INSTALLATION, OPERATION & MAINTENANCE MANUAL

FOR

HEATLESS REGENERATIVE

COMPRESSED AIR DRYER

models

HLS-55 through HLS-150

SEPTEMBER 2004

P/N 32-0266-C

2950 MECHANIC STREET

LAKE CITY, PA 16423

PHONE:814-774-2631

FAX: 814-774-3482

HLS-55/80

HLS-120/150

WARNING

READ ALL INFORMATION IN THIS MANUAL BEFORE BEGINNING INSTALLATION OR OPERATION OF THE

DRYER. BEFORE STARTING INSTALLATION AND/OR MAINTENANCE PROCEDURES, TURN OFF THE MAIN

POWER TO THE DRYER AND COMPLETELY DEPRESSURIZE THE UNIT TO PREVENT PERSONAL INJURY.

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THIS DRYER WHILE IT IS UNDER PRESSURE.

NEVER OPERATE THIS DRYER ABOVE THE RATED OPERATING CONDITIONS. OPERATION ABOVE SPECIFIED CONDITIONS WILL RESULT IN DECREASED PERFORMANCE, POSSIBLE DAMAGE TO THE UNIT AND/

OR PERSONAL INJURY.

SEE BACK OF THIS MANUAL FOR ADDITIONAL SAFETY INSTRUCTIONS

PRINTED IN THE U.S.A. PAGE 1

HANDLING THE DRYER SECTION 1

1.1 HANDLING INSTRUCTIONS

DO NOT LIFT THE DRYER BY THE INLET PIPING OR CONTROL

WARNING

BOX. THESE COMPONENTS ARE NOT DESIGNED TO HOLD

THE WEIGHT OF THE DRYER. PERSONAL INJURY AND/OR

EQUIPMENT DAMAGE MAY RESULT.

If the unit is to be stored outdoors, it MUST BE covered completely.

The cover must be adequate enough to prevent rain or snow from

accumulating on the dryer. The location must be free of standing

water and mud. The preferred location if outdoors, is on a paved

surface.

Lift the dryer by the outlet (top) piping or vessel center connector bar.

When lifting the unit make sure that the chains or cables are clear of

all tubing and fragile components.

1.2 STORAGE INSTRUCTIONS

The ideal place to store the unit is indoors. The location should be

free from corrosive gasses and extreme humidity. These conditions

will cause damage to the unit. The unit should be covered with a

tarpaulin to keep the unit clean.

1.3 EQUIPMENT CHECK

Inspect the dryer for any damage that may have occurred during

shipment. Inspect all fittings, piping connections, fasteners, etc. for

loose connections. Also check gauges for cracks or breakage.

IF DRYER HAS BEEN DAMAGED DURING SHIPMENT:

(1) NOTIFY CARRIER IMMEDIATELY AND FILE A CLAIM.

(2) CONSULT FACTORY BEFORE OPERATING THE DRYER.

SAFETY INSTRUCTIONS SECTION 2

2.1 HANDLING

DO NOT LIFT THE DRYER BY INLET (BOTTOM) PIPING OR

CONTROL BOX. THESE COMPONENTS ARE NOT DESIGNED TO

HOLD THE WEIGHT OF THE DRYER. PERSONAL INJURY AND/

OR EQUIPMENT DAMAGE MAY RESULT.

MAKE SURE THAT ALL EQUIPMENT BEING USED TO LIFT THE

DRYER IS CAPABLE OF LIFTING THE WEIGHT OF THE DRYER.

IF THE DRYER IS TO BE TRANSPORTED OVERHEAD, MAKE

SURE THAT ALL PERSONNEL ARE ALERTED AND SAFETY

PROCEDURES ARE FOLLOWED.

2.2 INSTALLATION

BEFORE STARTING INSTALLATION AND/OR MAINTENANCE

PROCEDURES, TURN OFF POWER AND DEPRESSURIZE UNIT TO

PREVENT INJURY. SERIOUS PERSONAL INJURY MAY RESULT IF

THESE SAFETY RULES ARE NOT FOLLOWED.

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON DRYER

WHILE IT IS UNDER PRESSURE. TURN OFF MAIN POWER TO THE

DRYER AND DEPRESSURIZE THE DRYER COMPLETELY BEFORE

STARTING INSTALLATION AND/OR MAINTENANCE PROCEDURES.

WHEN INSTALLING AND OPERATING THIS EQUIPMENT, COMPLY

WITH THE NATIONAL ELECTRICAL CODE AND ANY APPLICABLE

FEDERAL, STATE, AND LOCAL CODES.

WHEN INSTALLING THIS DRYER, MAKE SURE THAT THE NEMA

RATING OF THE CONTROL BOX IS APPLICABLE TO THE

INSTALLATION.

MAKE SURE THAT ALL CUSTOMER SUPPLIED WIRING AND

ELECTRICAL DEVICES ARE PROPERLY SIZED TO HANDLE THE

ELECTRICAL REQUIREMENTS OF THE DRYER.

2.3 OPERATION

DO NOT OPERATE DRYER IF THERE IS A LEAK IN EITHER VESSEL.

IMMEDIATELY TAKE THE DRYER OUT OF SERVICE.

ANY DAMAGE TO THE VESSELS CAN MAKE THEM UNSAFE TO

USE. INSPECT OUTSIDE AND INSIDE OF VESSELS REGULARLY

FOR CORROSION AND ANY DAMAGE (I.E., DENTS, GOUGES OR

BULGES). IF DAMAGED, TAKE OUT OF SERVICE IMMEDIATELY.

DO NOT OPERATE THIS DRYER ABOVE THE MAXIMUM RATED

WORKING PRESSURE.

OPERATING CONDITIONS FOR PROPER PERFORMANCE OF THIS

DRYER ARE DIFFERENT THAN MAXIMUM OPERATING CONDITIONS

FOR THE VESSELS. BE SURE TO CHECK THE DRYER OPERATING

CONDITIONS. SEE SECTION 3.1.

USE THIS DRYER FOR COMPRESSED AIR ONLY.

AIR FROM THIS DRYER IS NOT SUITABLE FOR BREATHABLE

AIR SYSTEMS WITHOUT FURTHER TREATMENT.

DO NOT OPERATE THIS DRYER IF EITHER VESSEL HAS BEEN

DAMAGED BY FIRE. TAKE OUT OF SERVICE IMMEDIATELY.

2.4 MAINTENANCE

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THE

DRYER WHILE IT IS UNDER PRESSURE. TURN OFF MAIN

POWER TO THE DRYER AND DEPRESSURIZE THE DRYER

COMPLETELY BEFORE STARTING MAINTENANCE PROCEDURES.

DO NOT WELD OR GRIND ON EITHER VESSEL. IT WILL NOT BE

SAFE TO OPERATE.

ALWAYS WEAR EYE PROTECTION, GLOVES AND A RESPIRATORY

PROTECTIVE DEVICE WHEN HANDLING THE DESICCANT. THE

DUST FROM THE DESICCANT MAY CAUSE EYE AND SKIN

IRRITATION. AVOID BREATHING THE DUST AND PROLONGED

CONTACT WITH THE SKIN.

FIRST AID IN CASE OF EYE CONTACT WITH DESICCANT DUST;

IMMEDIATELY FLUSH THE EYES WITH PLENTY OF WATER FOR

AT LEAST 15 MINUTES. CONSULT A PHYSICIAN.

PAGE 2 PRINTED IN THE U.S.A.

DIMENSIONS AND SPECIFICATIONS SECTION 3

3.1 DRYER SPECIFICATIONS

WEIGHT (with desiccant installed)

HLS-55 .... 230 lbs HLS-80.... 280 lbs HLS-120.... 385 lbs

HLS-150.... 445 lbs

DIMENSIONS See SECTION 3.2

IN/OUT CONNECTION

HLS-55....1/2"NPT HLS-80....1"NPT HLS-120....1" NPT

HLS-150....1"NPT

VESSELS (desiccant towers)

Design Pressure ............ 150 PSIG

Design Temperature ...... -20OF TO 200OF

PIPING

Threaded pipe fittings: ANSI B16.3

Threaded union fittings: ANSI B16.39

Pipe: Carbon Steel, Schedule 40

VALVES

Inlet ............... 4-Way, solenoid piloted

Outlet ............. Shuttle valve

Purge .............. 3-Way Valve (run as a 2-Way Valve), solenoid piloted

CONTROL AIR FILTER

Construction ... Zinc housing

ELECTRICAL

Nema 4 Electrical enclosure

Standard 115V ...... 115V/1PH/50-60Hz

Optional 230V: ....... 230V/1PH/50-60Hz

DESICCANT

Material .............. Activated Alumina, 1/8" (2-5 MM) Bead type

Quantity Per Tower (LBS)

HLS-55....30.5 lbs HLS-80....43.5 lbs HLS-120....67.5 lbs

HLS-150....82.5 lbs

OPERATING CONDITIONS

Inlet Air Pressure ............... MIN 60 PSIG ......... MAX 150 PSIG

Inlet Air Temperature ......... MIN 40OF ............... MAX 120OF

Ambient Air Temperature .. MIN 40OF ............... MAX 120OF

RATED INLET CONDITIONS

Inlet Air Pressure ................................ 100 PSIG

Inlet Air Temperature ..........................100OF

Relative Humidity (saturation) ............ 100% RH

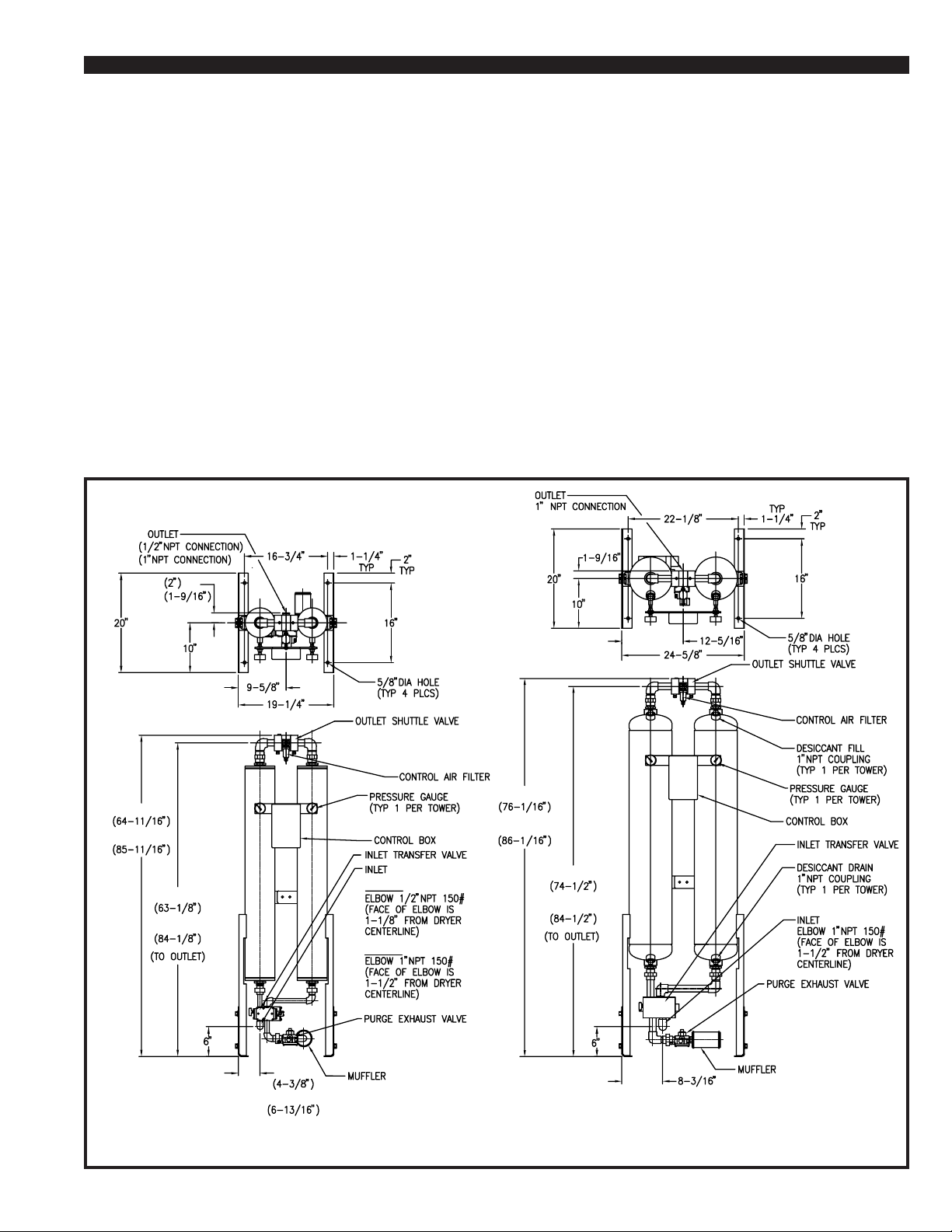

3.2 DIMENSIONS Models HLS-55 through HLS-150

HLS-55

HLS-80

HLS-55

HLS-80

HLS-55

HLS-80

HLS-55

HLS-80

HLS-120

HLS-150

HLS-120

HLS-55

HLS-150

HLS-80

HLS-55

HLS-80

HLS-55 & HLS-80

PRINTED IN THE U.S.A. PAGE 3

HLS-120 & HLS-150

* (ROTATED TO BACK ON HLS-150)

INSTALLING THE DRYER SECTION 4

4.1 LOCATION

WARNING

DO NOT INSTALL THIS DRYER IN AN ENVIRONMENT OF

CORROSIVE CHEMICALS, EXPLOSIVE GASSES, POISONOUS

GASSES, OR SATURATED STEAM HEAT.

Locate dryer in a protected, well vented area where ambient

temperatures are between 40oF and 120oF. If this dryer must be

installed where ambient temperatures are below 40

heat tracing must be properly installed on the inlet piping, purge exhaust

line and the desiccant towers to prevent freezing of the equipment.

Position the dryer in the upright position on a solid, level, vibration free

surface capable of supporting the dryer’s weight. Allow sufficient

clearance over and around the dryer. Refer to SECTION 3.2 for dryer

dimensions.

The dryer should not be located in extremely dirty areas where airborne

contaminants can accumulate on the dryer. If this cannot be prevented,

the dryer should be cleaned periodically.

o

F, insulation and

4.2 PIPING AND ANCILLARY EQUIPMENT

IMPORTANT

Make sure that the inlet air piping is connected to the bottom and the

outlet air piping is connected to the top of the dryer.

Make sure that the inlet and outlet piping to and from the dryer is

properly supported. Excessive stress may cause damage and/or

dryer malfunction.

Remove protective caps or covers from all valves before installing this

dryer.

If this dryer is to be installed into an existing piping system, clean the

existing inlet piping to remove all accumulated dirt, pipe scale, etc.,

before connecting the dryer. Make sure that the inlet and outlet shutoff

valves are tightly closed before connecting to the existing piping system.

When installing the piping and any additional components, make sure

that adequate pipe supports are used. Excessive stress on the dryer

and components may cause damage or premature failure. Use either

overhead or stiff-leg type supports.

Make sure that the piping is correctly connected to the dryer. The inlet

is the bottom connection and the outlet is the top connection.

Reference SECTION 3.2 for dryer dimensions and connection

locations.

Once the location has been determined, place the dryer into position.

Reference SECTION 1 for handling instructions.

4.2-1 BYPASS PIPING (optional)

The installation of bypass piping is not required, but will allow the

dryer and filter(s) to be taken off stream without interrupting the air

system.

In Figure 4A, a recommended bypass piping layout and additional

components are shown. Basic bypass piping should include an inlet

isolation valve, a bypass valve, and an outlet isolation valve. The

isolation and bypass valves must be bubble-tight.

4.2-2 FILTERS

A PROPERLY RATED COALESCING PREFILTER MUST BE

INSTALLED BEFORE THE DRYER TO REMOVE LUBRICATING

OILS, DUST AND PIPE SCALE CONTAMINATION. FAILURE TO

USE A PREFILTER WILL RESULT IN DAMAGE TO THE DRYER

AND VOIDS THE WARRANTY.

CAUTION

A coalescing prefilter must be installed before the dryer to remove

lubricating oils, dust and pipe scale contamination. It is

recommended that a high efficiency coalescing filter with an

automatic drain or electric drain valve be installed. The filter should

be equipped with a pressure differential indicator to monitor the

condition of the element.

A particulate afterfilter should be installed downstream of the dryer.

The afterfilter will remove any desiccant dust. The afterfilter should

be equipped with a pressure differential indicator to monitor the

condition of the element.

Make sure that the filters are properly installed according to the

instructions provided with them.

4.3 REMOTE PURGE EXHAUST PIPING

To reduce the noise during purging and tower depressurization, this

dryer was supplied with a muffler for installation on the purge exhaust

valve. If the sound or humidity discharged from this dryer is unacceptable, the purge of this dryer can be piped remotely away.

IMPORTANT

Make sure that the piping is as short as possible and does not

create back pressure on the dryer. To prevent liquid accumulation in the piping and purge valve, the piping must be at the

same level or lower than the purge valve.

The purge line must be vented to atmospheric pressure. If the

ambient temperature at the venting end of the piping is subject

to temperatures below 32oF, freeze protection must be installed.

The purge valve has threaded pipe connections. Reference Section

3.2 for location. Use adequate pipe supports on the piping to prevent

stress on the valve.

The distance will determine the size of piping that is recommended.

For distances of 10 feet or less, use piping of the same size as the

purge valve. For distances up to 20 feet, use piping one size larger

than the purge valve.

4.4 INSTALLING PRESSURE RELIEF VALVES

CAUTION

THESE VESSELS MUST BE PROTECTED BY PRESSURE RELIEF

VALVES. Refer to OSHA 1910.169 Par. b, Sub. Par (3) and ASME

Boiler and Pressure Vessel Code, Section VIII, Division 1, UG-1 25

through UG-136. Also check government regulations, i.e., state

and local codes.

Relief valve connection ports were NOT provided on this dryer. It is

recommended that relief valves be installed to comply with all

applicable codes. The relief valves should be full flow type, rated for

the dryer operating conditions. For recommended location see Figure

4A.

4.5 INSTALLING THE PURGE MUFFLER

To reduce the sound level during purge and tower depressurization,

this dryer was supplied with a muffler for installation on the purge

exhaust valve. For muffler location Reference SECTION 3.2.

The muffler was shipped separately. It should NOT be installed until

the dryer has been operated for several hours. From desiccant

installation, some dust may be present in the desiccant towers.

Operating the dryer with the muffler installed immediately after the

towers have been filled with desiccant or at initial start up may cause

the muffler to clog.

IMPORTANT

The dryer must be operated for several hours without the

muffler after the towers have been filled with desiccant. This

will prevent the muffler from becoming clogged.

Make sure that the elements are installed in all filter housings

prior to start up.

PAGE 4 PRINTED IN THE U.S.A.

INSTALLING THE DRYER SECTION 4

FIGURE 4A RECOMMENDED PIPING CONFIGURATION AND COMPONENTS

MODEL

HLS-55

HLS-80

HLS-120

HLS-150

DRYER

IN/OUT

1/2" NPT(F)

1" NPT(F)

1" NPT(F)

1" NPT(F)

F200-0055-1/2-C-AD

F200-0085-3/4-C-AD

F200-0150-1-C-AD

F200-0150-1-C-AD

PREFILTER

MODEL

IN/OUT

1/2" NPT(F)

3/4" NPT(F)

1" NPT(F)

1" NPT(F)

4.6 ELECTRICAL CONNECTIONS

SERIOUS PERSONAL INJURY AND DAMAGE TO THE DRYER

WILL OCCUR IF THE DRYER IS CONNECTED TO A POWER

SOURCE OTHER THAN THE VOLTAGE LISTED ON THE DATA

TAG.

WHEN INSTALLING THE ELECTRICAL CONNECTIONS FOR

THIS DRYER, COMPLY WITH NATIONAL ELECTRICAL CODE

AND ALL APPLICABLE FEDERAL, STATE AND LOCAL

CODES.

The power supply to the dryer will be connected into the dryer control

box. A 7/8" dia hole was provided in the bottom of the box for the

connection of conduit or a cord grip connector.

FIGURE 4B ELECTRICAL CONNECTIONS

WARNING

DEL-P

INDICATOR

MODEL

PD-6

PD-6

PD-6

PD-6

Check the electrical rating of the dryer as listed on the dryer data tag.

Make sure that the power source is correct for the dryer rating.

Remove the box cover to access the power supply and alarm

terminals. Wire the power supply as shown in Figure 4B. Connect

the wiring and necessary components to the dryer box. Comply with

all codes applicable for this installation.

AFTERFILTER

MODEL

F200-0055-1/2-RB-MD

F200-0085-3/4-RB-MD

F200-0150-1-RB-MD

F200-0150-1-RB-MD

INDICATOR

IN/OUT

1/2" NPT(F)

3/4" NPT(F)

1" NPT(F)

1" NPT(F)

DEL-P

MODEL

PD-6

PD-6

PD-6

PD-6

PRINTED IN THE U.S.A. PAGE 5

START UP SECTION 5

5.1 START UP

WARNING

BEFORE STARTING THIS DRYER, FOLLOW THE INSTALLATION

INSTRUCTIONS AND PROCEDURES COMPLETELY. SERIOUS

PERSONAL INJURY CAN RESULT IF INSTRUCTIONS ARE NOT

CAREFULLY AND COMPLETELY FOLLOWED.

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THIS

DRYER WHILE IT IS UNDER PRESSURE.

IMPORTANT

TO START THE DRYER YOU MUST PRESS THE RUN SWITCH

WHICH WILL LIGHT THE RUN LED.

If the dryer is being started up for the first time or after the

desiccant has been changed, the purge muffler must be removed.

Operate the dryer until no desiccant dust is visible at the purge

valve. Then the muffler can be reinstalled.

If bypass piping was installed on this dryer as outlined in SECTION

4.2, close the inlet and outlet isolation valves. Open the bypass valve.

Pressurize the air system. Once the air system is pressurized, slowly

open the inlet isolation valve. Check timing settings in control box.

The dryer should be factory set as shown in Figure 4B.

Energize the power supply to the dryer. Both towers will pressurize.

Several seconds later one tower will depressurize. Open the outlet

isolation valve.

5.2 PURGE FLOW ORIFICE

DRYER

MODEL

HLS-55

HLS-80

HLS-120

HLS-150

The Purge Orifice is located at the top of the outlet valve. Purge

can be adjusted by taking a blank orifice and drilling a new size

hole.

ORIFICE

SIZE

3/32" DIA

7/64" DIA

9/64" DIA

5/32" DIA

FLOW AT

100 PSIG

9.5 SCFM

12.9 SCFM

21.4 SCFM

26.4 SCFM

BLANK

ORIFICE P/N

26-1933

26-1933

26-1933

26-1933

5.3 CONDITIONING THE DESICCANT BED

To condition the desiccant bed, the dryer is operated withou t any

outlet flow, while the towers regenerate with purge air.

Close the outlet isolation valve and pressurize the system. Energize the

power supply and start the dryer. Observe the dryer for several cycles.

Make sure that it is operating properly.

At initial start up or after extended shutdowns (over one month), the dryer

may take 24 to 48 hours of continuous operation for the bed to be

conditioned. Moisture that has accumulated on the desiccant bed should

be removed before the dryer is placed on stream.

PRINCIPLE OF OPERATION SECTION 6

6.1 PRINCIPLE OF OPERATION

HLS Series Heatless Regenerative Air Dryers utilize the pressure swing

principle of operation. The desiccant bed in one tower dries the air stream

while the desiccant bed in the other tower is regenerated.

A purge of dry air is used for tower regeneration. It is taken from the outlet

of the dryer. To allow the correct amount of dry air to flow into the

regenerating tower, dryers are equipped with a purge metering orifice.

The heat created during adsorption of moisture in the drying tower is

retained in the desiccant bed and increases the moisture removal

capacity of the purge air.

When the dryer is pressurized and the power supply to the dryer is

energized, the dryer will begin operation. To achieve maximum

performance from this dryer, it should be operated continuously.

Operating this dryer for single shift periods may result in varied outlet

dew point performance.

The dryer operation consists of four stages; REPRESSURIZATION,

CHANGEOVER/DEPRESSURIZATION, DRYING and

REGENERATION.

The regeneration stage of one tower occurs at the same time as the

drying stage in the opposite tower. During the regeneration stage, a

percentage of dry air is directed through the desiccant bed of the

offstream tower. The purge air is vented through the purge valve to the

atmosphere.

FIGURE 6A PNEUMATIC SCHEMATIC

6.1-1 REPRESSURIZATION STAGE

Repessurization occurs in the regenerating tower. Repessurization

must occur before tower changover. This reduces shock to the

desiccant and the possibility of downstream pressure spikes.

The purge valve is closed and the purge air, which was vented to

atomosphere earlier in the cycle, is now used to repressurize the

regenerated tower.

6.1-2 CHANGEOVER/DEPRESSURIZATION STAGE

Tower changeover occurs after the previous regenerating tower is

pressurized. The controller signals the inlet transfer valve to switch.

The tower that was on line and drying the process air will begin to

depressurize.

6.1-3 DRYING AND REGENERATION STAGE

During the drying stage, one tower is pressurized with process air. This

tower is in the drying stage. The process air passes through the

desiccant bed, which adsorbs moisture from the air.

PAGE 6 PRINTED IN THE U.S.A.

USING THE DRYER SECTION 7

7.1 CONTROLLER

The Controller is a compact NEMA 4 control box. It has the following features:

• Dryer Status LEDs

- POWER ON LED - L/R TOWER DRYING LEDS

- RUN LED - L/R TOWER REGENERATING

LEDS

- HOLD LED - DRYER PURGING LED

- SWITCHING FAILURE LED

The Dryer Status LEDs are located on the front panel of the control box.

Figure 7A shows the location of each.

FIGURE 7A

When the Left tower is pressurized and on line drying the process air, the

corresponding LEFT TOWER DRYING LED is illuminated. When the right

tower is pressurized and on line drying the process air, the corresponding

RIGHT TOWER DRYING LED is illuminated.

The DRYER PURGING LED is illuminated when the purge exhaust valve

is energized open. During repressurization this LED will not be illuminated.

Repressurization occurs for approximately 20 seconds just before tower

changeover.

The operation sequence of the dryer is shown in FIGURE 7B TIMING

CHART.

SWITCHING FAILURE:

When there is a switching failure, the LED will be lit. This will energize

the contacts shown in FIGURE 4B. The contacts can be wired for

remote annunciation. To reset the Switching Failure Alarm press the

run button on the control box front panel.

HOLD FEATURE:

For low load or static pressure conditions, the hold contacts shown on

Figure 4B can be wired to an auxillary set of normally closed contacts

on the compressor starter. This will stop the cycling of the dryer and

repressurize both towers of the dryer, until there is demand on the

compressor. The Hold LED will light, if the dryer is wired as described

and the compressor is not running.

7.2 SETTING THE CYCLE TIME

Reference Figure 4B:

The setting for the time cycle is a 5 min/half cycle. For the half cycle

time setting, the switches indicated for DS1 (2, 5, 7, & 8) as shown in

the CYCLE TIME DETAIL have been factory set by pushing the

switches up. The values for these switches are (256, 32, 8, & 4) sec.,

so when added together equal 300 sec or 5 min. WE DO NOT

RECOMMEND a time cycle setting below 2 min/half cycle. For this

half cycle time setting, the switches that need to be pushed up are DS1

(4, 5, 6, & 7) there values are (64, 32, 16, & 8) sec. so when added

together equal 120 sec or 2 min.

The setting for the pressurization time is 20 sec. For the pressurization time setting, the switches indicated for DS2 (2 & 4) as shown in

the CYCLE TIME DETAIL have been factory set by pushing the

switches up. The values for these switches are (16 & 4) sec., so when

added together equal 20sec. WE DO NOT RECOMMEND CHANG-

ING THIS SETTING.

POWER ON

HOLD

STOP

RUN

RUN

SWITCHING FAILURE

TOWER DRYING

TOWER REGENERATING

LEFT

RIGHT

DRYER PURGING

The setting for the alarm time is 96 sec. For the alarm time setting,

the switches indicated for DS2 (5 & 6) as shown in the CYCLE TIME

DETAIL have been factory set by pushing the switches up. The values

for these switches are (64 & 32) sec., so when added together equal

96 sec. WE DO NOT RECOMMEND CHANGING THIS SETTING.

NOTE: THE ALARM TIME SETTING NEEDS TO BE LESS THEN

THE HALF CYCLE TIME SETTING OR THIS WILL NEGATE

THE ALARM FUNCTION.

Operating this dryer on the 4 minute cycle will more than

double the wear on the dryer components. To reduce wear on

the dryer, operate the dryer on the 10 minute cycle if the -40OF

dew point is acceptable.

IMPORTANT

FIGURE 7B CYCLE TIMING CHART

PRINTED IN THE U.S.A. PAGE 7

SHUTDOWN SECTION 8

8.1 SHUTDOWN PROCEDURES

Shutoff the air supply to the dryer. If bypass piping and valves were

installed, close the inlet and outlet isolation valves and open the

bypass valve. Let the dryer cycle until it is totally depressurized.

MAINTENANCE & TROUBLESHOOTING SECTION 9

9.1 DAILY INSPECTION

The following procedures should be performed daily:

• Check the dryer operating conditions, inlet temperature, ambient

temperature, inlet pressure and inlet flow.

• Monitor the dryer for one complete cycle. Make sure that it is

operating properly. Visually check the dryer and piping for damage.

• Check the purge muffler. Purge air should be exhausting from

the valve. If oil is present, the dryer and air system may be

contaminated with lubricants.

• Inspect all upstream equipment, aftercoolers, separators, drains

and filters. Make sure that all bypass valves are tightly closed.

• Check the prefilter(s) for proper draining. If the prefilter is not

equipped with an automatic drain, it must be manually drained.

Check the pressure differential indicator on all prefilters and

afterfilters. If the differential pressure is unacceptable, replace the

elements.

9.2 SCHEDULED MAINTENANCE

12 MONTHS

• Replace purge muffler element

• Replace the control air filter element

24-60 MONTHS

• The desiccant in the towers should be replaced every two to five

years. The life of the desiccant will vary depending on the inlet air

conditions. Systems with excessive contaminants and/or inadequate filtration will decrease the life span of the desiccant

drastically. Once the desiccant is contaminated with lubricants, it

must be replaced.

9.3 DESICCANT REPLACEMENT

WARNING

DO NOT ATTEMPT TO REMOVE ANY ITEM UNTIL ALL AIR

PRESSURE IS OUT OF THE VESSEL. CHECK ALL TOWER

PRESSURE GAUGES, MAKING SURE THAT THEY ARE AT 0

PSIG AND THAT INCOMING PRESSURE HAS BEEN TURNED

OFF.

ALWAYS WEAR EYE PROTECTION AND GLOVES WHEN

HANDLING THE DESICCANT. DUST FROM THE DESICCANT

MAY CAUSE EYE AND SKIN IRRITATION. AVOID BREATHING

THE DUST AND PROLONGED CONTACT WITH THE SKIN.

Remove any oil, dirt, or scale from the towers and piping. Do NOT

weld, grind or sandblast the vessels. The vessels may be steam

cleaned internally and externally to remove dirt and oil.

CAUTION

Make sure that the towers are clean to prevent contamination of

new desiccant.

Reinstall the bushing/diffusers in the bottom of the vessels. Install the

inlet piping assembly. Apply pipe thread sealant as necessary.

Remove the bushing/diffusers from the top of the vessels. Load

desiccant through these ports. REFER TO SECTION 3.1 FOR

PROPER DESICCANT AMOUNTS.

Reinstall the bushing/diffusers in the top of the vessels. Install the

outlet piping assembly. Reconnect the dryer to the process piping.

Apply pipe thread sealant as necessary.

Follow START UP PROCEDURES IN SECTION 5.1 to start up and place

dryer in operation.

For HLS-120 and HLS-150 fill and drain ports are provided, so piping

disassembly is not required.

9.4 CONTROL AIR FILTER REPLACEMENT

Close the dryer inlet and outlet isolation valves (and open bypass

valve if provided). Turn off the power and completely depressurize the

dryer.

WARNING

DO NOT REMOVE THE FILTER BOWL FROM HEAD UNTIL

HOUSING IS COMPLETELY DEPRESSURIZED.

After all pressure is out of the dryer, grasp the filter bowl firmly. While

pushing the bowl upward, turn it clockwise to remove it from the filter

head.

Unthread the used element from the head. Discard the used element

properly.

FIRST AID IN CASE OF EYE CONTACT, IMMEDIATELY FLUSH

EYES WITH PLENTY OF WATER FOR AT LEAST 15 MINUTES.

CONSULT A PHYSICIAN.

Take dryer off stream following the SHUTDOWN PROCEDURES IN

SECTION 8.

For HLS-55 and HLS-80:

Carefully disconnect the inlet and outlet piping assemblies from the

dryer and process piping. Disconnect the piping assemblies at the

union connections. Unthread the bushing/diffusers from the bottom of

each vessel to drain the old desiccant.

PAGE 8 PRINTED IN THE U.S.A.

Remove new element from the shipping package. Thread the new

element into the filter head.

Position the bowl in the filter head. While pushing the bowl upward

into the head, turn the bowl counterclockwise to lock it in place.

Following the start up procedures for the dryer, place the dryer on

stream.

MAINTENANCE & TROUBLESHOOTING SECTION 9

9.5 TROUBLESHOOTING

The following check list should be used as a guideline for troubleshooting problems.

IS THE POWER ON AND RUN SWITCH PRESSED?

Check the main power source and check that the Power LED is

lit. Make sure that the dryer Run switch has been pressed and

that the Run LED is lit

IS THE SYSTEM PRESSURIZED?

The dryer is designed to operate at 60 to 150 psig. Check the

upstream equipment and any isolation or bypass valves.

IS THE DRYER CYCLING?

• IS THE CONTROL SYSTEM WORKING?

Is there incoming power to the control box.

• IS THERE CONTROL AIR PRESSURE, 60 PSIG MINIMUM.

Make sure that the dryer inlet pressure is above 60 PSIG. Check

the control air filter element and replace it with a new element.

Reference Section 9.4 for element replacement instructions.

• IS THE INLET VALVE FAULTY?

Rebuild or replace the inlet valve as necessary. Use manual

override to check.

• IS THE PURGE EXHAUST VALVE FAULTY?

Rebuild or replace the faulty purge exhaust valve. Use manual

override to check.

• IS THE OUTLET VALVE FAULTY?

Check the outlet shuttle valve.

ARE THE TOWERS DEPRESSURIZING?

Check the purge valve for proper operation. Check the purge

muffler. It might be clogged. If clogged or damaged, replace it.

Use manual overide to check. (This should cause

depressurization.)

IS THE DEW POINT ACCEPTABLE?

• ARE THE INLET CONDITIONS WITHIN THE SPECIFICATIONS?

Reference Section 3.1 for the inlet conditions of the dryer.

Correct the inlet conditions if necessary. Excessive inlet flow will

greatly reduce the performance of the dryer.

• WAS THE DESICCANT INSTALLED?

Make sure that the desiccant was installed. Reference Section 9.3

for desiccant installation procedures.

• IS THE DESICCANT CONTAMINATED WITH LUBRICANTS?

Check the condition of the desiccant bed. If the bed is

contaminated with lubricants, replace the desiccant following the

procedures in Section 9.3.

• IS THE DESICCANT CONTAMINATED WITH MOISTURE?

If the dryer was operated under excessive inlet conditions, the

desiccant bed may be saturated with liquid moisture. Check

upstream equipment such as aftercoolers. Check the actual inlet

conditions, correct them and condition the bed following the

procedures in Section 5.3.

• ARE THE BYPASS VALVES OPEN OR LEAKING?

Check the valves (if installed). Repair or replace if faulty.

9.6 WIRING DIAGRAMS

THE DRYER CONTROL CIRCUIT IS DUAL VOLTAGE RATED.

NEVER SET THE BOARD TO A VOLTAGE OTHER THAN THE

VOLTAGE RATING OF THE DRYER LISTED ON THE DRYER

DATA TAG. SETTING THE BOARD INCORRECTLY WILL CAUSE

DAMAGE TO THE INLET AND PURGE VALVES AND POSSIBLE

PERSONAL INJURY OR FIRE.

PRINTED IN THE U.S.A. PAGE 9

CAUTION

REPLACEMENT PARTS SECTION 10

ITEM

1

Inlet Transfer Valve, 4-way

a

Repair kit for 4-way valve

b

Valve pilot for 4-way valve

c

4-way valve without base

2

Outlet Shuttle Valve

3

Purge Valve, 3-way

a

Repair Kit for 3-way valve

b

Valve pilot for 3-way valve

4

Pressure Gauge

5

Diffuser/Desiccant Retainer

6

Purge Exhaust Muffler

a

Element, purge exhaust muffler

7

Control Air Filter

a

Element, control air filter

8

Desiccant

Activated Alumina, 1/8" dia, 25# pail

9

Control Box (complete)

a

Circuit Board only

b

Membrane Panel

c

Pressure Switch

DESCRIPTION

HLS-55

(115V)

PART NO.

14-2072

26-6516

26-6518

26-6520

14-2071

14-2076

26-6514

26-6517

29-0344

26-6464

26-6152

26-6251

26-6830

26-6831

33-0237

46-2771

26-6469

26-6356

26-5284

QTY

HLS-55

(230V)

PART NO.

1

14-2073

1

26-6516

1

26-6518

1

26-6522

1

14-2071

1

14-2077

1

26-6514

1

26-6517

2

29-0344

4

26-6464

1

26-6152

1

26-6251

1

26-6830

1

26-6831

3

33-0237

1

46-2771

1

26-6469

1

26-6356

2

26-5284

QTY

1

1

1

1

1

1

1

1

2

4

1

1

1

1

3

1

1

1

2

HLS-80

(115V)

PART NO.

14-2074

26-6515

26-6518

26-6521

14-2071

14-2078

26-6514

26-6517

29-0344

26-6464

26-3734

26-6539

26-6830

26-6831

33-0237

46-2771

26-6469

26-6356

26-5284

QTY

1

1

1

1

1

1

1

1

2

4

1

1

1

1

4

1

1

1

2

HLS-80

(230V)

PART NO.

14-2075

26-6515

26-6518

26-6523

14-2071

14-2079

26-6514

26-6517

29-0344

26-6464

26-3734

26-6539

26-6830

26-6831

33-0237

46-2771

26-6469

26-6356

26-5284

QTY

1

1

1

1

1

1

1

1

2

4

1

1

1

1

4

1

1

1

2

PAGE 10 PRINTED IN THE U.S.A.

REPLACEMENT PARTS SECTION 10

ITEM

1

Inlet Transfer Valve, 4-way

a

Repair kit for 4-way valve

b

Valve pilot for 4-way valve

c

4-way valve without base

2

Outlet Shuttle Valve

3

Purge Valve, 3-way

a

Repair Kit for 3-way valve

b

Valve pilot for 3-way valve

4

Pressure Gauge

5

Diffuser/Desiccant Retainer

6

Purge Exhaust Muffler

a

Element, purge exhaust muffler

7

Control Air Filter

a

Element, control air filter

8

Desiccant

Activated Alumina, 1/8" dia, 25# pail

9

Control Box (complete)

a

Circuit Board only

b

Membrane Panel

c

Pressure Switch

DESCRIPTION

HLS-120

(115V)

PART NO.

14-2074

26-6515

26-6518

26-6521

14-2071

14-2078

26-6514

26-6517

29-0344

26-6464

26-3734

26-6539

26-6830

26-6831

33-0237

46-2771

26-6469

26-6356

26-5284

QTY

HLS-120

(230V)

PART NO.

1

14-2075

1

26-6515

1

26-6518

1

26-6523

1

14-2071

1

14-2079

1

26-6514

1

26-6517

2

29-0344

4

26-6464

1

26-3734

1

26-6539

1

26-6830

1

26-6831

6

33-0237

1

46-2771

1

26-6469

1

26-6356

2

26-5284

QTY

1

1

1

1

1

1

1

1

2

4

1

1

1

1

6

1

1

1

2

HLS-150

(115V)

PART NO.

14-2074

26-6515

26-6518

26-6521

14-2071

14-2080

26-6250

26-6519

29-0344

26-6464

26-3262

26-5774

26-6830

26-6831

33-0237

46-2771

26-6469

26-6356

26-5284

QTY

1

1

1

1

1

1

1

1

2

4

1

1

1

1

7

1

1

1

2

HLS-150

(230V)

PART NO.

14-2075

26-6515

26-6518

26-6523

14-2071

14-2081

26-6250

26-6519

29-0344

26-6464

26-3262

26-5774

26-6830

26-6831

33-0237

46-2771

26-6469

26-6356

26-5284

QTY

1

1

1

1

1

1

1

1

2

4

1

1

1

1

7

1

1

1

2

PRINTED IN THE U.S.A. PAGE 11

Safety is everybody•s business and is based on your use of good common sense. All situations or circumstances cannot

SAFETY PRECAUTIONS

always be predicted and covered by established rules. Therefore, use your past experience, watch out for safety hazards

and be cautious.

DANGER

DISCHARGE AIR USED FOR

BREATHING WILL CAUSE SEVERE

INJURY OR DEATH. CONSULT

FILTRATION SPECIALIST FOR

ADDITIONAL FILTRATIONS AND

TREATMENT EQUIPMENT TO

MEET HEALTH AND SAFETY

REGULATIONS.

DANGER

AIR AND OIL UNDER PRESSURE

WILL CAUSE SEVERE

PERSONAL INJURY OR DEATH.

SHUT DOWN COMPRESSOR AND

RELIEVE SYSTEM OF ALL

PRESSURE BEFORE REMOVING

VALVES, CAPS, PLUGS,

FITTINGS, BOLTS AND FILTER.

WARNING

ELECTRICAL SHOCK FROM

IMPROPER GROUNDING CAN

CAUSE INJURY OR DEATH.

GROUND UNIT AND RELATED

EQUIPMENT ACCORDING TO

NATIONAL ELECTRICAL CODE

AND LOCAL REGULATIONS.

WARNING

READ THE OPERATOR•S

MANUAL BEFORE STARTING

THIS UNIT. FAILURE TO ADHERE

TO INSTRUCTIONS CAN RESULT

IN SEVERE PERSONAL INJURY

OR DEATH. REPLACEMENT

MANUALS CAN BE

PURCHASHED BY CONTACTING

THE MANUFACTURER.

PAGE 12 PRINTED IN THE U.S.A.

Loading...

Loading...