Van Air Systems HLSXA-55 User Manual

INSTALLATION, OPERATION & MAINTENANCE MANUAL

FOR

HEATLESS REGENERATIVE

COMPRESSED AIR DRYER SYSTEM

April 2014

Revision: A

2950 Mechanic Street

Lake City, PA 16423 USA

P: 800-840-9906

Fax: 814-774-3482

Email: info@vanairsystems.com

www.vanairsystems.com

MODEL: HLSXA55 115V

PART NO: 81-2368

WARNING

READ ALL INFORMATION IN THIS MANUAL BEFORE BEGINNING INSTALLATION OR OPERATION

OF THE DRYER. BEFORE STARTING INSTALLATION AND/OR MAINTENANCE PROCEDURES, TURN

OFF THE MAIN POWER TO THE DRYER AND COMPLETELY DEPRESSURIZE THE UNIT TO PREVENT

PERSONAL INJURY.

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THIS DRYER WHILE IT IS PRESSURIZED.

NEVER OPERATE THIS DRYER ABOVE THE RATED OPERATING CONDITIONS. OPERATION ABOVE

SPECIFIED CONDITIONS WILL RESULT IN DECREASED PERFORMANCE, POSSIBLE DAMAGE TO

THE UNIT AND/OR PERSONAL INJURY.

PAGE 1

www.vanairsystems.com

HANDLING SECTION 1

1.1 HANDLING INSTRUCTIONS

WARNING

DO NOT LIFT THE DRYER BY THE INLET PIPING (BELOW

VESSELS). THIS PIPING IS NOT DESIGNED TO SUPPORT THE

WEIGHT OF THE DRYER. PERSONAL INJURY AND/OR EQUIPMENT DAMAGE MAY RESULT.

Lift the dryer by the outlet piping (above vessels).

When lifting the dryer, make sure that the chains or cables are clear of

all tubing and fragile components.

If outside storage is required, the unit MUST BE adequately covered to

prevent rain or snow from accumulating on the dryer. The unit must be

placed on a paved surface to keep it out of standing water and mud.

1.3 EQUIPMENT CHECK

Inspect the dryer for any damage that may have occurred during ship-

ment. Inspect all ttings, piping connections, fasteners, etc. for loose

connections. Also check gauges and lights for cracks or breakage.

IF DRYER HAS BEEN DAMAGED DURING SHIPMENT:

(1) NOTIFY CARRIER IMMEDIATELY AND FILE A CLAIM.

(2) CONSULT FACTORY BEFORE OPERATING THE DRYER.

1.2 STORAGE INSTRUCTIONS

The unit should be stored indoors and covered with a tarpaulin to

keep it clean. The location should be free from corrosive gasses and

extreme humidity, which will cause damage to the unit.

SAFETY SECTION 2

2.1 HANDLING

LIFT THE DRYER BY THE OUTLET PIPING (ABOVE THE VESSELS) AS THE OTHER COMPONENTS ARE NOT DESIGNED

TO SUPPORT THE WEIGHT OF THE DRYER.

LIFTING BY OTHER COMPONENTS MAY CAUSE PERSONAL

INJURY AND/OR EQUIPMENT DAMAGE.

2.2 INSTALLATION

BEFORE STARTING INSTALLATION PROCEDURES, TURN

OFF POWER TO THE AREA WHERE THE DRYER WILL BE INSTALLED. SERIOUS PERSONAL INJURY MAY RESULT IF THIS

SAFETY RULE IS NOT FOLLOWED.

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON

DRYER WHILE IT IS PRESSURIZED.

THESE ASME CODE VESSELS MUST BE PROTECTED BY

PRESSURE RELIEF VALVES. Refer to OSHA 1910.169 Par.

b, Sub. Par (3) and ASME Boiler and Pressure Vessel Code,

Section VIII, Division 1, UG-125 through UG-136. Also comply with all state and local codes.

WHEN INSTALLING AND OPERATING THIS EQUIPMENT, COMPLY WITH THE NATIONAL ELECTRICAL CODE AND ALL APPLICABLE FEDERAL, STATE, AND LOCAL CODES.

2.3 OPERATION

DO NOT OPERATE DRYER IF EITHER OF THE VESSELS IS

LEAKING. IMMEDIATELY TAKE THE DRYER OUT OF SERVICE.

DO NOT OPERATE THIS DRYER ABOVE THE MAXIMUM RATED

WORKING PRESSURE.

NOTE

OPERATING CONDITIONS FOR PROPER PERFORMANCE OF

THIS DRYER ARE DIFFERENT FROM MAXIMUM OPERATING

CONDITIONS FOR THE VESSELS. BE SURE TO CHECK THE

DRYER OPERATING CONDITIONS. SEE SECTION 3.1

USE THIS DRYER FOR COMPRESSED AIR ONLY.

DO NOT OPERATE THIS DRYER IF EITHER VESSEL HAS

BEEN DAMAGED BY FIRE. TAKE OUT OF SERVICE IMMEDIATELY AND NOTIFY YOUR CERTIFYING AUTHORITY.

2.4 MAINTENANCE

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON

THE DRYER WHILE IT IS PRESSURIZED. TURN OFF MAIN

POWER TO THE DRYER AND DEPRESSURIZE THE DRYER

COMPLETELY BEFORE STARTING MAINTENANCE PROCEDURES.

ALWAYS WEAR EYE PROTECTION, GLOVES AND A

RESPIRATORY PROTECTIVE DEVICE WHEN HANDLING THE

DESICCANT. DESICCANT DUST MAY CAUSE EYE AND

SKIN IRRITATION. AVOID BREATHING THE DUST AND

PROLONGED CONTACT WITH THE SKIN.

FIRST AID IN CASE OF EYE CONTACT WITH DESICCANT

DUST; IMMEDIATELY FLUSH THE EYES WITH PLENTY

OF WATER FOR AT LEAST 15 MINUTES. CONSULT A

PHYSICIAN.

IT IS CUSTOMER'S RESPONSIBILITY TO FILL ALL CONDUIT SEAL

FITTINGS (INCLUDING THE ONES TO THE SOLENOID VALVES)

WITH CHICO COMPOUND AND CHICO FIBER TO ENSURE THE

INTEGRITY OF THE EXPLOSION PROOF RATING.

PAGE 2

DO NOT WELD OR GRIND THE VESSELS. THEY WILL NOT

BE SAFE TO OPERATE. (Note: Any uncertified alteration to

the vessels VOIDS the ASME Code Certification.)

INSPECT OUTSIDE AND INSIDE OF VESSELS REGULARLY

FOR CORROSION AND DAMAGE (I.E. DENTS, GOUGES OR

BULGES). ANY DAMAGE TO THE VESSELS CAN MAKE

THEM UNSAFE TO USE. IF DAMAGED, TAKE OUT OF SERVICE IMMEDIATELY.

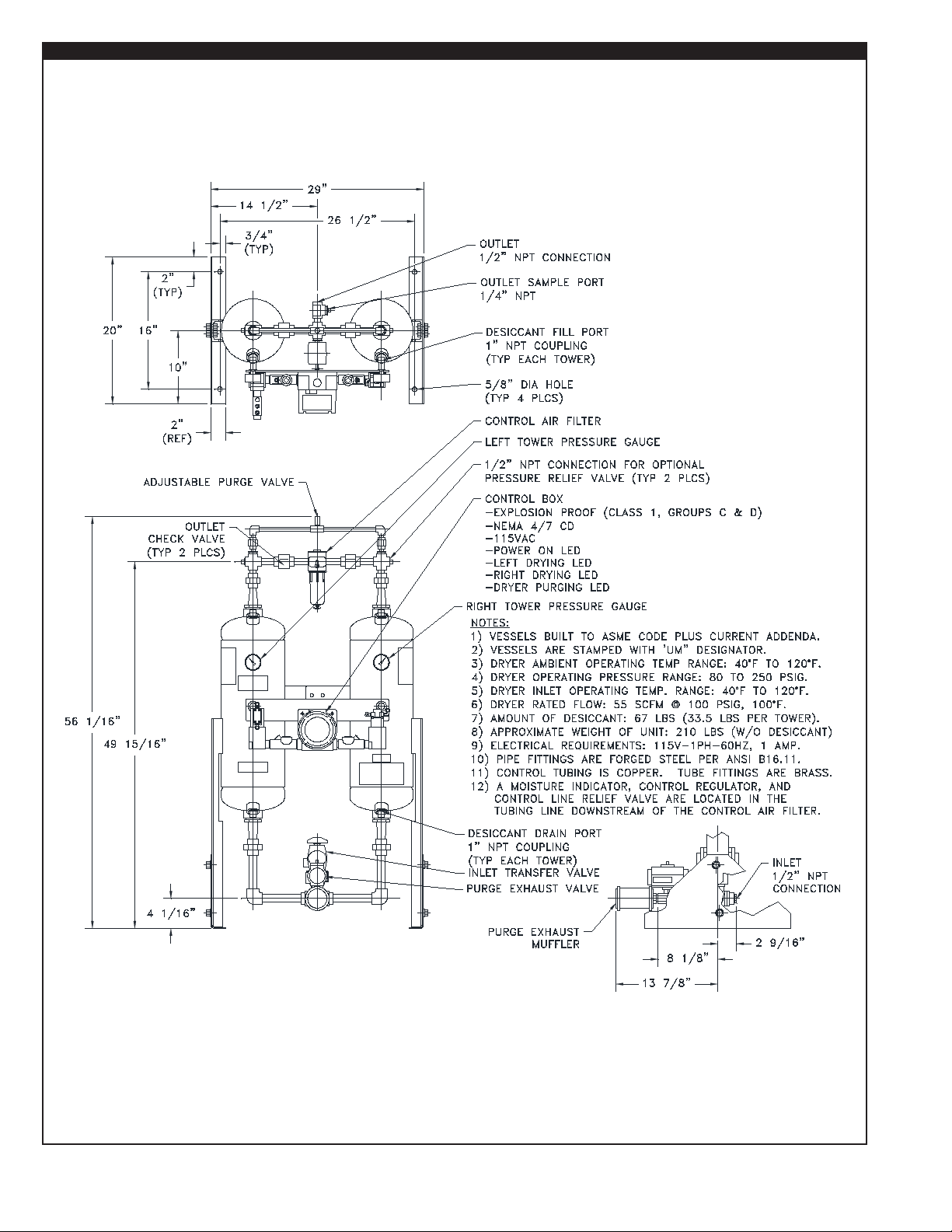

SPECIFICATIONS SECTION 3

3.1 DRYER SPECIFICATIONS

DIMENSIONS ..... ................See SECTION 3.2

VESSELS (desiccant towers)

Construction ................... Manufactured to ASME CODE, Section VIII, Div. 1.

Vessels stamped "UM" designator.

Design Pressure ............. 300 PSIG

Design Temperature ....... -20OF TO 200OF

PIPING

Threaded ttings: ANSI B16.11

Threaded unions: ANSI B16.11

Pipe: Carbon steel, Schedule 40

VALVES

Inlet ............................... 4-Way ball valve w/ actuator (Qty. 1)

Outlet .............................. Check valves (Qty. 2)

Purge .............................. Ball valve w/ actuator N.C. (Qty. 1)

Purge Metering .............. Needle valve (Qty. 1)

CONTROL AIR FILTER

Construction ................... Aluminum housing

ELECTRICAL

Voltage ...........................115V/1PH/60HZ

CONTROL BOX

NEMA 4/7 CD

Explosion Proof (Class 1, Div 1, Groups C & D)

DESICCANT

Material ........................................... Activated Alumina, 1/8" (2-5 MM) Bead type

Quantity Per Tower: ........................ See SECTION 3.2

OPERATING CONDITIONS

Inlet Operating Pressure ................ MIN 80 PSIG ...........MAX 250 PSIG

Inlet Operating Temperature ........... MIN 40OF ................MAX 120OF

Ambient Operating Temperature .... MIN 40OF ................MAX 120OF

PROCESS GAS

Compressed Air

RATED INLET CONDITIONS

Inlet Air Pressure ............................ 100 PSIG

Inlet Air Temperature ...................... 100°F

Relative Humidity (saturation) ........ 100% RH

RATED FLOW CAPACITIES

Flow capacities at various pressures

MODEL

HLSXA55

80 PSIG

45

100 PSIG55125 PSIG

61

150 PSIG66175 PSIG71200 PSIG75225 PSIG

SCFM

80

250 PSIG

84

PAGE 3

SPECIFICATIONS SECTION 3

3.2: DIMENSIONS

PAGE 4

Loading...

Loading...