Van Air Systems FD-250 User Manual

OPERATION AND MAINTENANCE INSTRUCTIONS

FOR

BLAST PAK

PACKAGED COMPRESSED AIR TREATMENT SYSTEM

MODELS: FD-250 & FD-250-DC

WARNING

DO NOT OPERATE THIS SYSTEM ABOVE MAXIMUM WORKING

PRESSURE (MWP) AND/OR MAXIMUM OPERATING

TEMPERATURE (

PLATE.

THIS ASME CODE VESSEL MUST BE PROTECTED BY A

PRESSURE RELIEF VALVE. Refer to OSHA 1910.169 Par. b,

Sub. Par (3) and ASME Boiler and Pressure Vessel Code,

Section VIII, Division 1, UG-125 through UG-136. Also comply

with all applicable state and local codes.

O

F) SHOWN ON THE VESSEL ASME DATA

December 2007

P/N 32-0294

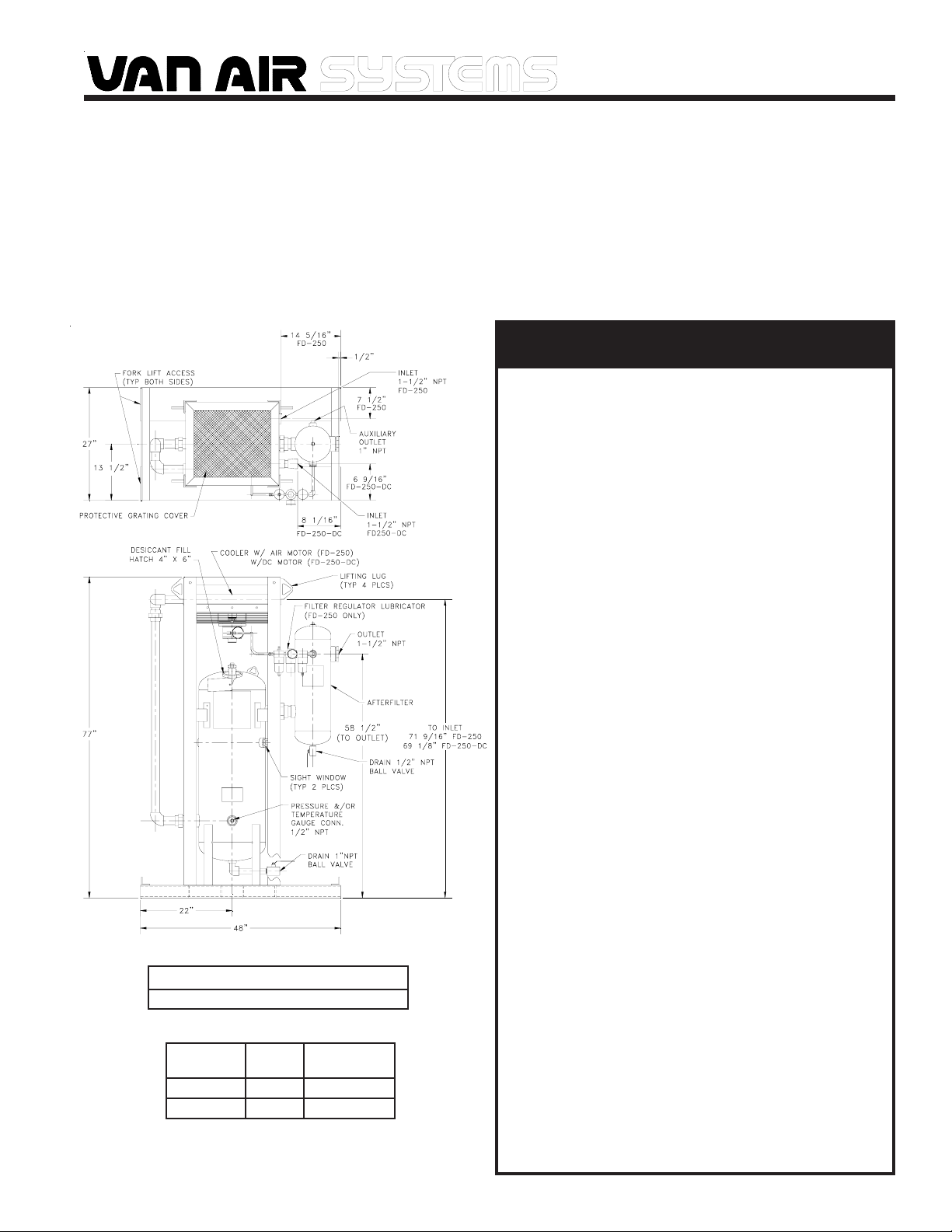

REGULATOR SETTING FOR AIR MOTOR

22 PSIG TO GET 3450 RPM

DRY-O-LITE

MODEL

FD-250

FD-250-DC

* - ORIGINAL FILL OF DESICCANT SUPPLIED - CUSTOMER

WEIGHT

660 lbs

675 lbs

TO INSTALL

DESICCANT *

250 lbs

250lbs

DO NOT ATTEMPT TO REMOVE OR REPAIR ANY PART OF THE

SYSTEM UNTIL IT IS COMPLETELY DEPRESSURIZED. SERIOUS

PERSONAL INJURY MAY RESULT IF THIS SAFETY RULE IS

NOT FOLLOWED.

DO NOT WELD, GRIND, OR SAND VESSEL, THIS WILL MAKE

IT UNSAFE TO OPERATE. (Note: Any alteration to the vessel

will void the ASME Code Certification and the warranty.)

INSPECT VESSEL, INSIDE AND OUT, REGULARLY FOR

BULGES, CORROSION, DENTS, GOUGES, LEAKS OR SIGNS

OF FIRE. IF DAMAGED, REMOVE FROM SERVICE

IMMEDIATELY AND NOTIFY YOUR CERTIFYING AUTHORITY.

DO NOT TRY TO TIGHTEN A LEAKING HATCH COVER.

IMMEDIATELY SHUT OFF THE AIR SUPPLY AND

DEPRESSURIZE THE SYSTEM.

DO NOT ATTEMPT TO REMOVE THE HATCH COVER UNTIL

THE SYSTEM IS COMPLETELY DEPRESSURIZED. WHEN

THE VESSEL PRESSURE IS REDUCED TO ZERO, THE

HATCH COVER CAN BE REMOVED BY HAND.

INSTALL A NEW GASKET EVERY TIME THE HATCH COVER

IS REMOVED, OR AT LEAST ONCE PER YEAR. INSPECT

THE COVER AND SEALING SURFACE FOR DAMAGE SUCH

AS CORROSION, CRACKS, OR DISTORTION. IF THERE IS

ANY DAMAGE, REPLACE COVER. REPLACE THE HATCH

COVER EVERY FIVE YEARS REGARDLESS OF CONDITION.

USE VAN AIR AUTHORIZED PARTS ONLY.

DO NOT USE POWER TOOLS OR CHEATER BARS TO

TIGHTEN THE NUT ON THE HATCH COVER. TOO MUCH

FORCE CAN DISTORT THE COVER AND/OR THE GASKET. IF

DAMAGED BY OVERTIGHTENING, THE COVER CAN BLOW

OUT AND CAUSE SERIOUS INJURY. (Note: Tighten the nut

until it is snug. When the vessel is pressurized, the pressure

on the cover will complete the seal.)

THE USE OF CHEMICALS OTHER THAN VAN AIR

DESICCANT WILL VOID THE WARRANTY ON THE BLAST

PAK.

PAGE 1

SECTION 1 DESCRIPTION OF OPERATION

A Blast Pak is a skid mounted system consisting of an air-cooled trim cooler, a single tower dryer with a bed of desiccant tablets and a

coarse afterfilter. Wet warm air enters the trim cooler where it is cooled to a temperature approaching ambient. Water is condensed out

during this cooling process. The saturated air and the liquid water proceed to the inlet of the single tower dryer. The liquid water and any

solid particles present are separated by gravity and fall to the dryer sump area. The process air moves upward through the bed of desiccant

tablets which attract and absorb moisture from the air before it flows through the dryer outlet. The tablets dissolve gradually as they absorb

the moisture. The solution, which consists of dissolved desiccant and water, falls into the sump area at the bottom of the vessel. The dryer

must be drained periodically to remove the accumulated solution. A manual ball valve is supplied for this purpose. A pneumatic drain valve

is available as optional equipment for automatic draining. Likewise, the desiccant in the dryer must be periodically replenished to maintain

performance. The coarse afterfilter is supplied to catch any residuals that may work their way downstream.

SECTION 2 PERFORMANCE

2.1 INLET CONDITIONS

The FD-250 and the FD-250-DC Blast Paks are rated for 250 SCFM at 100 PSIG, 180° F into the trim cooler [sized for 90° F ambient and 10°

approach (FD-250-DC) and 15° approach (FD-250)]. Approach temperatures will vary with changes to the inlet conditions (flow, pressure,

temperature) and the ambient temperature. The dew point out of the dryer tower is directly related to the inlet temperature entering the dryer

vessel. The lower the inlet temperature, the lower the dew point of the outlet air.

The aftercooler maximum inlet temperature is 250° F. When using DRY-O-LITE desiccant, the inlet temperature to the dryer tower should not

exceed 100° F.

2.2 MAXIMUM CAPACITIES FOR DRYER - SCFM (Nm3/hr)

MAXIMUM

WORKING

PRESSURE

200 PSIG

13.8 Bar

60 PSIG

4.1 Bar

163

262

80 PSIG

5.5 Bar

206

331

100 PSIG

6.9 Bar

250

402

125 PSIG

8.6 Bar

304

489

150 PSIG

10.3 Bar

359

577

175 PSIG

12.1 Bar

413

664

200 PSIG

13.8 Bar

468

752

SECTION 3 OPTIONS

3.1 PRESSURE RELIEF VALVE

A 1" NPT coupling is provided on the back of the dryer vessel for

installing the relief valve. A pressure relief valve should be installed to

conform to OSHA safety standards. Refer to OSHA Standard Section

1910.169, paragraph “b”, subparagraph “3” and all other federal, state

or local codes concerning pressure vessels.

See section 6 for recommended relief valve (available from your Van Air

rep.)

3.2 PNEUMATIC DRAIN VALVE (P/N 39-0284)

The 1"NPT drain connection can be fitted with a PDV-500T pneumatic

drain valve for automatic draining of the vessel. Ask your local Van

Air representative for details.

3.3 GAUGE KITS

A 1/2" NPT connection is provided on the lower front of the dryer for

installing gauges.

See Section 6 for optional gauge kits (available from your Van Air

rep.)

SECTION 4 OPERATION

4.1 DESICCANT INSTALLATION

IMPORTANT

The Blast Pak is shipped WITHOUT the desiccant installed.

The desiccant MUST BE INSTALLED before using the

system.

THE USE OF CHEMICALS OTHER THAN VAN AIR

DESICCANT WILL VOID THE WARRANTY ON THE DRYER.

The procedure for filling the dryer with desiccant is outlined in

Section 5.6 of this manual.

4.2 LUBRICATOR OIL (FD-250 only)

Check oil level in lubricator regularly and add oil as required.

Note: 1 Quart of oil shipped with the BlastPak.

plug shown in section 6 of this manual. Another way to make

the connections is to cut the plug off the motor leads and

wirenut the supply wires to the motor wires.

The BLUE wire is POSITIVE and the BLACK wire is NEGATIVE.

Make sure all electrical connections comply with the National

Electrical Code and all applicable state and local codes.

4.4 START UP PROCEDURES

SLOWLY pressurize the air system. Allow some air to bleed

through the manual drain valve. Once the system starts to

pressurize, the manual drain valve can be closed. The Blast Pak

is now in operation.

IMPORTANT

The Blast Pak is shipped WITHOUT the lubricator oil

installed. The lubricator oil MUST BE INSTALLED before

using the system.

4.3 ELECTRICAL CONNECTIONS (FD-250-DC only)

Electrical requirement for trim cooler motor is 12 VDC 19 Amps.

Connect 12 VDC supply to the air motor by using optional male

PAGE 2

Make sure that the Blast Pak is not subjected to sudden

CAUTION

flow surges. Always open the valves slowly to permit

gradual equalization of pressure between the Blast Pak

and the air supply lines.

Verify that regulator pressure is set as shown on page 1 of this

manual to maintain 3450 rpm fan speed to ensure proper

aftercooler performance. (FD-250 only)

Loading...

Loading...