Van Air Systems D2 User Manual

March 2009

P/N: 432-00159-B

INSTALLATION INSTRUCTIONS

SINGLE TOWER DRYER MODEL D-2

®

VAN AIR PAR T NUMBER: 80-0104

PRODUCT PURPOSE & FUNCTION:

Van Air's Single Tower (Delinquescent) Dryer model D-2 is designed to remove water vapors from compressed air systems

in low flow applications. The housing is made of lightweight cast aluminum and coated with an epoxy powdercoating for corrosion

resistance. A PVC plastic support grid promotes efficient drying and drainage. A sight glass window provides a visual indication for

when to add more Dry-O-Lite desiccant.

FIGURE 1 SPECIFICATIONS

1/2" NPT

OUTLET

(PORT A)

STEM &

GRID

1/2" NPT

INLET

(PORT B)

DRY-O-LITE

DESICCANT

1/4" BALL

VALVE

OPERATING CONDITION

MAXIMUM

WORKING

PRESSURE

200 PSIG 35-100°F 4 LBS 2LBS

INLET

TEMP

RANGE

HOUSING

WEIGHT

APPROX.

DESICCANT

REQUIRED

HEAD

CLAMP

SIGHT

GLASS

BOWL

5-1/2"

3-1/2"

FILL

LEVEL

LOW

®

3-5/8"

LEVEL

FLOW CAPACITIES

200

175

150

125

100

75

50

25

OPERATING PRESSURE (PSIG)

1234567891011121314

FLOW CAPACITIES (SCFM)

5-1/2"

11/16"

12-1/4"

13-7/16"

1-3/16"

WARNINGS

READ INSTRUCTION CAREFULLY BEFORE INSTALLING DRYER.

•

DO NOT REPLACE ANY ITEM ON DRYER UNTIL DRYER IS COMPLETELY DEPRESSURIZED.

•

DO NOT OPERATE DAMAGED OR LEAKING DRYER, REMOVE FROM SERVICE IMMEDIATELY.

•

DO NOT OPERATE ABOVE MAXIMUM WORKING PRESSURE (MWP) AND/OR MAXIMUM OPERATING TEMPERATURE (°F).

•

TAKE PROPER SAFETY PRECAUTIONS FOR THE GAS BEING PROCESSED.

•

PAGE 1

INSTALLATION

The ability of a dryer to provide dry compressed air is

dependent on the correct location of the unit. Temperature and

pressure are the keys to selecting the proper location.

IMPORTANT

ALWAYS PROCESS AIR THROUGH THE DRYER AT THE

LOWEST POSSIBLE TEMPERATURE AND THE HIGHEST

PRACTICAL PRESSURE.

INLET AIR TEMPERATURE

The dew point of the outlet air is directly related to the inlet air

temperature. The lower the inlet temperature, the lower the dew

point of the outlet air. Determine the lowest ambient temperature

where the compressed air is used or where the lines are located.

Install the dryer where the inlet temperature will not be more than

10°F above the lowest system operating temperature, do not

exceed 100°F inlet air temperature.

CAUTION

NEVER LOCATE THE DRYER IN AN AREA OF EXCESSIVE

HEAT. THE INLET AIR TEMPERATURE SHOULD NEVER

EXCEED 100°F.

OPERATING PRESSURE

More air can be processed through the dryer at higher pressures.

Locate the dryer at the highest practical pressure, but do not

exceed the maximum rated working pressure of 200 PSIG. Refer

to the flow capacity chart on page 1.

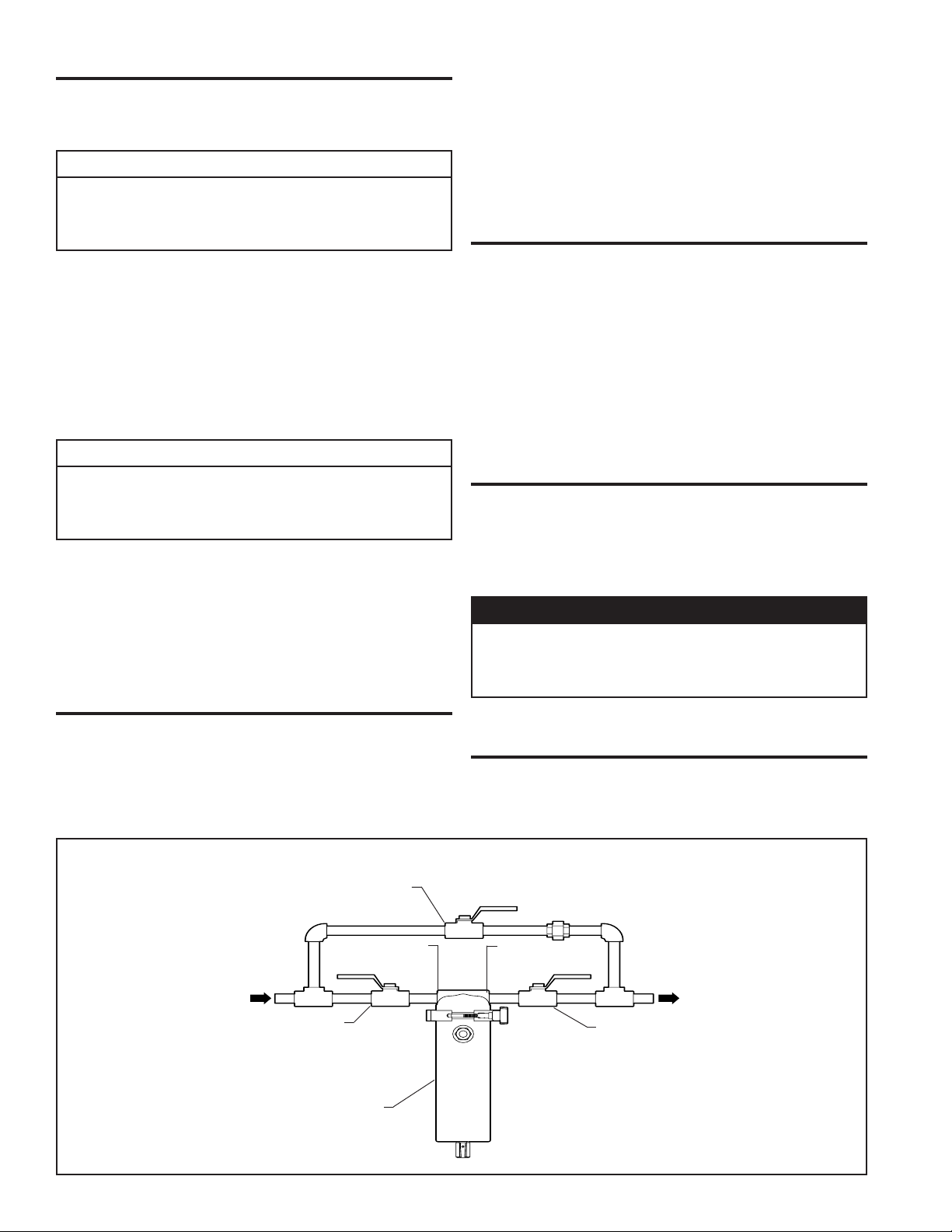

PIPING AND ANCILLARY EQ UIPMENT

Check markings on vessel head. Connect inlet pipe to side

4.

marked "B" and outlet to side marked "A". Dryer must be

installed in a vertical and upright position with the bowl below

the head, as shown in Figure 2.

Fill bowl with desiccant (with the stem and grid assembly

5.

inside) until the desiccant reaches the fill line (as shown in

Figure 1).

Place dryer bowl onto head.

6.

Place clamp onto head and bowl and tighten.

7.

ADDING DESICCANT

Close dryer inlet and outlet shutoff valves. Slowly open drain

1.

on bottom of bowl until vessel is completely depressurized.

Grasp bowl in one hand. Loosen clamp with other and slide

2.

clamp down off bowl.

Twist bowl slightly and pull down off of head. The stem and grid

3.

assembly must come loose from o-ring seal in head.

Add desiccant until the fill line is reached (Reference Figure

4.

1).

Position stem on head and push bowl upward so bowl and

5.

head meet.

Hold bowl in place, reinstall clamp and tighten.

6.

START-UP

Close dryer inlet and outlet shutoff valves. Open bypass valve.

1.

Close dryer drain valve. See Figure 2 Recommended Installation

Slowly pressurize dryer by opening dryer inlet shutoff valve.

2.

Open dryer outlet shutoff valve slowly and close bypass valve.

3.

WARNING

MAKE SURE THAT THE DRYER IS NOT SUBJECTED TO

SUDDEN SURGES. ALWAYS OPEN VALVES SLOWLY TO

PERMIT A GRADUAL EQUALIZATION OF PRESSURE

BETWEEN THE DRYER AND THE AIR SUPPLY LINES.

Locate dryer as close as possible to equipment to be pro-

1.

tected.

If large amounts of liquids are present in the air lines, install

2.

a separator with drain valve ahead of the dryer.

Install bypass piping around dryer to facilitate servicing (Ref-

3.

erence Figure 2).

FIGURE 2 RECOMMENDED INSTALLATION

BYPASS VALVE

INLET

PORT B

INLET

SHUTOFF

VALVE

D-2

SHUT DOWN

Close dryer inlet and outlet shutoff valves. Open bypass valve.

1.

Slowly open drain valve to depressurize dryer.

2.

OUTLET

PORT A

OUTLET

SHUTOFF

VALVE

PAGE 2

Loading...

Loading...