OCTOBER 2012

2950 Mechanic Street

Lake City, PA 16423 USA

Phone: 800-840-9906

Fax: 814-774-3482

www.vanairsystems.com

INSTALLATION, OPERATION & MAINTENANCE MANUAL

FOR

PREP-40 PORTABLE COMPRESSED AIR DRYER SYSTEM

model

FR-400 (P/N 81-2441)

REV A

WARNING

READ ALL INFORMATION IN THIS MANUAL BEFORE INSTALLATING OR OPERATING THE DRYER SYSTEM.

BEFORE STARTING MAINTENANCE PROCEDURES, TURN OFF THE MAIN POWER TO THE DRYER SYSTEM

AND COMPLETELY DEPRESSURIZE THE UNIT TO PREVENT PERSONAL INJURY.

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THIS DRYER SYSTEM WHILE IT IS PRESSURIZED.

NEVER OPERATE THIS DRYER SYSTEM ABOVE THE RATED OPERATING CONDITIONS. OPERATION

ABOVE SPECIFIED CONDITIONS WILL RESULT IN DECREASED PERFORMANCE, POSSIBLE DAMAGE TO

THE UNIT AND/OR PERSONAL INJURY.

PAGE 1

HANDLING SECTION 1

1.1 HANDLING INSTRUCTIONS

DO NOT LIFT THE DRYER SYSTEM BY PIPING OR CONTROL BOX

WARNING

SUPPORT BARS. THESE COMPONENTS ARE NOT DESIGNED TO

HOLD THE WEIGHT OF THE DRYER. PERSONAL INJURY AND/OR

EQUIPMENT DAMAGE MAY RESULT.

Lift the dryer system by the lifting lugs on both vessels in combination with

the lifting lugs on the pre-cooler supports, or by the base using a fork lift

truck.

If the unit is to be lifted by an overhead device, attach the lifting chains or

cables to the vessel lifting lugs and the lifting lugs on the pre-cooler

supports. Make sure that the chains or cables are clear of all piping and

dryer components.

If outside storage is required, the unit MUST BE adequately covered

to prevent rain or snow from accumulating on the dryer system. The

unit must be placed on a paved surface to keep it out of standing

water and mud.

1.3 EQUIPMENT CHECK

Inspect the dryer system for any damage that may have occurred

during shipment. Inspect all ttings, piping connections, fasteners,

etc. for loose connections. Also check gauges and lights for cracks

or breakage.

IF DRYER SYSTEM WAS DAMAGED DURING SHIPMENT:

(1) NOTIFY CARRIER IMMEDIATELY AND FILE A CLAIM.

(2) CONSULT FACTORY BEFORE OPERATING THE DRYER

SYSTEM.

1.2 STORAGE INSTRUCTIONS

If the unit is to be placed in storage before it is installed, it should be stored

indoors and covered with a tarpaulin to keep it clean. The location should

be free from corrosive gasses and extreme humidity, which can cause

damage to the unit.

SAFETY SECTION 2

2.1 HANDLING

DO NOT LIFT THE DRYER SYSTEM BY PIPING OR CONTROL BOX

SUPPORT BARS. THESE COMPONENTS ARE NOT DESIGNED TO

HOLD THE WEIGHT OF THE DRYER SYSTEM. PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE MAY RESULT.

LIFT THE DRYER SYSTEM BY THE LIFTING LUGS ON BOTH

VESSELS IN COMBINATION WITH THE LIFTING LUGS ON THE

PRE-COOLER SUPPORTS, OR BY THE BASE USING A FORK LIFT

TRUCK.

MAKE SURE THAT ALL LIFTING EQUIPMENT IS CAPABLE OF

SUPPORTING THE WEIGHT OF THE DRYER SYSTEM.

DURING NORMAL OPERATION, THE INLET PIPING MAY REACH

TEMPEREATURES OF 150°F. CONTACT WITH THE PIPING MAY

RESULT IN SERIOUS PERSONAL INJURY.

DO NOT OPERATE THIS DRYER SYSTEM ABOVE THE MAXIMUM

RATED WORKING PRESSURE.

OPERATING CONDITIONS FOR PROPER PERFORMANCE OF THIS

DRYER SYSTEM ARE DIFFERENT THAN MAXIMUM OPERATING

CONDITIONS FOR THE VESSELS. BE SURE TO CHECK THE

DRYER SYSTEM OPERATING CONDITIONS. SEE SECTION 3.1.

USE THIS DRYER SYSTEM FOR COMPRESSED AIR ONLY.

2.2 INSTALLATION

THESE ASME CODE VESSELS MUST BE PROTECTED BY

PRESSURE RELIEF VALVES. Refer to OSHA 1910.169 Par. b, Sub.

Par (3) and ASME Boiler and Pressure Vessel Code, Section VIII,

Division 1, UG-125 through UG-136. Also comply with all state and

local codes.

WHEN INSTALLING AND OPERATING THIS EQUIPMENT, COMPLY

WITH THE NATIONAL ELECTRICAL CODE AND ALL APPLICABLE

FEDERAL, STATE, AND LOCAL CODES.

ALWAYS WEAR EYE PROTECTION, GLOVES AND A RESPIRATORY

PROTECTIVE DEVICE WHEN HANDLING THE DESICCANT.

DESICCANT DUST MAY CAUSE EYE AND SKIN IRRITATION. AVOID

BREATHING THE DUST AND PROLONGED CONTACT WITH THE SKIN.

FIRST AID IN CASE OF EYE CONTACT WITH DESICCANT DUST;

IMMEDIATELY FLUSH THE EYES WITH PLENTY OF WATER FOR AT

LEAST 15 MINUTES. CONSULT A PHYSICIAN.

2.3 OPERATION

DO NOT OPERATE DRYER SYSTEM IF EITHER VESSEL IS LEAKING.

IMMEDIATELY TAKE THE DRYER SYSTEM OUT OF SERVICE.

DO NOT OPERATE DRYER SYSTEM IF THE AFTERCOOLER CORE,

OR OTHER COMPONENTS ARE LEAKING. IMMEDIATELY TAKE THE

DRYER SYSTEM OUT OF SERVICE AND FIX OR REPLACE THE

LEAKING COMPONENT.

ANY DAMAGE TO THE VESSELS CAN MAKE THEM UNSAFE TO

USE. INSPECT OUTSIDE AND INSIDE OF VESSELS REGULARLY

FOR CORROSION AND ANY DAMAGE (I.E., DENTS, GOUGES OR

BULGES). IF DAMAGED, TAKE OUT OF SERVICE IMMEDIATELY.

AIR FROM THIS DRYER SYSTEM IS NOT SUITABLE FOR

BREATHABLE AIR SYSTEMS WITHOUT FURTHER TREATMENT.

DO NOT OPERATE THIS DRYER SYSTEM IF EITHER VESSEL

HAS BEEN DAMAGED BY FIRE. TAKE OUT OF SERVICE

IMMEDIATELY AND NOTIFY YOUR CERTIFYING AUTHORITY.

FILTER AND SEPARATOR DISCHARGE MAY CONTAIN

COMPRESSOR LUBRICANTS. COMPLY WITH ALL

REGULATIONS CONCERNING THEIR DISPOSAL.

2.4 MAINTENANCE

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THE

DRYER SYSTEM WHILE IT IS PRESSURIZED. TURN OFF MAIN

POWER TO THE DRYER SYSTEM AND DEPRESSURIZE THE

DRYER SYSTEM COMPLETELY BEFORE STARTING

MAINTENANCE PROCEDURES.

DO NOT WELD OR GRIND EITHER VESSEL. IT WILL NOT BE

SAFE TO OPERATE. (Note: Any uncertied alteration to the

vessels VOIDS the ASME Code Certication and the Warranty.)

NEVER REMOVE THE FAN GUARD WHILE THE AFTERCOOLER

IS OPERATING. CONTACT WITH THE ROTATING FAN BLADES

MAY RESULT IN SERIOUS PERSONAL INJURY.

PAGE 2

SPECIFICATIONS SECTION 3

3.1 SPECIFICATIONS

WEIGHT.............................. 1790 lbs (with desiccant installed)

DIMENSIONS...... ............... See SECTIONS 3.2

IN/OUT CONNECTION...... 2" 4-lug coupling (Dixon #AM28)

VESSELS (desiccant towers)

Construction ................... Manufactured to the ASME CODE, Section VIII, Division 1.

Vessels stamped "U" symbol.

Design Pressure ............. 175 PSIG

Design Temperature ....... -20OF TO 300OF

PIPING

Threaded ttings: ........... ASME B16.3

Threaded unions: .......... ASME B16.39

Flanges: ......................... ASME B16.5

Pipe: .............................. Carbon steel, Schedule 40

VALVES

Inlet ............................... Proprietary 3-Way piloted shuttle valve

Outlet .............................. Two (2) Check valves, buttery type

Purge .............................. Normally closed, air operated type

CONTROL AIR FILTER

Construction ................... Aluminum housing

PREFILTER/AFTERFILTER

Construction ................... Aluminum housing

PRE-COOLER

Core. ............... ................Aluminum

Fan..................................Polypropylene blades with Aluminum hub

Fan Guard ......................Steel

SEPARATOR/PREFILTER

Construction ................... Aluminum housing

ELECTRICAL

Standard 115 Volt ........... 115-120V/1PH/50-60Hz

DESICCANT

Material ........................... Activated Alumina, 1/8" (2-5 MM) Bead type

Quantity Per Tower..........215 LBS

OPERATING CONDITIONS

Inlet Air Pressure ............................ MAX 175 PSIG

Inlet Air Temperature ...................... MAX 150OF

Ambient Air Temperature................ MIN 40OF..........MAX 120OF

SYSTEM RATED INLET CONDITIONS

Inlet Air Pressure ............................ 100 PSIG

Inlet Air Temperature ...................... 150OF (based on 85°F ambient and 15°F approach from the pre-cooler)

Relative Humidity (saturation) ........ 100% RH

DRYER FLOW CAPACITIES (SCFM) at various pressures (1000F)

60 PSIG 80 PSIG 100 PSIG 110 PSIG 125 PSIG 140 PSIG 150 PSIG 160 PSIG 175 PSIG

FR-400 260 330 400 417 441 465 479 494 514

PAGE 3

SPECIFICATIONS SECTION 3

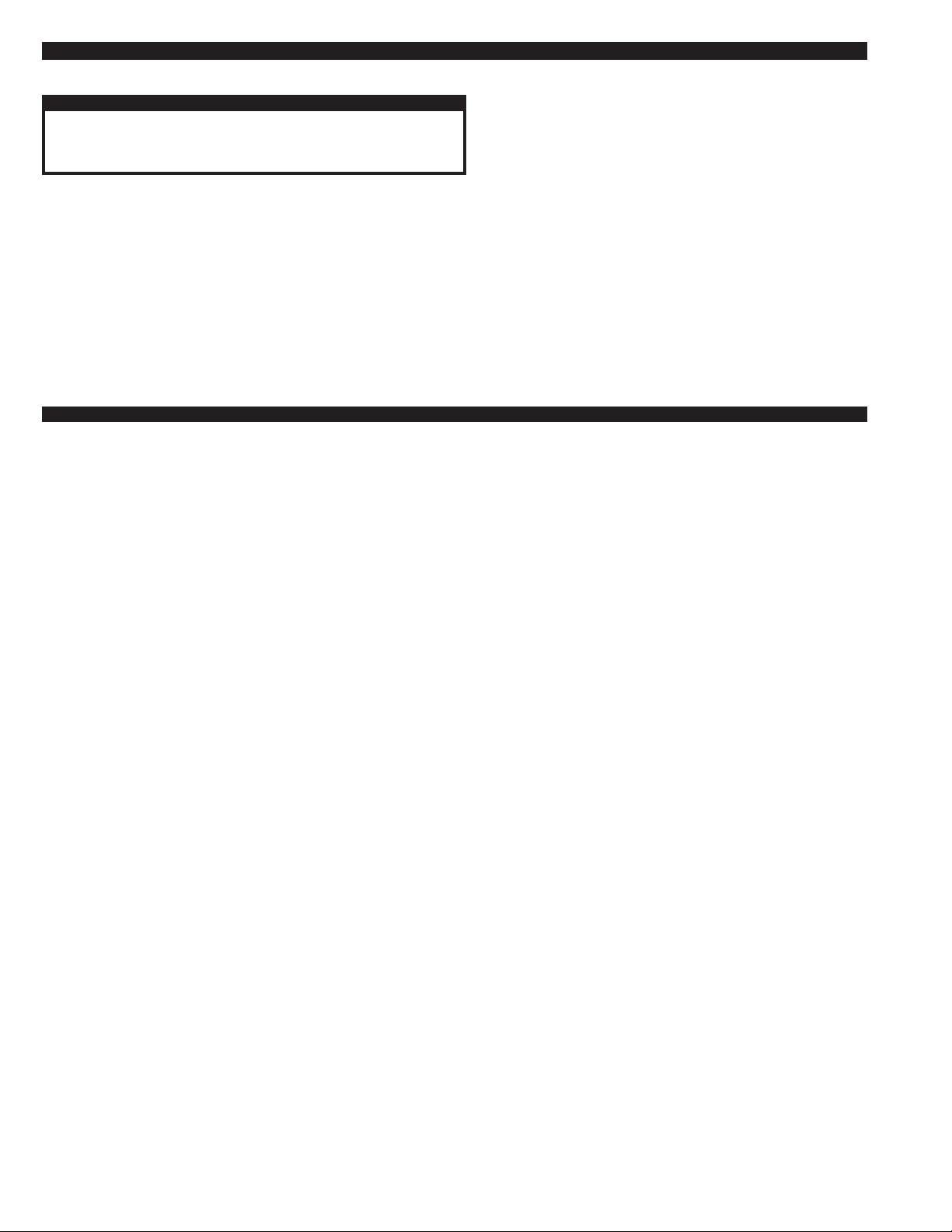

3.2 DIMENSIONS

PAGE 4

INSTALLATION SECTION 4

4.1 LOCATION

WARNING

DO NOT INSTALL THIS DRYER SYSTEM IN AN ENVIRONMENT

OF CORROSIVE CHEMICALS, EXPLOSIVE GASSES, POISONOUS

GASSES, OR SATURATED STEAM HEAT.

Locate dryer system in a protected, well vented area where ambient

temperatures are between 40oF and 120oF. Allow sufcient clearance

over and around the dryer system for access to desiccant ll and drain

ports and controls. Refer to SECTION 3.2 for dryer dimensions.

If this dryer system must be installed where ambient temperatures are

below 40oF, insulation and heat tracing must be properly installed on

the inlet piping, separator, prelter, purge exhaust line and the

desiccant towers to prevent freezing of the equipment.

Position the dryer system in the upright position on a solid, level,

vibration free surface capable of supporting the dryer system’s weight.

Refer to SECTION 3.1 for dryer system specications.

The dryer system should not be located in extremely dirty areas where

airborne contaminants can accumulate on the dryer system. If this

cannot be prevented, the dryer system should be cleaned periodically.

An accumulation of dirt on the precooler will greatly reduce its

efciency. Accumulated dirt may also cause the inlet transfer valve to

fail.

4.2 DESICCANT INSTALLATION

The desiccant was factory installed in both towers before the dryer

shipped.

4.3 ELECTRICAL CONNECTIONS

SERIOUS PERSONAL INJURY AND DAMAGE TO THE

DRYER SYSTEM WILL OCCUR IF THE DRYER SYSTEM IS

CONNECTED TO A POWER SOURCE OTHER THAN THE

VOLTAGE LISTED ON THE DATA TAG.

Connect the dryer system power cord to a 115V/1PH/60Hz power

source capable of supplying a minimum of 2 AMPS.

WARNING

4.4 INSTALLING THE PURGE MUFFLERS

Purge mufers were shipped separately. They should NOT be installed

until the dryer system has been operated for several hours. From

desiccant installation, some dust may be present in the desiccant

towers. Operating the dryer system with the mufers installed immediately after the towers have been lled with the desiccant or during

initial start up may cause the mufers to clog. See SECTION 5.6 for

purge mufer installation.

4.5 FILL LUBRICATOR WITH OIL

The lubricator is located in the air line between the regulator and the

pre-cooler air motor. Fill the lubricator with Pneumatic Lubricating Oil

SAE10 AD220 (Van Air p/n 26-7032 quart).

4.6 CONNECT DRAIN LINES

Connect the automatic drains for the separator/prelter and the prelter

to an appropriate collection container. Filter and separator/prelter

discharge may contain compressor lubricants. Comply with all regulations concerning their disposal.

4.7 CONNECTING THE INLET AND OUTLET

The inlet and outlet of this dryer system are equipped with 2" 4-lug

couplings. Connect the inlet and outlet air hoses to the dryer system.

Remember to use SAFETY CLIPS.

PAGE 5

START UP SECTION 5

5.1 START UP

WARNING

BEFORE STARTING THIS DRYER SYSTEM, FOLLOW THE

INSTALLATION INSTRUCTIONS AND PROCEDURES COMPLETELY.

SERIOUS PERSONAL INJURY CAN RESULT IF INSTRUCTIONS ARE

NOT CAREFULLY AND COMPLETELY FOLLOWED.

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THIS

DRYER SYSTEM WHILE IT IS PRESSURIZED.

Make sure that the Power switch is in the OFF position.

If the dryer system is being started up for the rst time or after the

desiccant has been changed, the purge mufers must be removed.

See SECTION 2.2 for safety precautions concerning the desiccant

dust.

WARNING

WHEN OPERATING THIS DRYER SYSTEM WITHOUT THE

MUFFLERS INSTALLED, USE HEARING PROTECTION.

Pressurize the air system.

Place the Power switch in the ON position. One tower will already be

pressurized. The other tower will depressurize. The purge valve on

the tower that is not pressurized will be open, air should be exhausting

from the mufer.

The dryer system is equipped with a purge metering valve. The setting

should be checked per SECTION 5.2 before placing the dryer system

on stream.

Set the control pressure regulator per SECTION 5.3.

Set the lubricator and regulator for the pre-cooler air motor per

SECTION 5.4.

Condition the desiccant bed per SECTION 5.5 before placing the dryer

system on-stream.

Install the purge mufers per SECTION 5.6.

5.2 ADJUSTING THE PURGE FLOW

IMPORTANT

NEVER OPERATE THE DRYER SYSTEM WITH THE PURGE

METERING VALVE CLOSED. IF THE VALVE IS CLOSED, THE

TOWERS WILL NOT REPRESSURIZE AND SWITCHING FAILURE

WILL OCCUR.

DO NOT ADJUST THE PURGE METERING VALVE ABOVE OR BELOW

THE RECOMMENDED SETTING FOR THE OPERATING CONDITIONS

OF THIS INSTALLATION. IMPROPER SETTING MAY CAUSE POOR

DRYER SYSTEM PERFORMANCE AND/OR

EXCESSIVE USE OF PROCESS AIR.

The Prep-40 dryer system is equipped with a purge metering valve and

gauge. Reference SECTION 3.2 for Location. The gauge indicates the

back pressure on the purge ow orice, which is in direct correlation to

the purge ow in SCFM.

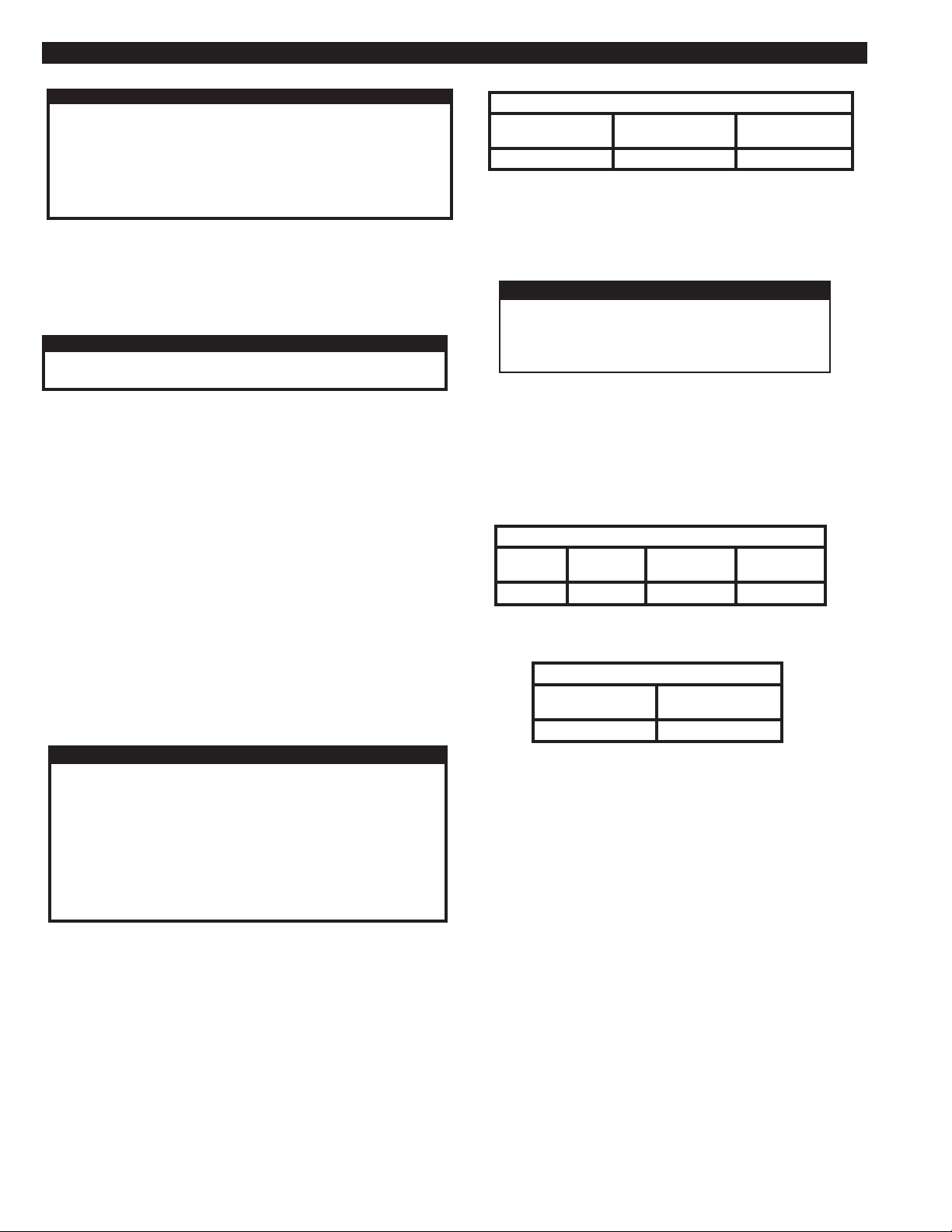

FIGURE 5B REQUIRED PURGE FLOW

DRYER

MODEL

FR-400

PURGE

FLOW

72.0 SCFM

PURGE FLOW

GAUGE SETTING

39 PSIG

5.3 SETTING THE CONTROL PRESSURE REGULATOR

The control pressure regulator is located in line with the control lter and

it is used to protect the pneumatic control components. This regulator

should be set at 115 PSIG.

CAUTION

DO NOT OPERATE THIS DRYER SYSTEM WITH

THE CONTROL AIR PRESSURE REGULATOR

ABOVE 115 PSIG TO PREVENT DAMAGE TO

THE PNEUMATIC CONTROLS.

5.4 ADJUST THE REGULATOR & LUBRICATOR

The regulator and lubricator for the pre-cooler air motor must be properly

set to ensure trouble-free air motor operation.

The regulator is used to set the speed of the pre-cooler fan. The regulator

is factory set using a tachometer and a clean precooler core. See FIGURE

5C. As the core becomes dirty, a higher regulator pressure setting may

be required to maintain the fan speed.

FIGURE 5C FACTORY REGULATOR SETTING

DRYER

MODEL

FR-400

Set the lubricator per FIGURE 5D.

SETTING

(PSIG)

22

FIGURE 5D LUBRICATOR SETTING

DRYER

MODEL

FR-400

AIR USAGE

(SCFM)

15

DROPS PER

MINUTE

FAN SPEED

(RPM)

1725

1

5.5 CONDITIONING THE DESICCANT BED

To condition the desiccant bed, the dryer system is operated without any

outlet ow while the towers regenerate with purge air.

Observe the dryer system for several cycles to make sure that it is

operating properly.

At initial start up or after extended shutdowns (over one month), the

dryer system may take 24 to 48 hours of continuous operation for the

bed to be conditioned. Moisture that has accumulated on the desiccant

bed should be removed before the dryer system is placed on stream.

Once the moisture indicator on the dryer system turns blue, the desiccant

bed is ready. The Prep-40 dryer is now ready for operation.

The purge ow can be adjusted for the operating conditions.

This dryer system was shipped with the purge ow set for the rated inlet

ow at 100 PSIG. Reference SECTION 3.1 for rated ow. This setting

should be correct for most installations. Before placing the dryer system

on stream, check the purge metering valve setting.

FIGURE 5B shows the purge ow, in SCFM, and the pressure setting

required for each model. This ow is required to properly regenerate

the desiccant beds.

PAGE 6

START UP SECTION 5

5.6 INSTALLING THE PURGE MUFFLERS

To reduce the sound level during purge and tower depressurization,

this dryer system was supplied with mufers for installation on the

purge exhaust valves.

Mufers were shipped separately. They should NOT be installed until

the dryer system has been operated for several hours. From

desiccant installation, some dust may be present in the desiccant

towers. Operating the dryer system with the mufers installed

immediately after the towers have been lled with the desiccant or

during initial start up may cause the mufers to clog.

Operate the until NO desiccant dust is visible at the purge valves.

Then the mufers can be installed.

IMPORTANT

The dryer system must be operated for several hours without

the mufers after the towers have been lled with desiccant.

This will prevent the mufers from becoming clogged.

FIGURE 5A PURGE MUFFLER INSTALLATION

OPERATION SECTION 6

6.1 DESCRIPTION OF OPERATION

The Prep-40 is a portable skid mounted system consisting of a strainer,

pre-cooler, separator, prelter, heatless regenerative dryer and an

afterlter. Wet warm air enters the pre-cooler where it is cooled to a

temperature approcahing ambient. Water is condensed out during

this cooling process. The saturated air and the liquid water proceed to

the inlet of the separator where the liquid water is removed. Then the

saturated air enters the coalescing lter where additional oil and liquid

water is removed. Then the air enters the heatless twin tower dryer where

it moves upward through the desiccant bed. The moisture is adsorbed

onto the surface of the desiccant. Dry air exits the heatless dryer and

passes through the general purpose particulate after-lter where residual

particulate is removed.

This package dryer will take saturated air at 100 psig @ 150°F and reduce

the mositure content to -40°F pressure dew point.

6.2 HEATLESS DRYER PRINCIPLE OF OPERATION

The Heatless Regenerative Air Dryer utilizes the pressure swing principle

of operation. The desiccant bed in one tower dries the air stream while

the desiccant bed in the other tower is regenerated.

A purge of dry air is used for tower regeneration. It is taken from the

outlet of the dryer.

The dryer is equipped with a purge metering valve to allow the correct

amount of dry air to ow into the regenerating tower. The heat created

during adsorption of moisture in the drying tower is retained in the desiccant

bed and increases the moisture removal capacity of the purge air.

The timing cycle of the dryer is controlled by two 3-way pilot valves.

A patented shuttle valve system is used to repressurize, changeover,

and depressurize the towers. The inlet transfer valve is controlled by

the pilot valves.

To achieve maximum performance from this dryer, it should be operated

continuously. Operating this dryer for single shift periods may result in

varied outlet dew point performance.

The dryer operation consists of four stages; REPRESSURIZATION,

CHANGEOVER/DEPRESSURIZATION, DRYING and

REGENERATION.

6.2-1 REPRESSURIZATION STAGE

Repessurization occurs in the off-stream (regenerating) tower.

Repessurization must occur before tower changover to reduce shock

to the desiccant and the possibility of downstream pressure spikes.

Pilot valve SV1 or SV2 de-energizes causing the purge valve on the

off-stream (regenerated) tower to close. The purge air, which was

vented to atomosphere earlier in the cycle, is now used to

repressurize the off-stream tower.

6.2-2 CHANGEOVER/DEPRESSURIZATION STAGE

Tower changeover occurs after the off-stream (regenerated) tower is

pressurized. The SmartRelay signals SV1 or SV2 to open causing pilot

air to be supplied to the opposite side of the inlet transfer valve and

cause exhaust valve to open on regenerative tower. The inlet transfer

valve shuttle will move to the side that has pilot pressure placing the

regenerated tower on-stream. The tower that was on line and drying

the process air is now off-stream.

When the inlet transfer valve changes position, the position indicator

will move.

6.2-3 DRYING AND REGENERATION STAGE

One tower is on-stream (pressurized) drying process air. The process

air passes through the desiccant bed, which adsorbs moisture from

the air.

The regeneration stage of the off-stream tower occurs at the same time

as the drying stage in the on-stream tower. During the regeneration

stage, a percentage of dry air is directed through the desiccant bed

of the offstream tower. The purge air is vented through the purge

valve to the atmosphere.

If pilot valve SV2 is energized, the LEFT tower is drying and if pilot

valve SV1 is energized, the RIGHT tower is drying.

PAGE 7

OPERATION SECTION 6

6.3 MOISTURE INDICATOR

The moisture indicator is in the center of the panel. The moisture

indicator is a clear plastic tube lled with moisture sensing crystals. A

sample of outlet air is directed through the indicator.

The crystals will change colors from PINK (indicating wet air) to

BLUE (indicating dry air) as the dew point of the air changes from

+20OF to -40OF.

6.4 DRYER CONTROLS

The control is housed in a NEMA 4X enclosure and it has the following

features:

- Power switch

- Power On light

- Fail to Switch light

- Alarm Reset pushbutton

- Hour Meter

See Figure 6B for control box door.

6.4-1 SMART RELAY:

The dryer cycle is controlled by a SmartRelay, two solenoid valves

and two pressure switches. The dryer timing chart is shown in

FIGURE 6C. The SmartRelay has a battery back-up that will hold

the program in memory safely for 2 years.

6.4-2 SWITCHING FAILURE:

When there is a switching failure (failure of control solenoid valves

SV1 & SV2; failure of exhaust valve to open; or clogging of exhaust

mufer), the Fail to Switch LED will be lit. This will energize the

Alarm Contacts shown in FIGURE 10D. The contacts can be wired

for remote annunciation. To reset the Switching Failure Alarm press

the Alarm Reset Pushbutton on the front of the control box. If the

condition causing the alarm is not corrected, the alarm will

re-activate in 90 seconds.

6.4-3 HOUR METER:

The Hour Meter is located on the front of the control box. It is used

to log the total number of hours that the Prep-40 dryer system has

been in operation.

FIGURE 6A PNEUMATIC SCHEMATIC

PAGE 8

OPERATION SECTION 6

FIGURE 6B CONTROL BOX DOOR

FIGURE 6C DRYER TIMING CHART

= ON

PAGE 9

SHUTDOWN SECTION 7

Shut off the air supply to the Prep-40 dryer system. Turn the dryer

system off by placing the Power Switch to the OFF position.

Manually drain the separator/prelter by lifting the manual override

collar, on the separator/prelter automatic drain, until no more uid is

discharged. Manually drain the prelter by lifting the manual override

collar, on the prelter automatic drain, until no more uid is discharged.

Open the ball valve on the afterlter and completely depressurize the

dryer system.

Disconnect the power supply to the dryer system.

If maintenance is to be preformed on the dryer system, make sure the

dryer system is completely depressurized. Tower pressure gauges

must read 0 PSIG before removing any item on the dryer system.

STORAGE SECTION 8

WARNING

DO NOT ATTEMPT TO REMOVE OR REPAIR ANY PART OF THE

SYSTEM UNTIL IT IS COMPLETELY DEPRESSURIZED.

SERIOUS PERSONAL INJURY MAY RESULT IF THIS SAFETY

RULE IS NOT FOLLOWED.

INSPECT VESSEL, INSIDE AND OUT, REGULARLY FOR

BULGES, CORROSION, DENTS, GOUGES OR LEAKS. IF

DAMAGED, REMOVE FROM SERVICE IMMEDIATELY AND

NOTIFY YOUR CERTIFYING AUTHORITY.

8.1 REMOVE THE PREP-40 FROM SERVICE

Shutdown the dryer system per SECTION 7.

Close the ball valve on the afterlter.

The pre-cooler air motor needs to be ushed to remove excessive

dirt, foreign particles, moisture and/or oil that accumulate in the air

motor during normal operation. Flushing helps to maintain proper

motor performance and extend service life.

8.3 CLEAN THE EXHAUST MUFFLER

Disassemble the exhaust mufer that was removed in STEP 8.2.

Clean the felt and reassemble the exhaust mufer.

Install the exhaust mufer on the air motor.

8.4 SET THE REGULATOR FOR THE AIR MOTOR

Set the regulator for the air motor per FIGURE 5C.

8.5 PREPARATION FOR STORAGE

Open the ball valve on the afterlter to completely depressurize

the Prep-40 system.

If long term storage is required, cover the inlet and outlet air

connections to prevent the accumulation of dirt and debris on the

piping.

8.6 STORAGE

Store the Prep-40 in location that is free from extreme humidity

and corrosive gasses, which can cause damage to the unit.

Perform Flushing procedure, per SECTION 8.2, when Prep-40 is

to be idle for more than 5 days, or if it is to be placed in storage.

Use only Van Air Flushing Solvent (p/n 26-7157). DO NOT use

kerosene or ANY other combustible solvents to ush the air

motor.

8.2 FLUSHING PROCEDURE

Remove the pipe plug in the air supply line near the air motor.

Remove exhaust mufer from air motor.

Spray ushing solvent (Van Air p/n 26-7157) into air motor through tee

for 5 to 10 seconds.

Rotate motor shaft/fan, by hand, for one minute in each direction.

Reinstall the plug in the tee and cover the exhaust port with a cloth.

You must wear eye protection for this step.

Restart the motor at a low pressure (approximately 10 PSIG) and run it

until there is no trace of solvent in the exhaust air.

Listen for changes in the sound of the motor. If the motor sounds

smooth, the Prep-40 is ready for storage. If the motor does not sound

like it is running smooth, the motor will need to be serviced.

PAGE 10

MAINTENANCE SECTION 9

9.1 DAILY INSPECTION

The following procedures should be performed daily:

• Check the dryer system operating conditions, ambient temperature

and inlet pressure.

• Monitor the dryer system for one complete cycle. Make sure it is

operating properly.

Make sure that the desiccant drain plugs are installed before

attempting to ll the towers. Load desiccant through the desiccant

ll ports. REFER TO SECTION 3.1 FOR PROPER DESICCANT

AMOUNTS.

Reinstall the ll plugs. Apply pipe thread sealant as necessary.

• Check the purge mufers. Purge air should be exhausting from

one of the valves. If oil is present, the dryer and air system may be

contaminated with lubricants.

• Inspect separator/prelter and prelter drains for proper draining.

• Check the pressure differential indicator on prelter and afterlter.

If the differential pressure is unacceptable, replace the elements.

• Visually check the dryer system and piping for damage.

• Visually check the dryer system moisture indicator (blue dry or pink

wet)

9.2 SCHEDULED MAINTENANCE

12 MONTHS

• Fill lubricator with oil

• Replace purge mufer elements

• Replace the control air lter element

• Replace the separator/prelter, prelter, and afterlter elements

• Clean the exterior of the pre-cooler

24-60 MONTHS

• The desiccant in the towers should be replaced every two to ve

years. The life of the desiccant will vary depending on the inlet air

conditions. Systems with excessive contaminants and/or

inadequate ltration will decrease the life span of the desiccant

drastically. Once the desiccant is contaminated with lubricants, it

must be replaced.

• Periodically the pre-cooler core should be cleaned internally if the

process air contains excesive amounts of lubricating uids.

9.3 DESICCANT REPLACEMENT

WARNING

DO NOT ATTEMPT TO REMOVE PLUGS UNTIL ALL AIR PRESSURE

IS OUT OF THE VESSEL. CHECK ALL TOWER PRESSURE

GAUGES, MAKING SURE THAT THEY ARE AT 0 PSIG AND

INCOMING PRESSURE HAS BEEN TURNED OFF.

ALWAYS WEAR EYE PROTECTION AND GLOVES WHEN

HANDLING THE DESICCANT. DESICCANT DUST MAY CAUSE

EYE AND SKIN IRRITATION. AVOID BREATHING THE DUST AND

PROLONGED CONTACT WITH THE SKIN.

FIRST AID IN CASE OF EYE CONTACT, IMMEDIATELY FLUSH

EYES WITH PLENTY OF WATER FOR AT LEAST 15 MINUTES.

CONSULT A PHYSICIAN.

Take dryer system off stream following the SHUTDOWN PROCEDURES

IN SECTION 7.

Remove the plugs from the desiccant drain and ll ports; drain old

desiccant from each tower.

Remove any oil, dirt, or scale from the towers and inlet piping. Do

NOT weld, grind or sandblast the vessels as this voids the ASME

Certication. The vessels may be steam cleaned internally and

externally to remove dirt and oil.

Follow START UP PROCEDURES IN SECTION 5.1 to start up and place

dryer in operation.

9.4 CONTROL AIR FILTER ELEMENT REPLACEMENT

Shutdown the dryer per Shut-Down Procedures SECTION 7.

Turn manual valve (petcock) on bottom of control air lter to ensure

that the dryer is completely depressurized.

WARNING

DO NOT REMOVE THE FILTER BOWL FROM HEAD UNTIL

HOUSING IS COMPLETELY DEPRESSURIZED.

After all pressure is out of the dryer, grasp the lter bowl rmly and

push upward while turning it counter-colckwise (as viewed from the

bottom) to remove it from the lter head. If prefered strap wrenches

can be used to remove bowl. Make sure that the bowl does not drop.

Remove the used element from element adaptor in lter head by

pulling down. Discard used element properly.

Remove new element from the shipping package. Check to make sure

that the o-ring is properly positioned in endcap and has been lightly

greased.

Grasp clean element by bottom endcap and push element onto

element adpater rmly, but do not force beyond normal stop.

Check o-ring in lter head. Replace if worn or damaged.

Clean and lubricate threads on bowl with light grease. This will

facilitate removal of bowl at next servicing.

Carefully raise lter bowl over element and screw into head, then

tighten. DO NOT OVERTIGHTEN.

Close manual drain valve (petcock).

Following the start up procedures in SECTION 5.1 for the dryer, place

the dryer on stream.

9.5 CLEANING THE EXTERIOR OF THE PRE-COOLER

The pre-cooler core should be cleaned regularly. Accumulation of dirt

or other contaminants shch as oils will greatly reduce the efciency of

the pre-cooler.

Normal accumulation of dirt can be removed by using compressed air

to blow off the core. If the core becomes contaminated with oil-laden

particles, it will need to be steam cleaned. Use extreme care when

cleaning the core as the aluminum ns can be easily damaged.

Make sure that the towers are clean to prevent contamination of

new desiccant.

Replace plugs securely on desiccant drain ports. Apply pipe thread

sealant as necessary.

PAGE 11

CAUTION

MAINTENANCE SECTION 9

9.6 CLEANING THE INTERIOR OF THE PRE-COOLER

The inside of the pre-cooler core should be cleaned periodically if the

process air has an excessive amount of lubricating uids. Excess

lubricating uids can build up on the inside of the core and greatly

reduce the efciency of the pre-cooler.

Shut down the dryer system per SECTION 7 and completely

depressurize the dryer system. Disconnect the core from the air

system.

The interior of the core can be cleaned by circulating a mild cleaning

solution through the core to remove the deposits. In most cases, a

mild alkaline solution such as OAKITE or equal is satisfactory. For

extreme conditions, it may be necessary to use a weak solution of

INHIBITED hydrochloric acid. Circulate the solution through the core

until it is clean. Once the core is clean, thouroughly rinse the core to

remove all traces of the cleaning solution before re-connecting it to the

air system.

9.7 REPLACING SEPARATOR/PREFILTER, PREFILTER,

AND AFTERFILTER ELEMENTS

Shutdown and depressurize dryer system per SECTION 7.

Disconnect drain line as required.

Remove lter bowl by turning it counterclockwise (as viewed from

below). Pull element from locator. Set bowl aside for use later.

9.8 CLEANING THE Y-STRAINER

Shutdown and depressurize dryer system per SECTION 7.

Remove the air supply hose from the dryer system inlet connection.

Remove the cap/plug from the strainer.

Clean the screen and Y-strainer body. Take care to remove all

debris that may have fallen out of the Y-strainer into the dryer

system piping.

Reinstall the screen and the cap/plug. Replace the gasket if

necessary. See SECTION 11.3 for part number.

Place the dryer system on-stream per SECTION 5.1.

Remove new element from packaging and make sure o-ring is in

place on element end cap. See SECTION 11.3 for replacement

element part number.

Install new element by pushing onto element locator on lter head.

Inspect the head to bowl o-ring for nicks and/or cracks. If nicks

or cracks are present, replace the o-ring. Re-install the o-ring in

the lter head. Check to make sure that the o-ring in the head

is in the proper position. Thread lter bowl into lter head and

tighten with strap wrench. Do not over tighten. Overtightening

could damage lter bowl or make it difcult to remove.

SEPARATOR/PREFILTER - Make sure the ball valve on bot-

tom of separator/prelter is open, so the auto drain will function.

Reconnect drain line to the auto drain.

PREFILTER - Make sure the ball valve on bottom of prelter is

open, so the auto drain will function. Reconnect drain line to

the auto drain.

AFTERFILTER - Make sure the ball valve on the bottom of the

lter is closed.

Place dryer system on stream per SECTION 5.1.

PAGE 12

TROUBLESHOOTING SECTION 10

10.1 TROUBLESHOOTING

The following check list should be used as a guideline for troubleshooting problems. Each of the topics will reference other sections in this

manual for further information.

IS THE POWER ON?

Check the main power source. Make sure the Power switch is in

the ON position.

IS THE SYSTEM PRESSURIZED?

The dryer system is designed to operate at 60 to 175 psig.

Check to make sure the air supply was connected to the dryer

system inlet.

Check the Differential Pressure indicator on the prelter. If the

needle is in the RED zone, replace the element.

IS THE DRYER CYCLING?

• IS THE FAILURE TO SWITCH ALARM ACTIVATED?

If the dryer system is not cycling the FAILURE TO SWITCH

ALARM should be activated. The dryer system should be

checked to determine the cause of switching failure.

• IS THERE CONTROL AIR PRESSURE, 60 PSIG MINIMUM?

Make sure that the dryer system inlet pressure is above 60 PSIG.

Replace control air lter element. Reference SECTION 9.4 for

element replacement instructions.

• IS THE Y-STRAINER PLUGGED?

If the Y-strainer is clogged, their may not be enough control air

pressure to operate the dryer system. Disassemble and clean the

Y-strainer per SECTION 9.8.

• DO THE SEPARATOR/PREFILTER, PREFILTER, &

AFTERFILTER ELEMENTS NEED CHANGED?

Check the differential pressure gauge on the prelter and

afterlter. If the needle on either gauge is in the red zone, replace

the element in that lter. Reference SECTION 9.7 for details.

• ARE THE PILOT VALVES FAULTY? (SV1 & SV2)

Reference SECTION 10.3 for procedures to check the operation

of the 3-way valves. Replace any faulty 3-way valves.

• IS THE INLET VALVE FAULTY?

Reference SECTION 10.4 for procedures to check the operation

of the inlet transfer valve.

Rebuild or replace the inlet valve as necessary. Reference

SECTION 11.3 for valve repair kit details.

• IS A PURGE EXHAUST VALVE FAULTY?

Reference SECTION 10.6 for procedures to check the operation

of the purge exhaust valves.

Rebuild or replace the faulty purge exhaust valve. Reference

SECTION 11.3 for valve repair kit details.

• IS AN OUTLET CHECK VALVE FAULTY?

Reference SECTION 10.7 for procedures to check the operation

of the outlet check valves.

If a valve is faulty, replace it.

• IS THE PU RGE METERING VALVE SET PROPERLY?

Reference SECTION 5.2 for purge metering valve settings and

procedures.

If the purge metering valve requires adjustment, follow the

procedures in SECTION 5.2.

• IS THE SMARTRELAY FUNCTIONING?

See SECTION 10.2 for explanation of Smart Relay operation.

IS THE VISIBLE MOISTURE INDICATOR BLUE?

Reference SECTION 6.3 for an explanation of operation for the

moisture indicator.

• IS THE BLEED ORIFICE FITTING OR SINTERED MUFFLER ON

THE MOISTURE INDICATOR CLOGGED?

Inspect the bleed orice tting and the sintered lter on the back

of the moisture indicator. They can be cleaned or replaced.

IS THE DEW POINT ACCEPTABLE?

• ARE THE INLET CONDITIONS WITHIN THE SPECIFICATIONS?

Reference SECTION 3.1 for the inlet conditions of the dryer

system.

Correct the inlet conditions if necessary. Excessive inlet ow will

greatly reduce the performance of the dryer system.

• IS THE PURGE METERING VALVE SET PROPERLY? Reference

SECTION 5.2 for purge metering valve settings and procedures.

Adjust purge metering valve as required.

• WAS THE DESICCANT INSTALLED?

Is there desiccant in the towers. Reference SECTION 9.3 for

desiccant replacement procedures.

• IS THE DESICCANT CONTAMINATED WITH LUBRICANTS?

Check the condition of the desiccant bed. If the bed is

contaminated with lubricants, replace the desiccant following the

procedures in SECTION 9.3.

• IS THE DESICCANT CONTAMINATED WITH MOISTURE?

If the dryer system was operated under excessive inlet conditions,

the desiccant bed may be saturated with liquid moisture. Check

upstream equipment such as aftercoolers. Check the actual

inlet conditions, correct them and condition the bed following the

procedures in SECTION 5.5.

• IS THE SEPARATOR/PREFILTER DRAINING PROPERLY?

Manually override the drain on the separator/prelter to ensure it

is not ooded.

• IS THE PREFILTER DRAINING PROPERLY?

Manually override the drain on the prelter to ensure it is not

ooded.

• IS THE FAN MOTOR ON THE PRECOOLER OPERATING?

Check the regulator setting for the air supply to the motor. See

SECTION 5.4 for details. Check the air motor and repair or

replace as necessary.

• ARE THE PURGE MUFFLERS CLOGGED?

Check the tower pressure gauge during the regeneration cycle. If

the tower pressure is above 5 PSIG, replace the purge mufers.

See SECTION 11.3 for part number.

• IS THE PRECOOLER DIRTY?

Inspect the outside of the core for dirt and /or oil deposits. If the

core is dirty, clean it per SECTION 9.5. If the outside of the core

is clean, the inside may be coated with oil. If the inside is coated

with oil the precooler will have to be cleaned per SECTION 9.6.

PAGE 13

TROUBLESHOOTING SECTION 10

10-2 CHECKING THE SMARTRELAY

The control system consists of three different control systems:

1. The SmartRelay

2. Input devices (120VAC components)

a. Pressure switches

b. Alarm Reset push-button

d. Power switch

3. Output components

a. Pilot valves

b. Lights

c. General alarm contact

The SmartRelay controls the cycling of the dryer system. The

program logic is stored on an electrically erasable non-volatile EEPROM. Loss of power will not cause loss of the program.

If the LCD display on the SmartRelay is not lit, the SmartRealy is not

operating. If this occurs, check fuse 1FU and replace as needed.

If there is power to the SmartRelay and is still does not function,

consult factory.

See SECTION 10.2A and 10.2B for procedures to verify the

operation of the input and output devices.

FIGURE 10A SMART RELAY DETAIL

POWER

LCD

DISPLAY

OUTPUTS

INPUTS

CONTROL

BUTTONS

FIGURE 10B INPUT AND OUTPUT LIST

INPUT DEVICES

I1 PS1

I2 PS2

I3 ARPB

I4 SPARE

I5 SPARE

I6 SPARE

I7 SPARE

I8 SPARE

NOTE:

The general alarm contact is a normally open dry contact which is wired to terminals #16

and #17.

OUTPUT DEVICES

Q1 SV1

Q2 SV2

Q3 PL2

Q4 ALARM CONTACT

10.2B TESTING THE OUTPUT DEVICES

The SmartRelay’s outputs are 120VAC. See FIGURE 10B for a

list of the dryer system output devices.

To check output devices SV1 and SV2, follow the procedure in

SECTION 10.3.

10.3 CHECKIING THE 3-WAY PILOT VALVES

(SV1 & SV2) TOWER CHANGEOVER

All 3-way pilot valves have manual override buttons on the top of the

valve. To test SV1 and SV2 do the following:

Make sure the dryer system is pressurized and the Power switch

is in the OFF position. Both towers should be at full line pressure

Pushing the manual override of SV1 should cause the left tower to

depressurize. Allow the left tower to come back up to full line

pressure. Pushing the manual override of SV2 should cause the

right tower to depressurize. If this does not happen, replace that

solenoid valve.

With the Power switch (SW) in the ON position and the dryer system

pressurized, monitor the dryer system for one complete cycle. SV1

should be activated when the left tower is in the regeneration stage

(depressurized) from 15 seconds to 5 minutes. SV2 should be

activated when the right tower is in the regeneration stage

(depressurized) from 5 minutes and 15 seconds to 10 minutes.

These two operations can be monitored in one 10 minute cycle.

Reference FIGURE 6C for dryer timing chart.

10.2A TESTING THE INPUT DEVICES

The input devices supply a 120VAC signal to the SmartRelay. See

FIGURE 10B for a list of the input devices.

The input devices can be easily tested for proper operation. With

power to the control box, set the Power switch to the ON position.

Press the Alarm Reset Pushbutton and verify that there is

120VAC between terminals N and I3 on the Smart Relay. If there

is no voltage, replace the Alarm Reset Pushbutton.

The pressure switches monitor the failure to switch option. The

inputs from the pressure switches (PS1, PS2) can be observed

while the dryer system is in operation. Any time there is more

than 30 psig pressure in the left tower, pressure switch (PS1)

should supply a 120VAC signal to Smart Relay terminal I1. Any

time there is more than 30 psig pressure in the right tower,

pressure switch (PS2) should supply a 120VAC signal to S

martRelay termial I2. If either of the pressure switches does not

respond as previously explained, check the wiring to the pressure

switch. If the wiring and device are good, theSmartRelay is faulty

and should be replaced. Reference FIGURE 10D WIRING

DIAGRAM for wiring and terminal numbers.

PAGE 14

If the above responses are not observed, rst check to see if power

is being supplied to each solenoid valve when it is supposed to

open. Check the wiring between the SmartRelay and solenoid

valves. If the SmartRelay is not supplying power to the valve as it

should, replace the SmartRelay. If the valve has power but does not

operate, it must be replaced.

TROUBLESHOOTING SECTION 10

10.4 CHECKING THE INLET TRANSFER VALVE

The inlet transfer valve should not change position until both towers

are at equal pressure. At tower changeover, the regenerating tower

should approach full line pressure before the inlet valve will switch.

Make sure that there are no leaks in the piping or ttings. Make

sure that the purge exhaust valves are closing and that the purge

metering valve is properly set.

The exhaust ports on top of the pilot valves (SV1 & SV2) should not

have air exhausting through them continuously. If air is exhausting

continuously through either of the exhaust ports, the inlet transfer

valve or exhaust valves are faulty and should be rebuilt or replaced.

To test the inlet transfer valve for proper operation, turn off the

power, isolate and depressurize the dryer.

Remove the two pilot lines to the inlet valve. The pilot lines are

connected to the outside anges of the valve. Reference FIGURE

10C. Using an air nozzle and clean air, pressurize one of the ports.

Observe the position indicator. It should move in the direction of

the port that is being pressurized. No air should be exhausting from

the other port. Pressurize the other port. The valve should move to

the other side. If the valve does not move or air is being exhausted

out of the port that is not pressurized, the inlet transfer valve must

be rebuilt or replaced. Reference SECTION 11.3 for repair kit part

numbers.

10.6 CHECKING THE PURGE EXHAUST VALVES

The purge exhaust valves are normally closed. They can be

checked by removing the pilot air lines to them. The valves should

be closed.

Using an air nozzle and clean air, pressurize the purge exhaust

valves. The valves should open when pressurized. If valve does

not open and close, it should be rebuilt or replaced. See SECTION

11.3 for repair kit part number.

10.7 CHECKING THE OUTLET CHECK VALVES

This dryer system uses two check valves for outlet air control. If

either of the outlet valves fails, one of the following will occur:

• A large amount of air will purge from one tower

• The outlet air ow will be blocked

If either happens, the faulty check valve must be replaced. See

SECTION 11.3 for part number.

FIGURE 10C INLET TRANSFER VALVE DETAIL

PAGE 15

TROUBLESHOOTING SECTION 10

FIGURE 10D WIRING DIAGRAM

PAGE 16

PARTS SECTION 11

11.1 GAUGE PANEL REPLACEMENT PARTS

ITEM

1

2

3

4

5

6

7

8

9

10

QTY

Panel

1

2-1/2" Pressure Gauge, 0-300 PSIG

2

1/4" Coupling

2

1/4" NPT Anchor Tube Fitting

2

1/4" NPT x 10-32 Reducer Bushing

1

10-32 Short Coupling

1

10-32 Choke Fitting

1

10-32 Sintered Filter

1

Visible Moisture Indicator Assembly

1

1/4" Tube x 1/4" NPT Branch Tee Fitting

3

DESCRIPTION

11.2 CONTROL BOX REPLACEMENT PARTS

QTY

ITEM

3

8

16

18

20

22

24

25

26

30

31

33

34

2

PRESSURE SWITCH

2

SOLENOID VALVE

1

SWITCH

1

LIGHT, BLUE

1

LIGH, RED

1

PUSHBUTTON

1

SMARTRELAY (PROGRAMMED)

1

HOUR METER

1

GASKET FOR HOUR METER

1

FUSE HOLDER

1

FUSE, 2 AMP

1

POWER CORD

STRAIN RELIEF FOR CORD

1

DESCRIPTION

PART NO.

27-1235

29-0394

12-0223

26-1497

26-0296

26-0657

26-0490

26-0623

46-2300

26-7532

PART NO.

26-5284

14-1721

26-3949

26-7350

26-7351

26-2038

46-3564

26-7352

26-7353

26-7312

26-0679

500-00010

510-00001

REPLACEMENT LED, RED

1

REPLACEMENT LED, BLUE

1

PAGE 17

26-7368

26-7369

PARTS SECTION 11

11.3 DRYER REPLACEMENT PARTS

ITEM

1

1a

1b

1c

2

3

3a

4

5

6

7

8

8a

9

9a

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

DESCRIPTION

Inlet Transfer Valve

Seat & Seal Kit for Inlet Transfer Valve

Position Indicator Kit for Inlet Transfer Valve

Shuttle Assembly Kit for Inlet Transfer Valve

Outlet Check Valve

Purge Exhaust Valve

Seal Kit for One Purge Valve

Diffuser basket

Fill/Drain Plug

Stud

Gasket for R.F. Flange

Purge Exhaust Mufer

Element, for one purge exhaust mufer

Control Air Filter (includes element)

Element, control air lter

Control Pressure Regulator

Bushing w/Screen (for twr pressure sw conn)

Purge Metering Valve

Purge Orice Union **

Purge Check Valve

Pressure Gauge

Safety Relief Valve

Gasket for Y-strainer

Screen for Y-strainer

Regulator for Pre-Cooler Air Motor

Lubricator for Pre-Cooler Air Motor

Core for Pre-Cooler

Air Motor for Pre-Cooler

Fan for Pre-Cooler

Guard for Pre-cooler Fan

1/2" NPT Isolation Valve

Float Drain FD1 (separator/prelter, prelter)

Manual Drain (afterlter)

PD-5 Differential Pressure Indicator

Separator/PreFilter Element

PreFilter Element

AfterFilter Element

Inlet/Outlet Coupling - 2" NPT 4-lug

Rubber Washer for In/Out Coupling (1 per)

Oil for Lubricator (quart)

Flushing Solvent for Pre-Cooler Air Motor

1" Victaulic Coupling

1-1/2" Victaulic Coupling

FR-800

PART NO.

14-2331

26-6272

26-6273

26-6274

14-2627

14-2123

26-6929

46-0224

14-0370

28-0409

18-0236

26-3149

26-5776

84-20106

26-10405

26-7655

14-1820

14-0535

14-1803

14-2642

29-0394

14-2601

26-7453

26-7456

26-7435

26-7438

34-0972

26-6277

26-7478

26-7479

14-2615

83-0751

84-10852

84-10001

26-10409

26-10415

26-10414

14-2602

26-7451

26-7032

26-7157

12-2142

12-2138

QTY

1

1

1

1

2

2

2

2

4

4

1

2

2

1

1

1

2

1

1

2

1

2

1

1

1

1

1

1

1

1

3

2

1

3

1

1

1

2

2

1

1

5

10

38

38a

38b

38c

** Orice union shipped without orice plate drilled. Center of plate must be drilled with 3/8" diameter hole for a FR-400.

Desiccant

Activated Alumina, 1/8" dia., 25# pail

Activated Alumina, 1/8" dia., 50# bag

Activated Alumina, 1/8" dia., 375# drum

33-0237

33-0238

33-0320

1

1

1

11.4 HOW TO ORDER PARTS

To order parts contact your local VAN AIR representative, the representative that sold the dryer, or the factory.

When contacting your local VAN AIR representative or the factory, the following information is necessary:

Dryer model

Dryer serial number

Dryer part number

This information can be found on the dryer data tag. The data tag is located inside the door of the control box.

The Service Department can be reached by calling 888-606-9303 or faxing 814-774-3482. Hours are 8:00 AM EST to 5:00 PM EST, M-F.

PAGE 18

Safety is everybody's business and is based on your use of good common sense. All situations or circumstances cannot

SAFETY PRECAUTIONS

always be predicted and covered by established rules. Therefore, use your past experience, watch out for safety hazards

and be cautious.

DANGER

DISCHARGE AIR USED FOR

BREATHING WILL CAUSE SEVERE

INJURY OR DEATH. CONSULT

FILTRATION SPECIALIST FOR

ADDITIONAL FILTRATION AND

TREATMENT EQUIPMENT TO

MEET HEALTH AND SAFETY

REGULATIONS.

DANGER

AIR AND OIL UNDER PRESSURE

WILL CAUSE SEVERE

PERSONAL INJURY OR DEATH.

SHUT DOWN COMPRESSOR

AND RELIEVE SYSTEM OF ALL

PRESSURE BEFORE REMOVING

VALVES, CAPS, PLUGS,

FITTINGS, BOLTS AND FILTERs.

WARN-

ELECTRICAL SHOCK FROM

IMPROPER GROUNDING CAN

CAUSE INJURY OR DEATH.

GROUND UNIT AND RELATED

EQUIPMENT ACCORDING TO

NATIONAL ELECTRICAL CODE

AND LOCAL REGULATIONS.

WARN-

READ THE OPERATOR'S

MANUAL BEFORE STARTING OR

SERVICING THIS UNIT. FAILURE

TO ADHERE TO INSTRUCTIONS

CAN RESULT IN SEVERE

PERSONAL INJURY OR DEATH.

REPLACEMENT MANUALS

CAN BE PURCHASHED

BY CONTACTING THE

MANUFACTURER.

PAGE 19

Loading...

Loading...