Van Air Systems E102 User Manual

P/N: 432-00128

INST ALLA TION INSTRUCTIONS

®

E101/102 SERIES FILTER ELEMENTS

(FOR F101, F102 AND FHP SERIES FILTER HOUSING - ALL GRADES)

APRIL 2000

GRADE

AA

A

B

C

To reduce energy consumption from excessive pressure drop and minimize chance of contaminant carryover, install new elements

before pressure drop reaches 10 psid (except grade RD). Install new RD elements when hydrocarbon vapors are first detected

downstream or every six months, whichever comes first.

DESCRIPTION

Extra Coarse Coalescing

Coarse Coalescing

General Purpose Coalescing

High Efficiency Coalescing

ENDCAP COLOR

Black

Green

Red

Blue

GRADE

RAA

RA

RB

RC

HT

RD

DESCRIPTION

Extra Coarse Particulate

Coarse Particulate

General Purpose Particulate

High Efficiency Particulate

High Temperature Particulate

Vapor Adsorbing

ENDCAP COLOR

Black

Green

Red

Blue

Zinc Plate

Black

WARNINGS

BEFORE INSTALLING NEW ELEMENT(S), READ INSTRUCTION MANUAL CAREFULLY. NOTE SERIES OF FILTER HOUSING

(F101, F102 OR FHP) AND CONSULT THE APPROPRIATE SECTION FOR SPECIFIC INSTRUCTIONS.

F101 SERIES

Close inlet and outlet shut-off valves (and open by-pass valve

1.

if provided); or lock out compressed air supply to filter housing.

WARNING

DO NOT LOOSEN FLANGE BOLTS BEFORE THE

VESSEL IS COMPLETELY DEPRESSURIZED.

FIGURE 1 LONG FLANGE BOLT (F101-500 thru 2000)

On units with manual drain valve, stand clear and turn manual

2.

valve until fully open. Leave valve open until all pressure is out

of filter housing and bottom blind flange is removed. On units

with automatic drain valves (timed electric type) allow valve to

cycle until all pressure is out of filter housing.

Provide support under blind flange to prevent it from falling

3.

when bolts are removed.

Remove bolts from flange and lower blind flange for access to

4.

elements.

5.

Remove hex fastener from tie rod and remove used element

from housing. Discard used element properly.

NOTE

Filter models F101-500 thru F101-2000 are equipped

TABLE 1 BOTTOM BLIND FLANGE WEIGHTS

(F101 Series)

BOTTOM

FILTER

MODEL

F101-500

F101-1000

F101-1500

F101-2000

F101-3500

F101-5000

PRINTED IN THE USA © 2000 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PAGE 1

BLIND FLANGE WEIGHT

(LBS.)

28

47

69

69

102

177

with a single long flange bolt to permit rotating of blind

flange for access to elements.

WARNING

BLIND FLANGES ARE HEAVY AND COULD CAUSE INJURY IF ALLOWED TO FALL. SEE (TABLE 1) FOR BLIND

FLANGE WEIGHTS.

6.

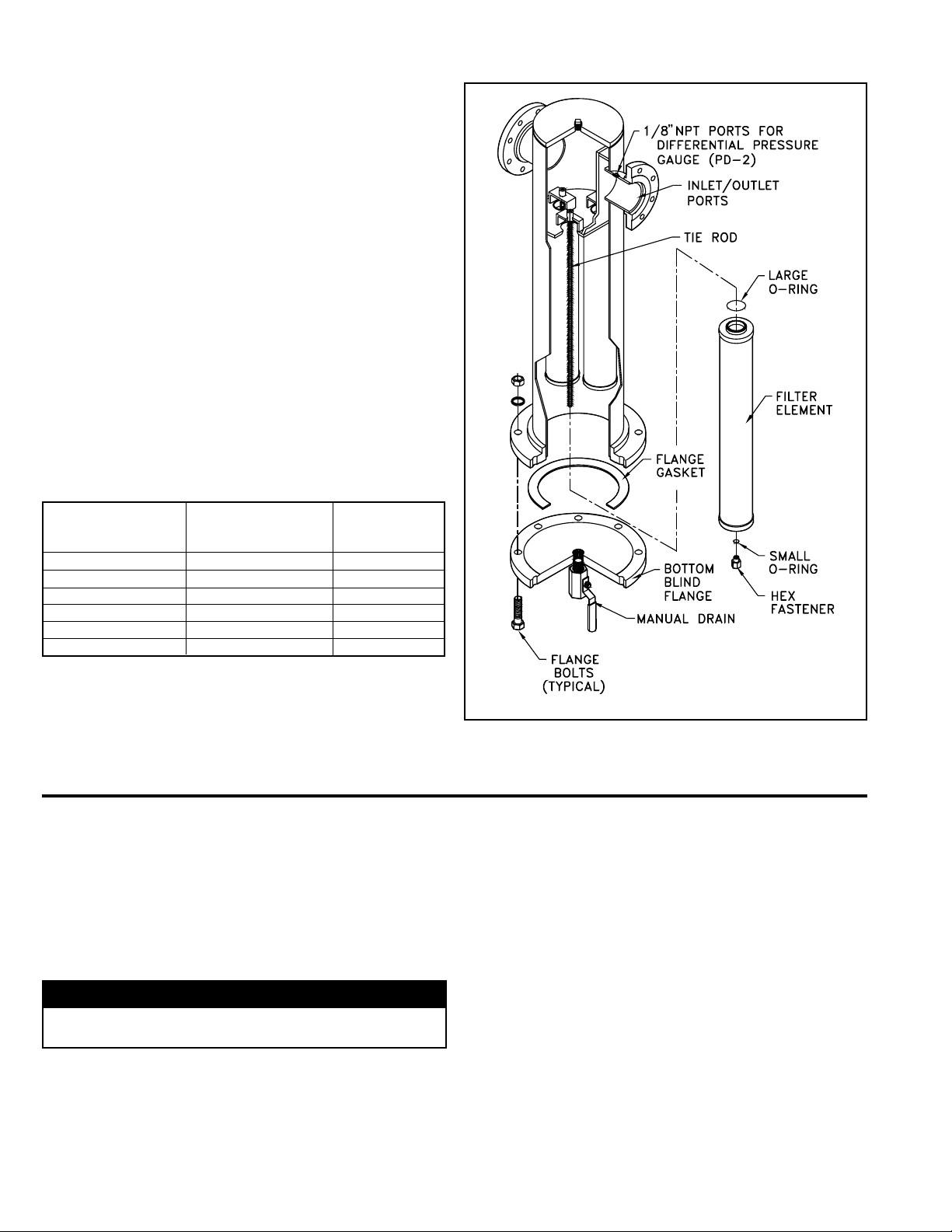

Remove new element from packaging. Remove small plastic

bag (o-ring inside)and rubber band from element. Install new

small o-ring in groove on hex fastener. Be sure that large o-ring

is firmly and squarely positioned on top end cap.

7.

Install element in housing so that the tie rod protrudes through

the small hole in the bottom endcap.

8.

Thread hex fastener onto the tie rod and tighten so that

element is held firmly in place. Do not overtighten. (See Figure

2).

9.

Repeat same procedure for each new element required. (See

Table 2 for Element Replacement Data).

10.

Before closing housing, inspect the interior to make certain all

of the new elements have been installed.

11.

With gasket in place, carefully raise blind flange and align bolt

holes. Insert all bolts and completely tighten all nuts evenly.

Close drain valve; then slowly open inlet and outlet valves.

12.

Close by-pass valve if provided. Check for leaks.

13.

Filter is now in service.

TABLE 2 ELEMENT REPLACEMENT DATA

(F101 Series)

REPLACEMENT

FILTER

MODEL

F101-500-(*)

F101-1000-(*)

F101-1500-(*)

F101-2000-(*)

F101-3500-(*)

F101-5000-(*)

*Insert appropriate filtration grades here; for example F101-3500-C uses

replacement element E101/102-625-C (five required).

ELEMENT

MODEL NUMBER

E101/102-500-(*)

E101/102-500-(*)

E101/102-500-(*)

E101/102-625-(*)

E101/102-625-(*)

E101/102-625-(*)

NUMBER OF

ELEMENTS IN

HOUSING

1

2

3

3

5

8

FIGURE 2 TYPICAL ASSEMBLY (F101 Series)

F102 SERIES

Close inlet and outlet shutoff valves (and open by-pass valve

1.

if provided); or lock out all compressed air supply to filter

housing.

2.

On units with manual drain valves stand clear and turn both

manual drain valves until fully open. Leave valves open until

all pressure is out of filter housing and T-bolt/swing bolt closure

is open. On units with automatic drain valves (timed electric

type) allow valve to cycle until all pressure is out of filter

housing.

WARNING

DO NOT LOOSEN SWING BOLTS BEFORE THE VESSEL

IS COMPLETELY DEPRESSURIZED.

Loosen swing bolt nuts until they will clear the tabs on the

3.

enclosure. It is not necessary to remove the nuts from the

bolts. (See Figure 3).

4.

Remove hex fasteners from tie rods and lift used elements

from housing. Discard used elements properly.

5.

Remove new element from packaging. Remove small plastic

bag (o-ring inside)and rubber band from element. Install new

PAGE 2 © 2000 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PRINTED IN THE USA

small o-ring in groove on hex fastener. Be sure that large oring is firmly and squarely positioned on the end cap with the

large opening.

Install element in housing so that the tie rod protrudes through

6.

the small hole in endcap. End cap with large opening faces

down.

7.

Thread hex fastener onto the tie rod and tighten so that

element is held firmly in place. Do not overtighten (See Figure

3).

8.

Repeat same procedure for each new element required. (See

Table 3 for Element Replacement Data).

Before closing housing, inspect baffle to make certain all the

9.

new elements have been installed.

10.

With enclosure o-rings in place, carefully lower enclosure and

raise all swing bolts over tabs. Tighten all nuts evenly.

11.

Close drain valve; then slowly open inlet and outlet valves.

Close by-pass valve if provided. Check for leaks.

12.

Filter is now in service.

Loading...

Loading...