without notice.

Patient-connected use: warning

Warning, These products are not designed for use in, and should not be used for patient

connected applications.

Publication history

m-624di-gb-01.htm: Watson-Marlow 624Di

First electronically published 12 02.

Decontamination certificate

In compliance with the UK Health and Safety at Work Act and the Control of Substances

Hazardous to Health Regulations, you are required to declare the substances which have

been in contact with product(s) you return to Watson-Marlow or its subsidiaries or

distributors. Failure to do so will cause delays. Please ensure that you fax us this form and

receive an RGA (Returned Goods Authorisation) before you despatch the product(s). A

copy of this form must be attached to the outside of the packaging containing the

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Page 37

Watson-Marlow Bredel E-Manuals

product(s). Please complete a separate decontamination certificate for each product.

Your name Company

Address

Postcode/zip Country

Telephone Fax

Product type Serial number

To speed the repair, please

describe all known faults

You are responsible for cleaning and decontaminating the product(s) before return.

The product has ...

Names of chemicals

handled with product(s)

Precautions to be taken in

handling these chemicals

Action to be taken in the

event of human contact

Signature

Been used Not been used

If the product has been used, please complete all the following sections. If the product has

not been used, please just sign this form.

I understand that the personal data collected will be kept confidentially in accordance with

the UK Data Protection Act 1998.

RGA number

Your position

Date

Please print out, sign and fax to Watson-Marlow Pumps at +44 1326 376009.

http://www.watson-marlow.it/pdfs-global/m-624Di-gb-01.htm[10/07/2012 13:59:15]

Loading...

Loading...