Page 1

Watson-Marlow Bredel E-Manuals

Search manual for ...

Go

WATSON-MARLOW BREDEL E-MANUALS

m-620r-gb-01

Watson-Marlow 620R, 620RE and

620RE4 pumpheads

Clickable index

1. Declaration of incorporation

2. One-year warranty

3. Information for returning pumps

4. Safety

5. Recommended operating

procedures

6. 620RE, 620RE4 and 620R Key

safety information

7. 620RE, 620RE4 and 620R Safeguarding

8. 620RE, 620RE4 and 620R

Pumping conditions

9. 620RE, 620RE4 and 620R Pump

installation

10. 620RE, 620RE4 and 620R

General operation

Double clicking anywhere in the manual will take you back to this index.

Declaration of incorporation

When this pump unit is to be installed into a machine or is to be assembled with other

machines for installations, it must not be put into service until the relevant machinery has

been declared in conformity with the Machinery Directive 2006/42/EC.

11. 620RE and 620RE4 tube element loading

12. 620RE, 620RE4 and 620R Continuous tube

loading

13. 620RE, 620RE4 and 620R Tube element or

continuous tube removal

14. 620RE, 620RE4 and 620R Maintenance

15. 620RE, 620RE4 and 620R CIP and SIP

16. Pumphead spares

17. Technical data: performance envelope and

flow rates

18. 620R product codes

19. 620RE and 620RE4 LoadSure product codes

20. Trademarks and disclaimer

21. Warning not to use pumps in patientconnected applications

22. Publication history

23. Decontamination certificate

Responsible person: Christopher Gadsden, Managing Director, Watson-Marlow Limited,

Falmouth, Cornwall TR11 4RU, England. Telephone +44 (0) 1326 370370 Fax +44 (0)

1326 376009.

One-year warranty

Watson-Marlow Limited warrants, subject to the conditions below, through either WatsonMarlow Limited, its subsidiaries, or its authorised distributors, to repair or replace free of

charge, including labour, any part of this product which fails within one year of delivery of

the product to the end user. Such failure must have occurred because of defect in material

or workmanship and not as a result of operation of the product other than in accordance

with the instructions given in this manual.

Conditions of and specific exceptions to the above warranty are

Consumable items such as tubing and rollers are excluded.

Products must be returned by pre-arrangement carriage paid to Watson-Marlow Limited,

its subsidiaries, or its authorised distributor.

All repairs or modifications must have been made by Watson-Marlow Limited, its

subsidiaries, or its authorised distributors or with the express permission of WatsonMarlow Limited, its subsidiaries, or its authorised distributors.

Products which have been abused, misused, or subjected to malicious or accidental

damage or electrical surge are excluded.

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 2

Watson-Marlow Bredel E-Manuals

Warranties purporting to be on behalf of Watson-Marlow Limited made by any person,

including representatives of Watson-Marlow Limited, its subsidiaries, or its distributors,

which do not accord with the terms of this warranty shall not be binding upon WatsonMarlow Limited unless expressly approved in writing by a Director or Manager of WatsonMarlow Limited.

Information for returning pumps

Equipment which has been contaminated with, or exposed to, body fluids, toxic chemicals

or any other substance hazardous to health must be decontaminated before it is returned

to Watson-Marlow or its distributor. A certificate included at the rear of these operating

instructions, or signed statement, must be attached to the outside of the shipping carton.

This certificate is required even if the pump is unused. If the pump has been used, the

fluids that have been in contact with the pump and the cleaning procedure must be

specified along with a statement that the equipment has been decontaminated.

Safety

In the interests of safety, this pump and the tubing selected should only be used by

competent, suitably trained personnel after they have read and understood this manual,

and considered any hazard involved.

Any person who is involved in the installation or maintenance of this equipment should be

fully competent to carry out the work. In the UK this person should also be familiar with

the Health and Safety at Work Act 1974.

Recommended operating procedures

DO keep delivery and suction lines as short as possible using a minimum number of swept

bends.

DO use suction and delivery pipelines with a bore equal to or larger than the bore of the

tube fitted in the pumphead. When pumping viscous fluids, the losses caused by increased

friction can be overcome by using pipe runs with a cross sectional area several times

greater than the pumping element.

DO fit an extra length of pump tube in the system to enable tube transfer. This will extend

tube life and minimise the downtime of the pumping circuit.

DO keep the track and rollers clean.

The self-priming nature of peristaltic pumps means valves are not required. Any valves

fitted must cause no restriction to flow in the pumping circuit.

When using Marprene tubing, after the first 30 minutes of running, re-tension the tube in

the pumphead. Open the guard, hold the tubing at one port whilst pulling the tube tight

through the second port. This is to counteract the normal stretching that occurs with

Marprene which can go unnoticed and result in poor tube life.

Tube selection The chemical compatibility list published in the Watson-Marlow catalogue

is only a guide. If in doubt about the compatibility of a tube material and the duty fluid,

request a tube sample card for immersion trials.

620RE, 620RE4 and 620R Key safety information

Before opening the pumphead guard please ensure that the

following safety directions are followed.

For close-coupled drives, ensure that the pump is isolated from mains voltage.

Ensure that there is no pressure in the pipeline.

If a tube failure has occurred, ensure that any product in the pumphead has been

allowed to drain through the controlled waste to a suitable drain.

Ensure that protective clothing and eye protection are worn if hazardous products

are being pumped.

620RE, 620RE4 and 620R Safe-guarding

Primary safety on 620 series pumps is provided by the tool-lockable pumphead

guard. On electrically-powered cased 600 series pumps, secondary (backup)

protection is provided in the form of an electrical interlock which stops the pump if

the pumphead guard is opened (and only for so long as the guard is opened). The

electrical interlock on cased pumps should never be used as primary protection.

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 3

Watson-Marlow Bredel E-Manuals

Always disconnect the mains power supply to the pump before opening the

pumphead guard.

Only primary protection through the tool-lockable guard is provided on pneumatically

powered 620 series cased pumps. Only primary protection through the tool lockable

pumphead guard is provided on 620 series pumps fitted with industrial AC motors,

but an interface kit to allow mains power to be switched by the pumphead guard

interlock is available as an extra-cost option.

620RE, 620RE4 and 620R Pumping conditions

Pressure and viscosity

All pressure values in this operating instruction, from which performance and life

figures have been calculated relate to peak pipeline pressures.

Although rated to 4 bar working pressure, this pump will generate in excess of 4 bar

working pressure if pipeline restrictions are in place. In instances where it is critical

that a working pressure of 4 bar is not exceeded, pressure relief valves should be

installed in the pipeline.

For pumping duties of 2-4 bar pressure, only close coupled pumps should be used,

fitted with 73 Shore hardness Marprene/Bioprene or standard STA-PURE tube

elements. "M" in the tube element’s product order code denotes suitability for high

pressure use.

When pumping duties of 0-2 bar pressure, use close coupled or cased pumps fitted

with 64 Shore hardness elements or the standard range of continuous peristaltic

pump tubing.

Viscosity handling is maximised by using 73 Shore hardness Marprene/Bioprene or

STA-PURE tube elements in the pumphead.

Ensure that there is always a minimum of one metre of smooth bore flexible tubing

connected to the discharge port of the pumphead. This will help minimise any

impulse losses and pulsation in the pipeline. This is especially important with viscous

fluids and rigid pipework.

620RE, 620RE4 and 620R Pump installation

A correctly engineered installation will promote the best possible tube life, so please ensure

that the following guidelines are followed:

Avoid tight pipeline bends, pipe reducers and excessive lengths of smaller bore

tubing than that in the pumphead, particularly in pipelines on the suction side.

Ensure that connecting pipe work and fittings are suitably rated to handle the

predicted pipeline pressure.

If rigid pipe work comes in close proximity to the pumphead, a drop out section of

pipe work will simplify tube replacement.

Ensure that the controlled waste blanking plug is in position if the controlled waste

port is not in use. See below.

It is advisable to use controlled waste pipe work if pumping hazardous, aggressive

or abrasive fluids or products which will harden in contact with air.

When connecting waste pipe work to the controlled waste port using the coupling

adaptor supplied, ensure that there is adequate clearance underneath the

pumphead. Waste pipe work should run to a suitable container or drain.

The leak detector installation procedure is included in the leak detector kit.

If unsure of an installation please contact your local Watson-Marlow Technical

Support Office for further assistance.

620RE, 620RE4 and 620R General operation

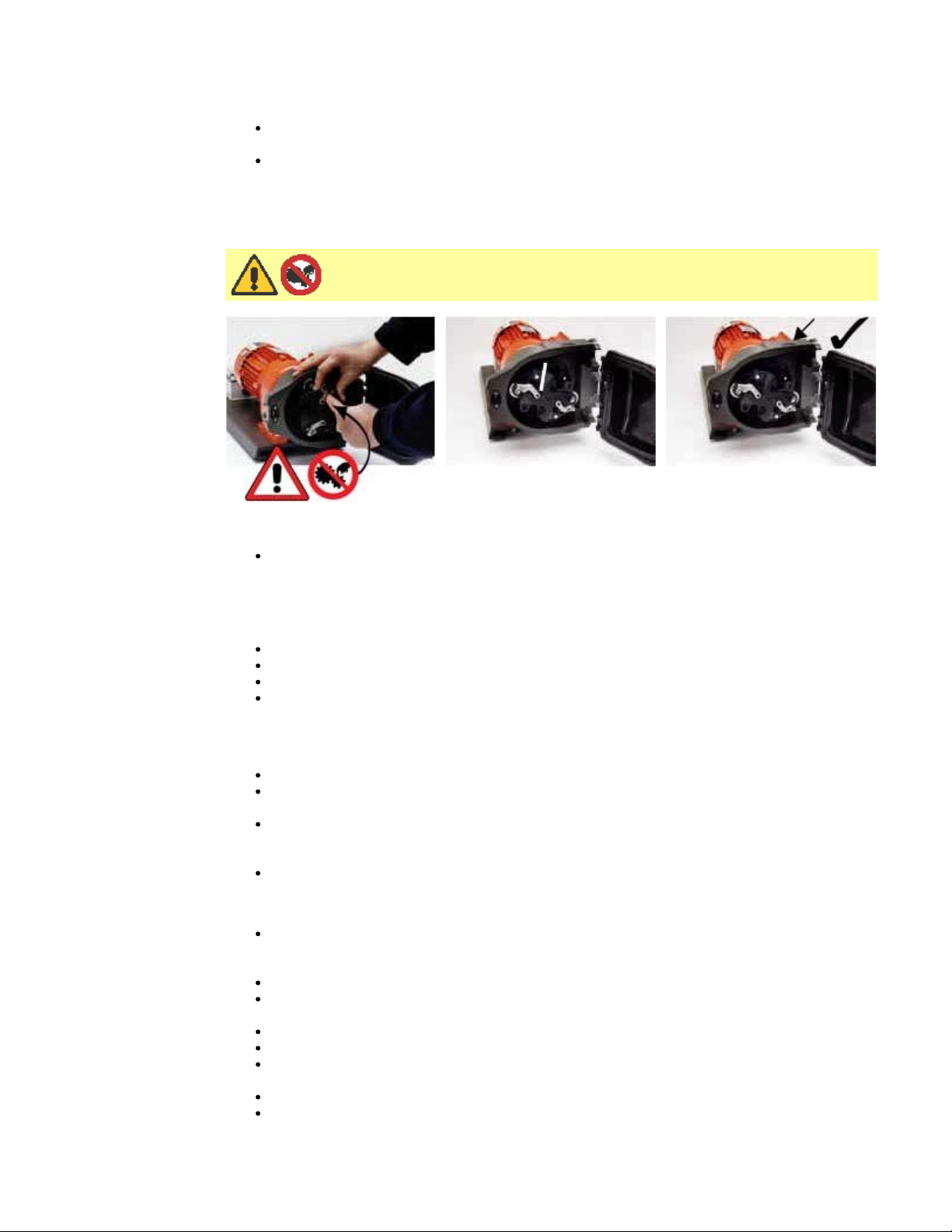

Opening the pumphead guard

Unlock the guard with a 5mm Allen key or a screw driver.

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 4

Watson-Marlow Bredel E-Manuals

Open the guard to its full extent. This creates the maximum clearance between the

tube ports and guard to remove the tubing.

Engaging/disengaging the rollers

The extent of travel of the roller release levers is indicated below. Do not try and

force the levers beyond their normal extent of travel as this will damage the rotor.

To engage the rollers snap the roller release levers counter clockwise making sure

that the rollers locked out against the tubing. To disengage the rollers, snap the

release levers clockwise to their disengaged position. For high pressure tubing

elements or four roller pumpheads, the 5mm Allen key can be used to aid leverage

when engaging/disengaging the rollers with the release levers.

Make sure that fingers are clear of the front face of the rotor hub

when using the roller release levers.

Pre-load checks

Before loading tubing, ensure that all rollers rotate freely, that the tube ports and

location grooves are clean and that if in use, the controlled waste pipe work is free

of any obstructions.

Closing the pumphead guard and start-up

Ensure that the guard seal is clean, replacing it if necessary.

Ensure that the rollers are engaged and locked out against the tubing

Close the guard and push it against the track until the latch engages.

Connect suitable pipe work to the pumphead using the appropriate connectors for

the tube element.

Continuous tubing clamp location in 620R pumpheads

Select the appropriate tube clamp set for the tubing size to be used.

Locate the two "U"-shaped track clamp halves into the pumphead ports (The "U"shape ensures correct loading)

Locate the corresponding guard clamp halves which have raised "T" locating

sections, into the slots on the inner guard face above and below the guard hinge.

Push and slide into their locked position.

Closing the guard will align the two halves of the clamp around the tubing.

620RE and 620RE4 tube element loading

620RE element pumpheads are factory set to accept Watson-Marlow LoadSure tube

elements. Pumping performance will be adversely affected if LoadSure elements are

not used.

Disengage rollers

Locate one of the "D"-shaped flanges into the lower port. (The "D" flange ensures

that the element can only be loaded correctly).

Wrap the tube element around the disengaged rollers of the rotor.

Locate the second "D"-shaped flange into the upper port.

Ensure the flat face of each "D" flange sits flush to the flange sealing face of the

track.

Engage rollers

Close the guard and push it against the track until the latch engages.

Tube element loading

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 5

Watson-Marlow Bredel E-Manuals

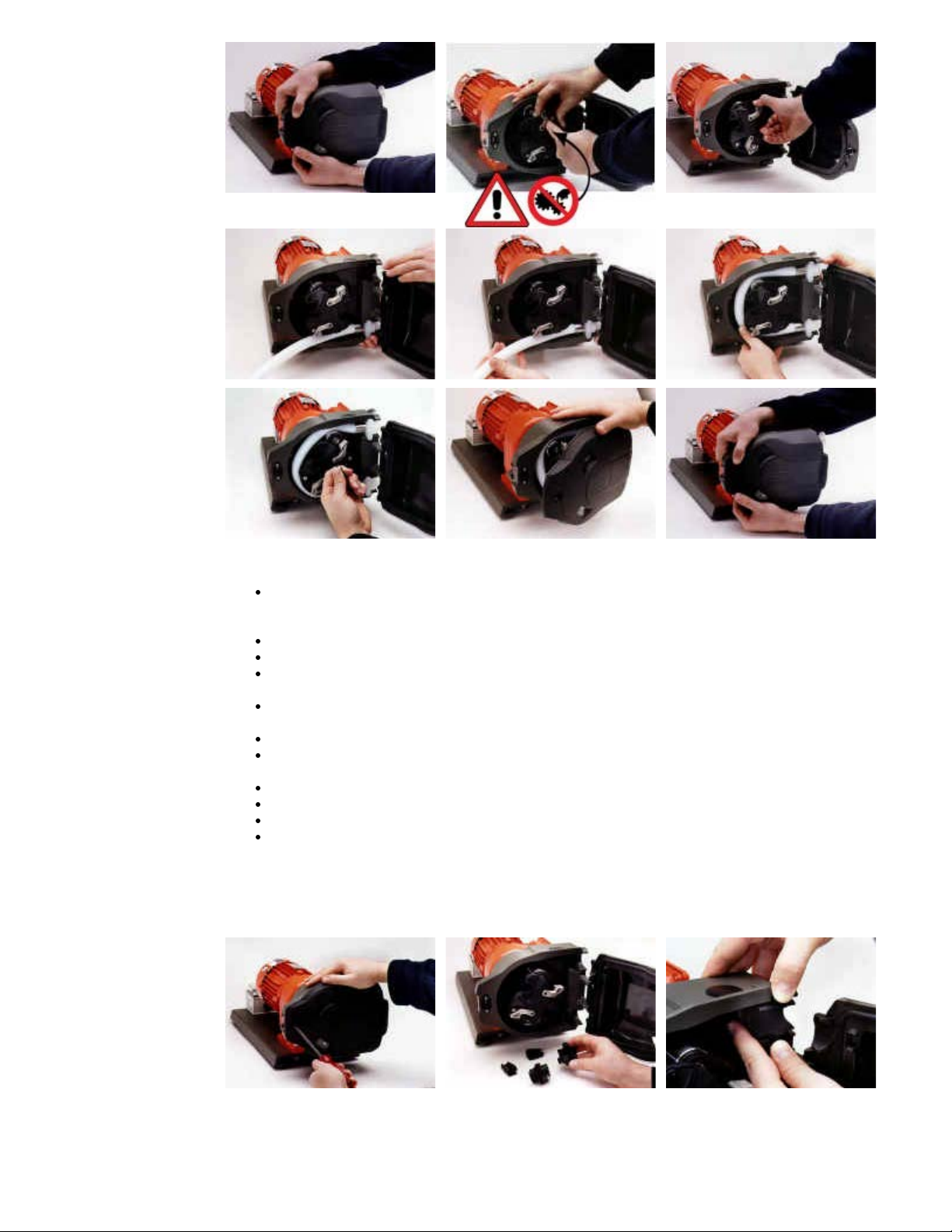

620RE, 620RE4 and 620R Continuous tube loading

620R continuous tubing pumpheads are factory set to accept Watson-Marlow 600

series 3.2mm wall tubing. Pumping performance will be adversely affected if

Watson-Marlow tubing is not used.

Select the tube clamp set which is correct for the tubing size to be used.

Disengage rollers

Locate one end of the tubing into the lower port "U" clamp and hold firmly in

position.

Wrap the tubing tightly around the retracted rollers, making sure that there is no

twisting through its length.

Locate the other end of the tubing into the upper port "U" clamp.

Hold both ends of the tubing in one hand maintaining tension around the retracted

rollers.

Engage rollers

Close the guard and push it against the track until the latch engages

Ensure that continuous tubing is not loosely clamped at the pumphead ports.

Ensure that when the pump is re-started all of the rollers have re-engaged. A roller

which has not re-engaged will "click" continuously. No damage will occur if this

happens but the roller should be re-engaged manually using the 5mm Allen key.

Please refer to the Troubleshooting section.

Continuous tube loading

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 6

Watson-Marlow Bredel E-Manuals

620RE, 620RE4 and 620R Tube element or continuous tube removal

Unlock the guard and disengage the rollers.

Disconnect the tubing from the external pipeline.

Remove the tubing from the pumphead.

620RE, 620RE4 and 620R Maintenance

Scheduled maintenance

The stainless steel pumping rollers run on sealed bearings and do not require

lubrication.

Remove the rotor and lubricate the follower rollers and roller engaging mechanisms

with a lithium-based grease. This should be carried out every six months for

intermittent duties and every three months for 24 hour duties.

If fluid is spilled inside the pumphead, flush the pumphead out with water and mild

detergent as soon as possible. If specific cleaning agents are required to clean the

spillage, please consult Watson-Marlow Technical Support Office before proceeding,

in order to confirm chemical compatibility.

If the rotor needs to be removed, refer to the guidelines below.

Roller adjustment

620 pumpheads have provision for adjustment to reset the roller/track gap to compensate

for wear after extended service in arduous applications.

Roller/track gaps can only be accurately judged without tubing in the pumphead. The gap

should be 4.6mm for 3.2mm wall tubing and 5.5mm for LoadSure elements.

If the gap is more than 0.2mm greater than these dimensions, the following may be

carried out:

Note the number on the roller arm to which the engraved line on the hexagonheaded main roller pin corresponds.

Remove the circlip (snap-ring) and roller pin.

Relocate the main roller pin, resetting the engraved line to one number lower. For

example, if the engraved line was at "-1", reset it to "-2" to reduce the roller track

gap.

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 7

Watson-Marlow Bredel E-Manuals

Ensure the roller pin is correctly seated into the roller arm thrust washer. Replace

the circlip.

Rotor removal and re-location

Remove the rotor cover and central locating bolt using a 5mm Allen key. Pull the

rotor off the keyed shaft, remove the key and clean thoroughly. Do not use tools to

lever the rear face of the rotor away from the inner face of the track, it should come

off by hand.

To replace the rotor, locate the key into the keyway and apply a thin layer of grease

over the shaft and key. Align the keyway of the rotor to the shaft key and slide the

rotor into position, ensuring that a positive "stop" is achieved and ensure that the

full length of the drive shaft is fitted into the rotor.

Do not force the rotor into position. The rotor will slide into place easily if correctly

aligned.

Tighten the hexagonal locating bolt to a nominal torque of 10Nm using a 5mm Allen

key.

The rotor bolt, which is impregnated with "Loctite 218" thread lock, should be

subjected to a maximum of three removals/relocations before renewal. To avoid

rotor bolt renewal after three removals, apply "Loctite 222" thread lock to the rotor

thread before relocation. This is critical to ensure prolonged, secure location of the

rotor hub to the drive shaft. Failure to complete this action will invalidate the

terms and conditions of the pumphead warranty.

Replace the rotor cover.

When closing the guard, check it does not make contact with the rotor. If it does, then the

rotor has been fitted incorrectly. Re-open the guard, remove and refit the rotor, and close

the guard.

Track removal (close coupled AC motor gearboxes)

Remove the rotor.

Disconnect the controlled waste pipework if attached.

Loosen the four track retaining screws using a Number 2 Pozi-Driv screwdriver.

Disconnect the mains interlock if connected to a mains contactor

Withdraw the track fully from the gearbox.

Track re-location (close coupled AC motor gearboxes)

Ensure that the track is clean.

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 8

Watson-Marlow Bredel E-Manuals

Fit the track over the gearbox boss.

Align the track horizontally so that the location holes are aligned with the threaded

gearbox holes.

Tighten the four track retaining screws using a Number 2 Pozi-Driv screwdriver.

Re-connect the guard interlock controlled waste pipework if required.

620RE, 620RE4 and 620R CIP and SIP

General

Unlock the guard and disengage the rollers within the tube zone.

Close the guard and squeeze against the track until the latch clicks.

Observe a 1m safety area.

CIP

LoadSure tube elements and continuous tubing can be cleaned using CIP processes.

Ensure that the tubing material is chemically compatible with the cleaning agent that

is to be used.

If cleaning agents are spilled over the pumphead, wash down immediately.

Ensure that controlled waste pipework is fitted to allow a safe release of cleaning

agent in the event of a tube failure.

SIP

Only STA-PURE tube elements can be used in a steam in place sterilisation

processes.

STA-PURE tubing elements can be sterilised to 3A Class two and FDA minimum

recommended standard which is 121C (250F) at 1bar (14.5 psi) saturated steam for

20 minutes.

Monitor the process continuously .

If a tube failure occurs, shut down the process. Do not touch the pumphead until a

20 minute cooling period has been observed.

Ensure a 20 minute acclimatisation period is observed before running the pump

following SIP.

Ensure that controlled waste pipework is fitted to allow a safe release of steam in

the event of a tube failure.

Ensure a 1m safety zone is maintained around the pumphead during SIP cycles.

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 9

Watson-Marlow Bredel E-Manuals

Ensure that the pumphead door is closed and locked before SIP

cleaning commences.

Pumphead spares

Number Spare Description

1 069.4101.000 620RTC: continuous tubing clamp set

2 MR2052C Oddie fastener

2 MR2053B Clip: Oddie retainer

2 MR2054T Oddie washer

2 SG0021 Oddie spring

2 CX0150 Oddie circlip (snap ring)

3 MRA0251A Track assembly (continuous pumphead)

3 MRA0297A Track assembly (element pumphead)

3 MR2000C Track

4 MRA0249A Roller assembly element pumphead

4 MRA0250A Roller assembly continuous pumphead

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 10

Watson-Marlow Bredel E-Manuals

5 MR2027T Controlled waste threaded fitting 620R

6 MR2028M Controlled waste port blanking plug

7 MR2018T Hinge pin

8 MR2055M Rotor cover

9 MR2021B Seal - guard

10 MR2002M Guard without latch and seal

11 MR2015T Follower roller spindle

12 CX0148 Roller assembly circlip (snap-ring) E type 6 dia

12 MR2014T Stainless steel roller spindle

12 MR2010T Thrust washer

13 MR2096T Controlled waste threaded fitting locking nut

14 MRA0320A Rotor assembly 2-roller element

14 MRA0321A Rotor assembly 4-roller element

14 MRA0322A Rotor assembly 2-roller continuous

15 MR2058B Grommet - door switch

16 XX0220 Key - metal

17 MR2029T Cased drive MG605 shaft/rotor hub spacer

18 MR2059T Adaptor - Bodine (white polypropylene ring)

19 FN0488 Cased drive track locating screws M6x10

20 FN0523 Close-coupled track locating screws M6x20

21 FN0581 Rotor locating washer M6

22 FN0520 Rotor locating bolt M6 x 25

23 TT0006 5mm Allen key

24 MA0017 Magnet

MRA0268A Cased drive door switch assembly

MRA0279A Close-coupled door switch assembly

CN0187 Plug blanking 10.72M

Technical data

Performance envelope of the 620R, 620RE and 620RE4 mark II rotor

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 11

Watson-Marlow Bredel E-Manuals

Flow rates

Tube bore Tube number - # rpm Pressure (+) Suction (-)

Note: Flow rates quoted have been rounded for simplicity, but are accurate to within 5% well within the normal tubing-tolerance variation of flow rate. They should therefore be

taken as a guide. Real flow rates in any application must be determined empirically.

620R

Flow rates: Marprene, Bioprene (l/min)

mm 6.4 9.6 12.7 15.9

inch 1/4 3/8 1/2 5/8

# 26 73 82 184

8-76 0.10-1.0 0.20-1.9 0.32-3.0 0.42-4.2

8-77 0.10-1.0 0.20-1.9 0.32-3.1 0.42-4.2

8-83 0.10-1.1 0.20-2.1 0.32-3.3 0.42-4.5

17-83 0.22-1.1 0.43-2.1 0.68-3.3 0.90-4.5

47-237 0.61-3.1 1.2-5.9 1.9-9.5 2.5-11

50-251 0.65-3.3 1.3-6.3 2.0-10 2.7-11

52-259 0.68-3.4 1.3-6.5 2.1-10 2.8-11

Flow rates: Marprene, Bioprene (USGPM)

mm 6.4 9.6 12.7 15.9

inch 1/4 3/8 1/2 5/8

# 26 73 82 184

8-76 0.03-0.3 0.05-0.5 0.08-0.8 0.11-1.1

8-77 0.03-0.3 0.05-0.5 0.08-0.8 0.11-1.1

8-83 0.03-0.3 0.05-0.5 0.08-0.9 0.11-1.2

17-83 0.06-0.3 0.11-0.5 0.18-0.9 0.24-1.2

47-237 0.16-0.8 0.31-1.6 0.50-2.5 0.67-2.9

50-251 0.17-0.9 0.33-1.7 0.53-2.7 0.72-3.0

52-259 0.18-0.9 0.34-1.7 0.55-2.7 0.75-3.0

Flow rates: Silicone (l/min)

mm 6.4 9.6 12.7 15.9

inch 1/4 3/8 1/2 5/8

# 26 73 82 184

8-76 0.10-0.9 0.22-2.1 0.34-3.2 0.44-4.7

8-77 0.10-0.9 0.22-2.1 0.34-3.2 0.44-4.7

8-83 0.10-1.0 0.22-2.2 0.34-3.5 0.44-5.1

17-83 0.20-1.0 0.46-2.2 0.71-3.5 0.95-5.1

47-237 0.56-2.8 1.3-6.4 2.0-10 2.8-14

50-251 0.60-3.0 1.4-6.8 2.1-11 3.0-14

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 12

Watson-Marlow Bredel E-Manuals

52-259 0.62-3.1 1.4-7.0 2.2-11 3.1-15

8-77 0.30.2.8 0.47-4.5

Flow rates: Silicone (USGPM)

mm 6.4 9.6 12.7 15.9

inch 1/4 3/8 1/2 5/8

# 26 73 82 184

8-76 0.03-0.2 0.06-0.5 0.09-0.8 0.12-1.2

8-77 0.03-0.2 0.06-0.5 0.09-0.9 0.12-1.3

8-83 0.03-0.3 0.06-0.6 0.09-0.9 0.12-1.4

17-83 0.05-0.3 0.12-0.6 0.17-0.9 0.25-1.4

47-237 0.15-0.8 0.34-1.7 0.46-2.6 0.73-3.7

50-251 0.16-0.8 0.36-1.8 0.55-2.8 0.78-3.8

52-259 0.16-0.8 0.37-1.8 0.58-2.9 0.82-3.9

Flow rates: Neoprene, STA-PURE (l/min)

mm 6.4 9.6 12.7 15.9

inch 1/4 3/8 1/2 5/8

# 26 73 82 184

8-76 0.10-0.9 0.20-1.9 0.32-3.0 0.49-4.6

8-77 0.10-0.9 0.20-1.9 0.32-3.1 0.49-4.7

8-83 0.10-1.0 0.20-2.1 0.32-3.3 0.49-5.1

17-83 0.20-1.0 0.43-2.1 0.68-3.3 1.0-5.1

47-237 0.56-2.8 1.2-5.9 1.9-9.51 2.9-14

50-251 0.60-3.0 1.3-6.3 2.01-10 3.1-15

52-259 0.62-3.1 1.3-6.5 2.1-10 3.2-16

Flow rates: Neoprene, STA-PURE (USGPM)

mm 6.4 9.6 12.7 15.9

inch 1/4 3/8 1/2 5/8

# 26 73 82 184

8-76 0.03-0.2 0.05-0.5 0.08-0.8 0.13-1.2

8-77 0.03-0.2 0.05-0.5 0.08-0.8 0.13-1.2

8-83 0.03-0.3 0.05-0.5 0.08-0.9 0.13-1.3

17-83 0.05-0.3 0.11-0.5 0.18-0.9 0.27-1.3

47-237 0.15-0.8 0.31-1.6 0.50-2.5 0.76-3.8

50-251 0.16-0.8 0.33-1.7 0.53-2.7 0.81-4.0

52-259 0.16-0.8 0.34-1.7 0.55-2.7 0.84-4.2

620RE

Flow rates: Marprene TM, Bioprene TM (l/min)

mm 12 17

LoadSure LoadSure

8-76 0.30-2.8 0.47-4.5

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 13

Watson-Marlow Bredel E-Manuals

8-83 0.30-3.1 0.47-4.9

17-83 0.63-3.1 1.0-4.9

47-237 1.7-8.8 2.8-14

50-251 1.9-9.3 2.9-15

52-259 1.9-9.6 3.1-15

Flow rates: Marprene TM, Bioprene TM (USGPM)

mm 12 17

LoadSure LoadSure

8-76 0.08-0.7 0.12-1.2

8-77 0.08-0.8 0.12-1.2

8-83 0.08-0.8 0.12-1.3

17-83 0.17-0.8 0.26-1.3

47-237 0.46-2.3 0.73-3.7

50-251 0.49-2.5 0.78-3.9

52-259 0.51-2.5 0.81-4.0

Flow rates: Marprene TL, Bioprene TL (l/min)

mm 12 17

LoadSure LoadSure

8-76 0.30-2.8 0.54-5.1

8-77 0.30-2.8 0.54-5.2

8-83 0.30-3.1 0.54-5.6

17-83 0.63-3.1 1.1-5.6

47-237 1.7-8.8 3.2-16

50-251 1.9-9.3 3.4-17

52-259 1.9-9.6 3.5-17

Flow rates: Marprene TL, Bioprene TL (USGPM)

mm 12 17

LoadSure LoadSure

8-76 0.08-0.7 0.14-1.4

8-77 0.08-0.8 0.14-1.4

8-83 0.08-0.8 0.14-1.5

17-83 0.17-0.8 0.30-1.5

47-237 0.46-2.3 0.84-4.2

50-251 0.49-2.5 0.89-4.5

52-259 0.51-2.5 0.92-4.6

Flow rates: Silicone (l/min)

mm 12 17

LoadSure LoadSure

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 14

Watson-Marlow Bredel E-Manuals

8-76 0.31-2.9 0.49-4.6

8-77 0.31-3.0 0.49-4.7

8-83 0.31-3.2 0.49-5.16

17-83 0.66-3.2 1.0-5.1

47-237 1.8-9.2 2.9-14

50-251 1.9-9.7 3.0-15

52-259 2.0-10 3.2-16

Flow rates: Silicone (USGPM)

mm 12 17

8-76 0.08-0.8 0.13-1.2

8-77 0.08-0.8 0.13-1.2

8-83 0.08-0.8 0.13-1.3

17-83 0.17-0.8 0.27-1.3

47-237 0.48-2.4 0.76-3.8

LoadSure LoadSure

50-251 0.51-2.6 0.80-4.0

52-259 0.53-2.6 0.84-4.2

Flow rates: Neoprene, STA-PURE (l/min)

mm 12 17

LoadSure LoadSure

8-76 0.32-3.0 0.58-5.5

8-77 0.32-3.1 0.58-5.6

8-83 0.32-3.3 0.58-6.0

17-83 0.68-3.3 1.2-6.0

47-237 1.9-9.4 3.4-17

50-251 2.0-10 3.6-18

52-259 2.1-10 3.8-19

Flow rates: Neoprene, STA-PURE (USGPM)

mm 12 17

LoadSure LoadSure

8-76 0.08-0.8 0.15-1.4

8-77 0.08-0.8 0.15-1.5

8-83 0.08-0.9 0.15-1.6

17-83 0.18-0.9 0.32-1.6

47-237 0.49-2.5 0.90-4.5

50-251 0.53-2.6 0.95-4.8

52-259 0.55-2.7 0.99-4.9

620RE4

Flow rates: Marprene TM, Bioprene TM (l/min)

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 15

Watson-Marlow Bredel E-Manuals

mm 12 17

LoadSure LoadSure

8-76 0.25-2.4 0.33-3.1

8-77 0.25-2.4 0.33-3.2

8-83 0.25-2.6 0.33-3.4

17-83 0.54-2.6 0.70-3.4

47-237 1.5-7.5 1.9-9.8

50-251 1.6-7.9 2.1-10

52-259 1.6-8.2 2.1-11

Flow rates: Marprene TM, Bioprene TM (USGPM)

mm 12 17

LoadSure LoadSure

8-76 0.07-0.6 0.09-0.8

8-77 0.07-0.6 0.09-0.8

8-83 0.07-0.7 0.09-0.9

17-83 0.14-0.7 0.19-0.9

47-237 0.39-2.0 0.51-2.6

50-251 0.42-2.1 0.54-2.7

52-259 0.43-2.2 0.57-2.8

Flow rates: Marprene TL, Bioprene TL (l/min)

mm 12 17

LoadSure LoadSure

8-76 0.25-2.4 0.38-3.6

8-77 0.25-2.4 0.38-3.6

8-83 0.25-2.6 0.38-3.9

17-83 0.54-2.6 0.80-3.9

47-237 1.5-7.5 2.2-11

50-251 1.6-7.9 2.4-12

52-259 1.6-8.2 2.4-12

Flow rates: Marprene TL, Bioprene TL (USGPM)

mm 12 17

LoadSure LoadSure

8-76 0.07-0.6 0.10-0.9

8-77 0.07-0.6 0.10-1.0

8-83 0.07-0.7 0.10-1.0

17-83 0.14-0.7 0.21-1.0

47-237 0.39-2.0 0.58-2.9

50-251 0.42-2.1 0.62-3.1

52-259 0.43-2.2 0.65-3.2

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 16

Watson-Marlow Bredel E-Manuals

Flow rates: Silicone (l/min)

mm 12 17

LoadSure LoadSure

8-76 0.26-2.5 0.34-3.2

8-77 0.26-2.5 0.34-3.3

8-83 0.26-2.7 0.34-3.5

17-83 0.56-2.7 0.72-3.5

47-237 1.5-7.8 2.0-10

50-251 1.6-8.3 2.1-11

52-259 1.7-8.5 2.2-11

Flow rates: Silicone (USGPM)

mm 12 17

LoadSure LoadSure

8-76 0.07-0.7 0.09-0.9

8-77 0.07-0.7 0.09-0.9

8-83 0.07-0.7 0.09-0.9

17-83 0.15-0.7 0.19-0.9

47-237 0.41-2.1 0.53-2.7

50-251 0.43-2.2 0.56-2.8

52-259 0.45-2.3 0.59-2.9

Flow rates: Neoprene, STA-PURE (l/min)

mm 12 17

LoadSure LoadSure

8-76 0.27-2.6 0.40-3.8

8-77 0.27-2.6 0.40-3.9

8-83 0.27-2.8 0.40-4.2

17-83 0.57-2.8 0.86-4.2

47-237 1.6-8.0 2.4-12

50-251 1.7-8.5 2.5-13

52-259 1.8-8.8 2.6-13

Flow rates: Neoprene, STA-PURE (USGPM)

mm 12 17

LoadSure LoadSure

8-76 0.07-0.7 0.11-1.0

8-77 0.07-0.7 0.11-1.0

8-83 0.07-0.7 0.11-1.1

17-83 0.15-0.7 0.23-1.1

47-237 0.42-2.1 0.63-3.2

50-251 0.45-2.2 0.67-3.3

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 17

Watson-Marlow Bredel E-Manuals

52-259 0.46-2.3 0.69-3.5

620R product codes

mm inch # Marprene Bioprene

6.4 1/4 26 902.0064.032 903.0064.032 910.0064.032 913.0064.032

9.6 3/8 73 902.0096.032 903.0096.032 910.0096.032 913.0096.032

12.7 1/2 82 902.0127.032 903.0127.032 910.0127.032 913.0127.032

15.9 5/8 184 902.0159.032 903.0159.032 910.0159.032 913.0159.032

mm inch # STA-PURE Neoprene Butyl Tygon

6.4 1/4 26 960.0064.032 920.0064.032 930.0064.032 950.0064.032

9.6 3/8 73 960.0096.032 920.0096.032 930.0096.032 950.0096.032

12.7 1/2 82 960.0127.032 920.0127.032 930.0127.032 950.0127.032

15.9 5/8 184 960.0159.032 920.0159.032 930.0159.032 950.0159.032

Gore

mm inch # Fluorel

6.4 1/4 26 970.0064.032 965.0064.032

9.6 3/8 73 970.0096.032 965.0096.032

fluoroelastomer

/PTFE

Peroxide

silicone

Platinum

silicone

12.7 1/2 82 970.0127.032 965.0127.032

15.9 5/8 184 970.0159.032 965.0159.032

620RE and 620RE4 LoadSure product codes

12mm

DIN 15

STA-PURE 960.0120.PFD 960.0120.PFT 960.0170.PFD 960.0170.PFT

Gore

fluoroelastomer

/PTFE

Bioprene TM 903.M120.PFD 903.M120.PFT 903.M170.PFD 903.M170.PFT

Bioprene 903.0120.PFD 903.0120.PFT 903.0170.PFD 903.0170.PFT

Platinum

silicone

Marprene TM 902.M120.PPC 902.M170.PPC

Marprene 902.0120.PPC 902.0170.PPC

965.0120.PFD 965.0120.PFT 965.0170.PFD 965.0170.PFT

913.0120.PFD 913.0120.PFT 913.0170.PFD 913.0170.PFT

12mm

Cam and Groove

3/4in

12mm

Tri-clamp 3/4in

17mm

Cam and Groove

3/4in

17mm

DIN 15

17mm

Tri-clamp

3/4in

Peroxide

silicone

Neoprene 920.0120.PPC 920.0170.PPC

Trademarks and disclaimer

Watson-Marlow, Loadsure, Bioprene and Marprene are trademarks of Watson-Marlow

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

910.0120.PPC 910.0170.PPC

Page 18

Watson-Marlow Bredel E-Manuals

Limited.

TYGON is a trademark of the Saint Gobain Performance Plastics Company.

STA-PURE is a trademark of W L Gore & Associates.

The information contained in this document is believed to be correct but Watson-Marlow

Limited accepts no liability for any errors it contains, and reserves the right to alter

specifications without notice.

Patient-connected use: warning

Warning: These products are not designed for use in, and should not be used for patient

connected applications.

Publication history

m-620r-gb-01.htm: Watson-Marlow 620R

First published 11 02.

Decontamination certificate

In compliance with the UK Health and Safety at Work Act and the Control of Substances

Hazardous to Health Regulations, you are required to declare the substances which have

been in contact with product(s) you return to Watson-Marlow or its subsidiaries or

distributors. Failure to do so will cause delays. Please ensure that you fax us this form and

receive an RGA (Returned Goods Authorisation) before you despatch the product(s). A

copy of this form must be attached to the outside of the packaging containing the

product(s). Please complete a separate decontamination certificate for each product.

Your name Company

Address

Postcode/zip Country

Telephone Fax

Product type Serial number

To speed the repair, please

describe all known faults

The product has ...

Names of chemicals

handled with product(s)

You are responsible for cleaning and decontaminating the product(s) before return.

Been used Not been used

If the product has been used, please complete all the following sections. If the product has

not been used, please just sign this form.

Precautions to be taken in

handling these chemicals

Action to be taken in the

event of human contact

I understand that the personal data collected will be kept confidentially in accordance with

the UK Data Protection Act 1998.

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Page 19

Watson-Marlow Bredel E-Manuals

RGA number

Signature

Your position

Date

Please print out, sign and fax to Watson-Marlow Pumps at +44 1326 376009.

http://www.watson-marlow.co.uk/pdfs-global/m-620r-gb-01.htm[02/02/2012 14:33:33]

Loading...

Loading...