Van Air Systems FR-1600 User Manual

January 2014

2950 Mechanic Street

Lake City, PA 16423 USA

Phone: 800-840-9906

Email: info@vanairsystems.com

Fax: 814-774-0778

www.vanairsystems.com

INSTALLATION, OPERATION & MAINTENANCE MANUAL

FOR

PREP-40 PORTABLE COMPRESSED AIR DRYER SYSTEM

model

FR-1600 (P/N 81-2444)

REV C

WARNING

READ ALL INFORMATION IN THIS MANUAL BEFORE INSTALLING OR OPERATING THE DRYER SYSTEM.

BEFORE STARTING MAINTENANCE PROCEDURES, TURN OFF THE MAIN POWER TO THE DRYER SYSTEM

AND COMPLETELY DEPRESSURIZE THE UNIT TO PREVENT PERSONAL INJURY.

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THIS DRYER SYSTEM WHILE IT IS PRESSURIZED.

NEVER OPERATE THIS DRYER SYSTEM ABOVE THE RATED OPERATING CONDITIONS. OPERATION

ABOVE SPECIFIED CONDITIONS WILL RESULT IN DECREASED PERFORMANCE, POSSIBLE DAMAGE TO

THE UNIT AND/OR PERSONAL INJURY.

PAGE 1

www.vanairsystems.com

HANDLING SECTION 1

1.1 HANDLING INSTRUCTIONS

If outside storage is required, the unit MUST BE adequately covered to

DO NOT LIFT THE DRYER SYSTEM BY PIPING OR CONTROL

WARNING

BOX SUPPORT BARS. THESE COMPONENTS ARE NOT DESIGNED TO HOLD THE WEIGHT OF THE DRYER. PERSONAL

INJURY AND/OR EQUIPMENT DAMAGE MAY RESULT.

Lift the dryer system by the lifting lugs on both vessels in combination

with the lifting lugs on the pre-cooler supports, or by the base using a

fork lift truck.

If the unit is to be lifted by an overhead device, attach the lifting chains

or cables to the vessel lifting lugs and the lifting lugs on the pre-cooler

supports. Make sure that the chains or cables are clear of all piping

and dryer components.

prevent rain or snow from accumulating on the dryer system. The unit

must be placed on a paved surface to keep it out of standing water and

mud.

1.3 EQUIPMENT CHECK

Inspect the dryer system for any damage that may have occurred

during shipment. Inspect all ttings, piping connections, fasteners,

etc. for loose connections. Also check gauges and lights for cracks or

breakage.

IF DRYER SYSTEM WAS DAMAGED DURING SHIPMENT:

(1) NOTIFY CARRIER IMMEDIATELY AND FILE A CLAIM.

(2) CONSULT FACTORY BEFORE OPERATING THE DRYER

SYSTEM.

1.2 STORAGE INSTRUCTIONS

If the unit is to be placed in storage before it is installed, it should be

stored indoors and covered with a tarpaulin to keep it clean. The location should be free from corrosive gasses and extreme humidity, which

can cause damage to the unit.

SAFETY SECTION 2

2.1 HANDLING

DO NOT LIFT THE DRYER SYSTEM BY PIPING OR CONTROL BOX

SUPPORT BARS. THESE COMPONENTS ARE NOT DESIGNED

TO HOLD THE WEIGHT OF THE DRYER SYSTEM. PERSONAL

INJURY AND/OR EQUIPMENT DAMAGE MAY RESULT.

LIFT THE DRYER SYSTEM BY THE LIFTING LUGS ON BOTH

VESSELS IN COMBINATION WITH THE LIFTING LUGS ON THE

PRE-COOLER SUPPORTS, OR BY THE BASE USING A FORK LIFT

TRUCK.

MAKE SURE THAT ALL LIFTING EQUIPMENT IS CAPABLE OF

SUPPORTING THE WEIGHT OF THE DRYER SYSTEM.

2.2 INSTALLATION

THESE ASME CODE VESSELS MUST BE PROTECTED BY PRESSURE RELIEF VALVES. Refer to OSHA 1910.169 Par. b, Sub. Par

(3) and ASME Boiler and Pressure Vessel Code, Section VIII, Division 1, UG-125 through UG-136. Also comply with all state and

local codes.

WHEN INSTALLING AND OPERATING THIS EQUIPMENT, COMPLY

WITH THE NATIONAL ELECTRICAL CODE AND ALL APPLICABLE

FEDERAL, STATE, AND LOCAL CODES.

ALWAYS WEAR EYE PROTECTION, GLOVES AND A RESPIRATORY

PROTECTIVE DEVICE WHEN HANDLING THE DESICCANT.

DESICCANT DUST MAY CAUSE EYE AND SKIN IRRITATION. AVOID

BREATHING THE DUST AND PROLONGED CONTACT WITH THE

SKIN.

FIRST AID IN CASE OF EYE CONTACT WITH DESICCANT DUST;

IMMEDIATELY FLUSH THE EYES WITH PLENTY OF WATER FOR

AT LEAST 15 MINUTES. CONSULT A PHYSICIAN.

DURING NORMAL OPERATION, THE INLET PIPING MAY REACH

TEMPERATURES OF 150°F. CONTACT WITH THE PIPING MAY RESULT IN SERIOUS PERSONAL INJURY.

DO NOT OPERATE THIS DRYER SYSTEM ABOVE THE MAXIMUM

RATED WORKING PRESSURE.

OPERATING CONDITIONS FOR PROPER PERFORMANCE OF THIS

DRYER SYSTEM ARE DIFFERENT THAN MAXIMUM OPERATING

CONDITIONS FOR THE VESSELS. BE SURE TO CHECK THE DRYER

SYSTEM OPERATING CONDITIONS. SEE SECTION 3.1.

USE THIS DRYER SYSTEM FOR COMPRESSED AIR ONLY.

AIR FROM THIS DRYER SYSTEM IS NOT SUITABLE FOR BREATHABLE AIR SYSTEMS WITHOUT FURTHER TREATMENT.

DO NOT OPERATE THIS DRYER SYSTEM IF EITHER VESSEL HAS

BEEN DAMAGED BY FIRE. TAKE OUT OF SERVICE IMMEDIATELY AND NOTIFY YOUR CERTIFYING AUTHORITY.

FILTER DISCHARGE MAY CONTAIN COMPRESSOR LUBRICANTS.

COMPLY WITH ALL REGULATIONS CONCERNING THEIR DISPOSAL.

2.4 MAINTENANCE

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THE

DRYER SYSTEM WHILE IT IS PRESSURIZED. TURN OFF MAIN

POWER TO THE DRYER SYSTEM AND DEPRESSURIZE THE

DRYER SYSTEM COMPLETELY BEFORE STARTING MAINTENANCE PROCEDURES.

DO NOT WELD OR GRIND EITHER VESSEL. IT WILL NOT BE

SAFE TO OPERATE. (Note: Any uncertied alteration to the vessels VOIDS the ASME Code Certication and the Warranty.)

2.3 OPERATION

DO NOT OPERATE DRYER SYSTEM IF EITHER VESSEL IS LEAKING. IMMEDIATELY TAKE THE DRYER SYSTEM OUT OF SERVICE.

DO NOT OPERATE DRYER SYSTEM IF THE FILTERS, OR OTHER

COMPONENTS ARE LEAKING. IMMEDIATELY TAKE THE DRYER

SYSTEM OUT OF SERVICE AND FIX OR REPLACE THE LEAKING

COMPONENT.

ANY DAMAGE TO THE VESSELS CAN MAKE THEM UNSAFE TO

USE. INSPECT OUTSIDE AND INSIDE OF VESSELS REGULARLY

FOR CORROSION AND ANY DAMAGE (I.E., DENTS, GOUGES OR

BULGES). IF DAMAGED, TAKE OUT OF SERVICE IMMEDIATELY.

PAGE 2

NEVER REMOVE THE FAN GUARD WHILE THE AFTERCOOLER IS

OPERATING. CONTACT WITH THE ROTATING FAN BLADES MAY

RESULT IN SERIOUS PERSONAL INJURY.

SPECIFICATIONS SECTION 3

3.1 SPECIFICATIONS

WEIGHT ............. 3625 Lbs (without desiccant installed)

5485 Lbs (with desiccant installed)

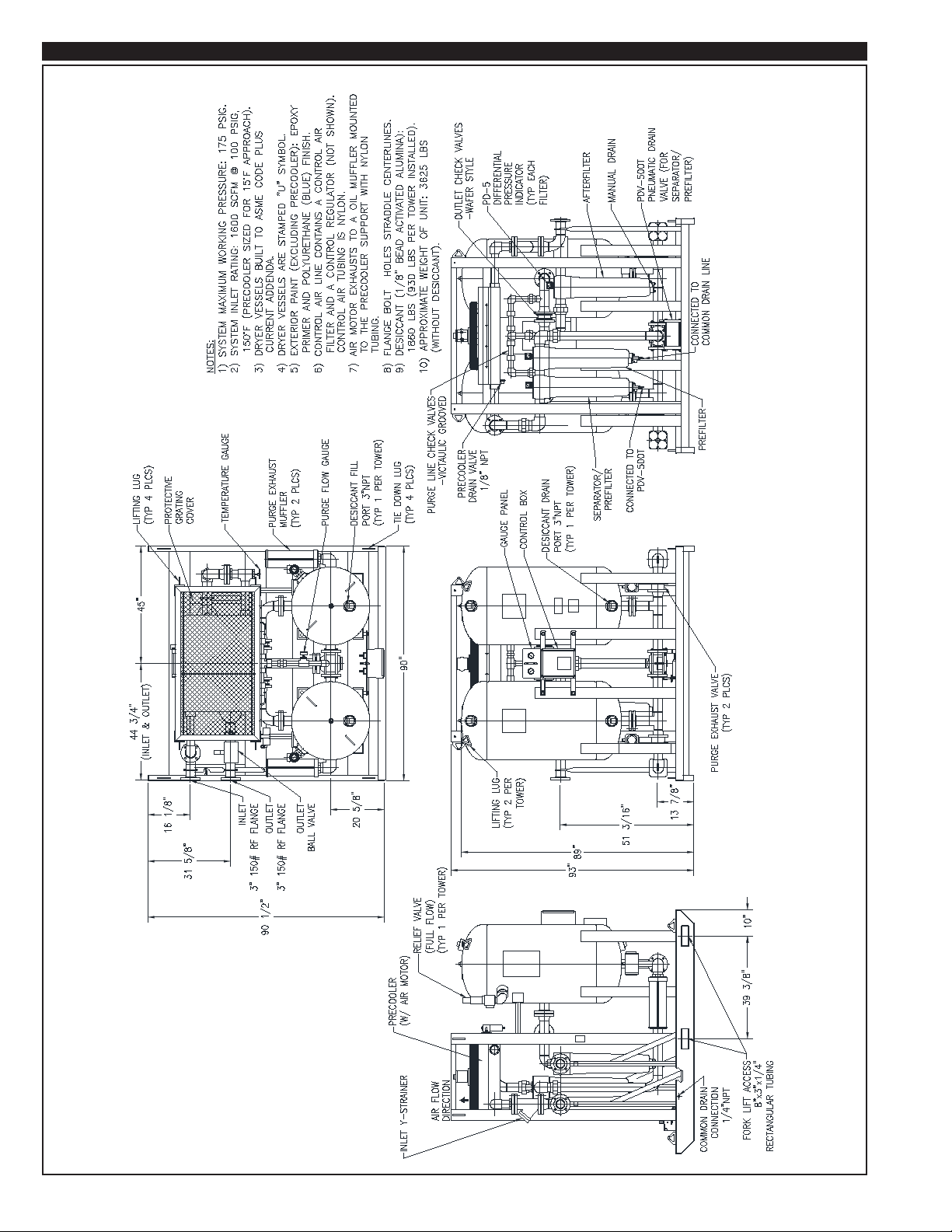

DIMENSIONS ..................... See SECTIONS 3.2

IN/OUT CONNECTION....... 3" 150# RF FLANGE

VESSELS (desiccant towers)

Construction ................... Manufactured to the ASME CODE, Section VIII, Division 1.

Vessels stamped "U" symbol.

Design Pressure ............. 175 PSIG

Design Temperature ....... -20OF TO 300OF

PIPING

Threaded ttings: ........... ASME B16.3

Threaded unions: .......... ASME B16.39

Flanges: ......................... ASME B16.5

Welded Fittings ............... ASME B16.9

Pipe: .............................. Carbon steel, Schedule 40

VALVES

Inlet ............................... Proprietary 3-way piloted shuttle valve

Outlet .............................. Two (2) Check valves, wafer type

Purge .............................. Two (2) Buttery valves with spring return actuators (air to open - fail closed)

CONTROL AIR FILTER

Construction ................... Aluminum housing

SEPARATOR/PREFILTER, PREFILTER, AFTERFILTER

Construction ................... Aluminum housing

PRE-COOLER

Core. ............... ................Aluminum

Fan..................................Polypropylene blades with Aluminum hub

Fan Guard ......................Steel

ELECTRICAL

Standard 115 Volt ........... 115-120V/1PH/50-60Hz

DESICCANT

Material ........................... Activated Alumina, 1/8" (2-5 MM) Bead type

Quantity Per Tower ....... 930 Lbs.

OPERATING CONDITIONS

Inlet Air Pressure ............................ MIN 80 PSIG ...........MAX 175 PSIG

Inlet Air Temperature ...................... MIN 40°F.................MAX 150OF

Ambient Air Temperature................ MIN 40OF ................MAX 120OF

SYSTEM RATED INLET CONDITIONS

Inlet Air Pressure ............................ 100 PSIG

Inlet Air Temperature ...................... 150OF (based on 85°F ambient and 15°F approach from the pre-cooler)

Relative Humidity (saturation) ........ 100% RH

DRYER FLOW CAPACITIES (SCFM) at various pressures (1000F)

80 PSIG 100 PSIG 110 PSIG 125 PSIG 140 PSIG 150 PSIG 160 PSIG 175 PSIG

FR-1600 1321 1600 1668 1766 1858 1917 1975 2058

PAGE 3

SPECIFICATIONS SECTION 3

3.2 DIMENSIONS

PAGE 4

INSTALLATION SECTION 4

4.1 LOCATION

WARNING

DO NOT INSTALL THIS DRYER SYSTEM IN AN ENVIRONMENT

OF CORROSIVE CHEMICALS, EXPLOSIVE GASSES, POISONOUS

GASSES, OR SATURATED STEAM HEAT.

Locate dryer system in a protected, well vented area where ambient

temperatures are between 40oF and 120oF. Allow sufcient clearance

over and around the dryer system for access to desiccant ll and drain

ports and controls. Refer to SECTION 3.2 for dryer dimensions.

If this dryer system must be installed where ambient temperatures are

below 40oF, insulation and heat tracing must be properly installed on

the inlet piping, prelter, purge exhaust line and the desiccant towers to

prevent freezing of the equipment.

Position the dryer system in the upright position on a solid, level,

vibration free surface capable of supporting the dryer system’s weight.

Refer to SECTION 3.1 for dryer system specications.

The dryer system should not be located in extremely dirty areas where

airborne contaminants can accumulate on the dryer system. If this

cannot be prevented, the dryer system should be cleaned periodically.

An accumulation of dirt on the precooler will greatly reduce its

efciency. Accumulated dirt may also cause the inlet transfer valve to

fail.

4.2 DESICCANT INSTALLATION

The desiccant was factory installed in both towers before the dryer

was shipped.

4.3 ELECTRICAL CONNECTIONS

WARNING

SERIOUS PERSONAL INJURY AND DAMAGE TO THE DRYER

SYSTEM WILL OCCUR IF THE DRYER SYSTEM IS CONNECTED

TO A POWER SOURCE OTHER THAN THE VOLTAGE LISTED

ON THE DATA TAG.

Connect the dryer system power cord to a 115V/1PH/60Hz power

source capable of supplying a minimum of 2 AMPS.

4.4 INSTALLING THE PURGE MUFFLERS

Purge mufers were shipped separately. They should NOT be installed

until the dryer system has been operated for several hours. From

desiccant installation, some dust may be present in the desiccant tow-

ers. Operating the dryer system with the mufers installed immediately

after the towers have been lled with the desiccant or during initial start

up may cause the mufers to clog. See SECTION 5.6 for purge mufer

installation.

4.5 FILL LUBRICATOR WITH OIL

The lubricator is located in the air line between the regulator and the

pre-cooler air motor. Fill the lubricator with Pneumatic Lubricating Oil

SAE10 AD220 (Van Air p/n 26-7032 quart).

4.6 CONNECT DRAIN LINE

Drain lines for the separator/prelter and prelter are run to a common

drain coupling located on the skid. Connect drain line from skid to an

appropriate collection container as lter discharge may contain

compressor lubricants. Comply with all regulations concerning their

disposal.

4.7 CONNECTING THE INLET AND OUTLET

The inlet and outlet of this dryer system are 3" 150# RF ange. Connect the inlet and outlet air piping to the dryer system.

START UP SECTION 5

5.1 START UP

WARNING

BEFORE STARTING THIS DRYER SYSTEM, FOLLOW THE INSTALLATION INSTRUCTIONS AND PROCEDURES COMPLETELY. SERIOUS PERSONAL INJURY CAN RESULT IF INSTRUCTIONS ARE NOT

CAREFULLY AND COMPLETELY FOLLOWED.

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THIS

DRYER SYSTEM WHILE IT IS PRESSURIZED.

Make sure that the Power switch is in the OFF position.

If the dryer system is being started up for the rst time or after the desiccant has been changed, the purge mufers must be removed. See

SECTION 2.2 for safety precautions concerning the desiccant dust.

Install the purge mufers per SECTION 5.6.

5.2 ADJUSTING THE PURGE FLOW

IMPORTANT

NEVER OPERATE THE DRYER SYSTEM WITH THE PURGE METERING VALVE CLOSED. IF THE VALVE IS CLOSED, THE TOWERS WILL

NOT REPRESSURIZE AND SWITCHING FAILURE WILL OCCUR.

DO NOT ADJUST THE PURGE METERING VALVE ABOVE OR

BELOW THE RECOMMENDED SETTING FOR THE OPERATING

CONDITIONS OF THIS INSTALLATION. IMPROPER SETTING MAY

CAUSE POOR DRYER SYSTEM PERFORMANCE AND/OR EXCESSIVE USE OF PROCESS AIR.

WARNING

WHEN OPERATING THIS DRYER SYSTEM WITHOUT THE MUFFLERS INSTALLED, USE HEARING PROTECTION.

Pressurize the air system.

Place the Power switch in the ON position. One tower will already be

pressurized. The other tower will depressurize. The purge valve on

the depressurized tower will be open, air should be exhausting from

the mufer.

The dryer system is equipped with a purge metering valve. The setting

should be checked per SECTION 5.2 before placing the dryer system

on stream.

Set the control pressure regulator per SECTION 5.3.

Set the lubricator and regulator for the pre-cooler air motor per

SECTION 5.4.

Condition the desiccant bed per SECTION 5.5 before placing the dryer

system on-stream.

PAGE 5

The Prep-40 dryer system is equipped with a purge metering valve and

gauge located in the purge piping. The gauge indicates the back pres-

sure on the purge ow orice, which is in direct correlation to the purge

ow in SCFM.

The purge ow can be adjusted for the operating conditions.

This dryer system was shipped with the purge ow set for the rated inlet

ow at 100 PSIG. Reference SECTION 3.1 for rated ow. This setting

should be correct for most installations. Before placing the dryer system

on stream, check the purge metering valve setting.

FIGURE 5B shows the purge ow, in SCFM, and the pressure setting

required. This ow is required to properly regenerate the desiccant beds.

FIGURE 5B REQUIRED PURGE FLOW

DRYER

MODEL

FR-1600

PURGE

FLOW

290 SCFM

PURGE FLOW

GAUGE SETTING

40 PSIG

START UP SECTION 5

5.3 SETTING THE CONTROL PRESSURE REGULATOR

The control pressure regulator is located in line with the control lter and

it is used to protect the pneumatic control components. This regulator

should be set at 100 PSIG.

CAUTION

DO NOT OPERATE THIS DRYER SYSTEM WITH

THE CONTROL AIR PRESSURE REGULATOR

ABOVE 100 PSIG TO PREVENT DAMAGE TO

THE PNEUMATIC CONTROLS.

5.4 ADJUST THE REGULATOR & LUBRICATOR

The regulator and lubricator for the pre-cooler air motor must be properly

set to ensure trouble-free air motor operation.

The regulator is used to set the speed of the pre-cooler fan. The regulator

is factory set using a tachometer and a clean precooler core. See FIGURE

5C. As the core becomes dirty, a higher regulator pressure setting may

be required to maintain the fan speed.

FIGURE 5C FACTORY REGULATOR SETTING

DRYER

MODEL

FR-1600

Set the lubricator per FIGURE 5D.

SETTING

(PSIG)

30

FIGURE 5D LUBRICATOR SETTING

DRYER

MODEL

FR-1600

AIR USAGE

(SCFM)

25

DROPS PER

FAN SPEED

(RPM)

1725

MINUTE

1

At initial start up or after extended shutdowns (over one month), the dryer

system may take 24 to 48 hours of continuous operation for the bed to be

conditioned. Moisture that has accumulated on the desiccant bed should

be removed before the dryer system is placed on stream.

Once the moisture indicator on the dryer system turns blue, the desiccant

bed is ready. The Prep-40 dryer is now ready for operation.

5.6 INSTALLING THE PURGE MUFFLERS

To reduce the sound level during purge and tower depressurization,

this dryer system was supplied with mufers for installation on the

purge exhaust valves.

Mufers were shipped separately. They should NOT be installed until

the dryer system has been operated for several hours. From desiccant installation, some dust may be present in the desiccant towers.

Operating the dryer system with the mufers installed immediately after

the towers have been lled with the desiccant or during initial start up

may cause the mufers to clog.

Operate the until NO desiccant dust is visible at the purge valves.

Then the mufers can be installed.

IMPORTANT

The dryer system must be operated for several hours without

the mufers after the towers have been lled with desiccant.

This will prevent the mufers from becoming clogged.

FIGURE 5A PURGE MUFFLER INSTALLATION

5.5 CONDITIONING THE DESICCANT BED

To condition the desiccant bed, the dryer system is operated without any

outlet ow while the towers regenerate with purge air.

Observe the dryer system for several cycles to make sure that it is operating properly.

OPERATION SECTION 6

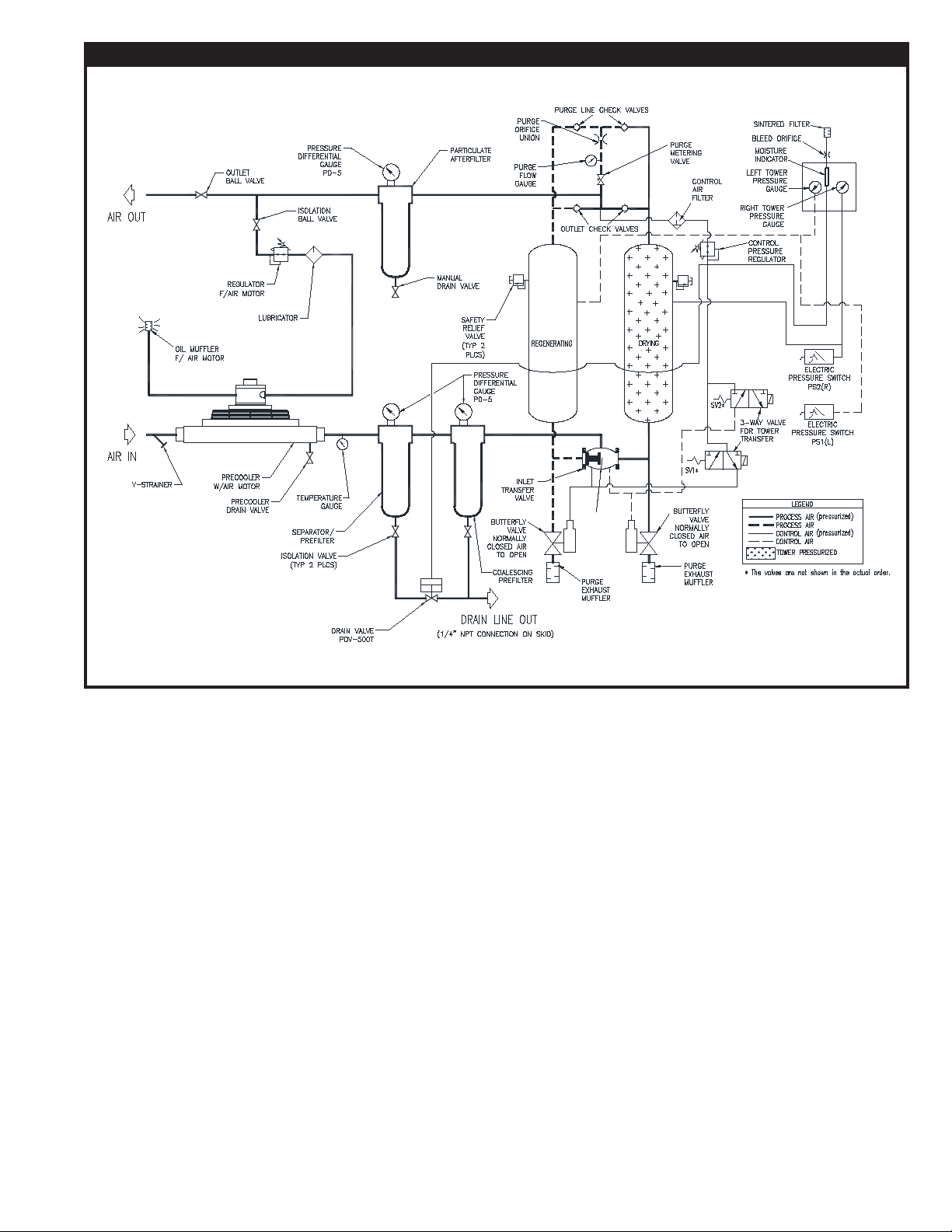

6.1 DESCRIPTION OF OPERATION

The Prep-40 is a portable skid mounted system consisting of a strainer,

pre-cooler, separator/prelter, prelter, heatless regenerative dryer and

an afterlter. Wet warm air enters the pre-cooler where it is cooled to a

temperature approaching ambient. Water is condensed out during this

cooling process. The saturated air and the liquid water proceed to the

inlet of the separator/prelter where the liquid water is removed. Then

the saturated air enters the coalescing lter where additional oil and liquid

water is removed. Then the air enters the heatless twin tower dryer where

it moves upward through the desiccant bed. The moisture is adsorbed

onto the surface of the desiccant. Dry air exits the heatless dryer and

passes through the general purpose particulate after-lter where residual

particulate is removed.

This package dryer will take saturated air at rated conditions and reduce

the mositure content to -40°F pressure dew point.

6.2 HEATLESS DRYER PRINCIPLE OF OPERATION

The Heatless Regenerative Air Dryer utilizes the pressure swing principle

of operation. The desiccant bed in one tower dries the air stream while

the desiccant bed in the other tower is regenerated.

A purge of dry air is used for tower regeneration. It is taken from the

outlet of the dryer.

The dryer is equipped with a purge metering valve to allow the correct

amount of dry air to ow into the regenerating tower. The heat created

during adsorption of moisture in the drying tower is retained in the desiccant

bed and increases the moisture removal capacity of the purge air.

The timing cycle of the dryer is controlled by two 3-way pilot valves.

To achieve maximum performance from this dryer, it should be operated

continuously. Operating this dryer for single shift periods may result in

varied outlet dew point performance.

PAGE 6

The dryer operation consists of four stages; REPRESSURIZATION,

CHANGEOVER/DEPRESSURIZATION, DRYING, and REGENERATION.

OPERATION SECTION 6

FIGURE 6A PNEUMATIC SCHEMATIC

6.2-1 REPRESSURIZATION STAGE

Repessurization occurs in the off-stream (regenerating) tower.

Repessurization must occur before tower changover to reduce shock

to the desiccant and the possibility of downstream pressure spikes.

Pilot valve SV1 or SV2 de-energizes causing the purge valve on the

off-stream (regenerated) tower to close. The purge air, which was

vented to atomosphere earlier in the cycle, is now used to

repressurize the off-stream tower.

6.2-2 CHANGEOVER/DEPRESSURIZATION STAGE

Tower changeover occurs after the off-stream (regenerated) tower is

pressurized. The SmartRelay signals SV1 or SV2 to open causing pilot

air to be supplied to the opposite side of the inlet transfer valve and

cause exhaust valve to open on regenerative tower. The inlet transfer

valve shuttle will move to the side that has pilot pressure placing the

regenerated tower on-stream. The tower that was on line and drying

the process air is now off-stream.

When the inlet transfer valve changes position, the position indicator

will move.

6.2-3 DRYING AND REGENERATION STAGE

One tower is on-stream (pressurized) drying process air. The process air

passes through the desiccant bed, which adsorbs moisture from the air.

The regeneration stage of the off-stream tower occurs at the same time

as the drying stage in the on-stream tower. During the regeneration

stage, a percentage of dry air is directed through the desiccant bed of

the offstream tower. The purge air is vented through the purge valve

to the atmosphere.

If pilot valve SV2 is energized, the LEFT tower is drying and if pilot

valve SV1 is energized, the RIGHT tower is drying.

6.3 MOISTURE INDICATOR

The moisture indicator is in the center of the panel. The moisture

indicator is a clear plastic tube lled with moisture sensing crystals. A

sample of outlet air is directed through the indicator.

The crystals will change colors from PINK (indicating wet air) to

BLUE (indicating dry air) as the dew point of the air changes from

+20OF to -40OF.

PAGE 7

OPERATION SECTION 6

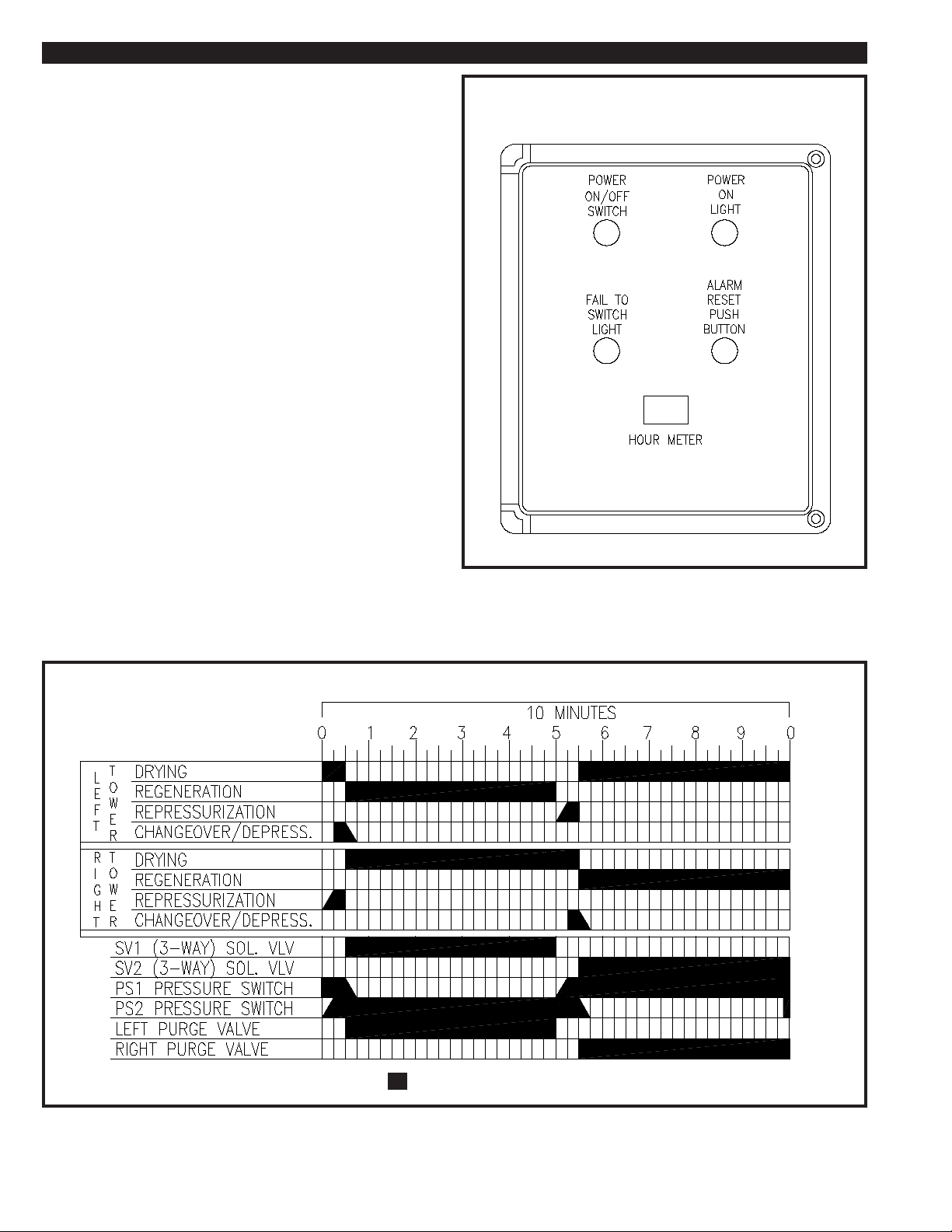

6.4 DRYER CONTROLS

The control is housed in a NEMA 4X enclosure and it has the following

features:

- Power switch

- Power On light

- Fail to Switch light

- Alarm Reset pushbutton

- Hour Meter

See Figure 6B for control box door.

6.4-1 SMART RELAY:

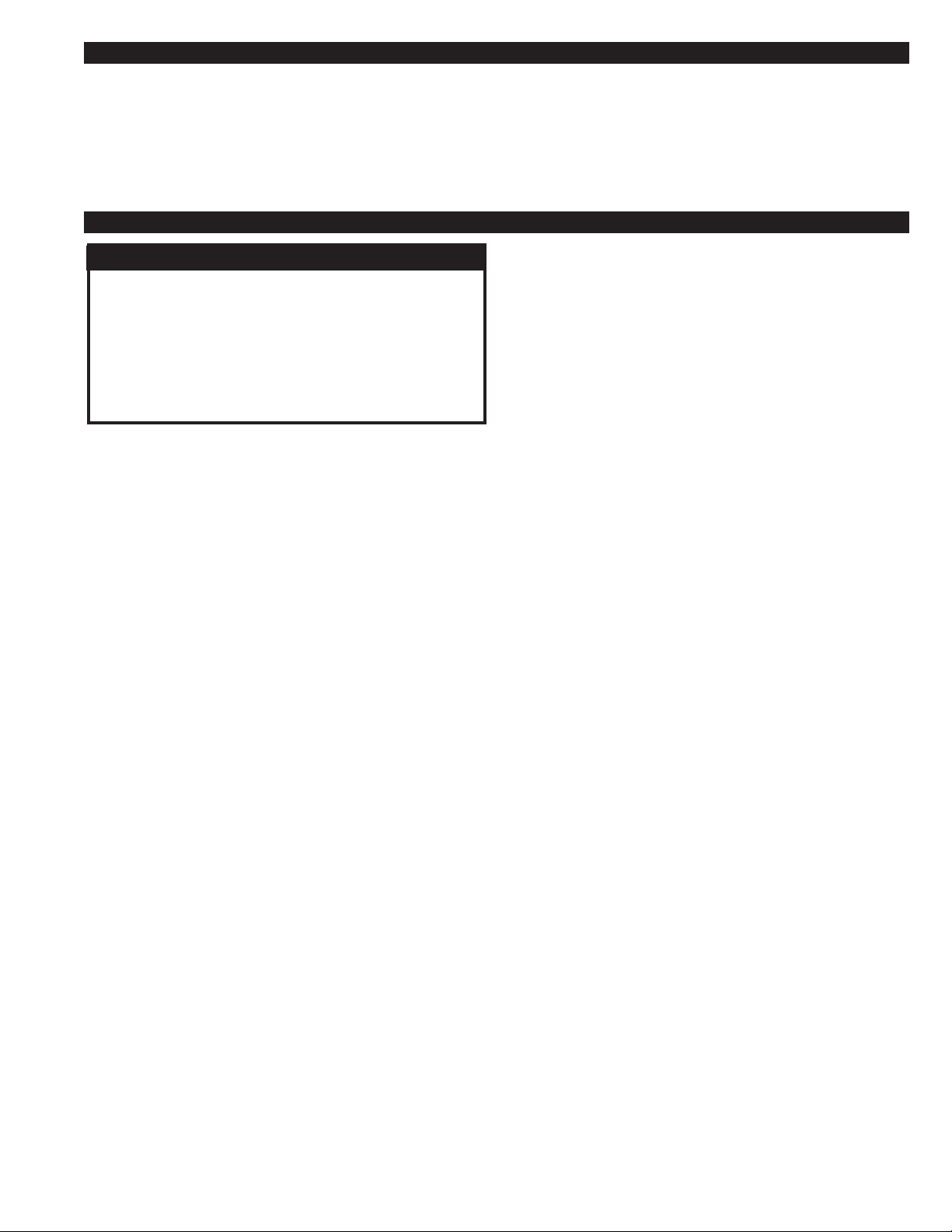

The dryer cycle is controlled by a SmartRelay, two solenoid valves

and two pressure switches. The dryer timing chart is shown in FIG-

URE 6C. The SmartRelay has a battery back-up that will hold the

program in memory safely for 2 years.

6.4-2 SWITCHING FAILURE:

When there is a switching failure (failure of control solenoid valves

SV1 & SV2; failure of exhaust valve to open; or clogging of exhaust

mufer), the Fail to Switch LED will be lit. This will energize the

Alarm Contacts shown in FIGURE 10D. The contacts can be wired

for remote annunciation. To reset the Switching Failure Alarm press

the Alarm Reset Pushbutton on the front of the control box. If the

condition causing the alarm is not corrected, the alarm will

re-activate in 90 seconds.

6.4-3 HOUR METER:

The Hour Meter is located on the front of the control box. It is used

to log the total number of hours that the Prep-40 dryer system has

been in operation.

FIGURE 6B CONTROL BOX DOOR

6.5 PDV-500T

The PDV-500T drain valve is an automatic drain valve tubed to the

separator/prelter to automatically drain liquid water from the lter.

Reference PDV-500T manual attached.

FIGURE 6C DRYER TIMING CHART

PAGE 8

= ON

SHUTDOWN SECTION 7

Shut off the air supply to the Prep-40 dryer system. Allow the dryer to

depressurize. Turn the dryer system off by placing the Power Switch to

the OFF position. Open the ball valve on the afterlter and completely

depressurize the dryer system.

Disconnect the power supply to the dryer system.

If maintenance is to be preformed on the dryer system, make sure the

dryer system is completely depressurized. Tower pressure gauges

must read 0 PSIG before removing any item on the dryer system.

STORAGE SECTION 8

WARNING

DO NOT ATTEMPT TO REMOVE OR REPAIR ANY PART OF THE

SYSTEM UNTIL IT IS COMPLETELY DEPRESSURIZED. SERIOUS PERSONAL INJURY MAY RESULT IF THIS SAFETY RULE

IS NOT FOLLOWED.

INSPECT VESSEL, INSIDE AND OUT, REGULARLY FOR

BULGES, CORROSION, DENTS, GOUGES OR LEAKS. IF

DAMAGED, REMOVE FROM SERVICE IMMEDIATELY AND

NOTIFY YOUR CERTIFYING AUTHORITY.

8.1 REMOVE THE PREP-40 FROM SERVICE

Shutdown the dryer system per SECTION 7.

Close the ball valve on the afterlter.

The pre-cooler air motor needs to be ushed to remove excessive

dirt, foreign particles, moisture and/or oil that accumulate in the air

motor during normal operation. Flushing helps to maintain proper

motor performance and extend service life.

8.3 SET THE REGULATOR FOR THE AIR MOTOR

Set the regulator for the air motor per FIGURE 5C.

8.4 PREPARATION FOR STORAGE

Open the ball valve on the afterlter to completely depressurize

the Prep-40 system.

If long term storage is required, cover the inlet and outlet air

connections to prevent the accumulation of dirt and debris on the

piping.

8.5 STORAGE

Store the Prep-40 in location that is free from extreme humidity

and corrosive gasses, which can cause damage to the unit.

Perform Flushing procedure, per SECTION 8.2, when Prep-40 is

to be idle for more than 5 days, or if it is to be placed in storage.

Use only Van Air Flushing Solvent (p/n 26-7157). DO NOT use

kerosene or ANY other combustible solvents to ush the air

motor.

8.2 FLUSHING PROCEDURE

Remove the pipe plug in the air supply line near the air motor.

Drain the exhaust mufer / oil lter.

Disconnect tubing line to air motor exhaust mufer / oil lter at the air

motor.

Spray ushing solvent (Van Air p/n 26-7157) into air motor through tee

for 5 to 10 seconds.

Rotate motor shaft/fan, by hand, for one minute in each direction.

Reinstall the plug in the tee and cover the exhaust port with a cloth.

You must wear eye protection for this step.

Restart the motor at a low pressure (approximately 10 PSIG) and run it

until there is no trace of solvent in the exhaust air.

Listen for changes in the sound of the motor. If the motor sounds

smooth, the Prep-40 is ready for storage. If the motor does not sound

like it is running smoothly, the motor will need to be serviced.

Install the exhaust mufer / oil lter tubing line to the air motor.

PAGE 9

Loading...

Loading...