INSTALLATION, OPERATION & MAINTENANCE MANUAL

FOR

HEATLESS REGENERATIVE

COMPRESSED AIR DRYER

models

HL-200 through HL-2000

September 2007

P/N 32-0263-F

2950 Mechanic Street

Lake City, PA 16423 USA

Phone: 800/840-9906

Corporate Fax: 814/774-0778

Order Entry Fax: 814/774-3482

www.vanairsystems.com

WARNING

READ ALL INFORMA TION IN THIS MANU AL BEFORE BEGINNING INST ALLA TION OR OPERATION OF THE

DRYER. BEFORE ST ARTING MAINTENANCE PR OCEDURES, TURN OFF THE MAIN POWER T O THE DR YER

AND COMPLETEL Y DEPRESSURIZE THE UNIT T O PREVENT PERSONAL INJURY.

DO NOT REMO VE, REPAIR, OR REPLACE ANY ITEM ON THIS DRYER WHILE IT IS PRESSURIZED.

NEVER OPERA TE THIS DRYER ABOVE THE RA TED OPERATING CONDITIONS. OPERA TION ABOVE SPECIFIED CONDITIONS WILL RESULT IN DECREASED PERFORMANCE, POSSIBLE DAMAGE TO THE UNIT AND/

OR PERSONAL INJURY.

SEE BACK OF THIS MANUAL FOR ADDITIONAL SAFETY INSTRUCTIONS.

PAGE 1

HANDLING THE DRYER SECTION 1

1.1 HANDLING INSTRUCTIONS

WARNING

DO NOT LIFT THE DRYER BY PIPING OR CONTROL BOX. THESE

COMPONENTS ARE NOT DESIGNED TO HOLD THE WEIGHT OF THE

DRYER. PERSONAL INJURY AND/OR EQUIPMENT DAMAGE MAY

RESULT.

Lift the dryer by the lifting lugs on both vessels.

If the unit is to be lifted by an overhead device, attach the lifting chains or

cables to the skid angle and the vessel lifting lugs. Make sure that the

chains or cables are clear of all piping and dryer components.

1.2 STORAGE INSTRUCTIONS

The ideal place to store the unit is indoors. The location should be free

from corrosive gasses and extreme humidity. These conditions will cause

damage to the unit. The unit should be covered with a tarpaulin to keep

the unit clean.

If the unit is to be stored outdoors, it MUST BE covered completely.

The cover must be adequate to prevent rain or snow from

accumulating on the dryer. The location must be free of standing

water and mud. The preferred location, if outdoors, is on a paved

surface.

1.3 EQUIPMENT CHECK

Inspect the dryer for any damage that may have occurred during

shipment. Inspect all fittings, piping connections, fasteners, etc. for

loose connections. Also check gauges and lights for cracks or

breakage.

IF DRYER HAS BEEN DAMAGED DURING SHIPMENT:

(1) NOTIFY CARRIER IMMEDIATELY AND FILE A CLAIM.

(2) CONSULT FACTORY BEFORE OPERATING THE DRYER.

SAFETY INSTRUCTIONS SECTION 2

2.1 HANDLING

DO NOT LIFT THE DRYER BY PIPING OR CONTROL BOX. THESE

COMPONENTS ARE NOT DESIGNED TO HOLD THE WEIGHT OF

THE DRYER. PERSONAL INJURY AND/OR EQUIPMENT DAMAGE

MAY RESULT.

WHEN LIFTING THE DRYER, ALWAYS USE THE LIFTING LUGS

PROVIDED ON BOTH TOWERS.

MAKE SURE THAT ALL LIFTING EQUIPMENT IS CAPABLE OF

SUPPORTING THE WEIGHT OF THE DRYER.

2.2 INSTALLATION

BEFORE STARTING INSTALLATION PROCEDURES, TURN OFF

POWER TO THE AREA WHERE THE DRYER WILL BE INSTALLED.

SERIOUS PERSONAL INJURY MAY RESULT IF THIS SAFETY RULE

IS NOT FOLLOWED.

THESE ASME CODE VESSELS MUST BE PROTECTED BY

PRESSURE RELIEF VALVES. Refer to OSHA 1910.169 Par. b, Sub.

Par (3) and ASME Boiler and Pressure Vessel Code, Section VIII,

Division 1, UG-125 through UG-136. Also comply with all state

and local codes.

2.3 OPERATION

DO NOT OPERATE DRYER IF EITHER VESSEL IS LEAKING.

IMMEDIATELY TAKE THE DRYER OUT OF SERVICE.

ANY DAMAGE TO THE VESSELS CAN MAKE THEM UNSAFE

TO USE. INSPECT OUTSIDE AND INSIDE OF VESSELS

REGULARLY FOR CORROSION AND ANY DAMAGE (I.E.,

DENTS, GOUGES OR BULGES). IF DAMAGED, TAKE OUT OF

SERVICE IMMEDIATELY.

DO NOT OPERATE THIS DRYER ABOVE THE MAXIMUM RATED

WORKING PRESSURE.

OPERATING CONDITIONS FOR PROPER PERFORMANCE OF

THIS DRYER ARE DIFFERENT THAN MAXIMUM OPERATING

CONDITIONS FOR THE VESSELS. BE SURE TO CHECK THE

DRYER OPERATING CONDITIONS. SEE SECTION 3.1.

USE THIS DRYER FOR COMPRESSED AIR ONLY.

AIR FROM THIS DRYER IS NOT SUITABLE FOR BREATHABLE

AIR SYSTEMS WITHOUT FURTHER TREATMENT.

WHEN INSTALLING AND OPERATING THIS EQUIPMENT, COMPLY

WITH THE NATIONAL ELECTRICAL CODE AND ALL APPLICABLE

FEDERAL, STATE, AND LOCAL CODES.

WHEN INSTALLING THIS DRYER, MAKE SURE THAT THE NEMA

RATING OF THE CONTROL BOX IS APPLICABLE TO THE

INSTALLATION.

MAKE SURE THAT ALL CUSTOMER SUPPLIED WIRING AND

ELECTRICAL DEVICES ARE PROPERLY SIZED TO HANDLE THE

ELECTRICAL REQUIREMENTS OF THE DRYER.

ALWAYS WEAR EYE PROTECTION, GLOVES AND A RESPIRATORY

PROTECTIVE DEVICE WHEN HANDLING THE DESICCANT.

DESICCANT DUST MAY CAUSE EYE AND SKIN IRRITATION. AVOID

BREATHING THE DUST AND PROLONGED CONTACT WITH THE

SKIN.

FIRST AID IN CASE OF EYE CONTACT WITH DESICCANT DUST;

IMMEDIATELY FLUSH THE EYES WITH PLENTY OF WATER FOR AT

LEAST 15 MINUTES. CONSULT A PHYSICIAN.

PAGE 2

DO NOT OPERATE THIS DRYER IF EITHER VESSEL HAS BEEN

DAMAGED BY FIRE. TAKE OUT OF SERVICE IMMEDIATELY

AND NOTIFY YOUR CERTIFYING AUTHORITY.

2.4 MAINTENANCE

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THE

DRYER WHILE IT IS PRESSURIZED. TURN OFF MAIN POWER

TO THE DRYER AND DEPRESSURIZE THE DRYER COMPLETELY BEFORE STARTING MAINTENANCE PROCEDURES.

DO NOT WELD OR GRIND EITHER VESSEL. IT WILL NOT BE

SAFE TO OPERATE. (Note: Any uncertified alteration to the

vessels VOIDS the ASME Code Certification and the

Warranty.)

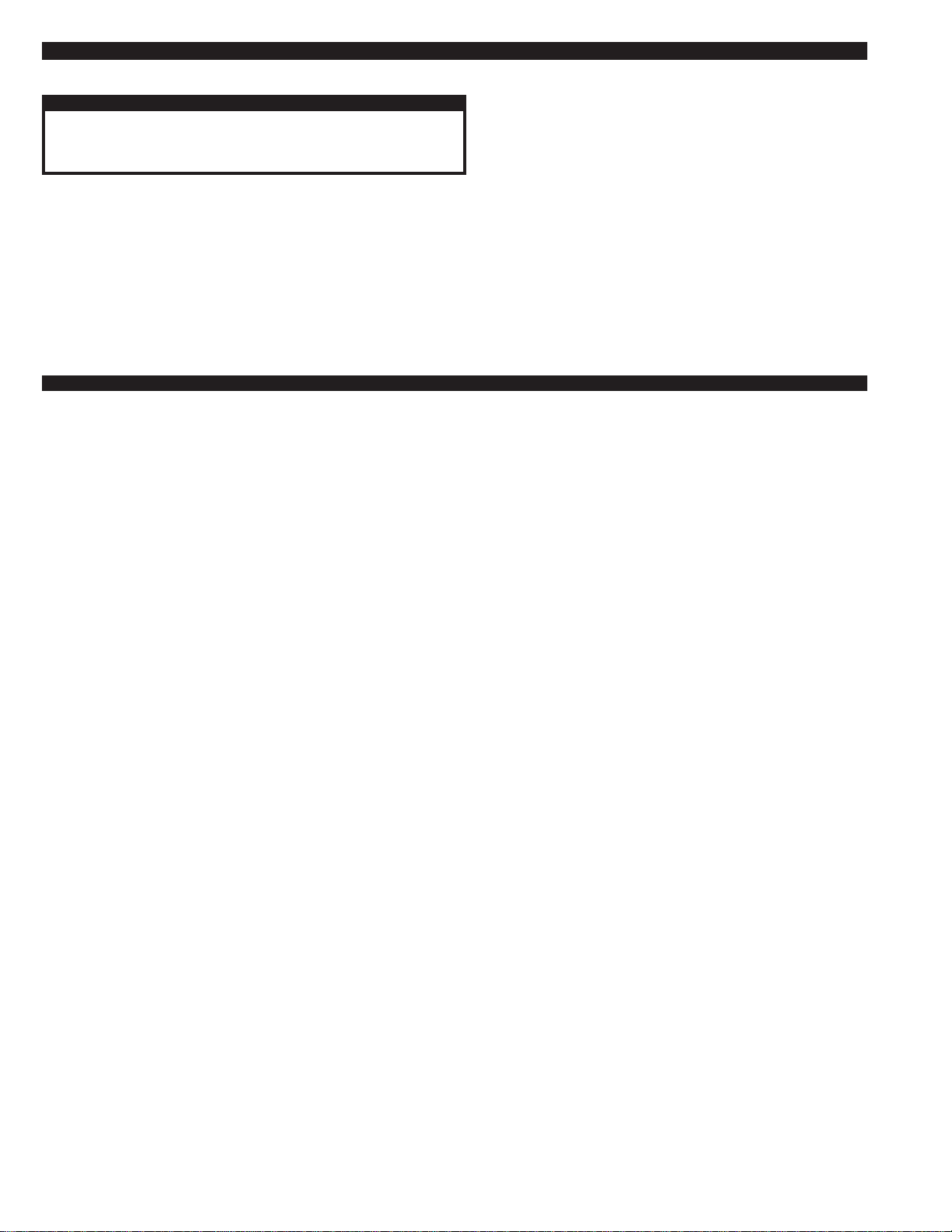

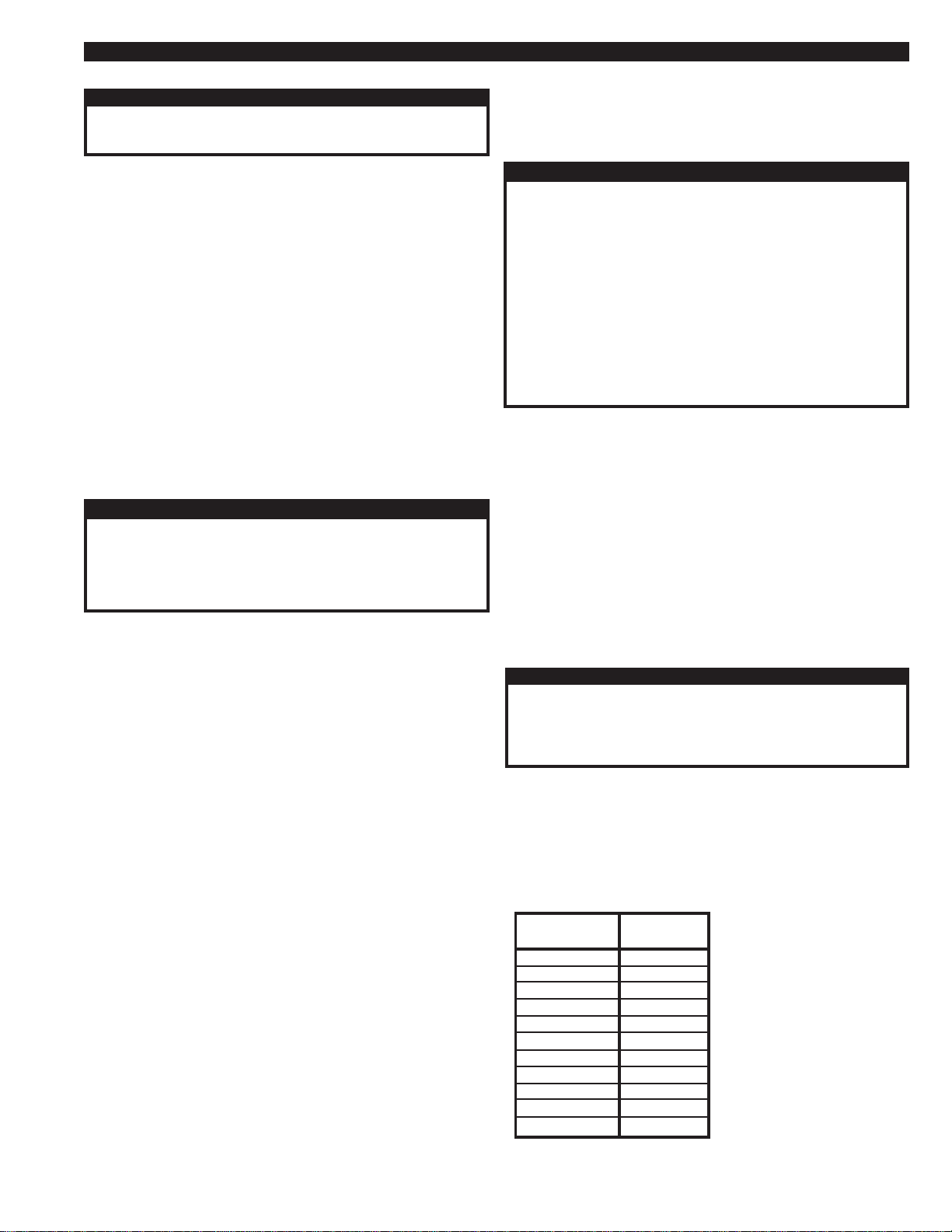

DIMENSIONS AND SPECIFICATIONS SECTION 3

3.1 DRYER SPECIFICATIONS

WEIGHT (with desiccant installed)

HL-200 HL-250 HL-375 HL-500 HL-650 HL-800 HL-1000 HL-1250 HL-1500 HL-1750 HL-2000

N4 STANDARD 660 lbs 715 lbs 1035 lbs 1160 lbs 1680 lbs 1830 lbs 2635 lbs 2885 lbs 3870 lbs 4095 lbs 4370 lbs

ALL OTHERS 700 lbs 755 lbs 1075 lbs 1200 lbs 1720 lbs 1870 lbs 2675 lbs 2925 lbs 3910 lbs 4135 lbs 4410 lbs

DIMENSIONS .............. See SECTIONS 3.2 through 3.4

IN/OUT CONNECTION All models have 150# ANSI RF flanged inlet and outlet connections. Bolt holes straddle centerlines.

HL-200 HL-250 HL-375 HL-500 HL-650 HL-800 HL-1000 HL-1250 HL-1500 HL-1750 HL-2000

1-1/2" 1-1/2" 1-1/2" 1-1/2" 2-1/2" 2-1/2" 2-1/2' 2-1/2" 3" 3" 3"

VESSELS (desiccant towers)

Construction.................. Manufactured to the ASME CODE, Section VIII, Division 1.

Design Pressure ............ 150 PSIG

Design Temperature...... -20

PIPING

Threaded fittings: .......... ANSI B16.3

Threaded unions: .......... ANSI B16.39

Flanges:......................... ANSI B16.5

Pipe:............................... Carbon steel, Schedule 40

VALVES

Inlet ............................... Proprietary 3-Way piloted shuttle valve

Outlet ............................. Two (2) Check valves, butterfly type

Purge ............................. Normally closed, diaphragm type

Models HL-200 through HL-250 vessels stamped "UM" symbol. Models HL-375 and larger vessels stamped "U" symbol.

O

F TO 300OF

CONTROL AIR FILTER

Construction.................. Zinc housing

ELECTRICAL

Standard 115 Volt.......... 115-120V/1PH/50-60Hz

Optional 230 Volt:.......... Main power: 220-240V/1PH/50-60Hz

Control power: Transformed to 115-120V/1PH/50-60Hz, on Emcon II units only

DESICCANT

Material .......................... Activated Alumina, 1/8" (2-5 MM) Bead type

Quantity Per Tower (LBS)

HL-200 HL-250 HL-375 HL-500 HL-650 HL-800 HL-1000 HL-1250 HL-1500 HL-1750 HL-2000

106 130 203 266 366 440 560 678 872 986 1119

OPERATING CONDITIONS

Inlet Air Pressure ............................MIN 60 PSIG ......... MAX 150 PSIG

Inlet Air Temperature .....................MIN 40OF ............... MAX 120OF

Ambient Air Temperature ............... MIN 40OF ............... MAX 120OF

RATED INLET CONDITIONS

Inlet Air Pressure ............................ 100 PSIG

Inlet Air Temperature .....................100OF

Relative Humidity (saturation) ........100% RH

FLOW CAPACITIES (SCFM) at various pressures (1000F)

60 PSIG 80 PSIG 100 PSIG 110 PSIG 125 PSIG 140 PSIG 150 PSIG

HL-200 130 165 200 209 221 232 240

HL-250 163 206 250 261 276 290 300

HL-375 244 310 375 391 414 436 449

HL-500 326 413 500 521 552 581 599

HL-650 423 537 650 678 717 755 779

HL-800 521 661 800 834 883 929 959

HL-1000 651 826 1000 1043 1104 1161 1198

HL-1250 814 1032 1250 1303 1380 1452 1498

HL-1500 977 1238 1500 1564 1655 1742 1797

HL-1750 1140 1445 1750 1825 1931 2032 2097

HL-2000 1303 1651 2000 2085 2207 2323 2397

PAGE 3

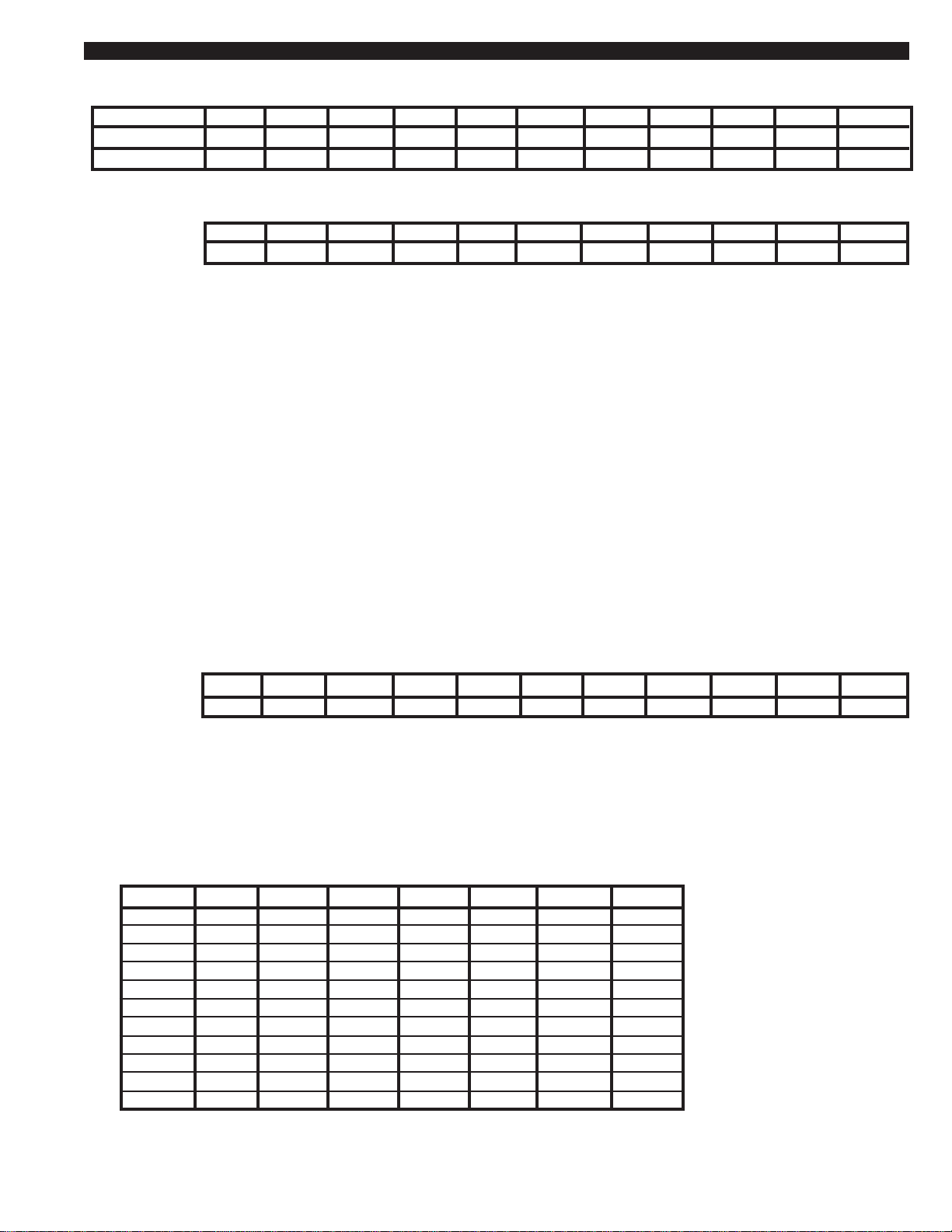

DIMENSIONS AND SPECIFICATIONS SECTION 3

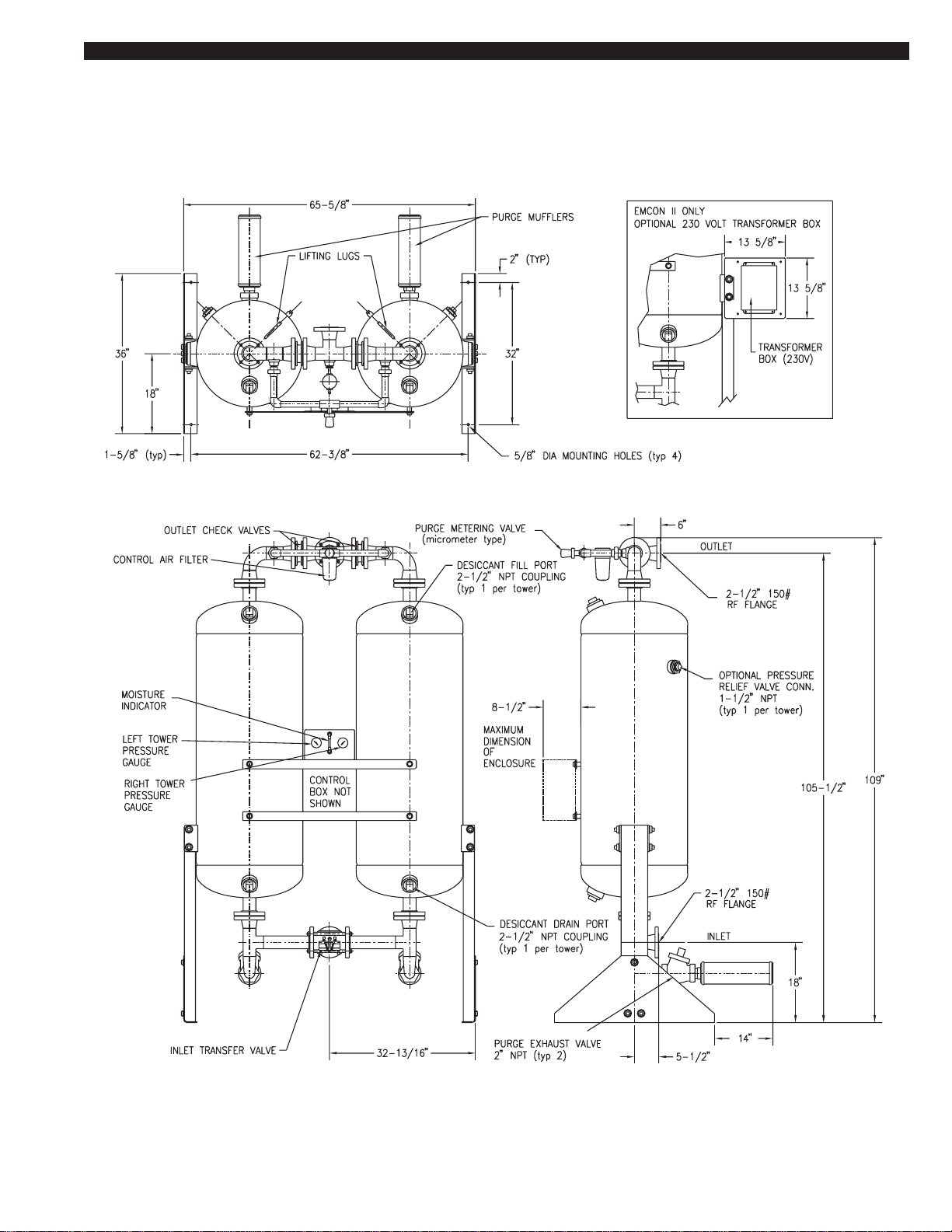

3.2 DIMENSIONS Models HL-200 through HL-800

AB CDEFGHIJKLMNOPQ

HL-200 37.50 24.00 12.00 18.75 9.00 84.38 4.38 3.38 3.75 3.25 1-1/2 35.00 20.00 2.00 1.25 8.50 .50

HL-250 37.50 24.00 12.00 18.75 9.00 84.38 4.38 3.38 3.75 3.25 1-1/2 35.00 20.00 2.00 1.25 8.50 .50

HL-375 43.13 24.00 12.00 21.57 9.00 81.13 4.38 3.38 7.25 8.00 1-1/2 40.63 20.00 2.00 1.25 8.50 1.00

HL-500 43.13 24.00 12.00 21.57 9.00 81.13 4.38 3.38 7.25 8.00 1-1/2 40.63 20.00 2.00 1.25 8.50 1.00

HL-650 53.75 36.00 18.00 26.88 16.75 95.25 5.50 4.00 8.00 13.25 2-1/2 50.50 32.00 2.00 1.63 8.50 1.50

HL-800 53.75 36.00 18.00 26.88 16.75 95.25 5.50 4.00 8.00 13.25 2-1/2 50.50 32.00 2.00 1.63 8.50 1.50

PAGE 4

DIMENSIONS AND SPECIFICATIONS SECTION 3

3.3 DIMENSIONS Models HL-1000 through HL-1250

PAGE 5

DIMENSIONS AND SPECIFICATIONS SECTION 3

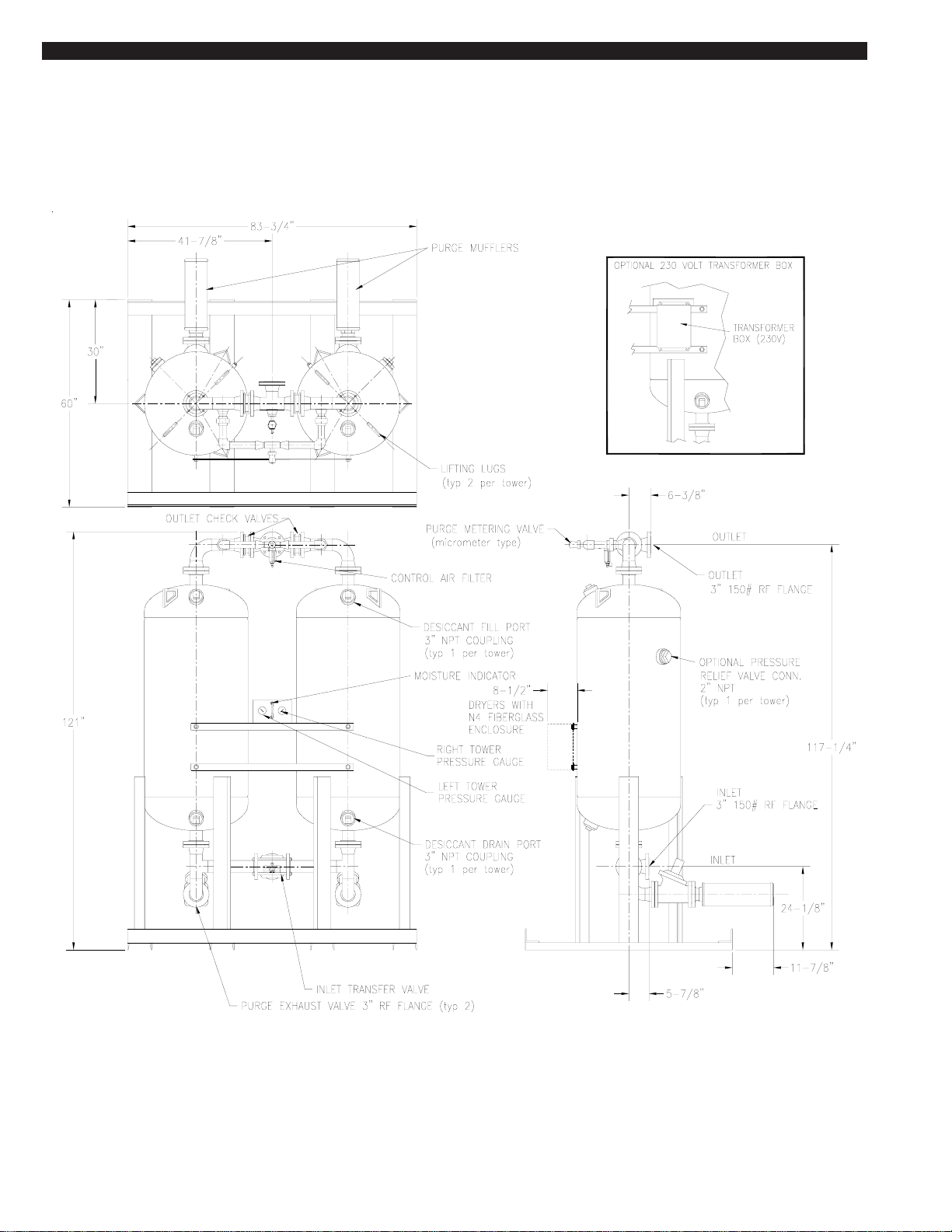

3.4 DIMENSIONS Models HL-1500 through HL-2000

PAGE 6

INSTALLING THE DRYER SECTION 4

4.1 LOCATION

WARNING

DO NOT INSTALL THIS DRYER IN AN ENVIRONMENT OF

CORROSIVE CHEMICALS, EXPLOSIVE GASSES, POISONOUS

GASSES, OR SATURATED STEAM HEAT.

Basic bypass piping should include an inlet isolation valve, a bypass

valve, and an outlet isolation valve. The isolation and bypass valves

must be bubble-tight.

4.2-2 FILTERS

Locate dryer in a protected, well vented area where ambient

temperatures are between 40oF and 120oF. Allow sufficient clearance

over and around the dryer for access to desiccant fill and drain ports

and controls. Refer to SECTIONS 3.2 through 3.4 for dryer

dimensions.

If this dryer must be installed where ambient temperatures are below

o

F, insulation and heat tracing must be properly installed on the inlet

40

piping, purge exhaust line and the desiccant towers to prevent freezing

of the equipment.

Position the dryer in the upright position on a solid, level, vibration free

surface capable of supporting the dryer’s weight. Refer to SECTION

3.1 for dryer specifications.

The dryer should not be located in extremely dirty areas where

airborne contaminants can accumulate on the dryer. If this cannot be

prevented, the dryer should be cleaned periodically. An accumulation

of dirt on the dryer may cause the inlet transfer valve to fail.

4.2 PIPING AND ANCILLARY EQUIPMENT

CAUTION

Make sure that the inlet air piping is connected at the bottom and the

outlet air piping is connected at the top of the dryer.

Make sure that the inlet and outlet piping to and from the dryer is

properly supported. Excessive stress may cause damage and/or

dryer malfunction.

CAUTION

A PROPERLY RATED COALESCING PREFILTER MUST BE

INSTALLED BEFORE THE DRYER TO REMOVE LUBRICATING

OILS, DUST AND PIPE SCALE CONTAMINATION. FAILURE TO

USE A PREFILTER WILL RESULT IN DAMAGE TO THE DRYER

AND VOIDS THE WARRANTY.

Make sure that the elements are installed in all filter housings

prior to start up.

THE DRYER AND PREFILTER ARE NOT DESIGNED TO HANDLE

LIQUID WATER. IF LIQUID WATER IS PRESENT IN THE AIR

SYSTEM, A SEPARATOR WITH AN AUTOMATIC DRAIN MUST BE

INSTALLED UPSTREAM TO THE PREFILTER AND DRYER TO

PREVENT FLOODING.

A coalescing prefilter must be installed before the dryer to remove

lubricating oils, dust and pipe scale contamination. It is recommended

that a high efficiency coalescing filter with an automatic drain or

electric drain valve be installed. The filter should be equipped with a

pressure differential indicator to monitor the condition of the element.

A particulate afterfilter should be installed downstream of the dryer to

remove any desiccant dust. The filter should be equipped with a

pressure differential indicator to monitor the condition of the element.

Make sure that the filters are properly installed according to the

instructions provided with them.

Remove protective caps or covers from all valves before installing this

dryer.

If this dryer is to be installed into an existing piping system, clean the

existing inlet piping to remove all accumulated dirt, pipe scale, etc.,

before connecting the dryer. Make sure that the inlet and outlet

shutoff valves are tightly closed before connecting to the existing

piping system.

If excessive vibrations are present in the piping, install a flexible hose

between the compressor and the dryer inlet.

When installing the piping and any additional components, make sure

that adequate pipe supports are used. Excessive stress on the dryer

and components may cause damage or premature failure. Use either

overhead or stiff-leg type supports.

Make sure that the piping is correctly connected to the dryer. The inlet

is the bottom connection and the outlet is the top connection.

Reference SECTIONS 3.2 through 3.4 for dryer dimensions and

connection locations.

Once the location has been determined, place the dryer into position.

Lift the dryer by the lifting lugs only. Reference SECTION 1 for

handling instructions.

When the dryer is in place, it can be fastened to the mounting surface.

Reference SECTIONS 3.2 through 3.4 for dryer dimensions.

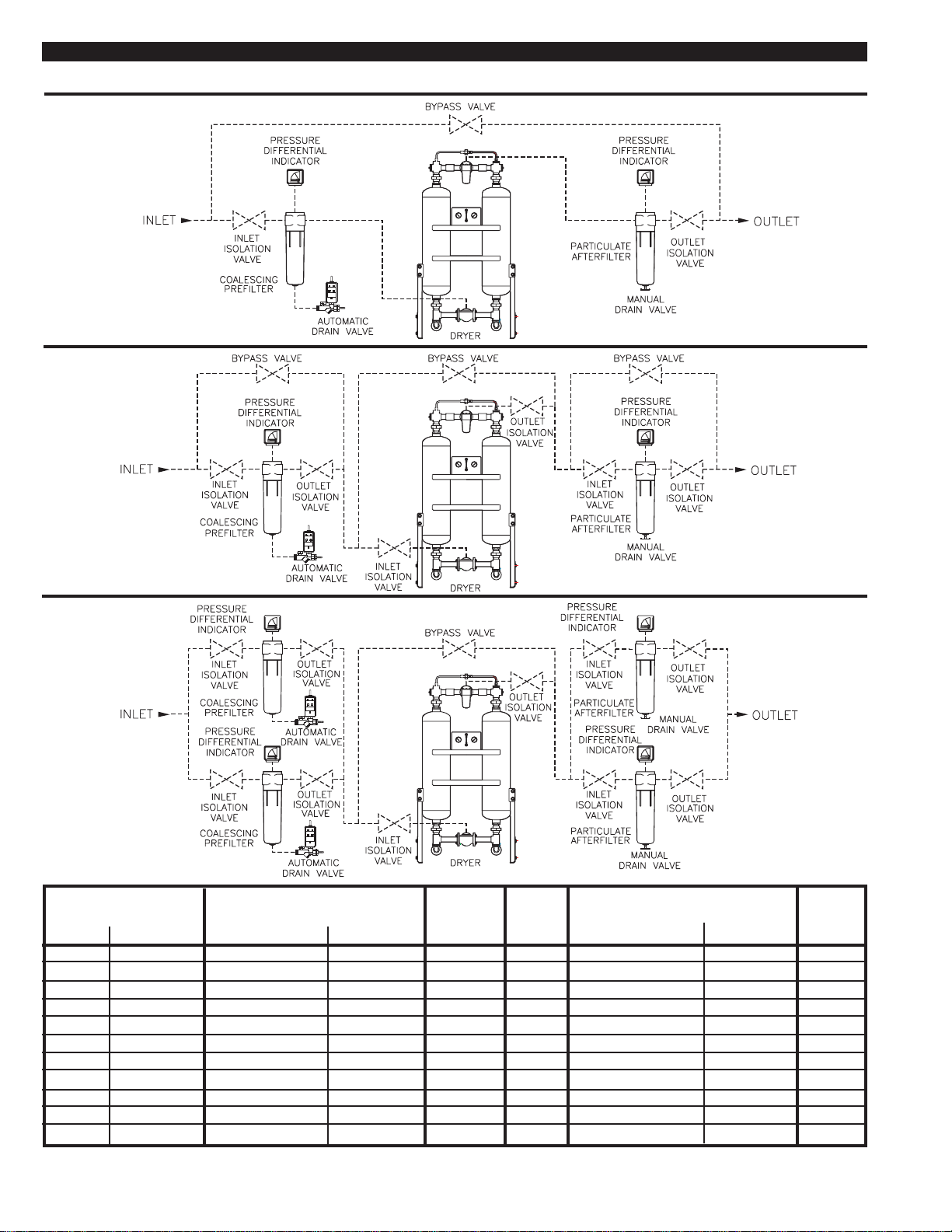

4.2-1 BYPASS PIPING (optional)

The installation of bypass piping is not required, but will allow the

dryer and filter(s) to be taken off stream without interrupting the air

system.

In Figure 4A, several recommended bypass piping layouts and

additional components are shown.

4.3 INSTALLING THE PRESSURE RELIEF VALVES

THESE ASME CODE VESSELS MUST BE PROTECTED BY

PRESSURE RELIEF VALVES. Refer to OSHA 1910.169 Par. b,

Sub. Par (3) and ASME Boiler and Pressure Vessel Code, Section

VIII, Division 1, UG-125 through UG-136. Also comply with all

state and local codes.

Connections are provided in the outlet piping for the installation of

pressure relief valves. Reference SECTIONS 3.2 through 3.4 for

location and connection size.

Install the pressure relief valves into the provided connections. If

pressure relief valves were not purchased with the dryer, the following

valve sets are available from your local VAN AIR representative.

DRYER

MODEL

HL-200

HL-250

HL-375

HL-500

HL-650

HL-800

HL-1000

HL-1250

HL-1500

HL-1750

HL-2000

PART NO.

14-1448 (2)

14-1448 (2)

14-1833 (2)

14-1833 (2)

14-1834 (2)

14-1834 (2)

14-1835 (2)

14-1835 (2)

14-1836 (2)

14-1836 (2)

14-1836 (2)

CAUTION

VALVE

PAGE 7

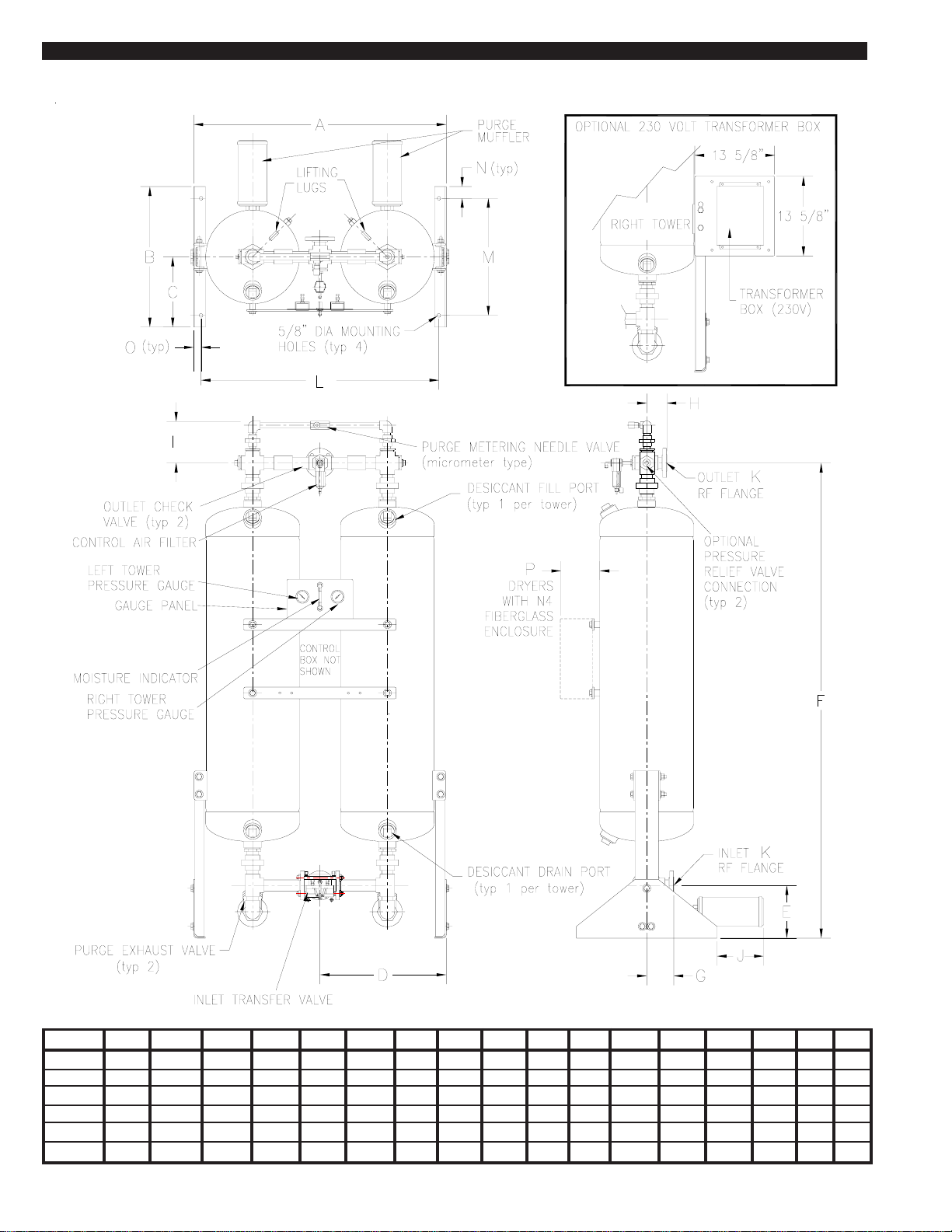

INSTALLING THE DRYER SECTION 4

FIGURE 4A RECOMMENDED PIPING CONFIGURATIONS AND COMPONENTS

3 VALVE BYPASS

9 VALVE BYPASS

11 VALVE BYPASS

MODEL

HL-200

HL-250

HL-375

HL-500

HL-650

HL-800

HL-1000

HL-1250

HL-1500

HL-1750

HL-2000

IN/OUT

1-1/2" RF FLG

1-1/2" RF FLG

1-1/2" RF FLG

1-1/2" RF FLG

2-1/2" RF FLG

2-1/2" RF FLG

2-1/2" RF FLG

2-1/2" RF FLG

3" RF FLG

3" RF FLG

3" RF FLG

PREFILTERDRYER

MODEL

F200-265-11/4-C

1

F200-265-1

/4-C

F200-350-11/2-C

F200-500-2-C

F200-600-3-C

F200-800-3-C

F200-1000-3-C

F101-1500-C

F101-1500-C

F101-2000-C

F101-2000-C

IN/OUT

1-1/4" NPT(F)

1-1/4" NPT(F)

1-1/2" NPT(F)

2" NPT(F)

3" NPT(F)

3" NPT(F)

3" NPT(F)

3" NPT(F)

3" NPT(F)

4" RF FLG

4" RF FLG

DRAIN

VALVE

MODEL

EDV-2006

EDV-2006

EDV-2006

EDV-2006

EDV-2006

EDV-2006

EDV-2006

EDV-2006

EDV-2006

EDV-2006

EDV-2006

DEL-P

IND.

MODEL

PD-5

PD-5

PD-5

PD-5

PD-5

PD-5

PD-5

PD-2

PD-2

PD-2

PD-2

AFTERFILTER

MODEL

1

F200-265-1

F200-265-1

/4-RB

1

/4-RB

F200-350-11/2-RB

F200-500-2-RB

F200-600-3-RB

F200-800-3-RB

F200-1000-3-RB

F101-1500-RB

F101-1500-RB

F101-2000-RB

F101-2000-RB

IN/OUT

NPT(F)

1-1/4"

1-1/4" NPT(F)

1-1/2" NPT(F)

2" NPT(F)

3" NPT(F)

3" NPT(F)

3" NPT(F)

3" NPT(F)

3" NPT(F)

4" RF FLG

4" RF FLG

DEL-P

IND.

MODEL

PD-5

PD-5

PD-5

PD-5

PD-5

PD-5

PD-5

PD-2

PD-2

PD-2

PD-2

PAGE 8

INSTALLING THE DRYER SECTION 4

4.4 REMOTE PURGE EXHAUST PIPING

To reduce noise during purging and tower depressurization, this dryer

was supplied with mufflers for installation on the purge exhaust valves.

If the sound or humidity discharged from the dryer is unacceptable, the

purge of this dryer can be remotely piped away.

Make sure that the piping is as short as possible and does not

create back pressure on the dryer. To prevent liquid accumulation in the piping and purge valves, the piping must be at the

same level or lower than the purge valves.

The purge line must be vented to atmospheric pressure. If the

ambient temperature at the venting end of the piping is subject

to temperatures below 40

The purge valves have threaded pipe connections. Reference

Sections 3.2 through 3.4 for location. Use adequate pipe supports to

prevent stress on valves.

The distance will determine the size of piping that is recommended.

For distances of 10 feet or less, use piping of the same size as the

purge valves. For distances up to 20 feet, use piping one size larger

than the purge valves.

IMPORTANT

o

F, freeze protection must be installed.

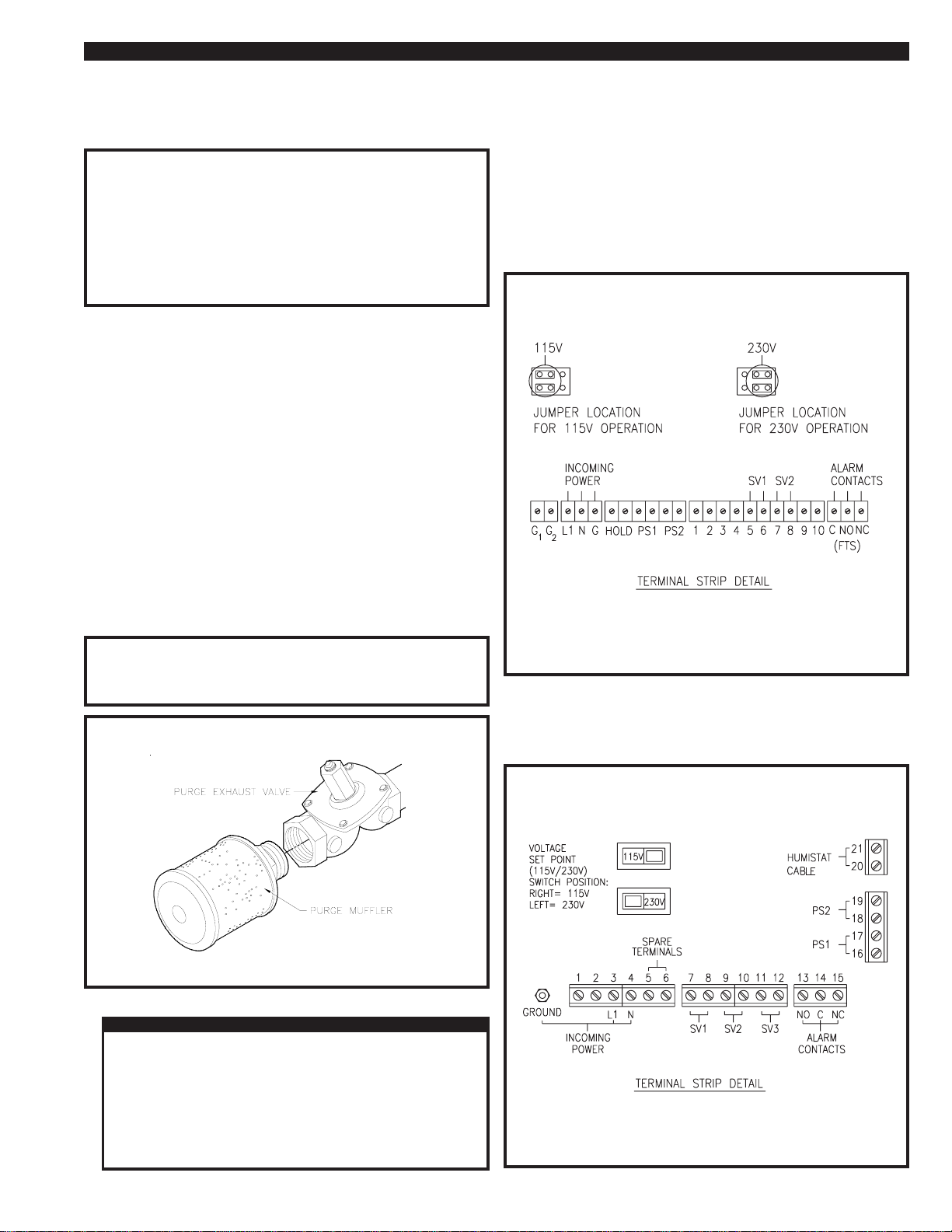

4.6-1 STANDARD CONTROL BOX (115V & 230V)

The power supply to the dryer is to be connected to the dryer control

box. A 7/8" dia hole was provided in the bottom of the box for the

connection of conduit or a cord grip connector.

Check the electrical rating of the dryer as listed on the dryer data tag.

Make sure that the power source is correct for the dryer rating.

Remove the box cover to access the power and alarm terminals.

Wire the power supply as shown in Figure 4C (Standard Control

Box). Connect the wiring to the dryer box. Comply with all codes

applicable for this installation.

FIGURE 4C ELECTRICAL CONNECTIONS

(STANDARD CONTROL BOX)

4.5 INSTALLING THE PURGE MUFFLERS

To reduce the sound level during purge and tower depressurization,

this dryer was supplied with mufflers for installation on the purge

exhaust valves.

Mufflers were shipped separately. They should NOT be installed until

the dryer has been operated for several hours. From desiccant

installation, some dust may be present in the desiccant towers.

Operating the dryer with the mufflers installed immediately after the

towers have been filled with the desiccant or during initial start up may

cause the mufflers to clog.

The dryer must be operated for several hours without the

mufflers after the towers have been filled with desiccant. This

will prevent the mufflers from becoming clogged.

IMPORTANT

FIGURE 4B PURGE MUFFLER INSTALLATION

NOTE

Dryer Models HL-1500 thru HL-2000

Have flanged muffler connections.

Control Power: 115V /1PH/50-60Hz; 230V/1PH/50-60Hz

Max amp draw: 0.3 AMPS; 0.15 AMPS

General Alarm Contacts: 115V-230V/1PH/60Hz, 0.25 amps

4.6-2 CYCLE SAVER / FAILURE TO SWITCH (115V & 230V)

Same instructions as Standard Control Box except wire the power

supply as shown in Figure 4D (Cycle Saver / Failure To Switch).

FIGURE 4D ELECTRICAL CONNECTIONS

(CYCLE SAVER / FAILURE TO SWITCH)

4.6 ELECTRICAL CONNECTIONS

WARNING

SERIOUS PERSONAL INJURY AND DAMAGE TO THE DRYER

WILL OCCUR IF THE DRYER IS CONNECTED TO A POWER

SOURCE OTHER THAN THE VOLTAGE LISTED ON THE DATA

TAG.

WHEN INSTALLING THE ELECTRICAL CONNECTIONS FOR

THIS DRYER, COMPLY WITH NATIONAL ELECTRICAL CODE

AND ALL APPLICABLE FEDERAL, STATE AND LOCAL

CODES

Control Power: 115V /1PH/50-60Hz; 230V/1PH/50-60Hz

Max amp draw: 1 AMPS; 0.5 AMPS

General Alarm Contacts: 115V-230V/1Ph/60Hz, 3 amps

PAGE 9

INSTALLING THE DRYER SECTION 4

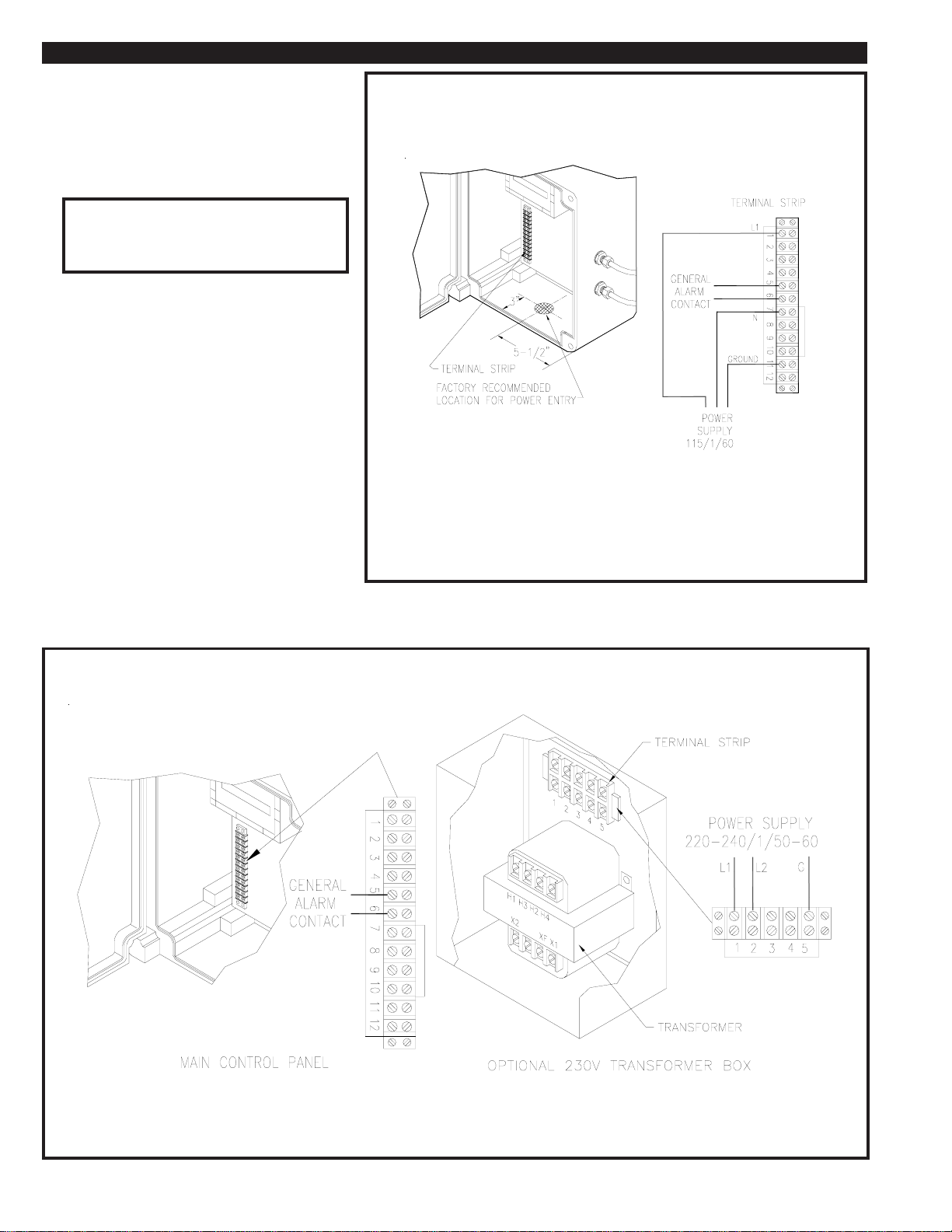

4.6-3 EMCON II (115 VOLT)

The electrical controls for the Emcon II dryers are

housed in a NEMA 4 rated fiberglass enclosure.

Reference Figure 4E to locate the power input

terminals. Access into the enclosure for wiring and

conduit can be made by carefully drilling a hole in

the bottom of the enclosure.

FIGURE 4E ELECTRICAL CONNECTIONS EMCON II (115 VOLT)

Do NOT wire the power supply directly to the

IMPORTANT

PLC. Wire the power supply to the input

terminals as shown in Figure 4E.

Connect the proper conduit and wiring as required

for this installation by all applicable codes.

Make the necessary connections to the power input

terminals.

4.6-4 EMCON II (230 VOLT)

The main electrical controls for the Emcon II dryers are

housed in a NEMA 4 rated fiberglass enclosure.

Dryers rated for 230V/1PH/60Hz are equipped with a

power transformer located in a separate enclosure on

the dryer. All main power supply (230V) connections

will be made in the transformer enclosure.

Reference Figure 4F for connection details. Connect

to the enclosure using the proper conduit and wiring as

required for this installation by all applicable codes.

Control Power: 115V/1PH/60Hz

Max amp draw: 2 AMPS

General Alarm Contacts: 115V-230V/1PH/60Hz, 2 amps

FIGURE 4F ELECTRICAL CONNECTIONS EMCON II (230 VOLT)

General Alarm Contacts: 115V-230V/1PH/60Hz, 2 amps

PAGE 10

START UP SECTION 5

5.1 START UP

WARNING

BEFORE STARTING THIS DRYER, FOLLOW THE INSTALLATION

INSTRUCTIONS AND PROCEDURES COMPLETELY. SERIOUS

PERSONAL INJURY CAN RESULT IF INSTRUCTIONS ARE NOT

CAREFULLY AND COMPLETELY FOLLOWED.

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THIS

DRYER WHILE IT IS PRESSURIZED.

For the Standard Control Box, make sure the Stop button is pressed.

For the Cycle Saver and Emcon II Control Boxes, make sure that the

Power switch is in the OFF position.

If the dryer is being started up for the first time or after the

desiccant has been changed, the purge mufflers must be removed.

The dryer should be operated until no desiccant dust is visible at

the purge valves. Then the mufflers can be reinstalled. See

Section 2.2 for safety precautions concerning the desiccant dust.

WARNING

WHEN OPERATING THIS DRYER WITHOUT THE MUFFLERS

INSTALLED, USE HEARING PROTECTION.

If bypass piping was installed on this dryer as outlined in SECTION 4.2,

close the inlet and outlet isolation valves. Open the bypass valve.

Pressurize the air system. Once the air system is pressurized, slowly

open the inlet isolation valve. DO NOT open the outlet isolation valve.

To start the dryer with a Standard Control Box, press the Run button

which will light the Run LED. For Cycle Saver and Emcon II Control

Boxes, place the Power switch in the ON position. One tower will

already be pressurized. The other tower will depressurize. The purge

valve on the tower that is not pressurized will be open, air should be

exhausting from the muffler.

Dryers equipped with CYCLE SAVER or EMCON II controls will begin a

20 minute start up cycle. While in the start up cycle the dryer will

operate for 5 minutes on each tower to allow the humistat(s) to reach

equilibrium. Any time the dryer is restarted after a loss of power or

pressure in both towers, it will restart in the start up cycle.

The dryer is equipped with a purge metering valve. The setting should

be checked before placing the dryer on stream.

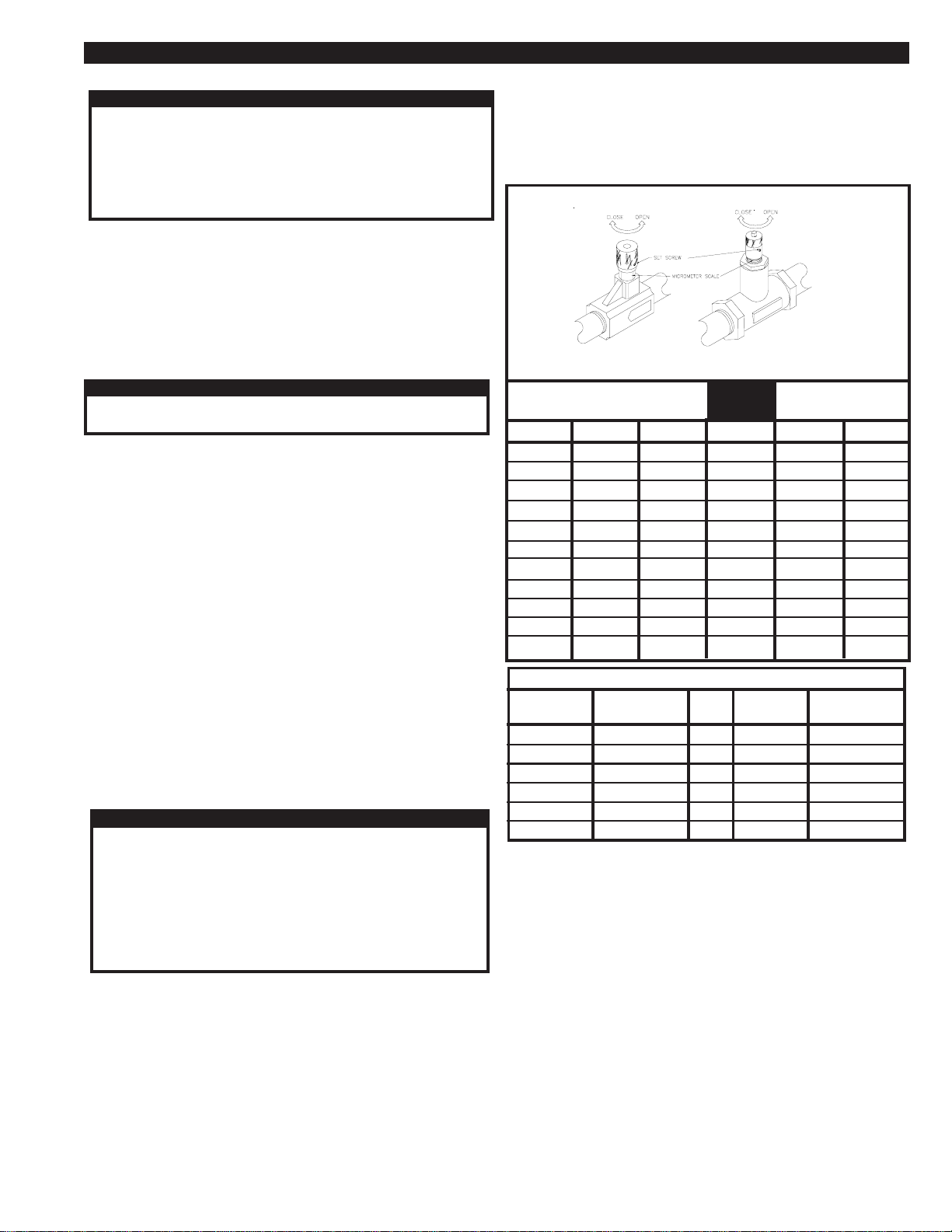

5.2 ADJUSTING THE PURGE FLOW

IMPORTANT

NEVER OPERATE THE DRYER WITH THE PURGE METERING

VALVE CLOSED. IF THE VALVE IS CLOSED, THE TOWERS WILL

NOT REPRESSURIZE AND SWITCHING FAILURE WILL OCCUR.

DO NOT ADJUST THE PURGE METERING VALVE ABOVE OR

BELOW THE RECOMMENDED SETTING FOR THE OPERATING

CONDITIONS OF THIS INSTALLATION. IMPROPER SETTING MAY

CAUSE POOR DRYER PERFORMANCE AND/OR EXCESSIVE USE

OF PROCESS AIR.

conditions, the purge metering valve must be adjusted to maintain the

required purge flow rate listed in Figure 5B.

Determine the dryer minimum operating pressure. Using the chart in Figure

5A, find the valve setting for that pressure. The valve is equipped with a set

screw which must be loosened before the valve is adjusted. Adjust the needle

valve to the desired setting. Tighten the set screw to prevent tampering.

FIGURE 5A PURGE METERING VALVE SETTINGS

1/2" & 3/4" VALVES used on

models HL-200 THROUGH HL-500

1" VALVE used on

models HL-650 through HL-2000

FACTORY

SETTING

MODEL

HL-200

HL-250

HL-375

HL-500

HL-650

HL-800

HL-1000

HL-1250

HL-1500

HL-1750

HL-2000

60 PSIG

3.5 turns

3.6 turns

4.5 turns

5.6 turns

2.7 turns

2.8 turns

3.0 turns

3.4 turns

3.8 turns

4.0 turns

4.2 turns

80 PSIG

3.3 turns

3.4 turns

4.0 turns

4.6 turns

2.6 turns

2.7 turns

2.8 turns

3.0 turns

3.3 turns

3.5 turns

3.9 turns

100 PSIG

3.2 turns

3.3 turns

3.8 turns

4.2 turns

2.5 turns

2.6 turns

2.7 turns

2.9 turns

3.0 turns

3.2 turns

3.4 turns

120 PSIG

3.1 turns

3.2 turns

3.7 turns

4.0 turns

2.3 turns

2.5 turns

2.6 turns

2.7 turns

2.9 turns

3.0 turns

3.2 turns

150 PSIG

3.0 turns

3.1 turns

3.5 turns

3.8 turns

2.2 turns

2.3 turns

2.5 turns

2.6 turns

2.7 turns

2.8 turns

3.0 turns

FIGURE 5B REQUIRED PURGE FLOW

DRYER

MODEL

HL-200

HL-250

HL-375

HL-500

HL-650

HL-800

PURGE

FLOW

36.0 SCFM

45.0 SCFM

67.5 SCFM

90.0 SCFM

117.0 SCFM

144.0 SCFM

DRYER

MODEL

HL-1000

HL-1250

HL-1500

HL-1750

HL-2000

PURGE

FLOW

180.0 SCFM

225.0 SCFM

270.0 SCFM

315.0 SCFM

360.0 SCFM

5.3 CONDITIONING THE DESICCANT BED

To condition the desiccant bed, the dryer is operated without any outlet flow,

while the towers regenerate with purge air.

To start the dryer with a Standard Control Box, press the Run button which

will light the Run LED. For Cycle Saver and Emcon II Control Boxes, place

the Power switch in the ON position.

The purge flow can be adjusted for the operating conditions. Standard

dryers are equipped with a micrometer type needle valve. The valve can

be adjusted to the desired setting.

This dryer was shipped with the purge flow set for the rated inlet flow at

100 PSIG. Reference Section 3.1 for rated flow. This setting should be

correct for most installations. Before placing the dryer on stream, check

the purge metering valve setting.

Figure 5B shows the purge flow required for each model. This flow is

required to properly regenerate the desiccant beds.

If the dryer is being operated at a pressure other than inlet rated

Dryers equipped with the Standard Contol Box should be set on the 10 minute

time cycle. Dryers equipped with Emcon II and Cycle Saver should be set in

the Fixed Mode. Observe the dryer for several cycles. Make sure that it is

operating properly.

At initial start up or after extended shutdowns (over one month), the dryer may

take 24 to 48 hours of continuous operation for the bed to be conditioned.

Moisture that has accumulated on the desiccant bed should be removed

before the dryer is placed on stream.

Once the moisture indicator on the dryer turns blue, the desiccant bed is

ready. Place the dryer on stream by opening the outlet isolation valve. Make

sure that the by-pass valve is closed.

PAGE 11

PRINCIPLE OF OPERATION SECTION 6

6.1 PRINCIPLE OF OPERATION

HL Series Heatless Regenerative Air Dryers utilize the pressure swing

principle of operation. The desiccant bed in one tower dries the air stream

while the desiccant bed in the other tower is regenerated.

To achieve maximum performance from this dryer, it should be

operated continuously. Operating this dryer for single shift periods may

result in varied outlet dew point performance.

A purge of dry air is used for tower regeneration. It is taken from the outlet

of the dryer.

The dryer is equipped with a purge metering valve to allow the correct

amount of dry air to flow into the regenerating tower. The heat created

during adsorption of moisture in the drying tower is retained in the

desiccant bed and increases the moisture removal capacity of the purge

air.

The timing cycle of the dryer is controlled by two 3-way pilot valves.

A patented shuttle valve system is used to repressurize, changeover, and

depressurize the towers. The inlet transfer valve is controlled by the pilot

valves. The movement of the shuttle in the inlet transfer valve mechanically

actuates the external pneumatic limit switches, which open the purge

valves and depressurize the tower. The shuttle cannot shift until the tower

pressures are nearly equal. The dryer cannot depressurize until the

shuttle has fully seated and the one of the limit switches is engaged.

The dryer operation consists of four stages; REPRESSURIZATION,

CHANGEOVER/DEPRESSURIZATION, DRYING and

REGENERATION.

6.1-1 REPRESSURIZATION STAGE

Repessurization occurs in the regenerating tower. Repessurization

must occur before tower changover. This reduces shock to the

desiccant and the possibility of downstream pressure spikes.

The purge valve is closed and the purge air, which was vented to

atomosphere earlier in the cycle, is now used to repressurize the

regenerated tower.

The pilot valves SV1 & SV2 de-energize causing the purge valve on the

regenerating tower to close. The purge air, which was vented to

atmosphere earlier in the cycle, is now used to repressurize the

regenerated tower.

FIGURE 6A PNEUMA TIC SCHEMATIC for DRYERS WITH STANDARD CONTROL

PAGE 12

PRINCIPLE OF OPERATION SECTION 6

6.1-2 CHANGEOVER/DEPRESSURIZATION STAGE

Tower changeover occurs after the previous regenerating tower is

pressurized. The controller signals the inlet transfer valve to switch.

The tower that was on line and drying the process air will begin to

depressurize.

Pressure in the regenerating tower will approach full line pressure. The

pilot valves SV1 or SV2 will energize. Pilot air will be supplied to one

side of the inlet transfer valve. The inlet transfer valve shuttle will move

to the side that has pilot pressure.

When the inlet transfer valve changes position, the position indicator

will move and actuate the other pneumatic limit switch. This will open

the purge valve on the tower that was drying the process air, causing

the tower to depressurize.

CYCLE SAVER and EMCON II models:

If the dryer is being operated in the AUTO MODE, tower changeover

is delayed until the dew point controller(s) signal the circuit board or

PLC. The dryer will automatically change towers after 4 hours of

ENERGY SAVINGS.

6.1-3 DRYING AND REGENERATION STAGE

During the drying stage, one tower is pressurized with process air.

This tower is in the drying stage. The process air passes through the

desiccant bed, which adsorbs moisture from the air. The

regeneration stage of one tower occurs at the same time as the drying

stage in the opposite tower. During the regeneration stage, a

percentage of dry air is directed through the desiccant bed of the

offstream tower. The purge air is vented through the purge valve to

the atmosphere.

The pilot valves SV1 or SV2 are either energized or de-energized

depending on which tower is on stream (drying). If SV2 is energized, the

LEFT tower is drying and if SV1 is energized, the RIGHT tower is drying.

6.2 MOISTURE INDICATOR

The moisture indicator is in the center of the panel. The moisture

indicator is a clear plastic tube filled with moisture sensing crystals. A

sample of outlet air is directed through the indicator.

The crystals will change colors from PINK (indicating wet air) to

BLUE (indicating dry air) as the dew point of the air changes from

O

F to -40OF.

+20

FIGURE 6B PNEUMATIC SCHEMA TIC for DRYERS WITH CYCLE SAVER OR EMCON II

Pneumatic schematic shown above for units equipped with CYCLE

SAVER.

Pneumatic schematic shown above for units equipped with PLC controls

featuring EMCON II.

PAGE 13

USING THE STANDARD CONTROL SECTION 7

7.1 STANDARD CONTROL

The STANDARD CONTROL is a compact NEMA 4X control box. It has the

following features:

• Dryer Status LEDs

- POWER ON - L/R TOWER DRYING

- RUN - L/R TOWER REGENERATING

- HOLD - DRYER PURGING

- SWITCHING FAILURE

The Dryer Status LEDs are located on the front panel of the control box.

Figure 7A shows the location of each. Note: There is a Red LED located

on the inside of the control box. This LED flashes on and off indicating

the timer is active.

Start the dryer per SECTION 5.1. When the Left tower is pressurized and on

line drying the process air, the corresponding LEFT TOWER DRYING LED is

illuminated. When the right tower is pressurized and on line drying the

process air, the corresponding RIGHT TOWER DRYING LED is illuminated.

The DRYER PURGING LED is illuminated when the corresponding purge

exhaust valve is open. During repressurization this LED will not be illuminated. Repressurization occurs for approximately 20 seconds just before

tower changeover. The operation timing sequence of the dryer is shown in

Figure 7C TIMING CHART FOR STANDARD CONTROL.

FIGURE 7A CONTROL BOX FRONT PANEL

POWER ON

HOLD

LEFT

STOP

RUN

SWITCHING FAILURE

TOWER DRYING

TOWER REGENERATING

RUN

RIGHT

SWITCHING FAILURE:

When there is a switching failure, the LED will be lit. This will energize the

contacts shown in Figure 4C. The contacts can be wired for remote

annunciation. To reset the Switching Failure Alarm press the Run button

on the control box front panel.

HOLD FEATURE:

For Low load or Static pressure conditions, the hold contacts shown on

Figure 4C can be wired to an auxiliary set of normally closed contacts on

the compressor starter. This will stop the cycling of the dryer and

repressurize both towers of the dryer, until there is demand on the

compressor. The Hold LED will light, if the dryer is wired as described and

the compressor is not running.

7.2 SETTING THE CYCLE TIME

Reference Figure 7B:

The setting for the time cycle is a 5 min/half cycle. For the half cycle

time setting, the switches indicated for DS1 (2, 5, 7, & 8) as shown in

the CYCLE TIME DETAIL have been factory set by pushing the

switches up. The values for these switches are (256, 32, 8, & 4) sec.,

so when added together equal 300 sec or 5 min. WE DO NOT

RECOMMEND a time cycle setting below 2 min/half cycle. For this

half cycle time setting, the switches that need to be pushed up are DS1

(4, 5, 6, & 7) their values are (64, 32, 16, & 8) sec. so when added

together equal 120 sec or 2 min.

The setting for the pressurization time is 20 sec. For the pressurization time setting, the switches indicated for DS2 (2 & 4) as shown in

the CYCLE TIME DETAIL have been factory set by pushing the

switches up. The values for these switches are (16 & 4) sec., so when

added together equal 20sec. WE DO NOT RECOMMEND CHANG-

ING THIS SETTING.

DRYER PURGING

FIGURE 7B CYCLE TIME DETAIL

5

6

FTS

ALARM

The setting for the alarm time is 96 sec. For the alarm time setting,

the switches indicated for DS2 (5 & 6) as shown in the CYCLE TIME

DETAIL have been factory set by pushing the switches up. The values

for these switches are (64 & 32) sec., so when added together equal

96 sec. WE DO NOT RECOMMEND CHANGING THIS SETTING.

NOTE: THE ALARM TIME SETTING NEEDS TO BE LESS THAN

THE HALF CYCLE TIME SETTING OR THIS WILL NEGATE

THE ALARM FUNCTION.

Operating this dryer on the 4 minute cycle will more than

double the wear on the dryer components. To reduce wear on

the dryer, operate the dryer on the 10 minute cycle if the -40OF

dew point is acceptable.

IMPORTANT

FIGURE 7C TIMING CHART FOR STANDARD CONTROL

PAGE 14

USING THE CYCLE SAVER CONTROL SECTION 8

8.1 CYCLE SAVER CONTROL

The CYCLE SAVER control uses a printed circuit board. It is housed

in a NEMA 4X fiberglass enclosure. It has the following features:

- POWER SWITCH

- POWER ON LED

- CYCLE MODE PUSHBUTTON

- FIXED MODE LED

- AUTO MODE LED

The Dryer Status LEDs are located on the front panel of the control

box. Figure 8A shows the location of each. Note: There are six

other LEDs located on the inside of the control box. Reference

SECTION 8.5.

Start the dryer per SECTION 5.1. When the left tower is pressurized

and on line drying the process air, the corresponding LEFT TOWER

DRYING LED will be lit. When the right tower is pressurized and on

line drying process air, the corresponding RIGHT TOWER LED is

illuminated. The operation timing sequence of the dryer is shown in

Figure 8B TIMING CHART FOR CYCLE SAVER.

- ENERGY SAVINGS LED

- SWITCHING FAILURE LED

- RESET PUSHBUTTON

- L/R TOWER DRYING LEDS

- L/R TOWER REGENERATING LEDS

8.2 SETTING THE CYCLE MODE

Pressing the Cycle Mode Pushbutton will alternate between the FIXED

and AUTO modes. This will light either the Fixed or Auto Mode LED.

8.2-1 OPERATING THE DRYER IN THE FIXED MODE

When operating the dryer in the FIXED MODE, press the Cycle

Mode Pushbutton until the Fixed Mode LED is lit. The dryer will not

utilize the ENERGY SAVINGS feature.

The fixed cycle is a normal 10 minute cycle. The dryer changes

towers every five minutes. The dryer goes through a normal tower

changeover sequence (repressurization, tower changeover,

depressurization).

The SWITCHING FAILURE ALARM is operational in both the

FIXED and AUTO modes.

8.2-2 OPERATING THE DRYER IN AUTO MODE

When operating the dryer in the AUTO MODE, press the Cycle

Mode Pushbutton until the Cycle Mode LED is lit.

The dryer will operate in the start up cycle for the first 20 minutes of

operation at every start up. After the start up cycle has been

completed, the dryer will operate in the mode that the Cycle Mode is

set (FIXED or AUTO).

In the Auto Mode, the length of time that a tower is in the drying

stage is controlled by the humistat set point adjustment on the

printed circuit board.

8.2-2A ENERGY SAVINGS

At the end of a normal regeneration stage, if the tower humistat

indicates a good dew point, ENERGY SAVINGS has been

activated. If the dew point is not low enough to activate ENERGY

SAVINGS, the dryer will switch towers.

When ENERGY SAVINGS is activated, the ENERGY SAVINGS

LED is illuminated. The purge exhaust valve on the regenerating

tower is closed and that tower comes up to full line pressure. No

purge air will be exhausted at this time.

The tower that was in the drying stage will remain on line and

drying the process air until the dew point rises to the set point of

the humistat.

The maximum time a tower can stay in energy savings is four

hours. This is to prevent channeling of the desiccant under very

low flow conditions.

FIGURE 8A CYCLE SA VER CONTROL BOX

PAGE 15

USING THE CYCLE SAVER CONTROL SECTION 8

LEFT TOWER PRESSURE (PS1)

RIGHT TOWER PRESSURE (PS2)

8.3 FAILURE TO SWITCH ALARM

The FAILURE TO SWITCH ALARM is operational in

the FIXED and AUTO modes.

The dryer is continuously being monitored for

switching failure. Two pressure switches monitor the

pressure in the desiccant towers. If pressure is

present in the tower that should be in the regenerating stage, the alarm is activated. The printed circuit

board gives the dryer 90 seconds to depressurize

after tower changeover before the alarm is activated.

If one or both of the pressure switches fail, the

alarm is NOT activated, but the dryer is switched into

a 10 minute fixed cycle.

When the alarm is activated, the FAILURE TO

SWITCH LED is illuminated. The alarm does not

stop the dryer from cycling. The FAILURE TO

SWITCH ALARM is a latching alarm. Once the

problem causing the switching failure is corrected,

the FAILURE TO SWITCH RESET PUSHBUTTON

must be pressed to reset the alarm. If the alarm is

reset and the problem is not corrected, the alarm will

be re-activated after 90 seconds.

The switching failure alarm will activate when:

• The inlet transfer valve does not change

positions and does not direct the process flow

through the proper tower.

• The purge exhaust valve does not open on the

regenerating tower or if tower pressure in the

regenerating tower does not drop below 40 psig.

• The purge exhaust valve does not close on the

regenerating tower to allow repressurization.

FIGURE 8B TIMING CHART FOR CYCLE SAVER

The GENERAL ALARM contact is closed when this

alarm is activated.

8.4 GENERAL ALARM

The general alarm contact was provided for the customer to wire the

dryer’s alarm into a main control room, or to a warning light or horn.

The contact is a normally open dry contact. The contact is closed if

the SWITCHING FAILURE ALARM has been activated. The contact

will only reset if the alarm condition is corrected.

8.5 PRINTED CIRCUIT BOARD (LEDs)

The Humidity Indication LED (RED) is on when the humidity is above

the set point.

The SV1 Indication LED (GREEN) is on when the valve is energized.

The SV2 Indication LED (GREEN) is on when the valve is energized.

The SV3 Indication LED (GREEN) is on when the valve is energized

The PS1 Indication LED (GREEN) is on when the switch is closed.

The PS2 Indication LED (GREEN) is on when the switch is closed.

Note: These LEDs are located on the inside of the control box on

the printed circuit board. Figure 8C illustrates the LEDs locations.

FIGURE 8C CYCLE SAVER PRINTED CIRCUIT BOARD

PAGE 16

USING THE EMCON II CONTROL SECTION 9

9.1 EMCON II CONTROL

The EMCON II control is programmable logic

controller (PLC) based. It is housed in a NEMA 4X

fiberglass enclosure.

The EMCON II control has the following features:

• Power Push-button/Light

• Cycle Selector Switch Fixed/Auto

• Energy Saving Activated Light

• Tower Status Lights

Left and Right Tower Drying

Left and Right Tower Regenerating

• Failure To Switch Alarm Light/Reset Push-button

• High Humidity Alarm Light/Reset Push-button

The Tower Status Lights are used to indicate which

tower is on line drying the process air and which

tower is regenerating.

The FAILURE TO SWITCH ALARM LIGHT is

illuminated when the Failure To Switch Alarm is

activated. The light is also a push-button which

resets the alarm.

The HIGH HUMIDITY ALARM LIGHT is illuminated

when the High Humidity Alarm is activated. The

light is also a push-button which resets the alarm.

FIGURE 9A EMCON II CONTROL BOX

9.2 SETTING THE CYCLE SELECTOR

SWITCH

The Cycle Selector Switch is used to switch the

dryer cycle. When the switch is set to the FIXED

MODE, the dryer will operate on a 10 minute

cycle. When the switch is set to the AUTO

MODE, the dryer cycle is controlled by the PLC,

the tower dew point controller and the outlet dew

point controller.

When the dryer is operated in the AUTO MODE and the dew point

controllers allow the dryer to operate in an extended cycle, the

ENERGY SAVINGS ACTIVATED LIGHT is activated.

9.2-1 OPERATING THE DRYER IN FIXED MODE

To operate the dryer in the FIXED MODE, set the CYCLE SELECTOR SWITCH to the FIXED position. The dryer will not utilize the

ENERGY SAVINGS feature.

The fixed cycle is a normal 10 minute cycle. The dryer changes

towers every five minutes. The dryer goes through a normal tower

changeover sequence (repressurization, tower changeover,

depressurization).

ENERGY SAVINGS, the dryer will switch towers.

When ENERGY SAVINGS is activated, the ENERGY SAVINGS

ACTIVATED light will be illuminated. The purge exhaust valve on

the regenerating tower is closed and that tower comes up to full

line pressure. No purge air will be exhausted at this time.

The tower that was in the drying stage will remain on line and

drying the process air until the dew point rises to the set point of

either humistat.

The maximum time a tower can stay in energy savings is four

hours. This is to prevent channeling of the desiccant under very

low flow conditions.

The SWITCHING FAILURE ALARM and the HIGH HUMIDITY

ALARM are operational in both the FIXED and AUTO modes.

9.2-2 OPERATING THE DRYER IN AUTO MODE

To operate the dryer in the AUTO MODE, set the CYCLE SELECTOR SWITCH to the AUTO position.

The dryer will operate in the start up cycle for the first 20 minutes of

operation at every start up. After the start up cycle is completed,

the dryer will operate in the mode that the CYCLE SELECTOR

SWITCH is set (FIXED or AUTO).

In the auto mode, the length of time that a tower is in the drying

stage is controlled by the microprocessor and both the tower and

outlet humistats.

9.2-2A ENERGY SAVINGS

At the end of a normal regeneration stage, if both the outlet and

tower humistats indicate good dew points, ENERGY SAVINGS is

activated. If the dew points are not low enough to activate

9.2-2B DEW POINT CALIBRATION CYCLE

When the dryer is in the calibration, cycle it will switch towers

every 2.5 minutes. By reducing the drying cycle, the inlet

moisture load on the towers will be decreased. This will try to

push the drying mass transfer zone lower in the desiccant bed.

If the dew point of either tower stays high continuously for five

consecutive drying cycles on that tower, the microprocessor will

start short cycling the dryer. The dryer will remain in the

calibration cycle until the tower dew point meter detects a good

dew point in each tower for at least 10 seconds of each drying

stage.

If the outlet dew point rises above the set point of the outlet

humistat any time after the 20 minute start up cycle, the dryer will

be switched into the calibration cycle for a minimum of 20

minutes, even if the outlet dew point returns to a good dew point

(below the humistat set point).

If the outlet dew point remains above the humistat set point

PAGE 17

USING THE EMCON II CONTROL SECTION 9

continuously for 15 minutes on either tower,

the HIGH HUMIDITY ALARM is activated.

The HIGH HUMIDITY ALARM is a latching

alarm. Before the alarm can be reset, the

dryer must operate for one complete cycle

with the outlet dew point below the outlet

humistat set point. Then the HIGH

HUMIDITY ALARM LIGHT/PUSH-BUTTON

can be pressed to clear the alarm condition.

9.3 FAILURE TO SWITCH ALARM

The FAILURE TO SWITCH ALARM is

operational in the FIXED and AUTO modes.

Two pressure switches monitor the pressure in

the desiccant towers. If pressure is present in

the tower that should be in the regenerating

stage, the alarm is activated. The microprocessor gives the dryer 90 seconds to depressurize after tower changeover before the alarm

is activated.

If one or both of the pressure switches fail, the

alarm is NOT activated, but the dryer is

switched into a 10 minute fixed cycle.

When the alarm is activated, the FAILURE TO

SWITCH LIGHT/Push-button is illuminated.

The alarm does not stop the dryer from cycling.

The FAILURE TO SWITCH ALARM is a

latching alarm. Once the problem causing the

switching failure is corrected, the FAILURE TO

SWITCH LIGHT/PUSH-BUTTON must be

pressed to reset the alarm. If the alarm is reset

and the problem is not corrected, the alarm will

be re-activated after 90 seconds.

FIGURE 9B TIMING CHART FOR EMCON II

The switching failure alarm will activate when:

• The inlet transfer valve does not change

positions and does not direct the process

flow through the proper tower.

• The purge exhaust valve does not open

on the regenerating tower or if the tower

pressure in the regenerating tower does not

drop below 30 psig.

• The purge exhaust valve does not close

on the regenerating tower to allow

repressurization.

The GENERAL ALARM contact is closed when

this alarm is activated.

LEFT TOWER PRESSURE (PS1)

RIGHT TOWER PRESSURE (PS2)

9.4 HIGH HUMIDITY ALARM

The HIGH HUMIDITY ALARM is operational in the FIXED and

AUTO modes. The alarm is disabled while the dryer is in the 20

minute start up cycle. When it is activated the dryer will continue

to operate.

The HIGH HUMIDITY ALARM is a latching alarm condition. To

turn off the light the reset button must be pushed. The GENERAL ALARM contacts are closed when this alarm is activated.

FIXED MODE

After the 20 minute start up cycle, if the outlet dew point

remains above the humistat set point continuously for 15

minutes on either tower, the HIGH HUMIDITY ALARM is

activated.

PAGE 18

AUTO MODE

If the outlet dew point rises above the set point of the outlet humistat

anytime after the 20 minute start up cycle, the dryer will be forced into

the calibration cycle for a minimum of 20 minutes. If the outlet dew

point remains above the humistat set point continuously for 15

minutes on either tower, the HIGH HUMIDITY ALARM is activated.

9.5 GENERAL ALARM

The general alarm contact was provided for the customer to wire the

dryer’s alarms into a main control room, or to a warning light or horn.

The contact is a normally open dry contact. The contact is closed if

either the HIGH HUMIDITY ALARM or the SWITCHING FAILURE

ALARM is activated. The contact will only reset if the alarm condition

has been corrected. There is an individual reset push-button for each

alarm.

SHUTDOWN SECTION 10

10.1 SHUTDOWN PROCEDURES

Close the inlet and outlet isolation valves (if installed). Open the bypass

valve (if installed). Let the dryer depressurize completely.

Turn the dryer off by either pressing the Stop button if the dryer has a

Standard Control Box or place the Power switch to the OFF

MAINTENANCE & TROUBLESHOOTING SECTION 11

11.1 DAILY INSPECTION

The following procedures should be performed daily:

• Check the dryer operating conditions, inlet temperature, ambient

temperature, inlet pressure and inlet flow.

• Monitor the dryer for one complete cycle. Make sure it is

operating properly.

• Check the purge mufflers. Purge air should be exhausting from

one of the valves. If oil is present, the dryer and air system may be

contaminated with lubricants.

• Inspect all upstream equipment, aftercoolers, separators, drains

and filters.

• Check the pressure differential indicator on all prefilters and

afterfilters. If the differential pressure is unacceptable, replace the

elements.

• Check the prefilter(s) for proper draining. If the prefilter is not

equipped with an automatic drain, it must be drained manually.

• Make sure that all bypass valves are tightly closed.

• Visually check the dryer and piping for damage.

•

Visually check the dryer moisture indicator (blue dry or pink wet)

position for the Cycle Saver or Emcon II Control Boxes.

If maintenance is to be preformed on the dryer, make sure the dryer is

completely depressurized. Tower pressure gauges must read 0

PSIG before removing any item on the dryer.

Remove any oil, dirt, or scale from the towers and inlet piping. Do

NOT weld, grind or sandblast the vessels as this voids the ASME

Certification. The vessels may be steam cleaned internally and

externally to remove dirt and oil.

CAUTION

Make sure that the towers are clean to prevent contamination of

new desiccant.

Replace plugs securely on desiccant drain ports. Apply pipe thread

sealant as necessary.

Make sure that the drain ports or hatch covers are installed before

attempting to fill the towers. Load desiccant through the desiccant

filler ports or hatches. REFER TO SECTION 3.1 FOR PROPER

DESICCANT AMOUNTS.

Reinstall the fill port plugs. Apply pipe thread sealant as necessary.

Follow START UP PROCEDURES IN SECTION 5.1 to start up and place

dryer in operation.

11.4 CONTROL AIR FILTER REPLACEMENT

Close the dryer inlet and outlet isolation valves (and open bypass

valve if provided). Turn off the power and completely depressurize

the dryer.

11.2 SCHEDULED MAINTENANCE

12 MONTHS

• Replace purge muffler elements

• Replace the control air filter element

24-60 MONTHS

• The desiccant in the towers should be replaced every two to five

years. The life of the desiccant will vary depending on the inlet air

conditions. Systems with excessive contaminants and/or inadequate filtration will decrease the life span of the desiccant

drastically. Once the desiccant is contaminated with lubricants, it

must be replaced.

DO NOT REMOVE THE FILTER BOWL FROM HEAD UNTIL

HOUSING IS COMPLETELY DEPRESSURIZED.

After all pressure is out of the dryer, grasp the filter bowl firmly, while

pushing the bowl upward turn it clockwise to remove it from the filter

head.

Remove the used element from the head. Discard used element

properly.

WARNING

11.3 DESICCANT REPLACEMENT

WARNING

DO NOT ATTEMPT TO REMOVE PLUGS OR HATCH COVERS

UNTIL ALL AIR PRESSURE IS OUT OF THE VESSEL. CHECK

ALL TOWER PRESSURE GAUGES, MAKING SURE THAT THEY

ARE AT 0 PSIG AND INCOMING PRESSURE HAS BEEN TURNED

OFF.

ALWAYS WEAR EYE PROTECTION AND GLOVES WHEN

HANDLING THE DESICCANT. DESICCANT DUST MAY CAUSE

EYE AND SKIN IRRITATION. AVOID BREATHING THE DUST

AND PROLONGED CONTACT WITH THE SKIN.

FIRST AID IN CASE OF EYE CONTACT, IMMEDIATELY FLUSH

EYES WITH PLENTY OF WATER FOR AT LEAST 15 MINUTES.

CONSULT A PHYSICIAN.

Take dryer off stream following the SHUTDOWN PROCEDURES IN

SECTION 10.

Remove the plugs from the desiccant drain and fill ports; drain old

desiccant from each tower.

Remove new element from the shipping package. Place the new

element into the filter head.

While pushing the bowl upward into the head turn the bowl

counterclockwise to lock it in place.

Following the start up procedures in SECTION 5.1 for the dryer,

place the dryer on stream.

PAGE 19

MAINTENANCE & TROUBLESHOOTING SECTION 11

11.5 TROUBLESHOOTING

The following check list should be used as a guideline for troubleshooting problems. Each of the topics will reference other sections in this

manual for further information.

IS THE POWER ON?

Check the main power source. For dryers equipped with the

Standard Control Box make sure the Run button is pressed and

the Run LED is lit. For dryers equipped with Cycle Saver or

Emcon II Control Boxes make sure the Power switch is in the

ON position.

IS THE SYSTEM PRESSURIZED?

The dryer is designed to operate at 60 to 150 psig. Check the

upstream equipment and any isolation or bypass valves.

IS THE DRYER CYCLING?

• IS THE FAILURE TO SWITCH ALARM ACTIVATED?

If the dryer is not cycling the FAILURE TO SWITCH ALARM

should be activated. The dryer should be checked to determine

the cause of switching failure.

• IS THERE CONTROL AIR PRESSURE, 60 PSIG MINIMUM.

Make sure that the dryer inlet pressure is above 60 PSIG. Check

the control air filter element and replace it with a new element.

Reference Section 11.4 for element replacement instructions.

• ARE THE PILOT VALVES FAULTY? (SV1 & SV2)

Reference Section 11.5-3 for procedures to check the

operation of the 3-way valves.

Replace any faulty 3-way valves.

• IS THE INLET VALVE FAULTY? Reference Section 11.5-5 for

procedures to check the operation of the inlet transfer valve.

Rebuild or replace the inlet valve as necessary. Reference

Sections 12.9 & 12.10 for valve breakdowns and repair kit details.

• IS A PURGE EXHAUST VALVE FAULTY? Reference Section

11.5-7 for procedures to check the operation of the purge

exhaust valves.

Rebuild or replace the faulty purge exhaust valve. Reference

Section 12.11 through 12.15 for valve breakdowns and repair kit

details.

• IS AN OUTLET CHECK VALVE FAULTY? Reference Section

11.5-8 for procedures to check the operation of the outlet check

valves.

If a valve is faulty, replace it.

• IS THE PURGE METERING VALVE SET PROPERLY? Reference

Section 5.2 for purge metering valve settings and procedures.

If the purge metering valve requires adjustment, follow the

procedures in Section 5.2.

ARE THE TOWERS DEPRESSURIZING?

•ARE THE PNEUMATIC LIMIT SWITCHES FAULTY?

Reference Section 11.5-6 for procedures to check the operation

of the pneumatic limit switches.

If either of the pneumatic limit switches are faulty, replace them

both.

IS THE VISIBLE MOISTURE INDICATOR BLUE? Reference

Section 6.2 for an explanation of operation for the moisture

indicator.

• IS THE BLEED ORIFICE FITTING OR SINTERED MUFFLER

ON THE MOISTURE INDICATOR CLOGGED?

Inspect the bleed orifice fitting and the sintered filter on the back

of the moisture indicator. They can be cleaned or replaced.

IS THE DEW POINT ACCEPTABLE?

• ARE THE INLET CONDITIONS WITHIN THE SPECIFICATIONS?

Reference Section 3.1 for the inlet conditions of the dryer.

Correct the inlet conditions if necessary. Excessive inlet flow will

greatly reduce the performance of the dryer.

IS THE DEW POINT ACCEPTABLE?

• IS THE PURGE METERING VALVE SET PROPERLY? Reference

Section 5.2 for purge metering valve settings and procedures.

If the purge metering valve requires adjustment, follow the

procedures in Section 5.2.

• WAS THE DESICCANT INSTALLED?

Make sure that the desiccant was installed. Reference Section

11.3 for desiccant replacement procedures.

• IS THE DESICCANT CONTAMINATED WITH LUBRICANTS?

Check the condition of the desiccant bed. If the bed is

contaminated with lubricants, replace the desiccant following

the procedures in Section 11.3.

• IS THE DESICCANT CONTAMINATED WITH MOISTURE?

If the dryer was operated under excessive inlet conditions, the

desiccant bed may be saturated with liquid moisture. Check

upstream equipment such as aftercoolers. Check the actual

inlet conditions, correct them and condition the bed following

the procedures in Section 5.3.

• ARE THE BYPASS VALVES OPEN OR LEAKING?

Check the valves (if installed). Repair or replace if faulty.

IS THE ENERGY SAVINGS BEING ACTIVATED?

(CYCLE SAVER AND EMCON II MODELS ONLY)

• IS THE CYCLE SELECTOR SWITCH SET IN THE "AUTO"

MODE?

The Cycle Selector must be set in the "AUTO" mode in order for

the dryer to activate the energy savings feature.

• IS THE DRYER BEING OPERATED AT THE MAXIMUM

OPERATING CONDITIONS? Reference Section 3.1 for rated

inlet conditions.

Little or no energy savings will occur if the dryer is being operated

at the maximum operating conditions.

• IS THE SOLENOID VALVE SV3 FAULTY? Reference Section

11.5-4 for procedures to check the operation of SV3.

If the valve SV3 is faulty replace it.

• ARE THE TOWER HUMISTAT AND SENSOR WORKING

PROPERLY?

Reference Section 11.5-9 for procedures to check the operation

of the sensor and humistat.

Check the sample cell isolation valve and the bleed orifice fitting.

If necessary, replace the bleed orifice fitting and/or the bleed

muffler.

• IS THE SAMPLE LINE DAMAGED OR PLUGGED?

Check the sample line following the procedures in Section 11.5-

10. Repair or replace the components as necessary.

11.5-2 CHECKING THE PROGRAMMABLE CONTROLLER

EMCON II MODELS ONLY:

The control system consists of three different control systems:

1. The programmable controller (PLC)

2. Input devices (24 volts DC components)

a. Pressure switches

b. Humistat(s)

c. Reset push-button(s)

d. Low voltage side of the Power ON/OFF Pushbutton

e. Cycle selector switch

3. Output components

a. Pilot valve(s)

b. Light(s)

c. General alarm contact

The PLC controls the cycling of the dryer. The program logic is

stored on an electrically erasable EEPROM. Loss of power to the

PLC will not cause loss of the logic program.

PAGE 20

MAINTENANCE & TROUBLESHOOTING SECTION 11

THE POWER ON/OFF PUSH-BUTTON ON THE CONTROL BOX

WARNING

DOES NOT TURN THE POWER OFF TO THE PLC.

The PLC is wired so it is energized when power is supplied to the

control box, even if the power push-button is in the off position.

This is to prevent loss of retentive counter memory. The counters

are used to monitor run time and cycle life of components. The

retentive memory will hold the data safely for at least 30 days. The

information stored in memory is accessible with a HMI Kit (not

supplied).

11.5-2A (Optional) HMI KIT

EMCON II MODELS ONLY:

A Human Machine Interface is available for this dryer. The

monitor can be fastened to the PLC. It will allow the operator to

view the counters and registers in the program on the PLC.

With the purchase of this HMI kit, a list of the counters and

registers will be included. With the list and monitor, the operator

can find out the following information:

• How long the dryer has been in operation.

• How many times the valves have been activated.

• How many times the HIGH HUMIDITY ALARM has been

activated.

• How many times the FAILURE TO SWITCH ALARM has been

activated.

• How long the dryer has operated in ENERGY SAVINGS.

• How long the dryer has operated in the CALIBRATION

CYCLE.

The PLC has power, run and error LEDs. If there is power to the

PLC, the power LED will be illuminated. If the power LED is not

illuminated, check the power supply to the PLC. If there is power

present, the PLC is faulty.

If the error LED is lighted, an error has occurred in the program

logic. Consult factory.

Reference Sections 11.5-2B and 11.5-2C for procedures to verify

that the input and output devices are operating properly. If the

devices are operating properly, the PLC will need to be replaced.

11.5-2B TESTING THE INPUT DEVICE

EMCOM II MODELS ONLY:

The PLC supplies a 24 volt DC signal to the input devices and alarm

contacts. If the input device is activated, it will cause that input LED

to light. The input LEDs are labeled 0 to 7.

The input devices can be easily tested for proper operation. With

power to the control box, set the Power Push-button (PB1) to the

OFF position, then the ON position. This should cause LED 0 to

light. Pushing the failure to switch light (PB2) should cause LED 3 to

light. Pushing the high humidity light (PB3) should cause LED 5 to

light. The fixed/auto selector switch can be tested as follows. In the

fixed mode, LED 6 should be off. In the auto mode, LED 6 should be

lighted. If these input devices do not function as described, they

should be replaced.

The pressure switches monitor the failure to switch option. The

inputs from the pressure switches (PS1, PS2) can be observed while

the dryer is in operation. Any time there is more than 30 psig

pressure in the left tower, pressure switch (PS1) should cause LED 1

to light. Any time there is more than 30 psig pressure in the right

tower, pressure switch (PS2) should cause LED 2 to light. If the

pressure switches do not respond as previously explained, replace

them.

To check input 4 or 7, follow the procedures in Section 11.5-9 for

calibrating the outlet humistat.

If the input devices are activated and LED is not illuminated, take a

voltage measurement across the input terminals. If the device is

faulty, it must be replaced. If the device is working properly, check

the wiring from the PLC. If the wiring and device are good, the PLC

is faulty and should be replaced. Reference Figure 11I DRYER

WIRING DIAGRAM for wiring and terminal numbers.

The run LED must be on for the PLC to operate. If the run LED is

off, turn the main power to the dryer off and on again. The PLC

should reset and the run LED should turn on. If the LED does not

turn on, consult factory.

If the power and run LEDs are on and the error LED off, the PLC

may still be faulty. To verify that the input and output of the PLC

are operating properly, the input and output devices must be

checked. Figure 11B lists the inputs and outputs on the PLC and the

corresponding devices.

FIGURE 11A PROGRAMMABLE CONTROLLER DETAIL

INPUT

LEDs

OUTPUT

LEDs

NOT

USED

FIGURE 11B INPUT AND OUTPUT LIST (EMCON II)

INPUT DEVICES

0 PB1

1 PS1

2 PS2

3 PB2

4 CDP1

5 PB3

6 SW1

7 CDP2

10 SPARE

NOTE:

The general alarm contact is a normally open dry contact which is wired to terminals #5 and

#6.

The lights are run off 120 volts AC which is reduced to 24 volts DC through resistors

and diodes on the printed circuit board.

The control relays (CR1, CR2, CR3) are mounted on the board which is mounted to the

back of the control box door. CR2 and CR3 are the control relays which give you the

general alarm contact.

OUTPUT DEVICES

0 SV1 & PL7

1 SV2 & PL8

2 SV3 & CR1

3 PL2 & CR2

4 PL3 & CR3

5 PL4

6 SPARE

11.5-2C TESTING THE OUTPUT DEVICES

EMCON II MODELS ONLY:

The microprocessor’s outputs are 120 volts AC. The output LEDs

are labeled 0 to 5. If the output’s LED is illuminated, that output is

supplying 120 volts AC to its component.

To check outputs 0 through 2, follow the procedures in Section

11.5-3.

PAGE 21

MAINTENANCE & TROUBLESHOOTING SECTION 11

There is no easy way to check outputs 3 through 5. Output 3 can

be checked by causing a switching failure. Output 4 can be

checked by creating a false outlet dew point by setting the outlet

dew point humistat lower than the factory setting and allowing the

dryer to go into HIGH HUMIDITY ALARM. Output 5 can be

checked when either output 3 or 4 are checked. Before attempt-

ing this procedure, consult the factory.

11.5-3 CHECKIING THE 3-WAY PILOT VALVES

(SV1 & SV2)

All 3-way pilot valves have manual override buttons on the top of

the valve. To test SV1 and SV2 do the following:

For dryers with the Standard Control Box make sure the Stop button

is pressed and the dryer is pressurized. For dryers with Cycle Saver

or Emcon II Control Boxes make sure the Power switch is in the

OFF position and the dryer is pressurized. Both towers should be

at full line pressure Pushing the manual override of SV1 should

cause the left tower to depressurize. Allow the left tower to come

back up to full line pressure. Pushing the manual override of SV2

should cause the right tower to depressurize. If this does not

happen, replace that solenoid valve.

EMCON II MODELS ONLY:

With the Power push-button (PB1) in the ON position, the fixed/

auto selector switch in the fixed mode, and the dryer pressurized,

monitor the outputs on the microprocessor. If output 0 is lighted,

SV1 should be activated, the left tower should be depressurized

and the right tower should be pressurized and drying the compressed air. If output 1 is lighted, SV2 should be activated, the

right tower should be depressurized and the left tower should be

pressurized and drying your compressed air. These two operations

can be monitored in one 10 minute fixed cycle.

If the above responses are not observed, first check to see if power

is being supplied to each solenoid valve when the corresponding

output LED on the PLC is lighted. Check the wiring between the

PLC and solenoid valves. If the PLC is not supplying power to the

valve when the LED is illuminated, replace the PLC. If the valve

has power but does not operate, it must be replaced.

TOWER CHANGEOVER

11.5-4 CHECKING THE SOLENOID VALVE

(SV3) TOWER SAMPLE SELECT

CYCLE SAVER AND EMCON II MODELS ONLY:

Solenoid valve (SV3) is used to switch the sample line to the tower

that is on line drying your compressed air. It then feeds a sample of

air to the tower dew point humistat's sample cell.

With the dryer pressurized, the Power push-button in the ON

position, and the dryer in the fixed mode, remove the bleed orifice

from the tower dew point humistat’s sample cell. Monitor the air

flow from the sample cell for one complete 10 minute cycle. There

should be full line pressure coming from that sample cell for the

whole cycle. If air pressure to the sample cell is lost at any part of

the cycle, check the sample line filters and the solenoid valve

(SV3). Repair or replace as necessary.

11.5-5 CHECKING THE INLET TRANSFER VALVE

The inlet transfer valve will not switch positions unless the pressure

in both desiccant towers is nearly equal. At tower changeover, the

regenerating tower should approach full line pressure before the

inlet valve will switch. Make sure that there are no leaks in the

piping or fittings. Make sure that the purge exhaust valves are

closing and that the purge metering valve is properly set.

The exhaust ports on top of the pilot valves (SV1 & SV2) should not

have air exhausting through them continuously. If air is exhausting

continuously through either of the exhaust ports, the inlet transfer

valve is faulty and should be rebuilt or replaced.

To test the inlet transfer valve for proper operation, turn off the

power, isolate and depressurize the dryer.

Remove the two pilot lines to the inlet valve. The pilot lines are

connected to the outside flanges of the valve. Using an air nozzle

and clean air, pressurize one of the ports. Observe the position

indicator. It should move in the direction of the port that is being

pressurized. No air should be exhausting from the other port.

Pressurize the other port. The valve should move to the other side.

If the valve does not move or air is being exhausted out of the port

that is not pressurized, the inlet transfer valve must be rebuilt or

replaced. Reference Section 12.9 & 12.10 for valve breakdown and

parts listing.

11.5-6 CHECKING THE PNEUMATIC LIMIT SWITCHES

Mounted on the inlet transfer valve is a set of 3-way pneumatic limit

switches. These switches control the pilot air to open and close the

purge exhaust valves.

When a pneumatic limit switch is activated by the inlet transfer valve

position indicator, pilot air is supplied to the purge exhaust valve on

that side of the dryer.

To check the pneumatic limit switches, allow the dryer to cycle.

Check the pilot line to the purge exhaust valve on the side of the

activated limit switch. If no air is present, the limit switch must be

replaced. The limit switches are sold in sets only.

FIGURE 13C INLET TRANSFER VALVE DETAIL

PAGE 22

MAINTENANCE & TROUBLESHOOTING SECTION 11

11.5-7 CHECKING THE PURGE EXHAUST VALVES

The purge exhaust valves are normally closed. They can be checked

by removing the pilot air lines to them. The valves should be closed.

Using an air nozzle and clean air, pressurize the purge exhaust

valves. The valves should open when pressurized. If valve does not

open and close, it should be rebuilt or replaced. See Section 12.11

through 12.15 for valve breakdown and parts listing.

11.5-8 CHECKING THE OUTLET CHECK VALVES

This dryer uses two check valves for outlet air control. If either of the

outlet valves fails, one of the following will occur:

• A large amount of air will purge from one tower

• The outlet air flow will be blocked

If either happens, the faulty check valve must be replaced.

11.5-9 CALIBRATING THE HUMISTAT

CYCLE SAVER AND EMCON II MODELS ONLY:

The set point for the humistat is calibrated by a set plug.

Unplug the cable from the sample cell. Plug the set plug into the end

of the humistat cable.

For dryers equipped with the Cycle Saver Control Box turn the

humistat set point adjustment located on the printed circuit board until

the Humidity Indication LED is lit. This will calibrate the dew point

meter. Reference Figure 11E.

For dryers equipped with the Emcon II Control Box turn the potentiometer on the humistat board until you see the LED input light turn on.

This will calibrate the dew point meter. Reference Figure 11D.

If you get no response from the humistat set point adjustment or the

potentiometer with the set plug in, first check the cable connection. If

the cable and set plug are good, replace the printed circut board

(Cycle Saver) or the humistat board (Emcon II).

Re-install the filter. Carefully push the assembly back into the tower

and tighten the bushing into the coupling. DO NOT FORCE THE

ASSEMBLY. An application of pipe sealant to the bushing threads

may be necessary. Reconnect the line at the tee fitting.

FIGURE 11D HUMISTAT DETAIL FOR EMCON II

DRYERS EQUIPPED WITH EMCON II HAVE TWO HUMISTATS AND SAMPLE CELLS.

FIGURE 11E HUMISTAT DETAIL FOR CYCLE SAVER

NOTE

The sensor can be tested by removing it from the sample cell and

plugging it into the cable. With the sensor in the ambient air, the

humistat should turn on the corresponding LED. Place the sensor

back into the sample cell and allow compressed air to pass over it.