Van Air Systems EDV-115-PA User Manual

JAN 2011

P/N 432-10045

2950 Mechanic Street

Lake City, PA 16423 USA

Phone: 800/840-9906

Fax: 814/774-3482

www.vanairsystems.com

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

TM

TERMINATOR

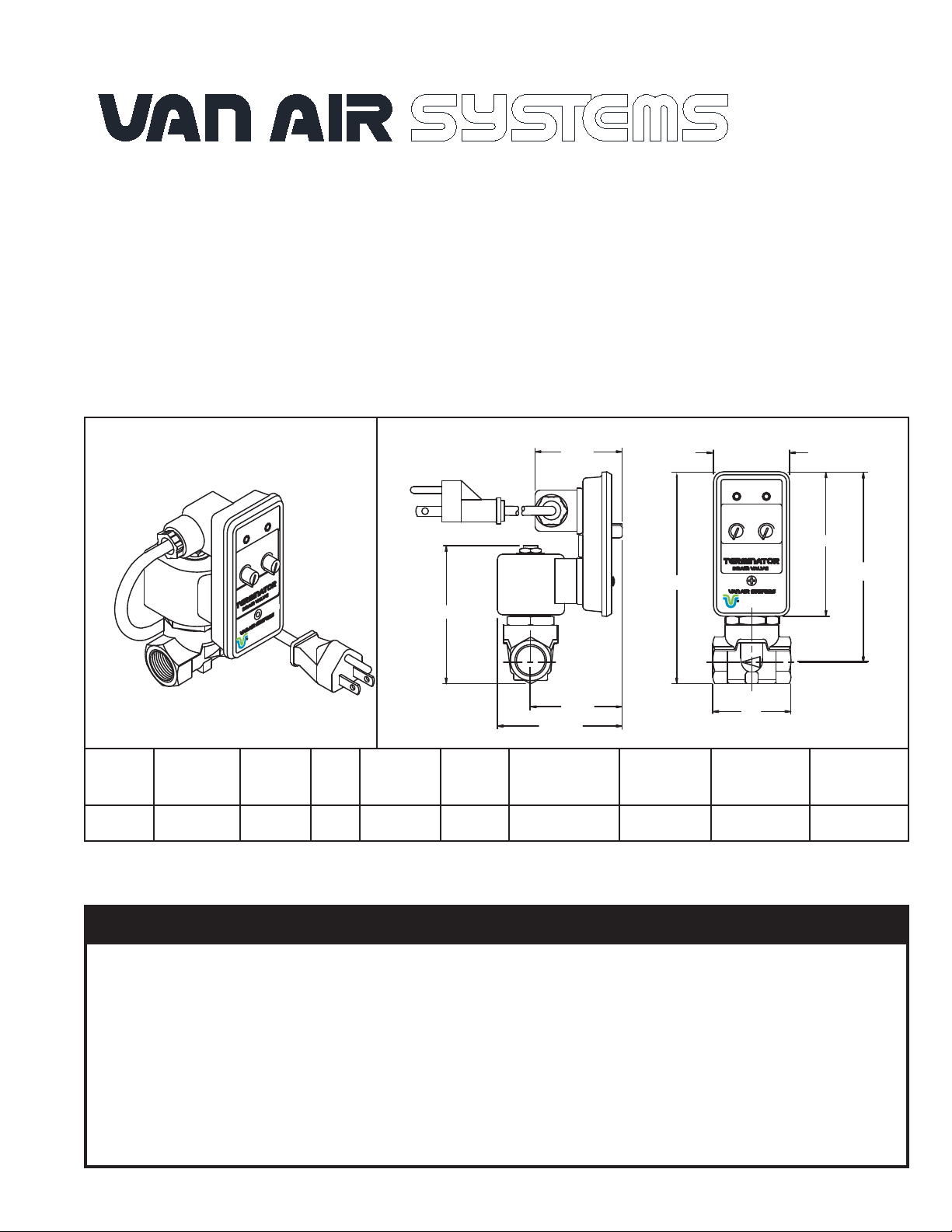

ELECTRONIC DRAIN VALVE Model EDV-115-PA

(1/2" VALVE, LARGE ORIFICE)

PRODUCT PURPOSE & FUNCTION:

V an Air's model EDV-1 15-PA series drain valve is designed to remove accumulated fl uids from compressed air & gas process-

ing equipment. With variable open time (1-60 seconds) and valve closed time (1-60 minutes), users can easily adjust the valve to drain

the required amount of accumulated fl uids. Power on and valve open status lights, as well as a built-in override/test function, give quick

verifi cation of valve operation.

FIGURE 1 SPECIFICATIONS

POWER

ON

CLOSED TIME

MINUTES

40

30

20

10

TEST

EDV-115-PA

OPEN TIME

30

50

20

60

10

Lake City, PA 16423 USA

Ph: (800) 840-9906

www.vanairsystems.com

2-1/4"

VALVE

OPEN

SECONDS

50

40

60

1

TM

5-7/16"

3-1/2"

1-15/16"

POWER

ON

CLOSED TIME

MINUTES

40

50

30

60

20

10

TEST

EDV-115-PA

Lake City, PA 16423 USA

www.vanairsystems.com

VALVE

OPEN

OPEN TIME

SECONDS

40

30

20

10

1

Ph: (800) 840-9906

50

60

3-11/16"

TM

4-13/16"

EDV-115-PA

Van Air

Part No

39-10510

Valve In/Out

Port Size

1/2"NPT

Orifi ce

Size

7/16"

C

2.75

v

Electrical

V/PH/HZ

115-1-50/60

Amps

.09

2-1/4"

3-1/16"

Working

Pressure Range

(psig/bar)

3-300/.2-20.7

Maximum

Fluid Temp

(°F/°C)

210/99

2"

Ambient

Temp Range

(°F/°C)

32-150/0-66

Approx

Weight

(lbs/Kg)

1.6/.7

WARNING

• READ INSTRUCTIONS CAREFULLY BEFORE INSTALLING OR OPERATING THIS DRAIN VALVE.

• DO NOT OPERATE LEAKING OR DAMAGED VALVES. REMOVE THEM FROM SERVICE IMMEDIATELY.

• DO NOT OPERATE VALVE ABOVE MAXIMUM OPERATING PRESSURE AND/OR MAXIMUM TEMPERATURE.

• MAKE SURE NEMA RATING OF VALVE IS COMPATIBLE WITH THE INSTALLATION ENVIRONMENT. FAILURE TO DO

SO MAY RESULT IN SERIOUS PERSONAL INJURY AND/OR DAMAGE TO THE UNIT.

• WHEN INSTALLING THIS UNIT, COMPLY WITH THE NATIONAL ELECTRICAL CODE AND ALL APPLICABLE

FEDERAL, STATE AND LOCAL CODES.

• DRAIN SOLUTION MAY CONTAIN LUBRICANTS AND/OR HAZARDOUS MATERIALS. BE SURE TO COMPLY WITH

ALL APPLICABLE REGULATIONS CONCERNING THEIR DISPOSAL.

• NOT FOR USE ON SINGLE TOWER (DELIQUESCENT) DRYERS OR WITH CORROSIVE LIQUIDS.

PAGE 1

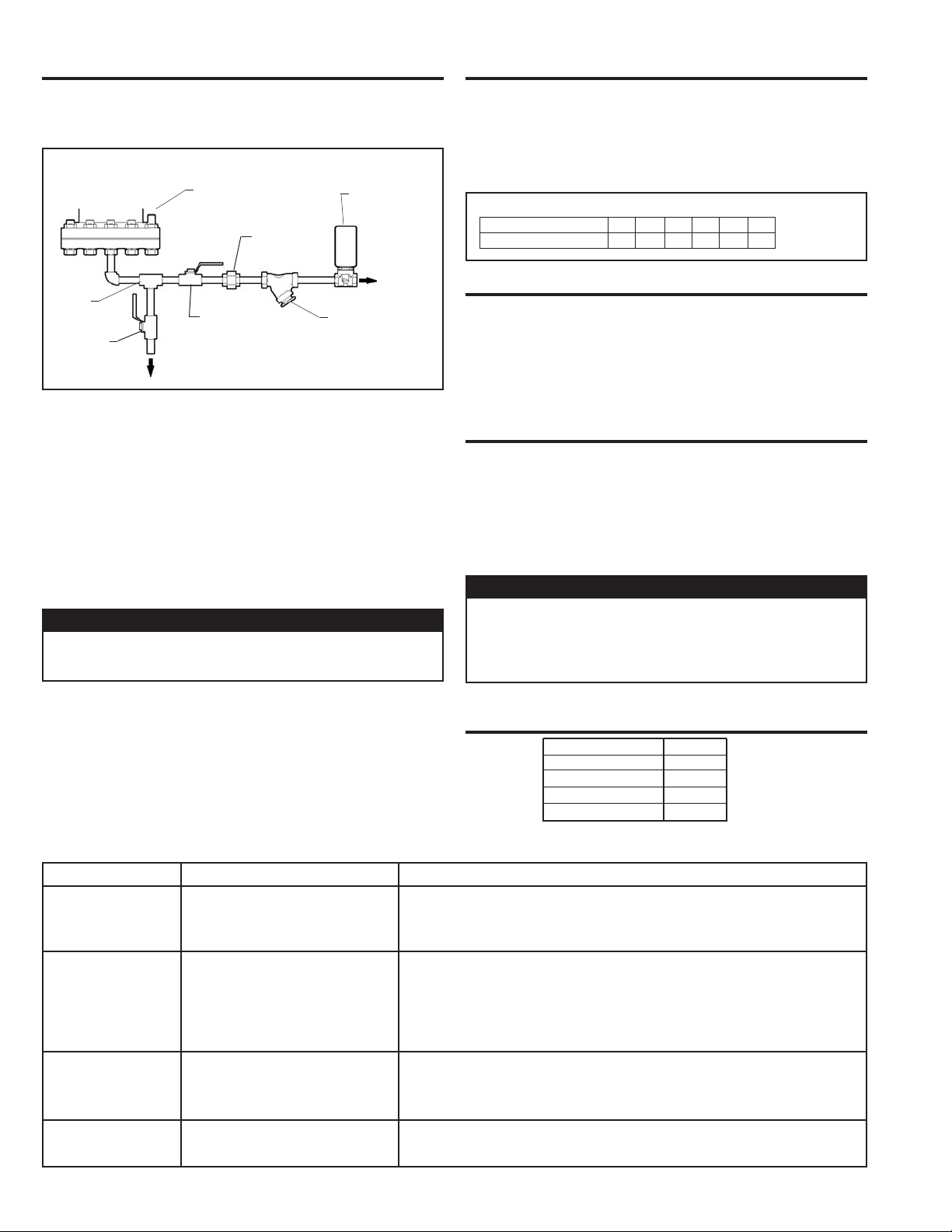

INSTALLATION

1.

Relieve and lock out all pressure from drain line.

2.

Clean existing drain line of any pipe scale, weld spatter or

accumulated debris.

FIGURE 2 RECOMMENDED INSTALLATION

UNIT TO BE DRAINED

(FILTER SHOWN AS

EXAMPLE)

UNION

EDV-115-PA

DRAIN VALVE

TIMER ADJUSTMENT

1.

Refer to Figure 3 for estimated discharge capacity . The chart

lists the valve discharge capacity at various pressures.

Set the valve open time & valve closed time control knobs to

2.

conform to the desired draining schedule. Note that the "V ALVE

OPEN" light is illuminated whenever the valve is open.

FIGURE 3 DISCHARGE CAPACITY

PRESSURE (PSIG)

GALLONS PER MIN-

50

19.2

100

27.6

150

34.2

200

38.4

250

43.2

300

46.8

TO DRAIN

TEE

ISOLATION BALL

TO DRAIN

SOURCE

VALVE

MANUAL

DRAIN

BALL VALVE

Install a tee onto the drain line. (Reference Figure 2).

3.

From the vertical tee outlet, install a manual drain ball valve.

4.

Y-STRAINER

SOURCE

This valve will allow the system to be drained during EDV115-PA servicing.

5.

On the horizontal tee outlet, install an isolation ball valve,

union and y-strainer. The y-strainer will prevent pipe scale,

weld spatter or accumulated debris from hindering the proper

function of the EDV-115-PA drain valve.

6.

Check EDV-115-PA valve body for fl ow direction arrows and

connect the valve in accordance with the arrows. (Note: To

ensure optimum performance, install EDV-115-PA drain valve

in a horizontal position.)

CAUTION

IF THE EDV-1 15-PA IS INSTALLED BACKW ARDS, IT WILL

NOT WORK.

7.

Close the manual and isolation ball valves.

8.

Adjust timer knobs to desired settings (Reference Timer

Adjustment Section).

9.

Wire or plug the valve into an appropriate grounded power

supply. The "POWER ON" light should now be illuminated.

10.

Open the isolation ball valve. Your EDV-115-PA drain valve is

now ready for operation.

TEST FUNCTION

To verify valve operation, or to manually discharge fl uid,

turn the "CLOSED TIME" knob counter clockwise until it stops in

the area labeled "TEST". The valve will open for the set "OPEN

TIME". After the valve closes, it will automatically repeat the test in

2 seconds unless the "CLOSED TIME" knob is reset to its regular

position.

REQUIRED MAINTENANCE

The EDV-1 15-P A drain valve must be cleaned periodically

to prevent malfunctions. In general, the time between cleanings will

vary depending on the discharge medium and operating conditions.

Leakage, sluggish operation and/or excessive noise (hissing) are

clear indications that the valve should be serviced. (NOTE: Noise

associated with air exhausting during valve open time is normal.)

WARNING

NEVER REMOVE OR REPLACE ANY PART ON EDV-115P A OR THE STRAINER WHILE THEY ARE PRESSURIZED.

CLOSE BALL VALVE AND DEPRESSURIZE DRAIN LINE

USING EDV-115-PA TEST FUNCTION.

REPLACEMENT PARTS & ACCESSORIES

REPLACEMENT

TIMER KIT

VALVE 115V

POWER CORD 115V

1/2" Y-STRAINER

39-10514

291-00003

500-00002

39-10022

PROBLEM

Valve not operating

("POWER ON" light

is off)

Valve not operating

("POWER ON" light

is on)

Valve draining

irregularly (Spitting

and sputtering)

Valve draining continually or leaking

PAGE 2

TROUBLE SHOOTING

POSSIBLE CAUSE

Power supply to valve turned off

or interrupted.

Printed circuit board malfunction.

Excessive drain line pressure.

Valve plugged with debris.

Valve installed backwards.

Printed circuit board malfunction.

Coil malfunction.

Dirty and/or corroded valve.

Valve installed backwards.

Excessive drain line pressure.

Dirty and/or corroded valve.

Defective valve body.

SOLUTION

Check electrical connections. Make sure that the drain valve is not

installed on a switched power supply line.

Replace timer assembly.

Install an EDV-115-PA with suitable maximum working pressure.

Clean or replace solenoid valve.

Verify proper fl ow direction. Repipe valve if necessary.

Replace timer assembly.

Replace solenoid valve.

Clean or replace solenoid valve.

Verify proper fl ow direction. Repipe valve if necessary.

Install an EDV-115-PA with suitable maximum working pressure.

Clean or replace solenoid valve.

Replace solenoid valve.

Loading...

Loading...