Van Air Systems F200 User Manual

April 2012

P/N 432-10016-D

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTION

F200 SERIES

COMPRESSED AIR FILTERS

PRODUCT PURPOSE & FUNCTION:

Van Air's F200 series lters are designed to remove contaminants from compressed air systems. Available in 1/4" to 3"

connection sizes and ow capacities from 15 to 1250 SCFM (at 100 psig) in 15 housings and 9 ltration grades, the F200 series

can remove oil aerosols, oil vapors, water and particulates. Housings are made of cast aluminum and coated with an epoxy powder

coating for corrosion resistance. All units include push-on elements with durable polyester drain layer (except RD grade).

Accessories include differential pressure indicators, wall mounting kits, connector kits, and automatic drain valves.

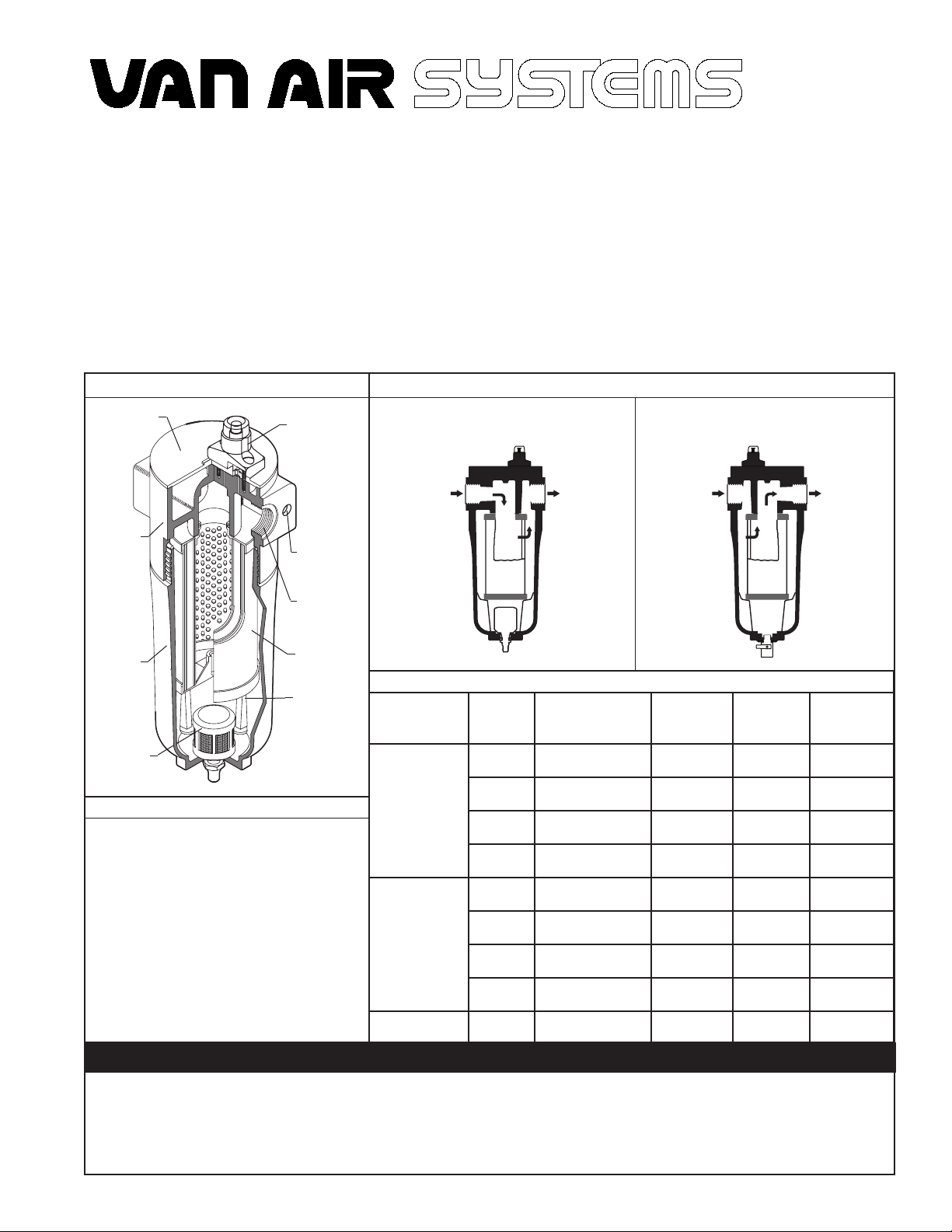

FILTER DETAILS

BLANKING

PLATE

FILTER

HEAD

FILTER

BOWL

ADM-2-2

(OPTIONAL)

OPERATING CONDITIONS

MAXIMUM WORKING PRESSURE

All Models

OPERATING TEMPERATURE

Minimum

Maximum

MAXIMUM RECOMMENDED INLET

TEMPERATURE

AA, A, RAA, RA, RB, and RC Series

B Series

C Series

RD Series

PD-6 POP-UP

INDICATOR

(STANDARD)

THRU-BOLT

HOLES

INLET/

OUTLET

ELEMENT

ELEMENT

SUPPORT

250 PSIG

35°F

225°F

225°F

175°F

125°F

80°F

FLOW DIRECTION THROUGH ELEMENT

(COALESCING)

IN/OUT

INLET

APPLICATION ELEMENT

OIL

REMOVAL

(LIQUIDS)

PARTICULATE

REMOVAL

(SOLIDS)

OIL VAPOR

REMOVAL

GRADE

AA

A

B

C

RAA

RA

RB

RC

RD

WARNINGS

OUTLET

INLET

FILTRATION GRADES

PURPOSE NOMINAL

Extra Coarse

Coalescing

Coarse

Coalescing

General Purpose

Coalescing

High Efciency

Coalescing

Extra Coarse

Particulate

Coarse

Particulate

General Purpose

Particulate

High Efciency

Particulate

Vapor Absorbing

PARTICULE

REMOVAL

25.00 μ IN/OUT WHITE

1.00 μ IN/OUT RED

25.00 μ OUT/IN WHITE

(PARTICULATE)

OUT/IN

OUTLET

ELEMENT

FLOW

DIRECTION

5.00 μ IN/OUT GREEN

0.01 μ IN/OUT BLUE

5.00 μ OUT/IN GREEN

1.00 μ OUT/IN RED

0.01 μ OUT/IN BLUE

0.01 μ OUT/IN WHITE

COLOR

CODE

DO NOT REPLACE ANY ITEM ON FILTER WHILE IT IS PRESSURIZED.

•

DO NOT OPERATE A LEAKING FILTER. TAKE FILTER OUT OF SERVICE IMMEDIATELY.

•

DO NOT OPERATE ABOVE MAXIMUM WORKING PRESSURE (MWP) AT MAXIMUM OPERATING TEMPERATURE (°F).

•

PAGE 1

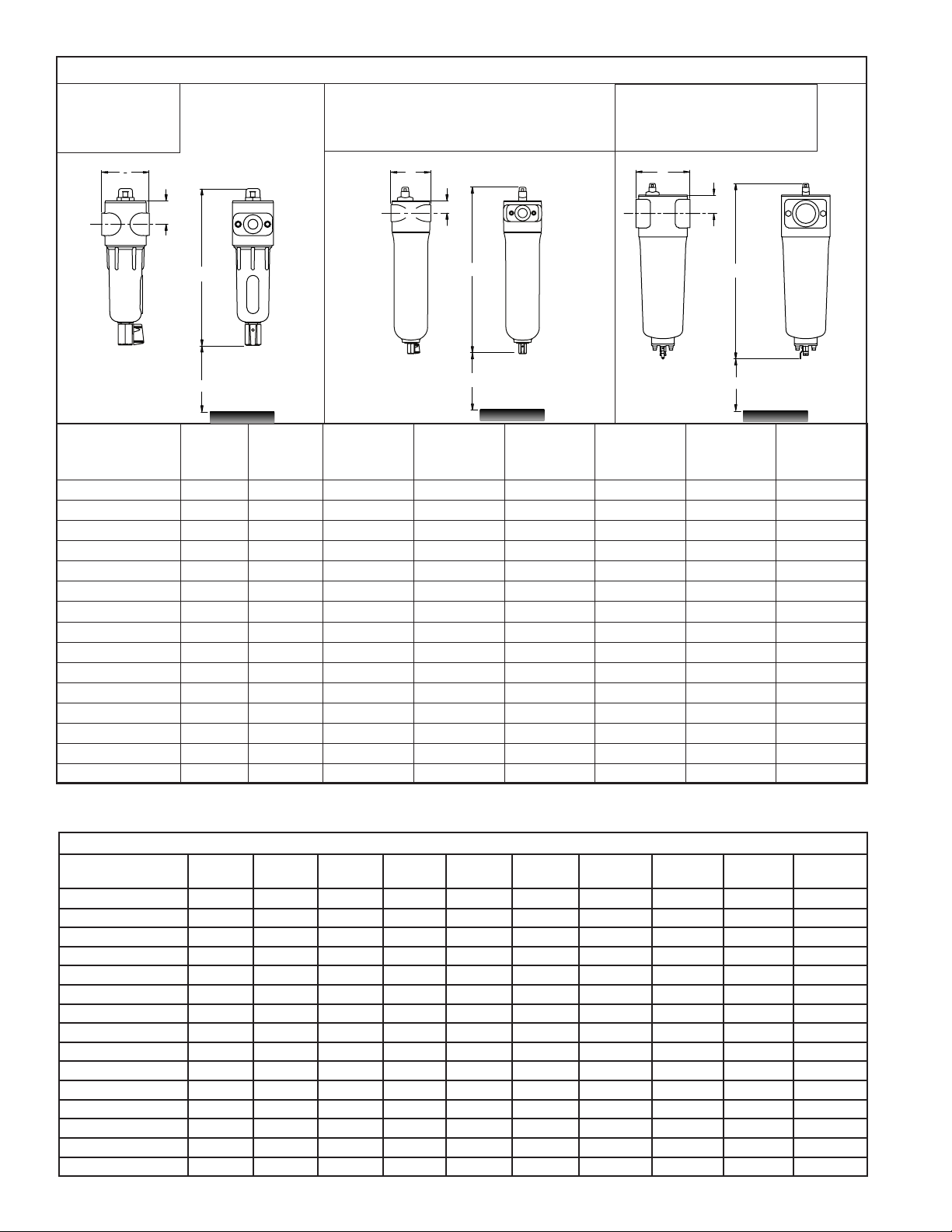

DIMENSIONS FOR:

F200-15-1/4

F200-25-3/8

F200-25-1/2

FILTER HOUSING DIMENSIONS & WEIGHTS

DIMENSIONS FOR:

F200-55-1/2

F200-85-3/4

F200-100-1

F200-150-1

F200-265-1-1/4

F200-350-1-1/2

F200-400-2

F200-500-2

DIMENSIONS FOR:

F200-600-3 F200-1250-3

F200-800-3

F200-1000-3

A

FILTER MODEL

B

C

ELEMENT

REMOVAL

D

CLEARANCE

FLOW**

(SCFM)

IN/OUT

CONN.

(NPT)

A

(INCHES)

A

B

C

D

B

(INCHES)

ELEMENT

REMOVAL

CLEARANCE

(INCHES)

C***

D

(INCHES)

A

B

C

ELEMENT

D

REMOVAL

CLEARANCE

HOUSING

WEIGHT****

(LBS)

ELEMENT

WEIGHT****

(LBS)

F200-15-1/4-(*) 15 1/4" 2-13/16 1-5/8 9-1/4 3 1.3 0.1

F200-25-3/8-(*) 25 3/8" 2-13/16 1-5/8 9-1/4 3 1.3 0.1

F200-25-1/2-(*) 25 1/2" 2-13/16 1-5/8 9-1/4 3 1.3 0.1

F200-55-1/2-(*) 55 1/2" 3-7/16 1-5/16 11-3/4 4 3.2 0.3

F200-85-3/4-(*) 85 3/4" 4-15/16 1-5/8 14-9/16 4 5.7 0.5

F200-100-1-(*) 100 1" 4-15/16 1-5/8 14-9/16 4 5.7 0.6

F200-150-1-(*) 150 1" 4-15/16 1-5/8 20-7/16 6 6.7 0.9

F200-265-1-1/4-(*) 265 1-1/4" 4-15/16 1-5/8 20-7/16 6 6.7 1

F200-350-1-1/2-(*) 350 1-1/2" 5-5/16 2-1/16 21-3/8 6 8.7 1.1

F200-400-2-(*) 400 2" 5-5/16 2-1/16 21-3/8 6 8.7 1.1

F200-500-2-(*) 500 2" 5-5/16 2-1/16 29-3/8 6 9.9 2.3

F200-600-3-(*) 600 3" 7-7/8 2-3/4 24-1/2 8 19.8 2.7

F200-800-3-(*) 800 3" 7-7/8 2-3/4 30-1/16 8 21.9 3.6

F200-1000-3-(*) 1000 3" 7-7/8 2-3/4 34-3/4 12 28.1 4.3

F200-1250-3-(*) 1250 3" 7-7/8 2-3/4 34-3/4 12 28.1 4.3

*Insert appropriate ltration grades here; for example F200-15-1/4-B.

***Dimensions include lter housing, PD-6 and manual drain.

**Flow is based on SCFM @ 100 PSIG @ 100°F.

****For total lter weight, add element weight to housing weight.

FLOW CAPACITIES AT VARIOUS OPERATING PRESSURES (SCFM)

FILTER MODEL 25

PSIG

50

PSIG

75

PSIG

100

PSIG

125

PSIG

150

PSIG

175

PSIG

200

PSIG

225

PSIG

F200-15-1/4 8 11 13 15 17 18 20 21 23 24

F200-25-3/8 13 18 22 25 28 31 33 35 38 40

F200-25-1/2 13 18 22 25 28 31 33 35 38 40

F200-55-1/2 28 39 48 55 62 67 73 78 83 87

F200-85-3/4 43 60 74 85 95 104 112 120 128 134

F200-100-1 50 71 87 100 11 2 122 132 141 150 158

F200-150-1 75 107 131 150 168 183 198 212 225 237

F200-265-1-1/4 133 188 231 265 297 323 350 374 398 419

F200-350-1-1/2 175 249 305 350 392 427 462 494 525 553

F200-400-2 200 284 348 400 448 488 528 564 600 632

F200-500-2 250 355 435 500 560 610 660 705 750 790

F200-600-3 300 426 522 600 672 732 792 846 900 948

F200-800-3 400 568 696 800 896 976 1056 1128 1200 1264

F200-1000-3 500 710 870 1000 1120 1220 1320 1410 1500 1508

F200-1250-3 625 888 1088 1250 1400 1525 1650 1763 1875 1885

PAGE 2

250

PSIG

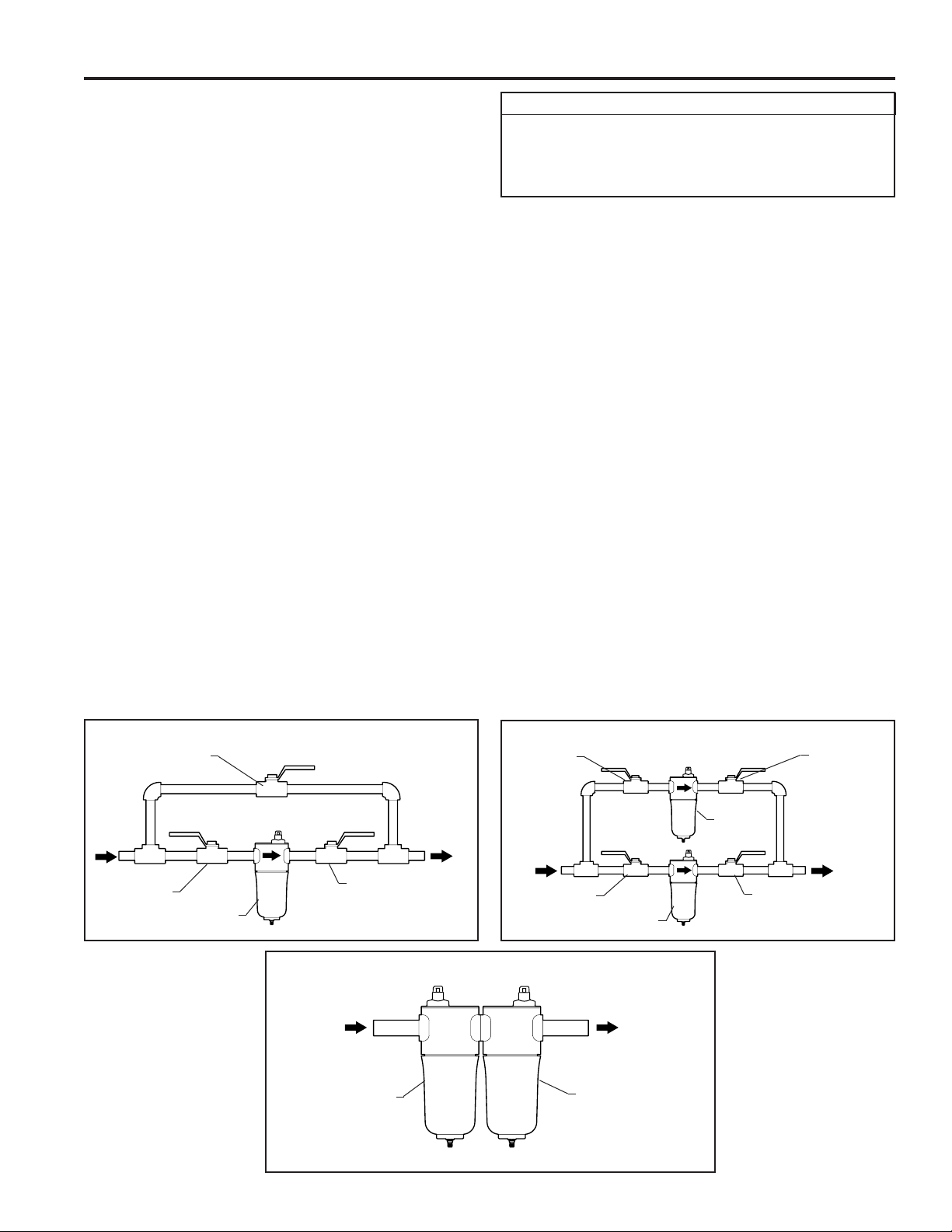

INSTALLATION

Before installing lter, check operating temperature and pres-

1.

sure conditions to verify that they are within the specied

ranges. (See Operating Conditions on page 1). Also verify

that system ow rate corresponds to the rated capacity of

the lter. Operating at ows above rated capacity will result

in increased pressure drop.

Locate Filter at the point of lowest operating temperature to

2.

ensure that water and oil vapor do not condense downstream

of the lter. Filter should be installed close to the point of

use to minimize the risk of pipe scale, dirt, etc. recontaminating the compressed air. This is particularly important when

installing a new lter on an existing system that has not had

proper ltration.

Install lter vertically. Provide required minimum clearance

3.

below lter to allow for replacement of element.

(See Element Removal Clearance on page 2).

Protect lter from reverse ow conditions. Do not install lter

4.

downstream of quick opening valves.

Remove lter head from the bowl by turning bowl counter-

5.

clockwise. Pull element from locator. Set bowl and element

aside for use later.

Install inlet and outlet shutoff valves to facilitate replacement

6.

of element. Bypass piping is recommended (See Figure 1A

and 1B). MAKE SURE VALVES ARE CLOSED BEFORE

PROCEEDING.

IMPORTANT

INSTALL FILTER HEAD INTO THE PIPING WITH ARROWS POINTING IN THE PROPER DIRECTION TO

ENSURE PROPER OPERATION. (SEE FLOW DIRECTION DIAGRAM BELOW).

8.

Install element by pushing onto element locator on lter head.

Check to make sure that the o-ring in the head is in the proper

9.

position. Thread lter bowl into lter head and tighten either

by hand (models F200-15 through 55) or with strap wrench

(models F200-85 through 1250). Do not over tighten. Overtightening could damage lter bowl or make it difcult to remove.

10.

Make sure drain valve on bottom of lter is closed. On lters

equipped with ADM2-2 auto drain, provide a drain line to

remove accumulated water and oil.

11.

Pressurize system and slowly open inlet and outlet shutoff

valves.

12.

Check piping for leaks. Depressurize system and repair leaks

as needed.

13.

Re-pressurize system and slowly open inlet and outlet shutoff

valves. Close bypass valve if provided.

14.

Filter is now in service.

Connect lter head into piping. Avoid reducers or bushings to

7.

match inlet size. The resulting restriction will increase pressure

drop. Make sure head is installed with ow arrows pointing

in proper direction. Use pipe thread compound as required.

FIGURE 1A BYPASS

BYPASS

VALV E

INLET

SHUTOFF

VALV E

FILTER

OUTLET

SHUTOFF

VALV E

FIGURE 1C FILTERS MANIFOLDED WITH CONNECTOR KIT

FIGURE 1B FILTERED BYPASS

INLET

BYPASS

VALV E

INLET

SHUTOFF

VALV E

FILTER

OUTLET

BYPASS

VALV E

BYPASS

FILTER

OUTLET

SHUTOFF

VALV E

PARTICULATE

FILTER

(LOWER EF-

FICIENCY)

PAGE 3

COALESCING FILTER

(HIGHER EFFICIENCY)

Loading...

Loading...