Van Air Systems High Dew Point Alarm Box User Manual

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

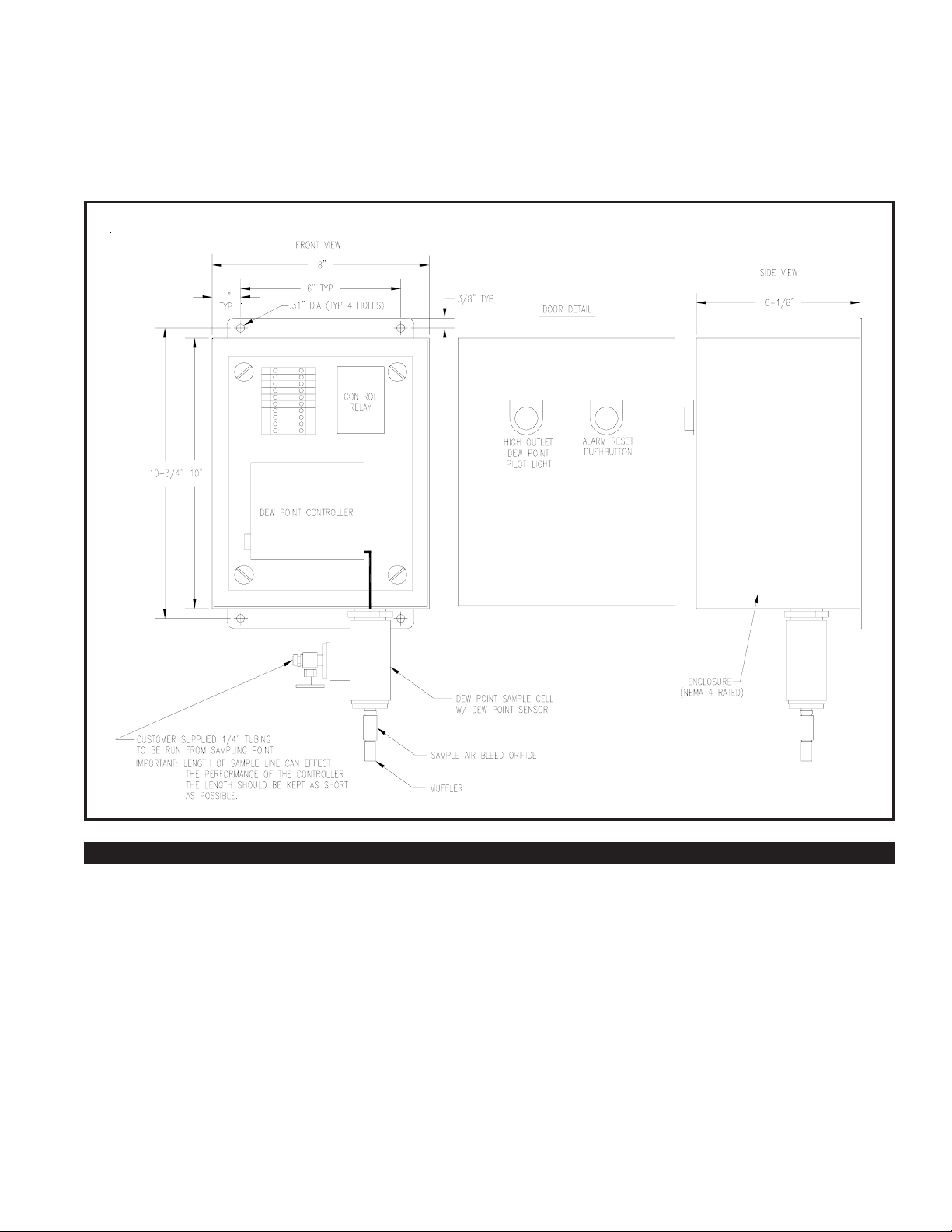

FIGURE 2A DIMENSIONS

FEBRUARY 2006

32-0283

FOR

HIGH DEW POINT ALARM BOX

P/N 46-2064

SPECIFICATIONS AND DIMENSIONS SECTION 1

WEIGHT ................ 25 LBS

DIMENSIONS........ see Figure 2A

MOUNTING .......... see Figure 2A

ENCLOSURE

• Enamel painted Steel Enclosure

• Nema 4 Rated

• Continuous Hinged

DEW POINT CONTROLLER (humistat)

RANGE OF CONTROL ................... 4% to 98% Relative Humidity

(NOTE: Set plug and sensor determine actual operating range)

INPUT POWER ................................. 115V-1PH-56/60Hz

OUTPUT MODE ............................... SPDT. relay, 1 amperes,

noninductive maximum

DEW POINT SENSOR (hygrosensor)

RANGE OF CONTROL ................... 1.4% to 6% RH @ 80oF

TYPE ................................................. DUNMORE-TYPE lithium

chloride element.

SET POINT PLUG

SET POINT ....................................... approx. 0OF Dew point @ 80oF

DEW POINT SAMPLE CELL

• Sample line isolation needle valve

• Sample cell bleed orifice fitting

MAXIMUM SAMPLE AIR PRESSURE ............. 150 PSIG

SAMPLE LINE CONNECTION SIZE ............... 1/4" tube fitting

ALARM OUTPUT CONTACT

ELECTRICAL RATING .................... 115V-1PH-60Hz, 10 ampere

OUTPUT MODE ............................... Normally open contact,

latching (push-button must be pressed to reset)

LIGHT & RESET PUSH-BUTTON

• High Dew Point Light (red)

• Alarm Reset Push-button

PAGE 1

SAFETY SECTION 2

2.1 HANDLING

DO NOT DROP THE UNIT.

DO NOT LIFT ALARM BOX BY THE SAMPLE CELL

2.2 INSTALLATION

BEFORE STARTING INSTALLATION PROCEDURES, TURN OFF

POWER AND DEPRESSURIZE THE PIPING WHERE SAMPLE LINE

IS TO BE INSTALLED, TO PREVENT INJURY. SERIOUS PERSONAL

INJURY MAY RESULT IF THIS SAFETY RULE IS NOT FOLLOWED.

WHEN INSTALLING AND OPERATING THIS EQUIPMENT, COMPLY

WITH THE NATIONAL ELECTRICAL CODE AND ALL APPLICABLE

FEDERAL, STATE, AND LOCAL CODES.

WHEN INSTALLING THIS ALARM BOX, MAKE SURE THAT THE

NEMA RATING IS APPLICABLE TO THE INSTALLATION.

MAKE SURE THAT ALL CUSTOMER SUPPLIED WIRING AND

ELECTRICAL DEVICES ARE PROPERLY SIZED TO HANDLE THE

ELECTRICAL REQUIREMENTS OF THE UNIT.

2.3 OPERATION

USE THIS DEVICE FOR COMPRESSED AIR ONLY.

2.4 MAINTENANCE

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THE

SAMPLE UNIT WHILE IT IS PRESSURIZED.

TURN OFF MAIN POWER TO THE CONTROL BEFORE

STARTING MAINTENANCE PROCEDURES.

INSTALLATION SECTION 3

3.1 INST ALLING THE UNIT

Mount the enclosure on a flat stable surface, where the alarm light

can be easily seen. The unit should be installed as close as

possible to the sample point. Allow enough space to open door and

to connect the sample line. Reference FIGURE 2A for mounting

hole dimensions.

3.2 INST ALLING THE DEW POINT SAMPLE LINE

A 1/4" sample line must be connected to the isolation needle valve

on the sample cell.

CAUTION

LENGTH OF SAMPLE LINE CAN EFFECT THE PERFORMANCE

OF THE CONTROLLER. THE LENGTH SHOULD BE KEPT AS

SHORT AS POSSIBLE

The sample source should be less than 150 PSIG. Do not use a

pressure regulating device between the source and the sample cell.

The sample source should be free of contaminants and high

temperatures (over 100oF).

Use copper or stainless steel tubing for the sample line. DO NOT

USE PLASTIC TUBING.

DO NOT CONNECT SAMPLE LINE TO A SOURCE EXCEEDING

150 PSIG.

DO NOT CONNECT SAMPLE LINE TO A SOURCE CONTAINING

CONTAMINANTS AND/OR HIGH TEMPERATURES.

3.3 ELECTRICAL CONNECTIONS

WHEN INSTALLING AND OPERATING THIS EQUIPMENT,

COMPLY WITH THE NATIONAL ELECTRICAL CODE AND ALL

APPLICABLE FEDERAL, STATE, AND LOCAL CODES.

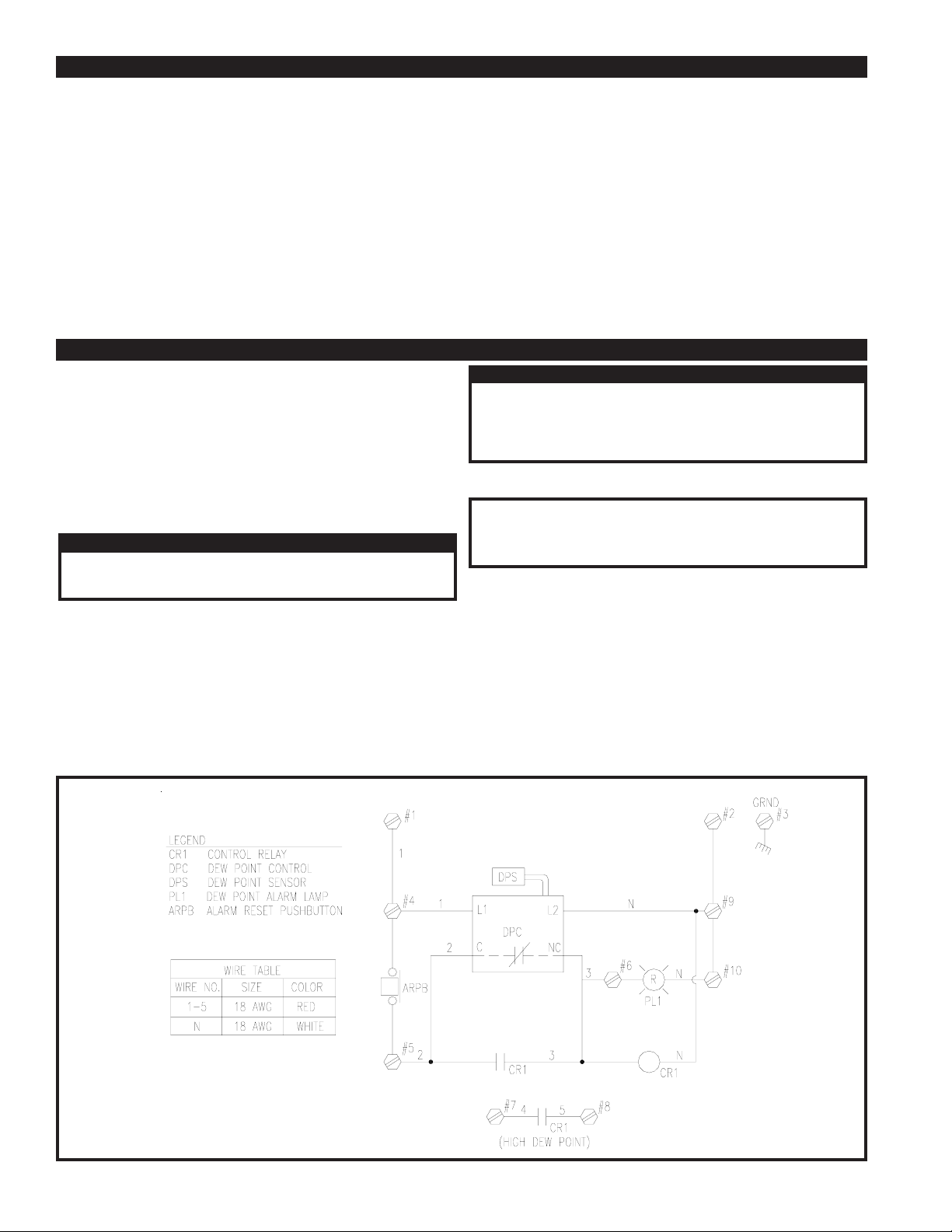

3.3-1 POWER SUPPLY

The unit requires a power source of 115V-1PH-60Hz for

operation. Make the necessary electrical connections from the

power source to the unit. Reference FIGURE 3A, Wiring Diagram.

3.3-2 ALARM OUTPUT CONTACT

The alarm output contact is labeled as terminals numbered 7 & 8

inside the enclosure. The contacts can be used to activate a

device in the event of an alarm condition.

If the alarm output contacts are to be used, make the necessary

wiring connections from the alarm enclosure terminal strip to the

remote device.

CAUTION

IMPORTANT

FIGURE 3A WIRING DIAGRAM

PAGE 2

Loading...

Loading...