MARCH 1993

P/N: 32-0130-B

®

INST ALLA TION AND MAINTENANCE INSTRUCTIONS

F102 SERIES FILTER HOUSINGS

TABLE 1 OPERATING CONDITIONS

MAXIMUM WORKING PRESSURE

All Standard Models

High Temperature Models (HT)

Special Models

AMBIENT TEMPERATURE

Minimum

Maximum

MAXIMUM INLET TEMPERATURE

AA, A, RAA, RA, RB, and RC Series

B Series

C Series

RD Series

HT Series

TABLE 2 AVAILABLE ELEMENT GRADES

FLOW DIRECTION

THRU ELEMENT

Oil

Removal

(Liquid)

Solid

Particle

Removal

Oil Vapor

Removal

ELEMENT

GRADE

AA

A

B

C

RAA

RA

RB

RC

HT

RD

PURPOSE

Extra Coarse Coalescing

Coarse Coalescing

General Purpose Coalescing

High Efficiency Coalescing

Extra Coarse Particulate

Coarse Particulate

General Purpose Particulate

High Efficiency Particulate

High Temperature Particulate

Vapor Adsorbing

250 PSIG

In/Out

In/Out

In/Out

In/Out

Out/In

Out/In

Out/In

Out/In

Out/In

Out/In

165 PSIG

35°F

150°F

225°F

175°F

125°F

80°F

450°F

COLOR

Zinc Plate

Consult Data Plate

TABLE 3 ENGINEERING DATA

CODE

Black

Green

Red

Blue

Black

Green

Red

Blue

Black

FILTER

MODEL

NO.

F102-1500-(*)

F102-2000-(*)

F102-3500-(*)

F102-5000-(*)

F102-7500-(*)

F102-10,000-(*)

F102-12,500-(*)

F102-15,000-(*)

F102-20,000-(*)

*Insert appropriate filtration grades here; for example F102-1500-B.

**Flow is based on SCFM @ 100 PSIG @ 100°F.

***Housing weight does not include elements. For element weights see Table 5.

FLOW

(SCFM)

1500

2000

3500

5000

7500

10,000

12,500

15,000

20,000

**

IN/OUT

CONN.

(INCHES)

3 FLG

4 FLG

6 FLG

6 FLG

8 FLG

10 FLG

10 FLG

12 FLG

16 FLG

DRAIN

CONN.

(NPT)

1"

1"

1"

1"

1"

1"

1"

1"

1"

A

(INCHES)

18-3/4

18-3/4

24-3/4

28

32

36

36

42

52

B

(INCHES)

10-3/4

10-3/4

12-3/4

16

20

24

24

30

36

C

(INCHES)

32

33-1/2

32

33-1/2

34-1/2

35-1/2

35-1/2

44-1/2

46

D

(INCHES)

70-3/4

78-1/2

77-1/2

78-1/2

80-1/2

83-3/4

83-3/4

94-3/4

99-1/4

E

(INCHES)

82

89-1/2

92

93

98-1/4

104-1/4

104-1/4

117-3/4

126

F

(INCHES)

24

30

30

30

30

30

30

30

30

HOUSING

***

WEIGHT

(LBS.)

300

325

400

550

775

1025

1050

1675

2300

TABLE 4 FLOW CAPACITIES AT VARIOUS OPERATING PRESSURES (SCFM)

MODEL NO.

F102-1500-(*)

F102-2000-(*)

F102-3500-(*)

F102-5000-(*)

F102-7500-(*)

F102-10,000-(*)

F102-12,500-(*)

F102-15,000-(*)

F102-20,000-(*)

*Insert appropriate filtration grades here; for example F102-1500-B.

PRINTED IN THE USA ©1993 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PAGE 1

25

PSIG

520

690

1210

1730

2595

3460

4325

5190

6920

50

PSIG

845

1130

1975

2820

4230

5640

7050

8460

11,280

75

PSIG

1175

1565

2735

3910

5865

7820

9775

11,730

15,640

100

PSIG

1500

2000

3500

5000

7500

10,000

12,500

15,000

20,000

125

PSIG

1830

2435

4265

6090

9135

12,180

15,225

18,270

24,360

150

PSIG

2155

2870

5025

7180

10,770

14,360

17,950

21,540

28,720

175

PSIG

2480

3310

5790

8270

12,405

16,540

20,675

24,810

33,080

200

PSIG

2810

3745

6550

9360

14,040

18,720

23,400

28,080

37,440

225

PSIG

3135

4180

7315

10,450

15,675

20,900

26,125

31,350

41,800

250

PSIG

3460

4615

8080

11,540

17,310

23,080

28,850

34,620

46,160

WARNINGS

DO NOT REMOVE, REPAIR OR REPLACE ANY ITEM ON VESSEL WHILE IT IS UNDER PRESSURE.

DO NOT OPERATE IF THERE IS A LEAK IN VESSEL. TAKE VESSEL OUT OF SERVICE IMMEDIATELY AND NOTIFY YOUR

CERTIFYING AUTHORITY.

DO NOT OPERATE ABOVE MAXIMUM WORKING PRESSURE (MWP) AT MAXIMUM OPERATING TEMPERATURE (°F)

SHOWN ON ASME NAMEPLATE.

THIS ASME CODE VESSEL MUST BE PROTECTED BY A PRESSURE RELIEF VALVE. Refer to OSHA 1910.169 Par b, Sub

Par (3) and ASME Boiler and Pressure Vessel Code, Section VIII, Div 1 UG-125, Par (1). Also check government regulations,

state and local codes.

DO NOT WELD, GRIND OR SAND VESSEL. IT WILL NOT BE SAFE TO OPERATE.

DO NOT OPERATE VESSEL IF THERE HAS BEEN A FIRE. TAKE VESSEL OUT OF SERVICE IMMEDIATELY AND NOTIFY

YOUR CERTIFYING AUTHORITY.

ANY DAMAGE TO VESSEL CAN MAKE IT UNSAFE. INSPECT OUTSIDE AND INSIDE OF VESSEL REGULARLY FOR

CORROSION OR ANY DAMAGE (i.e., DENTS, GOUGES OR BULGES). IF DAMAGED OR CORRODED TAKE OUT OF

SERVICE IMMEDIATELY AND NOTIFY YOUR CERTIFYING AUTHORITY.

USE THE PROPER RULES FOR THE GAS BEING PROCESSED.

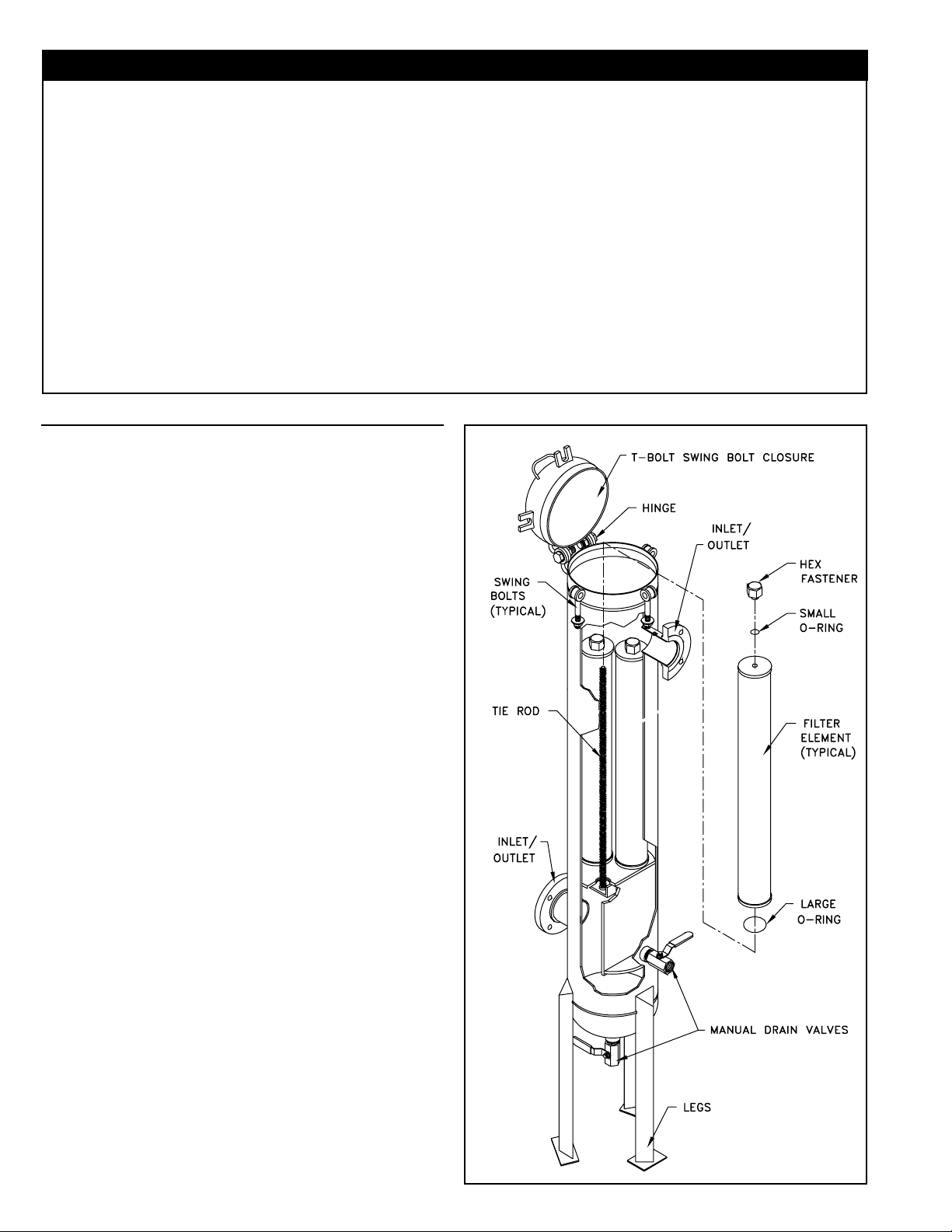

INSTALLATION (PART 1 HOUSING) FIGURE 1 TYPICAL ASSEMBLY

Locate compressed air and gas filters at the points of lowest

1.

operating temperatures to ensure that water and oil will not

condense downstream of the filter.

Filters should be installed close to the point of use to

2.

minimize the risk of pipe scale, dirt, etc. recontaminating the

compressed air or gas. This is particularly important when

installing new filters in an existing installation which has not

had proper filtration.

Protect filters from reverse flow conditions. Do not install

3.

filters downstream of quick opening valves.

Before installing filter, check ambient and operating tem-

4.

perature and pressure conditions to verify that they are

within the specified ranges. (See Table 1). Also verify that

system flow rate corresponds to the rated capacity of the

filter. (See table 4). Operating filter at flows above rated

capacity will result in increased pressure drop. Do not use

reducers to match filter inlet size. The resulting restriction will

cause high pressure drop.

Install filter in vertical position. Provide required minimum

5.

clearance above filter to allow for replacement of elements.

(See Table 3).

Install inlet and outlet shutoff valves to facilitate replacement

6.

of elements. By-pass piping is recommended.

Check labels on filter housing, and connect piping so that air

flows through inlet and outlet ports as indicated. Make sure

7.

that air flow through filter element is correct. Improper flow

direction can minimize filter performance. (See Table 2).

Install differential pressure gauge (optional) on filter housing

using instructions provided with gauge kit. Differential

8.

pressure is used to monitor element life (except grade RD)

and indicates when an element change is required.

Insert 1" NPT close nipples into 1" NPT couplings in vessel

and tighten securely. Screw 1" NPT manual valves onto 1"

9.

close nipples and tighten securely. (See Figure 1).

Loosen swing bolt nuts until they will clear the tabs on the

PAGE 2 ©1993 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PRINTED IN THE USA

INSTALLATION (PART 2 ELEMENT)

WARNING

DO NOT LOOSEN SWING BOLT NUTS BEFORE THE

FILTER IS COMPLETELY DEPRESSURIZED.

1.

enclosure. It is not necessary to remove the nuts from the

bolts. (See Figure 1).

6.

(See Table 5 ).

Before closing housing, inspect baffle to make certain that

7.

new elements have been installed in each position.

With enclosure o-rings in place, carefully lower enclosure

8.

and raise all swing bolts over tabs. Tighten all nuts evenly.

Close drain valve; then slowly open inlet and outlet valves.

9.

Close by-pass valves if provided.

Element(s) are shipped separately and must be installed

2.

before filter is ready for service. Remove hex fastener(s)

from tie rod(s) in housing.

Remove element(s) from packaging and remove o-ring(s)

3.

from end cap(s) of element(s). Install o-ring(s) in o-ring

groove(s) on hex fastener(s).

Install element(s) in housing so that tie rod protrudes

4.

through small hole in endcap.

Thread hex fastener(s) onto the tie rod(s) and tighten so that

5.

element(s) are held firmly in place. Do not over tighten.

(See Figure 1).

Repeat steps 11 thru 14 for each new element required.

REPLACEMENT PARTS

TABLE 5 REPLACEMENT PARTS

REPLACEMENT

FILTER

MODEL NO.

F102-1500-(*)

F102-2000-(*)

F102-3500-(*)

F102-5000-(*)

F102-7500-(*)

F102-10,000-(*)

F102-12,500-(*)

F102-15,000-(*)

F102-20,000-(*)

*Insert appropriate filtration grades here; for example F102-3500-C and

replacement element E101/102-625-C (five required).

ELEMENT

MODEL NUMBER

E101/102-500-(*)

E101/102-625-(*)

E101/102-625-(*)

E101/102-625-(*)

E101/102-625-(*)

E101/102-625-(*)

E101/102-625-(*)

E101/102-625-(*)

E101/102-625-(*)

ELEMENT

WEIGHT

LBS.

2.8

3.2

3.2

3.2

3.2

3.2

3.2

3.2

3.2

Filter is now in service.

10.

MAINTENANCE

Drain oil removal filters every shift.

•

Check differential pressures regularly on coalescing and

•

particulate filters (AA, A, B, C, RA, RB, RC, and HT grades).

When differential pressure reaches 10 psid, install clean

elements. On adsorbing filters (grade RD), install clean

elements when hydrocarbon vapors are first detected

downstream or every six months, whichever comes first.

For correct replacement element model numbers, see label

•

on filter housing and/or the bottom endcap of the element.

(Refer to Table 6).

NUMBER OF

ELEMENTS IN

HOUSING

3

3

5

8

12

16

20

24

32

SWING BOLT

CLOSURE

O-RING

26-5464

26-5465

26-5465

26-5528

26-5529

26-5530

CONSULT FACTORY

CONSULT FACTORY

CONSULT FACTORY

MANUAL

DRAIN VALVE

14-0451

14-0451

14-0451

14-0451

14-0451

14-0451

14-0451

14-0451

14-0451

ACCESSORIES

TABLE 6 DIFFERENTIAL PRESSURE GAUGE KITS:

PART

NUMBER

29-0255

29-0257

84-0129

84-0131

84-0130

84-0211

PRINTED IN THE USA ©1993 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PAGE 3

MODEL

NUMBER

PD-2 Gauge

PD-2/SW Gauge

PD-2 KIT

PD-2/SW KIT

PD-2/HT KIT

PD-2/HT SW KIT

DESCRIPTION

Differential pressure gauge. (Only)

Differential pressure gauge with N.O. reed switch. (Only)

Differential pressure gauge with nylon tubing and brass tube fittings.

Differential pressure gauge with N.O. reed switch, nylon tubing and brass tube fittings.

Differential pressure gauge with stainless steel tubing and steel tube fittings (for HT units).

Differential pressure gauge with N.O. reed switch, stainless steel tubing and steel tube fittings (for HT units).

TROUBLESHOOTING

CONDITION

Initial pressure

drop too

high

Oil carryover

POTENTIAL CAUSE

Filter undersized for flow rate.

Filter grade too fine.

Filter inlet smaller than pipe size.

Oil present in system before installing filter.

Excessive inlet oil > 50ppm.

Filter installed backwards.

Filter bowl not being drained.

High differential pressure.

Defective seal.

Incorrect replacement element.

By-pass valve leaking or open.

Unfiltered air entering from source down stream of filter.

High operating temperatures.

Cooling by refrigerated dryer.

Short element

life

Excessive particulate contamination.

High compression temperatures causing varnish/

carbon formation.

Oil water emulsion overloading element.

High viscosity oil or freeze-up due to low ambient

temperature.

WARRANTY

I. INSTALLATION.

Unless otherwise set forth in a quotation and/or acknowledgment, Seller shall not be responsible for

installation. Cost of and all risks of damage to the equipment and/or components thereof caused by

installation shall be the sole responsibility of Buyer. If supervision of installation and/or supervision of

start up of the equipment is to be provided by Seller, Buyer shall assume all costs incurred by Seller in

furnishing supervision. If supervision of installation and/or supervision of start up of the equipment is

provided by Seller, Seller shall only be responsible for any loss or damage growing out of a direct

negligent act or acts of Seller’s supervisor.

SELLER SHALL NOT BE RESPONSIBLE FOR IMPROPER OPERATION OF THE EQUIPMENT

DUE TO FAULTY ERECTION OR INSTALLATION.

II. PERFORMANCE.

Seller shall have no responsibility for the performance of its Goods when installed under conditions

varying materially from those under which the product is usually tested or operated under existing

industry standards.

III. WARRANTY

All filter housings manufactured by Seller are guaranteed to be free of defective materials and

workmanship for a period of five (5) years from the date of shipment. This warranty does not include

elements, drain line components, gaskets, o-rings or any other types of seals, or any accessories or

All goods manufactured by Seller are guaranteed to be free from defective materials and

workmanship for a period of one (1) year from date of shipment. The equipment and accessories

sold but not manufactured by Seller are guaranteed only to the extent that either Seller or Buyer

is able to recover under the manufacturer's warranty. This warranty shall not be assignable to

buyer.

expendable items.

The above warranties for all products described do not cover abuse, neglect, lack of normal maintenance,

accidents or other exceptional circumstances.

Date of shipment will be defined as the date of departure from the factory or from distributor stock. A

copy of the distributor invoice to the customer at time of shipment is required as verification of shipment

from distributor stock. Equipment start up will be verified by receipt of the product registration card.

Seller’s obligation under this warranty may, at its option, be discharged by furnishing or repairing,

without charge, FOB its factory, a similar part to replace any part of its own manufacture which within

the above specified periods, proves to have been defective, provided that within a reasonable time for

inspection after delivery, Seller is notified of such defects and the equipment, material or part claimed

to be defective is delivered pre-paid to Seller at Lake City, Pennsylvania with evidence that it has been

properly maintained and used in accordance with instructions. If, in connection with such warranties,

repairs are performed by the Buyer with the written authorization of Seller, then the expense in connection

with such repairs shall not exceed the cost of material and direct labor. If such repairs are performed by

Buyer without the written authorization of Seller, Seller will not assume any of the expenses in connection

with such repairs and will immediately void any remaining warranty on the Goods.

THE REPAIR OR REPLACEMENT WARRANTY HEREIN SET FORTH IS THE EXCLUSIVE

WARRANTY GIVEN BY SELLER FOR ITS GOODS. THIS WARRANTY IS GIVEN IN LIEU OF ANY

OR ALL WARRANTIES, WHETHER WRITTEN OR ORAL, EXPRESSED OR IMPLIED. ANY AND

ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

PURPOSE ARE HEREBY EXPRESSLY EXCLUDED BY SELLER. SELLER NEITHER ASSUMES,

RECOMMENDATION

Install larger filter.

Install coarser grade element.

Install larger filter.

Clean piping.

Check compressor and/or air/oil separator if compressor is rotary

vane or screw. Lower lube rate if reciprocating compressor. Install

coarse coalescer for prefiltration.

Check installation instructions.

Check and repair auto drain. Drain frequently if manual valve.

Check element if excessive (7-10 psid or above).

Check o-ring in element.

Check and use finer grade.

Close valve. Check seals.

Relocate filter or install additional filter.

Install, clean, replace or relocate aftercooler.

Install grade B or C filter downstream of dryer.

Install coarse coalescing filter immediately upstream of existing filter.

Use compressor lubricant with good temperature stability. Lower

lube rates where possible. Use coarser grade filter element.

Inspect separator. Remove water with better separation.

Raise ambient temperatures. Heat trace inlet piping and housing.

NOR DOES IT AUTHORIZE ANY OTHER PERSON TO ASSUME ON ITS BEHALF ANY OTHER

LIABILITY IN CONNECTION WITH THE SALE OF ITS GOODS.

IV. LIMITATIONS OF LIABILITIES AND INDEMNITIES.

IN NO CASE, WHETHER AS A RESULT OF BREACH OF CONTRACT, BREACH OF WARRANTY

OR TORT (INCLUDING SELLER’S OR BUYER’S NEGLIGENCE OR STRICT LIABILITY) SHALL

SELLER BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES INCURRED BY

BUYER, INCLUDING, BUT NOT LIMITED TO, LOSS OF SALES PROFIT, REVENUE, OR GOOD WILL;

LOSS OF USE OF GOODS OR ANY ASSOCIATED EQUIPMENT OR MATERIAL; COST OF CAPITAL;

COST OF SUBSTITUTE PRODUCTS, FACILITIES OR SERVICES; DOWN TIME COSTS;

ATTORNEY’S FEES; OR LOSSES OR CLAIMS OF CUSTOMERS OF BUYER FOR SUCH DAMAGES

BUYER HEREBY AGREES TO INDEMNIFY AND HOLD HARMLESS SELLER FROM ANY AND ALL

SUCH DAMAGES. BUYER FURTHER AGREES TO DEFEND, INDEMNIFY AND HOLD HARMLESS

SELLER FROM ANY AND ALL CLAIMS, LIABILITY, DAMAGES OR EXPENSES (INCLUDING

ATTORNEY’S FEES) DUE TO PERSONAL INJURIES OR DEATH, TO BUYER, ITS EMPLOYEES,

AND THIRD PARTIES AND FROM PROPERTY DAMAGE RESULTING FROM THE NEGLIGENCE

OR STRICT LIABILITY OF BUYER NOT WITHSTANDING THE PROVISIONS OF ANY WORKER

COMPENSATION OR SIMILAR STATUTE.

V. SERVICE, OPERATING PROCEDURE, WARNINGS.

Should Buyer request start up supervision by Seller, a maximum number of days required for this

supervision may be included and specified in the quotation and/or acknowledgment as a separate price item.

The specified days are only approximate, since start up supervision is contingent upon equipment and work

supplied by others and beyond the control of Seller, and Seller shall be paid for any days actually worked in

addition to those specified on a pro-rata basis.

Start up supervision and warranty supervision and warranty service time will include all elapsed time

during the standard working hours, as defined by Seller, or Seller’s representative from the time Seller’s

representative leaves his operating base or another customer’s plant.

Where the service to be performed is start up supervision. Seller should be notified approximately 30 days

prior to start up Seller’s representatives may be required to have standard time verification sheets approved

by Buyer’s authorized representative, and the name and title of this representative should be furnished to

Seller with the notification.

Unless set forth in the quotation and/or acknowledgment, Seller shall not be obligated to provide special

operating manuals or operating procedures for the operation of its equipment or supply special warning

placards to be affixed to the equipment. If such manuals, procedures or placards are provided by Seller,

Buyer shall be responsible for payment of cost of furnishing such items, for instructing any operator of the

equipment as to the contents of such manuals and/or procedures; for requiring that such procedures be

abided by; for insuring that warning placards remain affixed to the equipment and for requiring operators to

abide by warning placards.

Any safety equipment required to be worn by any operator or maintenance person shall be provided by

Buyer, and the failure to provide such equipment or the failure to require the use thereof shall be the Buyer’s

sole responsibility. Buyer shall indemnify and hold Seller harmless for any liability with respect thereto.

Seller shall not be responsible for providing safety devices and/or guarding of the equipment except as

provided for in the quotation and/or acknowledgment, and Buyer specifically assumes all responsibility for

supplying such safety devices and/or guarding necessary for the safe operation of the equipment. If safety

devices and/or guarding are specified in the quotation and/or acknowledgment, Buyer shall be solely

responsible for making certain that any operator of the equipment uses such safety devices and/or guarding

and Buyer shall indemnify and hold Seller harmless with respect to any property damage and/or personal

injury, including death, occasioned by any person by reason of such failure on the part of Buyer and/or its

operator.

2950 Mechanic Street

Lake City, PA 16423-2095

Phone: 814/774-2631

MAKING COMPRESSED AIR AND GAS WORK BETTER SINCE 1944.

Fax: 814/774-3482

PAGE 4 ©1993 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PRINTED IN THE USA

Loading...

Loading...