Van Air Systems HL-2500 User Manual

INSTALLATION, OPERATION & MAINTENANCE MANUAL

FOR

HEATLESS REGENERATIVE

COMPRESSED AIR DRYER

model HL-2500

January 2007

P/N 32-0289

WARNING

READ ALL INFORMA TION IN THIS MANU AL BEFORE BEGINNING INST ALLA TION OR OPERATION OF THE

DRYER. BEFORE STARTING INSTALLATION AND/OR MAINTENANCE PROCEDURES, TURN OFF THE MAIN

POWER TO THE DRYER AND COMPLETELY DEPRESSURIZE THE UNIT TO PREVENT PERSONAL INJURY.

DO NOT REMO VE, REPAIR, OR REPLACE ANY ITEM ON THIS DRYER WHILE IT IS PRESSURIZED.

NEVER OPERATE THIS DRYER ABOVE THE RA TED OPERATING CONDITIONS. OPERA TION ABOVE SPECIFIED CONDITIONS WILL RESULT IN DECREASED PERFORMANCE, POSSIBLE DAMAGE TO THE UNIT AND/

OR PERSONAL INJURY.

SEE BACK OF THIS MANUAL FOR ADDITIONAL SAFETY INSTRUCTIONS.

PAGE 1

HANDLING THE DRYER SECTION 1

1.1 HANDLING INSTRUCTIONS

WARNING

DO NOT LIFT THE DRYER BY PIPING OR CONTROL BOX. THESE

COMPONENTS ARE NOT DESIGNED TO HOLD THE WEIGHT OF THE

DRYER. PERSONAL INJURY AND/OR EQUIPMENT DAMAGE MAY

RESULT.

Lift the dryer by the lifting lugs on both vessels.

If the unit is to be lifted by an overhead device, attach the lifting chains or

cables to the skid angle and the vessel lifting lugs. Make sure that the

chains or cables are clear of all piping and dryer components.

1.2 STORAGE INSTRUCTIONS

The unit should be stored indoors and covered with a tarpaulin to keep it

clean. The location should be free from corrosive gasses and extreme

humidity, which will cause damage to the unit.

If outside storage is required, the unit MUST BE adequately

covered to prevent rain or snow from accumulating on the dryer.

The unit must be placed on a paved surface to keep it out of

standing water and mud.

1.3 EQUIPMENT CHECK

Inspect the dryer for any damage that may have occurred during

shipment. Inspect all fittings, piping connections, fasteners, etc. for

loose connections. Also check gauges and lights for cracks or

breakage.

IF DRYER HAS BEEN DAMAGED DURING SHIPMENT:

(1) NOTIFY CARRIER IMMEDIATELY AND FILE A CLAIM.

(2) CONSULT FACTORY BEFORE OPERATING THE DRYER.

SAFETY INSTRUCTIONS SECTION 2

2.1 HANDLING

DO NOT LIFT THE DRYER BY PIPING OR CONTROL BOX. THESE

COMPONENTS ARE NOT DESIGNED TO HOLD THE WEIGHT OF

THE DRYER. PERSONAL INJURY AND/OR EQUIPMENT DAMAGE

MAY RESULT.

WHEN LIFTING THE DRYER, ALWAYS USE THE LIFTING LUGS

PROVIDED ON BOTH TOWERS.

MAKE SURE THAT ALL EQUIPMENT BEING USED TO LIFT THE

DRYER IS CAPABLE OF LIFTING THE WEIGHT OF THE DRYER.

2.3 OPERATION

DO NOT OPERATE DRYER IF EITHER VESSEL IS LEAKING.

IMMEDIATELY TAKE THE DRYER OUT OF SERVICE.

NOTE

OPERATING CONDITIONS FOR PROPER PERFORMANCE OF

THIS DRYER ARE DIFFERENT FROM MAXIMUM OPERATING

CONDITIONS FOR THE VESSELS. BE SURE TO CHECK THE

DRYER OPERATING CONDITIONS. SEE SECTION 3.1

USE THIS DRYER FOR COMPRESSED AIR ONLY.

2.2 INSTALLATION

BEFORE STARTING INSTALLATION PROCEDURES, TURN OFF

POWER TO THE AREA WHERE THE DRYER WILL BE INSTALLED.

SERIOUS PERSONAL INJURY MAY RESULT IF THIS SAFETY RULE

IS NOT FOLLOWED.

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON DRYER

WHILE IT IS PRESSURIZED.

THESE ASME CODE VESSELS MUST BE PROTECTED BY

PRESSURE RELIEF VALVES. Refer to OSHA 1910.169 Par. b, Sub.

Par (3) and ASME Boiler and Pressure Vessel Code, Section VIII,

Division 1, UG-125 through UG-136. Also comply with all state

and local codes.

WHEN INSTALLING AND OPERATING THIS EQUIPMENT, COMPLY

WITH THE NATIONAL ELECTRICAL CODE AND ALL APPLICABLE

FEDERAL, STATE, AND LOCAL CODES.

WHEN INSTALLING THIS DRYER, MAKE SURE THAT THE NEMA

RATING OF THE CONTROL BOX IS APPLICABLE TO THE

INSTALLATION.

MAKE SURE THAT ALL CUSTOMER SUPPLIED WIRING AND

ELECTRICAL DEVICES ARE PROPERLY SIZED TO HANDLE THE

ELECTRICAL REQUIREMENTS OF THE DRYER.

ALWAYS WEAR EYE PROTECTION, GLOVES AND A RESPIRATORY

PROTECTIVE DEVICE WHEN HANDLING THE DESICCANT.

DESICCANT DUST MAY CAUSE EYE AND SKIN IRRITATION. AVOID

BREATHING THE DUST AND PROLONGED CONTACT WITH THE

SKIN.

AIR FROM THIS DRYER IS NOT SUITABLE FOR BREATHABLE

AIR SYSTEMS WITHOUT FURTHER TREATMENT.

DO NOT OPERATE THIS DRYER IF EITHER VESSEL HAS BEEN

DAMAGED BY FIRE. TAKE OUT OF SERVICE IMMEDIATELY

AND NOTIFY YOUR CERTIFYING AUTHORITY.

2.4 MAINTENANCE

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THE

DRYER WHILE IT IS PRESSURIZED. TURN OFF MAIN POWER

TO THE DRYER AND DEPRESSURIZE THE DRYER COMPLETELY BEFORE STARTING MAINTENANCE PROCEDURES.

DO NOT WELD OR GRIND EITHER VESSEL. IT WILL NOT BE

SAFE TO OPERATE. (Note: Any alteration to the vessels

VOIDS the ASME Code Certification.)

INSPECT OUTSIDE AND INSIDE OF VESSEL REGULARLY

FOR CORROSION AND DAMAGE (I.E. DENTS, GOUGES OR

BULGES). ANY DAMAGE TO THE VESSELS CAN MAKE

THEM UNSAFE TO USE. IF DAMAGED, TAKE OUT OF

SERVICE IMMEDIATELY.

FIRST AID IN CASE OF EYE CONTACT WITH DESICCANT DUST;

IMMEDIATELY FLUSH THE EYES WITH PLENTY OF WATER FOR AT

LEAST 15 MINUTES. CONSULT A PHYSICIAN.

PAGE 2

DIMENSIONS AND SPECIFICATIONS SECTION 3

3.1 DRYER SPECIFICATIONS

APPROXIMATE WEIGHT:5800 lbs (with desiccant installed)

DIMENSIONS .............. See SECTION 3.2

IN/OUT CONNECTION: 4" - 150# R.F. Flange

VESSELS (desiccant towers)

Construction.................. Manufactured to the ASME CODE, Section VIII, Division 1.

Design Pressure ........... 150 PSIG

Design Temperature..... -20 to 300OF

PIPING

Threaded fittings: ANSI B16.3

Threaded unions ANSI B16.39

Flanges: ANSI B16.5

Weld fittings: ANSI B16.9

Pipe: Carbon steel, Schedule 40

VALVES

Inlet ...............One (1) Proprietary 3-Way piloted shuttle valve

Outlet ............. Two (2) Check valves, metal hinge type

Purge ............. Two (2) Normally closed, diaphragm type valves

CONTROL AIR FILTER

Construction.................. Zinc housing

Vessels stamped "U" symbol.

ELECTRICAL

Standard 115 Volt.......... 115 -1 20V /1 PH /6 0H z

Optional 230 Volt ........... Main power: 220-240V/1ph/50-60Hz

Control Power: Transformed to 115V-120V/1ph/50-60Hz, on EMCON II only.

DESICCANT

Material .......................... Activated Alumina, 1/8" (2-5mm) Bead type

Quantity Per Tower: 1450 lbs

OPERATING CONDITIONS

Inlet Air Pressure ...........................MIN 60 PSIG ..........MAX 150 PSIG

Inlet Air Temperature ..................... MIN 40OF ............... MAX 120OF

Ambient Air Temperature ............... MIN 40OF ............... MAX 120OF

RATED INLET CONDITIONS

Inlet Air Pressure ........................... 100 PSIG

Inlet Air Temperature ..................... 100OF

Relative Humidity (saturation) ....... 100% RH

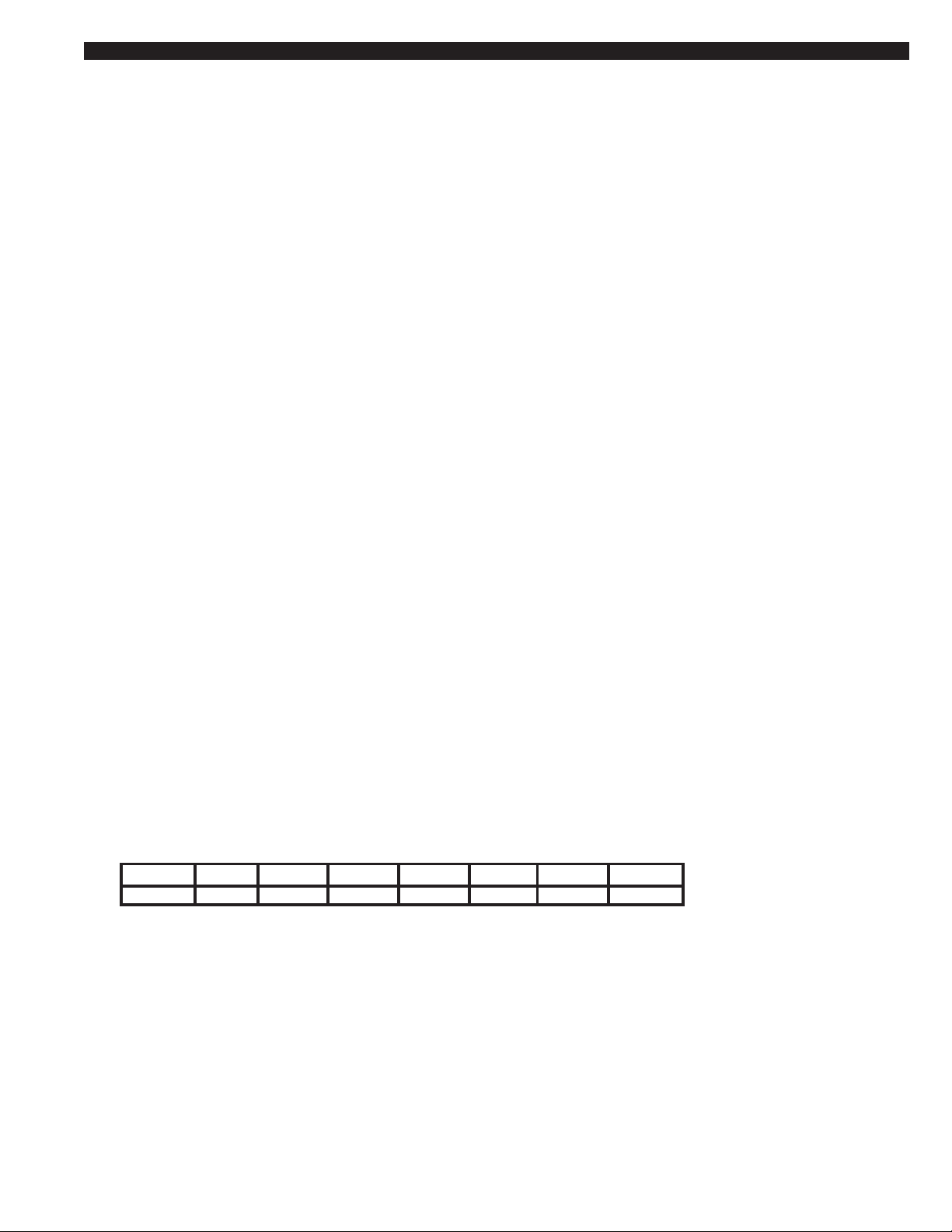

FLOW CAPACITIES (SCFM) at various pressures (1000F)

60 PSIG 80 PSIG 100 PSIG 110 PSIG 125 PSIG 140 PSIG 150 PSIG

HL-1500 1628 2064 2500 2607 2759 2903 2996

PAGE 3

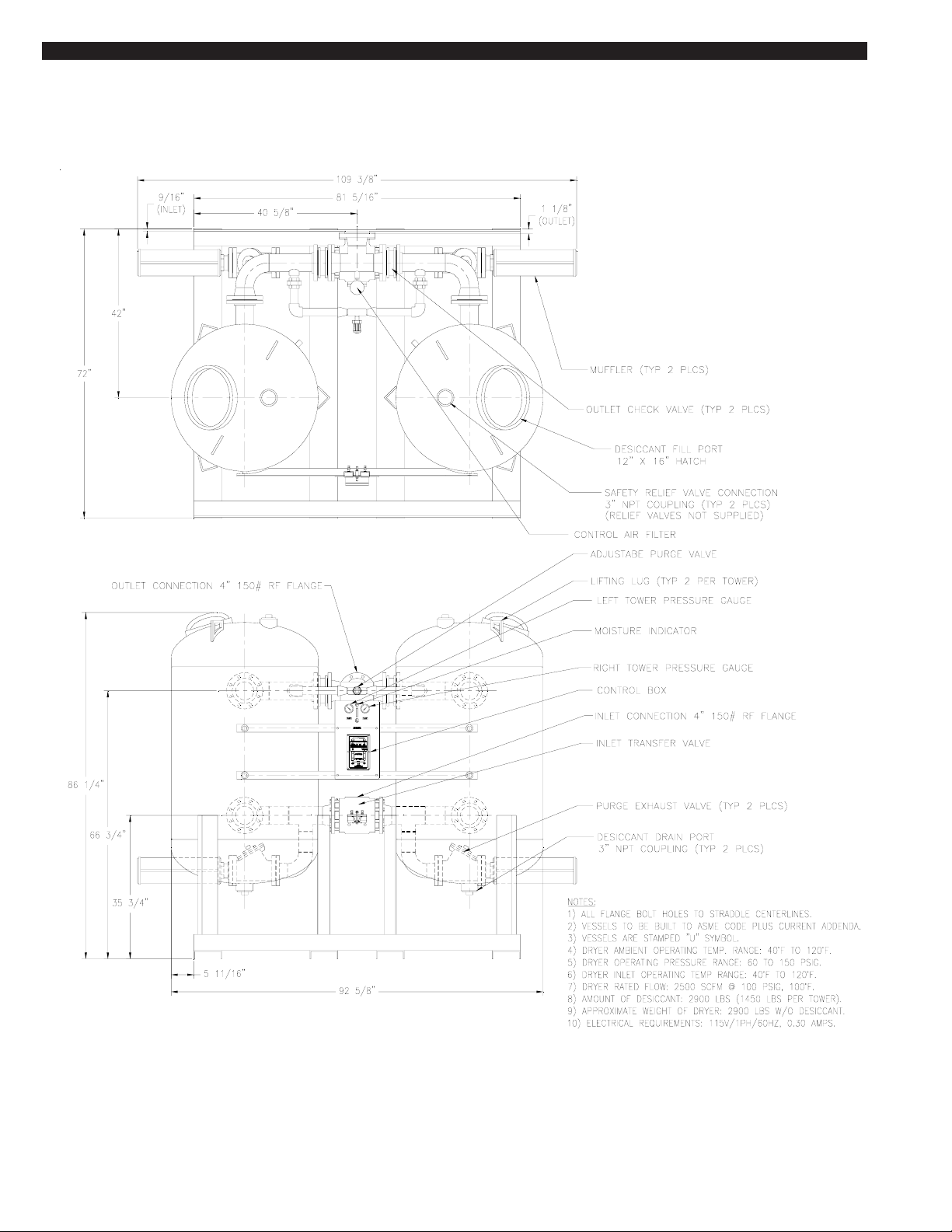

DIMENSIONS AND SPECIFICATIONS SECTION 3

3.2 DIMENSIONS

PAGE 4

Note: Standard control panel (115V) is depicted on this drawing

INSTALLING THE DRYER SECTION 4

4.1 LOCATION

WARNING

DO NOT INSTALL THIS DRYER IN AN ENVIRONMENT OF

CORROSIVE CHEMICALS, EXPLOSIVE GASSES, POISONOUS

GASSES, OR SATURATED STEAM HEAT.

Basic bypass piping should include an inlet isolation valve, a bypass

valve, and an outlet isolation valve. The isolation and bypass valves

must be bubble-tight.

4.2-2 FILTERS

Locate dryer in a protected, well vented area where ambient

temperatures are between 40oF and 120oF. Allow sufficient clearance

over and around the dryer for access to desiccant fill and drain ports

and controls. Refer to SECTION 3.2 for dryer dimensions.

If this dryer must be installed where ambient temperatures are below

40oF, insulation and heat tracing must be properly installed on the inlet

piping, purge exhaust line and the desiccant towers to prevent freezing

of the equipment.

Position the dryer in the upright position on a solid, level, vibration free

surface capable of supporting the dryer’s weight. Refer to SECTION

3.1 for dryer specifications.

The dryer should not be located in extremely dirty areas where

airborne contaminants can accumulate on the dryer. If this cannot be

prevented, the dryer should be cleaned periodically.

4.2 PIPING AND ANCILLARY EQUIPMENT

CAUTION

Make sure that the inlet air piping is connected at the bottom and the

outlet air piping is connected at the top of the dryer.

Make sure that the inlet and outlet piping to and from the dryer is

properly supported. Excessive stress may cause damage and/or

dryer malfunction.

Remove protective caps or covers from all valves before installing this

dryer.

If this dryer is to be installed into an existing piping system, clean the

existing inlet piping to remove all accumulated dirt, pipe scale, etc.,

before connecting the dryer. Make sure that the inlet and outlet

shutoff valves are tightly closed before connecting to the existing

piping system.

If excessive vibrations are present in the piping, install a flexible hose

between the compressor and the dryer inlet.

When installing the piping and any additional components, make sure

that adequate pipe supports are used. Excessive stress on the dryer

and components may cause damage or premature failure. Use either

overhead or stiff-leg type supports.

Make sure that the piping is correctly connected to the dryer. The inlet

is the bottom connection and the outlet is the top connection.

Reference SECTION 3.2 for dryer dimensions and connection

locations.

CAUTION

A PROPERLY RATED COALESCING PREFILTER MUST BE

INSTALLED BEFORE THE DRYER TO REMOVE LUBRICATING

OILS, DUST AND PIPE SCALE CONTAMINATION. FAILURE TO

USE A PREFILTER WILL RESULT IN DAMAGE TO THE DRYER

AND VOIDS THE WARRANTY.

Make sure that the elements are installed in all filter housings

prior to start up.

THE DRYER AND PREFILTER ARE NOT DESIGNED TO HANDLE

LIQUID WATER. IF LIQUID WATER IS PRESENT IN THE AIR

SYSTEM, A SEPARATOR WITH AN AUTOMATIC DRAIN MUST BE

INSTALLED UPSTREAM TO THE PREFILTER AND DRYER TO

PREVENT FLOODING.

A coalescing prefilter must be installed before the dryer to remove

lubricating oils, dust and pipe scale contamination. It is recommended

that a high efficiency coalescing filter with an automatic drain or

electric drain valve be installed. The filter should be equipped with a

pressure differential indicator to monitor the condition of the element.

A particulate afterfilter should be installed downstream of the dryer to

remove any desiccant dust. The filter should be equipped with a

pressure differential indicator to monitor the condition of the element.

Make sure that the filters are properly installed according to the

instructions provided with them.

4.3 INSTALLING THE PRESSURE RELIEF VALVES

CAUTION

THESE ASME CODE VESSELS MUST BE PROTECTED BY

PRESSURE RELIEF VALVES. Refer to OSHA 1910.169 Par. b,

Sub. Par (3) and ASME Boiler and Pressure Vessel Code, Section

VIII, Division 1, UG-125 through UG-136. Also check government

regulations, i.e., state and local codes.

Connections are provided on the top of the vessels for the installation

of pressure relief valves. Reference SECTION 3.2 for location and

connection size.

Install the pressure relief valves into the provided connections. If

pressure relief valves were not purchased with the dryer, they are

available from your local VAN AIR representative under part number

14-0990 quantity 2.

Once the location has been determined, place the dryer into position.

Lift the dryer by the lifting lugs only. Reference SECTION 1 for

handling instructions.

When the dryer is in place, it can be fastened to the mounting surface.

Reference SECTION 3.2 for dryer dimensions.

4.2-1 BYPASS PIPING (optional)

The installation of bypass piping is not required, but will allow the

dryer and filters to be taken off stream without interrupting the air

system.

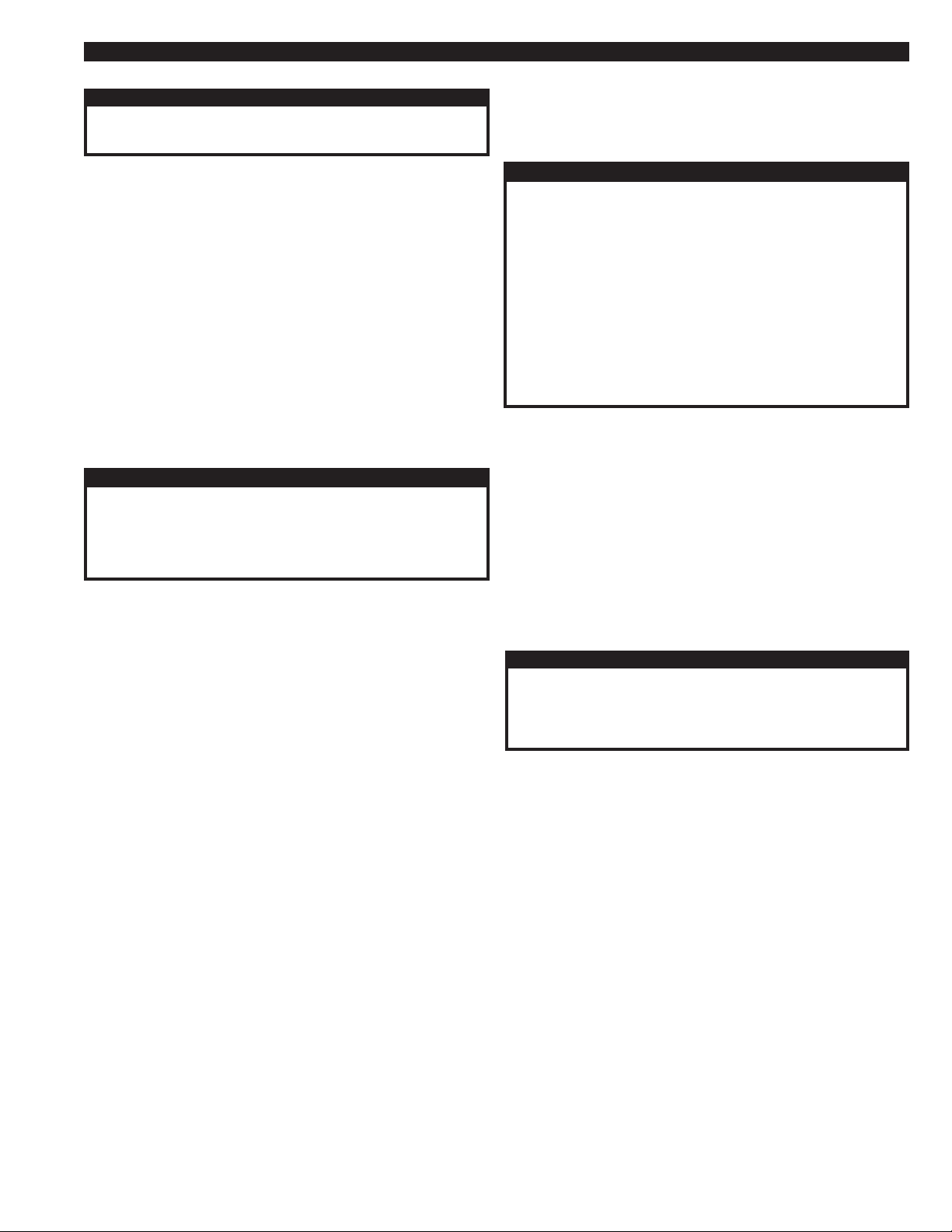

In Figure 4A, several recommended bypass piping layouts and

additional components are shown.

PAGE 5

INSTALLING THE DRYER SECTION 4

FIGURE 4A RECOMMENDED PIPING CONFIGURATIONS AND COMPONENTS

3 VALVE BYPASS

9 VALVE BYPASS

11 VALVE BYPASS

MODEL

HL-2500

IN/OUT

4" RF FLG

PREFILTERDRYER

MODEL

F101-3500-C

IN/OUT

6" RF FLG

DRAIN

VALVE

MODEL

EDV-2006

DEL-P

IND.

MODEL

PD-2

AFTERFILTER

MODEL

F101-2000-RB

IN/OUT

4" RF FLG

DEL-P

IND.

MODEL

PD-2

PAGE 6

INSTALLING THE DRYER SECTION 4

4.4 REMOTE PURGE EXHAUST PIPING

To reduce noise during purging and tower depressurization, this dryer

was supplied with mufflers for installation on the purge exhaust valves.

If the sound or humidity discharged from the dryer is unacceptable, the

purge can be piped to a remote location.

Make sure that the piping is as short as possible and does not

create back pressure on the dryer. To prevent liquid accumulation in the piping and purge valves, the piping must be at the

same level or lower than the purge valves.

The purge line must be vented to atmospheric pressure. If the

ambient temperature at the venting end of the piping is subject

to temperatures below 40

The purge valves have threaded pipe connections. Reference

Section 3.2 for location. Use adequate pipe supports to prevent

stress on valves.

The distance will determine the size of piping that is recommended.

For distances of 10 feet or less, use piping of the same size as the

purge valves. For distances up to 20 feet, use piping one size larger

than the purge valves.

IMPORTANT

o

F, freeze protection must be installed.

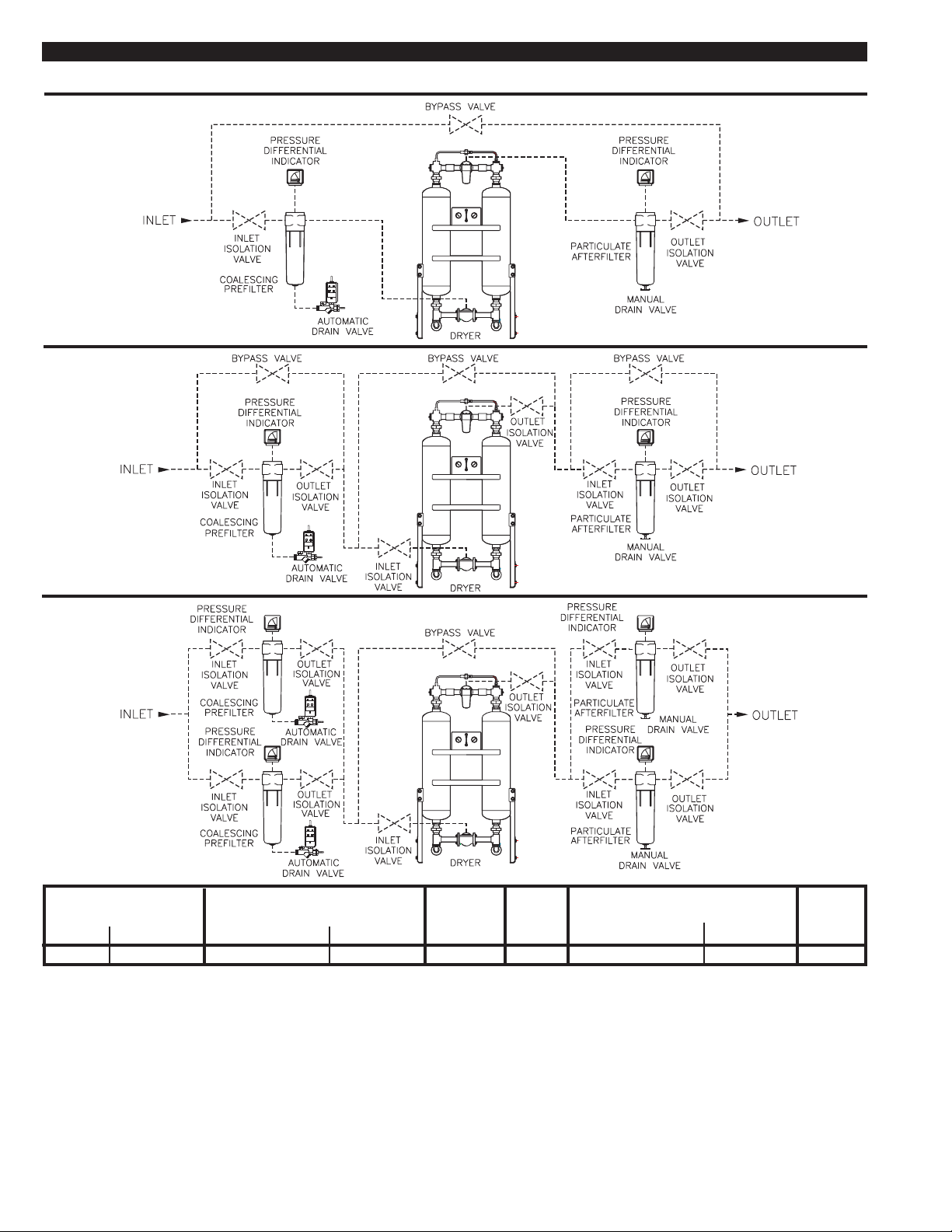

4.6-1 STANDARD CONTROL BOX (115V & 230V)

The power supply to the dryer is to be connected to the dryer control

box. A 7/8" dia hole was provided in the bottom of the box for the

connection of conduit or a cord grip connector.

Check the electrical rating of the dryer as listed on the dryer data tag.

Make sure that the power source is correct for the dryer rating.

Remove the box cover to access the power and alarm terminals.

Wire the power supply as shown in Figure 4C (Standard Control

Box). Connect the wiring to the dryer box. Comply with all codes

applicable for this installation.

FIGURE 4C ELECTRICAL CONNECTIONS

(STANDARD CONTROL BOX)

4.5 INSTALLING THE PURGE MUFFLERS

To reduce the sound level during purge and tower depressurization,

this dryer was supplied with mufflers for installation on the purge

exhaust valves.

Mufflers were shipped separately. They should NOT be installed until

the dryer has been operated for several hours. From desiccant

installation, some dust may be present in the desiccant towers.

Operating the dryer with the mufflers installed immediately after the

towers have been filled with the desiccant or during initial start up may

cause the mufflers to clog.

The dryer must be operated for several hours without the

mufflers after the towers have been filled with desiccant. This

will prevent the mufflers from becoming clogged.

IMPORTANT

FIGURE 4B PURGE MUFFLER INSTALLATION

NOTE

Dryer Model HL-2500 Has flanged

muffler connections.

Control Power: 115V /1PH/50-60Hz; 230V/1PH/50-60Hz

Max amp draw: 0.3 AMPS; 0.15 AMPS

General Alarm Contacts: 115V-230V/1PH/60Hz, 0.25 amps

4.6-2 CYCLE SAVER / FAILURE TO SWITCH (115V & 230V)

Same instructions as Standard Control Box except wire the power

supply as shown in Figure 4D (Cycle Saver / Failure To Switch).

FIGURE 4D ELECTRICAL CONNECTIONS

(CYCLE SAVER / FAILURE TO SWITCH)

4.6 ELECTRICAL CONNECTIONS

WARNING

SERIOUS PERSONAL INJURY AND DAMAGE TO THE DRYER

WILL OCCUR IF THE DRYER IS CONNECTED TO A POWER

SOURCE OTHER THAN THE VOLTAGE LISTED ON THE DATA

TAG.

WHEN INSTALLING THE ELECTRICAL CONNECTIONS FOR

THIS DRYER, COMPLY WITH NATIONAL ELECTRICAL CODE

AND ALL APPLICABLE FEDERAL, STATE AND LOCAL

CODES

Control Power: 115V /1PH/50-60Hz; 230V/1PH/50-60Hz

Max amp draw: 1 AMPS; 0.5 AMPS

General Alarm Contacts: 115V-230V/1Ph/60Hz, 3 amps

PAGE 7

INSTALLING THE DRYER SECTION 4

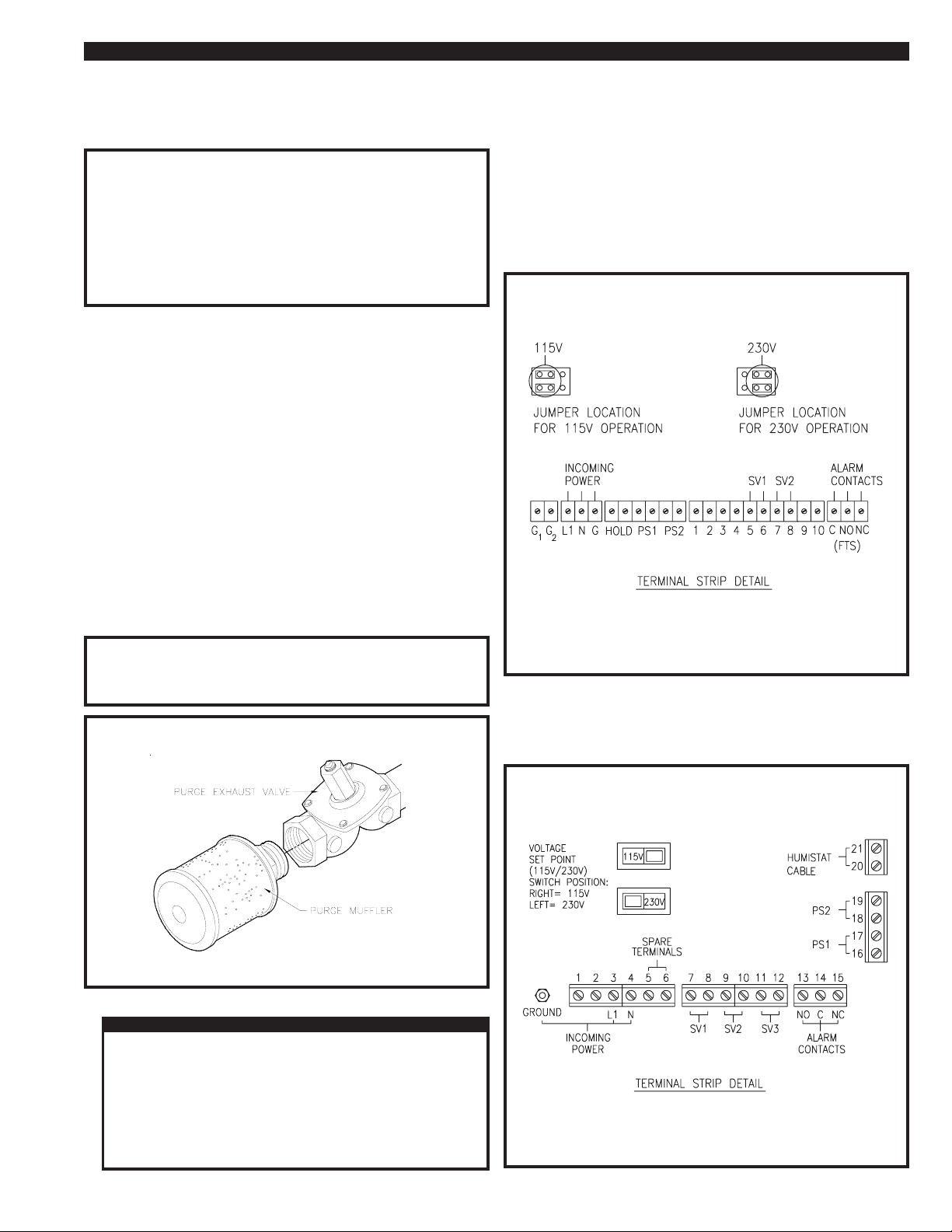

4.6-3 EMCON II (115 VOLT)

The electrical controls for the Emcon II dryers are

housed in a NEMA 4 rated fiberglass enclosure.

Reference Figure 4E to locate the power input

terminals. Access into the enclosure for wiring and

conduit can be made by carefully drilling a hole in

the bottom of the enclosure.

FIGURE 4E ELECTRICAL CONNECTIONS EMCON II (115 VOLT)

Do NOT wire the power supply directly to the

IMPORTANT

PLC. Wire the power supply to the input

terminals as shown in Figure 4E.

Connect the proper conduit and wiring as required

for this installation by all applicable codes.

Make the necessary connections to the power input

terminals.

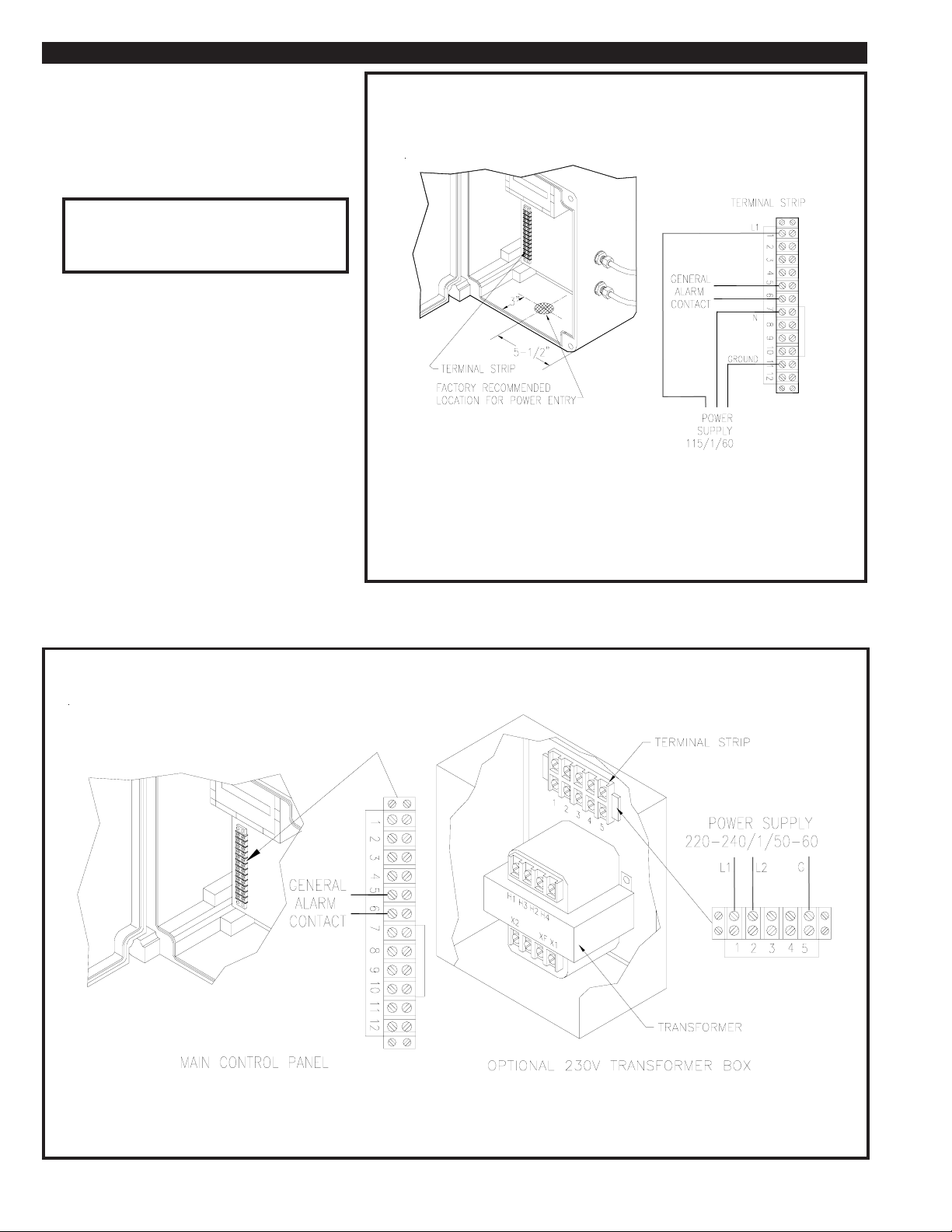

4.6-4 EMCON II (230 VOLT)

The main electrical controls for the Emcon II dryers are

housed in a NEMA 4 rated fiberglass enclosure.

Dryers rated for 230V/1PH/60Hz are equipped with a

power transformer located in a separate enclosure on

the dryer. All main power supply (230V) connections

will be made in the transformer enclosure.

Reference Figure 4F for connection details. Connect

to the enclosure using the proper conduit and wiring as

required for this installation by all applicable codes.

Control Power: 115V/1PH/60Hz

Max amp draw: 2 AMPS

General Alarm Contacts: 115V-230V/1PH/60Hz, 2 amps

FIGURE 4F ELECTRICAL CONNECTIONS EMCON II (230 VOLT)

General Alarm Contacts: 115V-230V/1PH/60Hz, 2 amps

PAGE 8

START UP SECTION 5

5.1 START UP

WARNING

BEFORE STARTING THIS DRYER, FOLLOW THE INSTALLATION

INSTRUCTIONS AND PROCEDURES COMPLETELY. SERIOUS

PERSONAL INJURY CAN RESULT IF INSTRUCTIONS ARE NOT

CAREFULLY AND COMPLETELY FOLLOWED.

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THIS

DRYER WHILE IT IS PRESSURIZED.

For the Standard Control Box, make sure the Stop button is pressed.

For the Cycle Saver and Emcon II Control Boxes, make sure that the

Power switch is in the OFF position.

If the dryer is being started up for the first time or after the

desiccant has been changed, the purge mufflers must be removed.

The dryer should be operated until no desiccant dust is visible at

the purge valves. Then the mufflers can be reinstalled. See

Section 2.2 for safety precautions concerning the desiccant dust.

WARNING

WHEN OPERATING THIS DRYER WITHOUT THE MUFFLERS

INSTALLED, USE HEARING PROTECTION.

If bypass piping was installed on this dryer as outlined in SECTION 4.2,

close the inlet and outlet isolation valves. Open the bypass valve.

Pressurize the air system. Once the air system is pressurized, slowly

open the inlet isolation valve. DO NOT open the outlet isolation valve.

To start the dryer with a Standard Control Box, press the Run button

which will light the Run LED. For Cycle Saver and Emcon II Control

Boxes, place the Power switch in the ON position. One tower will

already be pressurized. The other tower will depressurize. The purge

valve on the tower that is not pressurized will be open, air should be

exhausting from the muffler.

Dryers equipped with CYCLE SAVER or EMCON II controls will begin a

20 minute start up cycle. While in the start up cycle the dryer will

operate for 5 minutes on each tower to allow the humistat(s) to reach

equilibrium. Any time the dryer is restarted after a loss of power or

pressure in both towers, it will restart in the start up cycle.

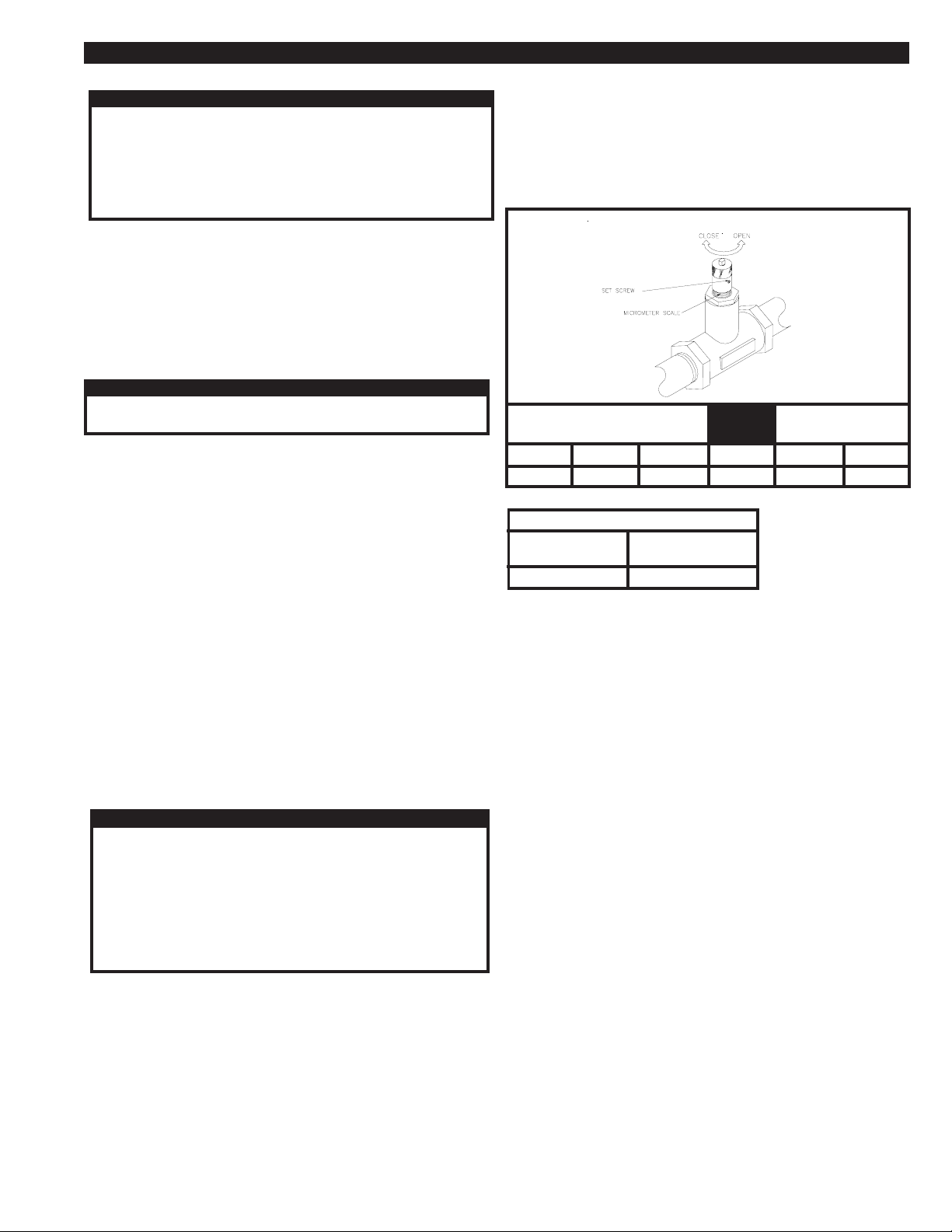

The dryer is equipped with a purge metering valve. The setting should

be checked before placing the dryer on stream.

5.2 ADJUSTING THE PURGE FLOW

IMPORTANT

NEVER OPERATE THE DRYER WITH THE PURGE METERING

VALVE CLOSED. IF THE VALVE IS CLOSED, THE TOWERS WILL

NOT REPRESSURIZE AND SWITCHING FAILURE WILL OCCUR.

conditions, the purge metering valve must be adjusted to maintain the

required purge flow rate listed in Figure 5B.

Determine the dryer minimum operating pressure. Using the chart in

Figure 5A, find the valve setting for that pressure. The valve is equipped

with a set screw which must be loosened before the valve is adjusted.

Adjust the needle valve to the desired setting. Tighten the set screw to

prevent tampering.

FIGURE 5A PURGE METERING VALVE SETTINGS

FACTORY

SETTING

PURGE

FLOW

100 PSIG

4.0 turns

120 PSIG

3.5 turns

150 PSIG

3.2 turns

MODEL

HL-2500

FIGURE 5B REQUIRED PURGE FLOW

4.5 turns

DRYER

MODEL

HL-2500

60 PSIG

80 PSIG

4.2 turns

450 SCFM

5.3 CONDITIONING THE DESICCANT BED

To condition the desiccant bed, the dryer is operated without any outlet

flow, while the towers regenerate with purge air.

To start the dryer with a Standard Control Box, press the Run button,

which will light the Run LED. For Cycle Saver and Emcon II Control Boxes,

place the Power switch to the ON position.

Dryers equipped with the Standard Contol Box should be set on the 10

minute time cycle. Dryers equipped with Emcon II and Cycle Saver

should be set in the Fixed Mode. Observe the dryer for several cycles.

Make sure that it is operating properly.

At initial start up or after extended shutdowns (over one month), the dryer

may take 24 to 48 hours of continuous operation for the bed to be

conditioned. Moisture that has accumulated on the desiccant bed should

be removed before the dryer is placed on stream.

DO NOT ADJUST THE PURGE METERING VALVE ABOVE OR

BELOW THE RECOMMENDED SETTING FOR THE OPERATING

CONDITIONS OF THIS INSTALLATION. IMPROPER SETTING MAY

CAUSE POOR DRYER PERFORMANCE AND/OR EXCESSIVE USE

OF PROCESS AIR.

The purge flow can be adjusted for the operating conditions. Standard

dryers are equipped with a micrometer type needle valve. The valve can

be adjusted to the desired setting.

This dryer was shipped with the purge flow set for the rated inlet flow at

100 PSIG. Reference Section 3.1 for rated flow. This setting should be

correct for most installations. Before placing the dryer on stream, check

the purge metering valve setting.

Figure 5B shows the purge flow required for each model. This flow is

required to properly regenerate the desiccant beds.

If the dryer is being operated at a pressure other than inlet rated

Once the moisture indicator on the dryer turns blue, the desiccant bed

is ready. Place the dryer on stream by opening the outlet isolation valve.

Make sure that the by-pass valve is closed.

PAGE 9

Loading...

Loading...