Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

®

F101 SERIES FILTER HOUSINGS

TABLE 1 OPERATING CONDITIONS

MAXIMUM WORKING PRESSURE

All Standard Models

High Temperature Models (HT)

Special Models

AMBIENT TEMPERATURE

Minimum

Maximum

MAXIMUM INLET TEMPERATURE

AA, A, RAA, RA, RB, and RC Series

B Series

C Series

RD Series

HT Series

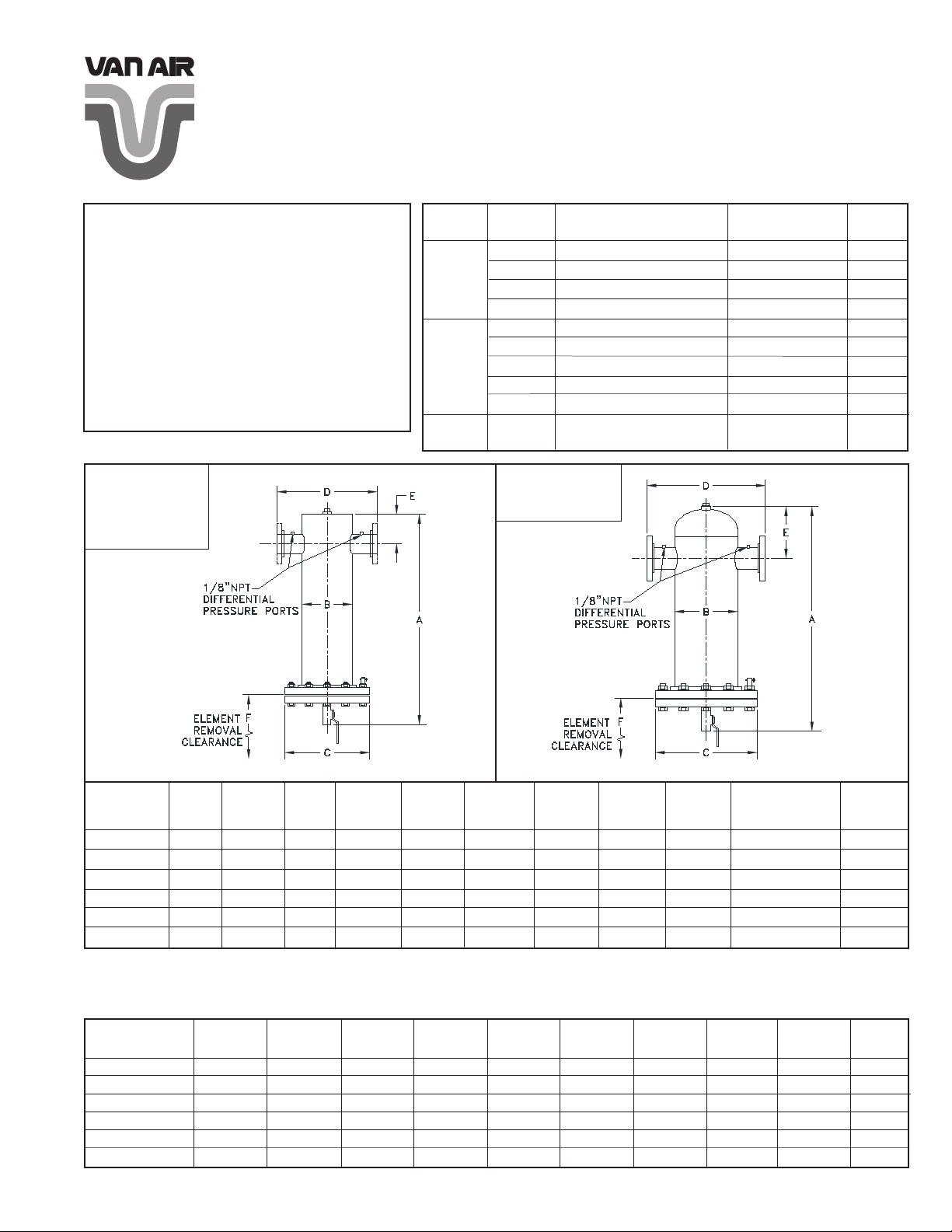

TABLE 3 ENGINEERING DATA

DIMENSIONS FOR:

F101-500

F101-1000

F101-1500

F101-2000

Consult Data Plate

250 PSIG

165 PSIG

35°F

150°F

225°F

175°F

125°F

80°F

450°F

TABLE 2 AVAILABLE ELEMENT GRADES

ELEMENT

Oil

Removal

(Liquid)

Solid

Particle

Removal

Oil Vapor

Removal

GRADE

RAA

DIMENSIONS FOR:

PURPOSE

AA

Extra Coarse Coalescing

A

Coarse Coalescing

B

General Purpose Coalescing

C

High Efciency Coalescing

Extra Coarse Particulate

RA

Coarse Particulate

RB

General Purpose Particulate

RC

High Efciency Particulate

HT

High Temperature Particulate

RD

Vapor Adsorbing

F101-3500

F101-5000

SEPTEMBER 2011

P/N: 32-0129-C

FLOW DIRECTION

THRU ELEMENT

In/Out

In/Out

In/Out

In/Out

Out/In

Out/In

Out/In

Out/In

Out/In

Out/In

COLOR

CODE

Black

Green

Red

Blue

Black

Green

Red

Blue

Zinc Plate

Black

FILTER

MODEL

NO.

F101-500-(*)

F101-1000-(*)

F101-1500-(*)

F101-2000-(*)

F101-3500-(*)

F101-5000-(*)

*Insert appropriate ltration grades here; for example F101-1500-B.

**Flow is based on SCFM @ 100 PSIG @ 100°F.

***Housing weight does not include elements. For element weights see Table 5.

FLOW

(SCFM)

500

1000

1500

2000

3500

5000

IN/OUT

**

CONN.

(INCHES)

2 NPT

3 NPT

3 NPT

4 FLG

6 FLG

6 FLG

DRAIN

CONN.

(NPT)

1/2"

1/2"

1/2"

1/2"

1/2"

1"

A

(INCHES)

39

41-1/8

44-1/2

50-7/8

56-5/8

61-5/8

B

(INCHES)

6-5/8

8-5/8

10-3/4

10-3/4

12-3/4

16

C

(INCHES)

11

13-1/2

16

16

19

23-1/2

D

(INCHES)

11-7/8

15-1/2

17-3/4

18

24-3/4

28

E

(INCHES)

4-5/8

5-1/4

6-1/4

6-3/8

14-1/2

16

F

(INCHES)

24

24

24

30

30

30

BOTTOM BLIND

FLANGE WEIGHT

(LBS.)

28

47

69

69

102

177

HOUSING

***

WEIGHT

(LBS.)

110

150

250

265

390

600

TABLE 4 FLOW CAPACITIES AT VARIOUS OPERATING PRESSURES (SCFM)

MODEL NO.

F101-500-(*)

F101-1000-(*)

F101-1500-(*)

F101-2000-(*)

F101-3500-(*)

F101-5000-(*)

*Insert appropriate ltration grades here; for example F101-1500-B.

PAGE 1

25

PSIG

175

345

520

690

1210

1730

50

PSIG

280

565

845

1130

1975

2820

75

PSIG

390

780

1175

1565

2735

3910

100

PSIG

500

1000

1500

2000

3500

5000

125

PSIG

610

1220

1825

2435

4265

6090

150

PSIG

720

1435

2155

2870

5025

7180

175

PSIG

825

1655

2480

3310

5790

8270

200

PSIG

935

1870

2810

3745

6550

9360

225

PSIG

1045

2090

3135

4180

7315

10,450

250

PSIG

1155

2310

3460

4615

8080

11,540

Page 2

WARNINGS

DO NOT REMOVE, REPAIR OR REPLACE ANY ITEM ON VESSEL WHILE IT IS UNDER PRESSURE.

DO NOT OPERATE IF THERE IS A LEAK IN VESSEL. TAKE VESSEL OUT OF SERVICE IMMEDIATELY AND NOTIFY YOUR

CERTIFYING AUTHORITY.

DO NOT OPERATE ABOVE MAXIMUM WORKING PRESSURE (MWP) AT MAXIMUM OPERATING TEMPERATURE (°F)

SHOWN ON ASME NAMEPLATE.

THIS ASME CODE VESSEL MUST BE PROTECTED BY A PRESSURE RELIEF VALVE. Refer to OSHA 1910.169 Par b, Sub

Par (3) and ASME Boiler and Pressure Vessel Code, Section VIII, Div 1 UG-125, Par (1). Also check government regulations, i.e.,

state and local codes.

DO NOT WELD, GRIND OR SAND VESSEL. IT WILL NOT BE SAFE TO OPERATE.

DO NOT OPERATE VESSEL IF THERE HAS BEEN A FIRE. TAKE VESSEL OUT OF SERVICE IMMEDIATELY AND NOTIFY

YOUR CERTIFYING AUTHORITY.

ANY DAMAGE TO VESSEL CAN MAKE IT UNSAFE. INSPECT OUTSIDE AND INSIDE OF VESSEL REGULARLY FOR CORROSION OR ANY DAMAGE (i.e., DENTS, GOUGES OR BULGES). IF DAMAGED OR CORRODED TAKE OUT OF SERVICE

IMMEDIATELY AND NOTIFY YOUR CERTIFYING AUTHORITY.

USE THE PROPER RULES FOR THE GAS BEING PROCESSED.

INSTALLATION (PART 1 FILTER HOUSING)

Locate compressed air and gas lters at the point of lowest

1.

operating temperatures to ensure that water and oil vapor will

not condense downstream of the lter.

Filters should be installed close to the point of use to mini-

2.

mize the risk of pipe scale, dirt, etc. recontaminating the

compressed air or gas. This is particularly important when

installing new lters on an existing installation which has not

had proper ltration.

Protect lters from reverse ow conditions. Do not install

3.

lters downstream of quick opening valves.

Before installing lter check ambient and operating tempera-

4.

ture and pressure conditions to verify that they are within the

specied ranges. (See Table 1). Also verify that system ow

rate corresponds to the rated capacity of the lter. (See Table

4). Operating lter at ows above rated capacity will result in

increased pressure drop. Do not use reducers to match lter

inlet size. The resulting restriction will cause high pressure

drop.

5.

Install lter in vertical position. Provide required minimum

clearance below lter to allow for replacement of elements.

(See Table 3).

Install inlet and outlet shutoff valves to facilitate replacement

6.

of elements. By-pass piping is recommended.

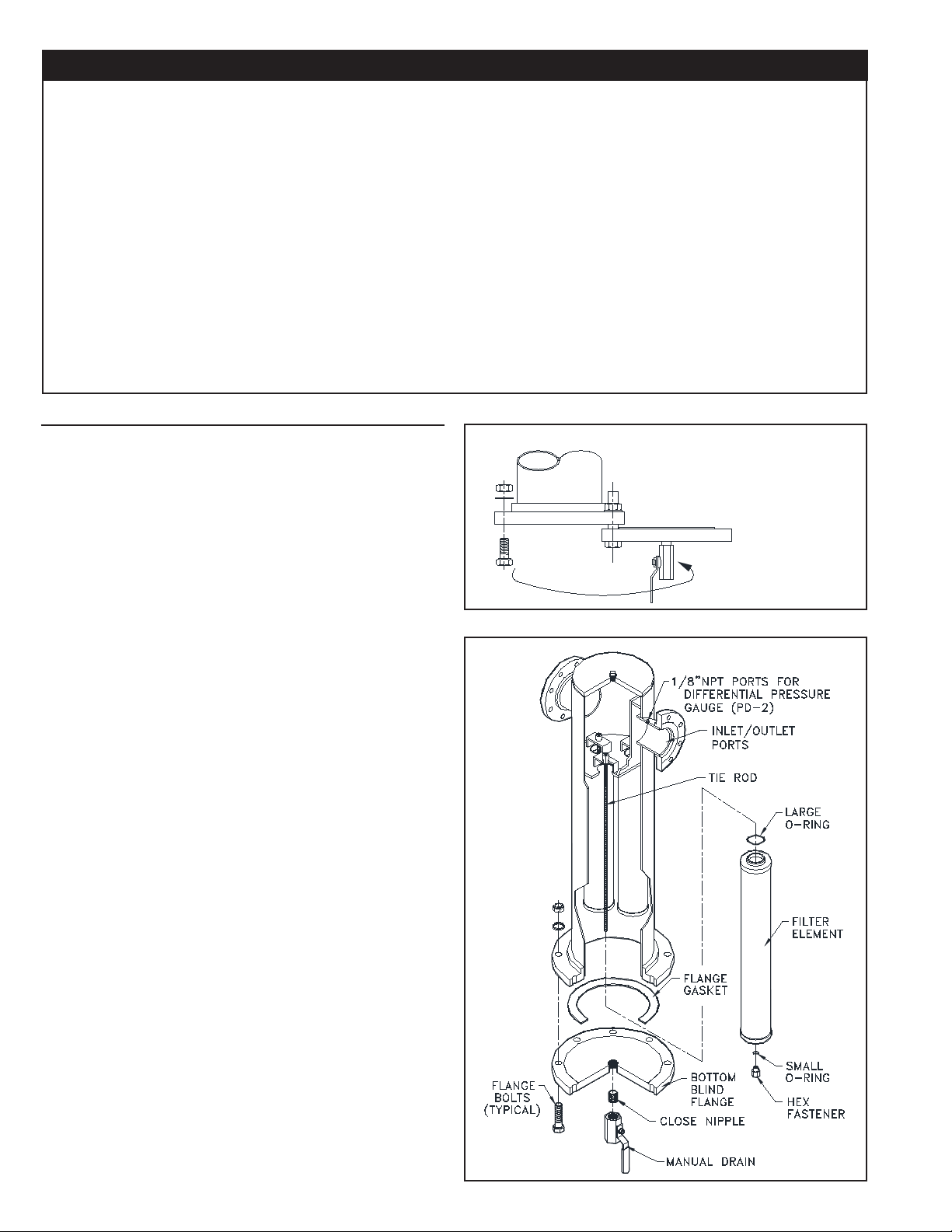

FIGURE 1 LONG FLANGE BOLT (Element access)

NOTE

Vessel models F101-500 thru

F101-2000 are equipped with a

single long ange bolt to permit

rotating of blind ange for access

to elements.

FIGURE 2 TYPICAL ASSEMBLY

Check labels on lter housing, and connect piping so that air

7.

ows through inlet and outlet ports as indicated. Make sure

air ow through lter element is correct. Improper ow direction can minimize lter performance. (See Table 2).

Install differential pressure gauge (optional) on lter housing

8.

using instructions provided with gauge kit. Differential pres-

sure is used to monitor element life (except grade RD) and

indicates when an element change is required.

(See Table 6).

Insert close nipple in threaded hole on bottom blind ange

9.

and tighten securely. Screw manual drain valve on close

nipple and tighten. (See Figure 2). When automatic draining

is required, a motorized ball valve or solenoid type is recommended.

PAGE 2

Page 3

INSTALLATION (PART 2 ELEMENT)

WARNING

DO NOT LOOSEN FLANGE BOLTS BEFORE THE VESSEL HAS BEEN COMPLETELY DEPRESSURIZED.

Provide support under blind ange to prevent it from falling

1.

when bolts are removed. Blind anges are heavy and could

cause injury if allowed to fall.

(See Table 3 for blind ange weights).

Remove bolts from ange and lower blind ange for access

2.

to elements. Filter models F101-500 through 2000 are

equipped with a single long ange bolt to permit rotation of

blind ange for access to elements. (See Figure 1).

6.

the element(s) are held rmly in place. Do not over tighten.

(See Figure 2).

Before closing housing, inspect bafe to make certain that

7.

new elements have been installed in each position.

(See Table 5 for element replacement data).

With gasket in place, carefully raise or swing blind ange

8.

into place and align bolt holes. Insert all bolts and completely tighten all nuts evenly.

Close drain valve; then slowly open inlet and outlet valves.

9.

Close by-pass valves if provided.

Filter is now in service.

10.

Element(s) are shipped separately and must be in-

3.

stalled before lter is ready for service. Remove hex

fasteners(s) from tie rod(s) in housing.

Remove element(s) from packaging and remove o-ring(s)

4.

from bottom end cap(s) of element(s). Install o-ring(s) in oring groove(s) on hex fastener(s). (See Figure 2).

Install element(s) in housing so that the tie rod protrudes

5.

through small hole in bottom end cap.

Thread hex fastener(s) onto the tie rod(s) and tighten so that

REPLACEMENT PARTS

TABLE 5 REPLACEMENT PARTS

FILTER

MODEL NO.

F101-500-(*)

F101-1000-(*)

F101-1500-(*)

F101-2000-(*)

F101-3500-(*)

F101-5000-(*)

*Insert appropriate ltration grades here; for example F101-3500-C and

replacement element E101/102-625-C (ve required).

REPLACEMENT

ELEMENT MODEL

NUMBER

E101/102-500-(*)

E101/102-500-(*)

E101/102-500-(*)

E101/102-625-(*)

E101/102-625-(*)

E101/102-625-(*)

ELEMENT

WEIGHT

LBS

2.8

2.8

2.8

3.2

3.2

3.2

MAINTENANCE

Drain oil removal lters every shift.

•

Check differential pressures regularly on coalescing and

•

particulate lters (AA, A, B, C, RA, RB, RC, and HT grades).

When differential pressure reaches 10 psid, install clean elements. On adsorbing lters (grade RD), install clean elements

when hydrocarbon vapors are rst detected downstream or

every six months, whichever comes rst.

For correct replacement element model numbers, see label on

•

lter housing and/or the bottom endcap of the element.

(Refer to Table 5).

NUMBER OF

ELEMENTS IN

HOUSING

1

2

3

3

5

8

HOUSING

GASKET

18-0207

18-0206

18-0210

18-0210

18-0209

18-0211

HEX

FASTENER

26-3258

26-3258

26-3258

26-3258

26-3258

26-3258

MANUAL DRAIN

VALV E

14-0450

14-0450

14-0450

14-0450

14-0450

14-0451

ACCESSORIES

TABLE 6 DIFFERENTIAL PRESSURE GAUGE KITS:

PART

NUMBER

29-0370

29-0371

84-0129

84-0131

84-0130

84-0211

PAGE 3

MODEL NUMBER

PD-2 GAUGE

PD-2/SW GAUGE

PD-2 KIT

PD-2/SW KIT

PD-2/HT KIT

PD-2/HT SW KIT

DESCRIPTION

Differential pressure gauge. (Only)

Differential pressure gauge with N.O. reed switch. (Only)

Differential pressure gauge with nylon tubing and brass tube ttings.

Differential pressure gauge with N.O. reed switch, nylon tubing and brass tube ttings.

Differential pressure gauge with stainless steel tubing and steel tube ttings (for HT units).

Differential pressure gauge with N.O. reed switch, stainless steel tubing and steel tube ttings (for HT units).

Page 4

TROUBLESHOOTING

CONDITION

Initial pressure

drop too

high

Oil carryover

Short element

life

POTENTIAL CAUSE

Filter undersized for ow rate.

Filter grade too ne.

Filter inlet smaller than pipe size.

Oil present in system before installing lter.

Excessive inlet oil > 50ppm.

Filter installed backwards.

Filter bowl not being drained.

High differential pressure.

Defective seal.

Incorrect replacement element.

By-pass valve leaking or open

Unltered air entering from source down stream of lter.

High operating temperatures.

Cooling by refrigerated dryer.

Excessive particulate contamination.

High compression temperatures causing varnish/carbon

formation.

Oil water emulsion overloading element.

High viscosity oil or freeze-up due to low ambient tem-

perature.

RECOMMENDATION

Install larger lter.

Install coarser grade element.

Install larger lter.

Clean piping.

Check compressor and/or air/oil separator if compressor is rotary vane

or screw. Lower lube rate if reciprocating compressor. Install coarse

coalescer for preltration.

Check installation instructions.

Check and repair auto drain. Drain frequently if manual valve.

Check element if excessive (7-10 psid or above).

Check o-ring in element.

Check and use ner grade.

Close valve. Check seals.

Relocate lter or install additional lter.

Install, clean, replace or relocate aftercooler.

Install grade B or C lter downstream of dryer.

Install coarse coalescing lter immediately upstream of existing lter.

Use compressor lubricant with good temperature stability. Lower lube

rates where possible. Use coarser grade lter element.

Inspect separator. Remove water with better separation.

Raise ambient temperatures. Heat trace inlet piping and housing.

PAGE 4

2950 Mechanic Street

Lake City, PA 16423-2095

Phone: 800/840-9906

Fax: 814/774-3482

www.vanairsystems.com

Loading...

Loading...