Van Air Systems Mist Eliminator User Manual

P/N 32-0233 REVA

INSTALLATION, OPERATION, & MAINTENANCE INSTRUCTIONS

FOR

MIST ELIMINATOR

VME-125 through VME-10,000

AUGUST 1998

SECTION 1 SAFETY

WARNING

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THE

VESSEL WHILE IT IS UNDER PRESSURE. DEPRESSURIZE THE

VESSEL COMPLETELY BEFORE ANY MAINTENANCE

PROCEDURES. SERIOUS PERSONAL INJURY MAY RESULT IF

THESE SAFETY RULES ARE NOT FOLLOWED.

DO NOT OPERATE THIS PRESSURE VESSEL ABOVE MAXIMUM

WORKING PRESSURE (MWP) AT MAXIMUM OPERATING

TEMPERATURE (OF) AS SHOWN ON THE ASME DATA PLATE.

THIS ASME CODE VESSEL MUST BE PROTECTED BY A

PRESSURE RELIEF VALVE. Refer to OSHA 1910.169 Par. b,

Sub. Par (3) and ASME Boiler and Pressure Vessel Code,

Section VIII, Division 1, UG-125 through UG-136. Also check

government regulations, i.e., state and local codes.

PRINTED IN THE U.S.A. © 1998 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PAGE 1

DO NOT WELD, GRIND, OR SAND VESSEL, OR IT WILL NOT

BE SAFE TO OPERATE. (Note: Any alteration to the vessel will

void the ASME Code Certification and the warranty.)

ANY DAMAGE TO THE VESSEL CAN MAKE IT UNSAFE.

INSPECT OUTSIDE AND INSIDE OF VESSELS REGULARLY

FOR BULGES, CORROSION, DENTS, GOUGES, LEAKS OR

SIGNS OF FIRE. IF DAMAGED, TAKE OUT OF SERVICE

IMMEDIATELY AND NOTIFY YOUR CERTIFYING AUTHORITY.

USE THE PROPER SAFETY RULES FOR THE GAS BEING

PROCESSED.

SECTION 2 HANDLING

2.1 HANDLING INSTRUCTIONS

If the unit is to be lifted by an overhead device, attach the lifting

chains or cables to the vessel lifting lugs on the top head.

must be free of standing water and mud. If the location is outdoors,

a paved surface is recommended.

Models VME-5000 through VME-10000 are shipped without the

elements installed. These elements are shipped separately in

wooden crates. Use extreme caution when unloading or moving the

elements with fork lifts. Always lift the crate from below the crate

supports to prevent the element from being pierced or torn.

2.2 STORAGE INSTRUCTIONS

If the unit is to be placed in storage before it is installed, the location

should be a clean, dry place. The ideal place to store the unit is

indoors. The location should be free from corrosive gasses and

extreme humidity. These conditions will cause damage to the unit.

The unit should be covered with a tarpaulin to keep the it clean.

If the unit is to be stored outdoors, it MUST BE covered completely

to prevent rain or snow from accumulating on the unit. The location

When storing the elements, they should be protected to prevent

them from being contaminated or saturated with water. Provisions

must be taken to prevent vermin from entering the elements and

using the element fibers for nesting material.

The large crated elements should be stored horizontally. Do not

stack them more than 4 crates high.

2.3 EQUIPMENT CHECK

Inspect the vessel and any elements for any damage that may have

occurred during shipment. Check the packing list to insure that all

items shipped with the unit are present.

IF EQUIPMENT HAS BEEN DAMAGED DURING SHIPMENT:

(1) NOTIFY CARRIER IMMEDIATELY.

(2) DO NOT OPERATE BEFORE CONSULTING FACTORY.

SECTION 3 SPECIFICATIONS AND DIMENSIONS

3.1 SPECIFICATIONS

VESSEL CONSTRUCTION

• Designed and manufactured to the ASME code plus current

addenda.

• Models VME-125 through VME-500 stamped "UM" symbol.

• Models VME-1250 through VME-10000 stamped "U" symbol.

• All models designed with a vessel corrosion allowance of

0.0625".

• Exterior primed white enamel finish.

• All flanged bolt holes oriented to straddle centerlines.

VESSEL WEIGHT (without elements)

VME-125 ........ 420 LBS

VME-250 ........ 440 LBS

VME-500 ........ 480 LBS

VME-850 ....... 525 LBS

VME-1250 ...... 710 LBS

VME-1500 ...... 820 LBS

VME-2000 ...... 1040 LBS

VME-2500 ...... 1170 LBS

VME-3000 ...... 1300 LBS

VME-7500 ...... 2500 LBS

VME-10000.... 2720 LBS

NOTE: Models VME-125 through VME-3000 are shipped with the elements

factory installed.

ELEMENT WEIGHTS

EVME-125 ..... 20 LBS

EVME-250 ..... 20 LBS

EVME-500 ..... 35 LBS

EVME-850 ..... 50 LBS

EVME-1250 ... 60 LBS

EVME-1500 ... 70 LBS

EVME-2000 ... 90 LBS

EVME-2500 ... 120 LBS

EVME-3000 ... 150 LBS

EVME-5000 ... 235 LBS

EVME-7500 ... 400 LBS

EVME-10000 . 460 LBS

RATED FLOW AT 100 PSIG, 100OF

VME-125 ........ 125 SCFM

VME-250 ........ 250 SCFM

VME-500 ........ 500 SCFM

VME-850 ....... 850 SCFM

VME-1250 ...... 1250 SCFM

VME-1500 ...... 1500 SCFM

VME-2000 ...... 2000 SCFM

VME-2500 ...... 2500 SCFM

VME-3000 ...... 3000 SCFM

VME-5000 ...... 5000 SCFM

VME-7500 ...... 7500 SCFM

VME-10000.... 10000 SCFM

MULTIPLIERS FOR PRESSURES OTHER THAN 100 PSIG

Pressure 50 60 70 80 90 100 110 120 130 140 150

Multiplier .56 .65 .74 .83 .91 1.00 1.09 1.17 1.26 1.35 1.44

MULTIPLIERS FOR TEMPERATURES OTHER THAN 100

Temp. 50 75 100 125 150 175 200 250 300

Multiplier 1.10 1.05 1.00 .96 .92 .88 .85 .79 .74

ELEMENT PRESSURE DROP

• Element pressure drop will be less than 1 PSID at initial start up

and throughout life.

• Element should be replaced when pressure drop reaches 3 PSID

ELEMENT EFFICIENCY

• 100% efficiency for particles over 3 MICRONS

• 99.5% efficiency for particles 3 MICRONS and less

MAXIMUM MIST CARRYOVER

• Mist carryover < 1 PPM, assuming an inlet loading of < 200 PPM

at 100oF inlet temperature.

O

F

OPERATING PRESSURE RANGE (all models)

Minimum ........ 50 PSIG Maximum ............... 150 PSIG

OPERATING TEMPERATURE (all models)

Maximum ....... 300

PAGE 2 © 1998 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PRINTED IN THE U.S.A.

O

F

SECTION 3 SPECIFICATIONS AND DIMENSIONS

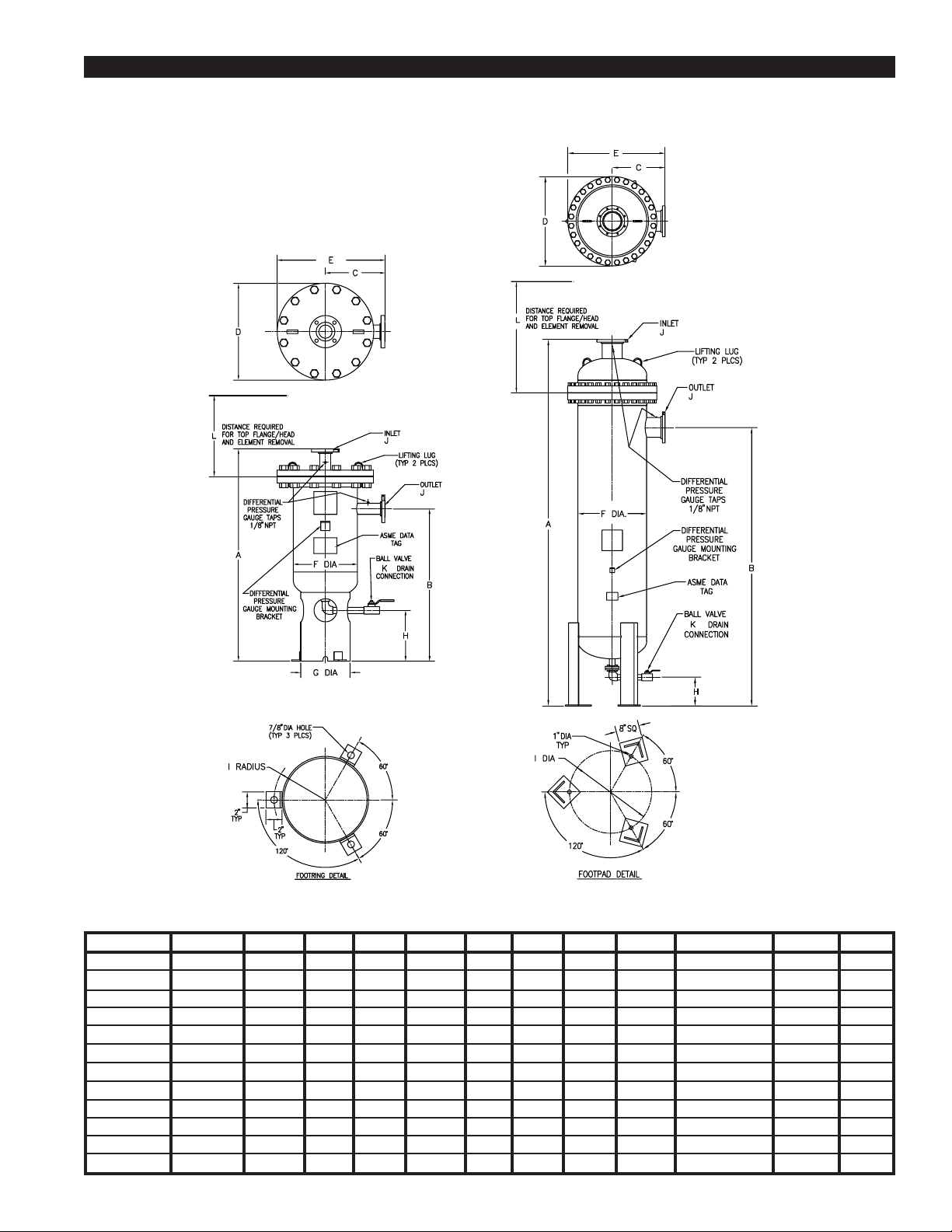

3.2 DIMENSIONS AND COMPONENT LAYOUT for VME-125 through VME-10000

MODELS VME-125 through VME-3000

MODEL A B C D E F G H I J K L

VME-125 42-1/8" 29" 13" 21" 23-1/2" 14" 10-3/4" 11" 6-3/8" 2" RF FLG 1" NPT 23"

VME-250 46-1/8" 33" 13" 21" 23-1/2" 14" 10-3/4" 11" 6-3/8" 2" RF FLG 1" NPT 27"

VME-500 58-1/8" 45" 13" 21" 23-1/2" 14" 10-3/4" 11" 6-3/8" 2-1/2" RF FLG 1" NPT 39"

VME-850 72-1/8" 59" 13" 21" 23-1/2" 14" 10-3/4" 11" 6-3/8" 2-1/2" RF FLG 1" NPT 39"

VME-1250 78-3/8" 63-1/4" 14" 23" 25-3/4" 16" 12-3/4" 10-1/2" 7-3/8" 4" RF FLG 1" NPT 59"

VME-1500 79-3/4" 64-5/8" 15" 25" 27-1/2" 18" 12-3/4" 10-3/8" 7-3/8" 4" RF FLG 1" NPT 59"

VME-2000 71-5/8" 55-1/8" 18" 32" 34" 24" 16" 9" 9" 4" RF FLG 1" NPT 52"

VME-2500 84-5/8" 68-1/8" 18" 32" 34" 24" 16" 9" 9" 4" RF FLG 1" NPT 66"

VME-3000 97-5/8" 81-1/8" 18" 32" 34" 24" 16" 9" 9" 4" RF FLG 1" NPT 79"

VME-5000 161-5/8" 140-1/2" 18" 32" 34" 24" ----- 14-3/4" 21-18" 6" RF FLG 2" NPT 126"

VME-7500 178-1/4" 140" 23" 38-3/4" 42-3/8" 30" ----- 12-1/2" 24" 8" RF FLG 2" NPT 142"

VME-10000 202-1/4" 164" 23" 38-3/4" 42-3/8" 30" ----- 12-1/2" 24" 8" RF FLG 2" NPT 166"

PRINTED IN THE U.S.A. © 1998 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PAGE 3

MODELS VME-5000 through VME-10000

Loading...

Loading...