Van Air Systems E200 User Manual

INSTALLATION INSTRUCTIONS

APRIL 2000

P/N: 432-00127

®

E200 & E100 SERIES FILTER

ELEMENTS

(FOR F200 & F100 SERIES FILTERS- ALL GRADES)

PRODUCT PURPOSE & FUNCTION:

Van Air's E200 & E100 series filter elements provide long service life as well as ease of maintenance. With push on style

elements, there are no tie rods, gaskets, nuts and bolts. Both the particulate and coalescing elements will operate efficiently for

extended periods of time until a pressure drop of 10 PSID has occurred. Our differential pressure indicators and gauges can visually

alert when element changeout is needed. The activated carbon elements (RD grade) must be changed to suit specific applications,

or at least every 6 months.

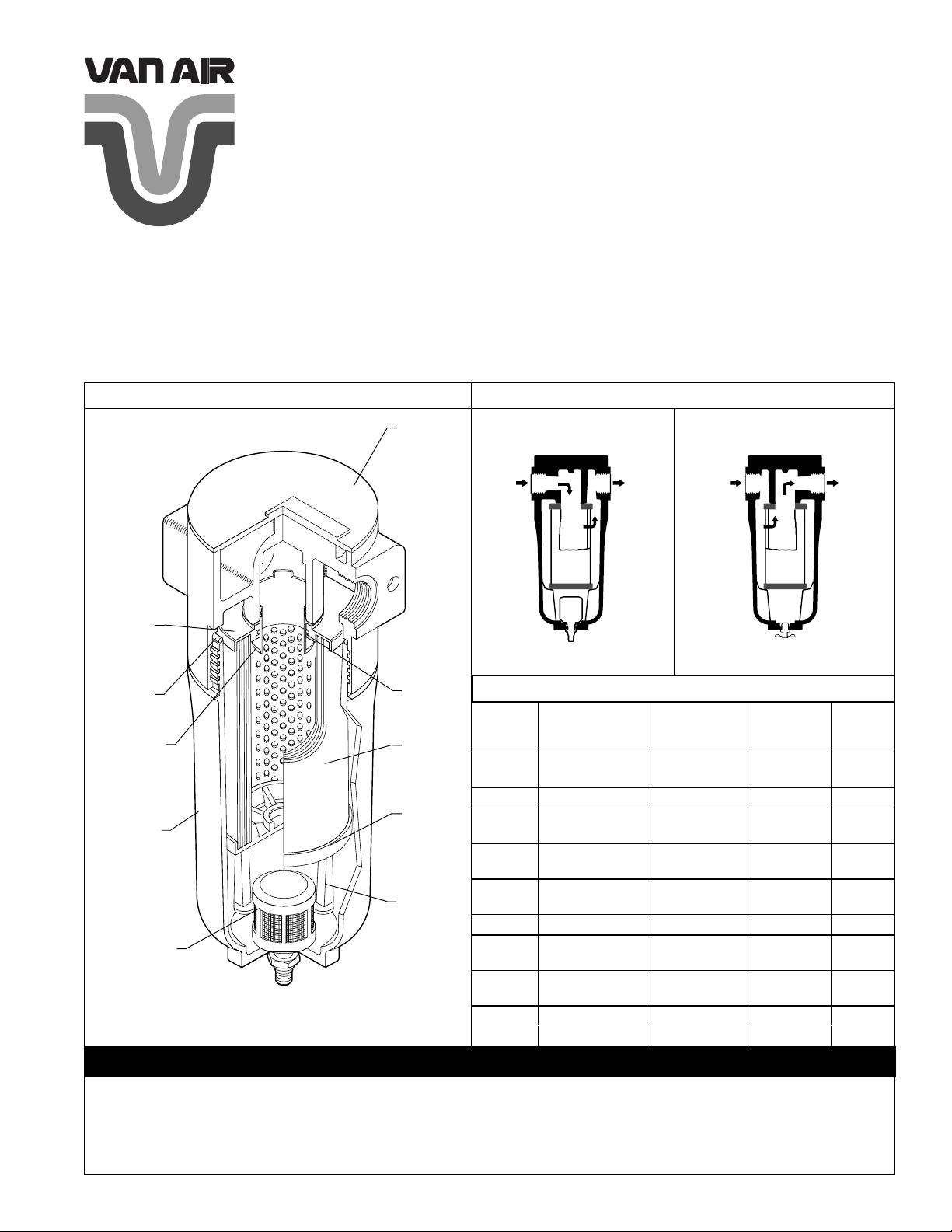

FILTER DETAILS

FILTER

HEAD

INLET

FLOW DIRECTION THROUGH ELEMENT

IN/OUT

(COALESCING)

OUTLET INLET

OUT/IN

(PARTICULATE)

OUTLET

ELEMENT

TOP

ENDCAP

HOUSING

O-RING

ELEMENT

ADAPTER

FILTER

BOWL

ADM-2-2

ELEMENT

O-RING

ELEMENT

ELEMENT

BOTTOM

ENDCAP

ELEMENT

SUPPORT

WARNINGS

FILTRATION GRADES

ELEMENT

GRADE PURPOSE

AA Extra Coarse

Coalescing

A Coarse Coalescing 5.00µ IN/OUT GREEN

B General Purpose

Coalescing

C High Efficiency

Coalescing

RAA Extra Coarse

Particulate

RA Coarse Particulate 5.00µ OUT/IN GREEN

RB General Purpose

Particulate

RC High Efficiency

Particulate

RD Vapor Absorbing 0.01µ OUT/IN BLACK

NOMINAL

PARTICULATE

REMOVAL

25.00µ IN/OUT BLACK

1.00µ IN/OUT RED

0.01µ IN/OUT BLUE

25.00µ OUT/IN BLACK

1.00µ OUT/IN RED

0.01µ OUT/IN BLUE

ELEMENT

FLOW

DIRECTION

ENDCAP

COLOR

CODE

READ INSTRUCTIONS CAREFULLY BEFORE INSTALLING NEW ELEMENT.

•

DO NOT REPLACE ANY ITEM ON FILTER WHILE IT IS UNDER PRESSURE.

•

DO NOT OPERATE IF THERE IS A LEAK IN FILTER. TAKE FILTER OUT OF SERVICE IMMEDIATELY.

•

DO NOT OPERATE ABOVE MAXIMUM WORKING PRESSURE (MWP) AT MAXIMUM OPERATING TEMPERATURE (°F).

•

PRINTED IN THE USA © 2000 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PAGE 1

ELEMENT REPLACEMENT

NING

TO REDUCE ENERGY CONSUMPTION FROM EXCESSIVE

PRESSURE DROP AND MINIMIZE CHANCE OF CONTAMINANT CARRYOVER, INSTALL NEW ELEMENT WHEN

PRESSURE DROP REACHES 10 PSID (EXCEPT GRADE

RD). INSTALL NEW RD ELEMENTS WHEN HYDROCARBON VAPORS ARE FIRST DETECTED DOWNSTREAM OR

AT LEAST EVERY 6 MONTHS.

Close inlet and outlet shutoff valves (and open bypass valve

1.

if provided), or lock out all compressed air supply to filter

housing.

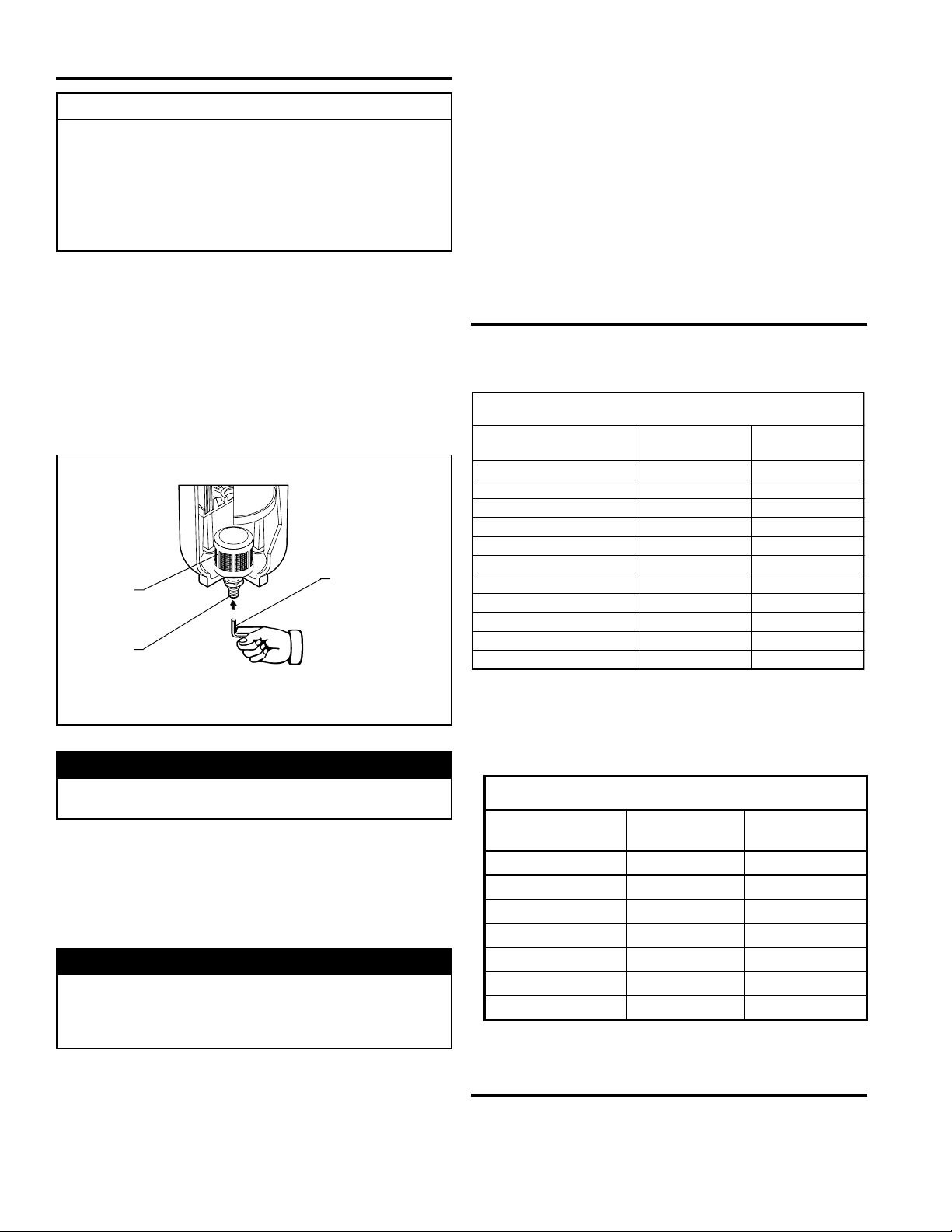

On units with auto drain valve, push a 3/16" allen wrench into

2.

the ADM-2 or ADM-2-2 outlet (See Figure 1) to open valve.

(Note: stand clear of outlet, liquids may be released.) Leave

valve open until all pressure is out of the filter housing. On units

with a manual drain valve, stand clear and turn manual valve

(petcock) until full open. Leave valve open until all pressure is

out of filter housing and bowl is removed.

FIGURE 1 ADM-2 & ADM-2-2 MANUAL OVERRIDE

ADM-2

OR

ADM-2-2

OUTLET

NOTE: LIQUIDS MAY BE RELEASED. WEAR GLOVES TO KEEP

HANDS CLEAN AND EYE PROTECTION.

IMPORTANT

3/16" ALLEN

WRENCH

WARNING

DO NOT UNSCREW FILTER BOWL FROM HEAD UNTIL

VESSEL IS COMPLETELY DEPRESSURIZED.

3.

After all pressure is out of filter, grasp filter bowl firmly with both

hands (models F200-15-1/4 through F200-55-1/2) or place

strap wrench around the bowl (models F200-85-3/4 through

F200-1000-3). Turn bowl counterclockwise as you face the

bottom to unscrew from filter head. If preferred, strap wrenches

can be used on all bowls. Make sure that the bowl does not

drop.

WARNING

ON MODELS F200-600-3 AND LARGER, PROVIDE SUPPORT UNDER BOWL BEFORE REMOVING. BOWL IS

HEAVY AND COULD CAUSE INJURY IF ALLOWED TO

FALL.

Grasp clean element by bottom endcap and push element

6.

onto element adapter firmly, but do not force beyond normal

stop.

Check o-ring in filter head. Replace if worn or damaged.

7.

Clean and lubricate threads on bowl with light grease. This will

8.

facilitate removal of bowl at next servicing.

Carefully raise filter bowl over element and screw into head,

9.

then tighten. DO NOT OVERTIGHTEN.

Close manual override if automatic drain or manual drain valve

10.

(petcock); then slowly open inlet and outlet shutoff valves.

Close bypass valve (if provided). Filter is now in service.

Monitor differential pressure regularly and replace element as

11.

indicated.

E100 FILTER ELEMENTS

Many E200 series replacement elements fit in the F100

series filter housings. See E100 & E200 Replacement Elements

Table below for a cross reference of both series.

E100 & E200 REPLACEMENT ELEMENTS

F100 FILTER MODEL E100 ELEMENT

MODEL

F100-15-(*) E100-15-(*) N/A

F100-30-(*) E100-30-(*) E200-55-(*)

F100-50-(*) E100-50-(*) N/A

F100-75-(*) E100-75-(*) E200-85-(*)

F100-100-(*) E100-100-(*) E200-100-(*)

F100-150-(*) E100-150-(*) E200-150-(*)

F100-225-(*) E100-225-(*) E200-265-(*)

F100-350-(*) E100-350-(*) N/A

F100-500-(*) E100-500-(*) N/A

F100-750-(*) E100-750-(*) E200-1000-(*)

F100-1000-(*) E100-1000-(*) N/A

(*)-Insert appropriate element grade here; for example E200-15-1/4-RB

Some E100 & E200 series replacement elements fit in

the FHP series high pressure filter housings. See E100/E200

Replacement Elements Used in FHP Filters Table below for a

cross reference of both series.

E100/E200 REPLACEMENT ELEMENTS USED IN FHP

FILTERS

FHP FILTER MODEL E100 ELEMENT

MODEL

FHP-20-7.25-(*) E100-15-(*) N/A

FHP-40-7.25-(*) E100-30-(*) E200-55-(*)

FHP-70-7.25-(*) E100-50-(*) N/A

FHP-105-7.25-(*) E100-105-(*) N/A

FHP-200-7.25-(*) E100-200-(*) N/A

FHP-325-7.25(*) E100-325/400-(*) N/A

FHP-400-7.25-(*) E100-325/400-(*) N/A

(*)-Insert appropriate element grade here; for example E100-15-RB

E200 ELEMENT

MODEL

E200 ELEMENT

MODEL

4.

Remove used element from element adaptor in filter head by

pulling downward. Discard used element properly.

5.

Remove new element from package and plastic bag. Check to

make sure that o-ring is properly positioned in endcap and has

been lightly greased.

as the E100 filter elements. For a reference on replacement

element model and part numbers see E200 Replacement Ele-

E200 FILTER ELEMENTS

Van Air E200 filter elements employ the same features

ment table on page 3.

PAGE 2 © 2000 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PRINTED IN THE USA

Loading...

Loading...