Van Air Systems ID35 User Manual

INSTALLATION & OPERATION INSTRUCTIONS

FOR

COMPRESSED AIR/GAS

IN-LINE DESICCANT DRYER

MODEL

ID-35 (P/N 80-1364)

September 2009

P/N 32-0288-B

WARNING

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THE DRYER WHILE IT IS PRESSURIZED. DEPRESSURIZE THE

DRYER COMPLETELY BEFORE STARTING INSTALLATION AND/OR MAINTENANCE PROCEDURES. SERIOUS

PERSONAL INJURY MAY RESULT IF THESE SAFETY RULES ARE NOT FOLLOWED.

DO NOT OPERATE THIS PRESSURE VESSEL ABOVE MAXIMUM WORKING PRESSURE (MWP) AND/OR MAXIMUM

OPERATING TEMPERATURE (OF) AS SHOWN ON THE ASME DATA PLATE.

THIS ASME CODE VESSEL MUST BE PROTECTED BY A PRESSURE RELIEF VALVE. Refer to OSHA 1910.169 Par.

b, Sub. Par (3) and ASME Boiler and Pressure Vessel Code, Section VIII, Division 1, UG-125 through UG-136. Also

comply with all applicable state and local codes.

DO NOT WELD, GRIND, OR SAND VESSEL, OR IT WILL NOT BE SAFE TO OPERATE. (Note: Any alteration to the

vessel will void the ASME Code Certification and the warranty.)

INSPECT OUTSIDE AND INSIDE OF VESSEL REGULARLY FOR CORROSION AND DAMAGE (I.E., DENTS GOUGES

OR BULGES). ANY DAMAGE TO THE VESSEL CAN MAKE IT SAFE TO USE. IF DAMAGED, TAKE OUT OF SERVICE

IMMEDIATELY.

USE THE PROPER SAFETY RULES FOR THE GAS BEING PROCESSED.

DO NOT REMOVE THE FILL PORT UNTIL ALL PRESSURE IS OUT OF THE VESSEL.

PAGE 1

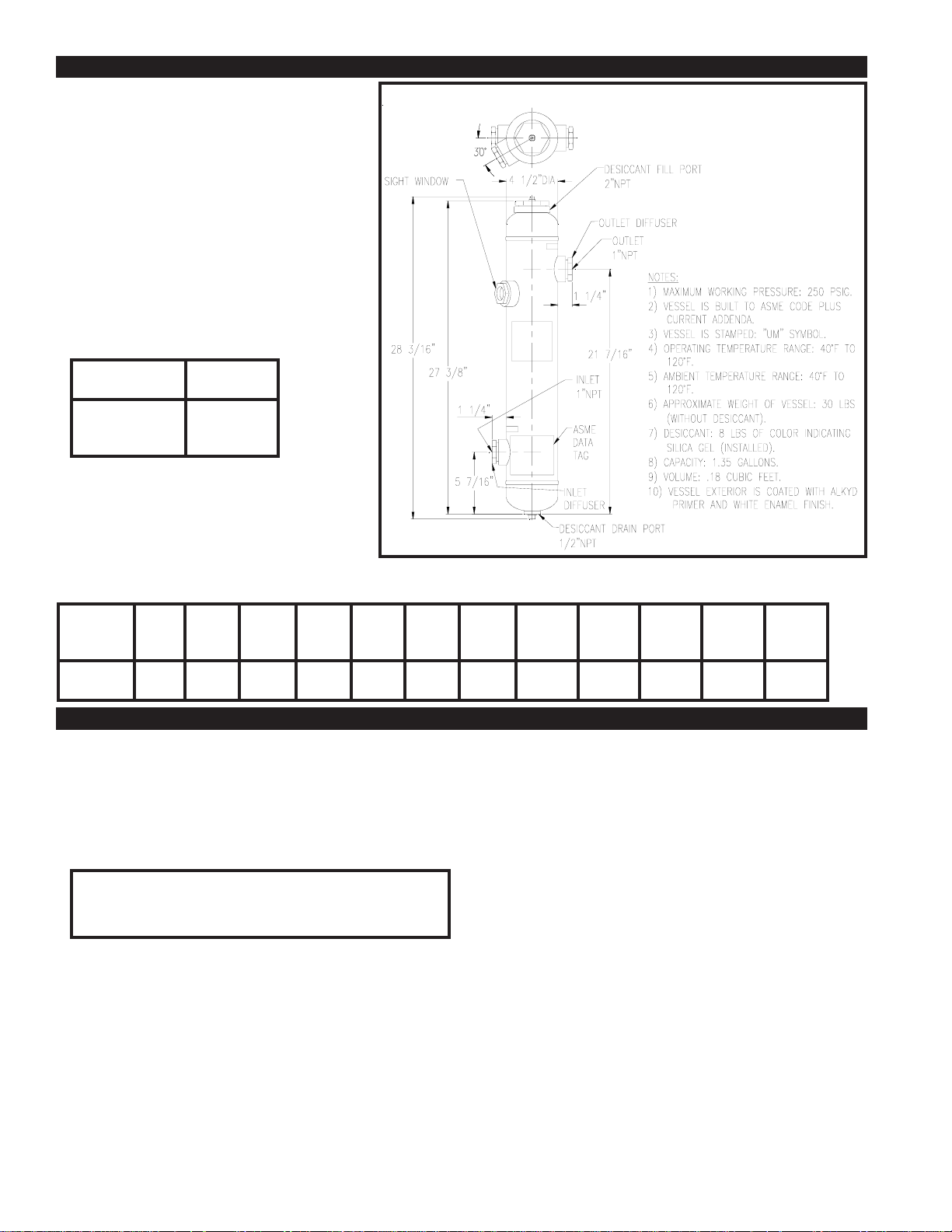

SECTION 1 SPECIFICATIONS

1.0 PURPOSE OF OPERATION

The Van Air In-Line Desiccant Dryer is designed to

be filled with adsorbent desiccant such as silica gel.

The saturated air or gas enters the bottom side

connection (inlet) on the vessel and travels through

the bed of adsorbent material.

Dry air or gas exits the top side connection (outlet)

on the vessel.

FIGURE 1 DRYER DETAILS

FIGURE 3 DRYING TIME USING SILICA GEL

(at rated flow at 100 PSIG)

INLET

TEMPERATURE

60°F

80°F

100°F

TIME

(MINUTES)

542

283

156

FIGURE 2 MAXIMUM CAPACITIES -SCFM (Nm3/hr)

MAXIMUM

WORKING

PRESSURE

250 PSIG

5 PSIG

0.3 Bar

6

9.6

10 PSIG

0.7 Bar

7.5

12.1

20 PSIG

1.4 Bar

10.5

16.9

40 PSIG

2.8 Bar

17

27.3

60 PSIG

4.1 Bar

23

37.0

80 PSIG

5.5 Bar

29

46.6

90 PSIG

6.2 Bar

32

51.4

100 PSIG

6.9 Bar

35

56.3

125 PSIG

8.6 Bar

43

69.1

150 PSIG

10.3 Bar

80.4

50

200 PSIG

13.8 Bar

66

106.1

250 PSIG

17.2 Bar

81

130.2

SECTION 2 INSTALLATION

2.1 LOCATION

Proper performance depends on the correct location of the unit. Locate

the dryer at the lowest temperature and highest pressure possible in the

system. If there is a pressure regulator in the system, install the dryer

upstream of the regulator.

Make sure that the system pressure does not exceed the 250 PSIG

maximum working pressure of the vessel.

IMPORTANT

ALWAYS PROCESS AIR THROUGH THE DRYER AT THE

LOWEST POSSIBLE TEMPERATURE AND THE HIGHEST

PRACTICAL PRESSURE.

2.2 PIPING AND ANCILLARY EQUIPMENT

If the dryer is being installed in an existing piping system, make sure

that the pipe is free of scale and rust.

The dryer is supported by the piping system. Adequate pipe supports

must be used to prevent damage to the pipeline and dryer.

2.2-A ISOLATION VALVES

Using Figure 3 as a reference, make the necessary piping connections

into the dryer.

Inlet and outlet isolation valves are required to isolate the dryer when

the adsorbent material is changed.

PAGE 2

These valves will also aid in start up and shutdown of the dryer. The

inlet isolation valve should be mounted before the pressure relief

valve. The outlet isolation valve should be installed on the dryer

outlet. A manual valve and a tee should be installed on either the inlet

or outlet side of the dryer to depressurize the unit.

A bypass is not recommended, as contamination can go downstream

while the unit is maintained. The bypass valve can also accidentally

be left open.

2.2-B OPTIONAL PRESSURE RELIEF VALVE (p/n 14-2213)

A pressure relief valve should be installed to conform to OSHA

safety standards. Refer to OSHA Standard Section 1910.169,

paragraph “b”, subparagraph “3”. Also comply with all applicable

federal, state and local codes concerning pressure vessels.

2.2-C OPTIONAL PRESSURE GAUGE (p/n 29-0160)

An optional pressure gauge is available to mount in the 1/4" NPT

connection on the fill port.

2.2-D AFTERFILTER (p/n 84-23256)

The installation of an F200-55-1/2-RB-MD-PD6 afterfilter prevents

any adsorbent material from going downstream.

The afterfilter should be installed upstream of the outlet isolation

valve. This will allow the filter to be isolated from the air system

when the dryer is isolated for maintenance.

Loading...

Loading...